Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Liquidmetal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquidmetal and Vitreloy are commercial names of a series of amorphous metal alloys developed by a California Institute of Technology (Caltech) research team and marketed by Liquidmetal Technologies. Liquidmetal alloys combine a number of desirable material features, including high tensile strength, excellent corrosion resistance, very high coefficient of restitution and excellent anti-wearing characteristics, while also being able to be heat-formed in processes similar to thermoplastics. Despite the name, they are not liquid at room temperature.

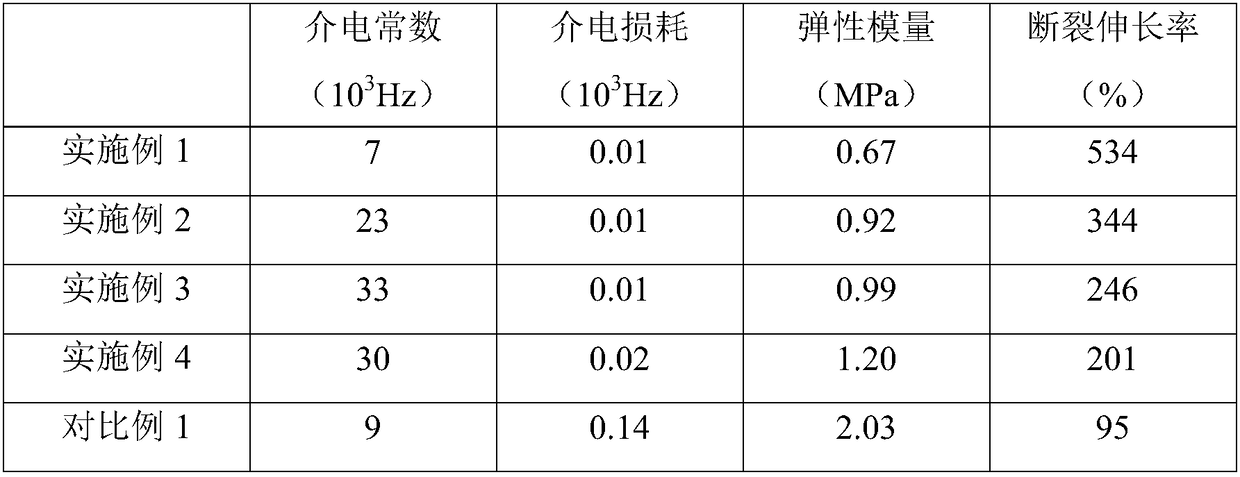

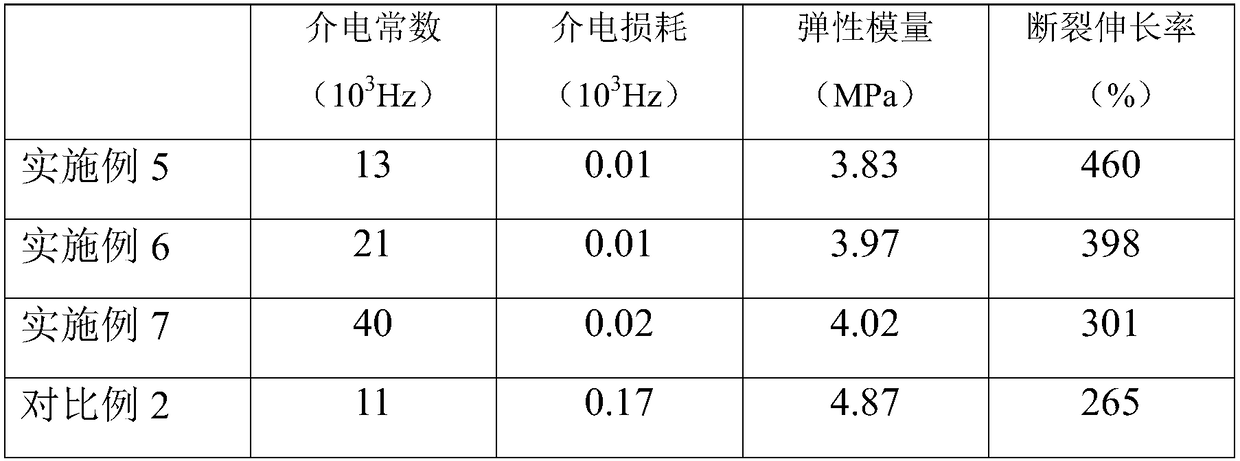

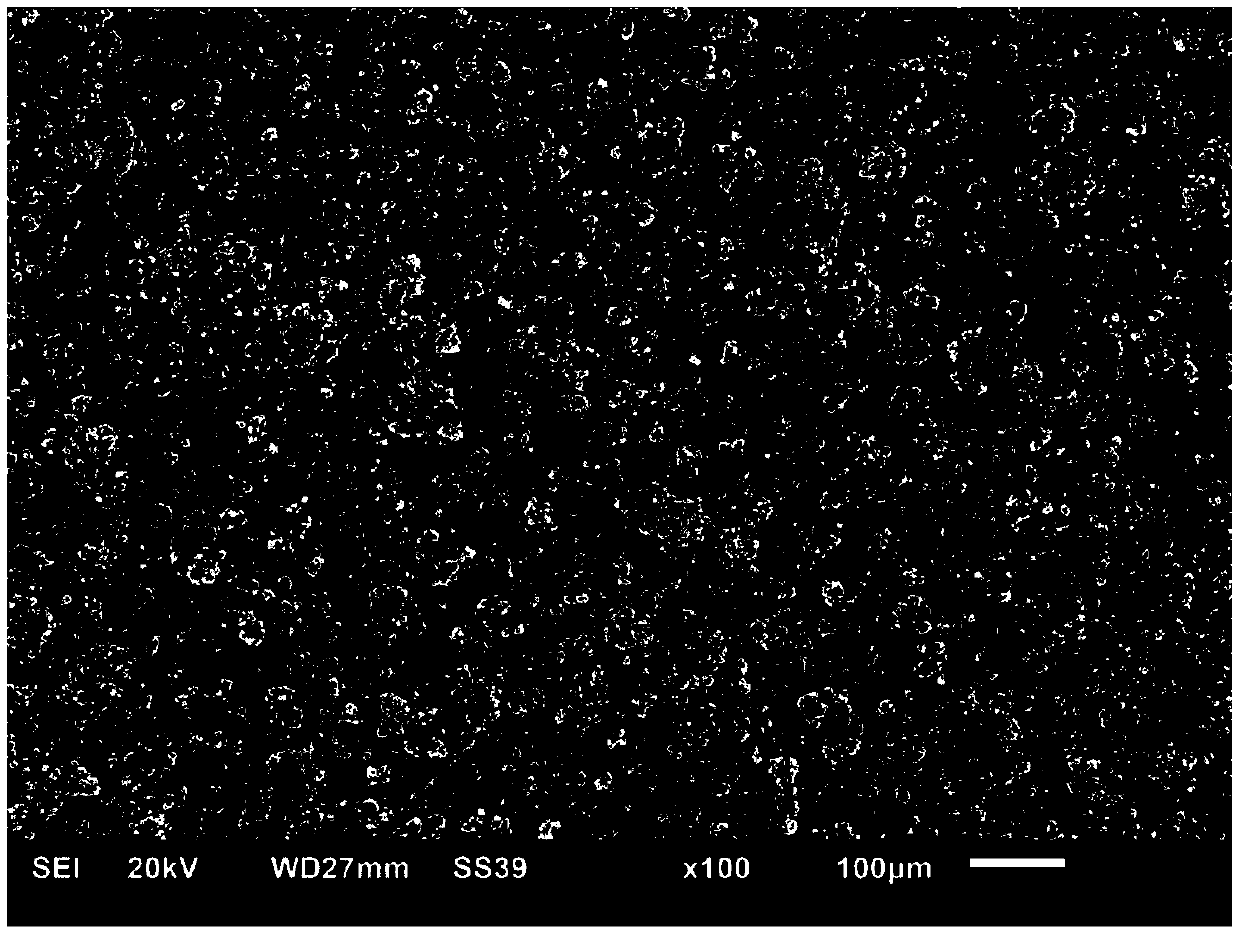

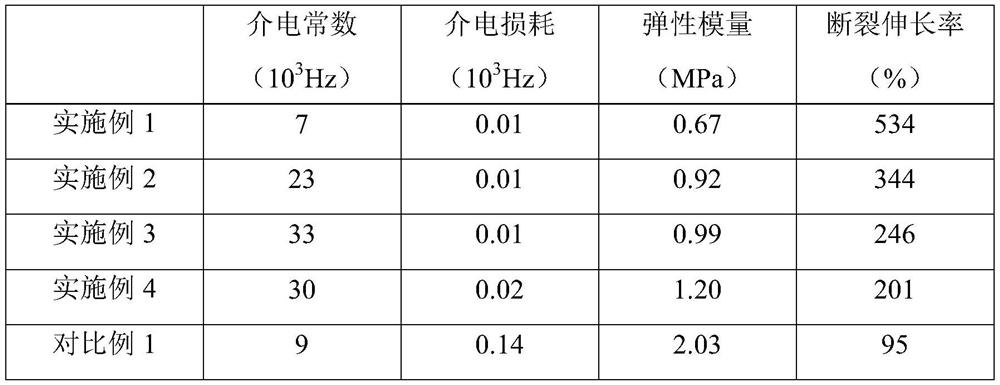

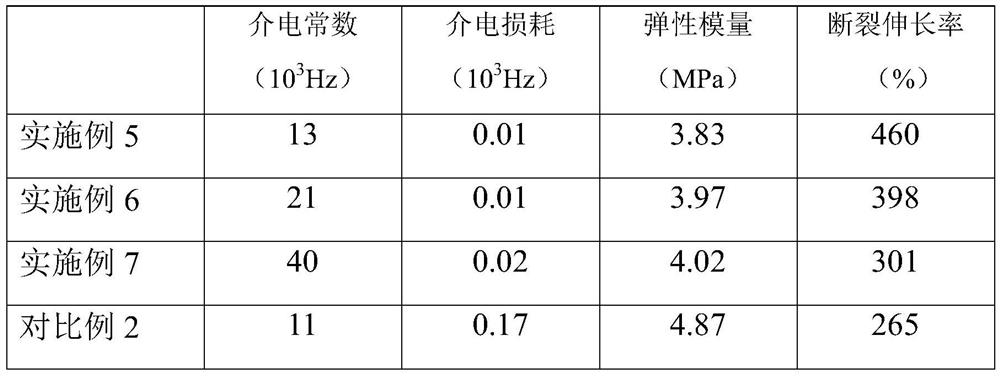

Flexible dielectric elastomer composite material based on nanometer liquid metal and preparation method thereof

The invention relates to a flexible dielectric elastomer composite material based on nanometer liquid metal. The flexible dielectric elastomer composite material comprises an elastomer and the liquidmetal and is prepared by the following steps: preparing a mercaptan-coated nanometer liquid metal emulsion through ultrasonic crushing, dissolving the elastomer in a solvent, then mixing with the nanometer liquid metal emulsion and uniformly stirring to obtain a liquid metal / elastomer / solvent suspension; obtaining the flexible dielectric elastomer composite material through hot pressing film formation or room-temperature curing. The flexible dielectric elastomer composite material provided by the invention has the benefits that dielectric constants of the composite material are improved, the dielectric loss is effectively reduced, and meanwhile, the elastic modulus of the composite material is not significantly increased, so that the problems of poor compatibility and flexibility of a dielectric elastomer modified by traditional inorganic rigid packing are solved, and the liquid metal-based dielectric elastomer composite material capable of meeting the requirements of a flexible wearable technology is prepared.

Owner:BEIJING UNIV OF CHEM TECH

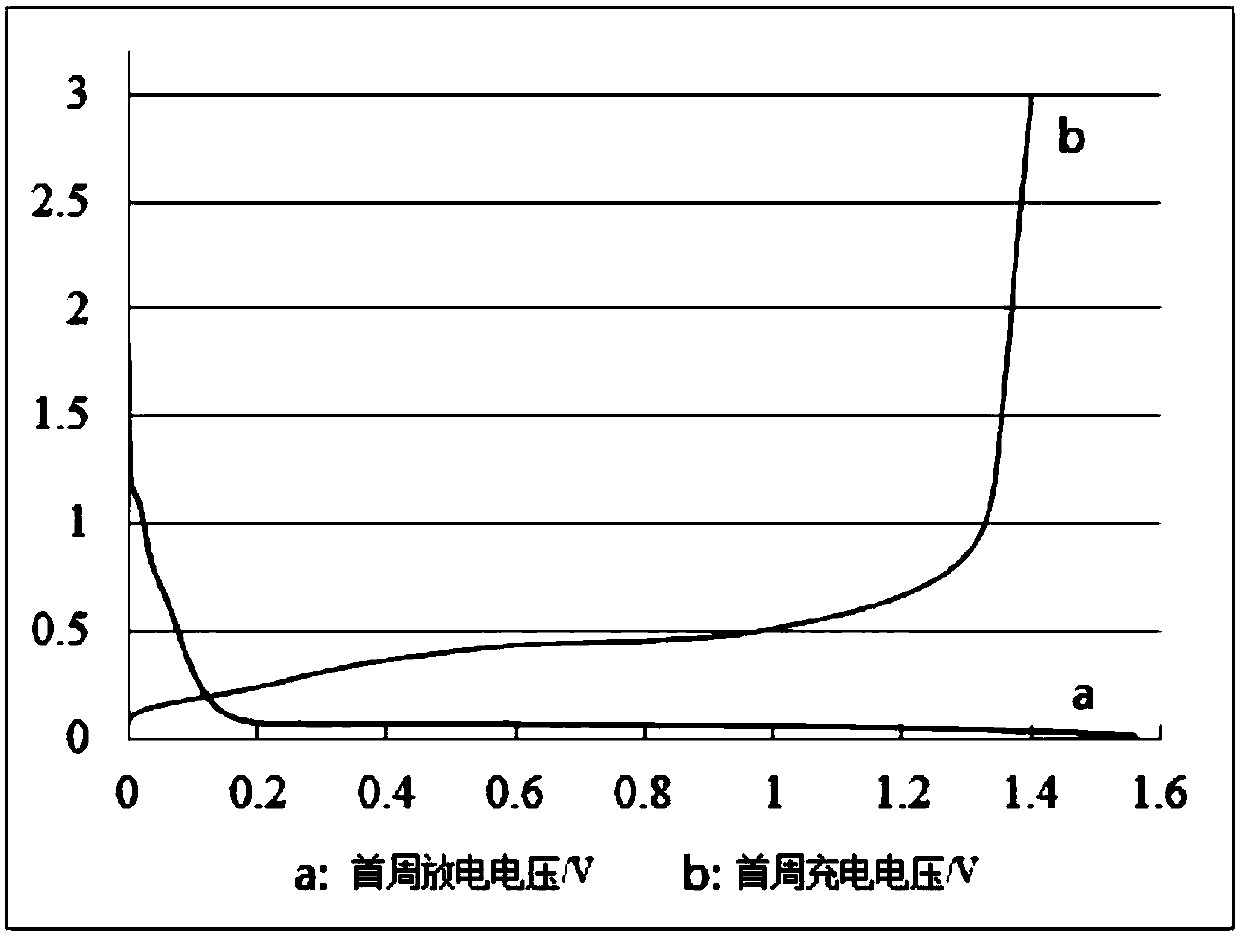

Method for preparing liquid metal nano-particles and method for preparing lithium ion batteries

InactiveCN108539188AIncrease energy densityImprove conductivityCell electrodesSecondary cellsSelf-healingAluminium-ion battery

The invention relates to a method for preparing liquid metal nano-particles and a method for preparing lithium ion batteries. The method for preparing the liquid metal nano-particles includes steps ofS1, mixing liquid metal alloy, ethyl alcohol solution and dodecyl mercaptan to obtain mixtures I and ultrasonically degrading the mixtures I; S2, allowing the mixtures I to stand still for 2-4 h, andthen filtering and drying the mixtures I to obtain the liquid metal nano-particles. The methods have the advantages that the electric conductivity of the lithium ion batteries with added liquid metalcan be greatly improved, and the liquid metal is high in energy density, can be used as an electrode material additive to provide extra capacity to the lithium ion batteries, and is a perfect material for lithium batteries with high energy density; the lithium ion batteries are little in damage in high-rate charge and discharge procedures owing to the excellent self-healing ability of the liquidmetal, the lithium ion batteries are excellent in high-rate performance as compared with pure lithium titanate batteries, the cycle lives of the lithium ion batteries can be prolonged, and the stability of the lithium ion batteries can be improved.

Owner:武汉新能源研究院有限公司

Method for achieving directional solidification based on 3D printing of multi-layer hollow shell mold

ActiveCN108746564ADirectional solidification under the same heat preservation conditions and stableDirectional solidification stabilityAdditive manufacturing apparatusFoundry mouldsDirectional solidificationMixed crystal

