Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

72results about How to "Small volume effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative pole material for lithium-ion secondary battery, negative pole containing negative pole material, preparation method of negative pole and battery containing negative pole

InactiveCN102122708APromote growthSmall volume effectNon-aqueous electrolyte accumulator electrodesLi-accumulatorsMobile electronicsPolyamide

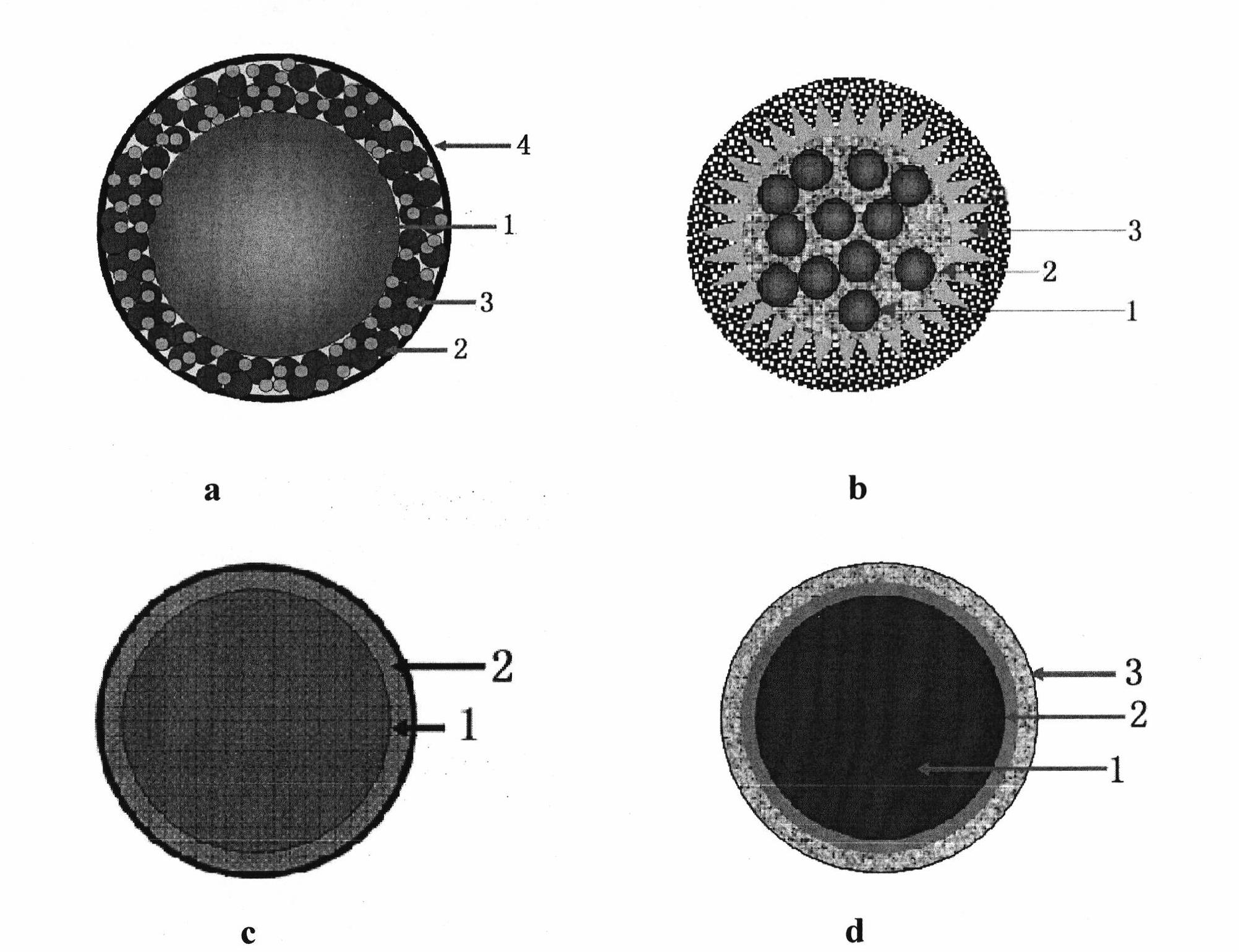

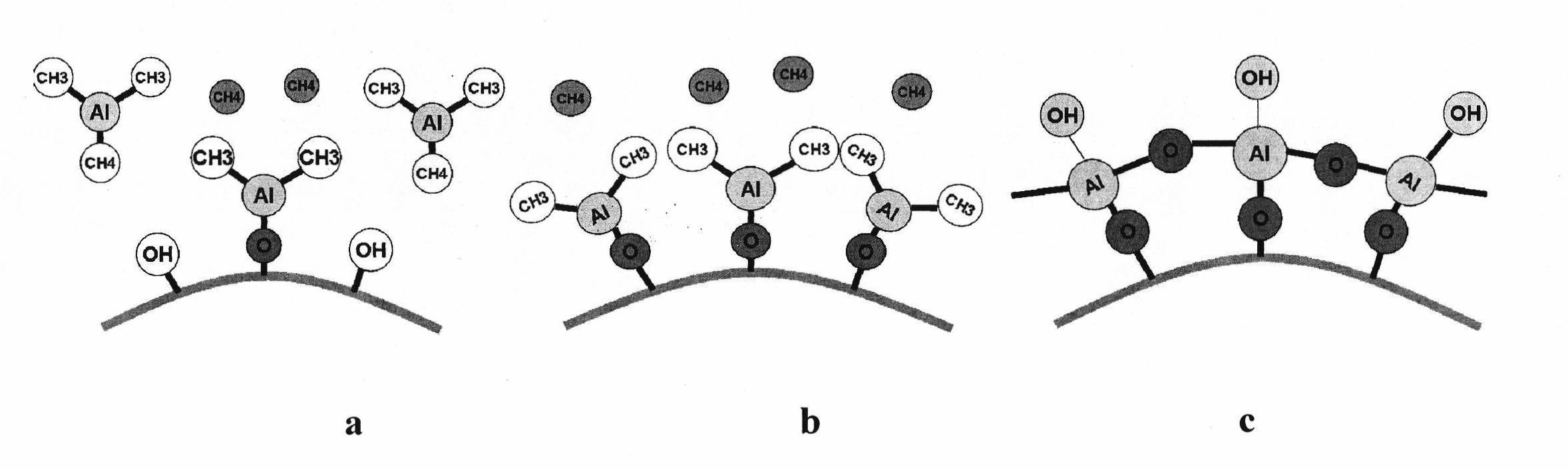

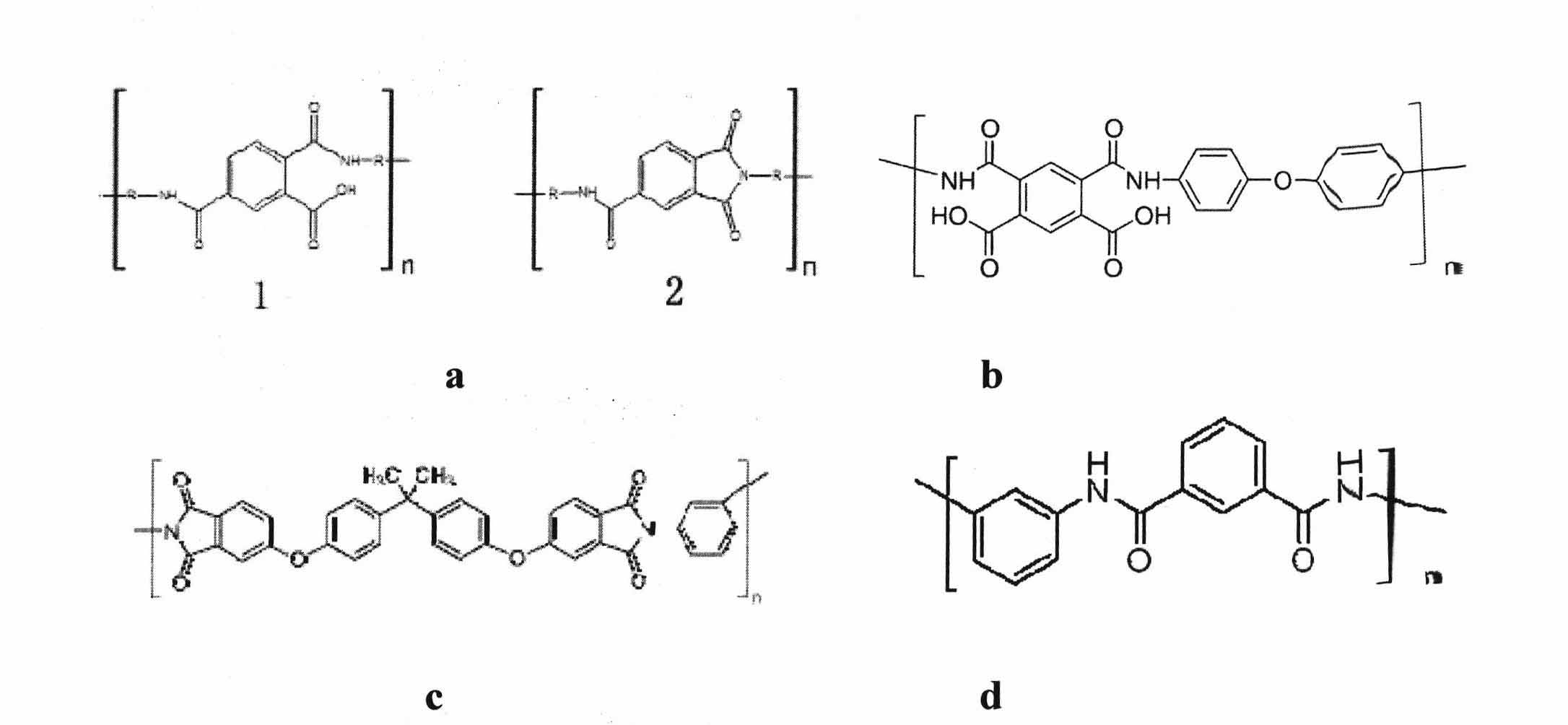

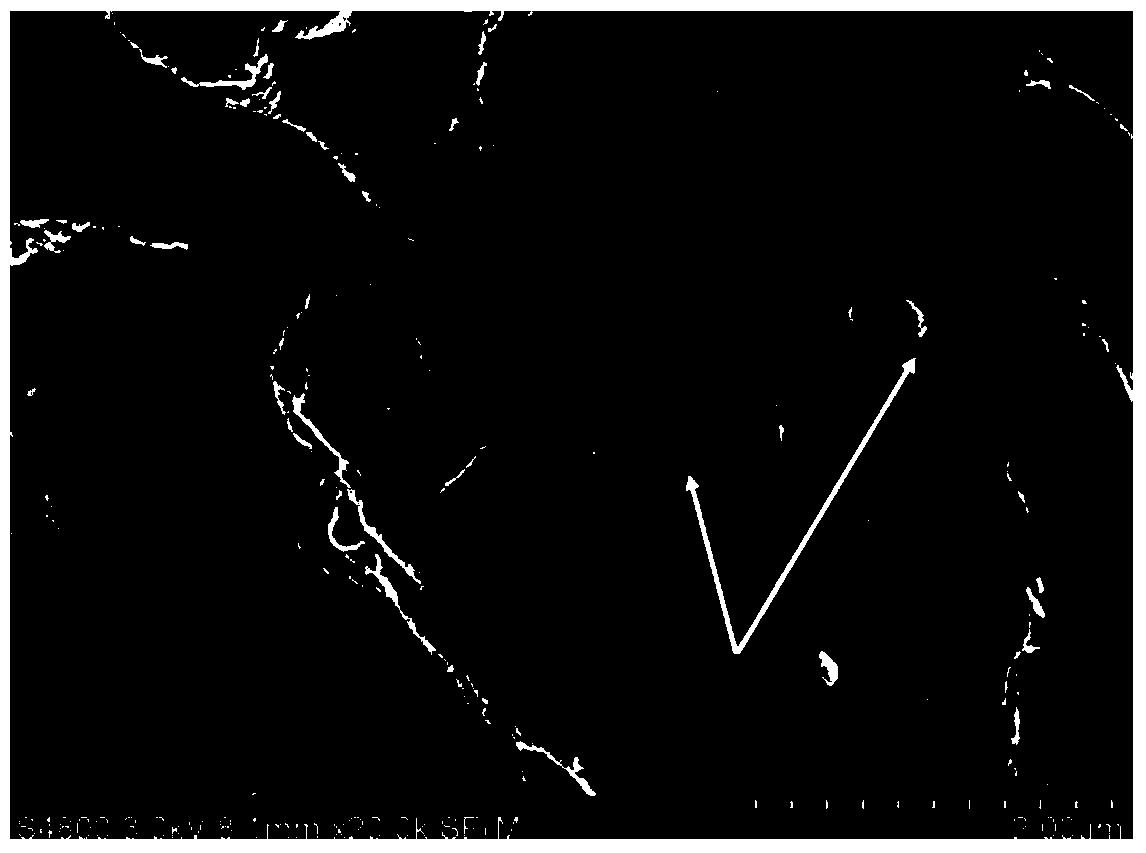

The invention relates to a negative pole material for a lithium-ion secondary battery, and the negative pole material comprises composite particles in core-shell structures, conductive additives and an amide type high-temperature-resistant binder, wherein each composite particle in the core-shell structure comprises an inner core and an outer shell layer, each inner core contains at least one of elemental silicon, a silicon oxide and a silicon alloy, and each outer shell layer is coated by one or more of inorganic materials, namely C, Cu, Ni, Fe, Cr, Al2O3, TiO2, LiPO3, Li2Si2O5, Li2SiO3, Li4SiO4, Li8SiO6 and SiO2; and the amide type high-temperature-resistant binder is one or more of polyamide, imide and amide-imide. The invention further relates to a negative pole containing the negative pole material and a preparation method thereof. The invention further relates to a battery containing the negative pole. The battery has the advantages of higher charge-discharge capacity, better cycle property and high safety, and is suitable for various mobile electronic devices or devices requiring mobile energy sources for driving.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

