Negative pole material for lithium-ion secondary battery, negative pole containing negative pole material, preparation method of negative pole and battery containing negative pole

A negative electrode material and secondary battery technology, applied in the field of negative electrode materials, can solve the problems of low reversible capacity, poor cycle performance, and high delithiation potential, and achieve reduced volume effect, high-strength bonding performance, and high lithium storage capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

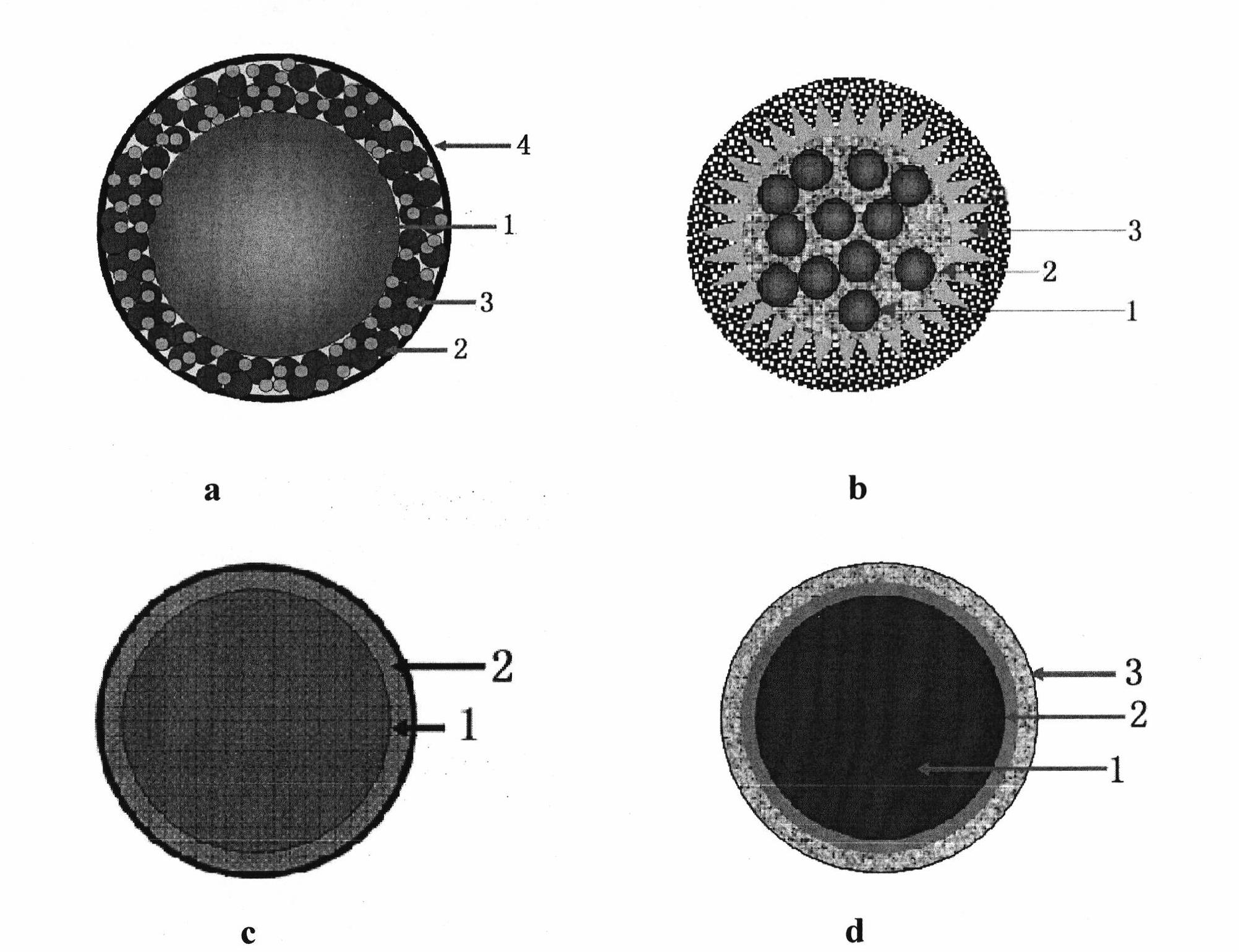

[0117] Example 1 Preparation of Negative Active Material I Containing Silicon Using Spray Drying

[0118] (1) dry commercial Si (particle size is 500 nanometers), commercial carbon material (particle size is 1-15 micron, carbon material can be mesophase carbon microsphere MCMB, natural graphite, artificial graphite), carbon black as conductive additive (average particle diameter is 40 nanometers), phenolic resin, by weight 1: 2: 0.4: 1 ratio is added in the ethanol solution, mixes evenly to obtain the slurry with certain concentration (also can not add conductive additive);

[0119] (2) Dry the slurry obtained above with a spray dryer at 70°C to obtain a spherical precursor powder. The drying gas can be compressed air or an inert gas. The flow rate of the drying gas is 10L / min, and the pressure of the compressed air is 7bar. The flow rate of the material is 300ml / h;

[0120] (3) Pyrolyze the spherical precursor powder obtained in step (2) under high-purity nitrogen gas. The...

Embodiment 2

[0130] Example 2 Preparation of Negative Active Material II Containing Silicon Using Spray Drying Method

[0131] (1) dry commodity Si (average particle size at 500 nanometers), conductive carbon black (average particle size 30 nanometers), and phenolic resin are added in the ethanol solution in a ratio of 10:0.5:3, and uniformly mixed to obtain a slurry with a certain concentration material;

[0132] (2) Dry the slurry obtained above with a spray dryer at 80° C. with compressed air to obtain a spherical precursor powder. The flow rate of the drying gas is 8 L / min, the pressure of the compressed air is 6 bar, and the flow rate of the slurry is 250 ml / h;

[0133] (3) The spherical precursor powder obtained in step (2) is pyrolyzed under high-purity nitrogen. The pyrolysis method is as follows: first use 4 hours to raise the temperature from room temperature to 400°C, and then use 5 hours to raise the temperature from 400°C to 800°C. ℃, then keep the temperature at 800℃ for 1...

Embodiment 3

[0137] Example 3 uses the spray method to prepare the negative electrode active material III of C / Cu / Si

[0138] (1) Si (average particle diameter is 1 micron), copper acetate, phenolic resin is added in the ratio of 10: 2: 3 in ethanol solvent and mixes and prepares slurry (also can add a certain amount of conductive additive);

[0139] (2) Dry the above prepared slurry with a spray dryer at 80°C to obtain a spherical precursor powder, the flow rate of the drying gas is 15L / min, the compressed air pressure is 8bar, and the flow rate of the slurry is 400ml / h;

[0140] (3) Heat the spherical precursor powder obtained in step (2) under high-purity nitrogen gas. The method of heat treatment is: first use 2 hours to heat up from room temperature to 700 ° C, keep the temperature at 700 ° C for 1 hour, and then use 2 The hour is down to room temperature, obtains containing Si, Cu composite particle;

[0141] (4) Under the mixed gas containing ethylene and high-purity nitrogen (vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com