Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Para-chlorobenzoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Para-chlorobenzoic acid. ClC6H4COOH A white powder with a melting point of 238°C; soluble in methanol, absolute alcohol, and ether; used in the manufacture of dyes, fungicides, and pharamaceuticals.

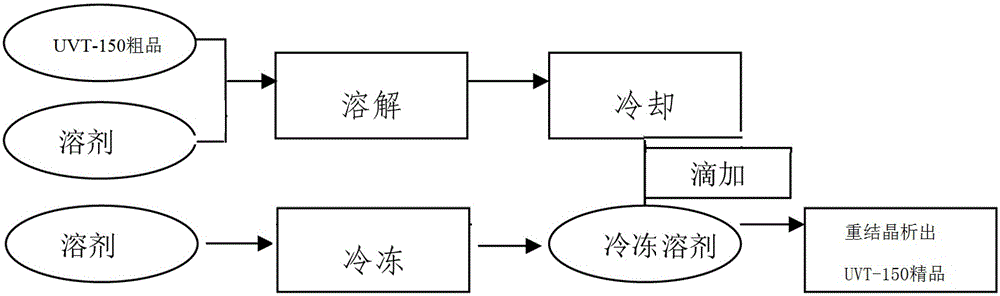

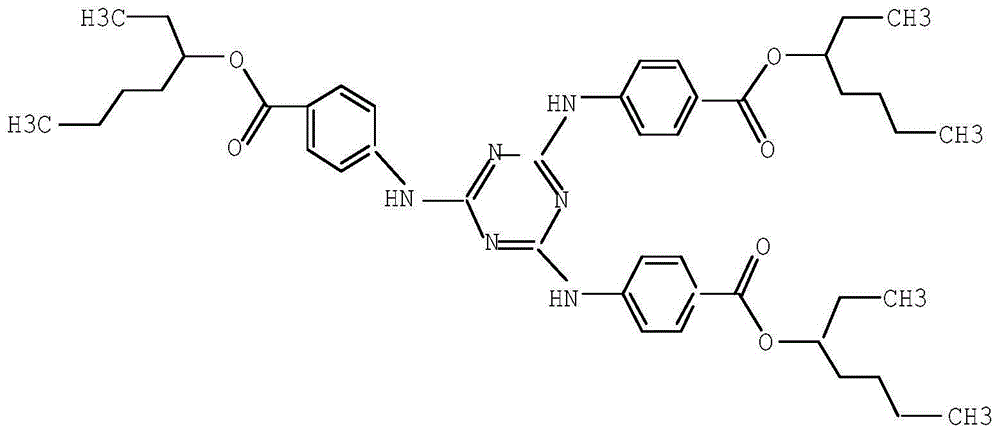

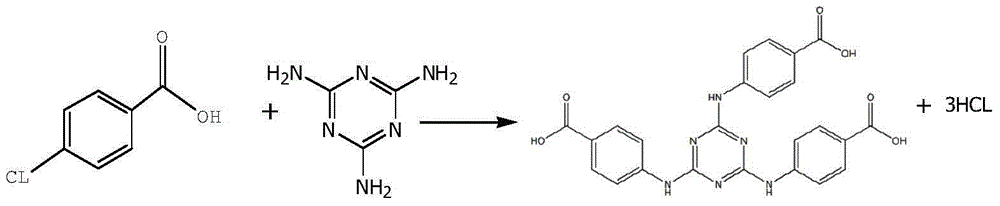

Synthesis method of UV absorbent ethylhexyl triazone

ActiveCN105061345ASimple process routeRaw materials are easy to getOrganic chemistrySynthesis methodsDistillation

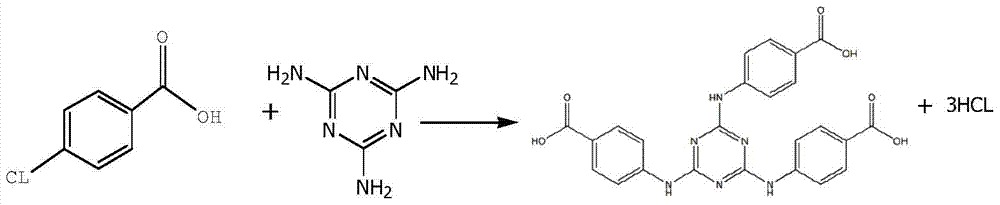

The invention discloses a synthesis method of a UV absorbent ethylhexyl triazone. The synthesis method comprises that melamine and 4-chlorobenzoic acid as initial raw materials undergo a trisubstitution reaction to produce 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine (H3TATAB), 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine (H3TATAB) and isooctanol undergo an esterification reaction to produce an ethylhexyl triazone crude product, the ethylhexyl triazone crude product is subjected to distillation desolvation and crystallization and the crystals are dried to form an ethylhexyl triazone finished product. The synthesis method has the characteristics of simple production route, easily available raw materials, mild reaction conditions, unique crystallization method, less three wastes and high product purity and is suitable for industrial production.

Owner:宜都市华阳化工有限责任公司

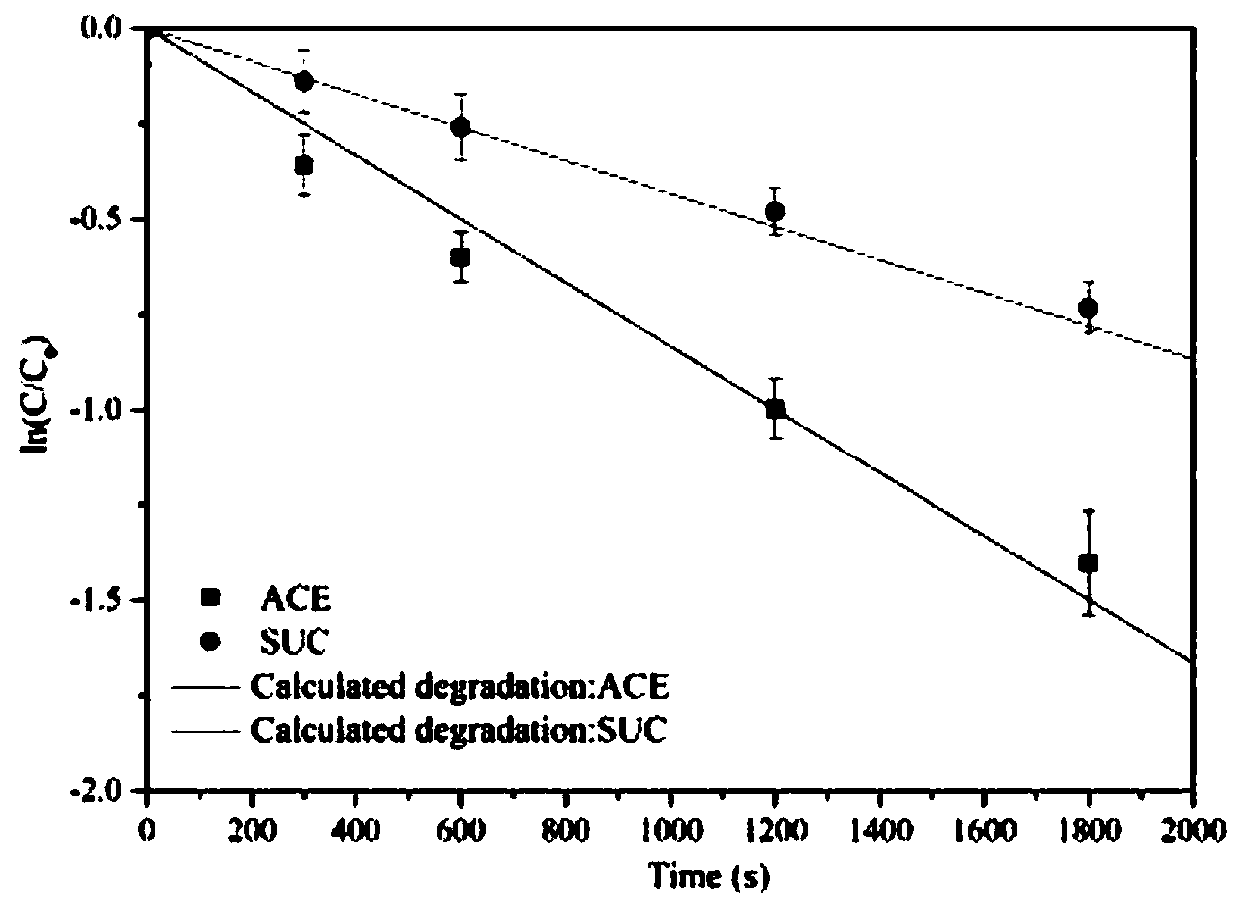

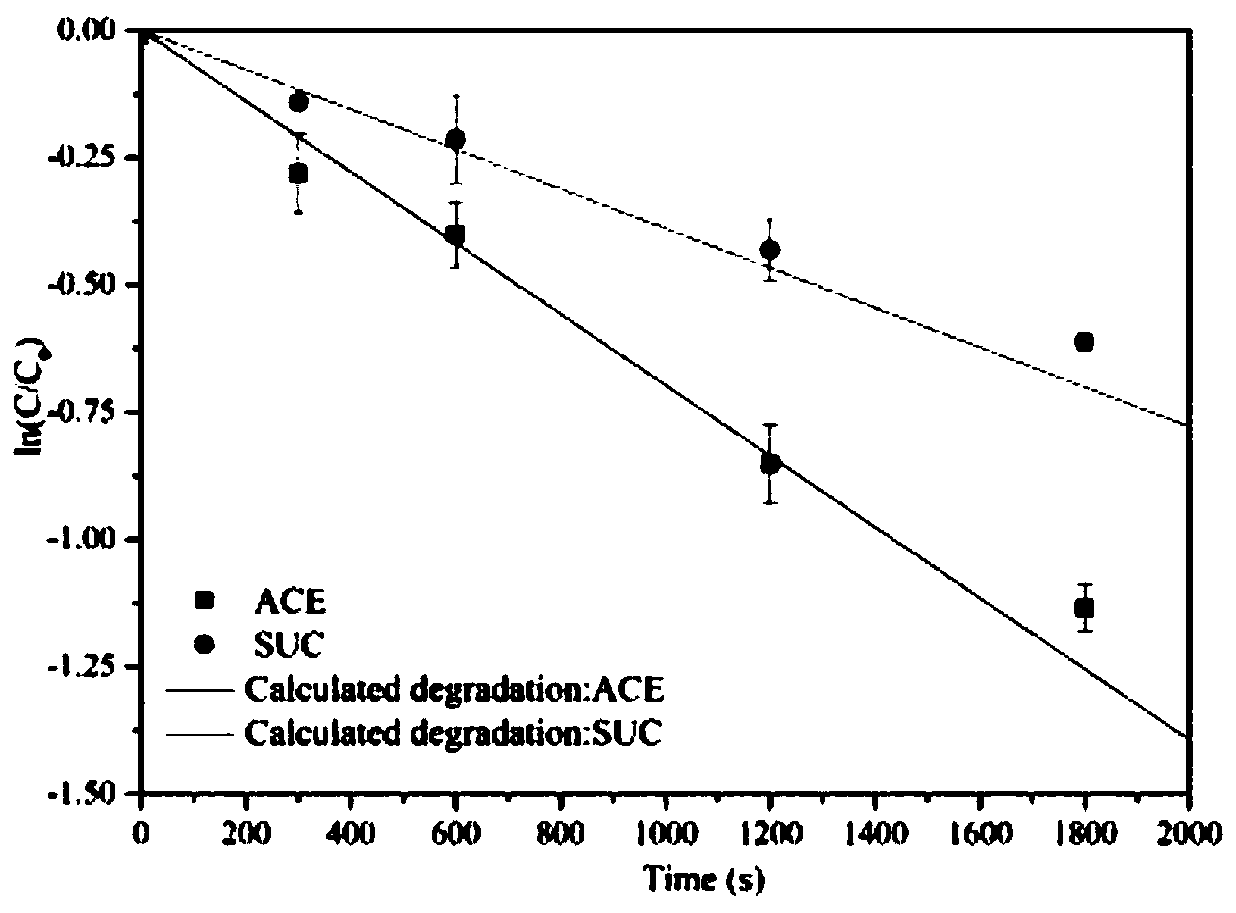

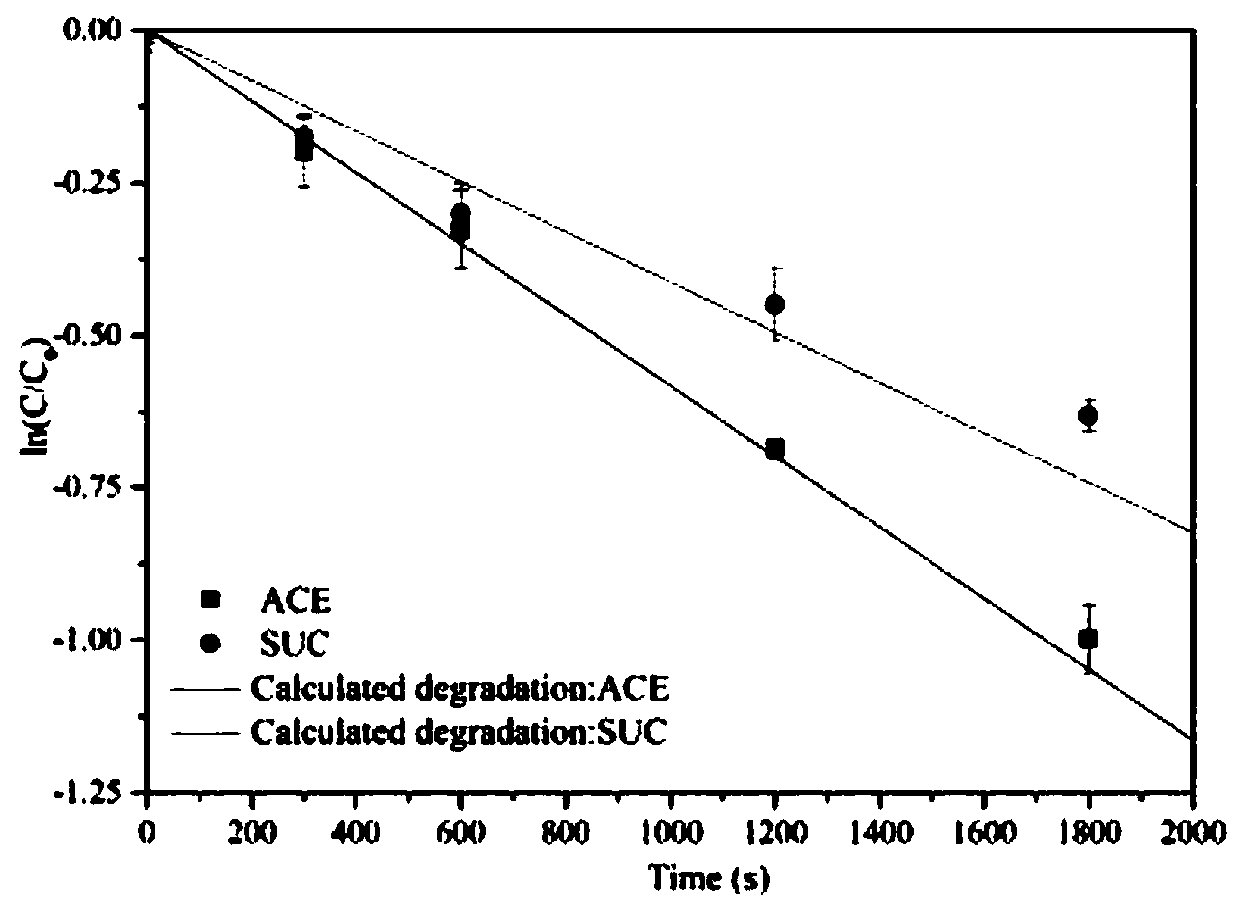

Degradation prediction method for removing micro-pollutants in secondary effluent by ultraviolet/sodium persulfate