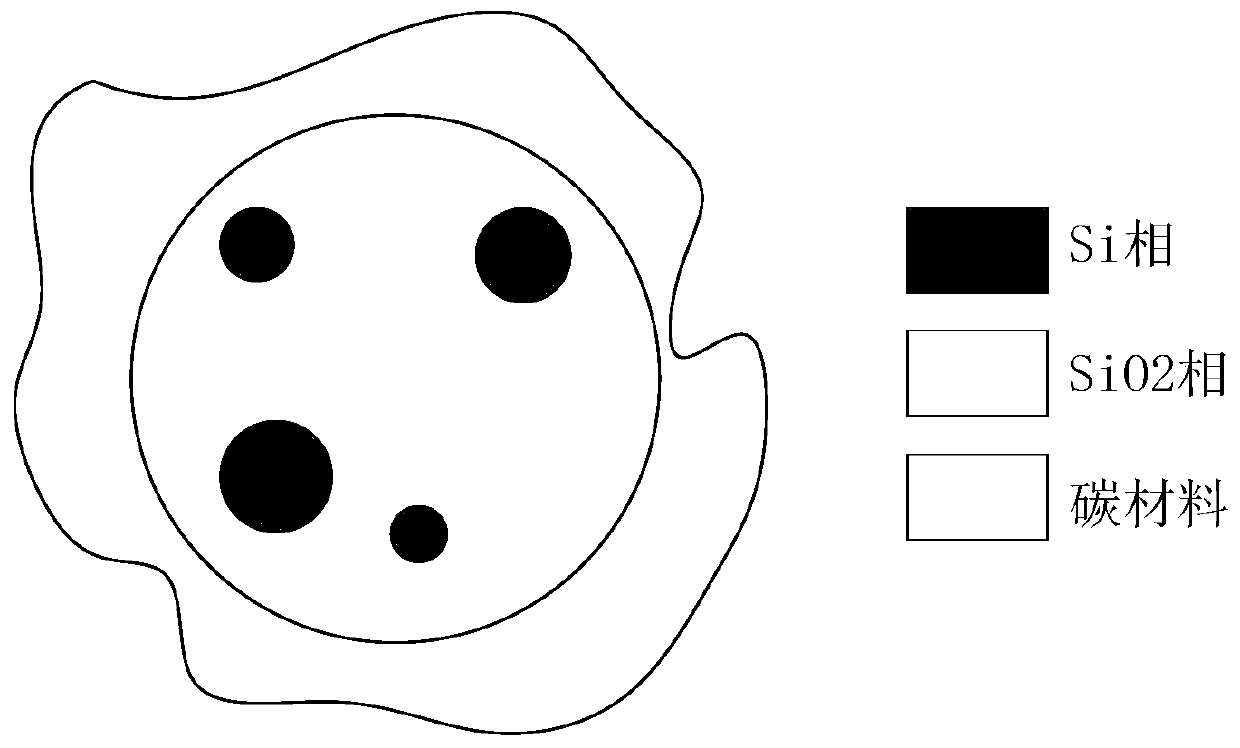

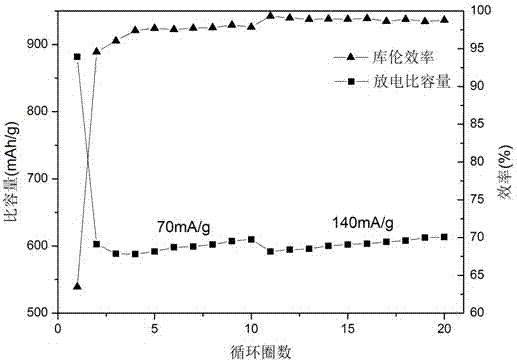

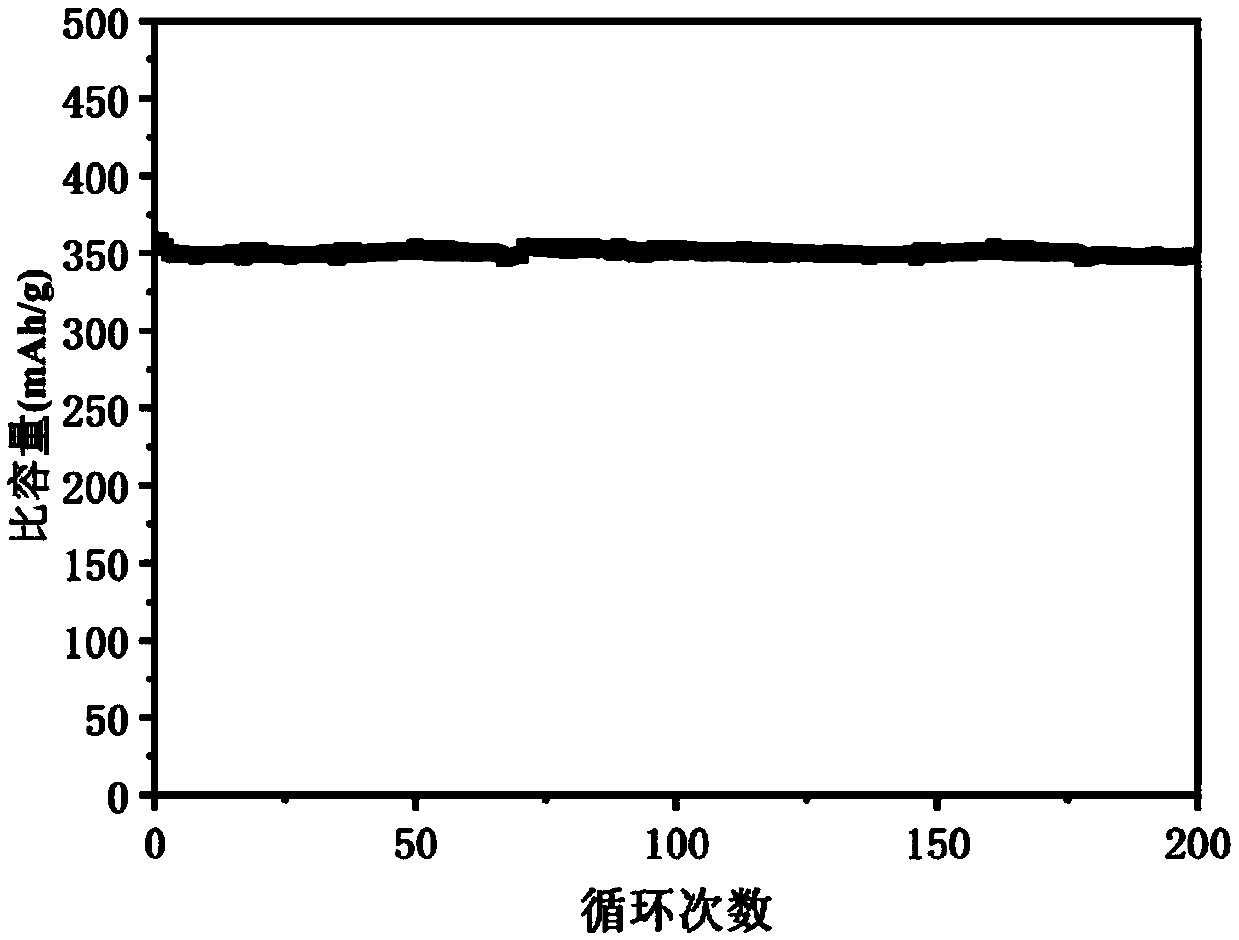

Silicon dioxide composite anode material for lithium ion battery, as well as preparation method and application of silicon dioxide composite anode material

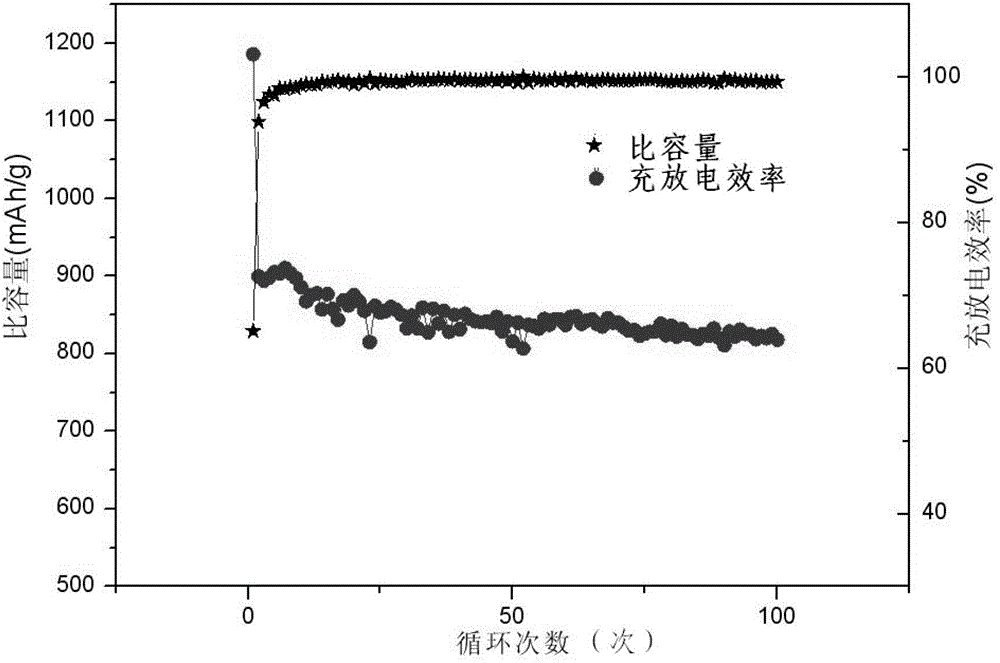

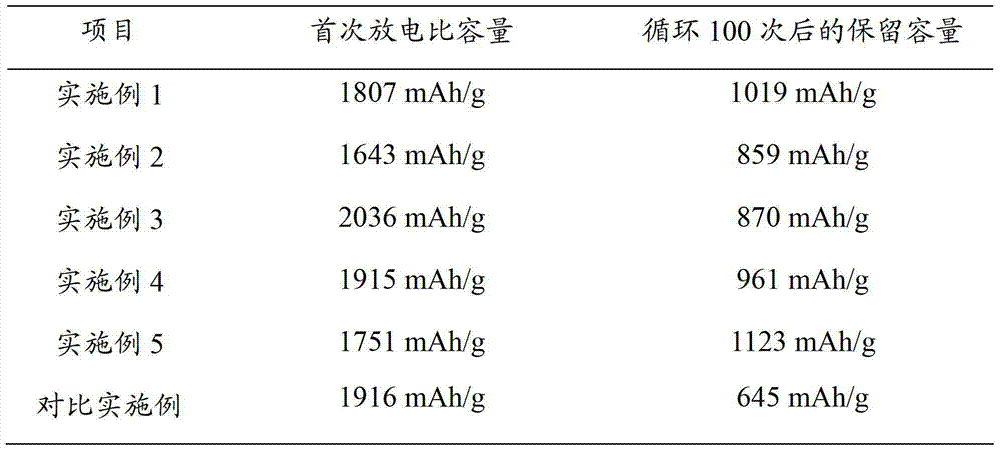

ActiveCN104022257AImprove electronic conductivityImprove efficiencyCell electrodesSecondary cellsLithium electrodeVolume effect

The invention discloses a silicon dioxide composite anode material for a lithium ion battery, as well as a preparation method and an application of the silicon dioxide composite anode material. The silicon dioxide composite anode material is prepared from the components of silicon dioxide powder and a conductive carbon layer with the surface of the silicon dioxide powder is uniformly and densely coated. With the adoption of the silicon dioxide composite anode material, the original component structure of an SiO material system is kept, so that the lower volume effect is ensured; the silicon dioxide dense carbon layer coating structure is successfully realized by adopting the technologies of mixing kneading, sheet rolling, press forming and the like, and thus the first coulombic efficiency of the silicon dioxide composite anode material is remarkably increased, and can reach a theoretical value being larger than 77 percent, and the cycle performance and the conductive characteristic are also remarkably improved, so that the silicon dioxide composite anode material is suitable for being charged and discharged with the large rate and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD +1

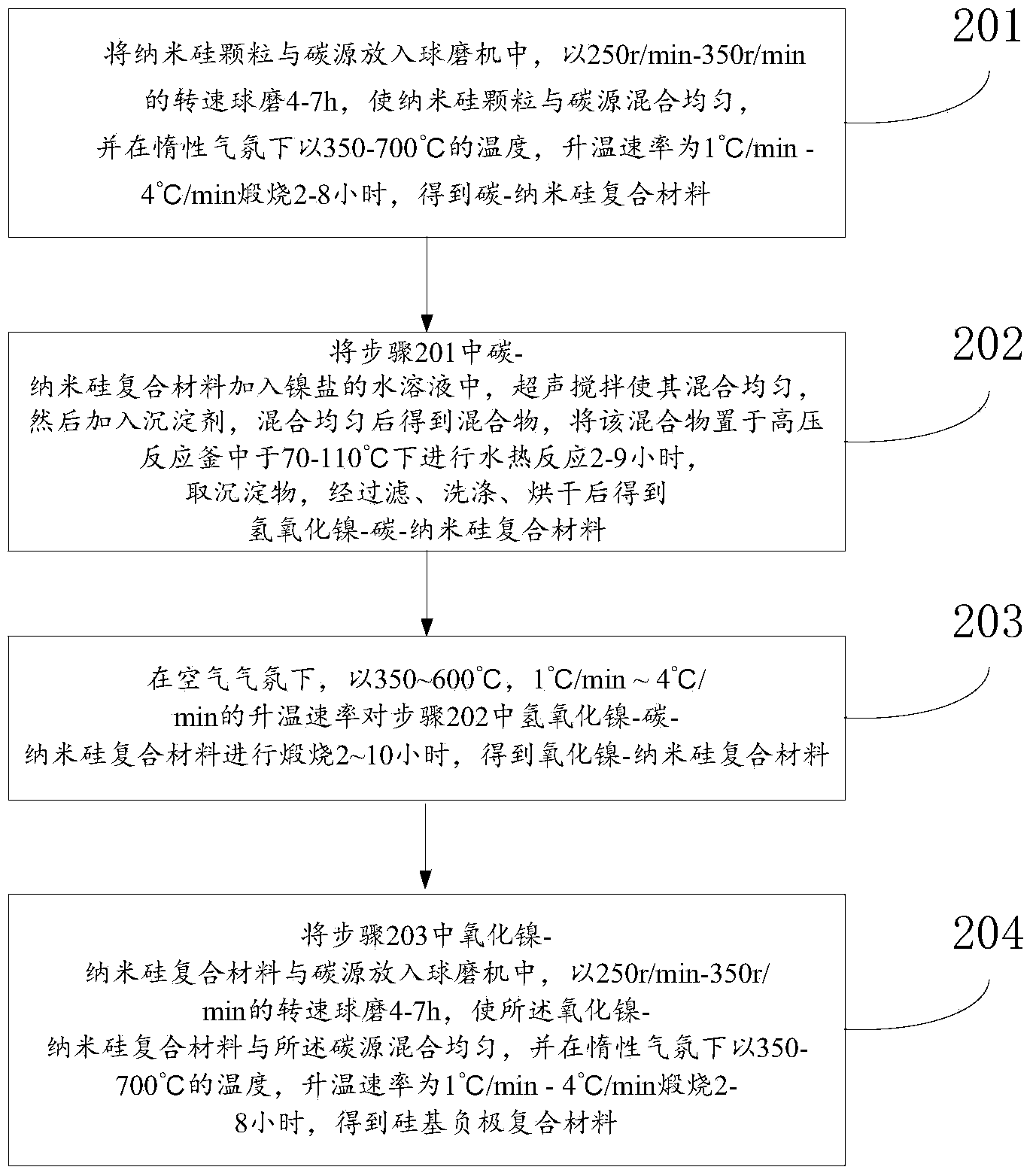

Silicon-based cathode composite material and preparation method thereof

ActiveCN104022266ASmall volume effectImprove specific capacity and cycle performanceCell electrodesSecondary cellsCarbon coatingNickel oxides

The embodiment of the invention discloses a silicon-based cathode composite material and a preparation method thereof, and belongs to the field of lithium battery cathode materials. An embodiment of the invention is as below: coating nickel hydroxide on the surface of a carbon-nano silicon composite material with a first carbon layer, calcining to remove the first carbon layer, so as to obtain nickel oxide-nano silicon composite material with gaps; then coating a second carbon layer on the surface of the nickel oxide-nano silicon composite material to obtain the silicon-based cathode composite material. The composite material comprises nano silicon particles, a nickel oxide layer arranged outside the nano silicon particles and carbon coating on the nickel oxide; gaps between nickel oxide and nano silicon particles are for containing embedded lithium ions, so as to keep stable structure of the cathode material during lithium deintercalation; and the method reduces the volume effect of the Si-based material and improves specific capacity and cycle performance of the cathode material. The method provided by the embodiment of the invention is safe and environment-friendly, and does not cause environment pollution.

