Metal surface heat reflection heat insulation type waterborne polyurethane finishing coat and preparation method thereof

A water-based polyurethane, metal surface technology, applied in polyurea/polyurethane coatings, reflective/signal coatings, devices for coating liquids on surfaces, etc. heat and other problems, to achieve the effect of good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

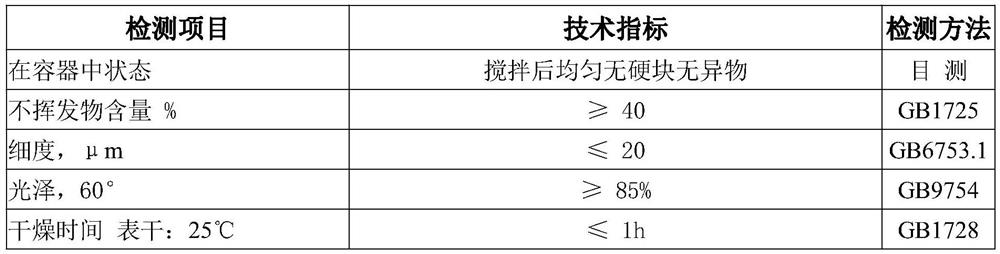

Image

Examples

Embodiment 1

[0048] Metal surface heat-reflecting heat-insulating water-based polyurethane topcoat, composed of two parts, A component and B component, the A component is 160 parts of purified water, 5 parts of wetting agent, 13 parts of dispersant, defoamer 2 parts, 620 parts of water-based resin (acrylate modified water-based polyurethane copolymer emulsion), 120 parts of infrared reflective pigment CICP, 12 parts of thermal insulation powder, 20 parts of filler, 5 parts of leveling agent, 5 parts of other additives, 38 parts of co-solvent ; The parts by weight of the B component are: 80 parts of water-based polyurethane curing agent, 20 parts of propylene glycol diacetate, and the ratio of the A component: B component is 5:1.

[0049] Its preparation method comprises the following steps:

[0050] 1. Add pure water and dispersant to the mixing container, then add 5 parts of wetting agent, 2 parts of defoamer, 220 parts of water-based resin under low-speed stirring, and then add 120 parts...

Embodiment 2

[0064] Metal surface heat-reflecting heat-insulating water-based polyurethane topcoat, composed of two parts, A component and B component, the A component is 190 parts of purified water, 5 parts of wetting agent, 13 parts of dispersant, defoamer 2 parts, 580 parts of water-based resin (acrylate modified water-based polyurethane copolymer emulsion), 110 parts of infrared reflective pigment CICP, 20 parts of thermal insulation powder, 30 parts of filler, 5 parts of leveling agent, 5 parts of other additives, 40 parts of co-solvent ; The parts by weight of the B component are: 70 parts of water-based polyurethane curing agent, 30 parts of propylene glycol diacetate, and the ratio of the A component: B component is 6:1.

[0065] Its production method and construction method are basically the same as embodiment 1, and the difference is that the production method water-based resin is 200 parts under the 1st step, and 380 parts under the 2nd step.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com