ActiveCN109650487AAchieve the correct fitAchieve forecastWater/sewage treatment by irradiationWater contaminantsUltravioletChlorobenzoic Acids

The invention discloses a degradation prediction method for removing micro-pollutants in secondary effluent by ultraviolet / sodium persulfate. The method includes the following steps: S1, selecting p-chlorobenzoic acid and naproxen as reference materials, and establishing a reaction kinetics model of target pollutants, p-chlorobenzoic acid, naproxen and free redicals under ultraviolet / sodium persulfate; S2, adding the target pollutants, p-chlorobenzoic acid and naproxen into actual water, and oxidative degradation is carried out by using ultraviolet / sodium persulfate advanced oxidation technology; and S3, calculating the free radical content according to a degradation effect of the p-chlorobenzoic acid and naproxen by using the model, and predicting degradation conditions of the target pollutants. The model is established by measuring the degradation of the two reference materials to fit the degradation of the multiple pollutants in the secondary effluent under the ultraviolet / sodium persulfate, thereby evaluating the feasibility of removing the target pollutants in the secondary effluent by the ultraviolet / sodium persulfate and effectively reducing the cost of small tests.

Owner:NANJING UNIV

Rosin organic acid metal salt resin with chemical structural characteristics and performances of acrylate metal salt resin and preparation method and application of rosin organic acid metal salt resin

ActiveCN104530986AThe synthesis method is simpleRaw materials are cheap and easy to getAntifouling/underwater paintsRosin coatingsBenzoic acidArginine

The invention relates to rosin organic acid metal salt resin with chemical structural characteristics and performances of acrylate metal salt resin and a preparation method and application of the rosin organic acid metal salt resin. The rosin organic acid metal salt resin disclosed by the invention has a structural formula of R-X-R1 (I), wherein R refers to acid radicals of benzoic acid, naphthenic acid, salicylic acid, furoic acid, parachlorobenzoic-acid, 2,4-dichlorobenzoic acid, proline, leucine, phenylalanine or arginine; and X refers to Zn<2+>, Cu<2+>, Mg<2+> or Ca<2+> metal ions; and R1 is selected from acid radicals of colopholic acid, ionated rosin acid or dimeric colopholic acid. The rosin organic acid metal salt resin disclosed by the invention is environment-friendly, has the similar chemical structural characteristics with the acrylate metal salt resin and is excellent in matching property with other components in the coating formula. The self-polishing antifouling paint taking the resin as a film forming matter is high in coating toughness, excellent in self-polishing performance and long in antifouling period, accords with the environment-friendly development trend of the antifouling coating and has wide application prospects.

Owner:OCEAN UNIV OF CHINA

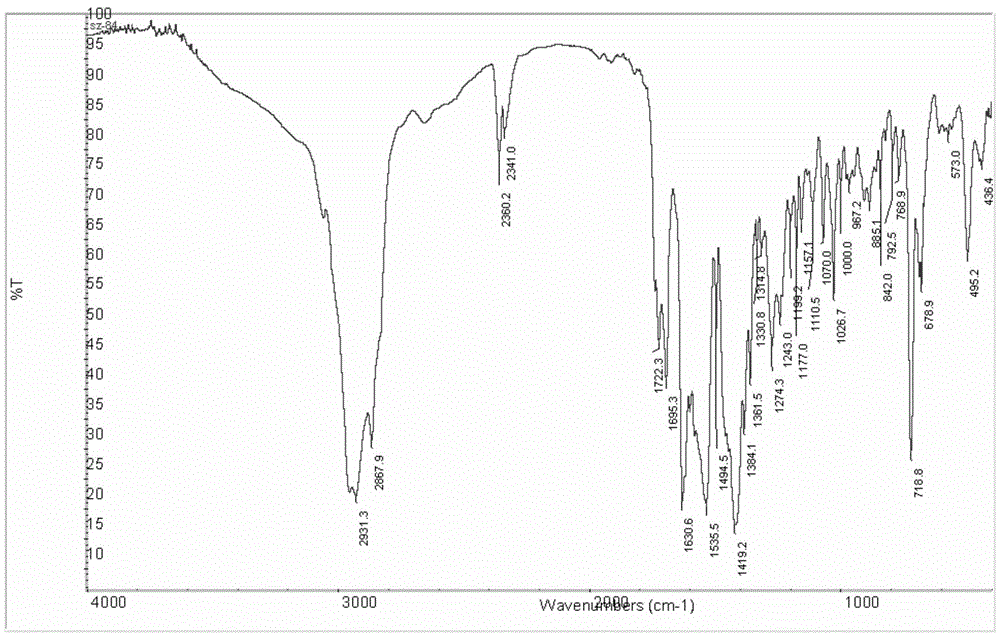

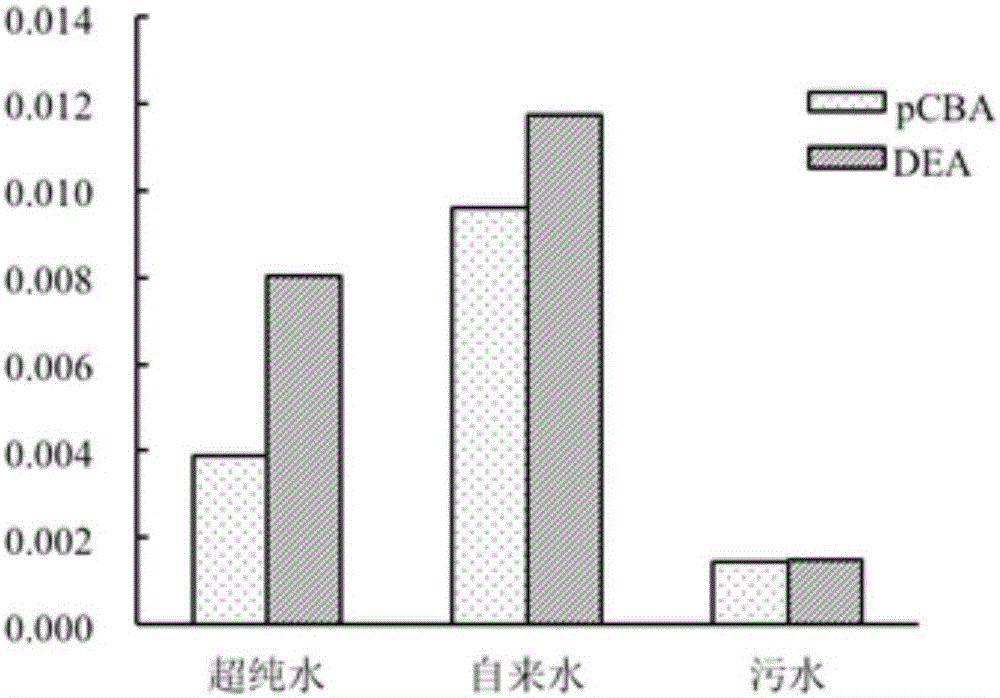

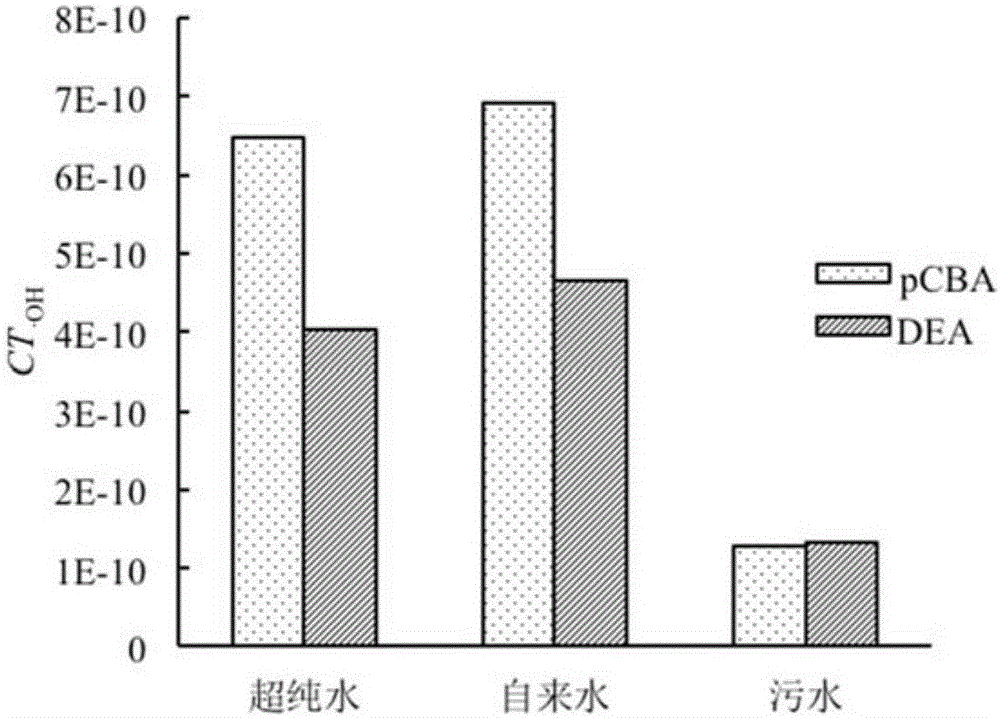

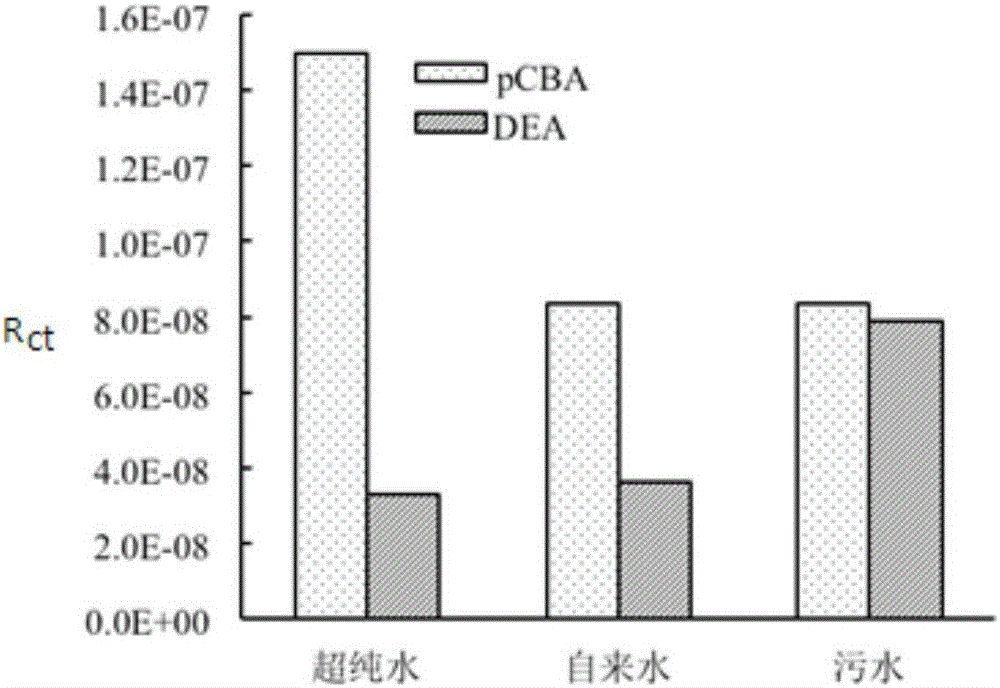

Method for determining hydroxyl free radicals of ozone system

InactiveCN105967316ADetermination of concentrationSlow reaction rateWater treatment parameter controlWater treatment compoundsReaction rateWater quality

The invention belongs to the field of water treatment, and particularly relates to a method for determining hydroxyl free radicals in an ozone system. The invention provides a new indicator, namely Deethylatrazine (DEA); the reaction rate of the DEA with ozone is very low, and the reaction rate of the DEA with free radicals is very high, so that the concentration of the hydroxyl free radicals (.OH) in the ozone system can be determined more accurately. Compared with a method for determining the hydroxyl free radicals in the ozone system by using the conventional hydroxyl free radical indicator namely para-chlorobenzoic acid (pCBA), the method provided by the invention can be used for determining the concentration of the hydroxyl free radicals more accurately, and can be applied to various types of water qualities, particularly to the water quality with lower free radical capturing capacity.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

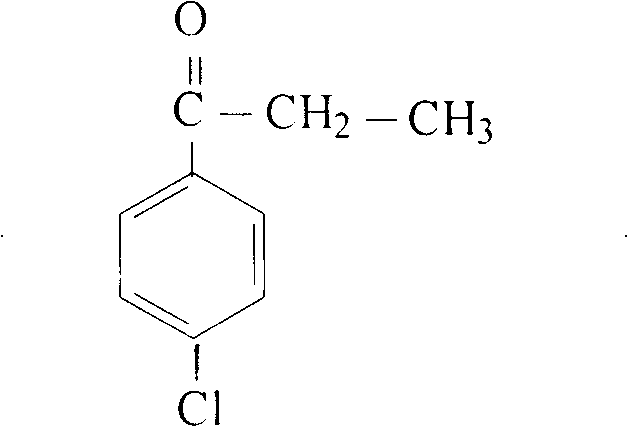

Preparation method of p-chloropropiophenone

InactiveCN101805250AReduce pollutionEasy to separate and purifyOrganic compound preparationCarbonyl compound preparationPara-chlorobenzoic acidEnergy consumption

The invention discloses a preparation method of p-chloropropiophenone. Parafluorobenzoic acid and propionic acid serve as raw materials; in the presence of catalyst, the raw materials react to prepare the p-chloropropiophenone, and the catalyst is reduced iron powder. The invention adopts the novel catalyst to synthetize the p-chloropropiophenone, thereby simplifying the separation and purification processes. The invention has short reaction time and high product yield, the yield of the product can reach above 86%, and the invention has higher purity in the obtained product, low energy consumption, less environment pollution and low cost. The invention is a more ideal process for realizing industrialized production.