Owner:CHERY AUTOMOBILE CO LTD

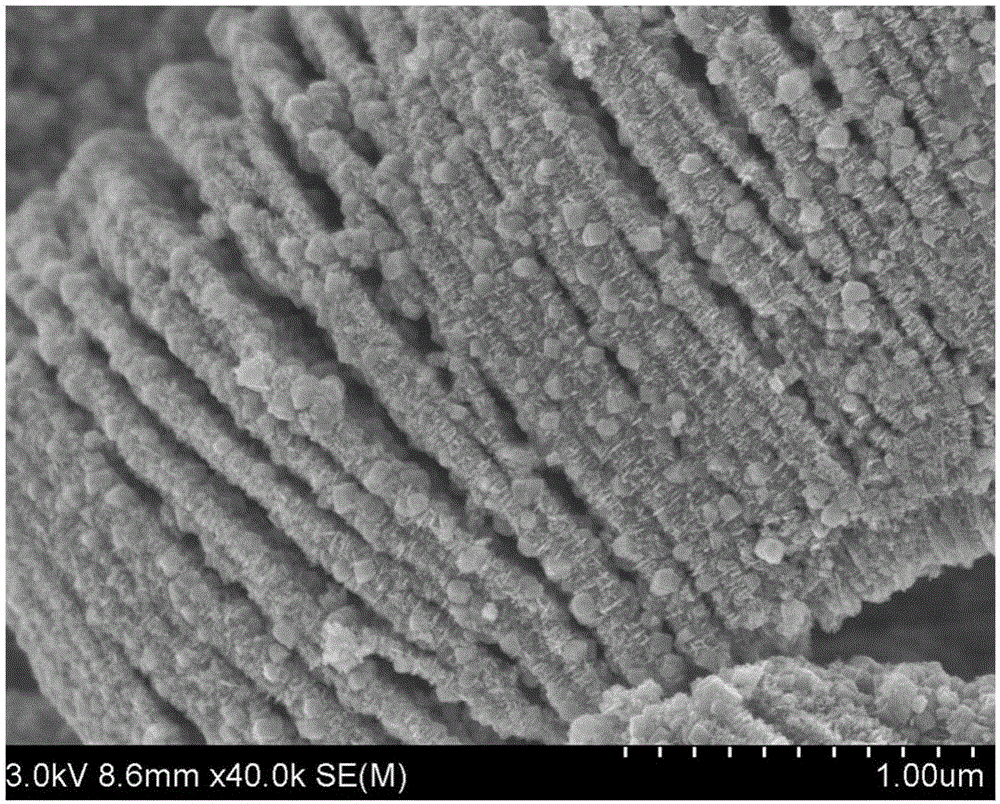

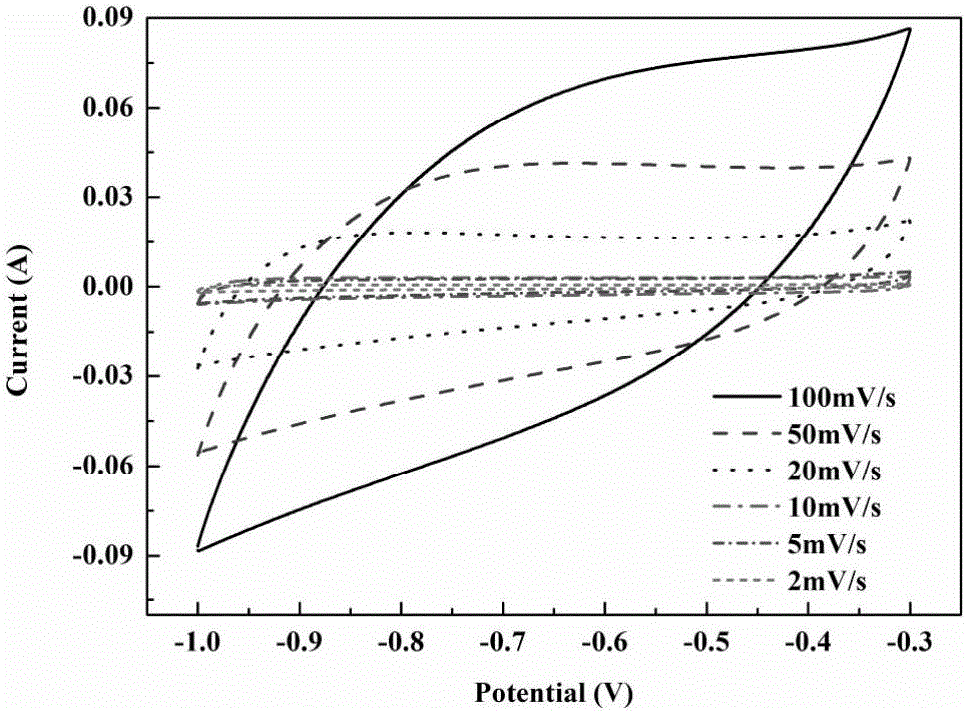

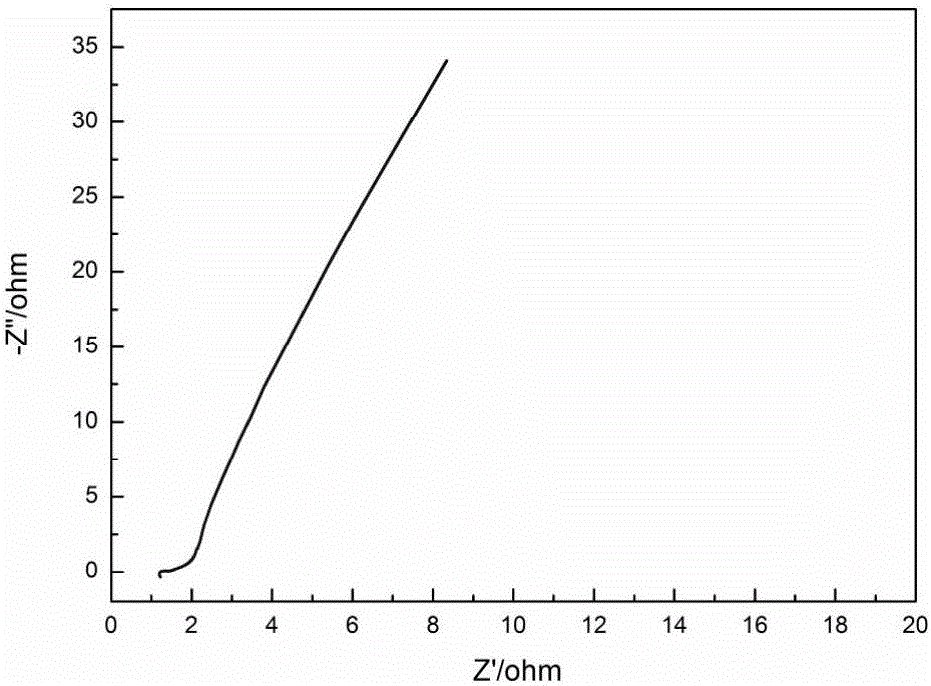

Flexible electrode with carbon fiber wrapped metal oxide for capacitor and preparation method

InactiveCN106449159AGood flexibilitySmall volume effectHybrid capacitor electrodesHybrid/EDL manufactureElectrospinningCapacitance

The invention discloses a flexible electrode with carbon fiber wrapped metal oxide for a capacitor and a preparation method. Through surface modification of metal oxide nanoparticles and the like, a flexible membrane that metal oxide nanoparticles are wrapped with a carbon nano fiber (a one-dimensional carbon material) is prepared by using an electrospinning technique, and the flexible membrane can be used in a flexible super-capacitor electrode. Not only is good flexibility achieved, a sufficient buffer space can be provided for volume variation of the metal oxide nanoparticles in operation through the carbon nano fiber, the volume effect of the metal oxide can be reduced, advantages of high specific capacitance, good stability and the like can be achieved, and the properties of a flexible capacitor can be further improved. In addition, methods such as surface chemical deposition or electric deposition are not needed in the production process, and the flexible electrode is simple to operate, controllable in material structure, low in cost and applicable to large-scale industrial production.

Owner:DALIAN OCEAN UNIV

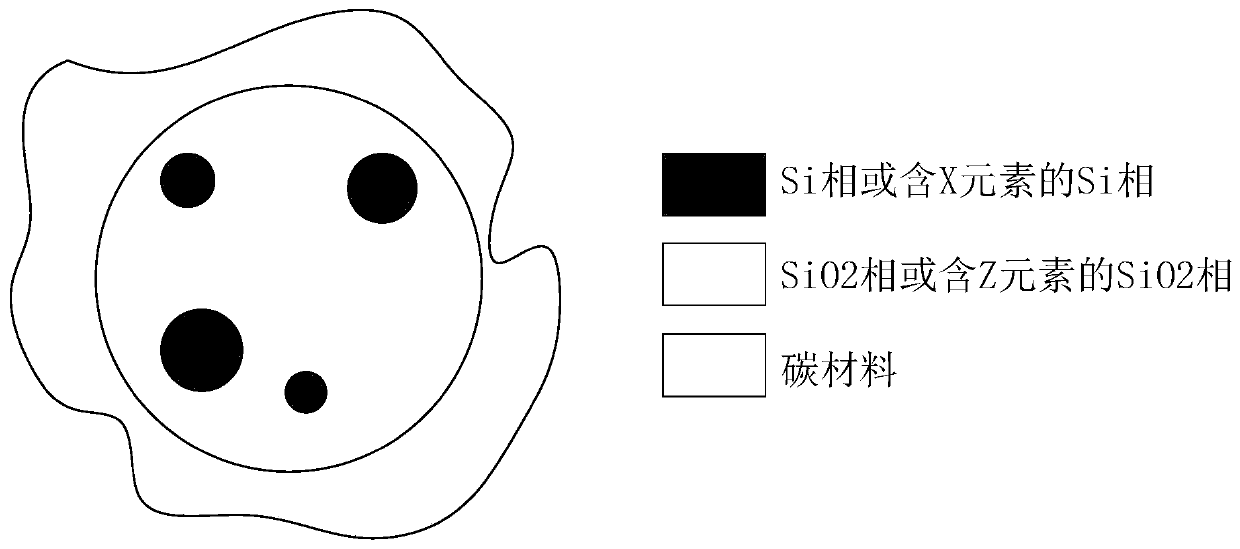

Silicon-based composite material and preparation method thereof, silicon-carbon composite material and lithium ion battery

The invention provides a silicon-based composite material and a preparation method thereof, a silicon-carbon composite material, and a lithium ion battery containing the materials, belongs to the technical field of lithium ion batteries, and can solve the problem of capacity fading caused by a volume effect of the existing silicon-based composite material and the lithium ion battery prepared by using the silicon-based composite material in the charge and discharge processes. The preparation method of the silicon-based composite material, disclosed by the invention, comprises the steps of: mixing SiOx (x is smaller than or equal to 1.5 and greater than or equal to 0.5) and a conductive carbon substrate to obtain compound powder of the SiOx ( the x is smaller than or equal to 1.5 and greater than or equal to 0.5); and coating the compound powder by a carbon precursor to obtain a coating and carrying out carbonization reaction on the coating. The silicon-based composite material and the silicon-carbon composite material with an excellent cycle performance are obtained by selecting proper technological parameters, and the lithium ion battery containing the materials is prepared. The composite materials disclosed by the invention are prepared by using the method, and the lithium ion battery disclosed by the invention contains the composite materials.

Owner:CHERY AUTOMOBILE CO LTD

Silicon-carbon composite material of closed cage structure and preparation method of silicon-carbon composite material of closed cage structure

ActiveCN107863513AExtend your lifeImprove buffering effectMaterial nanotechnologyCell electrodesCarbon compositesPorous carbon

The invention provides a silicon-carbon composite material of a closed cage structure and a preparation method of the silicon-carbon composite material of the closed cage structure. The silicon-carboncomposite material of the closed cage structure is a hollow filled structure material in a closed cage form; the core of the hollow filled structure material is a silicon material-filled porous carbon material; the porous carbon material is filled with a silicon material; the silicon material has the void content of 50-95% in the porous carbon material; and a carbon material coats the outside ofthe silicon material-filled porous carbon material and the specific component of the carbon material is (SiOx)yC, wherein x is smaller than or equal to 2 and greater than or equal to 0 and y is smaller than or equal to 1 and greater than 0. When the silicon-carbon composite material of the closed cage structure is used as a negative electrode of a battery, contact of the silicon material and an electrolyte is isolated, the life of the battery is prolonged and the capacity performance and the cycle performance of the battery are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

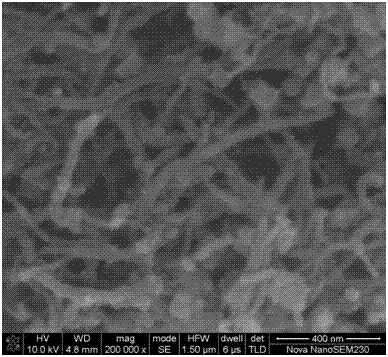

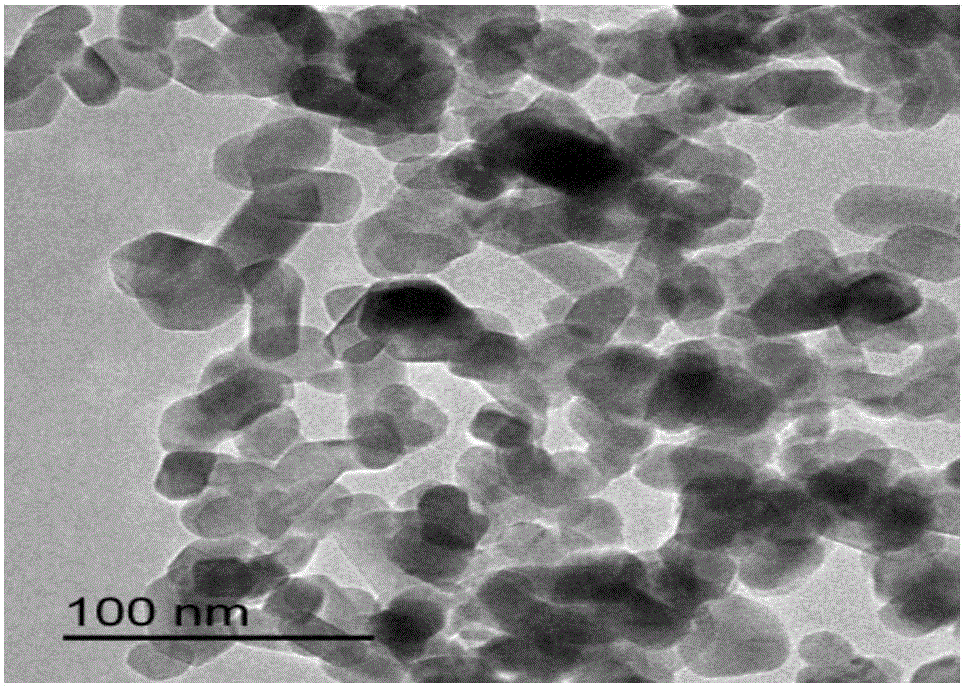

Nanometer silicon/graphene lithium ion battery cathode material and preparation method thereof

ActiveCN103400970AImprove cycle performanceGranularity controllableCell electrodesSolventLithium-ion battery

The invention relates to a nanometer silicon / graphene lithium ion battery cathode material and a preparation method thereof. The cathode material comprises nanometer silicon and graphene, wherein the granularity of nanometer silicon granules is 10-100nm, and the mass ratio of nanometer silicon to graphene is 1:(5-10). The preparation method of the nanometer silicon / graphene lithium ion battery cathode material comprises the following steps of: preparing an electron solution; reducing a silicon tetrachloride liquid phase into nanometer silicon; preparing a graphene oxide glue sample solution; loading the graphene oxide glue sample solution on nanometer silicon; and drying and sintering the semi-finished product of the composite electrode material. According to the preparation method, after the nanometer silicon granules the granularity of which can be controlled are obtained through a liquid phase reducing method; in a mode that a glue body is separated out through replacing a solvent graphene is reduced and a glue layer is formed at the same time, and moreover the glue layer is adsorbed on an existing nanometer silicon glue nucleus; the obtained nanometer silicon has a better size and a better structure, can combine graphene and nanometer silicon efficiently in the term of molecule size; the obtained silicon carbon material has stable circulation performance and excellent electric conducting performance.