Owner:TSINGHUA UNIV

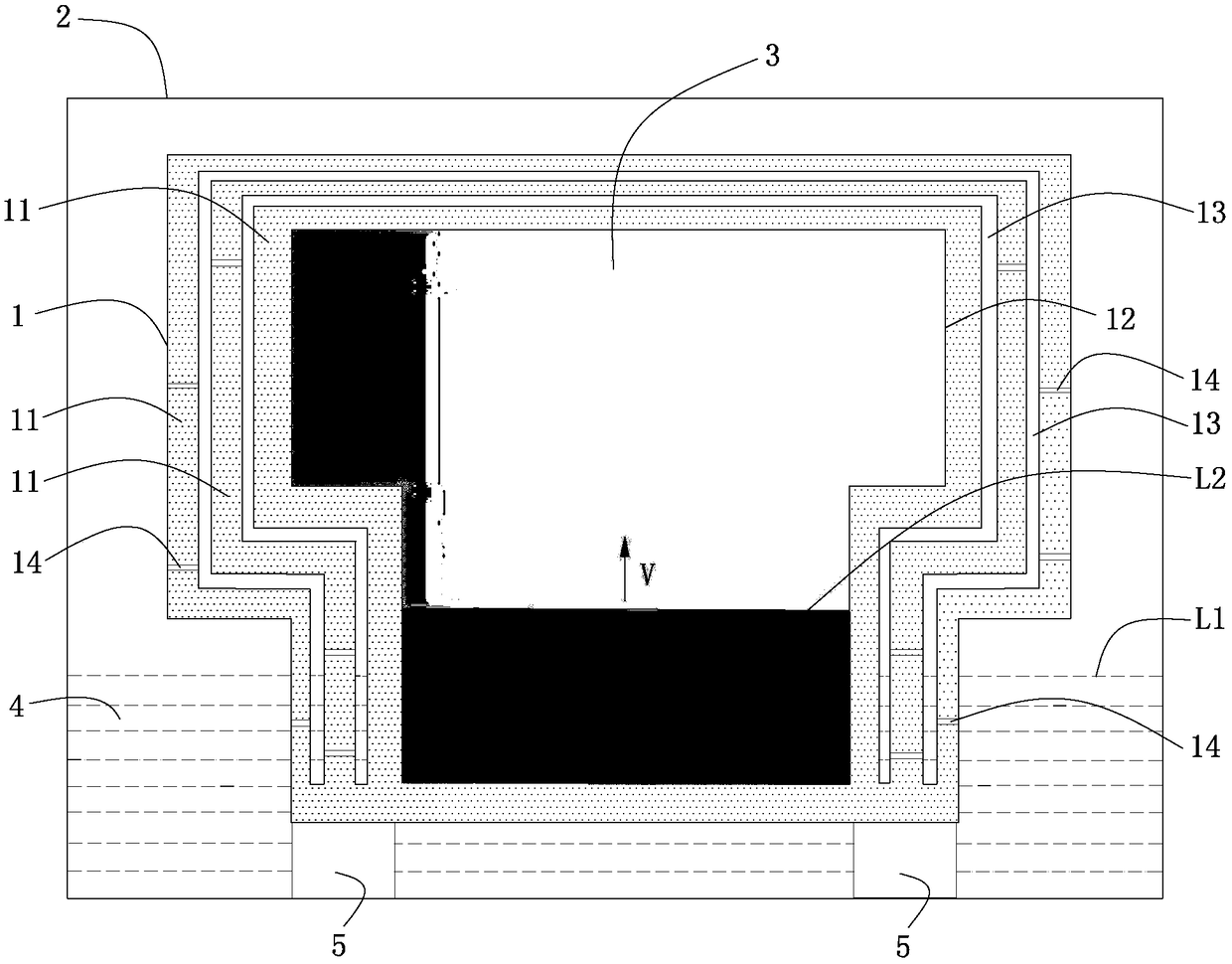

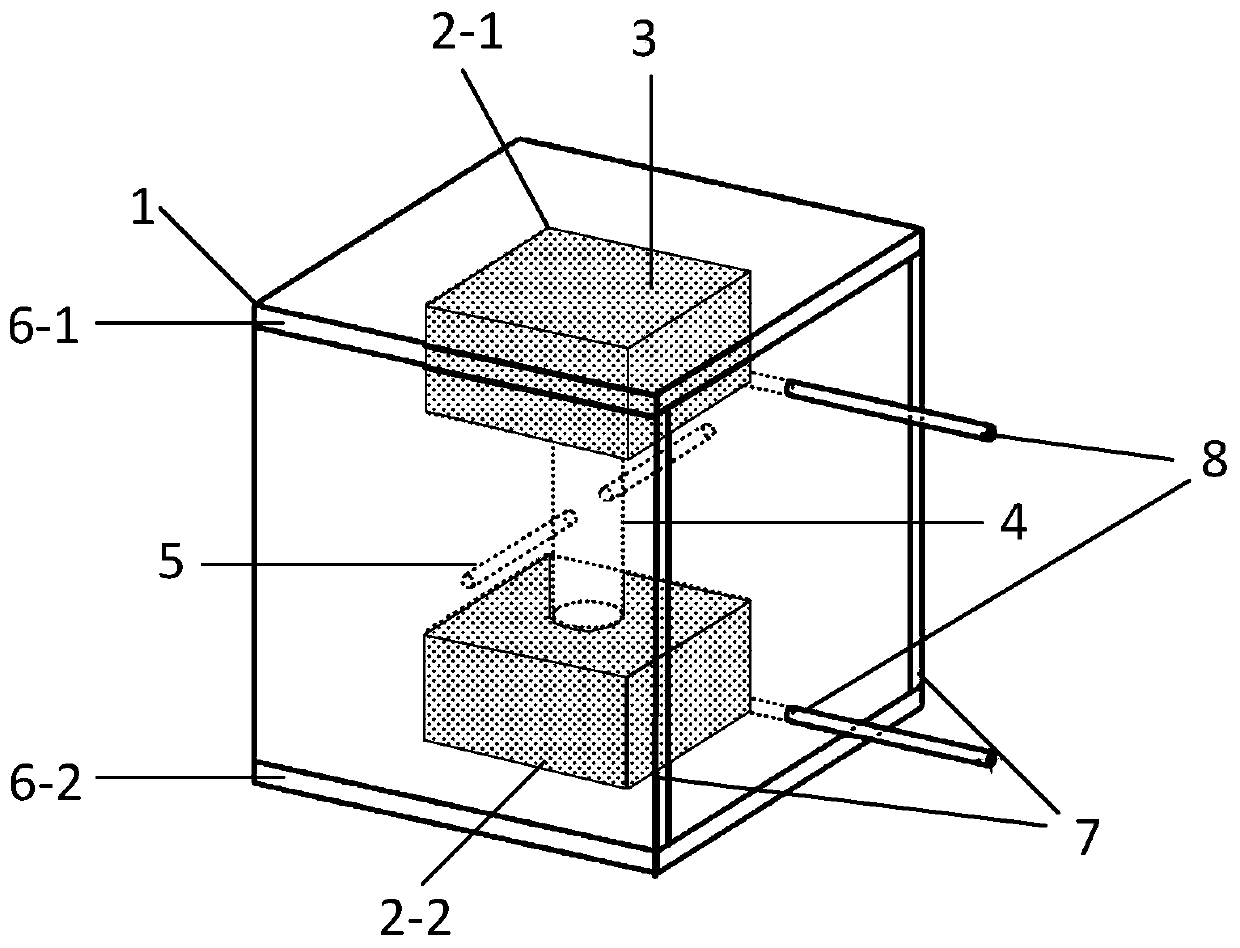

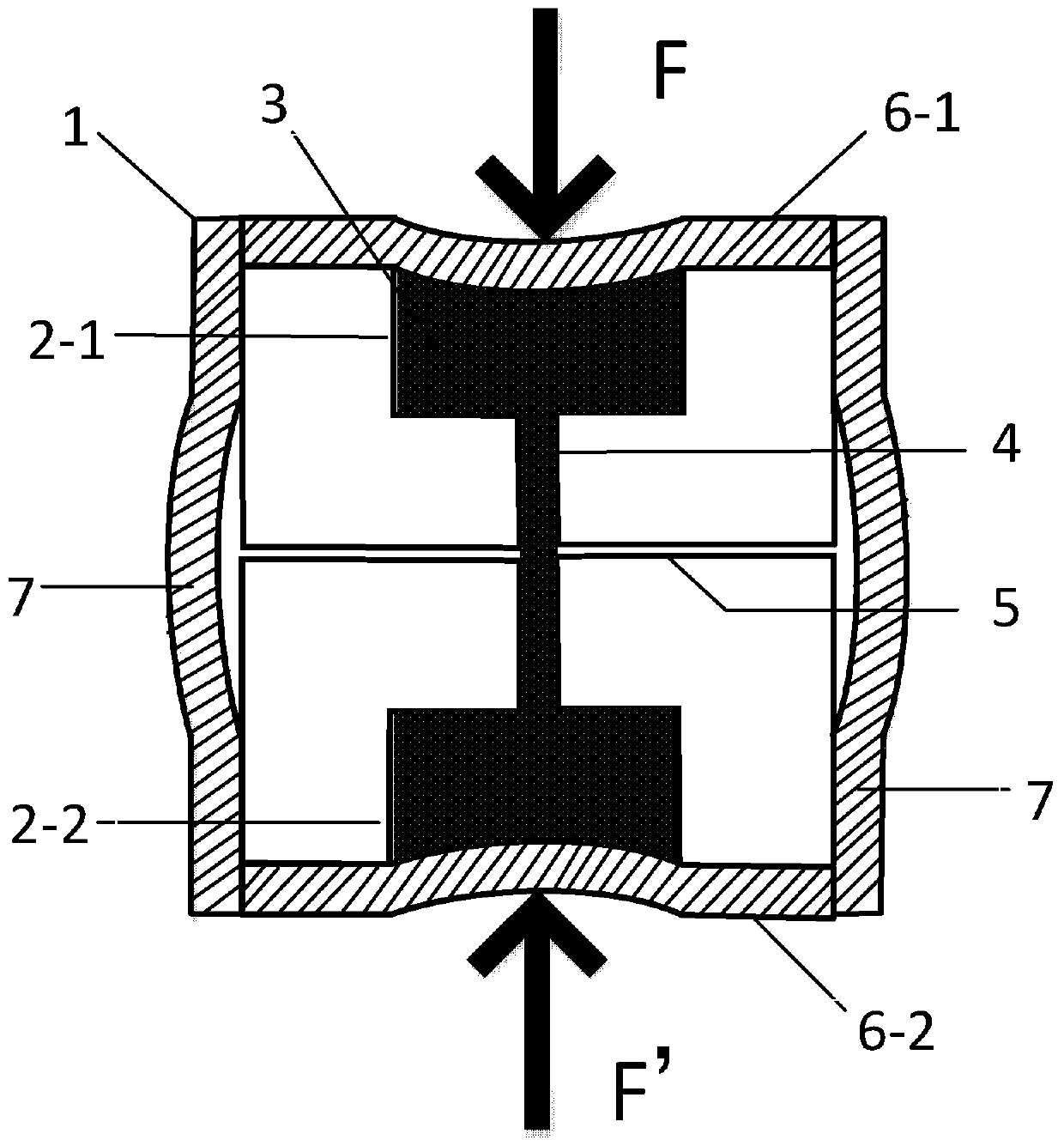

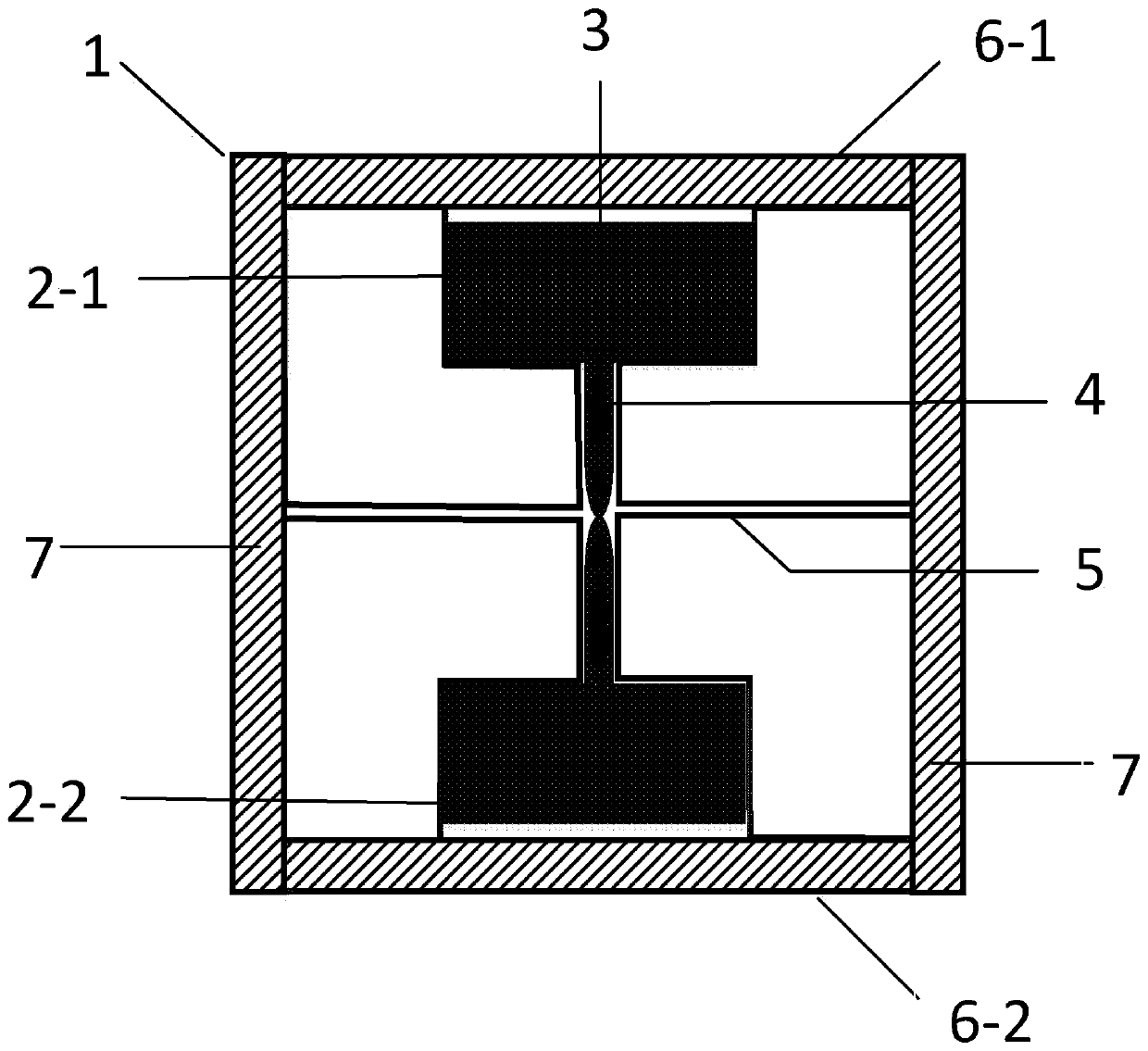

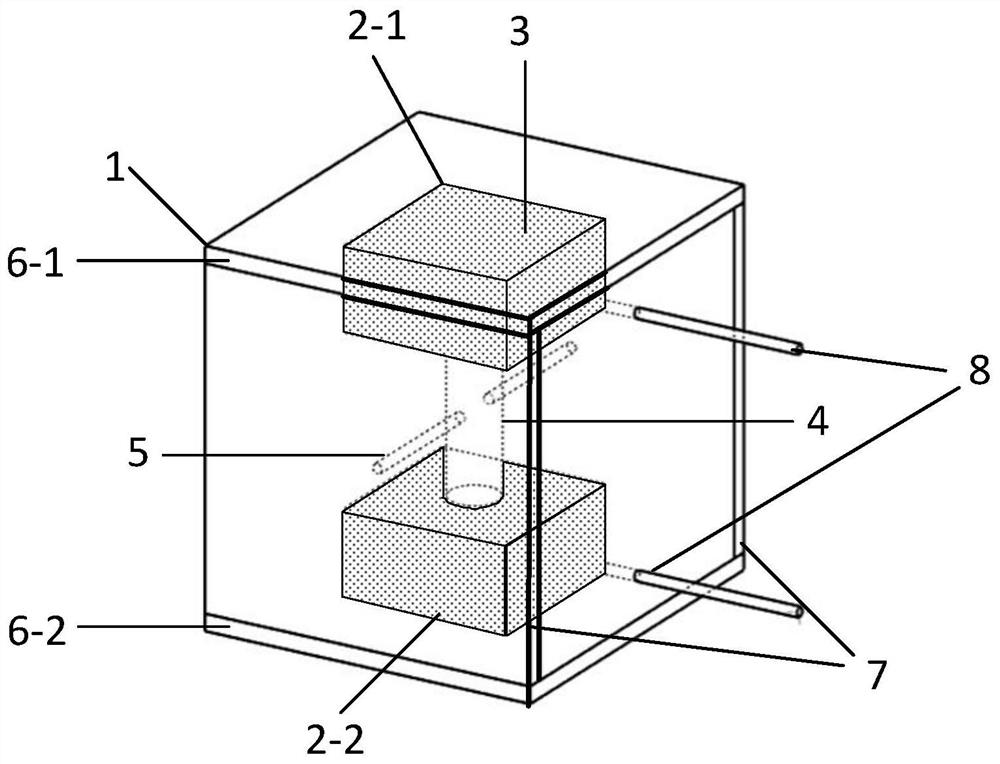

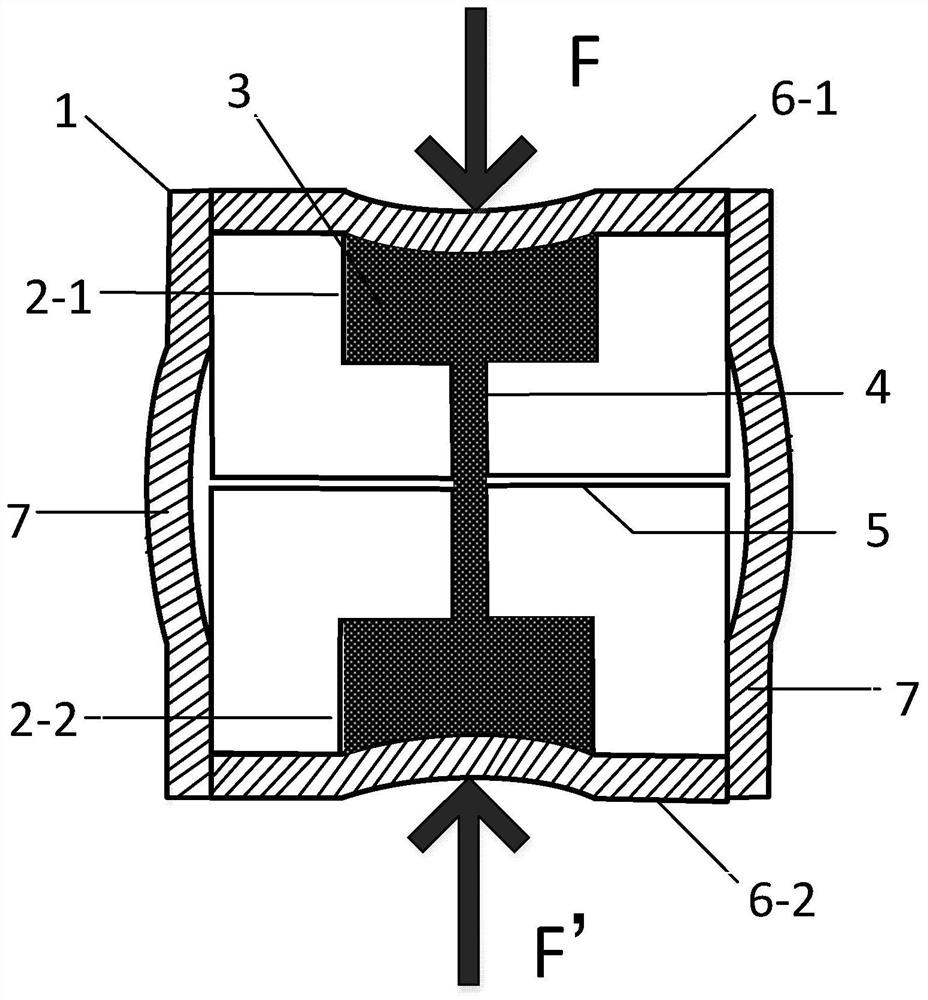

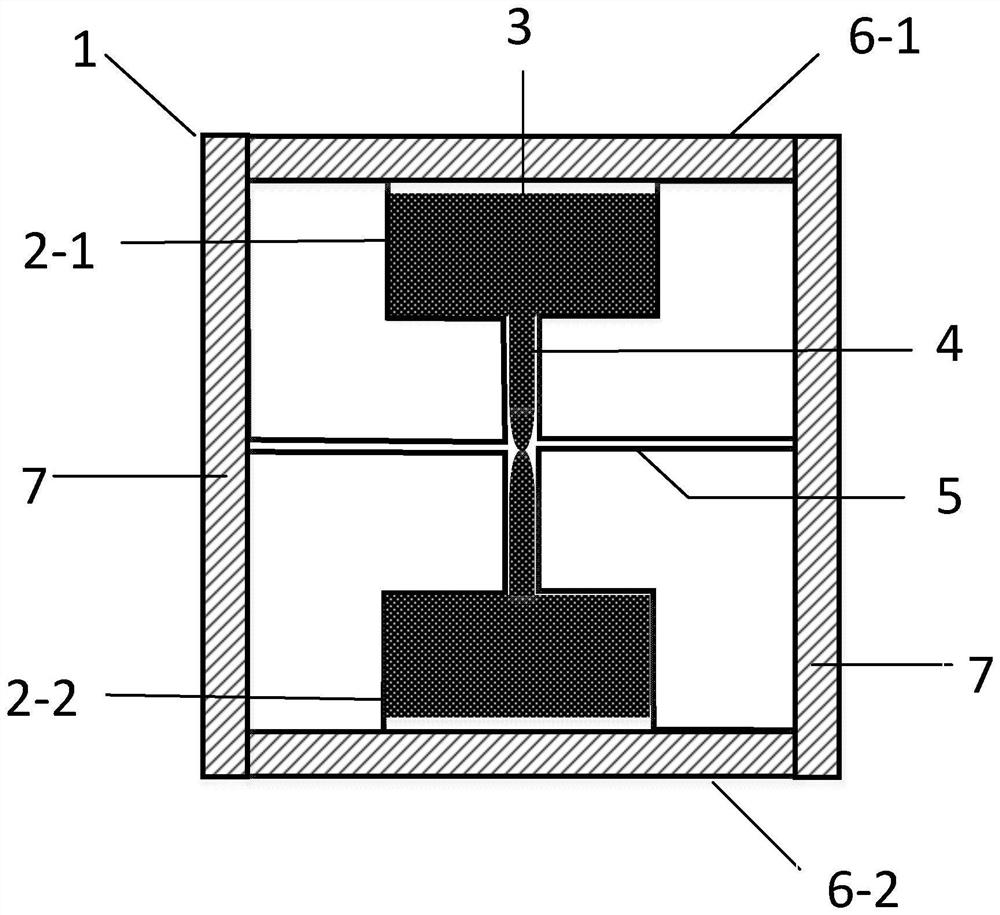

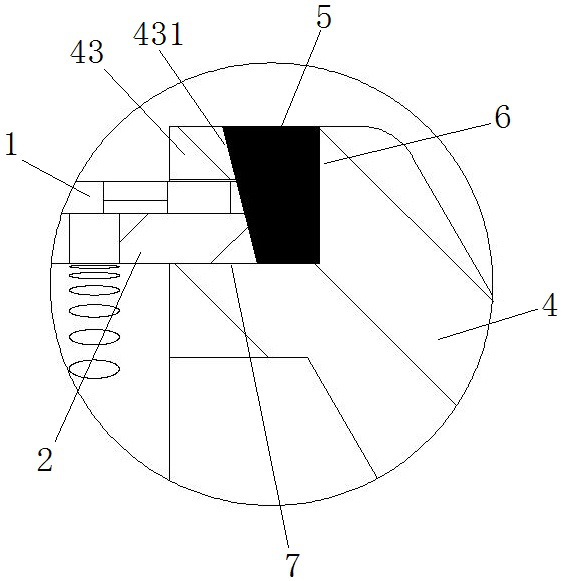

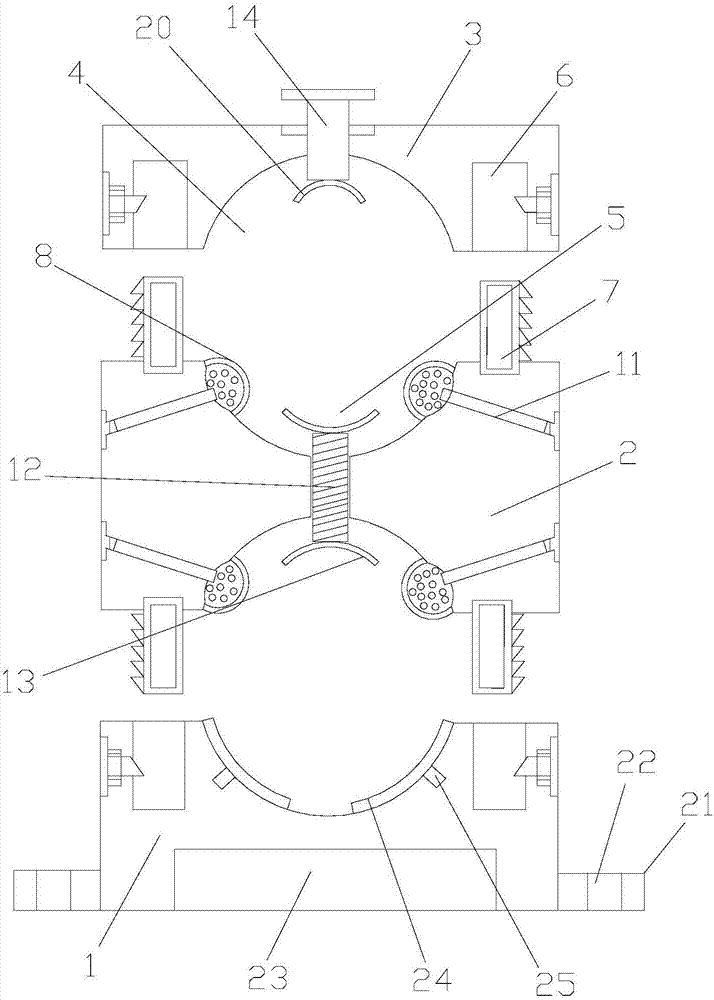

Miniature liquid metal switch with flexible structure

ActiveCN110033982ALow costGood effectElectric switchesElectrical resistance and conductanceLiquid storage tank

The invention discloses a miniature liquid metal switch with a flexible structure. The miniature liquid metal switch comprises a base body, an upper liquid storage tank, a lower liquid storage tank, liquid metal, a liquid metal flow channel, an air flow channel, a top surface sealing thin film, a bottom surface sealing thin film, a side surface sealing thin film and an external electrode. The invention further provides a control method of the miniature liquid metal switch with the flexible structure. A high-elasticity matrix can be extruded through an external mechanical stress to enable the liquid metal to move for communicating with a circuit; and rapid circuit breaking can be realized through automatic springback of a high-elasticity matrix material and surface tension contraction of the liquid metal. The liquid metal is used as a conducting medium, and no contact resistor exists, so that electric repulsive force under a normal rated, short-circuit or lightning impulse current can be avoided, and meanwhile, the service life problem of an existing solid-state metal contact switch due to bouncing, fusion welding, ablation and the like is also favorably solved. The miniature liquidmetal switch is simple in structure, small in size and good in on-off performance, and can be applied to power on-off occasions of circuits.

Owner:XI AN JIAOTONG UNIV

Method for producing cupronickel alloy round ingot

InactiveCN110777281AShort production processReduce Quality Control Influencing FactorsCupronickelIngot

The invention discloses a method for producing a cupronickel alloy round ingot. The general formula of produced cupronickel alloy is CuaNibFecMnd, wherein by mass percent, b is larger than or equal to4% and smaller than or equal to 31.5%, c is larger than or equal to 0% and smaller than or equal to 1.8%, d is larger than or equal to 0% and smaller than or equal to 1.2%, the balance is a, and thesum of impurities in the alloy is not larger than 0.5%. According to the method, solid metal is melted through an intermediate frequency furnace, a refining agent is added for refining, refined liquidmetal with qualified ingredients passes through a transferring runner and a graphite crucible and directly enters a crystallizer, and a round ingot producing process is simplified; and ingot castingquality control influence factors are reduced, and consumption of a graphite part in the cupronickel alloy round ingot production process is reduced. According to the method, a desoxidant is added atdifferent times to deoxidize the liquid metal, air sucked in the process that the liquid metal passes through the runner and is directly transferred is eliminated, the quality of the liquid metal is stabilized, and the quality of a round ingot crystal structure is improved.