Owner:NANTONG UNIVERSITY

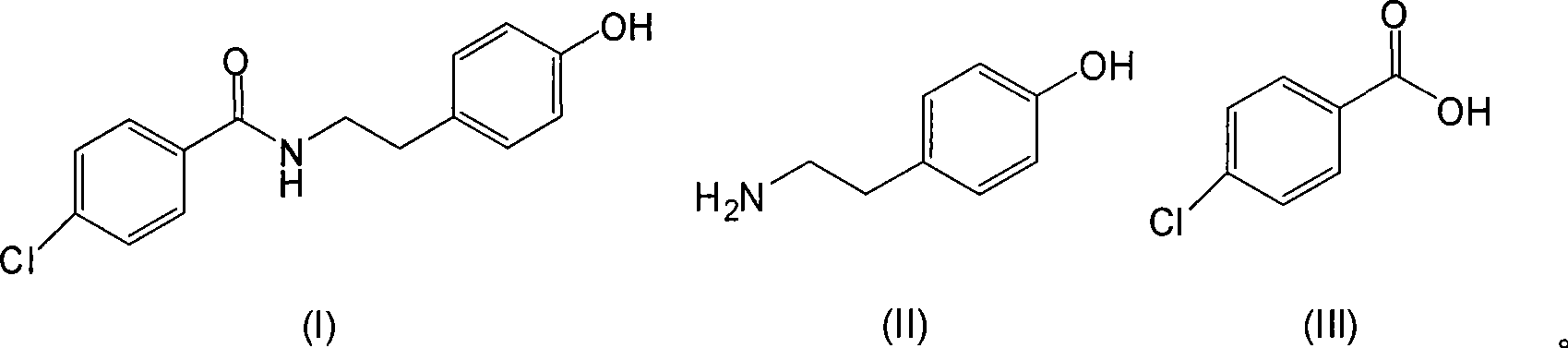

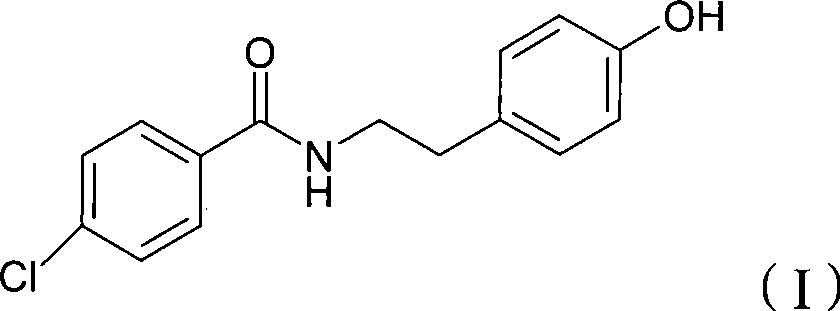

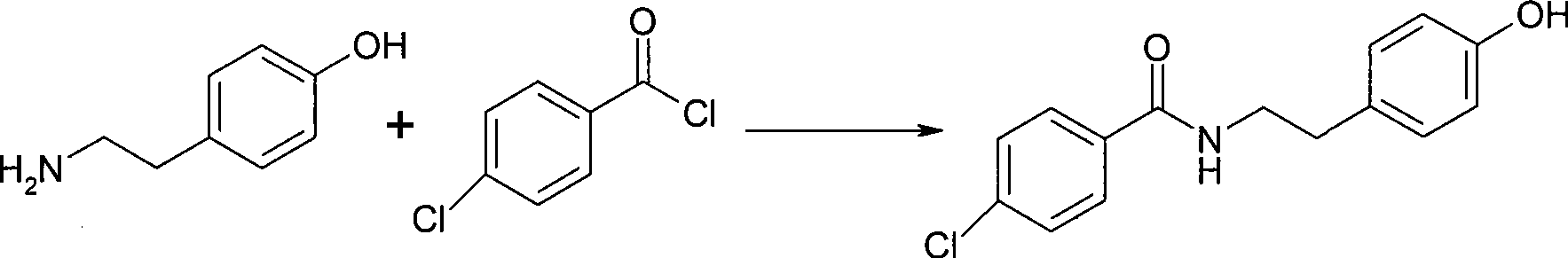

Chemical synthesis method of N-(4-chlorobenzoyl)-tyramine

ActiveCN101445467AEliminate security concernsEliminate pollutionOrganic compound preparationCarboxylic acid amides preparationChemical synthesisState of art

The invention discloses a chemical synthesis method of N-(4-chlorobenzoyl)-tyramine with a structure as shown in formula (I), and the method takes tyramine with a structure as shown in formula (II) and p-chlorobenzoic acid with a structure as shown in formula (II) as raw materials for full reaction to obtain the N-(4-chlorobenzoyl)-tyramine. Compared with the prior art, the raw materials used by the invention are cheap and easy to obtain (eliminating the use of the raw materials prepared by thionyl chloride), the invention basically eliminates the problems of great safety hidden troubles, serious pollution caused by three wastes, and the like of the traditional process and reduces the production cost; meanwhile, the invention has simple and safe operation, reasonable process conditions and high reaction yield, thereby having great implementing value and social and economic benefits.

Owner:ZHEJIANG JIUZHOU PHARM CO LTD

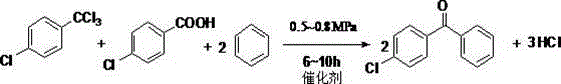

Method for preparing p-chlorodiphenyl ketone

InactiveCN104610036AFew reaction stepsLess investmentCarbonyl compound preparation by condensationBenzoic acidMeth-

The invention discloses a method for preparing p-chlorodiphenyl ketone. According to the method, p-chlorotrichloromethyl benzene, p-chlorobenzoic acid and benzene are subjected to Friedel-Crafts reaction in the presence of a catalytic amount of Lewis acid, such as FeCl3 to prepare p-chlorodiphenyl ketone. The method is performed under the conditions of a heating temperature of 150 DEG C-180 DEG C and a pressure of 0.5-0.8MPa, the molar ratio of p-chlorotrichloromethyl benzene to benzene is 1: (2-5), the molar ratio of p-chlorobenzoic acid to p-chlorotrichloromethyl benzene is 1: 1, the yield of p-chlorodiphenyl ketone is 90%, the disadvantage of aluminum-salt-containing wastewater pollution caused by catalysis of equimolar anhydrous AlCl3 used in the conventional acylation method is eliminated, the multi-step reaction of firstly preparing acyl chloride and then carrying out acylation in the traditional method is avoided, no isomer is generated and the product is high in quality.

Owner:JIANGSU MARINE RESOURCES DEV RES INST LIAN YUNGANG +1

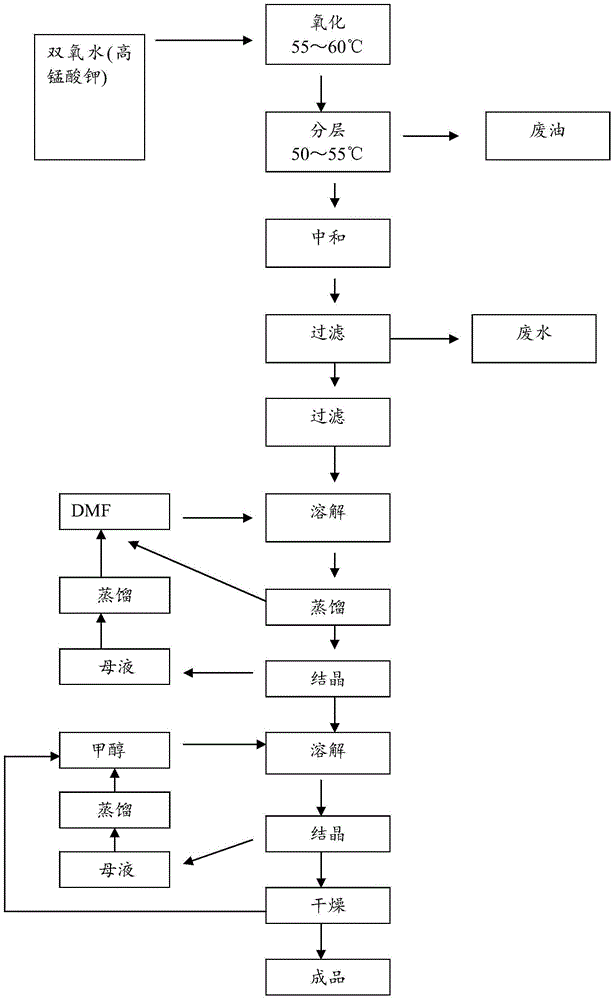

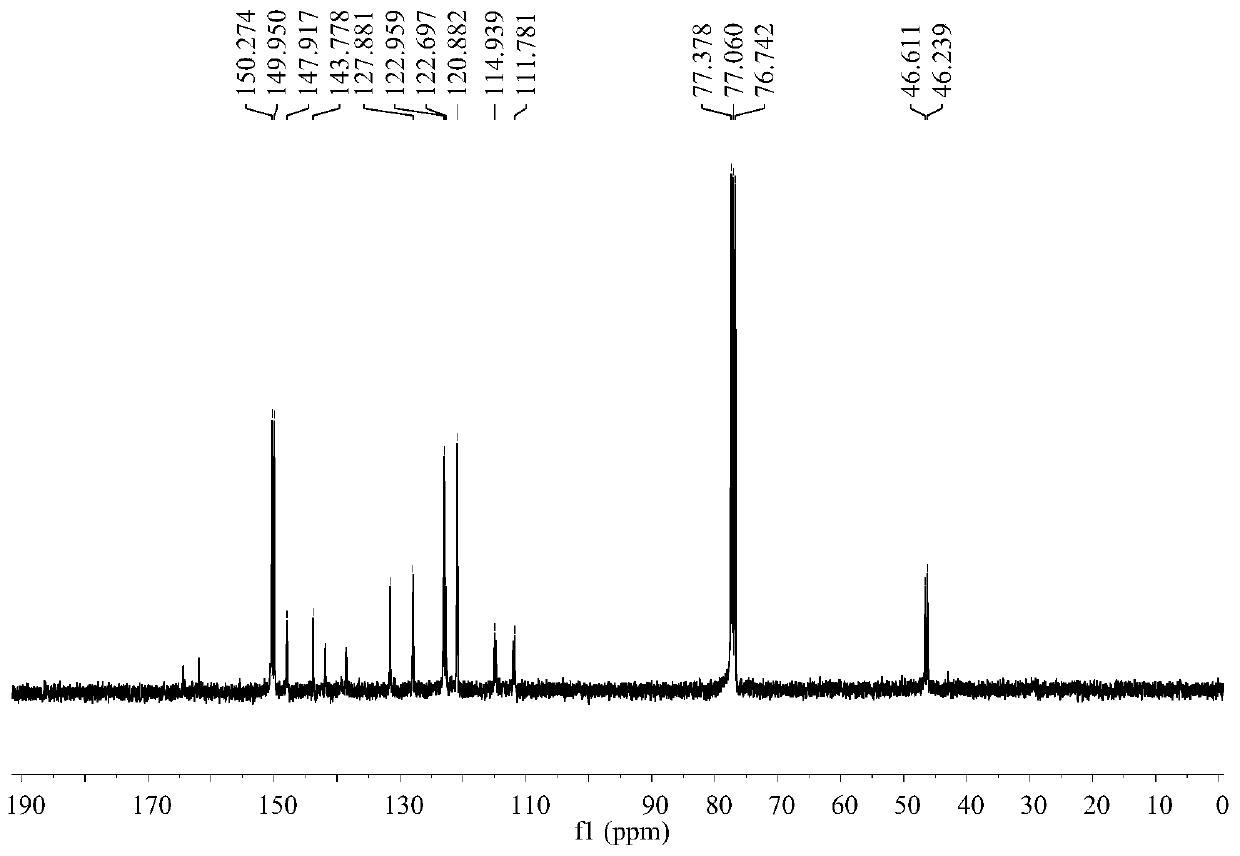

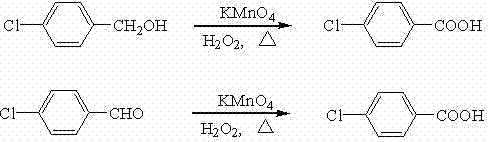

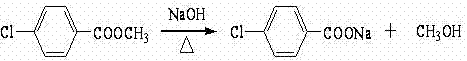

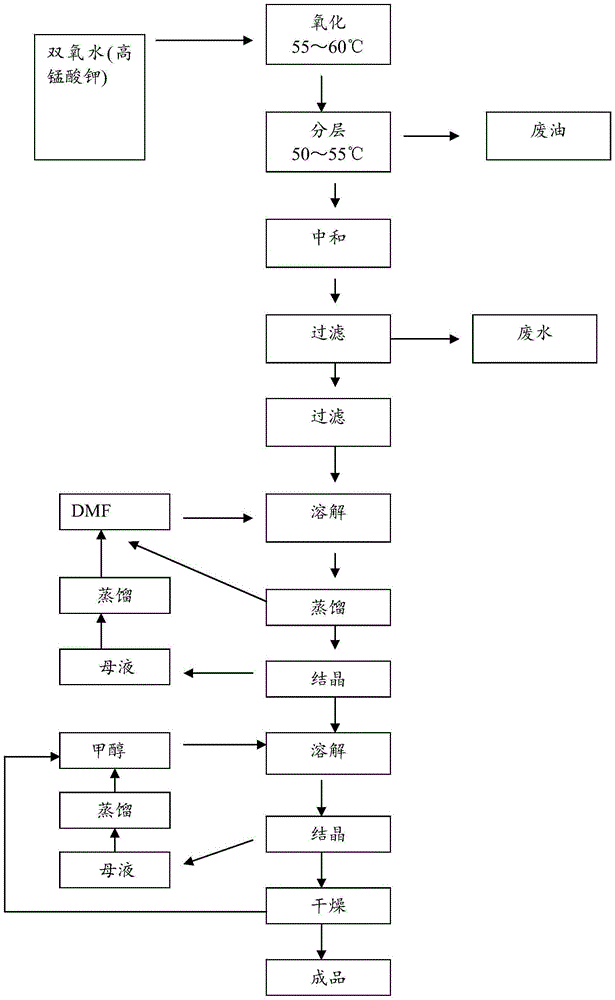

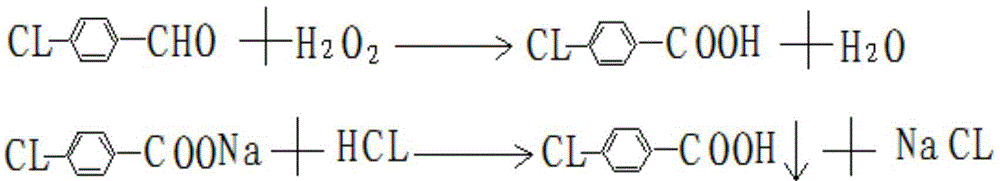

Method for extracting para-chlorobenzoic acid from ketene wastewater

ActiveCN104892405AHigh purityOrganic compound preparationCarboxylic preparation by oxidationN dimethylformamideImpurity

The invention discloses a method for extracting para-chlorobenzoic acid from ketene wastewater, which comprises the following steps: oxidizing sodium para-chlorophenylmethoxide in wastewater to obtain sodium para-chlorobenzoate, stratifying to separate part of organic matters, neutralizing with hydrochloric acid, crystallizing out para-chlorobenzoic acid, purifying by dissolving organic impurities in the crude product into DMF (N,N-dimethylformamide) and methanol to obtain a refined para-chlorobenzoic acid product, and drying to obtain the product. The purity of the product is greater than 99%, which is higher than that of the para-chlorobenzoic acid in the market.