Owner:湖北高地石墨烯科技有限公司

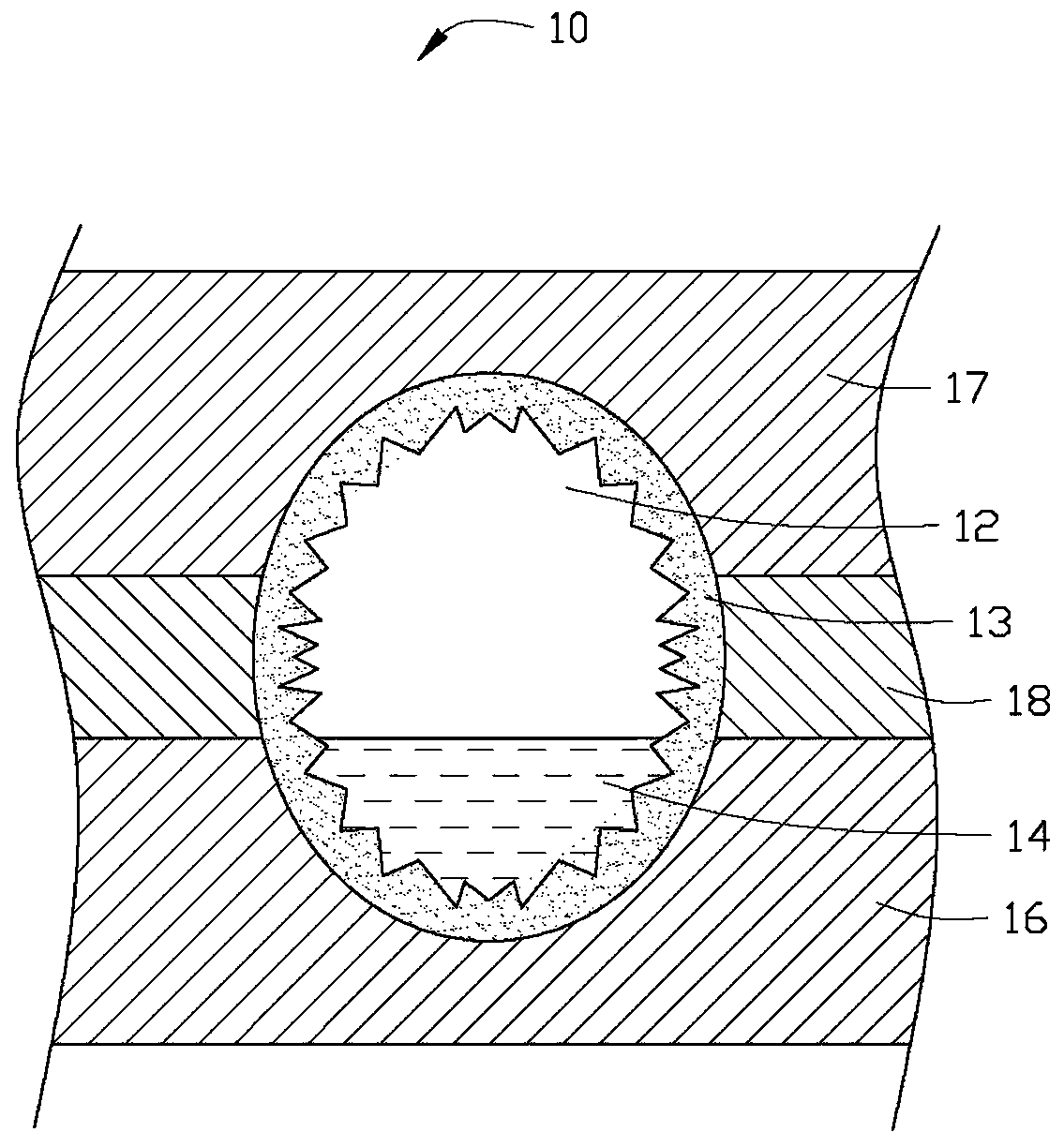

Preparation method of high-capacity anode material

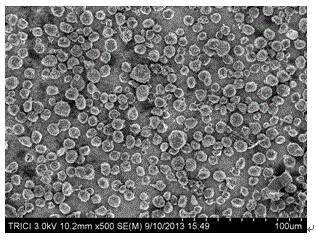

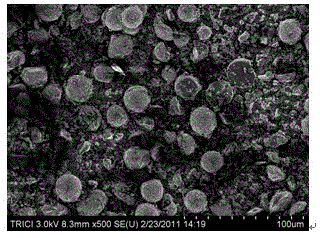

ActiveCN105489854ASmall volume effectImprove cycle performanceMaterial nanotechnologyCell electrodesElectricityLithium electrode

The invention relates to a preparation method of a high-capacity anode material, in particular to a method for synthesizing a high-capacity core-shell structure anode material for a lithium-ion battery. The method comprises the following steps: firstly, adding high-capacity nano-particles to raw materials of synthesizing mesocarbon microbeads, and carrying out high-speed stirring and high-temperature polymerization; with the high-capacity nano-particles as a core, generating the mesocarbon microbeads on the surface through polymerization of polycyclic aromatic molecules; and finally obtaining the high-capacity core-shell structure anode material with the high-capacity nano-particles as the core and the mesocarbon microbeads as the shell through high-temperature carbonization. Compared with a traditional synthesis process, the preparation method has the advantages ofachieving uniform coating, simple in process, excellent in electrochemical properties and the like.

Owner:TIANJIN NORMAL UNIVERSITY

Lithium ion battery anode material and preparation method thereof, and lithium ion battery

ActiveCN104425806ASmall volume effectAlleviate volume expansionCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention discloses a lithium ion battery anode material and a preparation method thereof, and a lithium ion battery. The preparation method comprises the following steps: (1) mixing aluminum and silicon (II) oxide to obtain a mixture, wherein the mass of silicon (II) oxide is greater than that of aluminum; and (2) firing the mixture under an inert atmosphere or vacuum condition at the temperature of 900-1150 DEG C for 2-12h to obtain the lithium ion battery anode material. According to the preparation method, the raw material aluminum is added in the raw material silicon (II) oxide, due to reaction of the raw material aluminum and silicon (II) oxide, the content of active oxygen in the anode material obtained finally is reduced, and the prepared anode material further comprises aluminum oxide. The content of the active oxygen in the anode material is reduced, the charge-discharge first-time efficiency of the anode material is greatly improved, the specific capacity of the anode material is greatly increased; meanwhile, aluminum oxide in the anode material can be used for relieving the volume expansion of silicon in the anode material, so that the volume effect of the whole anode material is reduced.

Owner:CHERY AUTOMOBILE CO LTD

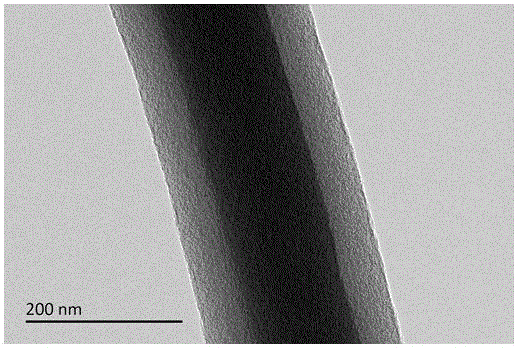

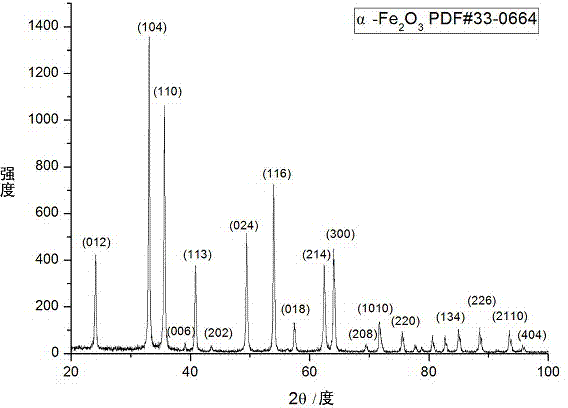

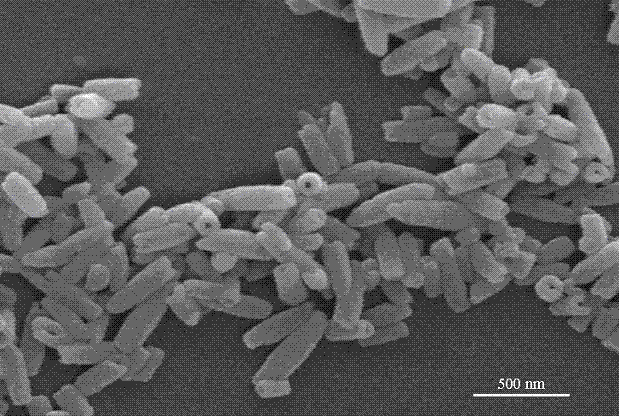

Iron trioxide monocrystal nanotube/graphene composite electrode material and preparation method thereof

InactiveCN104852024AMaintain propertiesLarge specific surface areaCell electrodesSecondary cellsNanotubeMaterials science

The invention relates to an iron trioxide monocrystal nanotube / graphene composite electrode material and a preparation method thereof. The composite electrode material of the invention is formed by coating an iron trioxide monocrystal nanotube with graphene via Van der Waals' force, wherein the mass ratio of the graphene and ferric oxide is 1:(1 to 10); the iron trioxide monocrystal nanotube is an alpha-Fe2O3 monocrystal nanotube, and the length thereof is 300 to 500 nm, and the outer diameter is 60 to 90 nm while the inside diameter is 10 to 50 nm. The method designed by the invention is simple in synthetic process and low in cost, and can be applied to lithium ion battery cathode materials. The iron trioxide monocrystal nanotube / graphene composite electrode material has excellent stability and electrochemical performance.

Owner:SHANGHAI UNIV

Composite material MoO3/Polyaniline/Ti3C2Tx and preparation method thereof

ActiveCN105869910AImprove conductivityHigh specific capacityHybrid capacitor electrodesHybrid/EDL manufactureFreeze-dryingAniline

The invention provides a composite material MoO3 / Polyaniline / Ti3C2Tx and a preparation method thereof. The preparation method includes the steps that 1, Ti3AlC2 powder is completely immersed in an HF solution with the volume fraction of 40%, centrifugation is conducted, and powder is obtained and dried; 2, ammonium molybdate tetrahydrate and tartaric acid are completely dissolved in water, and a water solution is obtained; 3, the powder Ti3C2Tx is added into the water solution; 4, suspension liquid obtained in the step 3 is centrifuged and dried in a vacuum drying oven; 5, the powder obtained in the step 4 is sintered and subjected to heat preservation, and a MoO3 / Ti3C2Tx composite material is obtained; 6, the obtained powder is ultrasonically dispersed in distilled water, aniline is added, and stirring is conducted in an ice bath; 7, (NH4)2S2O4 is dissolved in HCl, cooling is conducted, and the mixture is added into suspension liquid obtained the step 6; 8, suspension liquid obtained in the step 7 is centrifuged, washed, subjected to alcohol washing and freeze drying, and the target object is obtained. Due to the fact that the material is high in composition adjustability, the preparation process is simple and the synthesis process is easy to control, the application range of the composite material to an electrode material is widened.

