Electroconductive adhesive film and preparation method thereof

A technology of conductive adhesive film and adhesive film, which is applied in the direction of conductive adhesives, adhesives, films/sheets without carriers, etc., can solve the problems of poor heat resistance and low mechanical strength of conductive adhesive films, and achieve improved electrical conductivity. Effect of improving electron-withdrawing performance and reducing steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

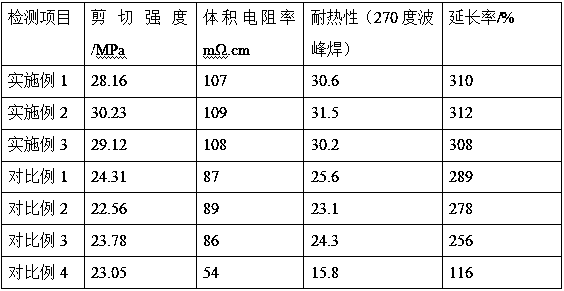

Examples

preparation example Construction

[0021] The preparation method of heat-resistant active agent is:

[0022] (1) Take phenyltrichlorosilane and add toluene at a mass ratio of 2~5:5~10, stir and mix for 50~60min, then add deionized water 1~3 times the mass of toluene dropwise, and control the dropping time for 60~90min. Stir and mix at 20~25°C for 2~4h, let stand for 30~50min, take the upper layer, wash with saturated saline and deionized water, and dry over anhydrous magnesium sulfate to obtain a dried product, which is obtained by mass ratio of 3~5 : 5~10: 0.01~0.05 Add toluene and catalyst, stir and mix at 70~80°C for 18~24h, filter with suction, take the filter cake, wash it with ether, dry it, and obtain the dried product a;

[0023] (2) Take the dry product a, add aluminum trichloride and dichloromethane according to the mass ratio of 3~5:10~15:70~80, pass through nitrogen protection, stir and mix at 0~4°C for 30~60min to obtain the mixture, Take 4-methylbenzenesulfonyl chloride and add it to the mixture ...

Embodiment 1

[0031] The catalyst is: take tetrabutylammonium hydroxide and add methanol to mix at a mass ratio of 1:10.

[0032] The preparation method of heat-resistant active agent is:

[0033] (1) Take phenyltrichlorosilane and add toluene at a mass ratio of 5:10, stir and mix for 60 minutes, then dropwise add deionized water 3 times the mass of toluene, control the dropping time for 90 minutes, stir and mix at 25°C for 4 hours, and let stand for 50 minutes , take the upper layer, wash with saturated brine and deionized water, and dry over anhydrous magnesium sulfate to obtain a dry product. Take the dry product and add toluene and catalyst at a mass ratio of 3:5:0.01, stir and mix at 80°C for 24 hours, and filter with suction , take the filter cake, wash it with ether, and dry it to obtain the dried product a;

[0034] (2) Take the dry product a, add aluminum trichloride and dichloromethane at a mass ratio of 5:15:80, pass through nitrogen protection, stir and mix at 4°C for 60 minute...

Embodiment 2

[0042] The catalyst is: take tetrabutylammonium hydroxide and add methanol at a mass ratio of 3:20 to mix.

[0043] The preparation method of heat-resistant active agent is:

[0044] (1) Take phenyltrichlorosilane and add toluene at a mass ratio of 2:5, stir and mix for 50 minutes, then dropwise add deionized water with 1 times the mass of toluene, control the dropping time for 60 minutes, stir and mix at 20°C for 2 hours, and let stand for 30 minutes , take the upper layer, wash with saturated brine and deionized water, and dry over anhydrous magnesium sulfate to obtain a dry product. Take the dry product and add toluene and catalyst at a mass ratio of 5:10:0.05, stir and mix at 70°C for 18 hours, and filter with suction , take the filter cake, wash it with ether, and dry it to obtain the dried product a;

[0045] (2) Take the dry product a, add aluminum trichloride and dichloromethane at a mass ratio of 3:10:70, pass through nitrogen protection, and stir and mix at 0°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com