Owner:内蒙古沙洲化学科技有限公司

1,2-di(pyridyl)-3,4-di(4-pyridylvinyl-3-fluorobenzene)cyclobutane and preparation method therefor

ActiveCN109705027AChemically stableFor long-term storageOrganic chemistryLuminescent compositionsUltraviolet lightsCyclobutane

The invention discloses 1,2-di(pyridyl)-3,4-di(4-pyridylvinyl-3-fluorobenzene)cyclobutane and a preparation method therefor. The preparation method for the 1,2-di(pyridyl)-3,4-di(4-pyridylvinyl-3-fluorobenzene)cyclobutane comprises the following steps: 1) weighing and dissolving 3,5-di(2-pyridylvinyl)fluorobenzene, cadmium nitrate tetrahydrate and parachlorobenzoic-acid in a solvent, adjusting a pH value of the obtained solution to be not greater than 6, placing the obtained mixed solution in a vessel, carrying out sealing, and carrying out a reaction under the condition of heating, so as to obtain an intermediate 1; 2) irradiating the intermediate 1 with ultraviolet light with the wavelength of 254nm to 450nm, so as to obtain an intermediate 2; and 3) soaking the intermediate 2 in an acidic solution with a pH value not greater than 4, carrying out filtering, collecting filter liquor, adjusting a pH value of the filter liquor to be alkaline, precipitating solids, and collecting the solids, thereby obtaining the 1,2-di(pyridyl)-3,4-di(4-pyridylvinyl-3-fluorobenzene)cyclobutane. According to the method disclosed by the invention, the process is simple and easy in operation, and the yield is high; and chemical properties of the target product and all the intermediates are stable.

Owner:GUANGXI UNIV FOR NATITIES

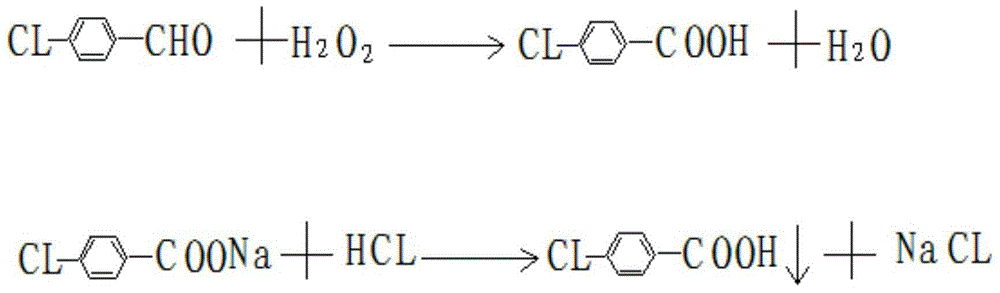

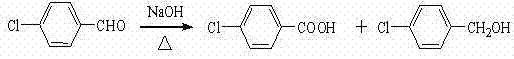

Recovery method for byproduct, p-chlorobenzoic acid, during production of p-chlorobenzaldehyde

ActiveCN109020801AHigh purityImprove qualityOrganic compound preparationCarboxylic preparation by oxidationRecovery methodP-chlorobenzaldehyde

The invention relates to a recovery method for byproduct, p-chlorobenzoic acid, during production of p-chlorobenzaldehyde, wherein the method includes oxidization, crude processing, fine processing and drying processes. By means of the method, the p-chlorobenzoic acid, recycled from washing water during the production of p-chlorobenzaldehyde, is high in purity and is low in content of p-chlorobenzaldehyde. The method is simple in process and low in recovery cost, and is free of environmental pollution. In addition, methylbenzene used in the recovery process can be recycled, so that the methodsatisfies the idea of green chemistry.

Owner:江苏超跃化学有限公司

4-phenoxybenzoic acid synthesis method

InactiveCN110407693ANovel synthetic routeSuitable for industrial productionOrganic compound preparationCarboxylic acid esters preparationChemical industrySodium Phenolate

The invention relates to the technical field of chemical industry synthesis, and particularly discloses a 4-phenoxybenzoic acid synthesis method, which comprises: carrying out a mixing heating reaction on phenol as a raw material, sodium hydroxide and water to obtain a sodium phenolate solution; slowly adding the sodium phenolate solution into a mixture of tetrahydronaphthalene and p-chlorobenzoicacid in a dropwise manner while heating, and carrying out a thermal insulation reaction; after completing the reaction, cooling the reaction liquid, filtering, washing the obtained solid, filtering,mixing by adding clear water, adjusting the pH value, and filtering to obtain crude and wet 4-phenoxybenzoic acid; and dissolving the crude and wet 4-phenoxybenzoic acid in ethanol, adsorbing with active carbon, filtering, cooling, and filtering to obtain the product. According to the present invention, the process route is simple and easy to operate, the reaction can be completed in one step, thestarting raw material is simple and cheap, and is easy to obtain, the generated waste water is less, and the method is suitable for industrial production, and is a completely-new synthesis route.