Owner:SHAANXI UNIV OF SCI & TECH

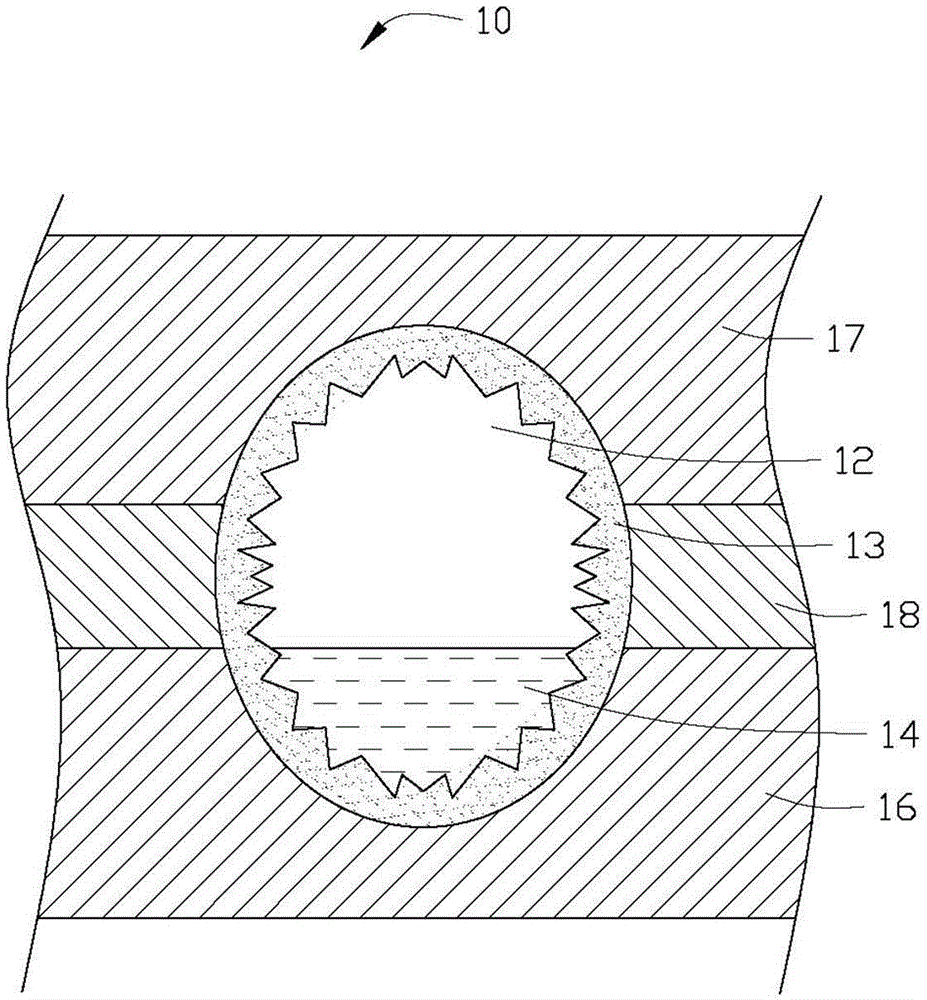

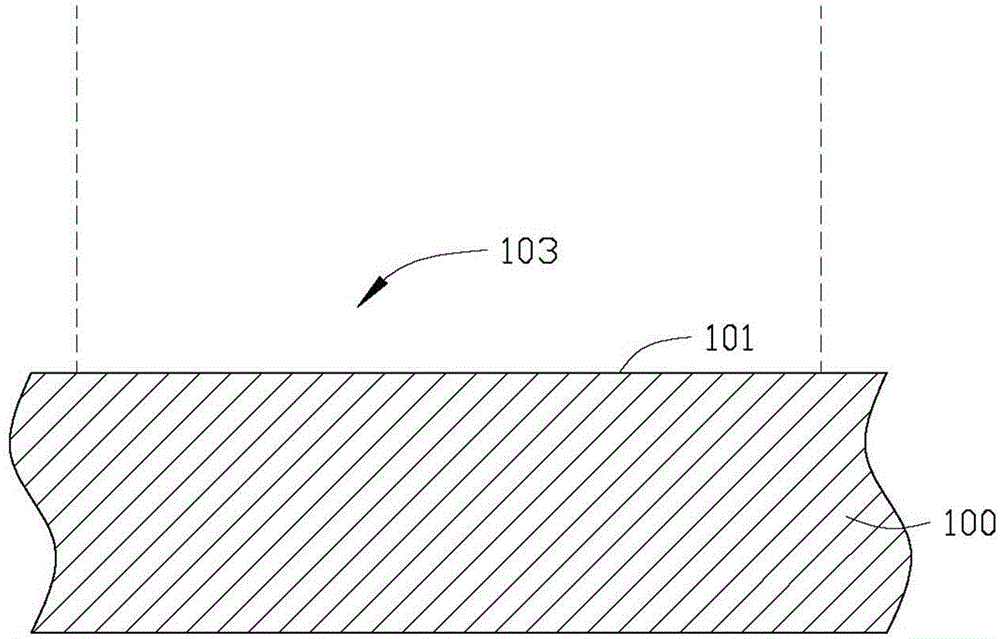

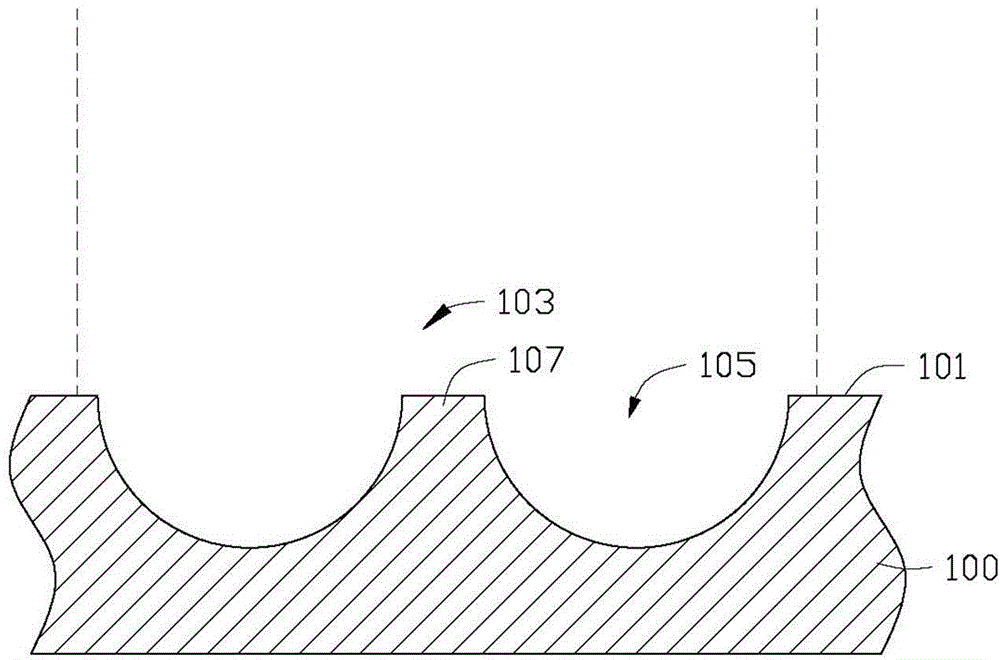

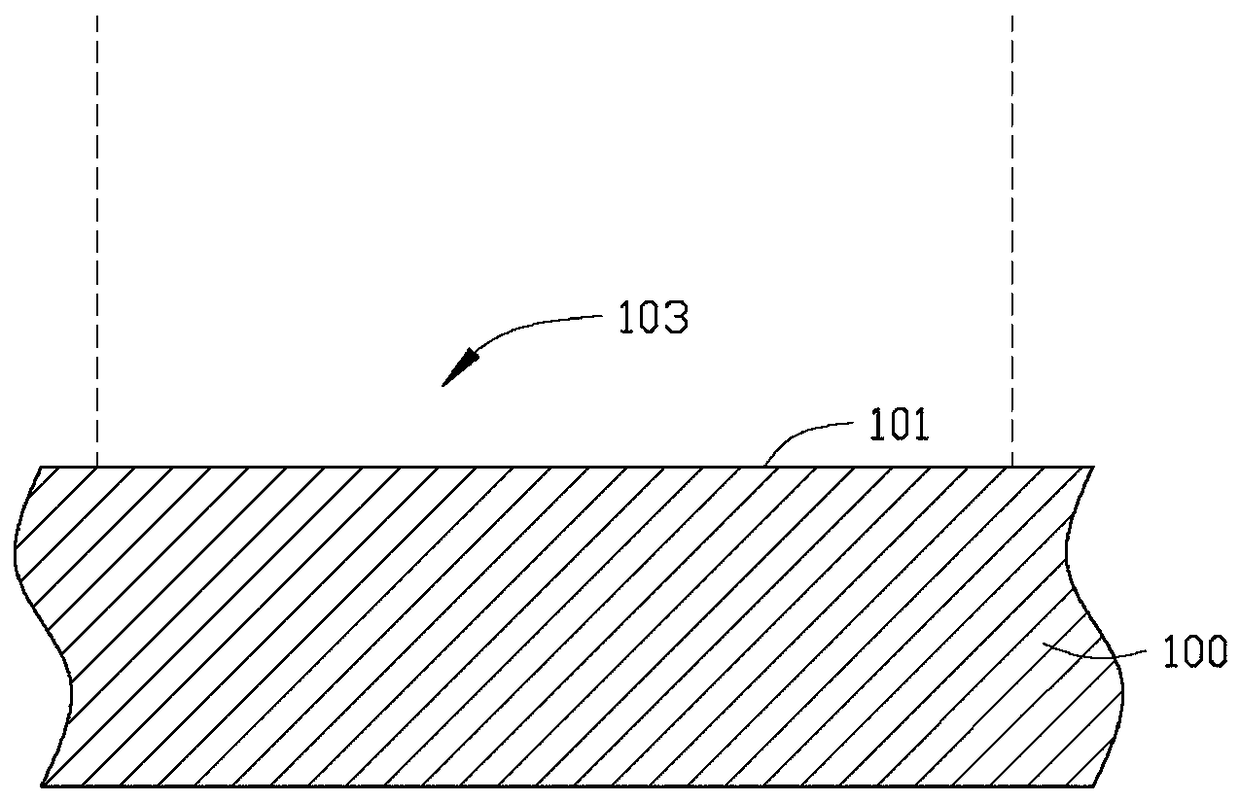

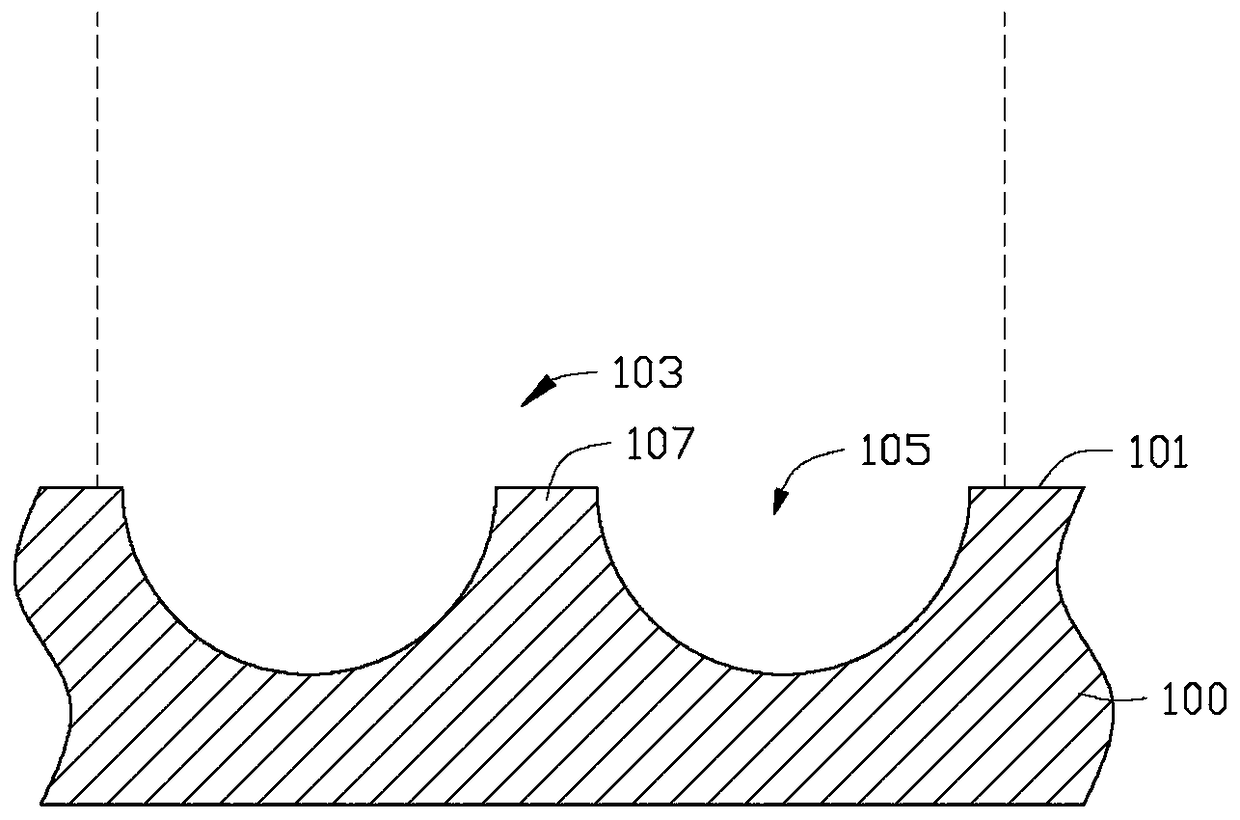

Temperature-uniforming plate and manufacturing method thereof

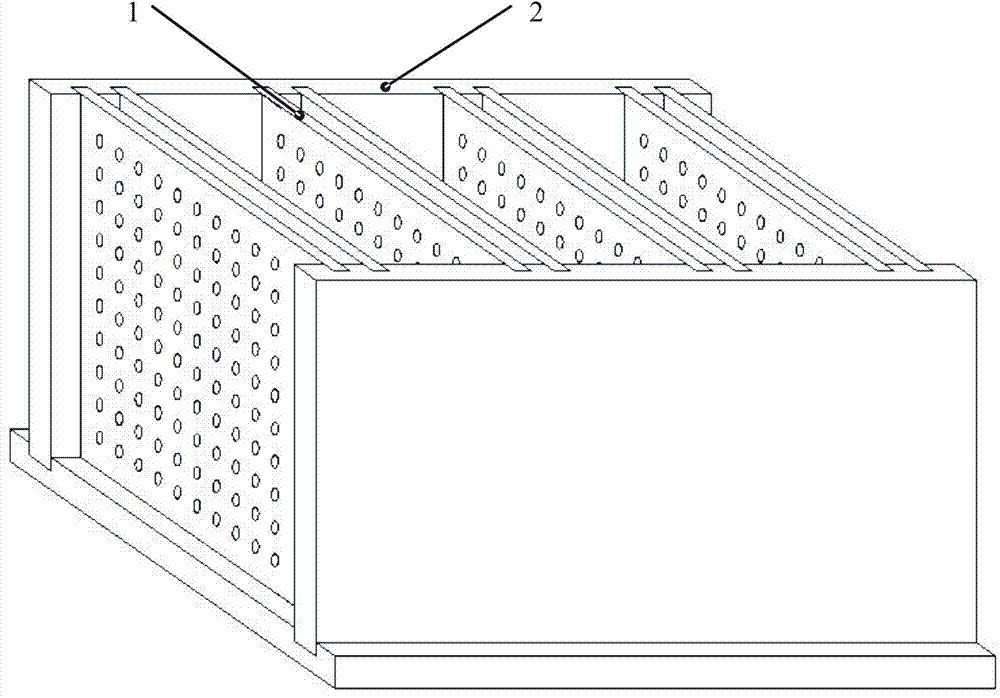

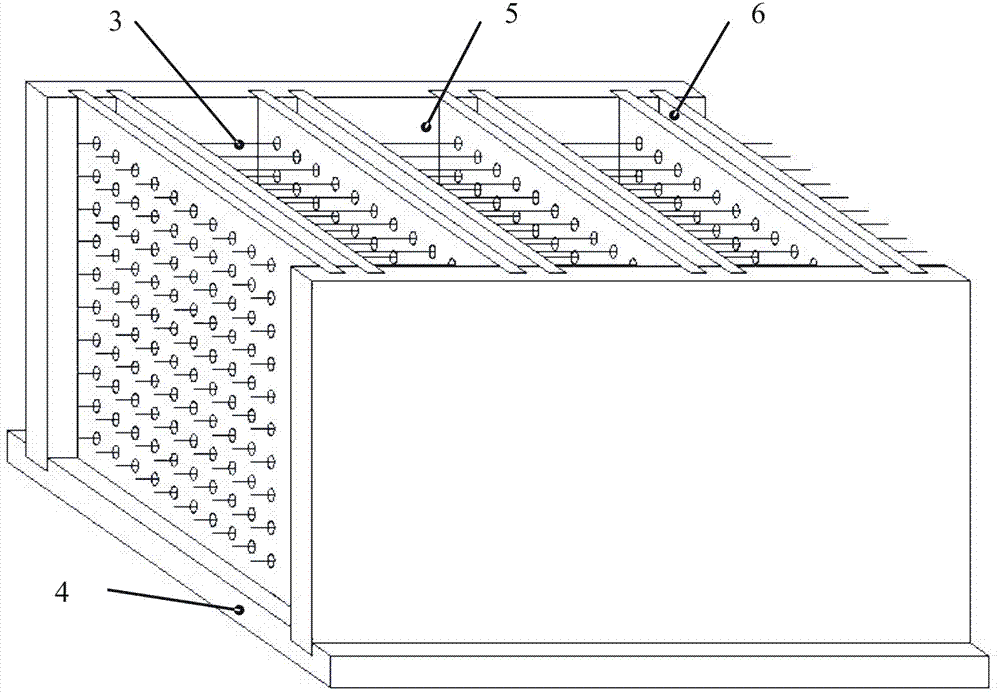

ActiveCN105764300AReduce the degree of collapseGuaranteed FARIndirect heat exchangersCooling/ventilation/heating modificationsWorking fluidAdhesive

The invention provides a manufacturing method of a temperature-uniforming plate, which comprises the steps of providing a flat first bottom plate with a first bottom surface, wherein the first bottom surface includes at least one cavity region; etching the first bottom plate to form at least two first grooves, and forming a non-etched first post between every two first grooves within the same cavity region; forming a first capillary structure on the surfaces of the first grooves and the first post; filling a working fluid in the first grooves; covering the adhesive on a first surface outside the cavity region; providing a second bottom plate with a second bottom surface, second grooves and a second post; laminating the first bottom plate and the second bottom plate together in the vacuum state to form a closed cavity by the first grooves and the second grooves; and curing the adhesive to obtain the temperature-uniforming plate. The invention also relates to a temperature-uniforming plate manufactured according to the above method.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Preparation method of iron-doped cobalt diselenide nanosheet/reduced graphene composite electrode material

InactiveCN110867570AIncrease profitReduce electrochemical activation timeCell electrodesSecondary cellsIron saltsComposite electrode

The invention provides a preparation method of an iron-doped cobalt diselenide nanosheet / reduced graphene composite electrode material. The preparation method comprises the following steps: (1) dispersing graphene oxide in a mixed solvent and carrying out ultrasonic dispersion to obtain a graphene oxide dispersion liquid; (2) adding cobalt salt and ferric salt into the graphene oxide dispersion liquid in the step (1) and stirring and dispersing to obtain a mixed dispersion liquid; and (3) adding selenium salt into the mixed dispersion liquid obtained in the step (2), stirring, soaking, heating, reacting, centrifuging, washing and drying to obtain the composite electrode material. The simple method is adopted, the iron-doped cobalt diselenide nanosheet and the composite material of the iron-doped cobalt diselenide nanosheet and graphene are prepared by taking low-cost transition metal salt as a precursor and adopting a one-step solvothermal method through optimization of the structure and composition of the material, and the material has the advantages of high specific capacity, good rate capability, long cycle life and the like as the negative electrode material of the sodium ion battery.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Negative electrode active material used for lithium battery and preparation method of negative electrode active material

ActiveCN107946552AAvoid chalkingPrevent peelingCell electrodesLi-accumulatorsDoped grapheneNew energy

The invention belongs to the technical field of a new energy negative electrode material of a lithium battery, and specifically relates to a negative electrode active material used for a lithium battery and a preparation method of the negative electrode active material. The preparation method comprises the steps of (1) enabling metal powder, silicon powder and graphene powder to be dispersed intodeionized water, and performing freezing and drying, and hot pressing and sintering to obtain a negative electrode template; (2) performing acid washing and washing until the liquid is neutral; (3) performing soaking in a processing liquid and drying; and (4) depositing a diamond coating layer on the surface of the negative electrode template to obtain the negative electrode material of the lithium battery. According to the negative active material used for the lithium battery provided by the invention, a silicon powder-doped graphene framework is adopted for suppressing volume change of the negative electrode material in the charging-discharging process; the diamond coating layer is deposited on the outer side of the graphene framework; and by virtue of matching of the external rigid diamond coating layer and the internal flexible graphene framework, the volume effect of the silicon-based material is reduced, and pulverization and stripping of the negative electrode material caused bysilicon particle volume expansion or contraction can be prevented.

Owner:INNER MONGOLIA HENGKE NEW MATERIAL TECH CO LTD

Cutting production technology of metal nanometer powder zero boundry particle

InactiveCN1911567AImprove product qualityEasy to shapeTransportation and packagingMetal-working apparatusIron powderGranularity

The present invention relates to preparation of nanometer metal powder, and is especially critical cutting nanometer metal powder producing process. The production process includes the steps of: setting iron powder at critical temperature of -10 deg.c to +10 deg.c, cutting iron powder particle at the speed of 4000-6000 times every minute, high frequency grinding at 4000-6000 rpm, physical reduction, surface treatment and final grading. By means of the technology of the present invention, may be produced nanometer level superfine iron powder with spherical form, homogeneous granularity, good flowability and high strength.

Owner:王惠民

Preparation method of high-capacity silicon-carbon composite negative electrode material with core-shell structure for lithium-ion battery

ActiveCN111354937AImprove structural stabilityAlleviate volume changesSecondary cellsNegative electrodesCarbon compositesLithium intercalation

The invention discloses a preparation method of a high-capacity silicon-carbon composite negative electrode material with a core-shell structure for a lithium-ion battery. The high-capacity silicon-carbon composite negative electrode material with the core-shell structure contains a silicon substance and a carbon substance, and the molar ratio of Si to C is 0.003-0.316. According to the invention,the problems in the prior art are solved, and the negative electrode material not only improves the structural stability of the core material silicon but also can effectively reduce the volume changeand particle fragmentation of an electrode in the lithium intercalation and deintercalation process. Meanwhile, the capacity bottleneck of a shell material carbon is solved, a difference between theresistance and the discharge potential of the core material and the shell material is reduced such that the core material and the shell material can reach a relatively consistent level in the aspect of lithium ion de-intercalation, and the advantage complementation between the core material silicon and the shell material carbon is realized. The coating effect is fully exerted, the structure of thesubstance is stabilized, and the safety stability and the electrochemical performance of the material are improved.