Owner:JINCHUAN GROUP LIMITED

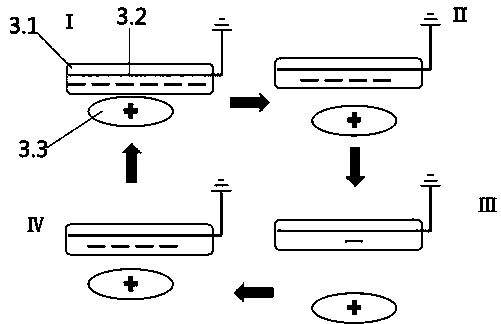

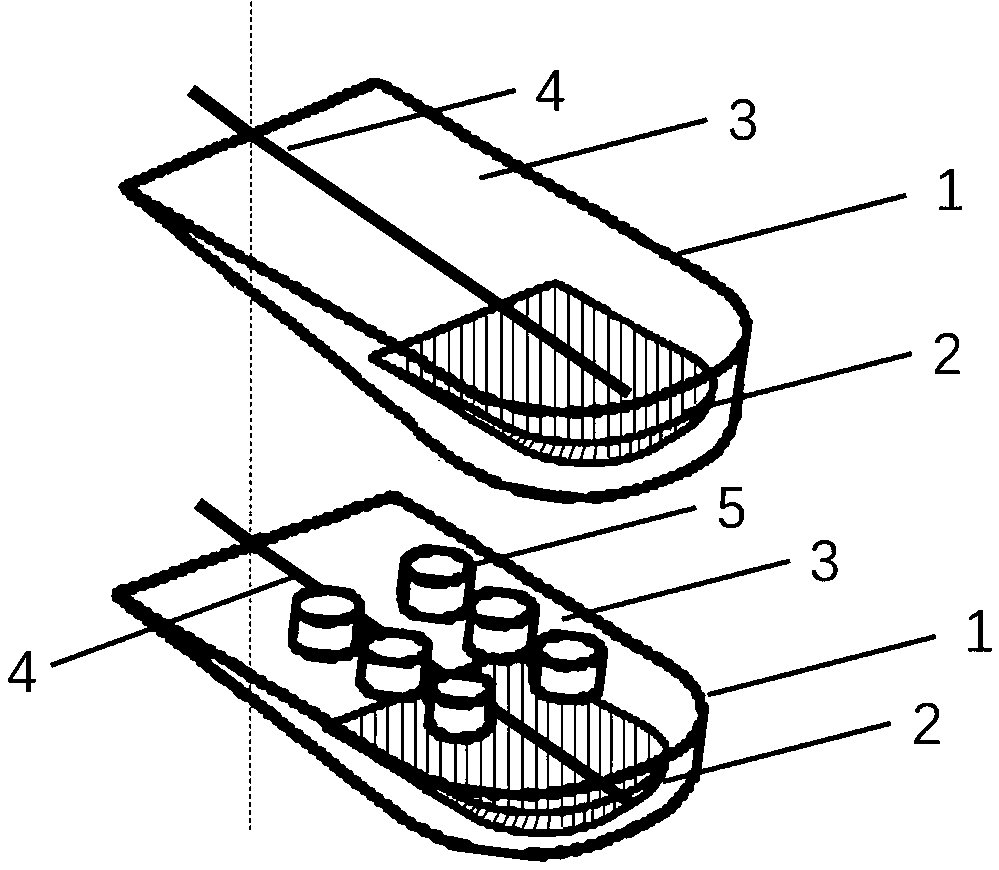

Power generation air bag device and insole or shoe sole applying same

ActiveCN110432581AFluorescence effectHigh mechanical energy collection efficiencySolesInsolesGeneration processNanogenerator

The invention provides a power generation air bag device and an insole or a shoe sole applying the same, and particularly a single-electrode contact structure friction nanometer generator using liquidmetal as an electrode; in a power generation process, the liquid metal moves to be in contact with an air bag to realize friction power generation, so that the problem that the mechanical energy collection efficiency and the buffering effect of a friction nanometer generator air bag device for collecting human foot movement mechanical energy in the prior art are mutually restricted is overcome; and the power generation air bag device in the insole serves as a power generation device which can serve as a self-driven motion sensor while supplying power to equipment.

Owner:HENAN UNIVERSITY

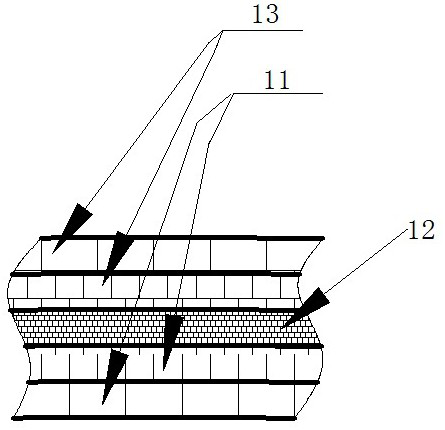

Flexible conductor wire and molding technology thereof

ActiveCN110098001AMeet high conductivity needsAvoid it happening againSingle bars/rods/wires/strips conductorsApparatus for manufacturing conducting/semi-conducting layersMolten stateEngineering

The invention discloses a flexible conductor wire and a molding technology thereof. The flexible conductor wire arranged in the surface of a fabric matrix comprises a flexible base, liquid metal and aflexible wrapping, and the flexible base and / or flexible wrapping are / is made of a flexible conducting material. The surface of the fabric matrix is printed with a basic glue material, and the liquidmetal and a wrapping glue material are sprayed and printed in a laminated alternative way to form the flexible conductor wire. The liquid metal is packaged in a flexible hose formed by the flexible base and the flexible wrapping, the conductivity and flexibility are higher, and the conductor wire is resistant to washing and bending. The flexible base has electric conductivity and thermal conductivity and insulation, can be adapted to improvement of the environmental temperature of the flexible hose, ensures that the liquid metal is in the fusion state, and meets the requirements for high conductivity of the flexible conductor, especially for use in areas at lower environmental temperature. The flexible conductor wire is easy to process and mold, satisfies conductance demands in intelligent dresses, prevents generation of bubbles by spraying and printing of the liquid metal and the wrapping glue material in the laminated alternative way, and ensures the stability of conductance.

Owner:KUNSHAN TENGFEI UNDERWEAR TECH

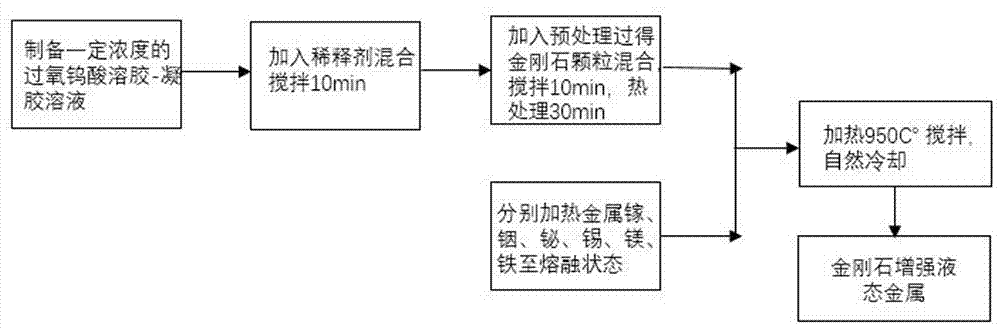

Diamond particle reinforced molten alloy thermal interface material and preparation method thereof

The invention discloses a diamond particle reinforced molten alloy thermal interface material and a preparation method thereof. The diamond reinforced molten alloy high-thermal conductivity material comprises the following raw materials in parts by mass: 40 to 100 parts of a molten alloy, 30 to 80 parts of diamond particles, 10 to 20 parts of tungsten metal and 10 to 20 parts of a diluent. The preparation method comprises the steps that diamond particles are subjected to surface treatment sequentially, the surfaces are coated with tungsten layers, the diamond particles are added into a liquidmetal, and the diamond particle reinforced molten alloy thermal interface material is obtained. Through adoption of the technical scheme, on one hand, interface bonding strength of the diamond particle reinforced molten alloy thermal interface material is improved, and on the other hand, the diamond particles are better dispersed in the liquid metal, the heat-conducting property is improved, operation is simple, the thermal conductivity is high, thermal stability is high, and the material can be utilized in the fields of heat dissipation of electric appliances and electronic packaging materials, and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Recyclable heart stent

InactiveCN107648682AStable mechanical propertiesGood biocompatibilityStentsSurgeryBiocompatibility TestingThrombus

The present invention provides a recyclable heart stent, which comprises a stent body and a heating device, the stent body is prepared by curing a liquid metal, the surface of the stent body is coatedwith a drug film, and the heating device is used for heating the stent body. The recyclable heart stent has the advantages of flexible liquid metal solid-liquid phase conversion, fast liquid metal curing speed and stable mechanical property after curing; if the recyclable heart stent needs to be taken out, the position where the stent body is located is heated by local heating, so that the liquidmetal is transformed into a liquid state, and is completely sucked out of blood vessels by a catheter to achieve recovery. The liquid metal is good in biocompatibility, anti-thrombosis, corrosion-resistant and non-damage to vessel walls, and avoids inflammatory reaction caused by stimulating of the blood vessels. In addition, the surface of the stent body is coated with the drug film, the concernthat the stent body acts as a foreign body to stimulate a local tissue can be eliminated, and the normal growth of tissues around contact areas between the stent body and the arteries can be ensured.

Owner:YUNAN JINGCHUANG LIQUID METAL THERMAL CONTROL TECH RES & DEV CO LTD

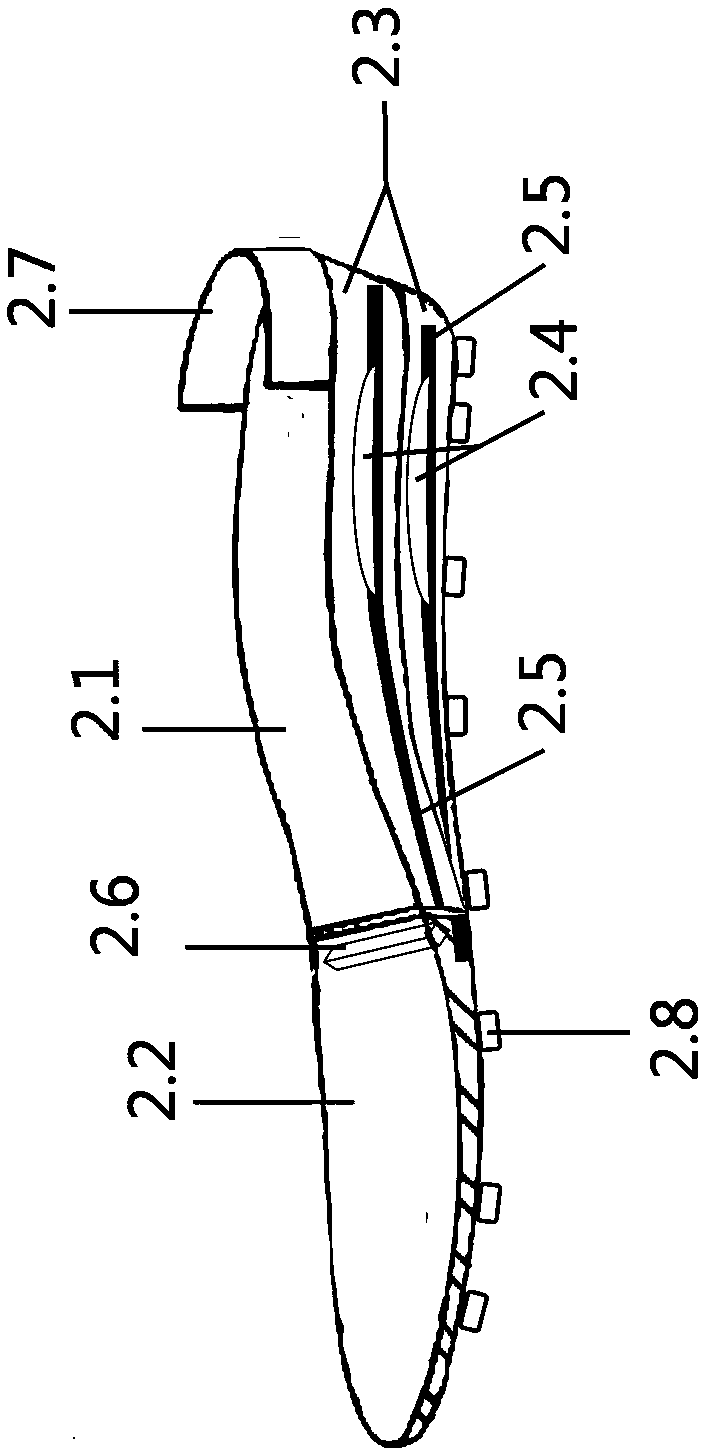

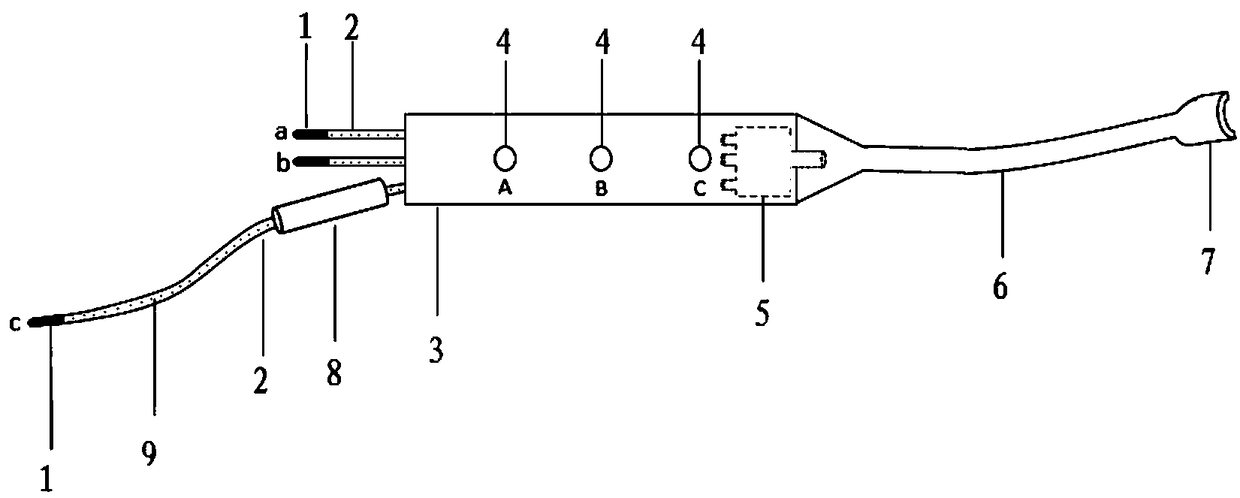

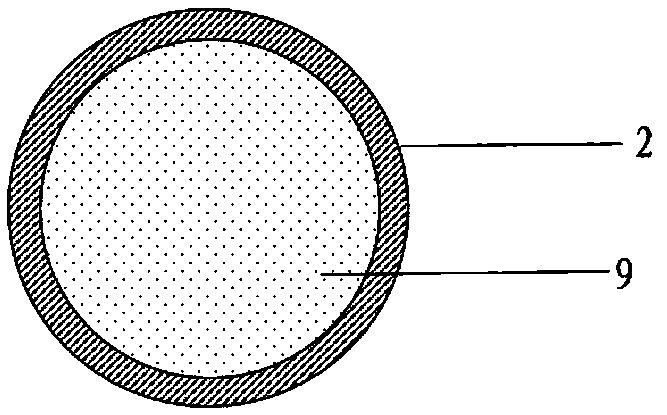

Nano knife probe and minimally invasive equipment

PendingCN109259855ASolve the disadvantage of difficult operation when the number increasesIncrease flexibilitySurgical instruments for heatingSyringe needleBiomedical engineering

A nano knife probe and minimally invasive equipment are provided in the embodiments of the present invention, The nano knife probe comprises: a liquid metal connection valve, an IRE generator connection port and multiple bendable probe transfer tubes, the probe transfer tubes are connected with one end of the liquid metal connection valve, the IRE generator connection port is electrically connected with the other end of the liquid metal connection valve, the free end of each probe transfer tube is provided with a probe head, and the probe transfer tube and the probe head are filled with liquidmetal. According to the nano knife probe and the minimally invasive equipment provided by an embodiments of the present invention, the several sets of the bendable probe transfer tubes are set and filled with liquid metal to form probe units, it can not only effectively solve the shortcomings of the traditional rigid monopole probes when the number of manipulation is increased, but also utilize the characteristics of bendable liquid metal probes, which can be introduced into the part of human internal organs through human respiratory tract and digestive tract for tumor treatment, so as to improve the flexibility of tumor treatment in clinic.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