Owner:CHENGWU CHENHUI ENVIRONMENTAL PROTECTION TECH CO LTD

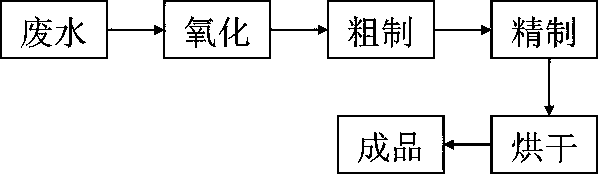

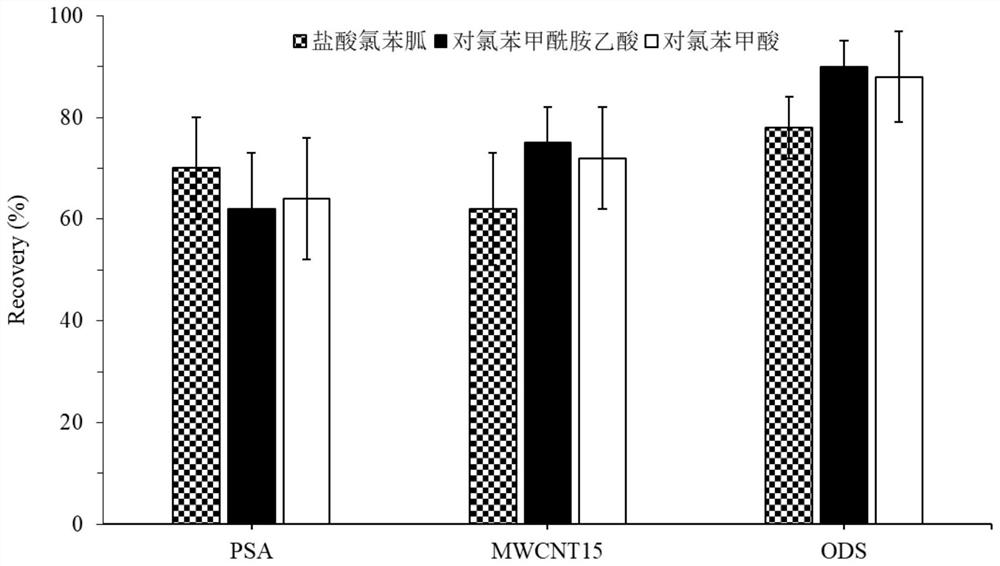

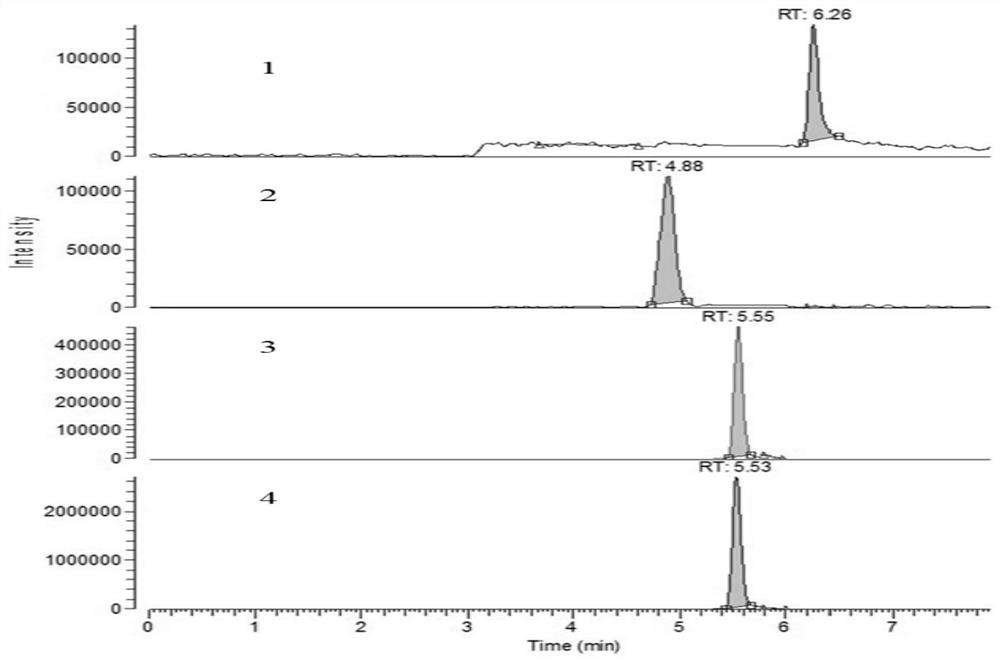

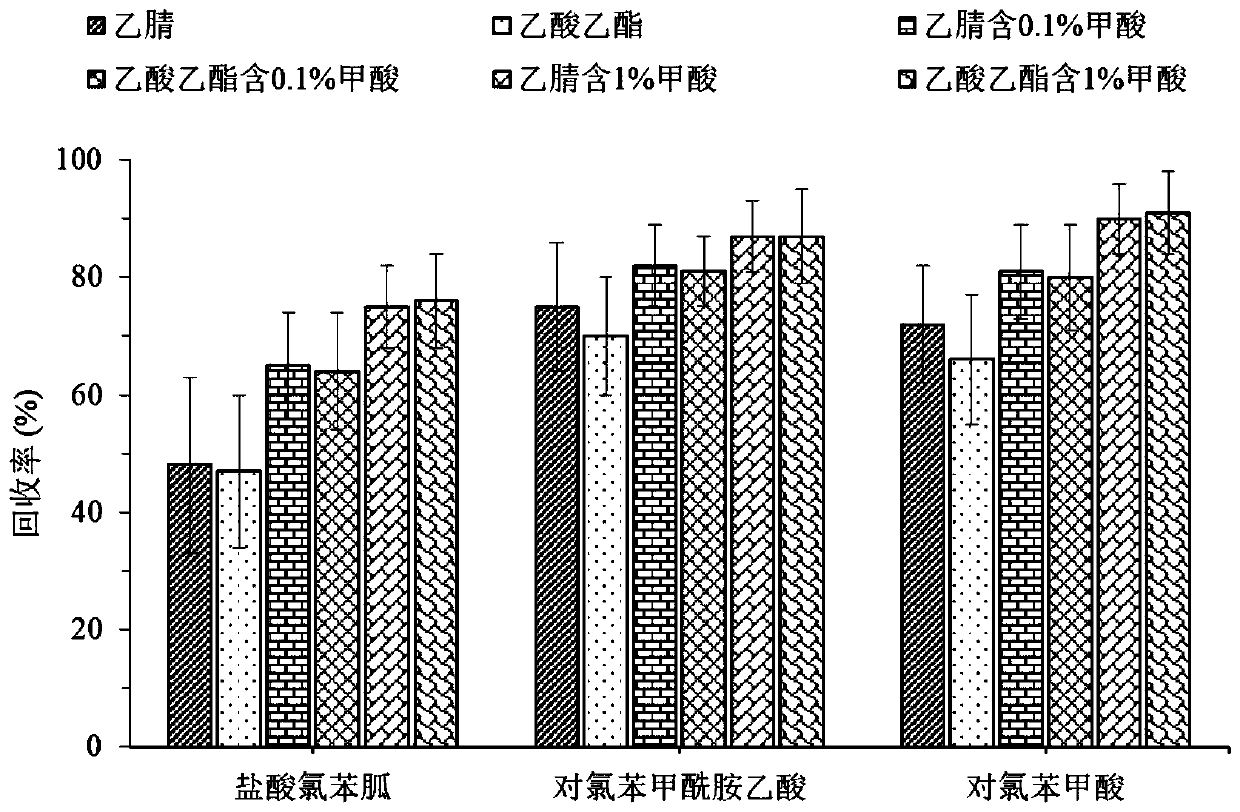

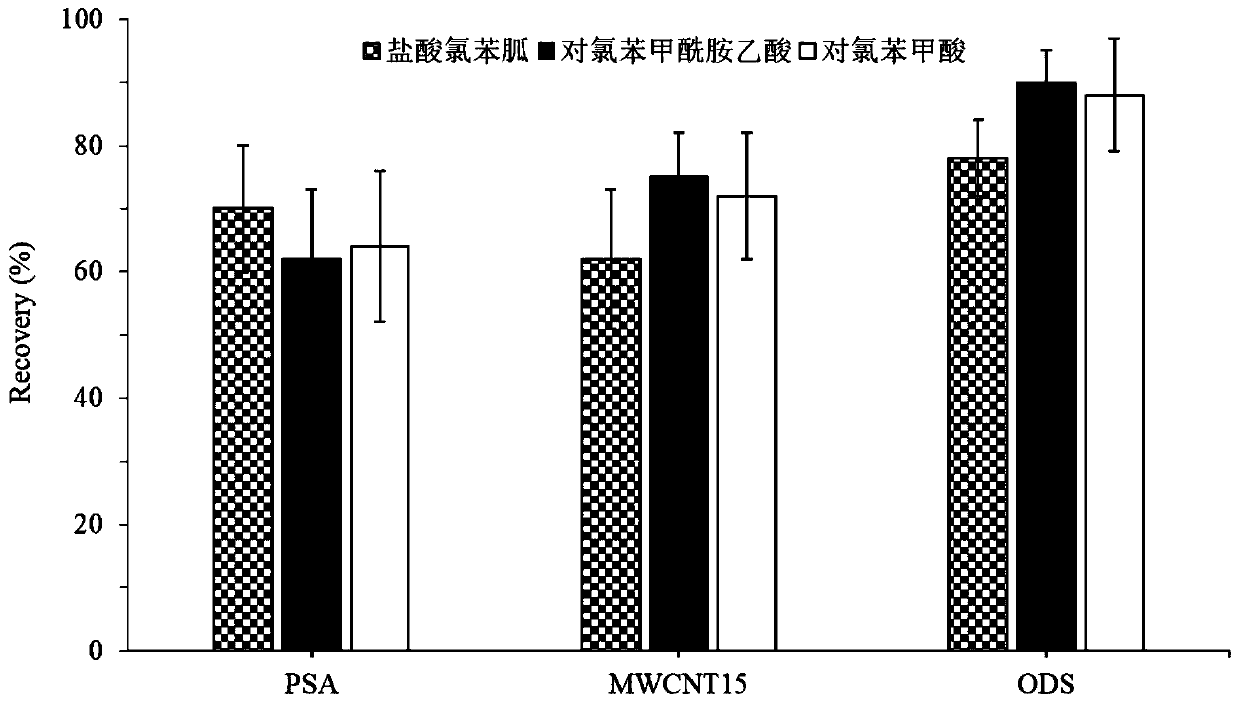

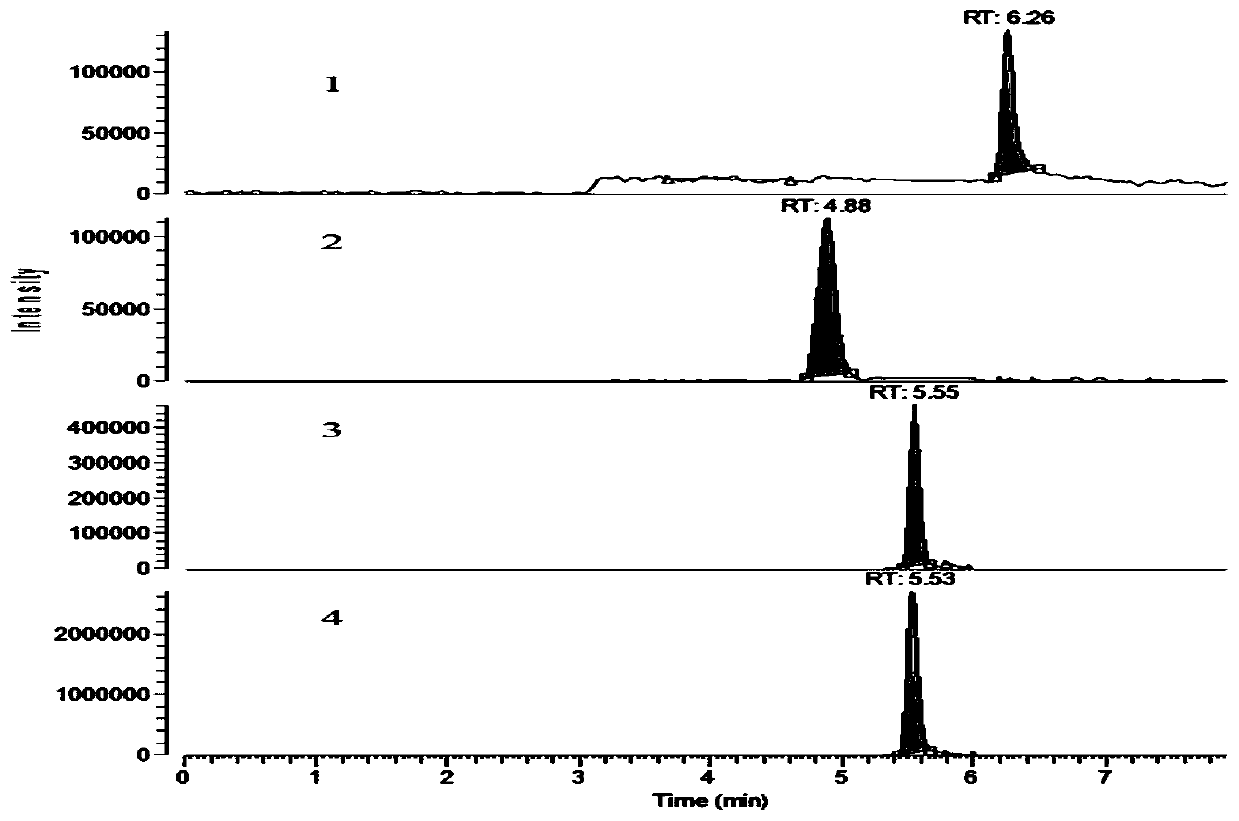

A method for the determination of prohezidine hydrochloride and its metabolite residues in aquatic products by high performance liquid chromatography-tandem mass spectrometry

The invention discloses a method for determining the residual amount of chlorhexidine hydrochloride and its metabolites in aquatic products by high performance liquid chromatography-tandem mass spectrometry based on time-segmented technology. The steps are: A. Weigh the muscle tissue of aquatic products, add acetonitrile containing 1% formic acid, anhydrous magnesium sulfate, ODS extraction and purification; B. Use high performance liquid chromatography-tandem mass spectrometry to switch between positive and negative ion modes and detect chlorophenylguanidine hydrochloride, p-chlorobenzoic acid, and p-chlorobenzene in muscle of aquatic products in different time periods The residual amount of formamide acetic acid; C. Quantification by standard curve method: Chlorhexenidine hydrochloride adopts internal standard method to quantify, and Chlorhexenidine hydrochloride-d 8 As internal standard, p-chlorobenzamidoacetic acid and p-chlorobenzoic acid were quantified by external standard method. The method is easy to operate, has low matrix effect, low detection limit, high accuracy and precision.

Owner:武汉言必行科技股份有限公司

Ketoside solid waste recycling method

InactiveCN107285993ASolve problems that cannot be sold as industrial productsReduce pollutionOxygen-containing compound preparationOrganic compound preparationFiltrationEconomic benefits

The invention relates to a ketoside solid waste recycling method which specifically comprises the following steps: 1) dissolving solid wastes in a caustic soda solution, and reacting at the temperature of 60-70 DEG C until the pH value is 10-11 so as to obtain a reaction solution I; 2) distilling the reaction solution I at the temperature of 75+ / -5 DEG C under the vacuum degree of not more than -0.09MPa until any fraction is not produced, thereby obtaining a product II and a mother solution III; 3) adding a composite oxidant into the mother solution III, carrying out an oxidizing reaction at the temperature of 40-45 DEG C for 2.0-3.0 hours, performing immediate filtration in vacuum, and taking the filtrate V; and 4) adding hydrochloric acid into the filtrate V under stirring conditions until the pH value is 5-6, continuously stirring and reacting for 30 minutes or more, performing suction filtration to obtain the filter residue VI, drying the filter residue VI, thereby obtaining the crude parachlorobenzoic-acid. The method has the advantages that the ketoside solid wastes are recycled, the recycled product is high in economic value, the production cost is reduced, environmental pollution is avoided in the whole production process, and the method is a green chemical process. Moreover, the parachlorobenzoic-acid product recycled from the solid wastes is stable and reliable in quality and high in purity and has excellent economic benefits.

Owner:HENAN UNIVERSITY

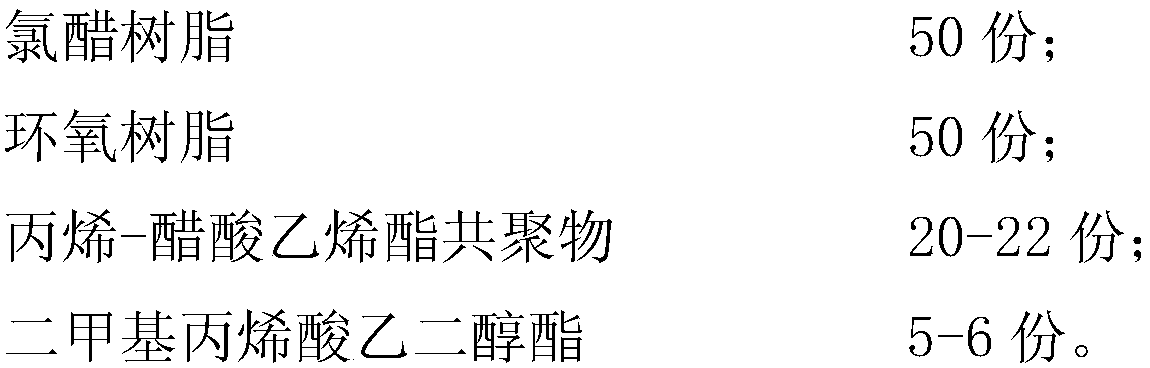

Formula of ultraviolet-resistant modified polyvinylidene fluoride

The invention discloses a formula of ultraviolet-resistant modified polyvinylidene fluoride. The ultraviolet-resistant modified polyvinylidene fluoride comprises modified polyvinylidene fluoride, an anti-aging agent, an anti-static agent, a nucleating agent, a stabilizing agent and a wear resisting agent, wherein the anti-aging agent is octylated diphenylamine, the anti-static agent is alanine sodium, the nucleating agent is sodium parachlorobenzoate, the stabilizing agent is calcium stearate, and the wear resisting agent is dioleic acid phosphite ester. According to the invention, the prepared ultraviolet-resistant modified polyvinylidene fluoride is ultraviolet-resistant, aging-resistant, oxidation-resistant and anti-static.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

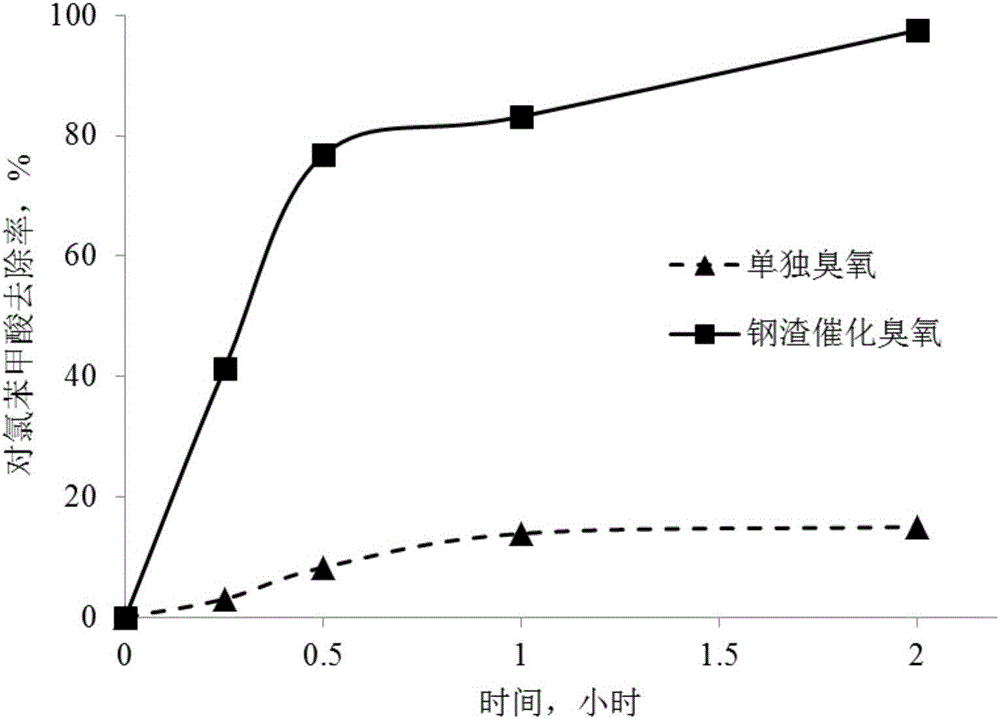

Method for treating water by using steel slag to catalyze ozone

InactiveCN106800332ALow priceEasy accessWater contaminantsWater/sewage treatment by oxidationSlagSewage

The invention relates to a method for treating water by using steel slag to catalyze ozone, aiming at solving the problems that a method for treating the water by using ozonization alone is low in reaction efficiency, and the existing method for treating the water by using catalytic ozonization is high in catalyst cost, complicated in preparation, poor in pollutant removal effect, and the like. The method provided by the invention comprises the steps of adding the steel slag into a reactor containing sewage, wherein 1-50g of steel slag is put into per liter of water to be treated; then, continuously replenishing the reactor with 0.5-3.0mg / L ozone, and controlling the reaction time to be 5-120min so as to realize the removal of organic matters in the water. The method has the characteristics that a catalyst is easy to obtain, low in cost, high in activity, long in service life, rapid in reaction speed and high in removal efficiency, can treat waste by using waste, is simple to operate, and the like. After the method for treating the water by using the steel slag to catalyze the ozone is used, the removal rate of parachlorobenzoic-acid reaches 98% or above.