Owner:LONG POWER SYST NANTONG CO LTD

Layered manganese-based positive electrode material of sodium-ion battery and preparation method thereof

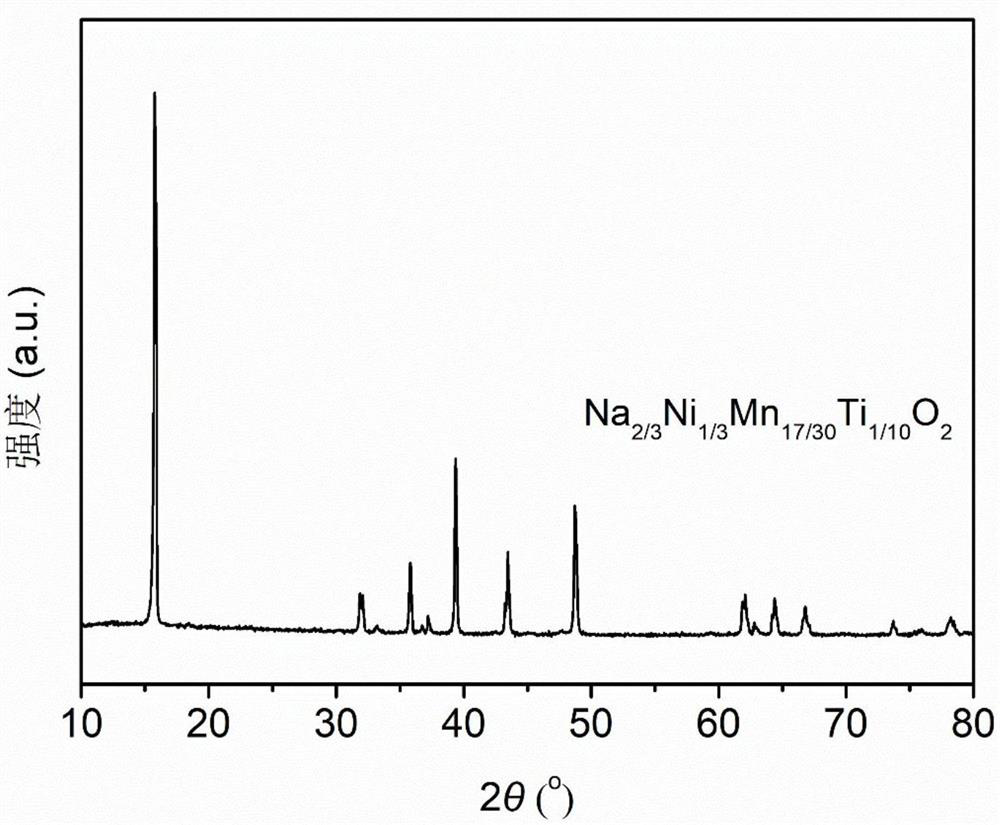

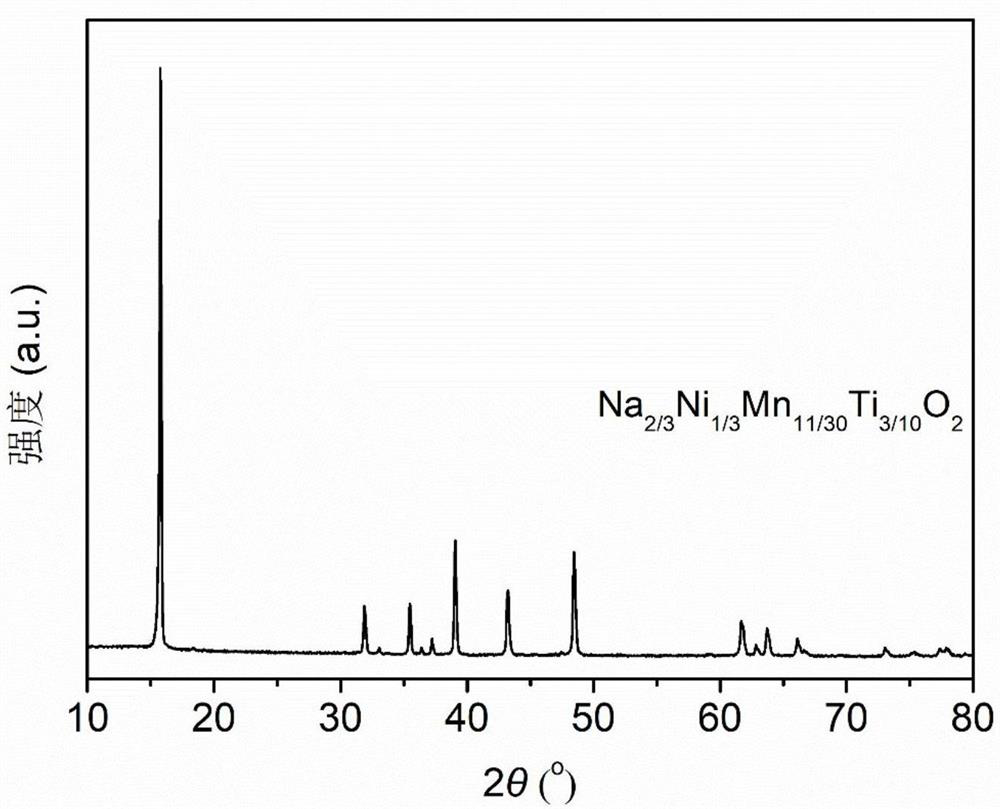

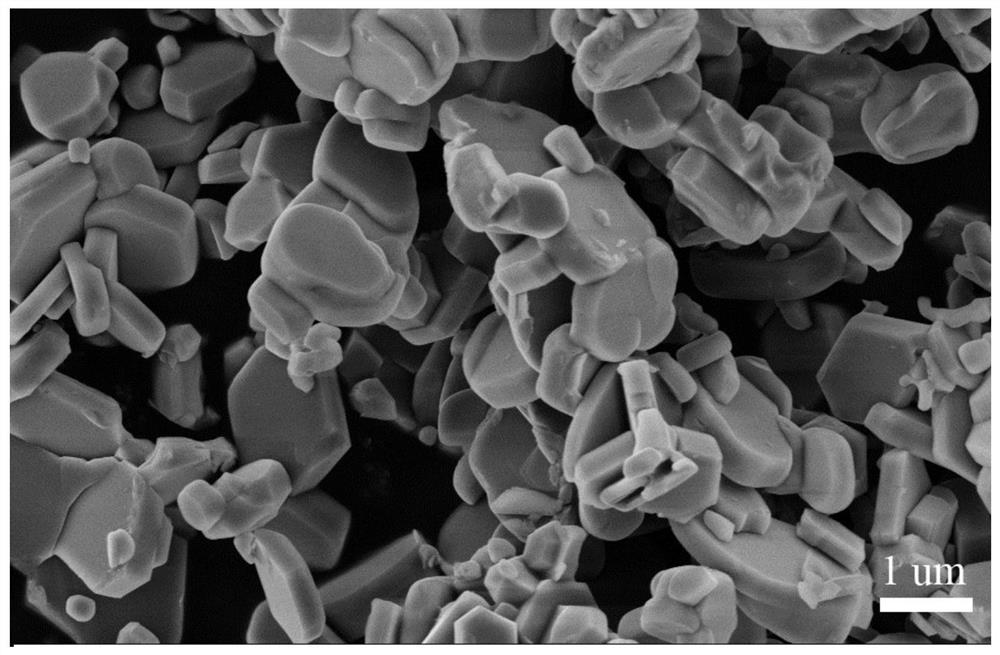

InactiveCN111762820ANo structural featuresImprove structural stabilityCell electrodesSecondary cellsElectrical batteryManganese

The invention discloses a layered manganese-based positive electrode material of a sodium-ion battery and a preparation method of the layered manganese-based positive electrode material. The general formula of the positive electrode material is Na<2 / 3>Ni<1 / 3>Mn<2 / 3-x>Ti<x>O<2> (1 / 10 < = x < = 3 / 10). The manganese-based positive electrode material prepared by the invention has a P2-phase layered structure, smooth surface morphology and uniform size, and the particle size is 1-3 microns. The material does not generate phase transformation in the charging and discharging process within a wide voltage range of 2.5-4.4 V, has good structural stability and stability in air, and has excellent rate capability and cycling stability. A sol-gel method and a high-temperature calcination method are adopted for synthesis, the preparation process is easy and convenient to operate, the sintering temperature is low, time is short, and energy consumption is low.

Owner:NINGXIA UNIVERSITY

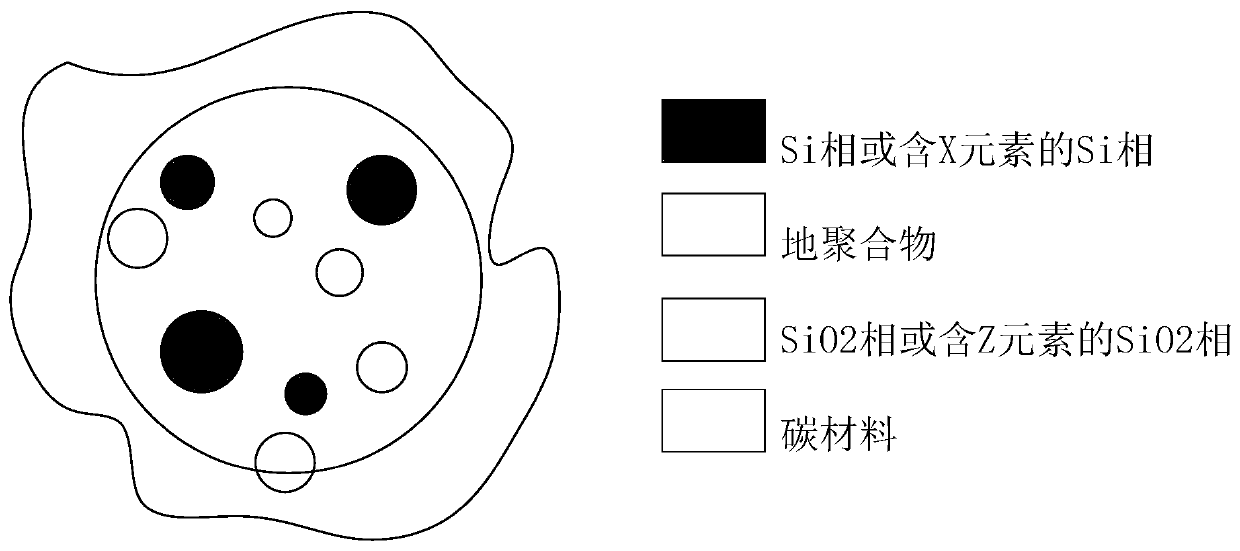

Silicon-containing material and preparation method and application thereof

ActiveCN111384385ASmall volume effectImprove efficiencySecondary cellsNegative electrodesPhysical chemistryGeopolymer

The invention discloses a silicon-containing material and a preparation method thereof. The silicon-containing material comprises silicon oxide particles and a geopolymer, and the geopolymer is dispersed in the silicon oxide particles and on the surfaces of the silicon oxide particles; or the geopolymer is dispersed inside or on the surface of the silicon oxide particles. The preparation method ofthe silicon-containing material comprises the following steps: (1) preparing required raw materials, mixing silicon and silicon dioxide, heating and depositing to obtain sediments, and crushing the sediments to obtain silicon oxide particles; (2) exciting the silicon oxide particles and aluminosilicate under specific conditions to react, thereby obtaining the silicon-containing material. The silicon-containing material has low volume effect and low sensitivity to water, and can effectively improve the first cycle efficiency and safety performance. The preparation method disclosed by the invention is simple in process, simple and convenient to operate, high in productivity and suitable for large-scale industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

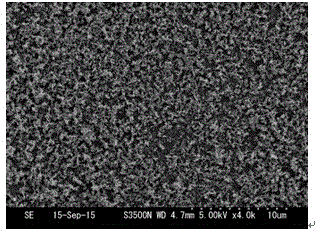

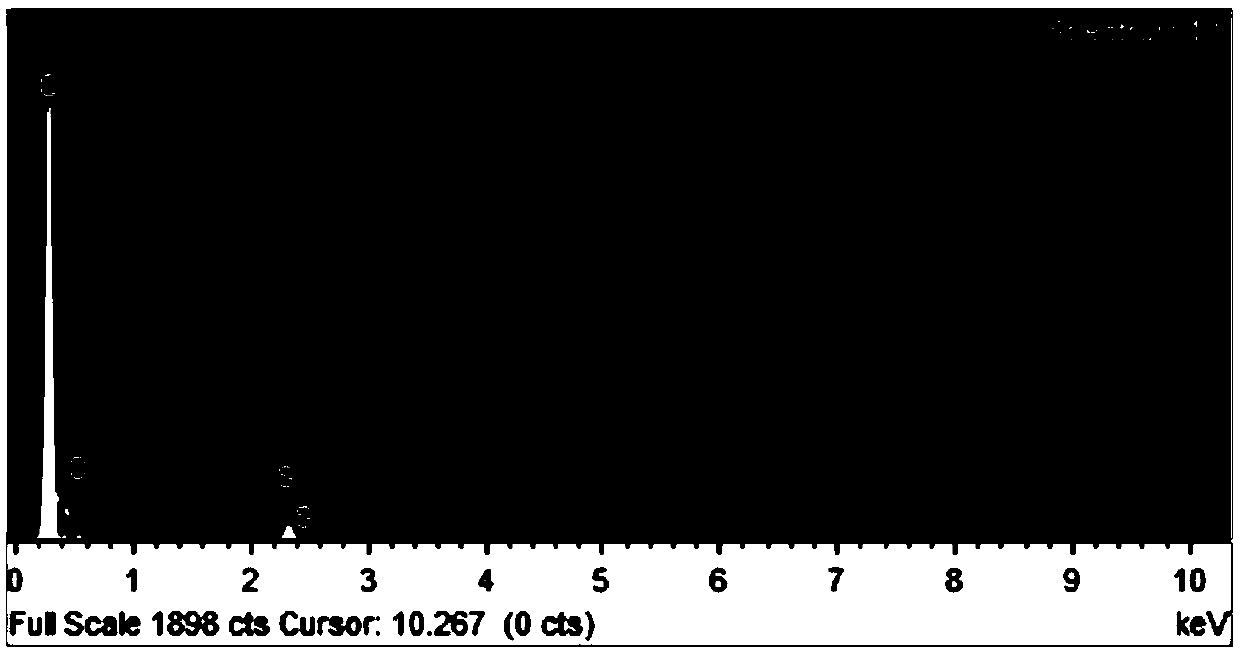

Lithium ion battery negative electrode material silicon oxide doped manganese oxide/carbon tube and preparation method thereof

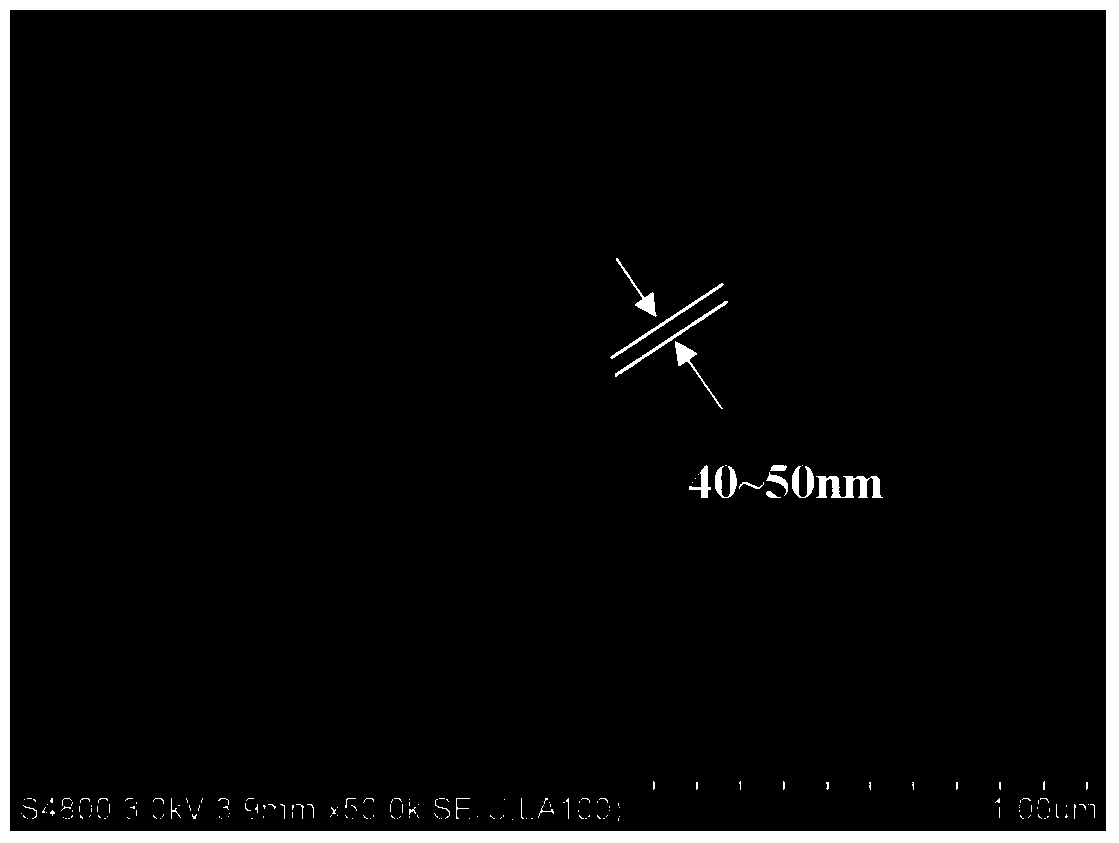

ActiveCN107104229AUniform shape and sizeUniform growthMaterial nanotechnologyNegative electrodesN dimethylformamideCarbon nanotube

The invention relates to a lithium ion battery negative electrode material silicon oxide doped manganese oxide / carbon tube and a preparation method thereof. The material is prepared according to the following method of (1) dispersing a carbon nanotube in a lower alcohol solution of N, N-dimethylformamide to obtain a carbon nanotube dispersion liquid; (2) dissolving a manganese source, a precipitator and a silicon source in the carbon nanotube dispersion liquid, uniformly stirring the mixture, naturally cooling the mixture to a room temperature after hydrothermal reaction, and performing filtering, washing, freezing and drying to obtain black powder; and (3) calcining the black powder in a protective atmosphere, and cooling the product with a furnace to the room temperature so as to obtain the lithium ion battery negative electrode material silicon oxide doped manganese oxide / carbon tube. The material is uniform in morphology and size, and silicon oxide doped manganese oxide particles are grown on a surface of the carbon nanotube; the material has the advantages of high electron conductivity and ion conductivity, short ion diffusion passage, small volume effect during lithium ion intercalation / de-intercalation process and the like; and the material is simple in preparation process, short in period, low in reaction temperature and low in cost, a large amount of materials can be synthesized, and the product yield is high.