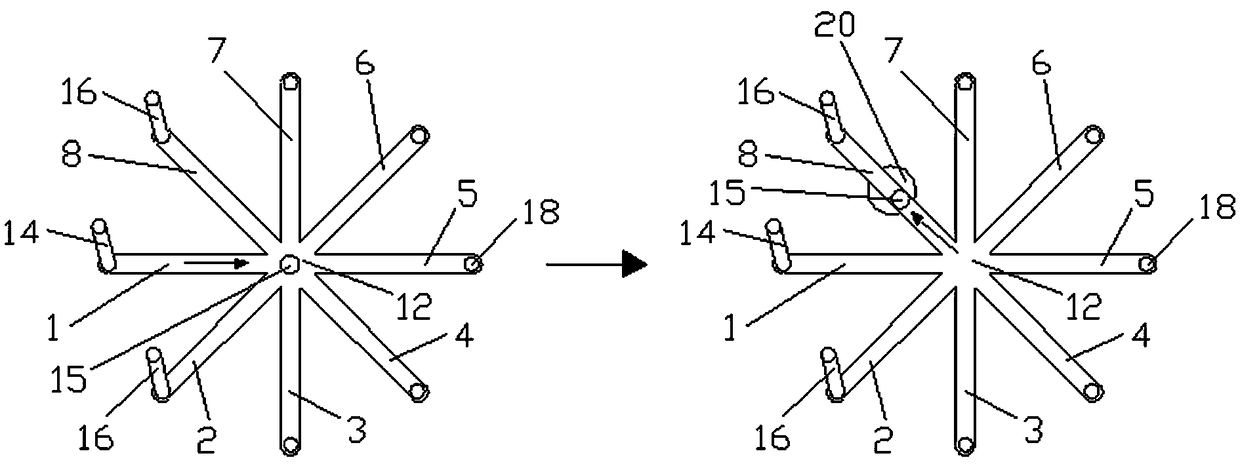

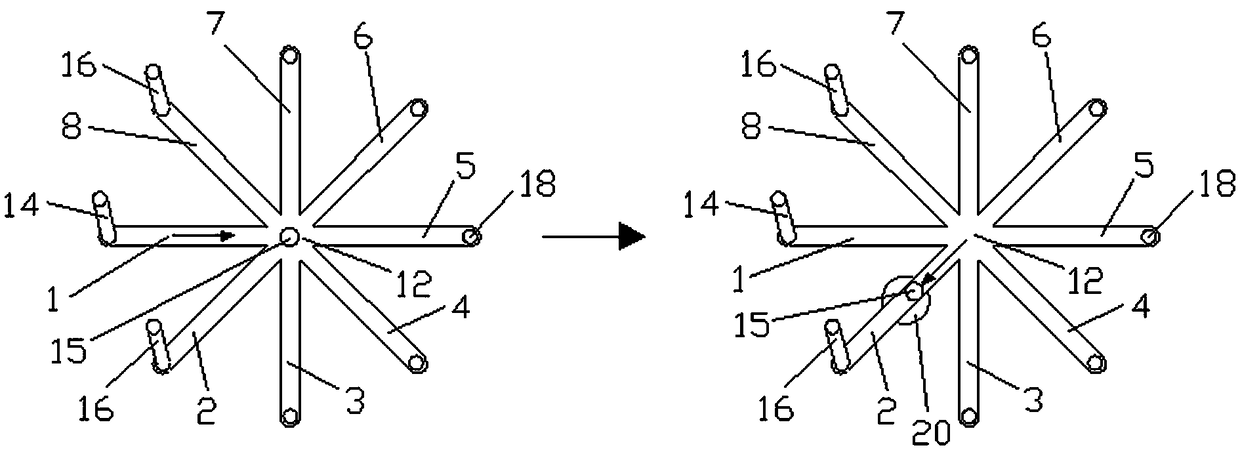

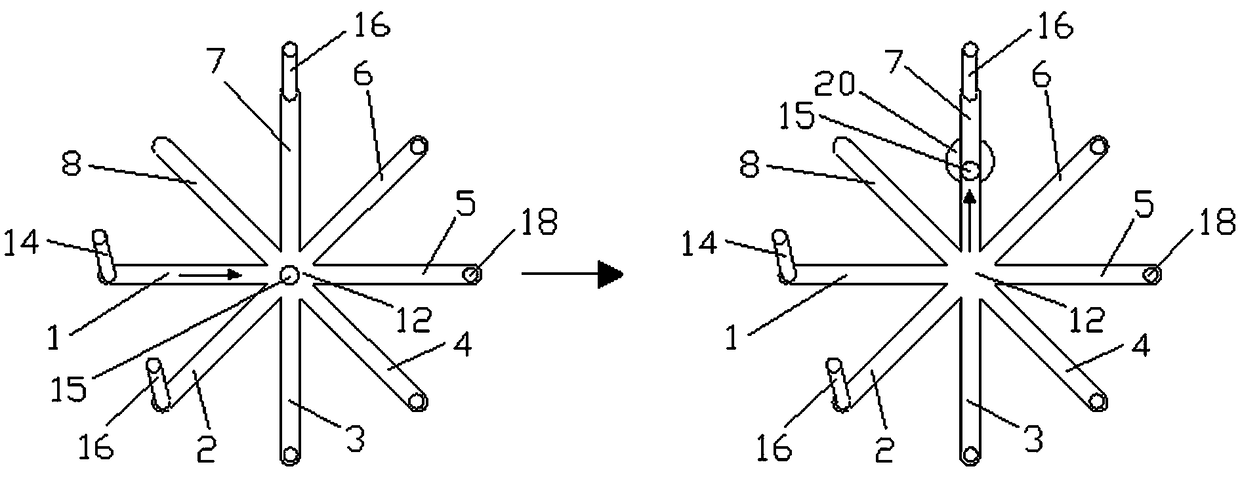

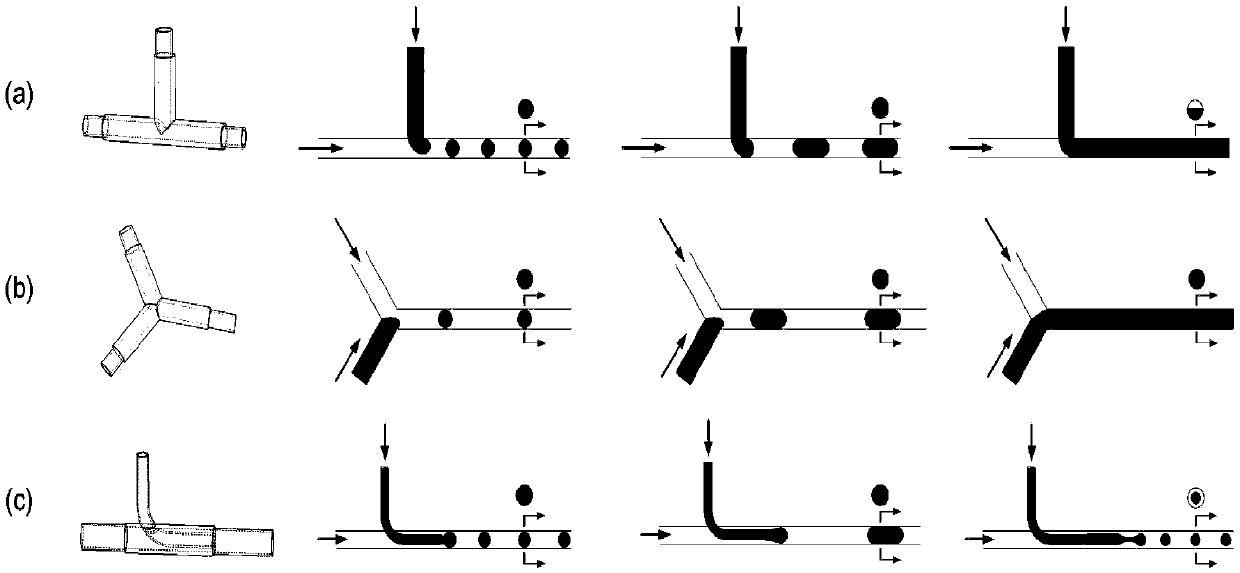

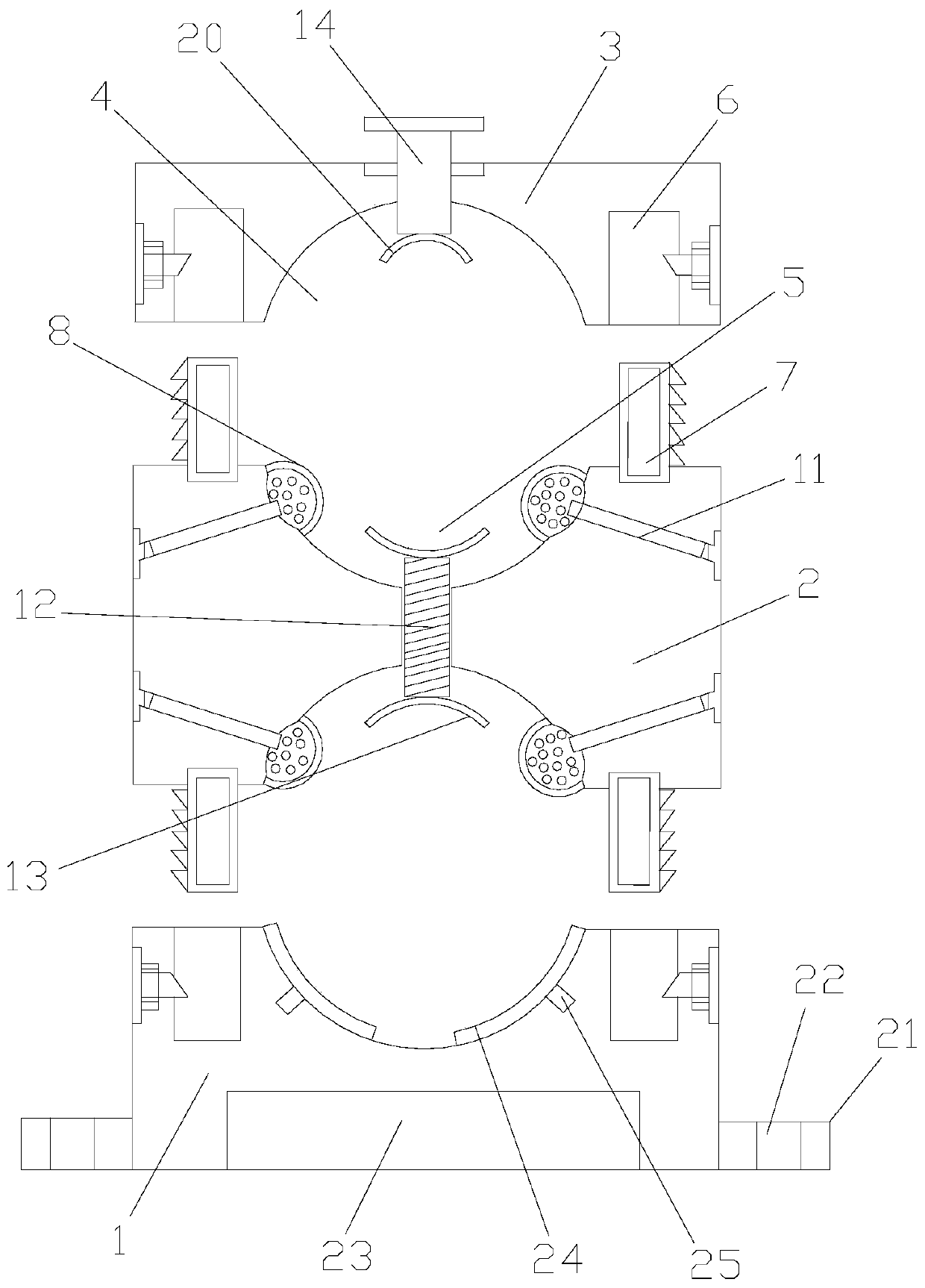

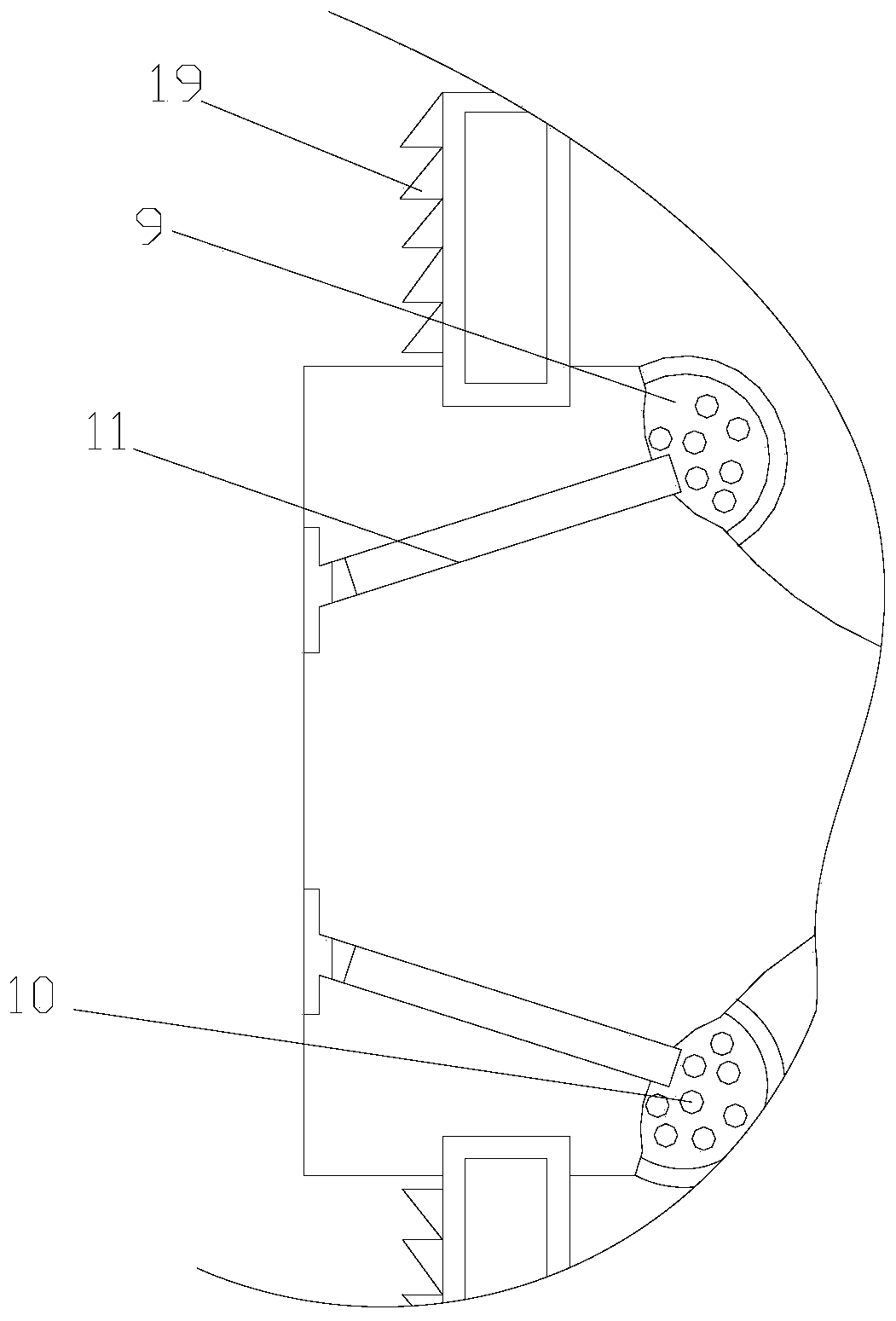

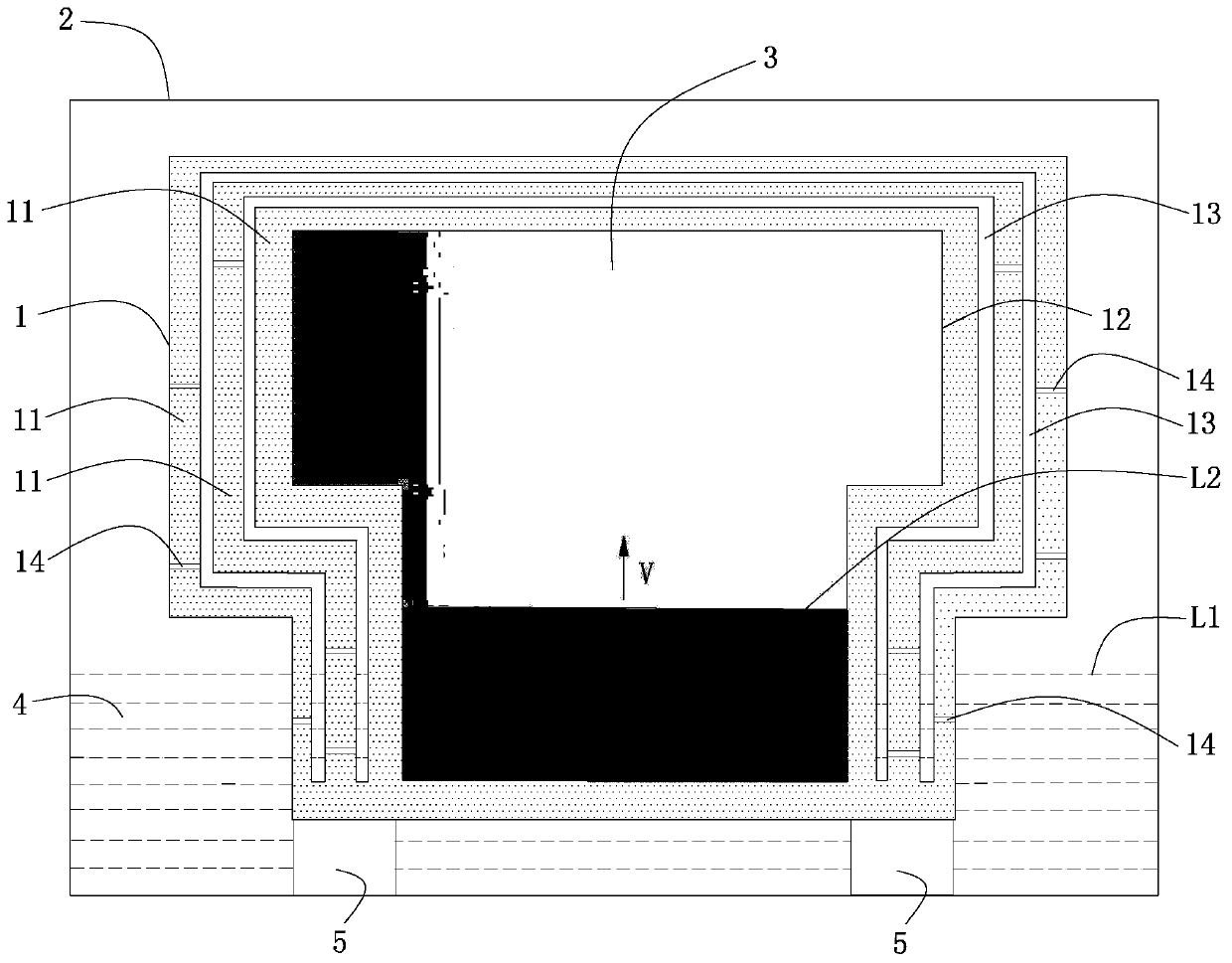

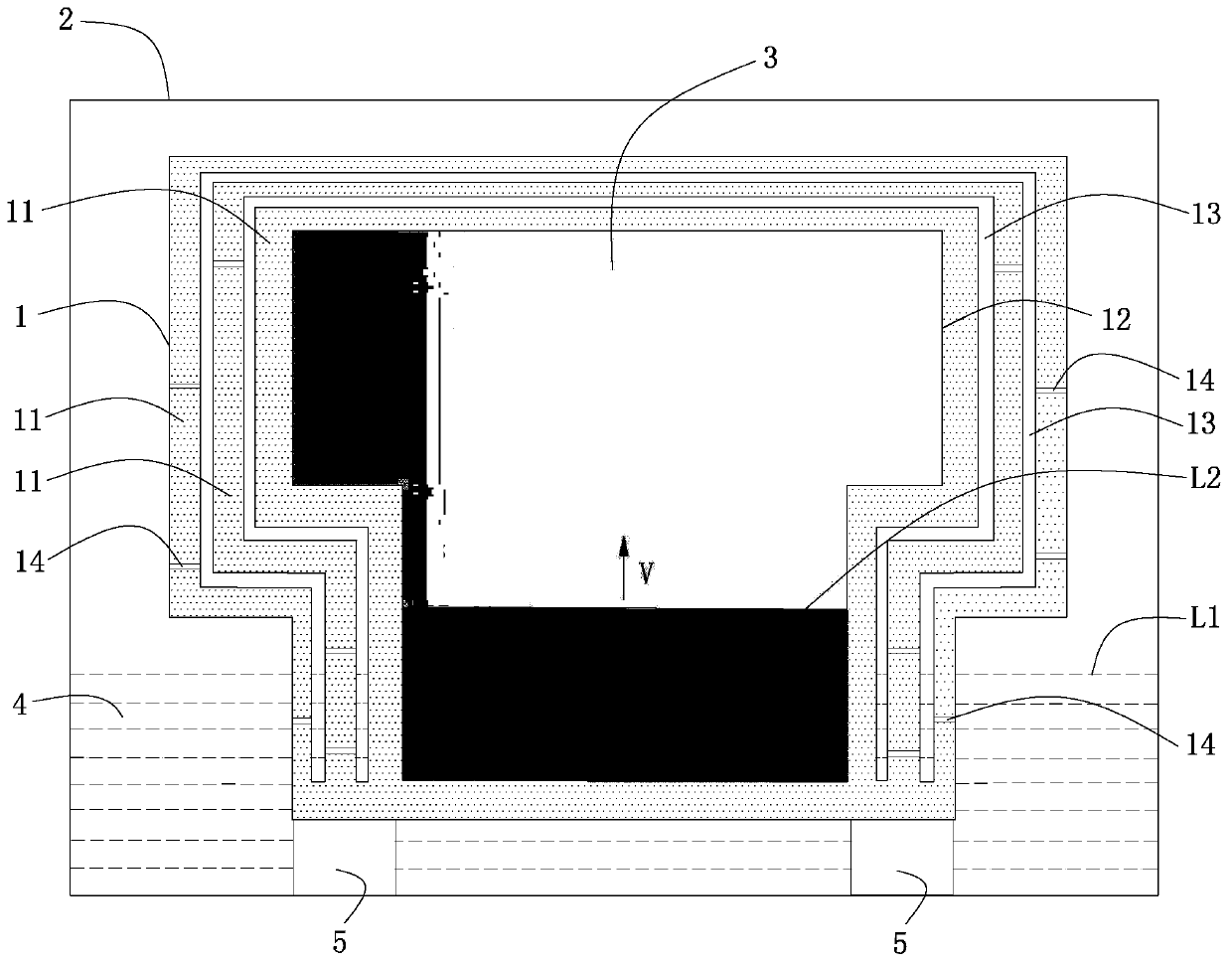

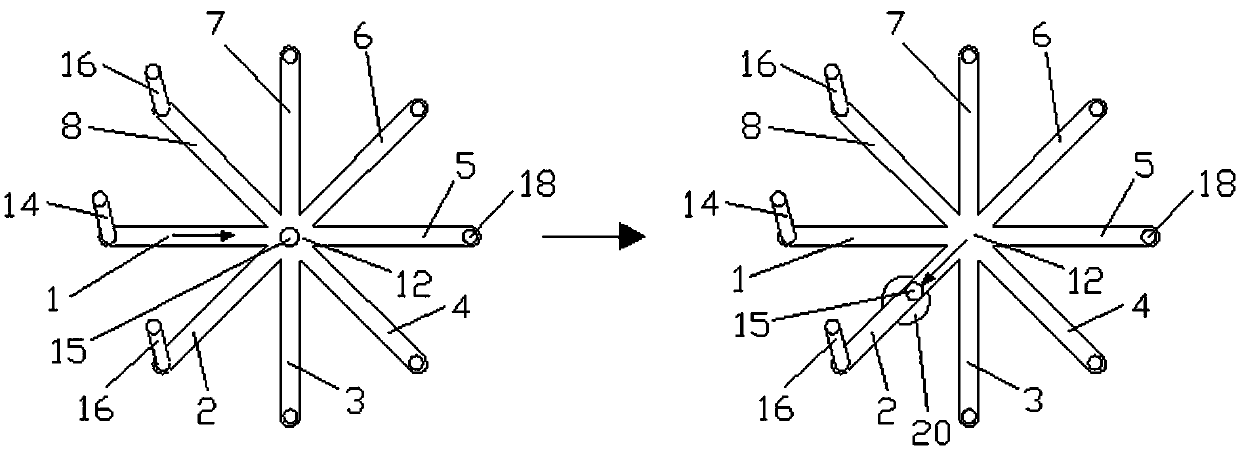

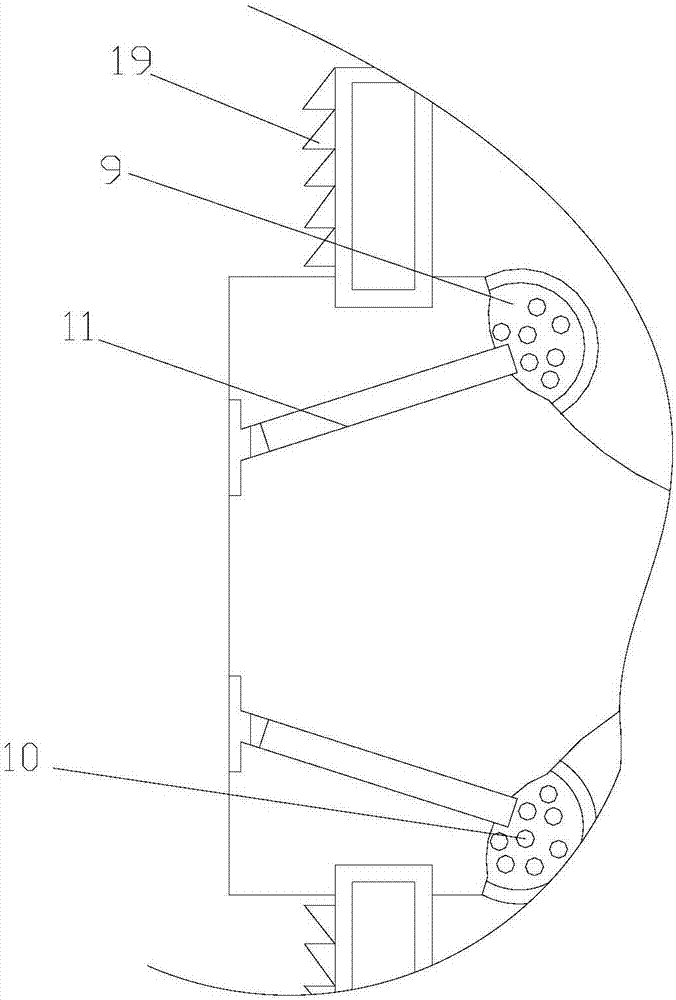

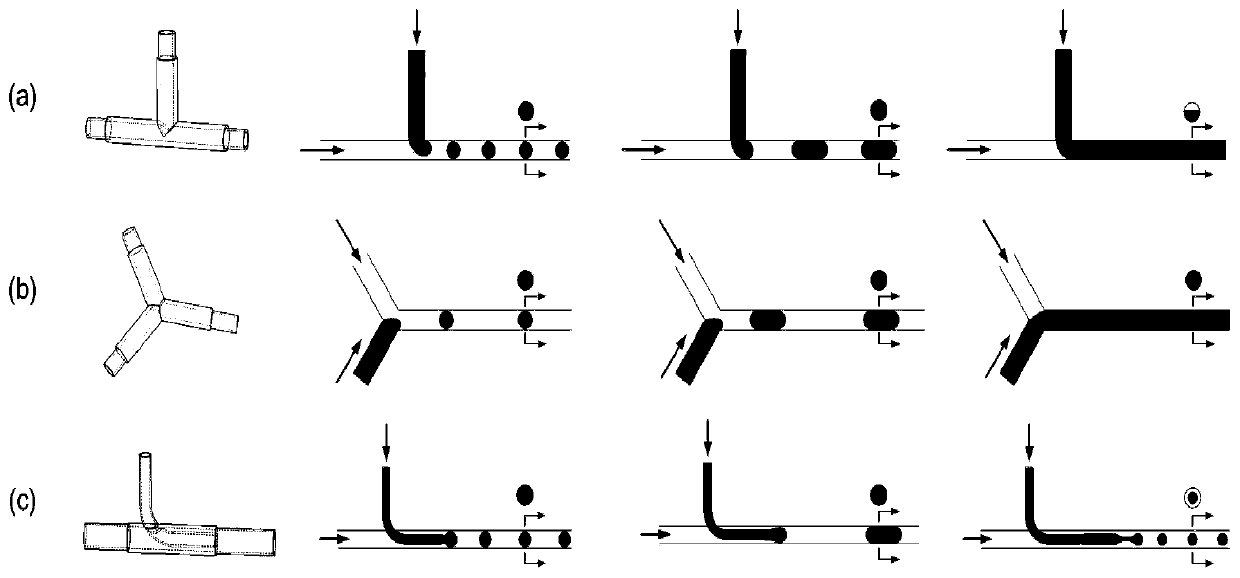

Channel device for controlling magnetic liquid metal by utilizing electromagnetic field coupling

ActiveCN108954004ASmooth goingAchieve normal progressMagnetic liquidsPermanent magnetsLiquidmetalElectric field

The invention relates to a channel device for controlling magnetic liquid metal by utilizing electromagnetic field coupling. The channel device comprises a power supply, a magnetic field element and aplurality of channels, wherein the channels are crossed at a branch; an electrolyte solution is arranged in each channel and the branch; a first electrode is arranged in one channel, and second electrodes are arranged in the rest of at least two channels; the first electrode is connected with a negative electrode of the power supply; each second electrode is connected with the positive electrodeof the power supply; when at least two positive electrode circuits are accessed, magnetic liquid metal moves to stop at the branch; after the magnetic field element gets close to the liquid metal, andthe magnetic liquid metal is attracted to an inlet of certain channel, the magnetic field element is removed, and under action of the electric fields, the magnetic liquid metal moves forwards along the channel. Magnetic fields are utilized for assisting magnetic liquid metal to move in the electric fields, and magnetic fields are applied to the bottoms of the channels, so that the magnetic liquidmetal smoothly moves in the target channel.