Owner:NORTHEASTERN UNIV LIAONING

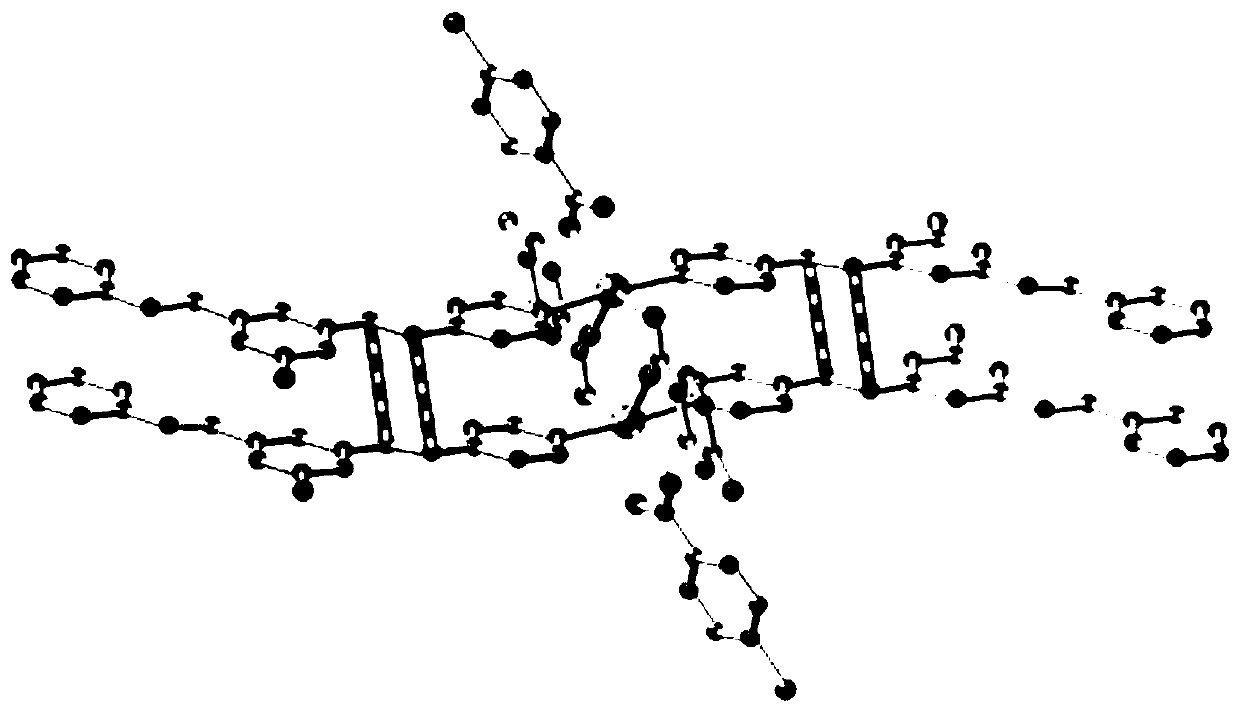

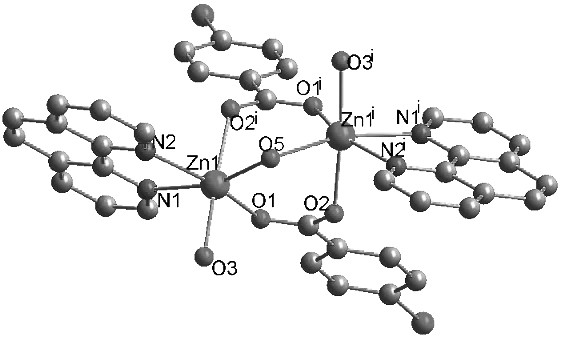

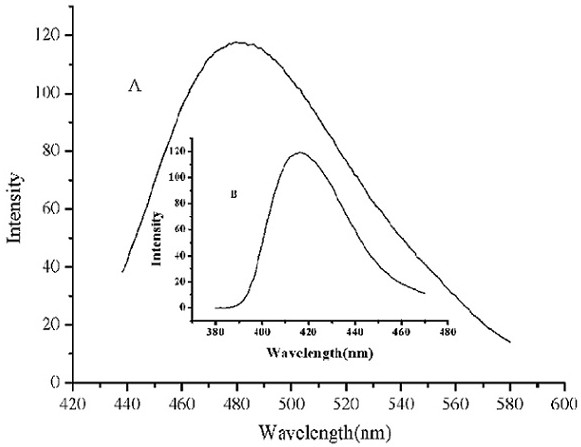

Binuclear zinc complex, preparation method and application thereof

ActiveCN111747973AImprove luminosityImprove antibacterial propertiesBiocideOrganic chemistry methodsEscherichia coliBenzoic acid

The invention discloses a binuclear zinc complex, a preparation method and application thereof. The invention relates to the technical field of multifunctional new materials. According to the binuclear zinc complex, p-chlorobenzoic acid radical ions and 1, 10-phenanthroline are used as the ligand, the complex has a binuclear structure, the complex molecular structure has good stability, also the binuclear zinc complex has good luminescence properties, can be applied as a luminescent material widely to preparation of luminescent devices, widens the selection range of the luminescent material, especially has good antibacterial properties, and especially has a good inhibition effect on staphylococcus aureus and escherichia coli. The preparation method of the binuclear zinc complex also has the advantages of simple operation, mild reaction conditions, high yield and uniform crystal particles.

Owner:HUNAN INST OF TECH

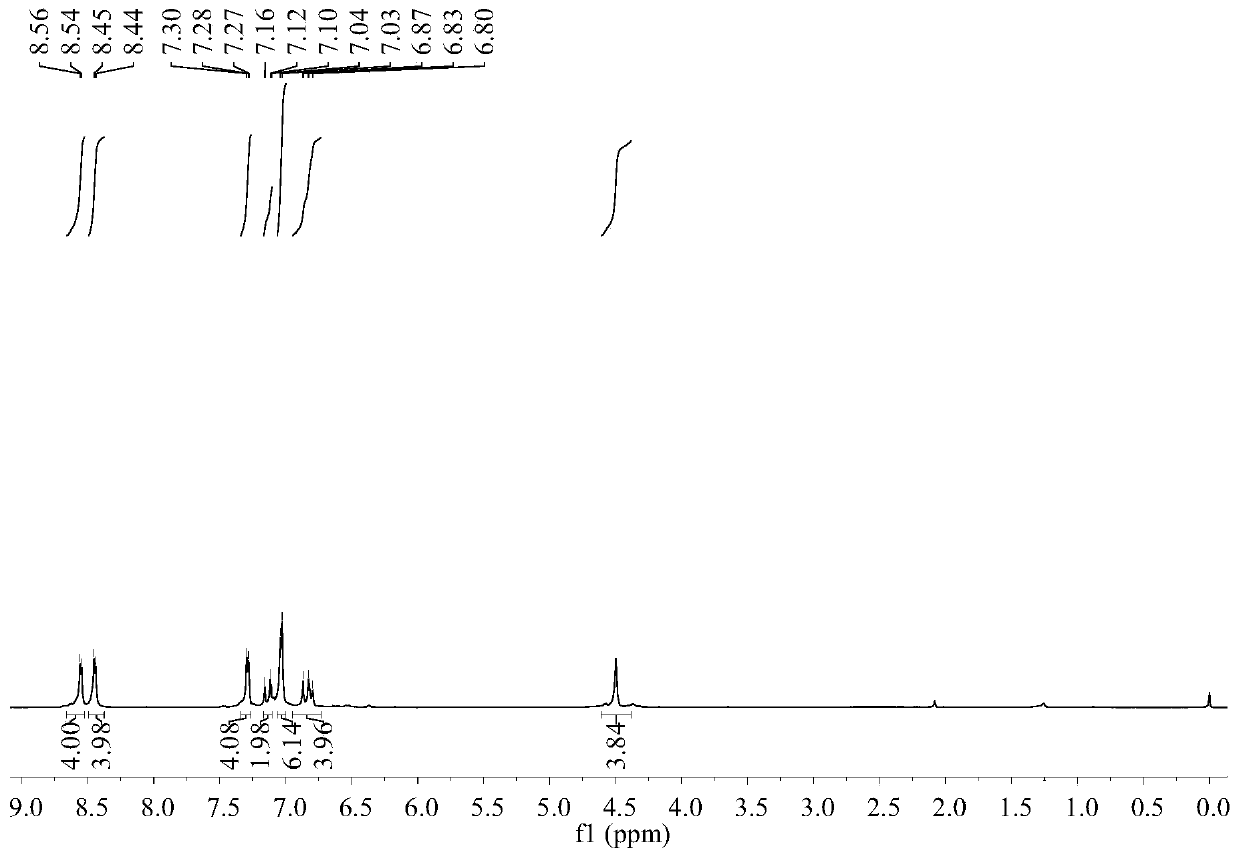

Method for measuring robenidine hydrochloride and metabolite residues in aquatic product through high performance liquid chromatography-tandem mass spectrometry

ActiveCN109709227AHigh sensitivityImprove accuracyComponent separationMuscle tissueProtein mass spectrometry

The invention discloses a method for measuring robenidine hydrochloride and metabolite residues in an aquatic product through high performance liquid chromatography-tandem mass spectrometry based on atime segment technology. The method comprises: A, weighing aquatic product muscle tissues, adding acetonitrile with 1% formic acid, anhydrous magnesium sulfate, and ODS, and extracting and purifying;B, using high performance liquid chromatography-tandem mass spectrometry to carry out positive and negative ion mode switching and detect the residues of robenidine hydrochloride, parachlorobenzoic acid and p-chlorobenzamide acetic acid in aquatic product muscles in different time periods; and C, carrying out standard curve method quantification: using an internal standard method to quantify therobenidine hydrochloride, taking robenidine hydrochloride-d8 as an internal standard, and using an external standard method to quantify the p-chlorobenzoyl aminoacetic acid and the parachlorobenzoic-acid. Operation is simple, a matrix effect is low, a detection limit is low and accuracy and precision are high.

Owner:武汉言必行科技股份有限公司

Method for detecting methyl hippuric acid in urine

The invention provides a method for detecting methyl hippuric acid in urine. The method comprises the following steps: taking a urine sample, adding parachlorobenzoic-acid, hydroquinone and 3,4-dihydroxyphenylanaline into the urine sample, and oscillating, mixing and centrifuging; then adding a hydrochlric solution, sodium chloride and ethyl acetate into a supernatant obtained through centrifugation, and oscillating, mixing and centrifuging; then conducting rotary evaporation on a supernatant obtained through centrifugation; finally, adding residues obtained in the step 3 into distilled water, concentrating by nanofiltration, and conducting efficient liquid phase analysis on the concentrated solution. The method provided by the invention is high in sensitivity, precision and recovery rate, and excellent in stability; all methodological indexes conform to related requirements of Guide for Establishing Occupational Health Standards Part 5-Method for Detecting Chemical Substances in Biomaterials; the method provided by the invention can be used for detecting 3 isomers of methyl hippuric acid in urine of both occupational workers exposed to dimethylbenzene and non-occupational people exposed to dimethylbenzene.

Owner:DONGCHEN LEADER TESTING

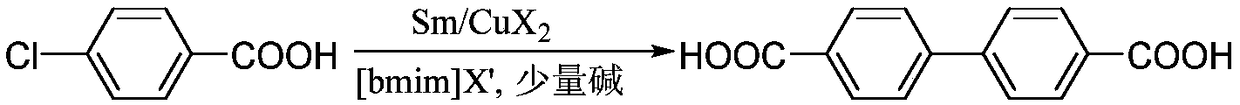

Preparation of biphenyl-4,4'-dicarboxylic acid through coupling of 4-chlorobenzoic acid in ionic liquid

ActiveCN108947801AImprove solubilityEnhanced coupling activityOrganic compound preparationCarboxylic compound preparationChromatographic separationIonic liquid

The invention discloses a method for preparing biphenyl-4,4'-dicarboxylic acid by promoting a coupled reaction of p-halobenzoic acid by utilizing samarium metal under catalysis of a bivalent copper salt in an ionic liquid. P-chlorobenzoic acid is mixed and dissolved in an ionic liquid [bmim]Cl(chlorobutyl methyl imidazole) under stirring, and then samarium metal powder, cupric chloride powder anda small amount of pyridine are sequentially added; a reaction system is performed under an anhydrous condition, and stirring is performed at a room temperature until the reaction reacts completely; and the obtained reaction mixture is subjected to ionic liquid recovery, a crude product is separated by column chromatography to obtain the biphenyl-4,4'-dicarboxylic acid, a pure product is obtained by recrystallization, and the yield is 70-90%.