Owner:CENT SOUTH UNIV

Organic material/graphene composite negative electrode, preparation method thereof and lithium ion battery

InactiveCN110323435AIncrease elasticityGood flexibilityGraphiteCell electrodesGraphite carbonOrganic acid

The invention discloses an organic material / graphene composite negative electrode. The composite negative electrode is formed by preparation of an organic material, a graphite carbon material and an auxiliary material, wherein the organic material is a mixture selected from one or more of organic acid / anhydride with a conjugate carbonyl structure. The invention also provides a preparation method of the composite negative electrode and a lithium ion battery manufactured by the composite negative electrode. The organic material / graphene composite negative electrode has the characteristics of high capacity, high power and long service lifetime and has a wide application prospect.

Owner:SUZHOU UNIV

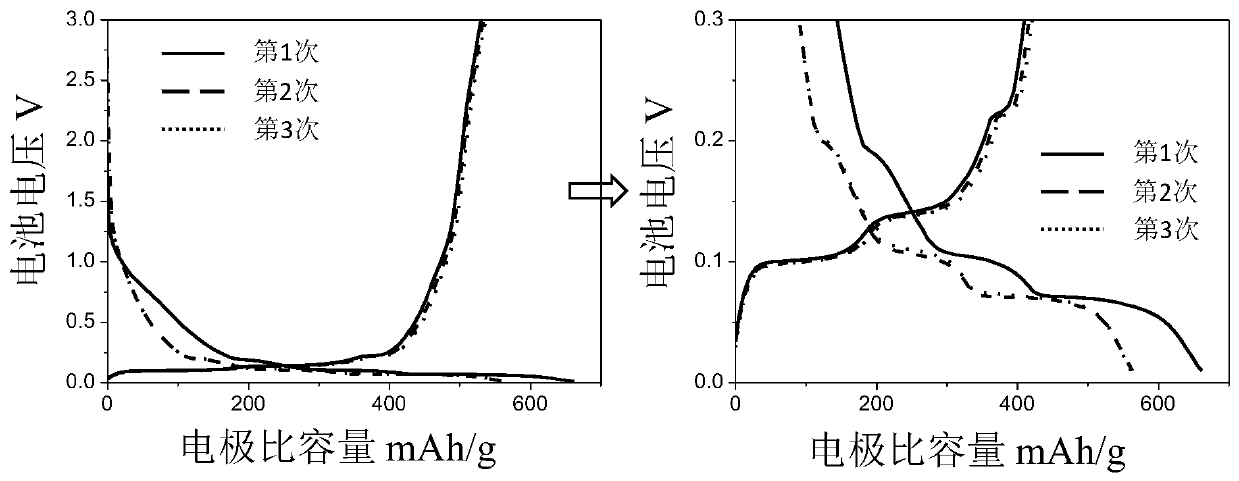

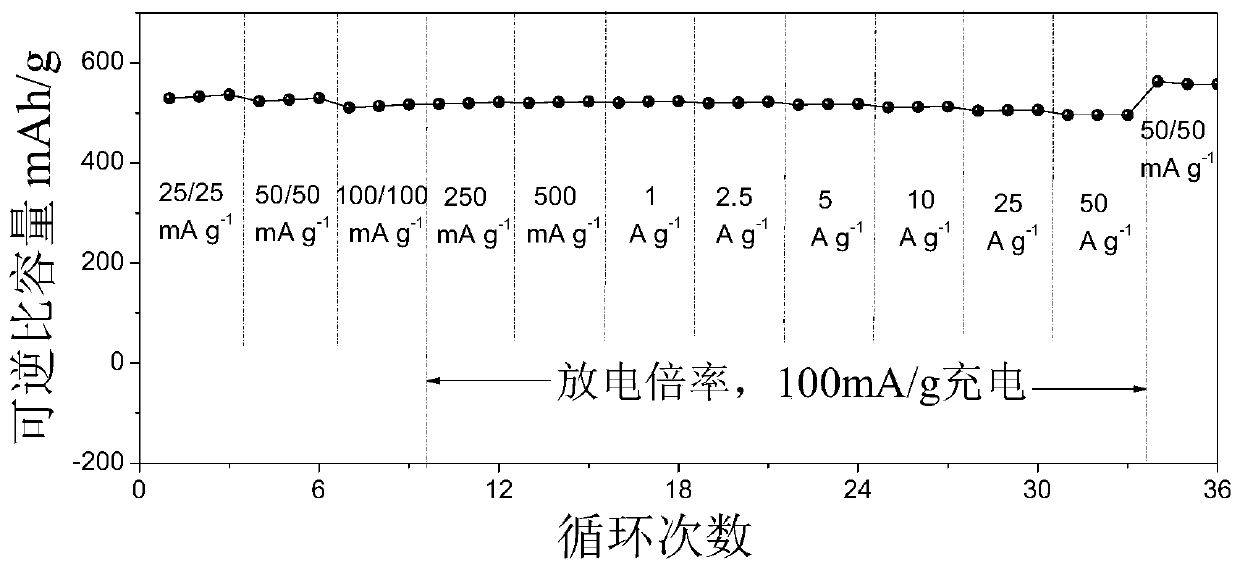

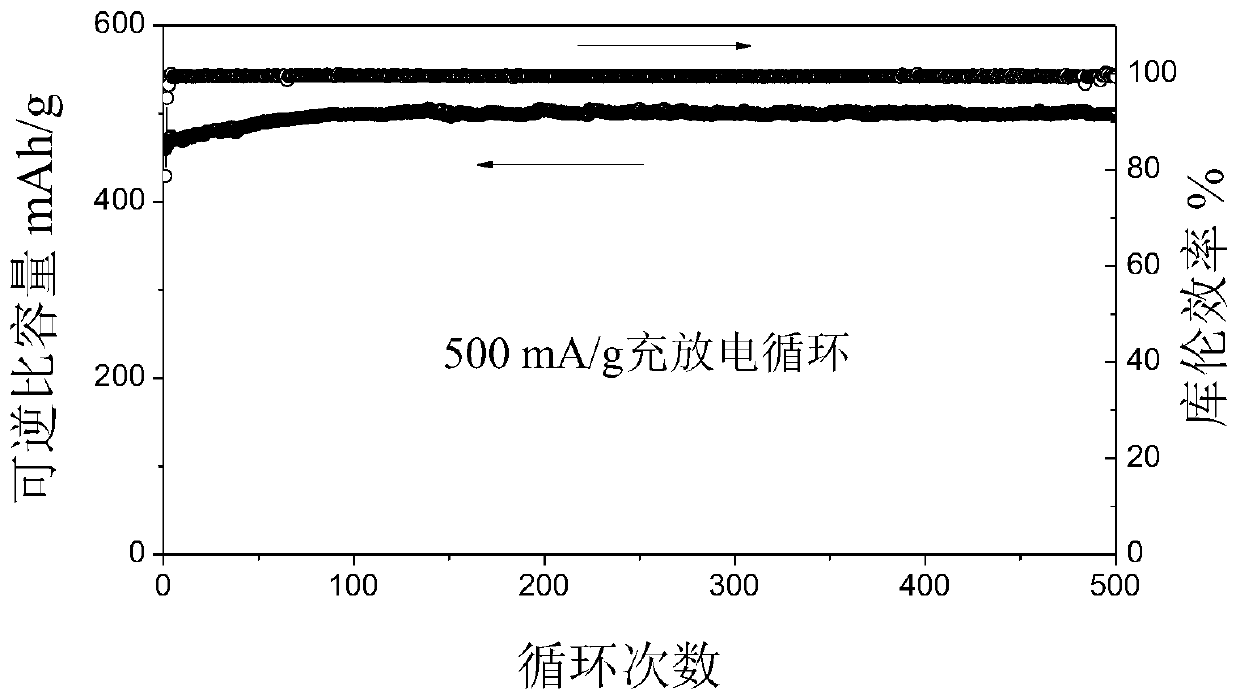

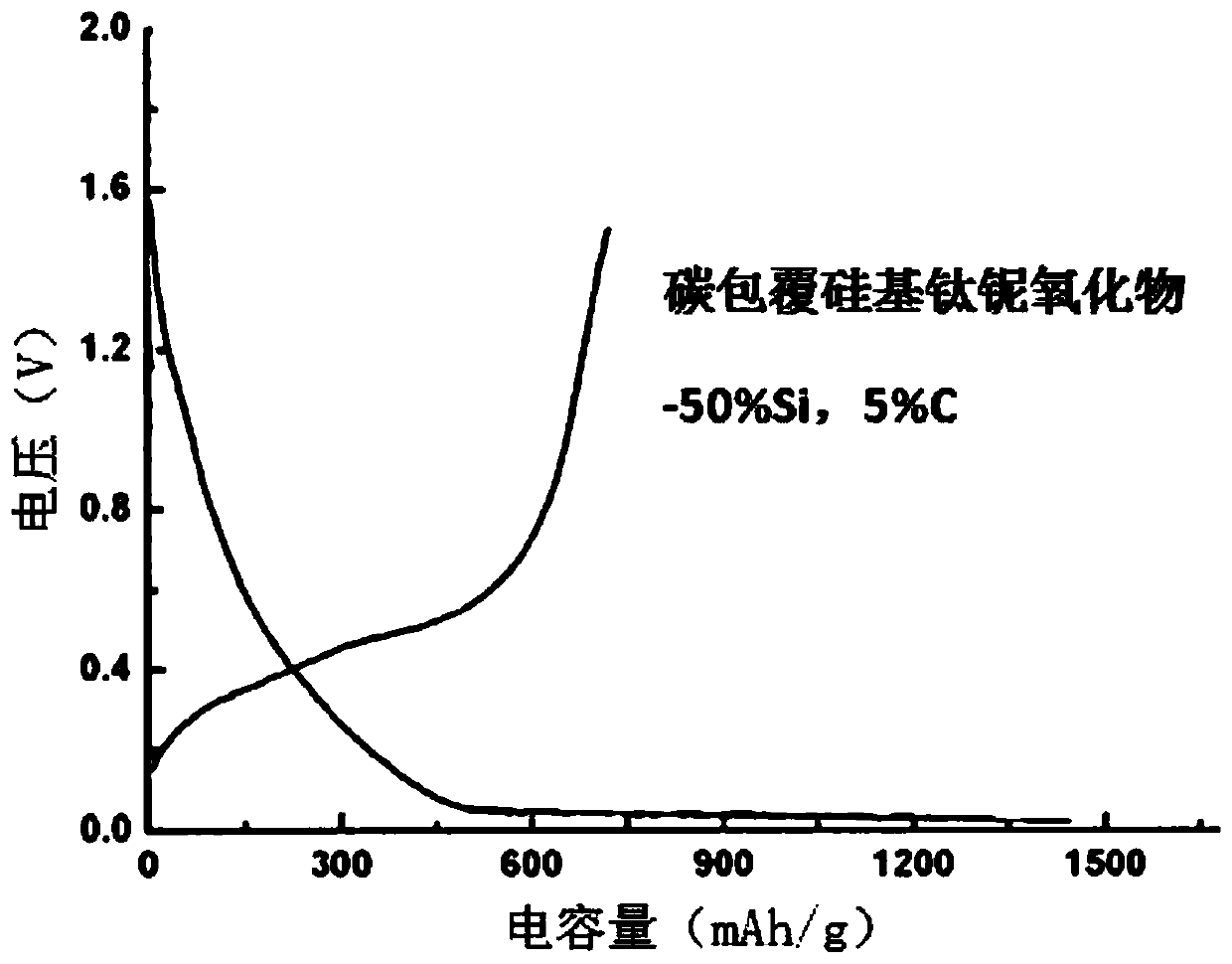

Carbon-coated silicon-based titanium-niobium composite material and preparation method thereof and lithium ion battery

PendingCN111170364AHigh affinityGood electrical contactSiliconFinal product manufactureSilicon monoxideHydrocotyle bowlesioides

The invention provides a carbon-coated silicon-based titanium-niobium composite material and a preparation method thereof, and a lithium ion battery. The preparation method comprises the following steps: with a titanium source and a niobium source as raw materials, carrying out a primary calcination process to obtain a first calcination product, wherein the temperature of the primary calcination process ranges from 800 DEG C to 1200 DEG C; and subjecting a silicon source, the first calcination product and a carbon source to a secondary calcining process so as to obtain the carbon-coated silicon-based titanium-niobium composite material, wherein the temperature of the secondary calcining process is 500-1000 DEG C, the titanium source is one or more selected from the group consisting of anatase titanium dioxide, anatase titanium dioxide hydrate silicon powder and silicon monoxide, the niobium source is niobium pentoxide, the silicon source is silicon powder or silicon monoxide, and the carbon source is hydrocarbon. The carbon-coated silicon-based titanium-niobium composite material prepared by adopting the method has a relatively small volume effect and relatively high cycle performance in the charging and discharging processes; and meanwhile, the preparation method also has the advantages of simple process, no pollution, high repeatability, large-scale production and the like.

