Silicon-containing material and preparation method and application thereof

A technology of silicon material and silicon phase, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of increased resistance, no obvious improvement in safety and stability, and sudden drop in cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

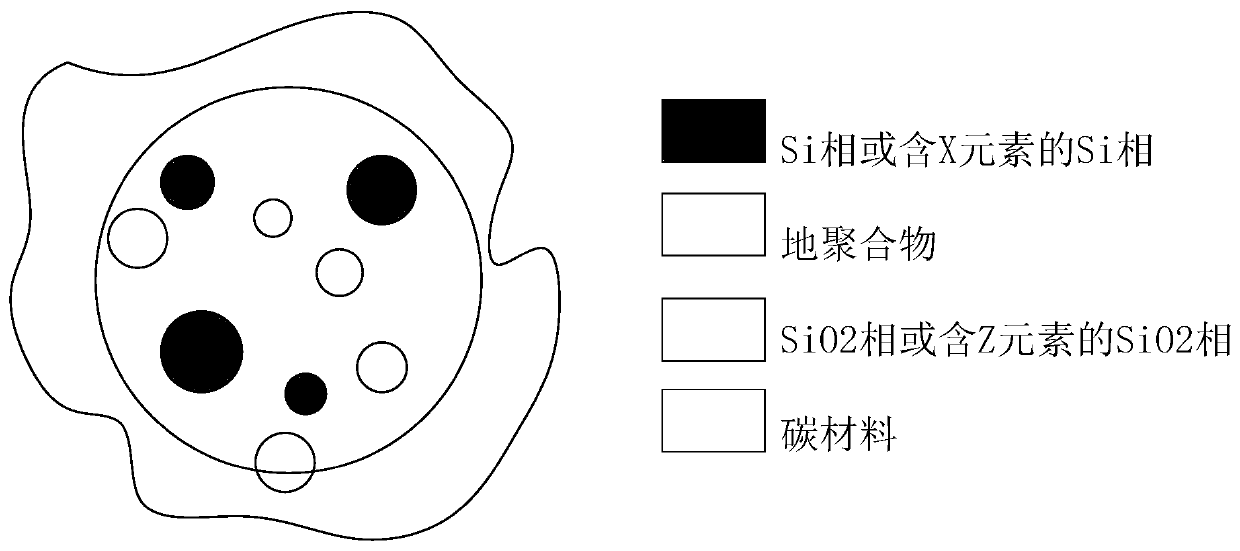

Embodiment 1

[0039]The silicon-containing material in this embodiment includes silicon oxide particles, a hard carbon layer covering the surface of the silicon oxide particles, and a geopolymer dispersed inside and / or on the surface of the silicon oxide particles, wherein the geopolymer occupies a silicon-containing The total mass of material is 7%. Schematic diagram of the structure of silicon-containing materials such as figure 1 As shown, wherein, X element can be one or more arbitrary elements in alkali metal, alkaline earth metal, titanium element and aluminum element, and Z element can be one or more of alkali metal, alkaline earth metal, titanium element and aluminum element A variety of arbitrary elements, X and Z elements can be the same or different. Its scanning electron microscope pictures are as Figure 5 shown.

[0040] The preparation method of the silicon-containing material of the present embodiment comprises the following steps:

[0041] (1) Mix silicon powder and sil...

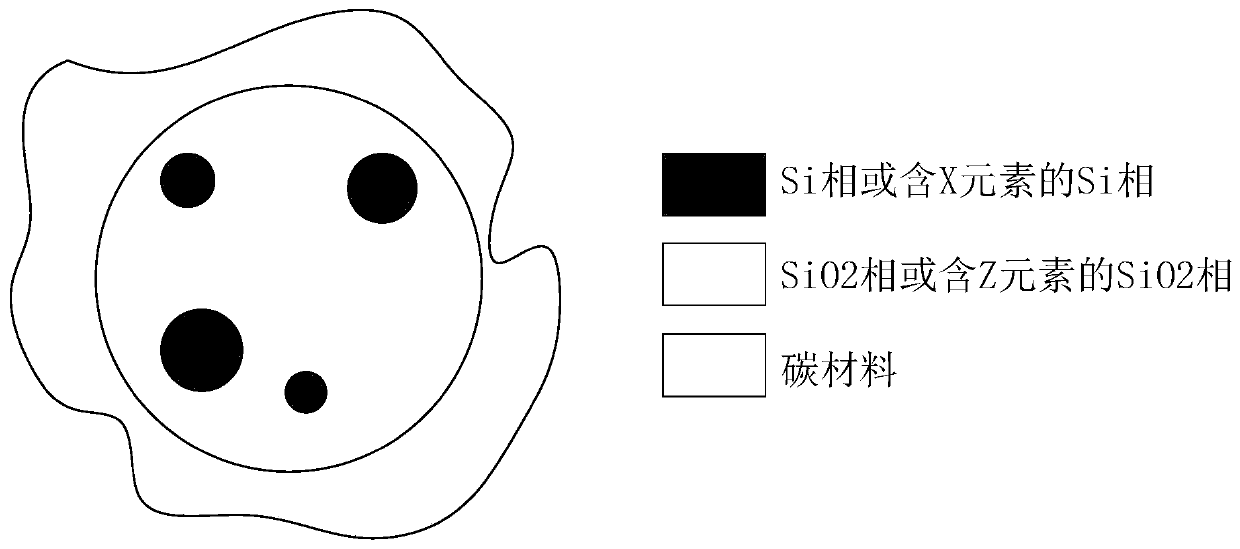

Embodiment 2

[0045] The silicon-containing material in this embodiment includes silicon oxide particles, a hard carbon layer covering the surface of the silicon oxide particles, and a geopolymer dispersed inside and / or on the surface of the silicon oxide particles, wherein the geopolymer occupies a silicon-containing 12% of the total mass of material.

[0046] The preparation method of the silicon-containing material of the present embodiment comprises the following steps:

[0047] (1) Mix silicon powder and silicon dioxide at a ratio of 1:1, heat at low pressure under the protection of an inert gas, and deposit on the top deposition plate to obtain SiO x The agglomeration of the ingredients, the agglomeration is crushed by jaws, jet milled, ball milled and then pulverized to obtain silicon oxide particles (SiO x particles).

[0048] (2) the above SiO x The particles are mixed with the slag produced by blast furnace iron smelting, immersed in NaOH solution for excitation and cured at 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com