Owner:SUZHOU UNIV

A tiny liquid metal switch with a flexible structure

The invention discloses a miniature liquid metal switch with a flexible structure. The miniature liquid metal switch comprises a base body, an upper liquid storage tank, a lower liquid storage tank, liquid metal, a liquid metal flow channel, an air flow channel, a top surface sealing thin film, a bottom surface sealing thin film, a side surface sealing thin film and an external electrode. The invention further provides a control method of the miniature liquid metal switch with the flexible structure. A high-elasticity matrix can be extruded through an external mechanical stress to enable the liquid metal to move for communicating with a circuit; and rapid circuit breaking can be realized through automatic springback of a high-elasticity matrix material and surface tension contraction of the liquid metal. The liquid metal is used as a conducting medium, and no contact resistor exists, so that electric repulsive force under a normal rated, short-circuit or lightning impulse current can be avoided, and meanwhile, the service life problem of an existing solid-state metal contact switch due to bouncing, fusion welding, ablation and the like is also favorably solved. The miniature liquidmetal switch is simple in structure, small in size and good in on-off performance, and can be applied to power on-off occasions of circuits.

Owner:XI AN JIAOTONG UNIV

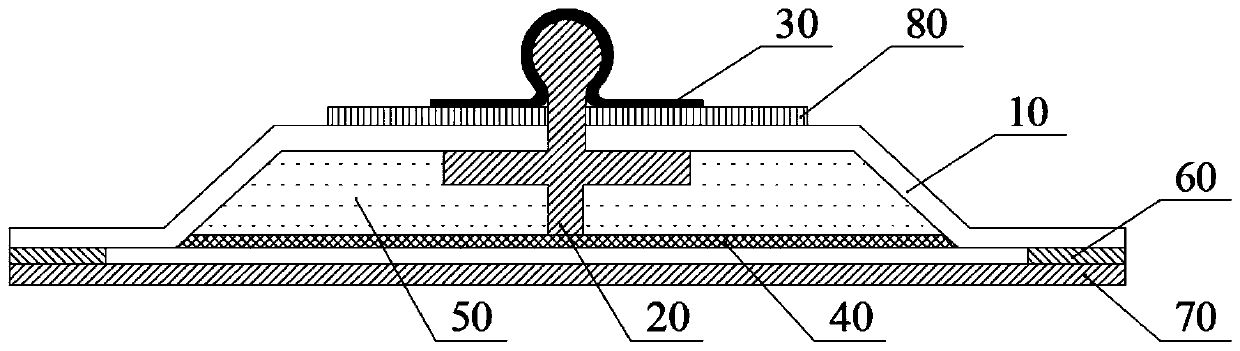

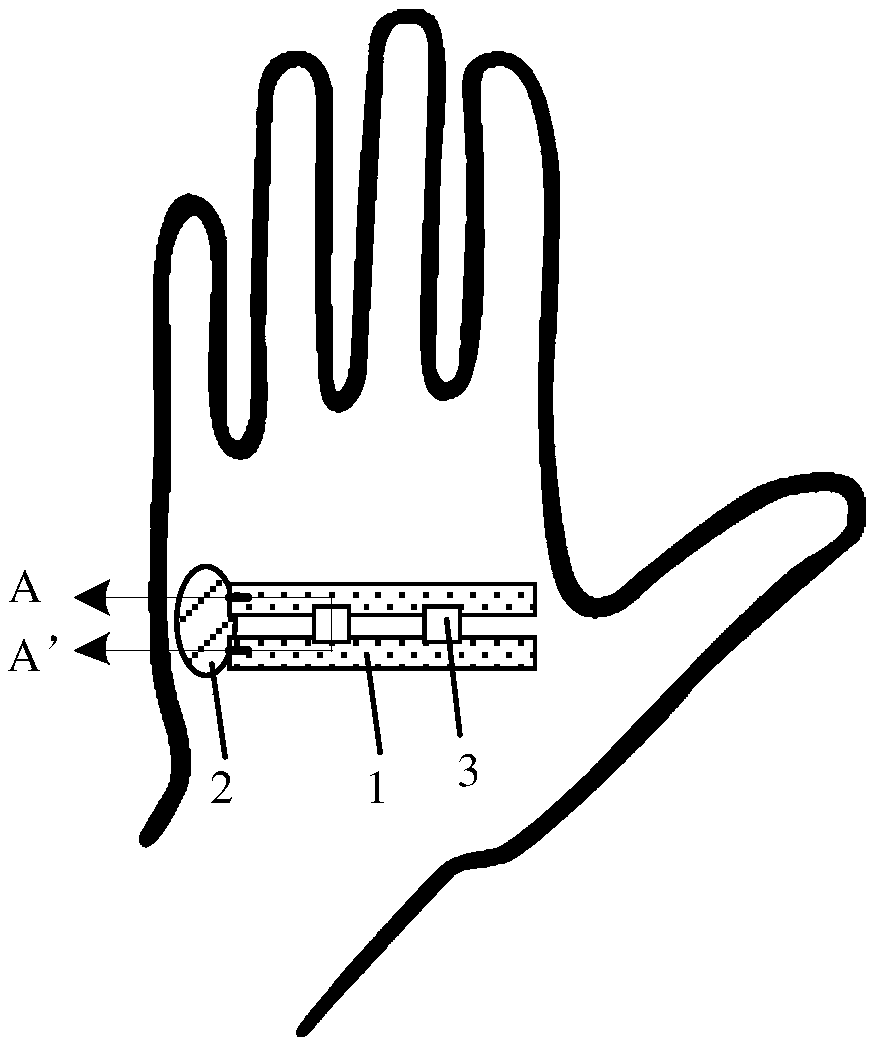

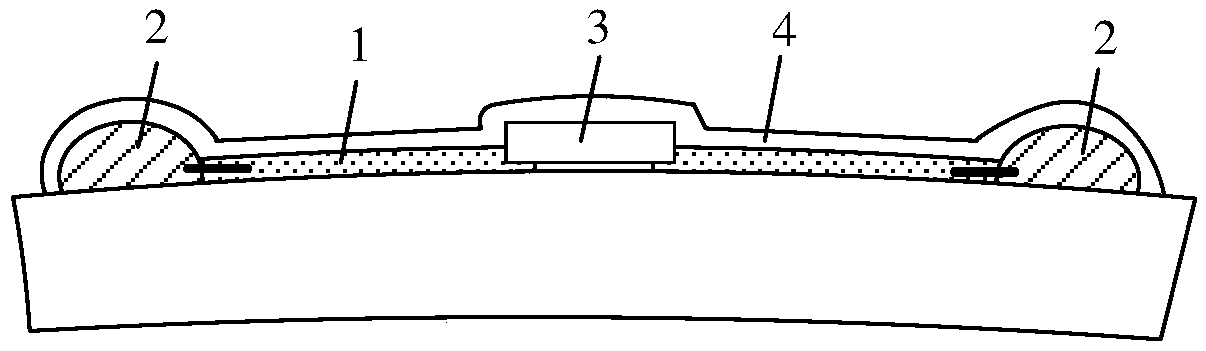

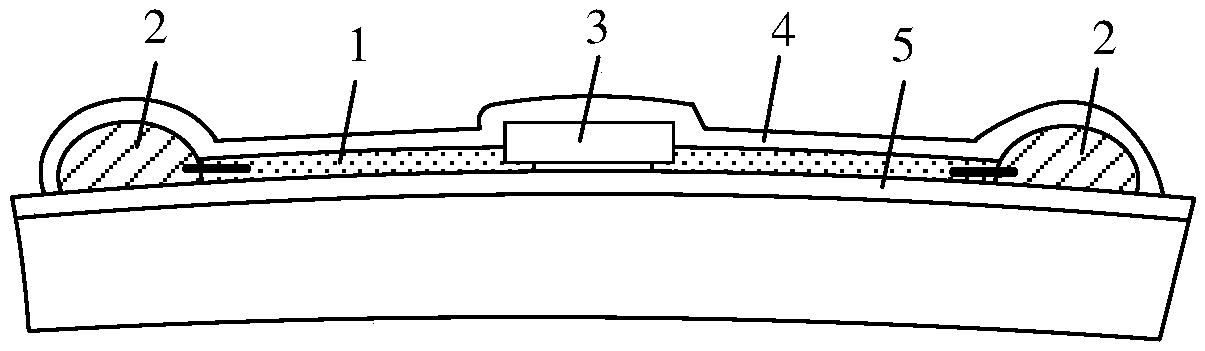

Electrocardiograph-monitoring electrode sheet

ActiveCN110367972AIncrease contactEnsure the accuracy of monitoring dataDiagnostic recording/measuringSensorsAdhesiveBiochemical engineering

The invention discloses an electrocardiograph-monitoring electrode sheet. The electrocardiograph-monitoring electrode sheet comprises a shell plate, a guide column, a buckle cap, a metal net, liquid metal and a double-side adhesive tape, the middle of the shell plate is concave to form an inner cavity, a guide column hole communicated with the inner cavity is arranged in the guide column, the guide column is arranged in the inner cavity through one end of the guide column hole, one end, arranged outside the inner cavity, of the pillar column includes a ball head used for connecting the bucklecap of the lead wire, the buckle cap wrapping the ball head is arranged on one side of the shell plate, the metal net is arranged on one side of the shell plate to enclose the inner cavity, the liquidmetal is filled in the inner cavity, and the double-side adhesive tape surrounding the metal net is arranged on one side, away from the buckle cap, of the shell plate. The electrocardiograph-monitoring electrode sheet can be reused, and the liquid metal maintains good contact with the skin, so that the accuracy of monitoring data of an electrocardiograph monitor is guaranteed, and the consumptionof electrode materials can be avoided.

Owner:重庆市职业病防治院

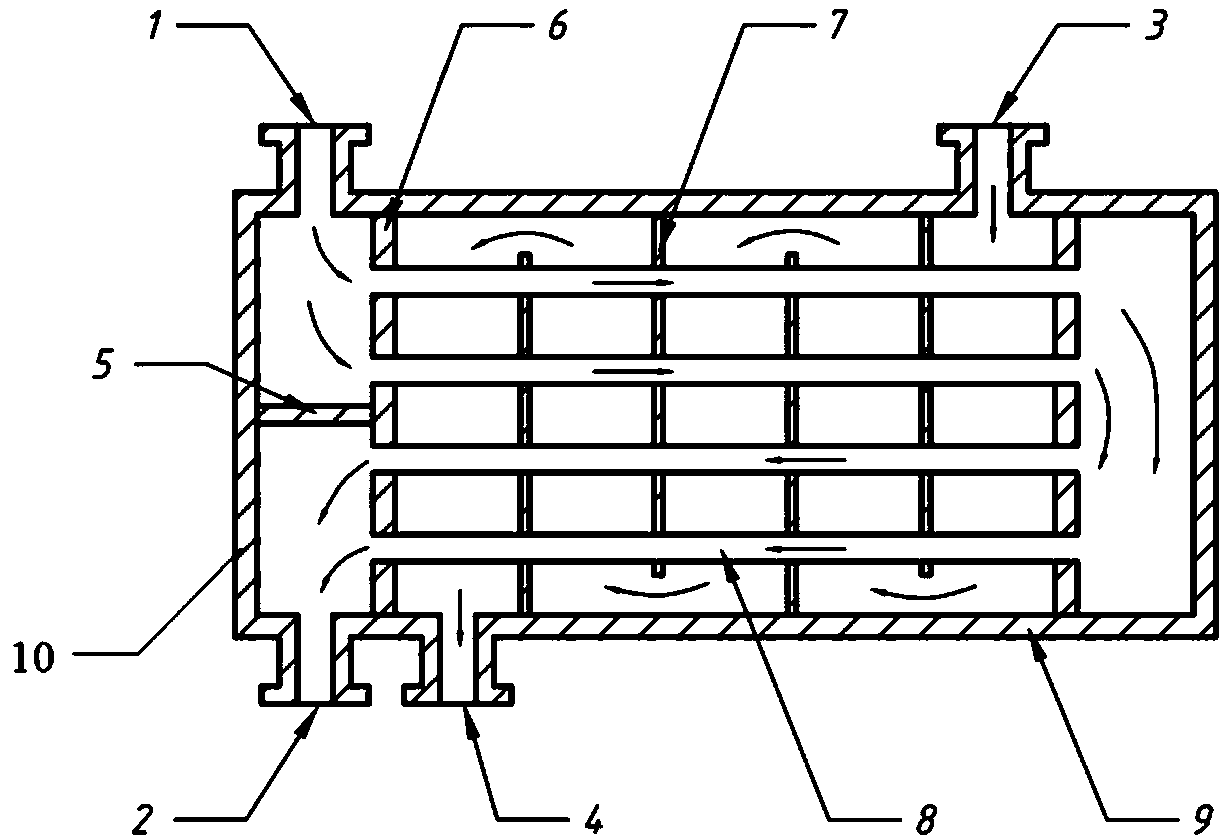

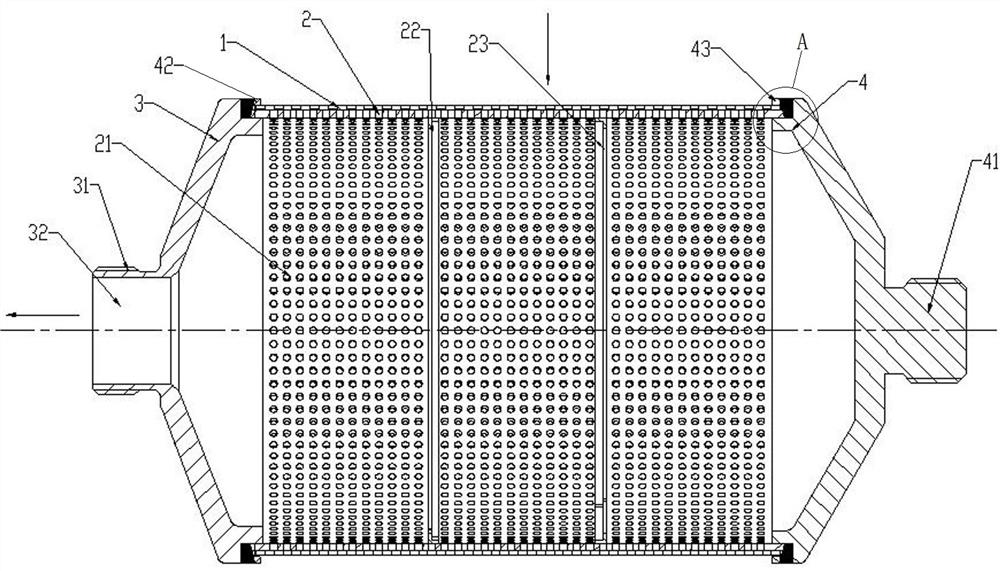

High-temperature heat exchanger for liquid metaland heat exchange system

InactiveCN109443052AReduce corrosionImprove high temperature resistanceStationary tubular conduit assembliesHeat exchange apparatusPlate heat exchangerEngineering

The invention relates to the technical field of heat exchange, and provides a high-temperature heat exchanger for liquid metaland heat exchange system. The heat exchanger comprises a shell and two pipe boxes arranged at the two ends of the shell correspondingly. The pipe boxes are connected with the shell through pipe plates. Multiple heat exchange pipes are arranged in the shell. The two ends ofeach heat exchange pipe extend out of the corresponding pipe plates correspondingly. A shell pass inlet and a shell pass outlet are formed in the side wall of the shell. A pipe pass inlet and a pipe pass outlet are formed in one pipe box. The pipe boxes and the heat exchange pipes are made of a refractory metal alloy. The system comprises multiple heat exchangers used for the liquid metal. According to the high-temperature heat exchanger and the heat exchange system, by arranging the pipe boxes, made of the refractory metal alloy, at the two ends of the shell and arranging the heat exchange pipes, made of the refractory metal alloy, in the shell, high temperature resistance, high pressure resistance and corrosion resistance of the heat exchanger can be remarkably improved, and the liquid metal can be used as a heat exchange medium for a long time when the heat exchanger conducts heat exchange; and in this way, the heat exchange effect can be improved, the corrosion effect of the liquidmetal on the heat exchanger can be reduced, and the service life can be prolonged.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