Owner:NORTHERN ALTAIR NANOTECH CO LTD +1

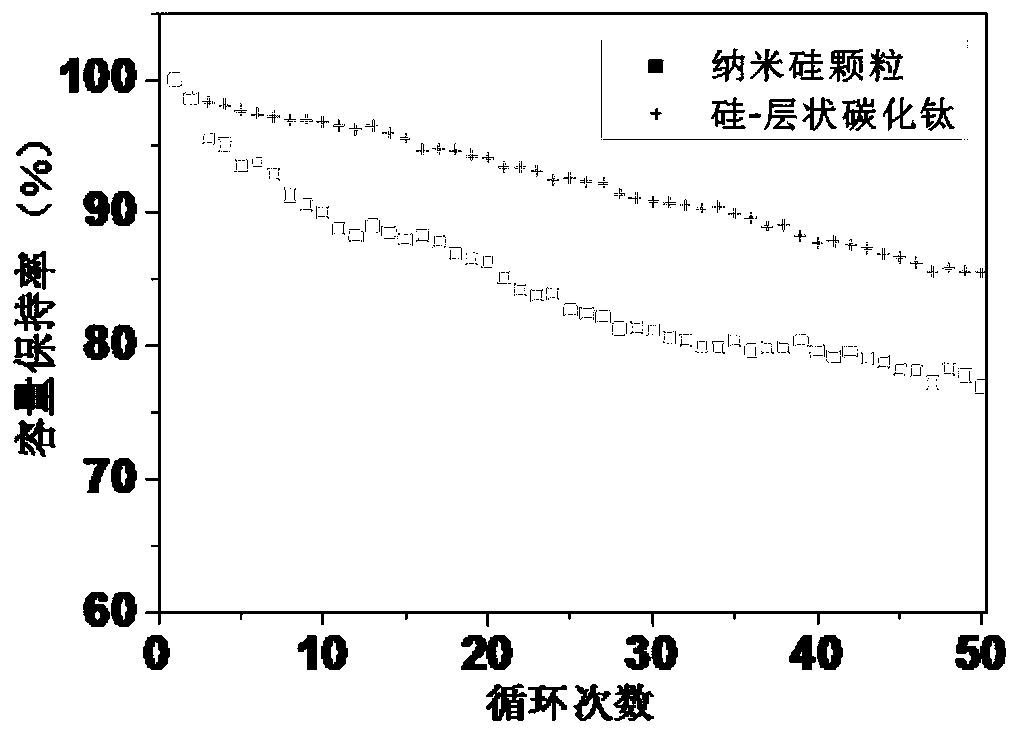

Silicon-layered titanium carbide cathode material and preparation method thereof

InactiveCN110165164ASmall volume effectGood electrical conductivitySecondary cellsNegative electrodesSolventSilicon particle

The invention discloses a silicon-layered titanium carbide cathode material and a preparation method thereof. A negative electrode material includes silicon particles and layered titanium carbide, wherein the silicon particles are uniformly distributed between a surface of a sheet layer of the layered titanium carbide and the sheet layer. The preparation method comprises steps that Ti3AlC2 or Ti3SiC2 is added to hydrogen fluoride solution to etch to obtain the layered titanium carbide; the layered titanium carbide and the silicon particles are added to solvent for ultrasonic dispersion, afterdrying, the silicon-layered titanium carbide cathode material is obtained. The preparation method of the silicon-layered titanium carbide cathode material is advantaged in that steps are simple, operability is high, the cathode material volume effect is small, and conductive performance and cycle stability are good.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

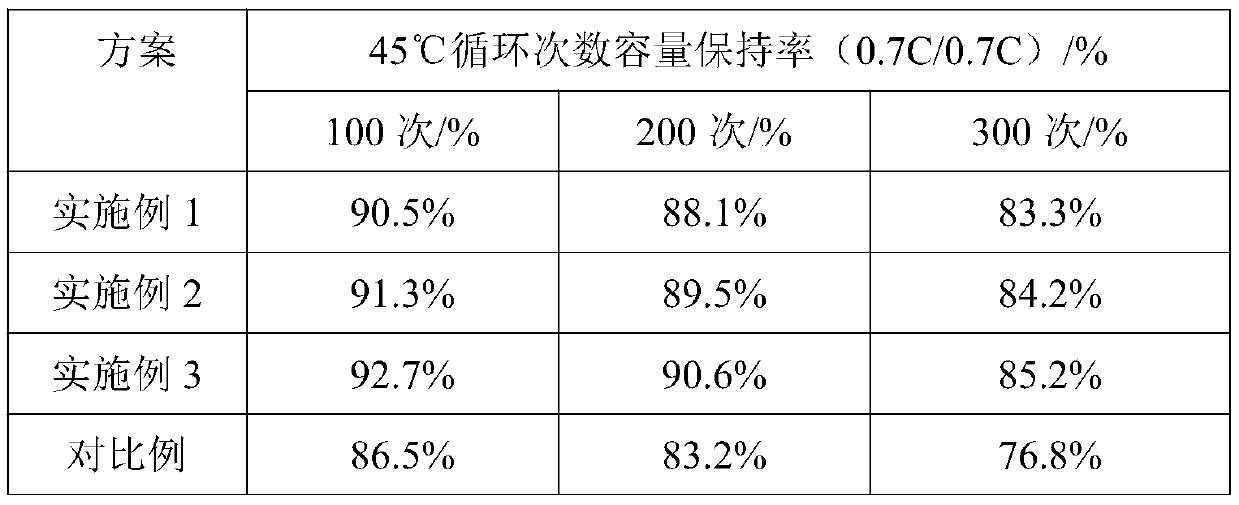

Lithium ion battery negative electrode and preparation method thereof

ActiveCN111463402AImprove cycle performanceLow gram capacitySecondary cellsNegative electrodesLithium-ion batteryBattery cell

The invention discloses a lithium ion battery negative electrode and a preparation method thereof, and belongs to the technical field of lithium-ion batteries. The specific scheme is as follows: the lithium ion battery negative electrode comprises a negative electrode current collector and a negative electrode coating, the negative electrode coating comprises a coating I and a coating II which arerespectively coated on two surfaces of the negative electrode current collector, the coating I comprises a negative electrode active material I, a conductive agent, a thickening agent I, a dispersingagent I and a binding agent I, the coating II comprises a negative electrode active material II, a conductive agent, a thickening agent II, a dispersing agent II and a binding agent II, the viscosityof the thickening agent I is greater than that of the thickening agent II, the viscosity of the dispersing agent I is greater than that of the dispersing agent II, the elastic modulus of the bindingagent I is greater than that of the binding agent II, and the high-viscosity thickening agent I, the high-viscosity dispersing agent I and the high-elastic modulus binding agent I are used in negativeelectrode slurry A, so that the consumption of the thickening I, the dispersing agent I and the binding I can be reduced, the consumption of the conductive agent is increased, and the dynamic performance of a long coating paste layer of the negative electrode is further improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

A lithium ion battery silicon oxide composite negative electrode material, preparation method and use thereof

ActiveCN104022257BImprove electronic conductivityImprove efficiencyCell electrodesSecondary cellsCarbon layerElectrical battery

The invention discloses a silicon dioxide composite anode material for a lithium ion battery, as well as a preparation method and an application of the silicon dioxide composite anode material. The silicon dioxide composite anode material is prepared from the components of silicon dioxide powder and a conductive carbon layer with the surface of the silicon dioxide powder is uniformly and densely coated. With the adoption of the silicon dioxide composite anode material, the original component structure of an SiO material system is kept, so that the lower volume effect is ensured; the silicon dioxide dense carbon layer coating structure is successfully realized by adopting the technologies of mixing kneading, sheet rolling, press forming and the like, and thus the first coulombic efficiency of the silicon dioxide composite anode material is remarkably increased, and can reach a theoretical value being larger than 77 percent, and the cycle performance and the conductive characteristic are also remarkably improved, so that the silicon dioxide composite anode material is suitable for being charged and discharged with the large rate and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD +1

High-strength efficient cement-based light transmission material and preparation method thereof

InactiveCN103043994BImprove air stabilityImprove machinabilityCeramic shaping apparatusFiberO-Phosphoric Acid

The invention provides a high-strength efficient cement-based light transmission material and a preparation method thereof, belonging to the field of novel building materials. The high-strength efficient cement-based light transmission material is prepared from the following materials in parts by weight: 100 parts of light calcined magnesia, 65-135 parts of magnesium chloride aqueous solution, 0-60 parts of admixture, 10-80 parts of light transmission fibers, 0.1-1 part of defoamer, 1-10 parts of polyvinyl alcohol micro powder, 0.1-1 part of phosphoric acid and 0.5-3 parts of ferrous sulfate. The preparation method has the advantage of preparing the high-strength efficient cement-based light transmission material based on the characteristics such as high strength, high abrasion resistance, high glossiness, low basicity and the like of the magnesium oxychloride cement. The novel light transmission material not only has good light transmittance performance to the visible light, but also reduces the chemical corrosion action of the cement base body to the light transmission fibers while ensuring the original mechanical properties of the cement base, as well as has the characteristics such as high strength, high durability, high ornamental value and the like.

Owner:WUHAN UNIV OF TECH

SnO2 nanorod for negative electrode of lithium ion battery, and preparation method of SnO2 nanorod

ActiveCN105932270AInhibition of agglomerationUniform particle size distributionMaterial nanotechnologyCell electrodesChemical physicsElectrical battery

The invention relates to a SnO2 nanorod for a negative electrode of a lithium ion battery, and a preparation method of the SnO2 nanorod. The preparation method comprises the following steps of: adding SnCl2*2H2O into deionized water to obtain milky solution, and performing ultrasonic treatment after adding super P into the milky solution so as to obtain uniform mixed solution; performing microwave hydrothermal reaction of the mixed solution to obtain a SnO2 / super P composite material; and sintering the SnO2 / super P composite material so as to obtain the SnO2 nanorod. According to the SnO2 nanorod for the negative electrode of the lithium ion battery, and the preparation method of the SnO2 nanorod disclosed by the invention, the super P is used as a template; the structure of a nano material can be controlled to a certain degree, such that aggregation of the nano material is inhibited; compared with the conventional hydrothermal method, a microwave hydrothermal method has the advantages that: microwave is used as a heating tool; stirring in a molecular level is realized; the non-uniform heating disadvantage of a hydrothermal container is overcome; the reaction time is shortened; the working efficiency is increased; and the nano material having complete crystallization and uniform particle size distribution can be prepared; and furthermore, the method is simple to operate, short in period and low in cost, and is suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

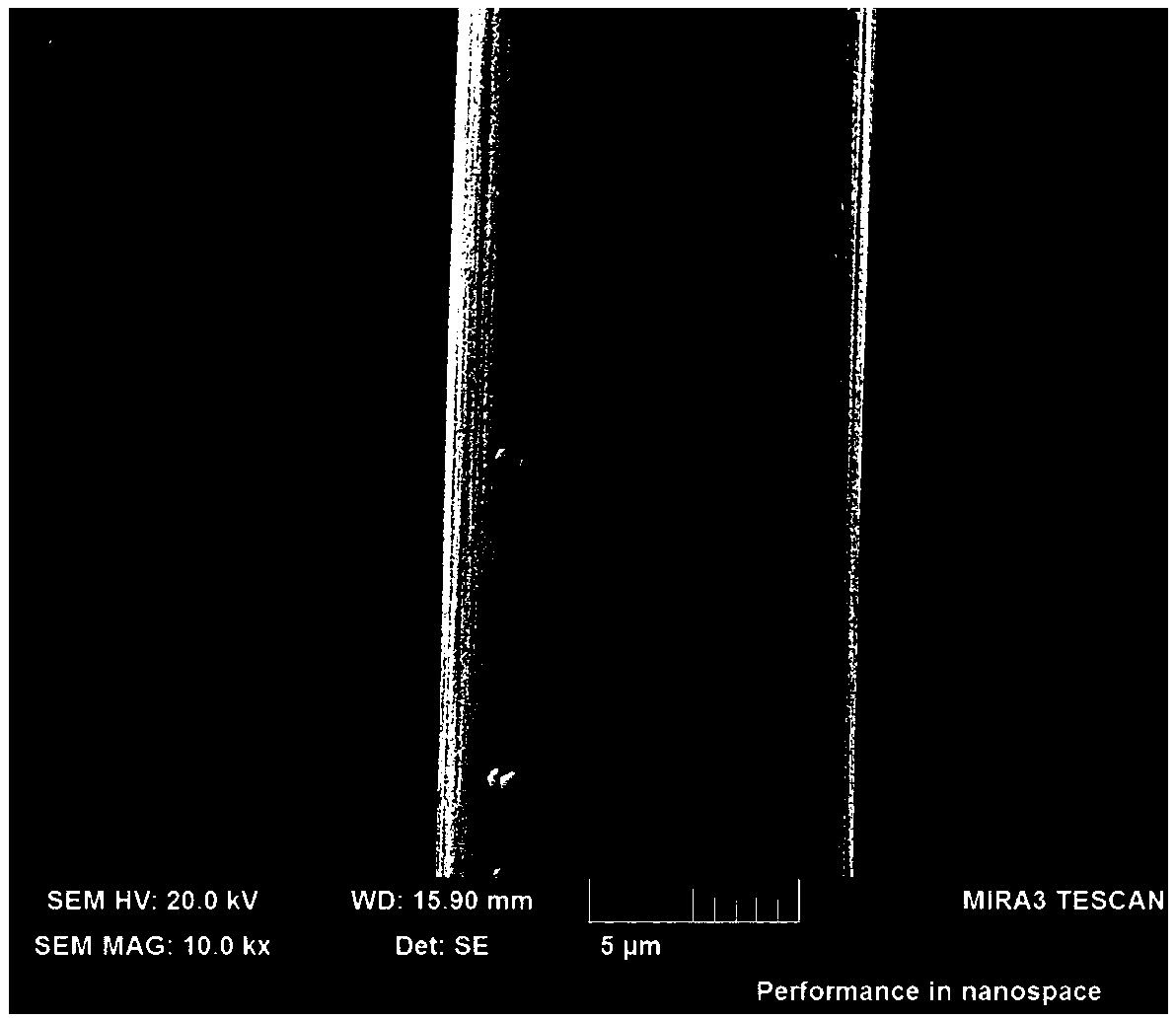

Preparation method of negative electrode of energy storage device, negative electrode of energy storage device, energy storage device, energy storage system and electric equipment

ActiveCN109671934AIncrease energy densityImprove cycle performanceCell electrodesSecondary cellsNew energyCarbonization

The invention relates to the field of new energy, and particularly provides a preparation method of the negative electrode of an energy storage device, the negative electrode of the energy storage device, the energy storage device, an energy storage system and electric equipment. The preparation method of the negative electrode of the energy storage device comprises the following steps: carrying out heating pretreatment on dried paper compounded with salt containing a sulfur element in an inert atmosphere to generate a sulfur-containing gas, further heating to realize the carbonization of thepaper and the doping of sulfur, thereby obtaining the negative electrode of the energy storage device. The method is simple in process, low in cost and suitable for industrial production. Based on themethod, the prepared negative electrode of the energy storage device is uniform and stable in structure, high in activity, and low in self weight. Therefore, the specific capacity, the energy densityand the cycle performance of the energy storage device can be improved.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD

Vapor chamber and manufacturing method thereof

ActiveCN105764300BReduce the degree of collapseGuaranteed FARIndirect heat exchangersCooling/ventilation/heating modificationsWorking fluidAdhesive

The invention provides a manufacturing method of a temperature-uniforming plate, which comprises the steps of providing a flat first bottom plate with a first bottom surface, wherein the first bottom surface includes at least one cavity region; etching the first bottom plate to form at least two first grooves, and forming a non-etched first post between every two first grooves within the same cavity region; forming a first capillary structure on the surfaces of the first grooves and the first post; filling a working fluid in the first grooves; covering the adhesive on a first surface outside the cavity region; providing a second bottom plate with a second bottom surface, second grooves and a second post; laminating the first bottom plate and the second bottom plate together in the vacuum state to form a closed cavity by the first grooves and the second grooves; and curing the adhesive to obtain the temperature-uniforming plate. The invention also relates to a temperature-uniforming plate manufactured according to the above method.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Silicon-based composite material, preparation method thereof, negative electrode and lithium ion battery

ActiveCN113471409AImprove conductivityImprove cycle performanceSecondary cellsNegative electrodesCarbon coatingSilicon oxide

The invention discloses a preparation method of a silicon-based composite material. The preparation method comprises the following steps: S1, carrying out primary carbon coating treatment on silicon powder and silicon oxide powder to obtain first powder; S2, performing secondary carbon coating treatment on the first powder to obtain second powder; and S3, screening and demagnetizing the second powder to obtain the silicon-based composite material. The invention also discloses the silicon-based composite material prepared by the method, a lithium ion battery negative electrode containing the silicon-based composite material and a lithium ion battery containing the negative electrode. The lithium ion battery has the advantages of high first coulombic efficiency, small volume expansion and the like.

Owner:新疆硅基新材料创新中心有限公司

Silicon-based negative electrode material and preparation method thereof, negative electrode and lithium ion battery

ActiveCN112952054AHigh reversible capacityImprove charge and discharge efficiencyCell electrodesSecondary cellsSilicon monoxideGraphite

The invention discloses a preparation method of a silicon-based negative electrode material, which comprises the following steps: taking silicon monoxide as a raw material, firstly carrying out surface modification treatment on the silicon monoxide raw material, then combining the silicon monoxide subjected to surface modification treatment with few layers of graphene to prepare a silicon-based capacity unit, and then mixing the silicon-based capacity unit with a carbon-based material to prepare the silicon-based negative electrode material. The invention also discloses the silicon-based negative electrode material of the lithium ion battery prepared by the method, a negative electrode containing the silicon-based negative electrode material, and the lithium ion battery. The reversible capacity and coulombic efficiency of the lithium ion battery can be improved, and volume expansion is reduced.

Owner:新疆硅基新材料创新中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com