Silicon-based cathode composite material and preparation method thereof

A composite material and silicon-based negative electrode technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve environmental pollution and other problems, achieve the effects of reducing volume effect, high specific capacity, improving specific capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

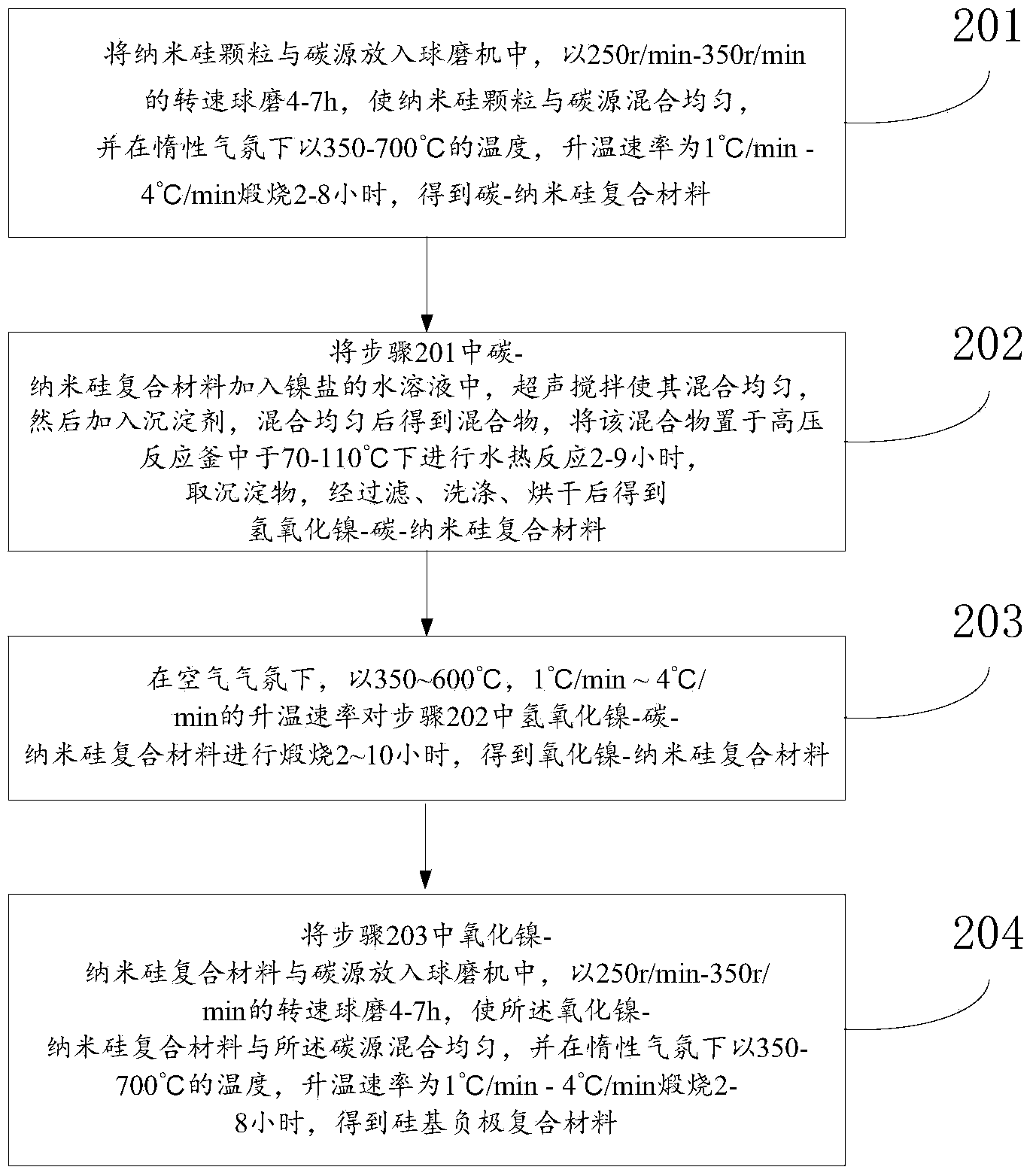

[0066] In the third aspect, the embodiment of the present invention provides a method for preparing a silicon-based negative electrode composite material, with figure 1 is a flowchart of the method. as attached figure 1 As shown, the method includes:

[0067] Step 101, uniformly mixing nano-silicon particles and carbon source, and calcining in an inert atmosphere to obtain a carbon-nano-silicon composite material.

[0068] Wherein, the structure of the carbon-nano-silicon composite material is that a first carbon layer is coated on the surface of the nano-silicon particle.

[0069] In step 101, the carbon source is evenly distributed on the surface of the nano-silicon particle by uniformly mixing the nano-silicon particle and the carbon source, and then calcined at a high temperature to carbonize the carbon source into carbon, thereby forming the first carbon on the surface of the nano-silicon particle layer. The thickness of the first carbon layer can be adjusted accordin...

Embodiment 1

[0099] In the embodiment of the present invention, a silicon-based negative electrode composite material is prepared, and the steps are as follows:

[0100] Step a, adding silicon powder and sucrose into a planetary ball mill, ball milling at a speed of 300r / min for 6 hours, and after mixing evenly, the sucrose is coated on the silicon powder. Then put it into a nitrogen atmosphere for high-temperature calcination, heat it to 450°C at a heating rate of 2°C / min, and keep it for 4 hours, so that the sucrose is carbonized into carbon, and at this time, the silicon-based material is coated with a layer of the first carbon. layer to obtain a carbon-nano-silicon composite material. Wherein the mass ratio of silicon powder and sucrose is 3:1.

[0101] Step b, preparation of NiCl 2 aqueous solution, the resulting carbon-nano-silicon composite was added to NiCl 2 In the aqueous solution, after ultrasonication for 50 minutes, stirring was carried out for 30 minutes to ensure that Ni ...

Embodiment 2

[0105] In the embodiment of the present invention, a silicon-based negative electrode composite material is prepared, and the steps are as follows:

[0106] Step a, add silicon monoxide (theoretical specific capacity of silicon monoxide is about 1200mAh / g) and polyvinyl alcohol into a planetary ball mill, ball mill for 6 hours at a speed of 300r / min, mix well, and coat the polyvinyl alcohol on Silicon-based materials. Then put it into a nitrogen atmosphere for high-temperature calcination, heat it to 500°C at a heating rate of 3 / min, and keep it warm for 4 hours, so that the glucose is carbonized into carbon. At this time, the silicon-based material is coated with a first carbon layer. , to obtain carbon-nano-silicon composites.

[0107] Step b, preparation Ni(NO 3 ) 2 aqueous solution, the obtained carbon-nano-silicon composite was added to Ni(NO 3 ) 2 In the aqueous solution, after ultrasonication for 50 minutes, stirring was carried out for 30 minutes to ensure that Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com