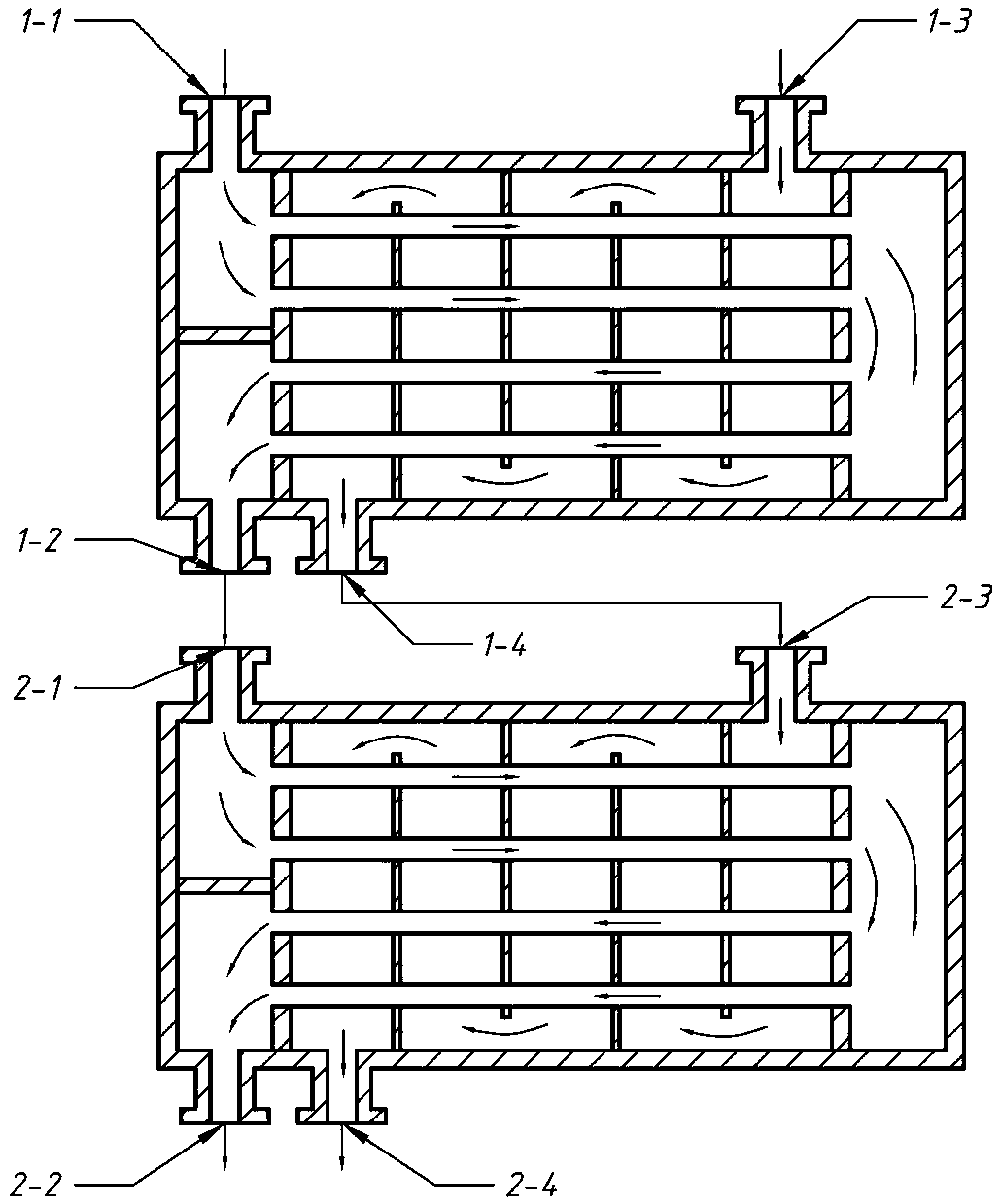

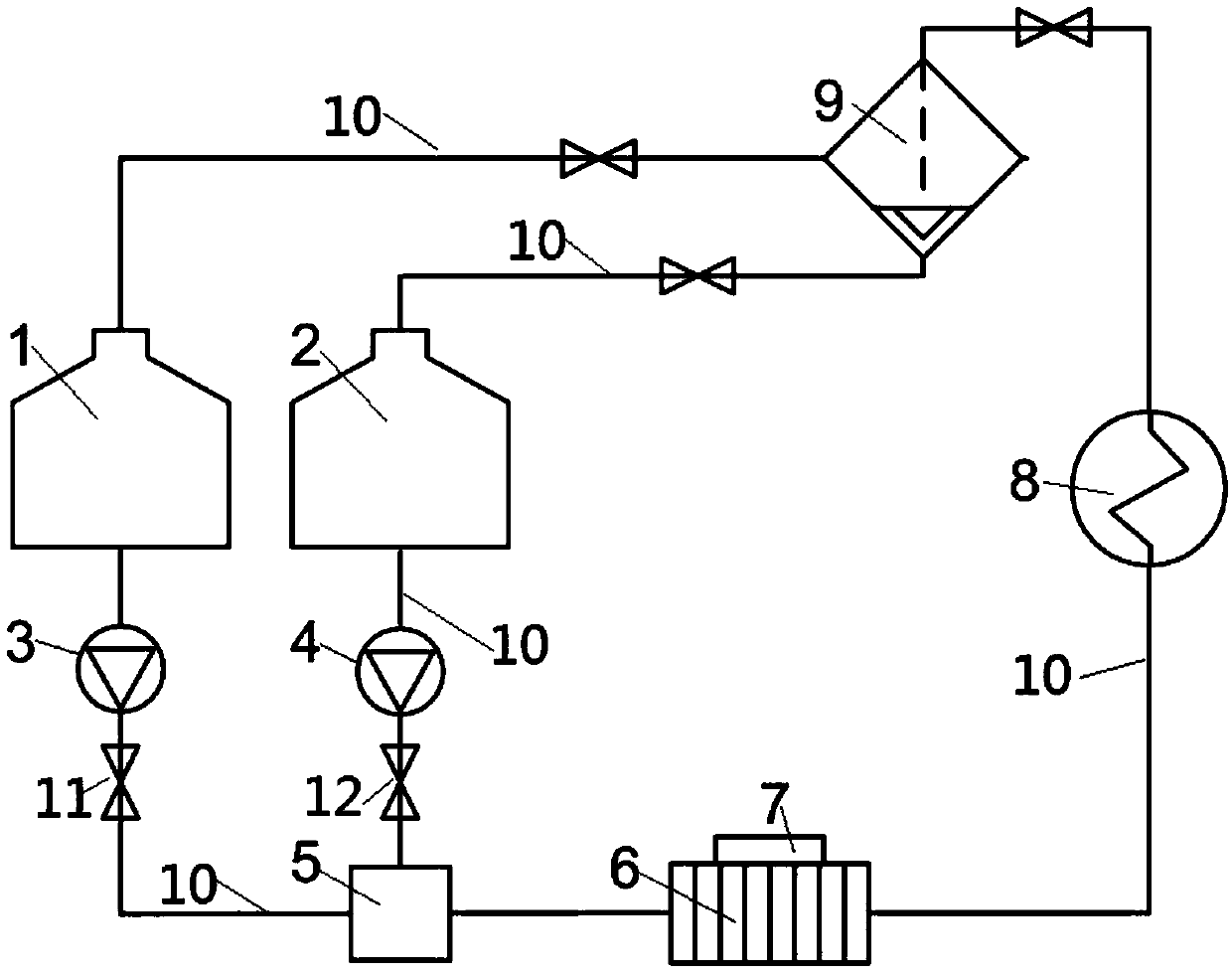

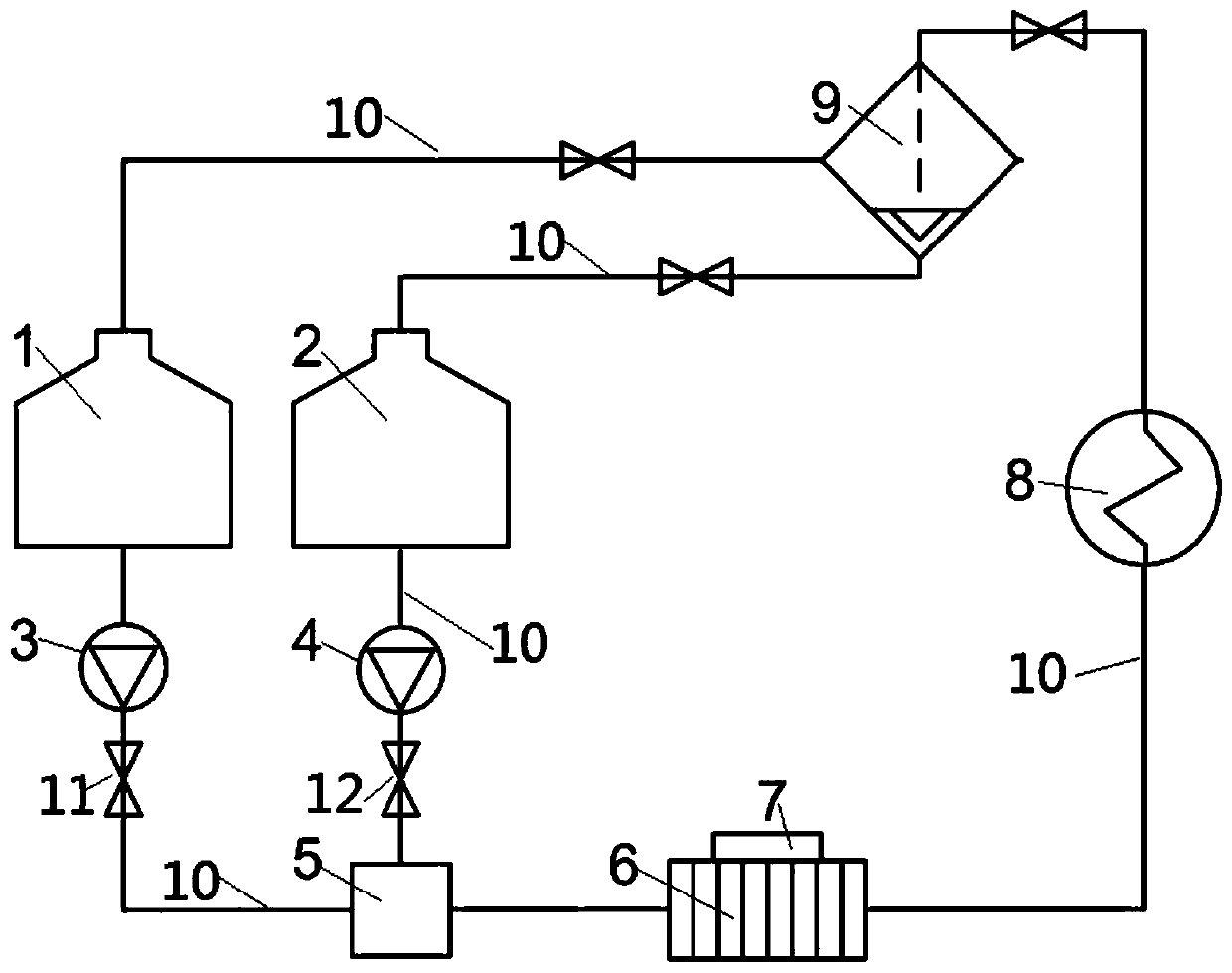

Heat sink based on liquid metal multiphase fluid

ActiveCN109686710AIncrease the critical heat flux valueGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesOperating temperature rangeThermal shock

The invention provides a heat sink based on a liquid metal multiphase fluid. The heat sink comprises a cooling medium container, a liquid metal container, a pipeline mixer, a heat exchange device, a cooling device and a separation device, the cooling medium container is filled with a cooling medium, the liquid metal container contains a liquid metal, and the cooling medium is mixed with the liquidmetal and then introduced into the heat exchange device to cool and dissipate heat source components. The heat sink mixes the liquid metal with another cooling medium to flow to achieve heat dissipation, and the liquid metal has a lower vapor pressure and a high boiling point, and can maintain a liquid state in a wide operating temperature range when used as a coolant; under the low pumping powerconsumption, the internal circulation of the liquid-liquid two-phase flow can effectively improve the heat transfer coefficient, the liquid metal can always perform single relative flow heat exchange, thereby improving the working critical heat flow density value of a heat dissipation system, the reliability of the heat dissipation system is ensured, and the ability of the system to withstand thermal shock is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

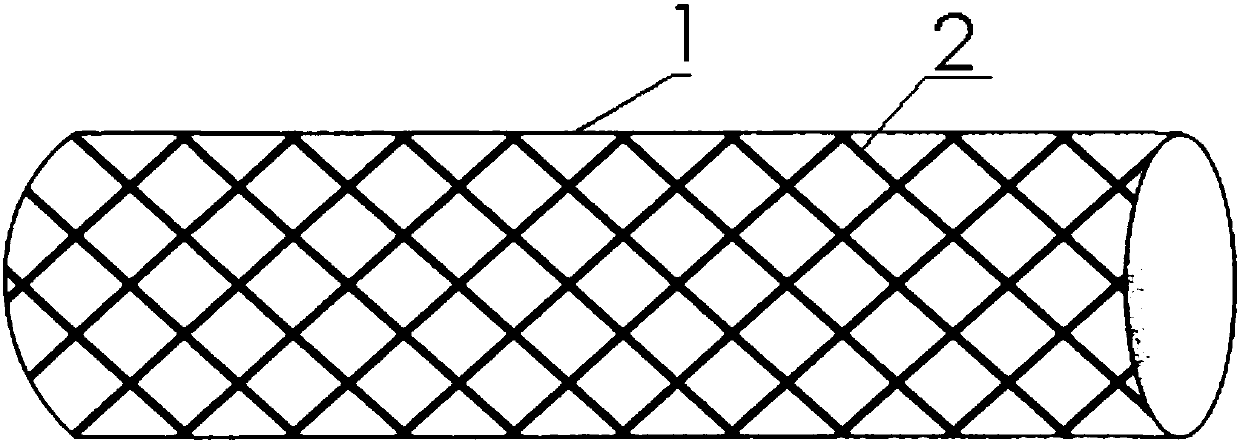

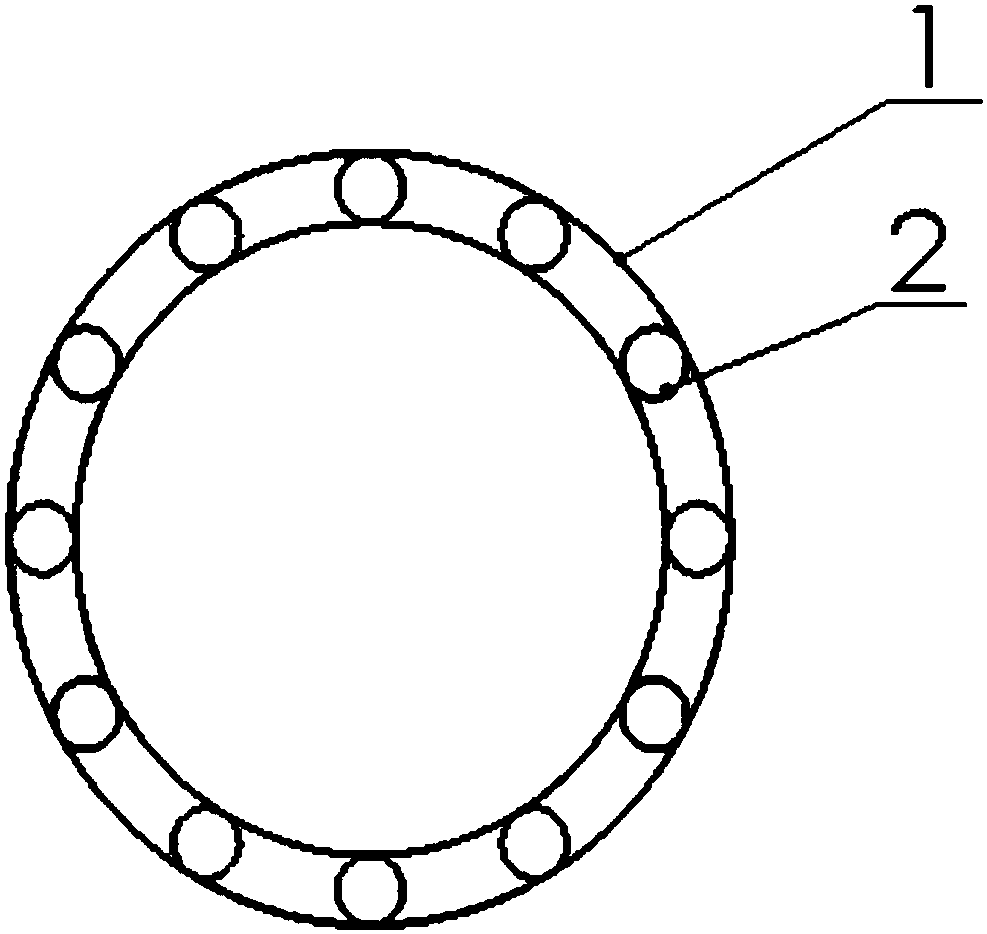

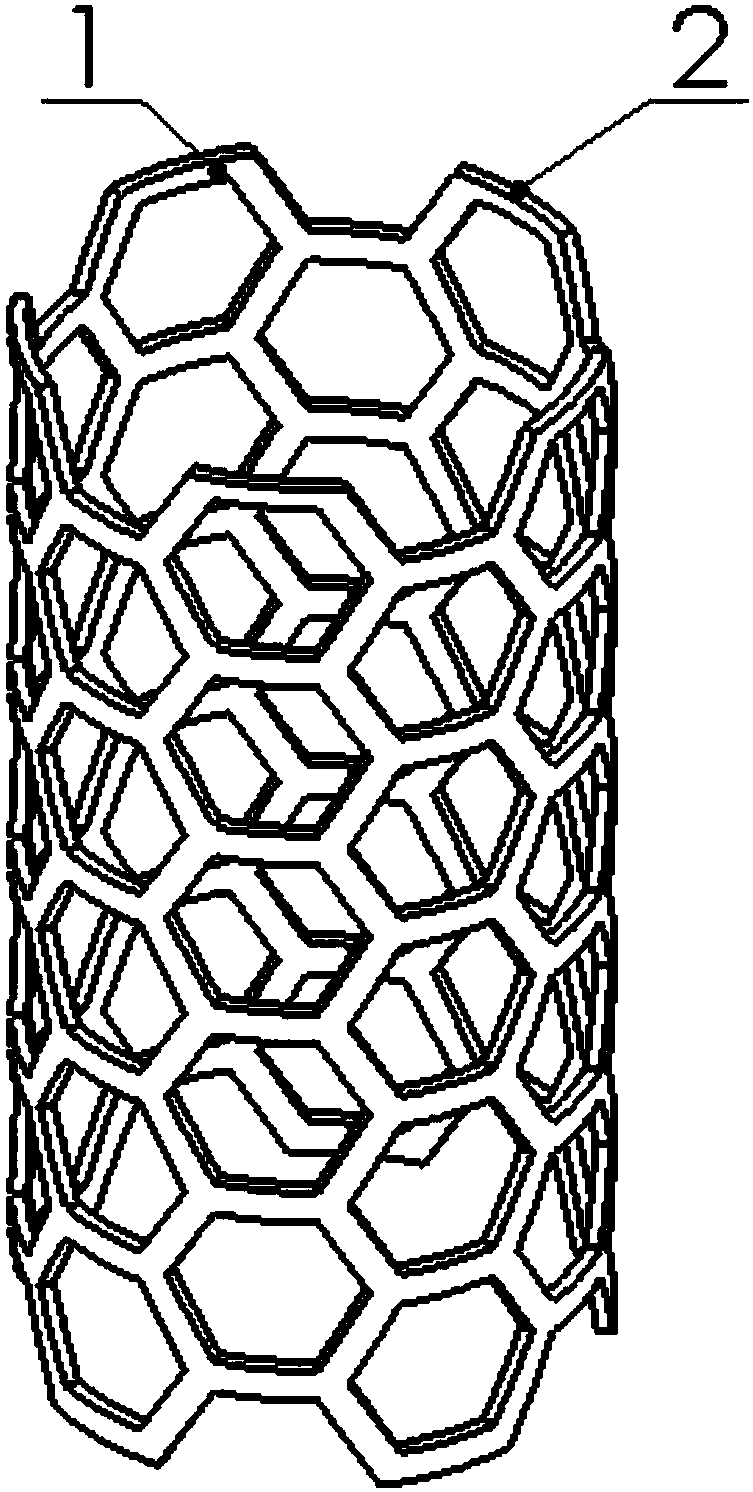

A filter element and a filter device using the filter element

ActiveCN108176102BPrevent flowHigh strengthMembrane filtersStationary filtering element filtersLiquid stateLiquidmetal

The invention relates to a filter core and a filter device using the same. The filter device consists of a shell and a filter core, the filter core includes a cylindrical filter screen, the inner sideor outer side of the filter screen is equipped with a skeleton for supporting the filter screen along the radial direction, and the other side is equipped with liquid metal retaining rings at the ends, two ends of the filter screen are respectively connected to a first end cover and a second end cover, during welding, a liquid metal formed at the ends of the filter screen is blocked by the liquidmetal retaining rings and cannot flow toward the middle of the filter screen along the axial direction, thereby preventing the liquid metal from flowing to the filtration part of the filter screen tocause filter screen blockage and other problems resulting in abnormal use of the filter screen. At the same time, the liquid metal retaining rings also can play the role of fixing and compressing thefilter screen and enhancing the strength of the skeleton.

Owner:新乡平原航空液压设备有限公司

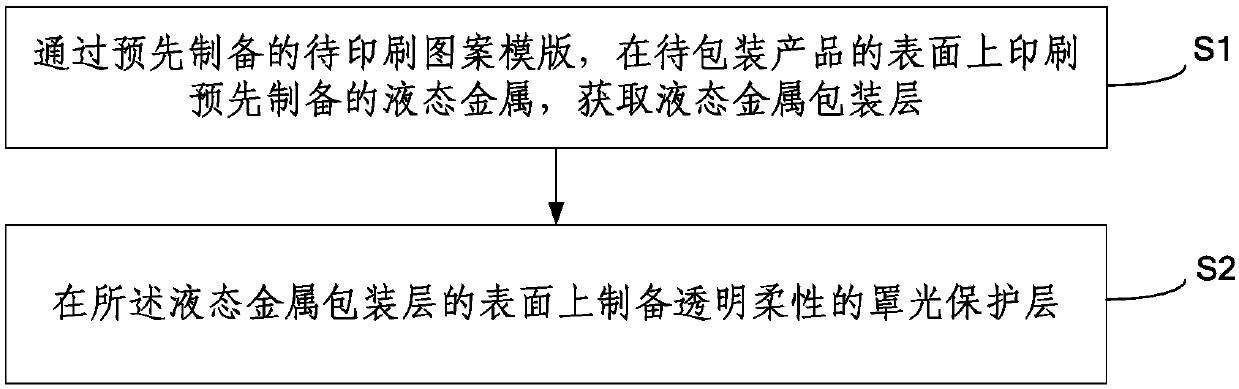

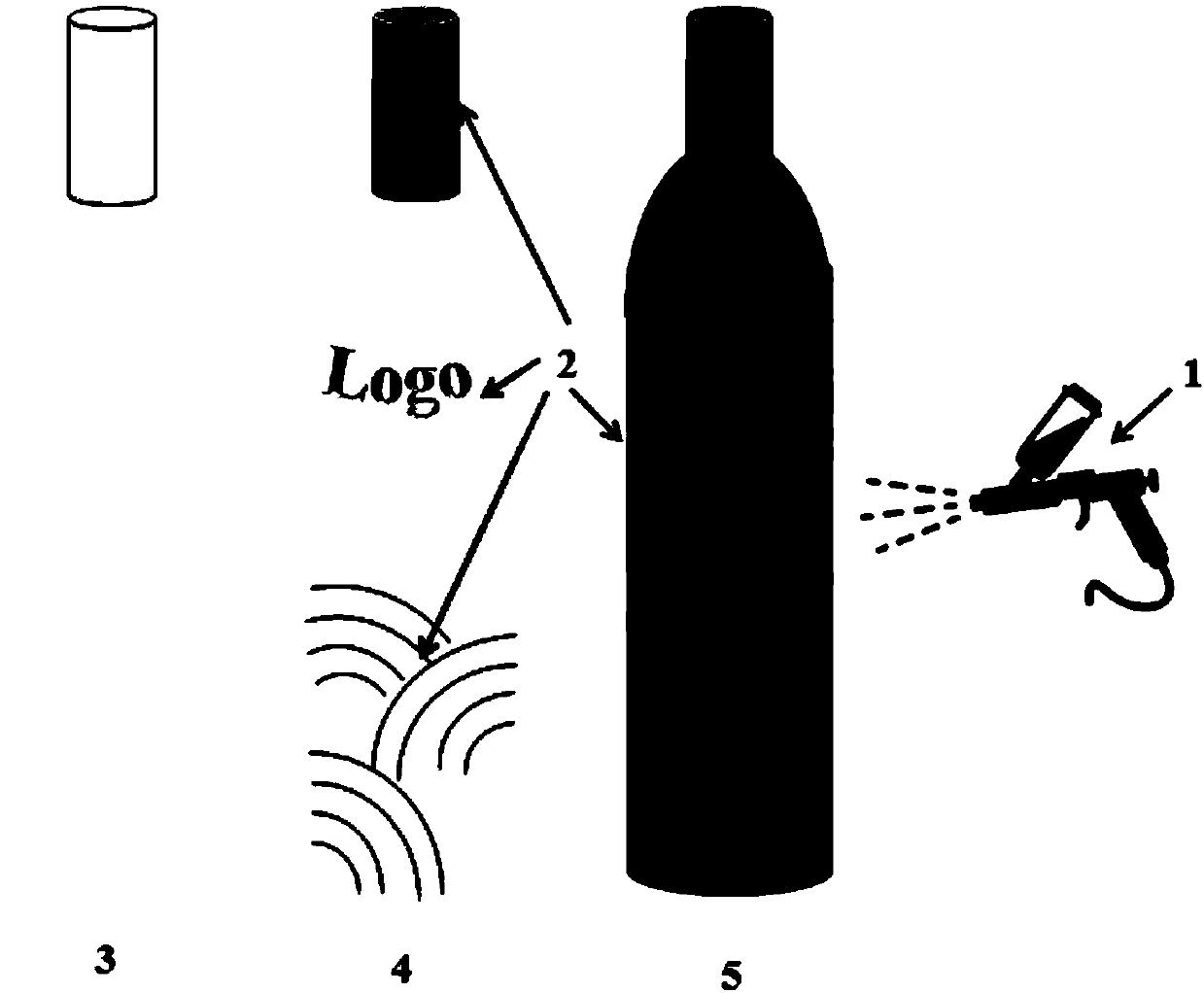

Method for packaging product by using liquid metal

ActiveCN109552711AAvoid processing operationsEasy printing methodLiquid surface applicatorsDuplicating/marking methodsLiquidmetalChemistry

The invention provides a method for packaging a product by using liquid metal. The method for packaging the product by using the liquid metal comprises the following steps that S1, the prepared liquidmetal is printed on the surface of the product to be packaged through a pre-prepared pattern template to be printed to obtain a liquid metal packaging layer; and S2, a transparent and flexible lightcovering protective layer is prepared on the surface of the liquid metal packaging layer. According to the method for packaging the product by using the liquid metal, the liquid metal is printed on the surface of the product to be packaged, so that complicated process operation in product packaging is avoided, the printing method is simple, convenient and pollution-free and has excellent anti-corrosion and anti-aging effects. The service life of the product can be prolonged through the light covering protective layer, and the attractiveness of the product is obviously improved. By using the conductive property of the liquid metal, a packaging pattern can be converted into a luminous circuit, so that the attraction of the product is increased.