Owner:CHONGQING CHANGFENG CHEM IND

A method for extracting p-chlorobenzoic acid in enone wastewater

ActiveCN104892405BHigh purityOrganic compound preparationCarboxylic preparation by oxidationN dimethylformamideImpurity

Owner:内蒙古沙洲化学科技有限公司

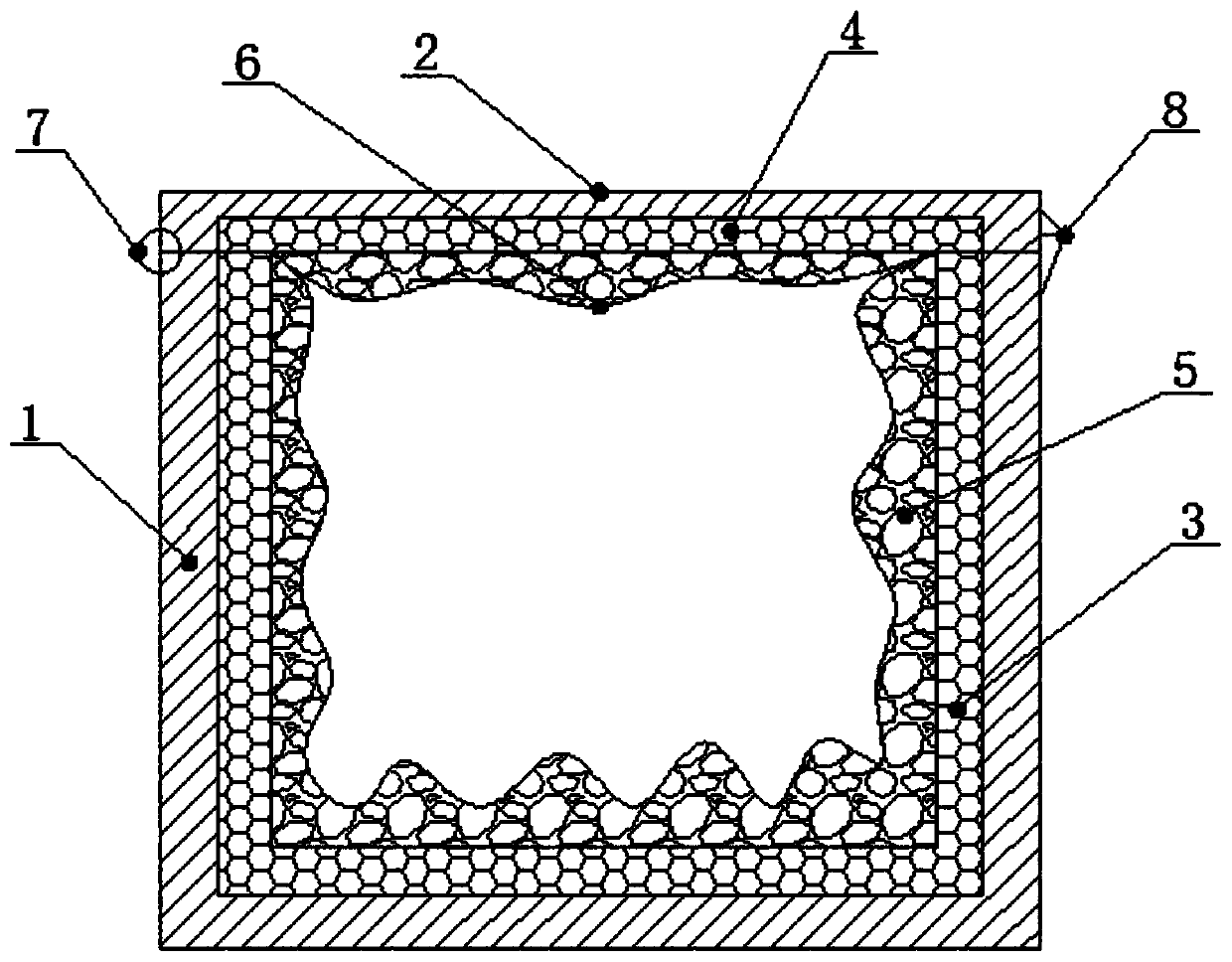

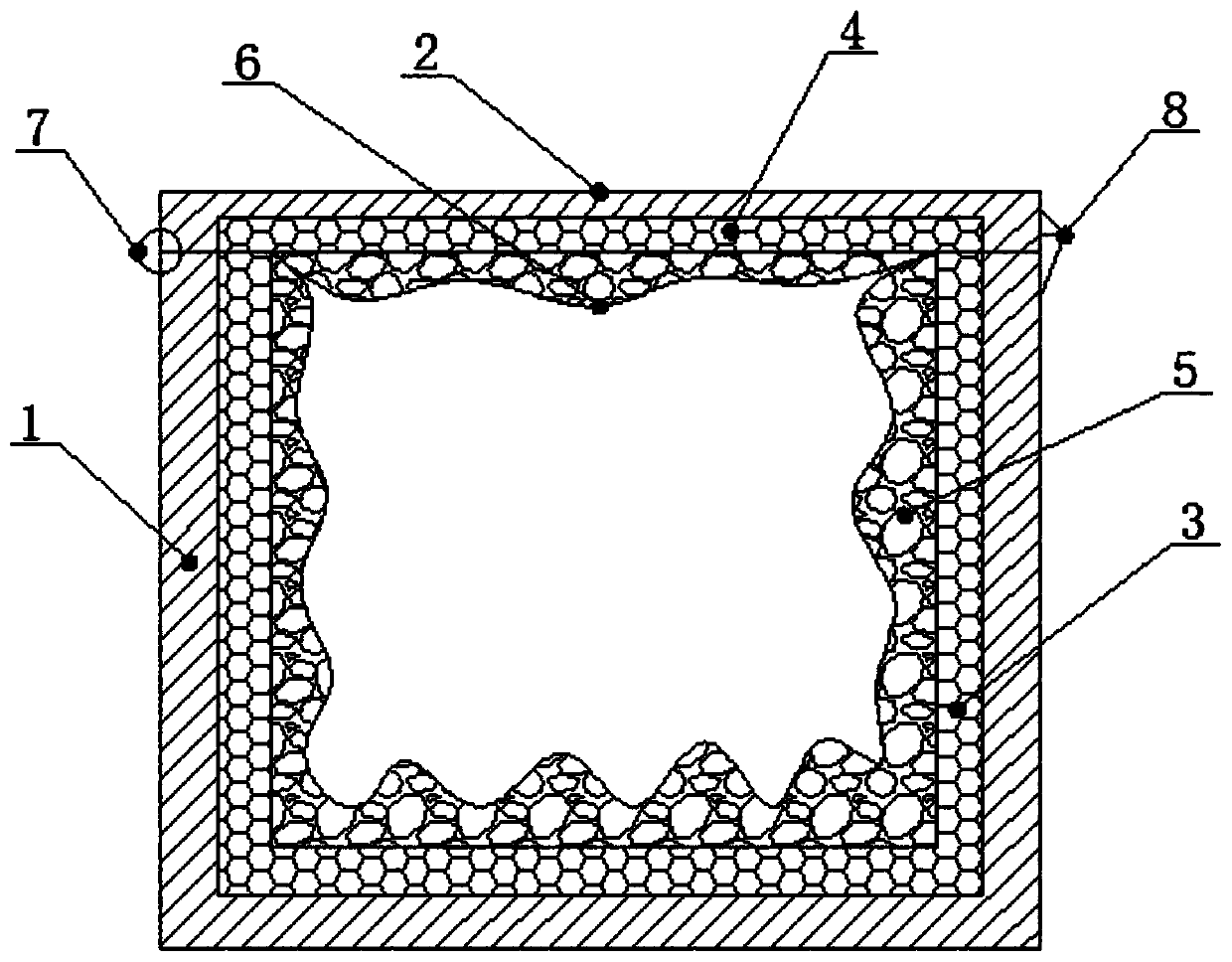

Portable device for transporting histological samples

InactiveCN109911419AImprove shock absorptionAvoid damageDomestic cooling apparatusLighting and heating apparatusSodium bicarbonateFiber

The invention discloses a portable device for transporting histological samples. The portable device comprises a box, a cover, a box heat preservation layer, a cover heat preservation layer, a box flexible vibration-absorptive material, a cover flexible vibration-absorptive material, a hinge and a buckle, wherein both the box flexible vibration-absorptive material and the cover flexible vibration-absorptive material are formed by mixing neoprene, carbon black, 2-dihydroquinoline, plant fibers, zinc oxide, dioctyl phthalate, para-chlorobenzoic acid, chlorinated polyethylene and sodium bicarbonate. The box is subjected to heat preservation through the heat preservation layer, and is simple in design, is only provided with the hinge and the buckle and is convenient to operate and use; especially, the flexible vibration-absorptive materials made of special materials have relatively strong flexibility and property of shock absorption and a relatively high cushioning effect on the built-in histological samples, and avoid the damage to the histological samples; and the portable device is convenient to use, and has the value of popularization and application.

Owner:XIAN PEIHUA UNIV

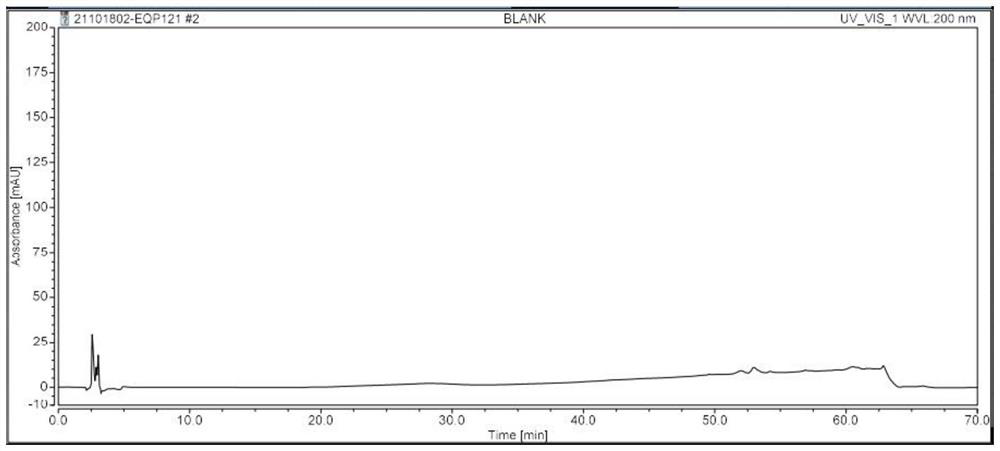

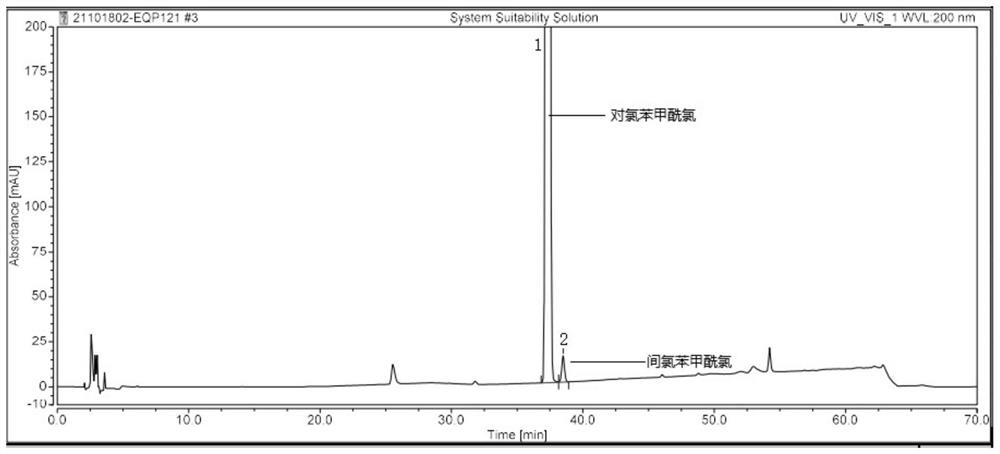

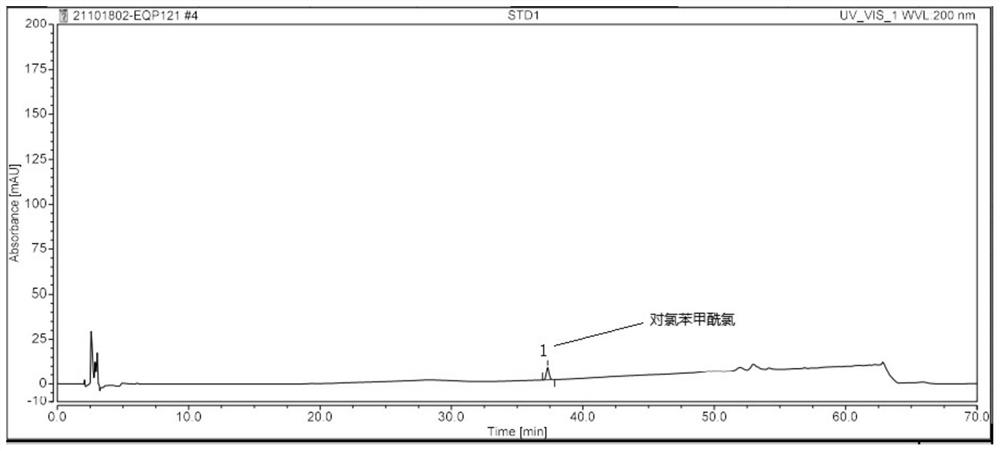

Liquid phase detection method for detecting p-chlorobenzoyl chloride

PendingCN114594193AQuality improvementEasy to operateComponent separationAgainst vector-borne diseasesBenzoic acidChlorobenzene

The invention discloses a liquid phase detection method for detecting p-chlorobenzoyl chloride, which achieves the purpose of detecting and controlling isomers by carrying out derivative reaction on an acyl chloride compound and excessive absolute methanol and detecting a generated methyl ester compound, can detect other impurities such as p-chlorobenzoic acid and the like, and has the advantages of simple derivative conditions, simplicity and convenience in operation, high detection efficiency and high detection accuracy. The method disclosed by the invention is efficient, convenient and simple to operate, completely conforms to guidance principles verified by methods in Chinese pharmacopoeia in the aspects of system applicability, specificity, accuracy, precision and durability, and can be used for quality control of p-chlorobenzoyl chloride.