Owner:BEIJING DREAM INK TECH CO LTD

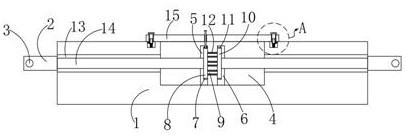

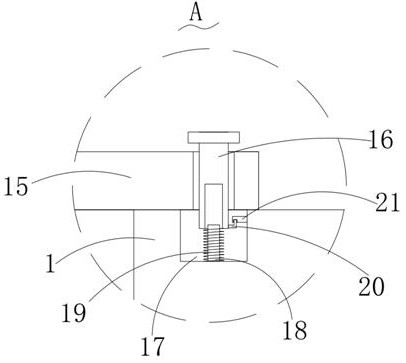

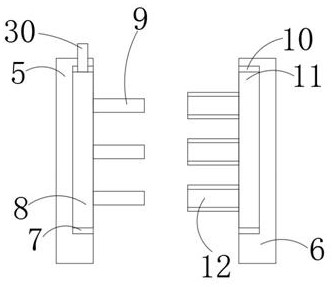

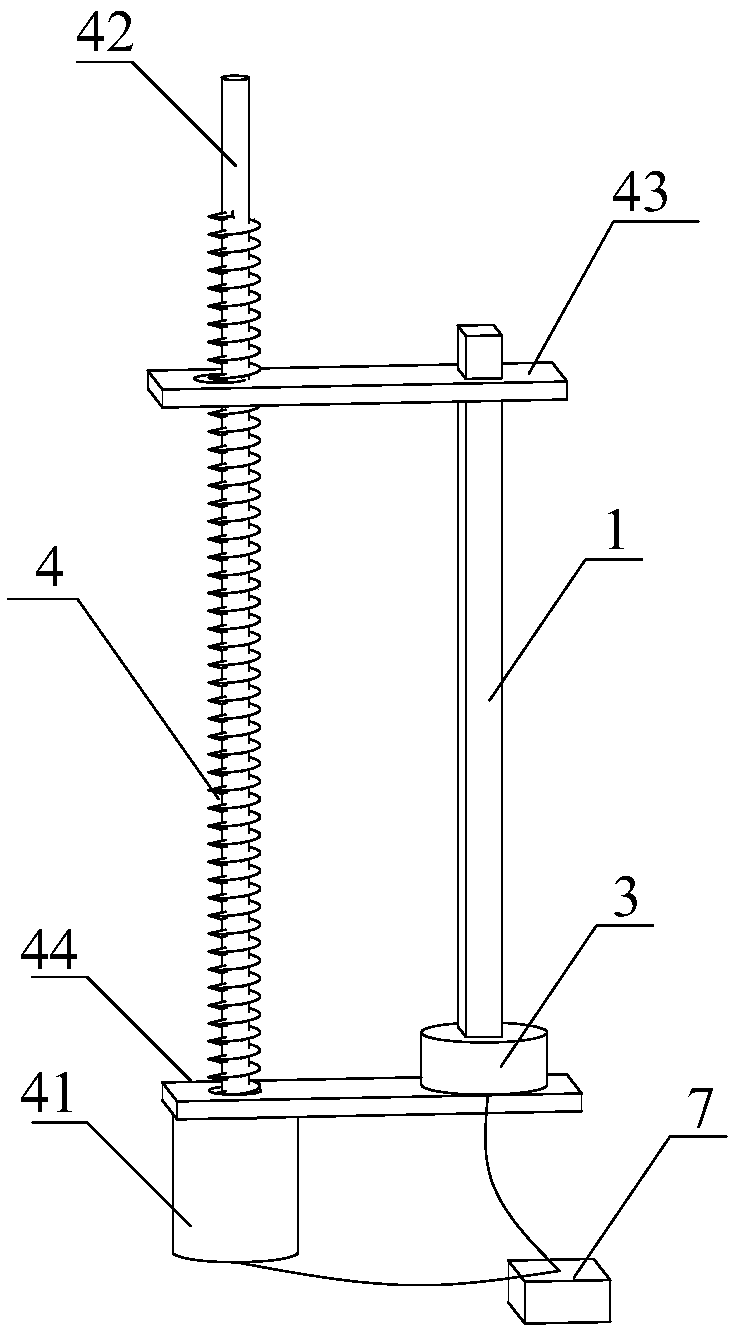

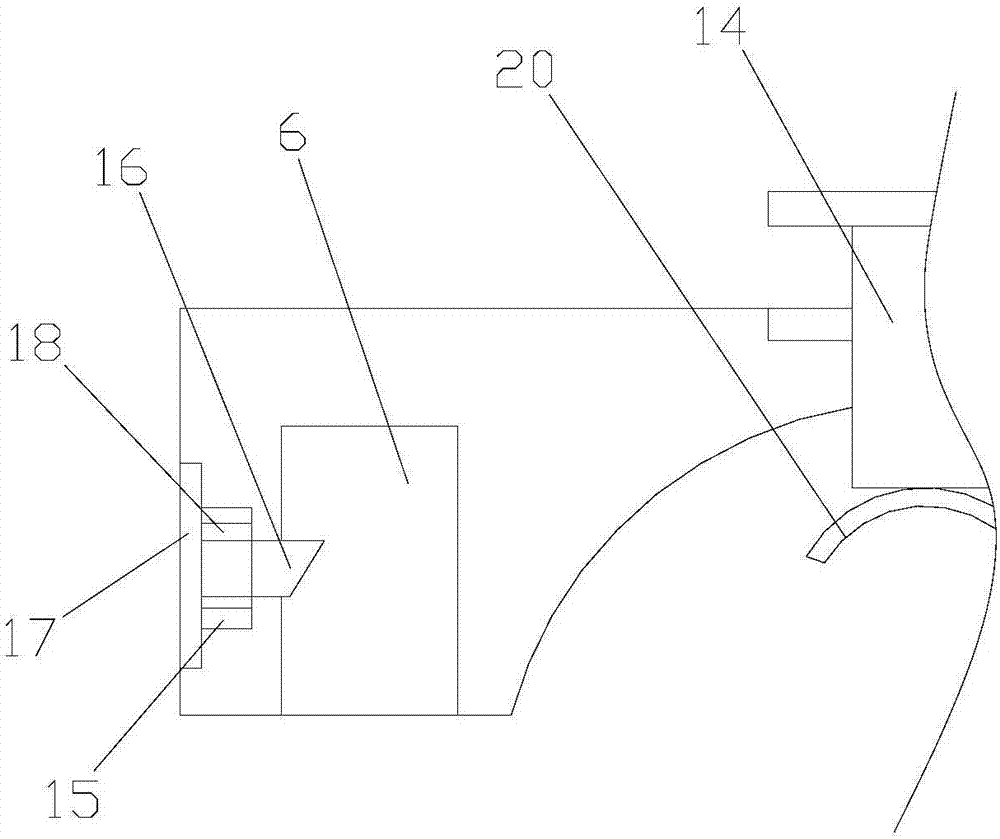

a fixed mechanism

The invention discloses a fixing mechanism. The fixing mechanism comprises a lower fixture, a middle fixture and an upper fixture, wherein each of the lower fixture and the upper fixture is provided with a first cable tray, each of the upper end surface and the lower end surface of the middle fixture is provided with a second cable tray matched with the first cable tray, each of the lower fixtureand the upper fixture is provided with an insert hole, each of the upper end surface and the lower end surface of the middle fixture is provided with an insert rod matched with the insert hole, the insert rod and the insert hole are fitted, the wall of the second cable tray is provided with an arc concave, the wall of the second cable tray is provided with a silicon rubber sheet covering the concave, the silicon rubber sheet and the wall of the second cable tray are bonded, a storage cavity is formed between the silicon rubber sheet and the arc concave, the storage cavity is filled with liquidmetal, the middle fixture is provided with an insert hole, the insert hole is communicated with the storage cavity, an electric heating tube is inserted into the insert hole, and the tail of the electric heating tube is inserted into the storage cavity. The fixing mechanism has high applicability.

Owner:无锡林亿机械制造有限公司

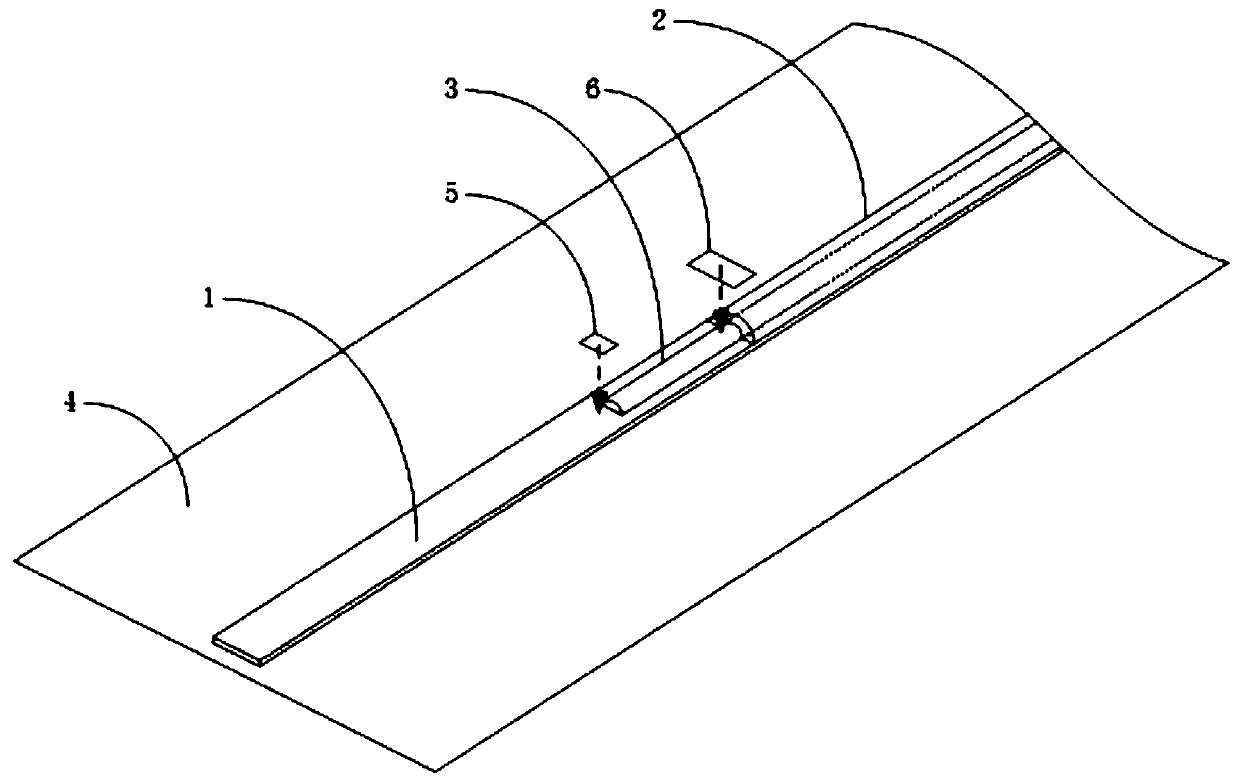

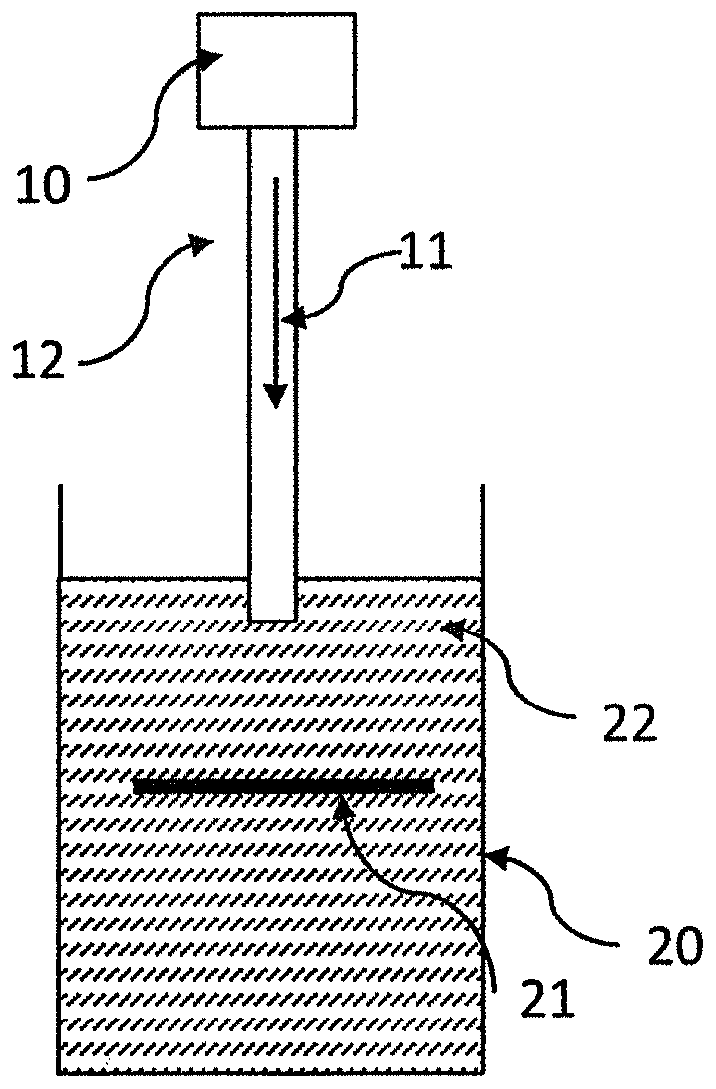

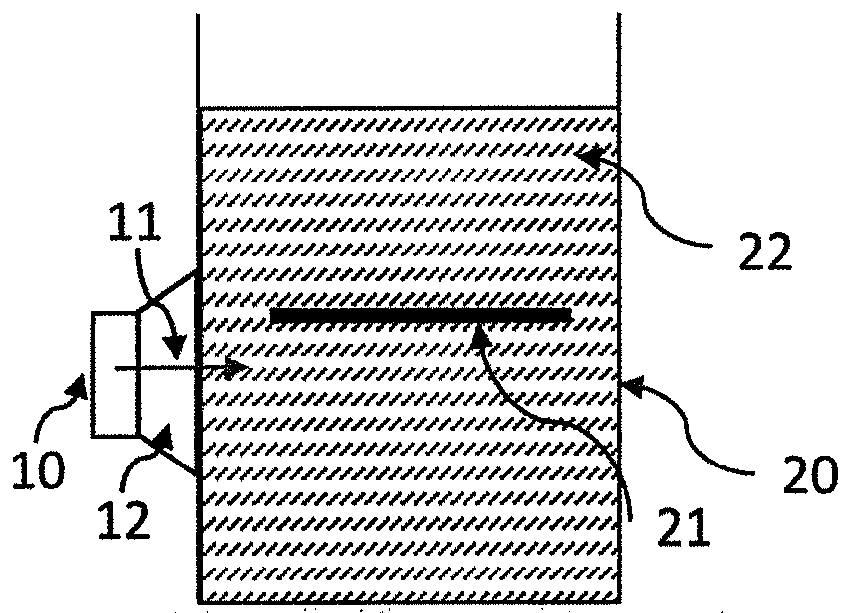

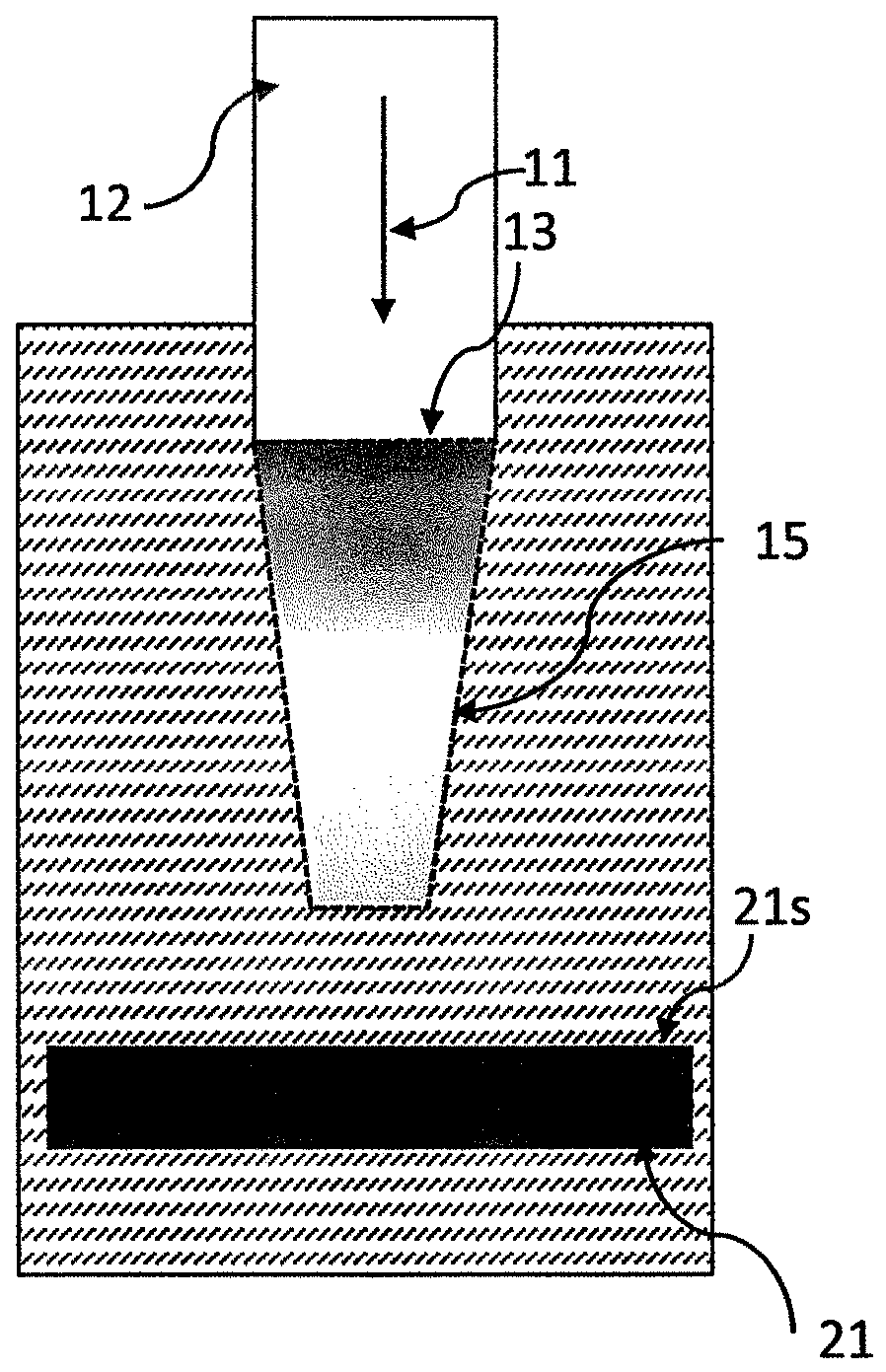

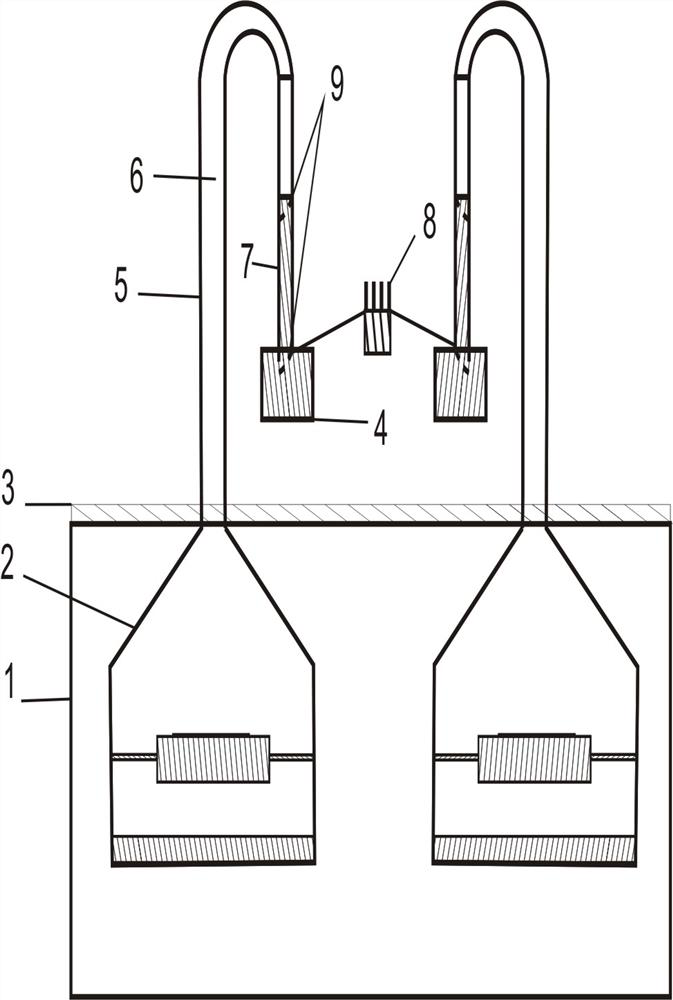

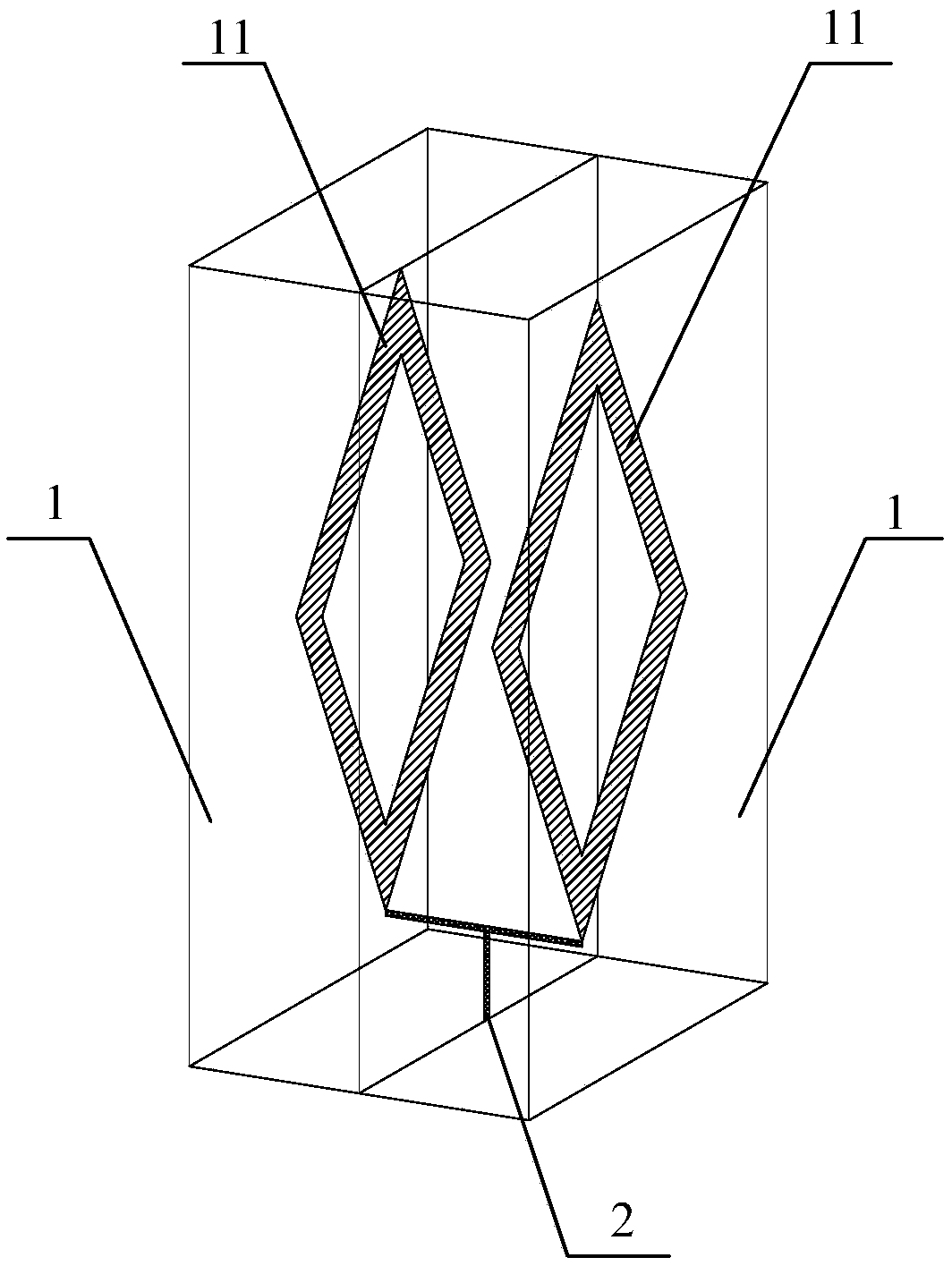

Method of directional solidification based on 3D printing multilayer hollow shell

ActiveCN108746564BDirectional solidification under the same heat preservation conditions and stableDirectional solidification stabilityAdditive manufacturing apparatusFoundry mouldsDirectional solidificationMixed crystal

The invention provides a method for achieving directional solidification based on 3D printing of a multi-layer hollow shell mold. The multi-layer hollow shell mold structure serving as a casting moldis suitable for casting a casting through directional solidification due to the excellent cooling capability, but the multi-layer hollow shell mold structure is complex, manufacturing is difficult through a conventional method, and the accurate multi-layer hollow shell mold structure can be manufactured on the basis of printing of the 3D printing technology. When the casting is cast, after liquidmetal is poured into a cavity of the multi-layer hollow shell mold structure, the bottom of the multi-layer hollow shell mold structure is immersed in cooling water to be cooled, directional solidification is formed, along with ascending of the cooling water liquid level, the hollow layer is gradually filled with the cooling water from bottom to top, the liquid metal solidification interface is gradually upwards pushed in the vertical direction under the situation that the height of the liquid metal solidification interface is larger than the cooling water liquid level height, the same heat preservation conditions of various positions of the casting and stable directional solidification are achieved, accordingly, the defects of mixed crystals, spots and the like are reduced, and the purposes that the casting quality and performance are optimized, and the casting qualification rate is increased are achieved.