Owner:浙江致新医药科技有限公司

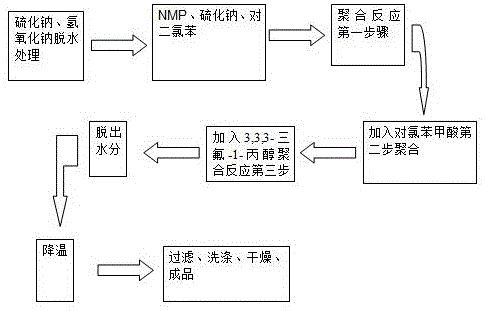

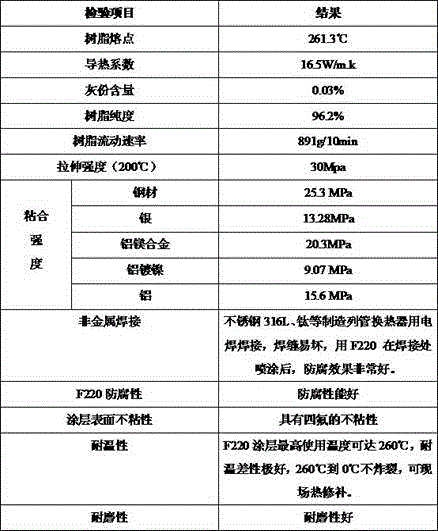

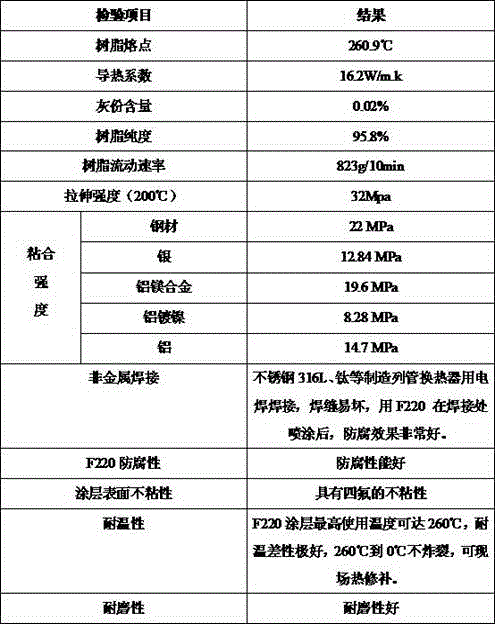

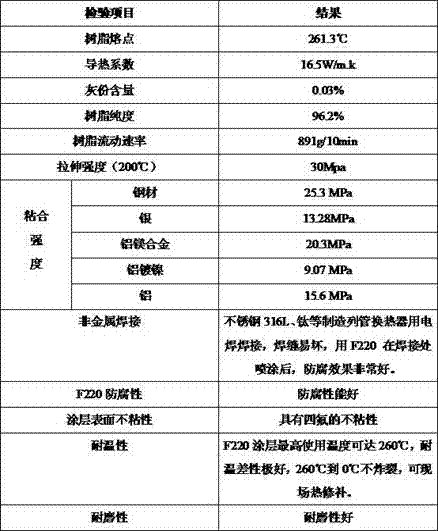

F220 resin preparing method

ActiveCN106317408AImprove high temperature resistanceImprove adhesion strengthFireproof paintsAnti-corrosive paintsFiltrationSodium hydroxide

The invention discloses a F220 resin comprising sodium sulphide crystal, N -methyl -2- pyrrolidone (NMP), sodium hydroxide, inert gases, santochlor, parachlorobenzoic-acid, natrium aceticum, and 3, 3, 3 -trifluoro -1 -propyl alcohol as raw materials, and prepared by the steps of dewater treatment, polymerization reaction, re-dehydration, cooling, filtration, washing and drying, with 4. The preparing method has low cost and high production efficiency, product yield and product purity. The prepared product is characterized by resistance to high temperature and abrasion, anti-corrosion of acid and alkali and tetrafluoro inadhesion on the coating surface with product yield reaching 85. 7%, product purity of 95.9% and ash content lower than 0. 03%, and has excellent high temperature resistance and strong adhesive capacity with multiple metals with the melting point reaching 260.9oC and heat conductivity coefficient of 15.7W / m.k. The finished product has strong adhesive strength and will not bubble, peel off or fall off in the environment of high temperature and vacuum with the resin flow rate lower than 891g / 10min and tensile strength reaching 36Mpa at 200oC. The preparing method is simple, practicable, and suitable for industrial production.

Owner:重庆卓之惠化工技术有限公司

Separation method of o-chlorobenzoic acid and p-chlorobenzoic acid mixture

ActiveCN100369883CAchieve separationMild separation conditionsCarboxylic compound separation/purificationChlorobenzoic AcidsPara-chlorobenzoic acid

A process for separating o-chlorobenzoic acid and p-chlorobenzoic acid from their mixture includes such steps as dispersing said mixture in water, stirring while heating, adding alkaline extractant, reaction, filter, drying the filtered cake to obtain p-chlorobenzoic acid, stirring the filtrate while heating, adding acidic extractant, reaction, filter, adding the acidic extractant to the filtrate until pH=1.0, filter, and drying the filtered cake to obtain o-chlorobenzoic acid.

Owner:南京资环工程技术研究院有限公司

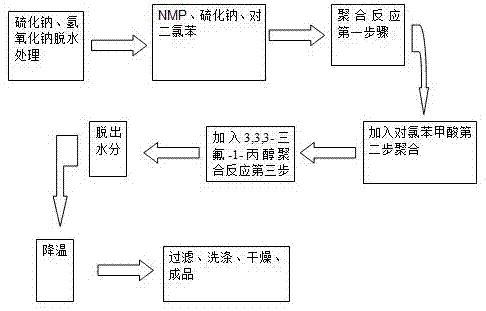

A kind of preparation method of f220 resin

ActiveCN106317408BImprove high temperature resistanceImprove adhesion strengthFireproof paintsAnti-corrosive paintsFiltrationSodium sulphide

The invention discloses a F220 resin comprising sodium sulphide crystal, N -methyl -2- pyrrolidone (NMP), sodium hydroxide, inert gases, santochlor, parachlorobenzoic-acid, natrium aceticum, and 3, 3, 3 -trifluoro -1 -propyl alcohol as raw materials, and prepared by the steps of dewater treatment, polymerization reaction, re-dehydration, cooling, filtration, washing and drying, with 4. The preparing method has low cost and high production efficiency, product yield and product purity. The prepared product is characterized by resistance to high temperature and abrasion, anti-corrosion of acid and alkali and tetrafluoro inadhesion on the coating surface with product yield reaching 85. 7%, product purity of 95.9% and ash content lower than 0. 03%, and has excellent high temperature resistance and strong adhesive capacity with multiple metals with the melting point reaching 260.9oC and heat conductivity coefficient of 15.7W / m.k. The finished product has strong adhesive strength and will not bubble, peel off or fall off in the environment of high temperature and vacuum with the resin flow rate lower than 891g / 10min and tensile strength reaching 36Mpa at 200oC. The preparing method is simple, practicable, and suitable for industrial production.

Owner:重庆卓之惠化工技术有限公司

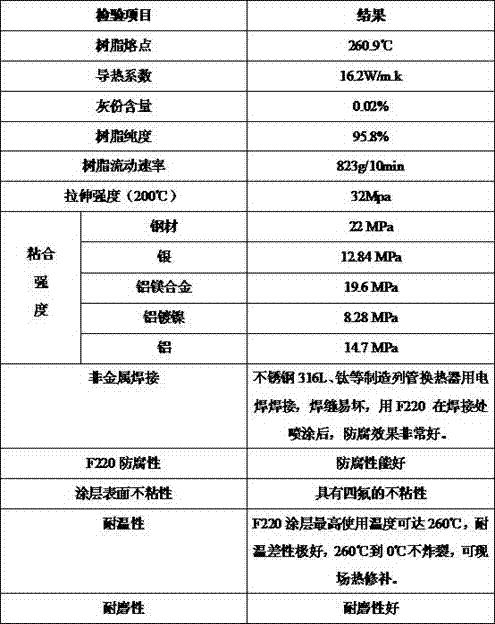

A kind of synthetic method of ultraviolet absorber ethylhexyl triazone

ActiveCN105061345BSimple process routeRaw materials are easy to getOrganic chemistryDistillationSynthesis methods

The invention discloses a synthesis method of a UV absorbent ethylhexyl triazone. The synthesis method comprises that melamine and 4-chlorobenzoic acid as initial raw materials undergo a trisubstitution reaction to produce 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine (H3TATAB), 2,4,6-tris[(p-carboxyphenyl)amino]-1,3,5-triazine (H3TATAB) and isooctanol undergo an esterification reaction to produce an ethylhexyl triazone crude product, the ethylhexyl triazone crude product is subjected to distillation desolvation and crystallization and the crystals are dried to form an ethylhexyl triazone finished product. The synthesis method has the characteristics of simple production route, easily available raw materials, mild reaction conditions, unique crystallization method, less three wastes and high product purity and is suitable for industrial production.

Owner:宜都市华阳化工有限责任公司

Preparation methods of p-chlorobenzonitrile and p-chlorobenzamide

InactiveCN110437101AReduce pollutionShort preparation routeOrganic compound preparationCarboxylic acid amides preparationDistillationAmmonia

The invention provides preparation methods of p-chlorobenzonitrile and p-chlorobenzamide, and belongs to the technical field of organic chemistry, further to the technical field of organic fine chemicals. The p-chlorobenzonitrile preparation method comprises: generating a p-chlorobenzonitrile-containing mixture by using a p-chlorobenzamide dewatering reaction, carrying out pressure reducing distillation on the p-chlorobenzonitrile-containing mixture to obtain crude nitrile, carrying out water washing on the crude nitrile, filtering, drying, and carrying out pressure reducing distillation to obtain a finished product p-chlorobenzonitrile. According to the present invention, p-chlorobenzamide is generated by carrying out a reaction on p-chlorobenzoic acid and ammonia, wherein p-chlorobenzoicacid and ammonia are used as raw materials, and are subjected to a series of reactions to generate p-chlorobenzonitrile, such that the whole reaction process is continuous and controllable, and the route is short; and the whole reaction process recovers and utilizes the unreacted raw material and the intermediate product so as to reduce the emission of three-waste, achieve the safe, clean and environmentally friendly production and significantly reduce the production cost.

Owner:三门峡环宇生化科技有限公司

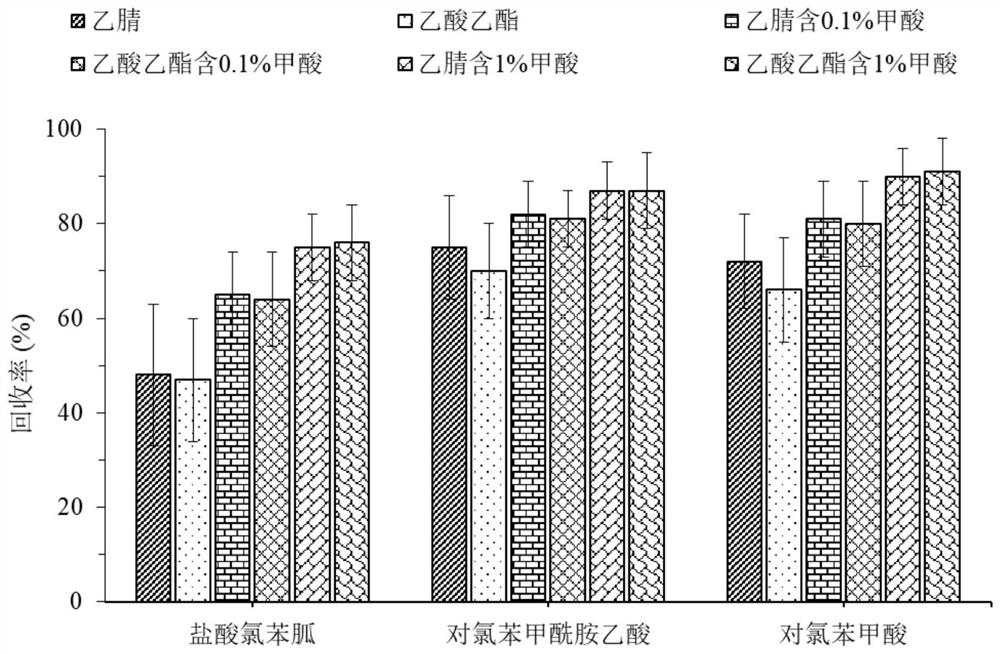

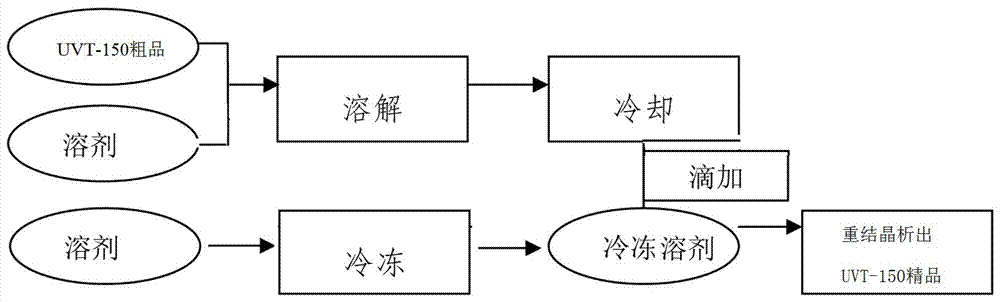

Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate

The invention provides a method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate. The method comprises the following steps: a, preparing a compound 2 from a cyclic imido group substituted compound 1, wherein the cyclic imido group is any one of phthalimide, succimide and maleimide; b, carrying out an amination reaction on a primary amine and the compound 2to generate a compound 3; and c, reacting the compound 3 with 4-chlorobenzoic acid to obtain a compound 4. A reaction route is shown in the description. The synthesis method is friendly to the environment, and is suitable for large-scale industrial production.

Owner:SHANGHAI ARK BIOSCI CO LTD

[3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method

The invention provides a method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate. The method comprises the following steps: a, preparing a compound 2 from a cyclic imido group substituted compound 1, wherein the cyclic imido group is any one of phthalimide, succimide and maleimide; b, carrying out an amination reaction on a primary amine and the compound 2to generate a compound 3; and c, reacting the compound 3 with 4-chlorobenzoic acid to obtain a compound 4. A reaction route is shown in the description. The synthesis method is friendly to the environment, and is suitable for large-scale industrial production.

Owner:SHANGHAI ARK BIOSCI CO LTD

High weather resistance and strong corrosion resistance lithification color steel plate

ActiveCN106280531BGood appearanceStrong UV resistanceSynthetic resin layered productsMetal layered productsLithificationWeather resistance

The invention relates to a high weather resistance and strong corrosion resistance type lithification color steel plate. The high weather resistance and strong corrosion resistance type lithification color steel plate is sequentially provided with a corrosion resistance layer, a weather resistance layer and a steel plate layer from top to bottom, wherein the corrosion resistance layer comprises, by weight, 100 parts of vinyl ester resin, 20-24 parts of polychlorotrifluoroethylene, 10-12 parts of acetylene-propylene copolymer, 6-8 parts of parachlorobenzoic-acid n-butyl ester and 8-10 parts of silica powder. Through the improvement of the lithification color steel plate formula, the lithification color steel plate itself not only has attractive appearance, but also has strong anti-ultraviolet, corrosion resistant and impact resistant performances, adhesive force between the membrane layer and the base material is good when the lithification color steel plate is in harsh environment for a long time, and the lithification color steel plate has no dehiscence, no exfoliation and no blister.

Owner:扬子江新型材料(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/639eed41-5a1a-4325-aa30-f8c01ea923e1/HDA0001145412350000011.png)

![Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/639eed41-5a1a-4325-aa30-f8c01ea923e1/FDA0001145412330000011.png)

![Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate Method for synthesizing p-methoxybenzyl [3-(aminomethyl)-oxetane-3-yl]carbamate p-chlorobenzoate](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/639eed41-5a1a-4325-aa30-f8c01ea923e1/DEST_PATH_GDA0001170870360000021.png)

![[3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method [3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7078d697-7d08-4e4c-a854-dff239412407/HDA0001145412350000011.png)

![[3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method [3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7078d697-7d08-4e4c-a854-dff239412407/DEST_PATH_GDA0001170870360000021.png)

![[3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method [3-(Aminomethyl)-oxetan-3-yl] p-methoxybenzyl carbamate p-chlorobenzoate synthetic method](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/7078d697-7d08-4e4c-a854-dff239412407/DEST_PATH_GDA0001170870360000041.png)