Owner:TSINGHUA UNIV

A Channel Device for Controlling Magnetic Liquid Metal Using Electromagnetic Field Coupling

ActiveCN108954004BSmooth goingAchieve normal progressMagnetic liquidsPermanent magnetsElectromagnetic field couplingMagnetic liquids

The invention relates to a channel device for controlling magnetic liquid metal by utilizing electromagnetic field coupling. The channel device comprises a power supply, a magnetic field element and aplurality of channels, wherein the channels are crossed at a branch; an electrolyte solution is arranged in each channel and the branch; a first electrode is arranged in one channel, and second electrodes are arranged in the rest of at least two channels; the first electrode is connected with a negative electrode of the power supply; each second electrode is connected with the positive electrodeof the power supply; when at least two positive electrode circuits are accessed, magnetic liquid metal moves to stop at the branch; after the magnetic field element gets close to the liquid metal, andthe magnetic liquid metal is attracted to an inlet of certain channel, the magnetic field element is removed, and under action of the electric fields, the magnetic liquid metal moves forwards along the channel. Magnetic fields are utilized for assisting magnetic liquid metal to move in the electric fields, and magnetic fields are applied to the bottoms of the channels, so that the magnetic liquidmetal smoothly moves in the target channel.

Owner:SUZHOU UNIV

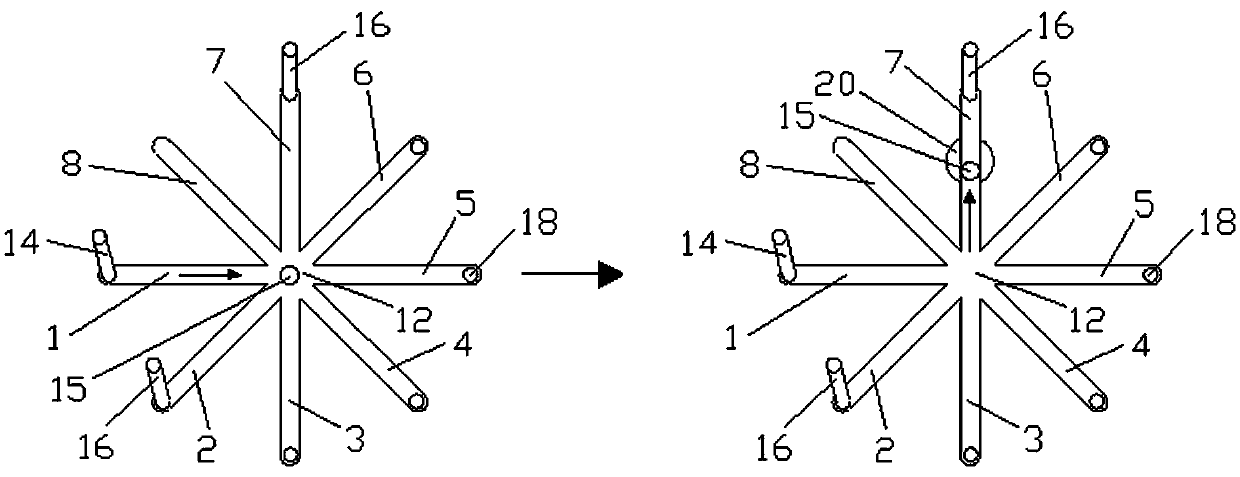

Massage equipment

PendingCN108542743AAvoid local/global overheating problemsReduce usageVibration massageTherapeutic coolingMassageChange positions

The invention discloses massage equipment. The massage equipment comprises an insulating cover body of a semi-closed structure and a non-metal conducting layer for sealing the insulating cover body. Apositive electrode with the changing position is arranged on the inner wall of the insulating cover body. The non-metal conducting layer is used for being connected with a negative electrode. Liquidmetal is arranged in a cavity between the insulating cover body and the non-metal conducting layer, wherein the volume of the metal is smaller than the capacity of the cavity. The remaining space in the cavity is filled with electrolyte. By means of the mode that the liquid-phase metal is driven by the electrodes to move, a vibrating part of the massage equipment is formed, and compared with a traditional vibrating motor, the problem of local / overall overheating of the massage equipment is avoided. In addition, use of a motor is avoided, so that the overall weight of the massage equipment is reduced.

Owner:BEIJING DREAM INK TECH CO LTD

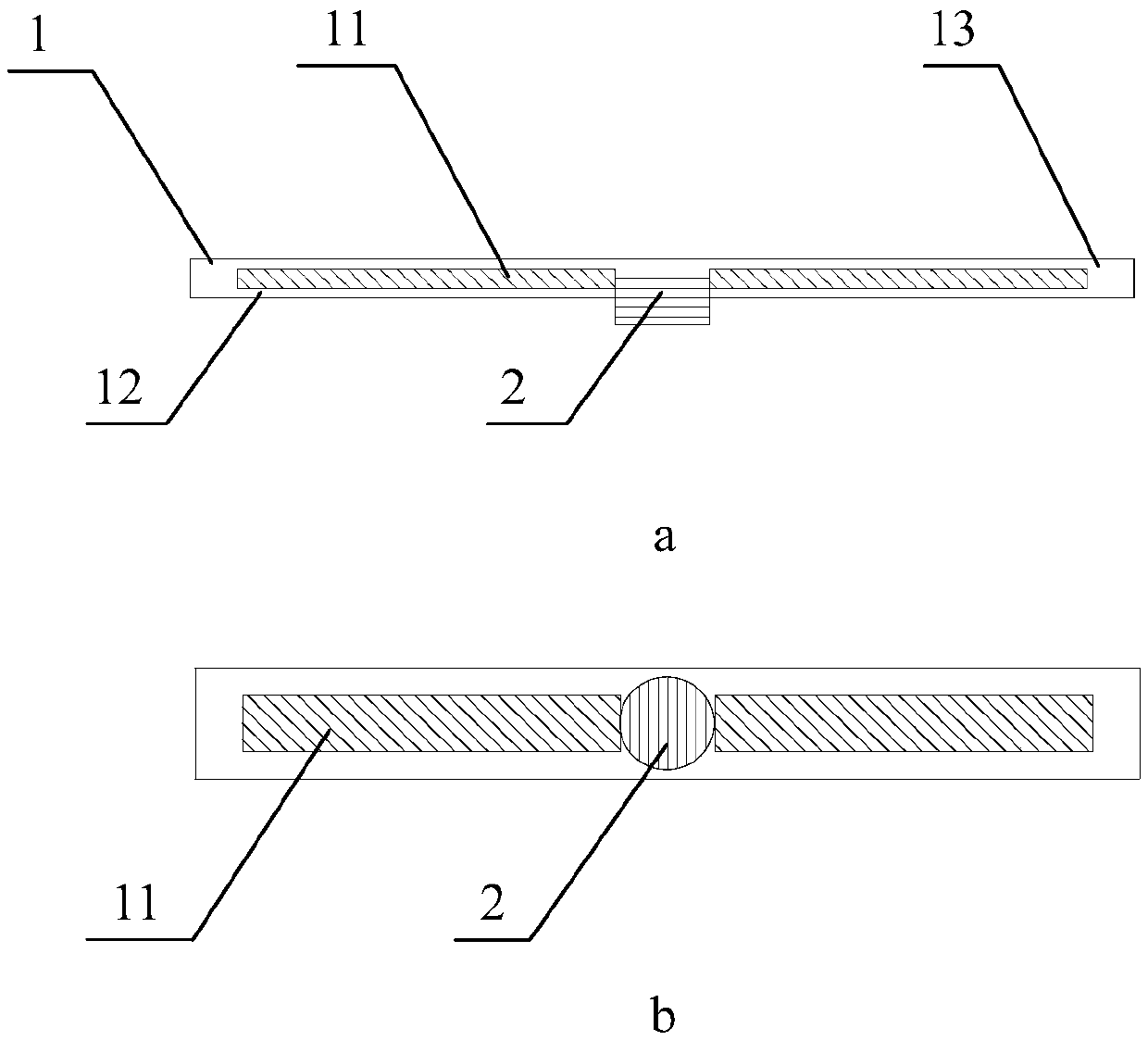

Conductive connecting piece for realizing electric conduction based on liquid metal

InactiveCN112271507AImprove contact effectImprove tensile propertiesConnections to liquidCoupling contact membersLiquid stateElectrical connection

The invention provides a conductive connecting piece for realizing electric conduction based on liquid metal. The conductive connecting piece for realizing electric conduction based on liquid metal comprises: a first mounting block; two copper blocks which are fixedly mounted on the outer walls of the two sides of the first mounting block; two connecting holes which are respectively formed in thetwo copper blocks; a first fixing groove which is formed in the top of the first mounting block; a first fixing block which is fixedly mounted on the inner wall of the bottom of the first fixing groove; and a second fixing block which is fixedly mounted on the inner wall of the bottom of the first fixing groove. The conductive connecting piece for realizing electric conduction based on the liquidmetal has the advantages of being convenient to use, disassemble and maintain.

Owner:刘春晓

Method for improving the wetting of surface of solid substrate by liquid metal

ActiveCN110049813AHot-dipping/immersion processesEnergy based chemical/physical/physico-chemical processesLiquid statePower flux

The invention relates to a method for treating a solid substrate, performed with a first material, of the metal or ceramic type, the method comprising bringing the substrate into contact with a liquidmetal, while the substrate is exposed to an ultrasound wave called a power ultrasound wave. On a surface of the substrate, the power flux density is higher than a cavitation threshold of the liquid metal. Such an exposition improves the wettability of the surface of the substrate by the liquid metal.

Owner:CONSTELLIUM ISSOIRE

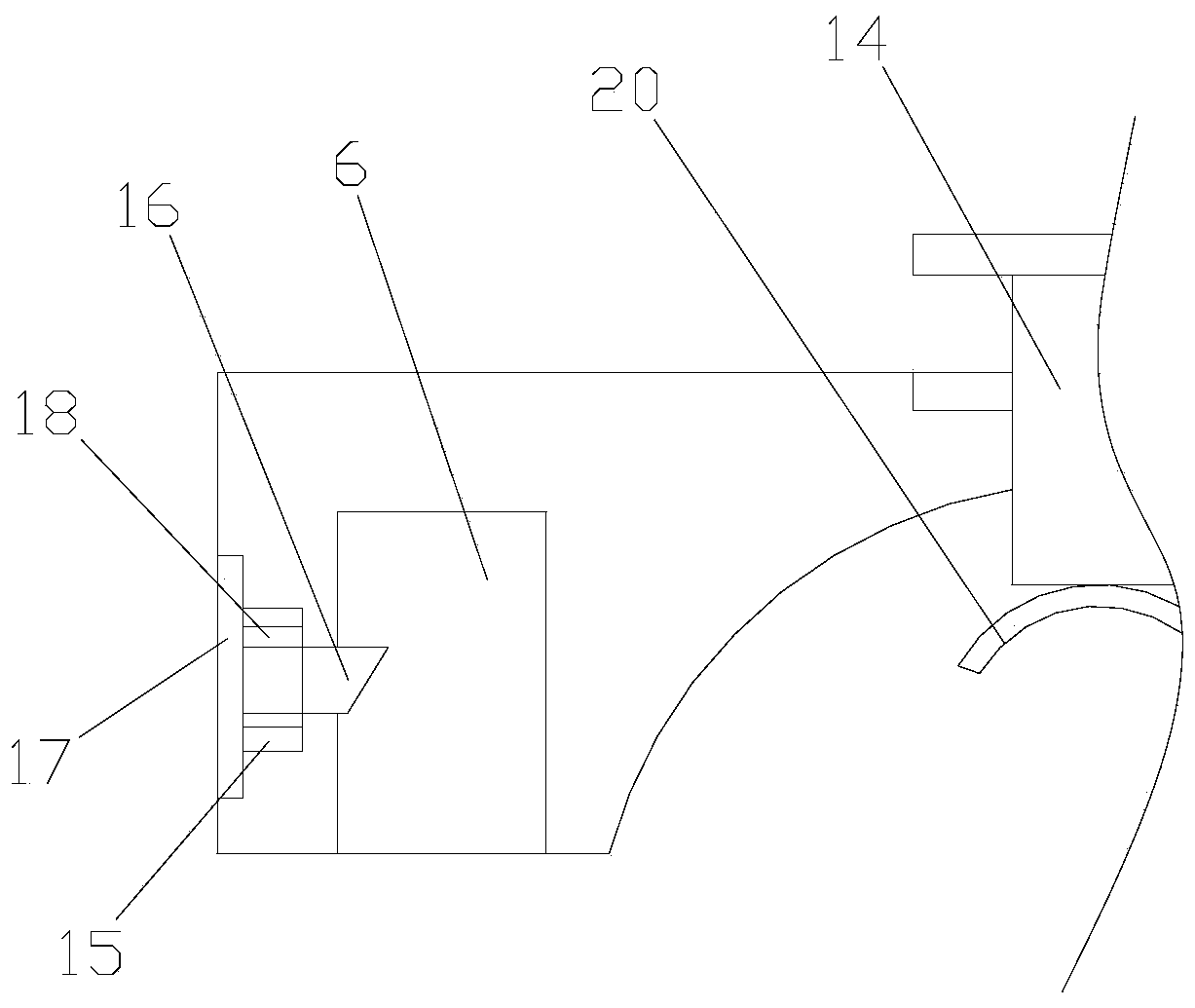

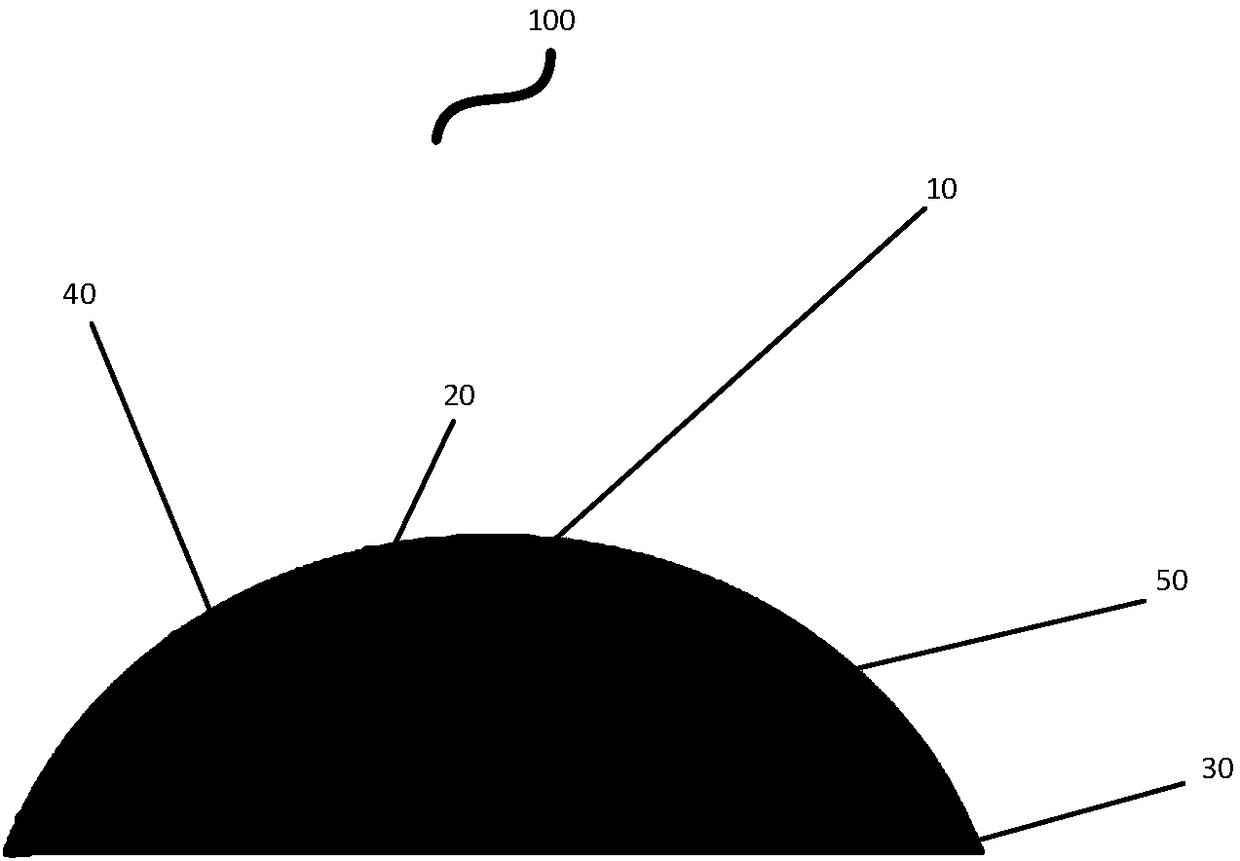

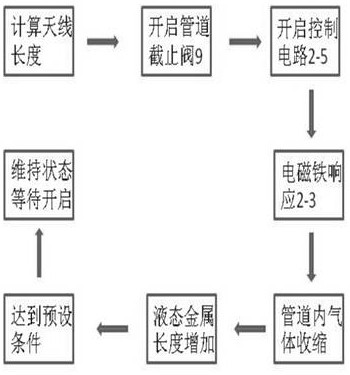

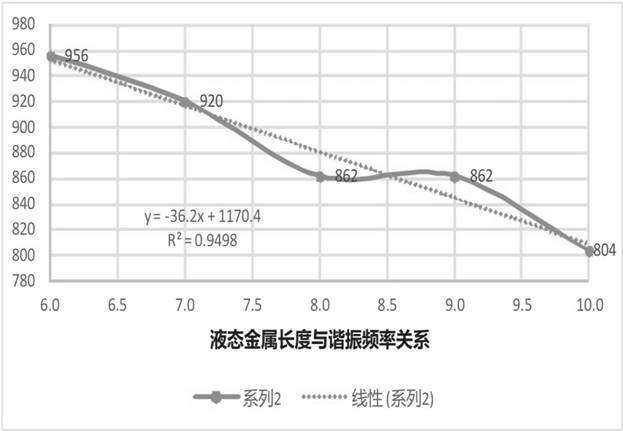

Adjustable liquid metal antenna array based on magnetic control voltage transformation technology

PendingCN111628284ARealize automatic controlPrevent oxidationOperating means/releasing devices for valvesAntenna arraysAutomatic controlLiquidmetal

The invention relates to the technical field of radio communication, in particular to an adjustable liquid metal antenna array based on a magnetic control voltage transformation technology. The liquidmetal antenna array is composed of an independent liquid metal antenna or more than one liquid metal antenna array, a flexible pipeline is filled with the liquid metal, and one end of the pipeline isconnected with a liquid metal storage tank; a controllable pipeline stop valve is used for executing the connection and disconnection operation, the other end of the pipeline is connected with a magnetic control device, and the controllable pipeline stop valve is used for executing the connection and disconnection operation in the middle. The beneficial effects are that the influence of the liquid metal storage tank on the antenna is effectively eliminated; a control area and an application area are divided by using an isolation plate, so that the electromagnetic interference is effectively reduced; the controllability of the magnetic control device is high, and the array frequency can be continuously changed in a short time; an inert gas effectively prevents the liquid metal from being oxidized; the system is high in controllability, and can achieve the automatic control of a large-scale antenna array.

Owner:杭州联芳科技有限公司

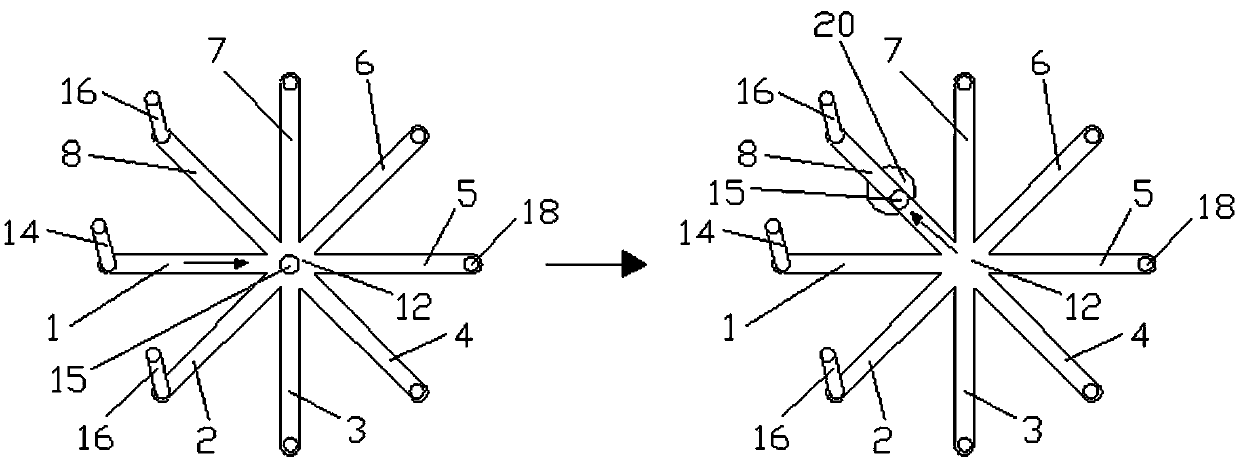

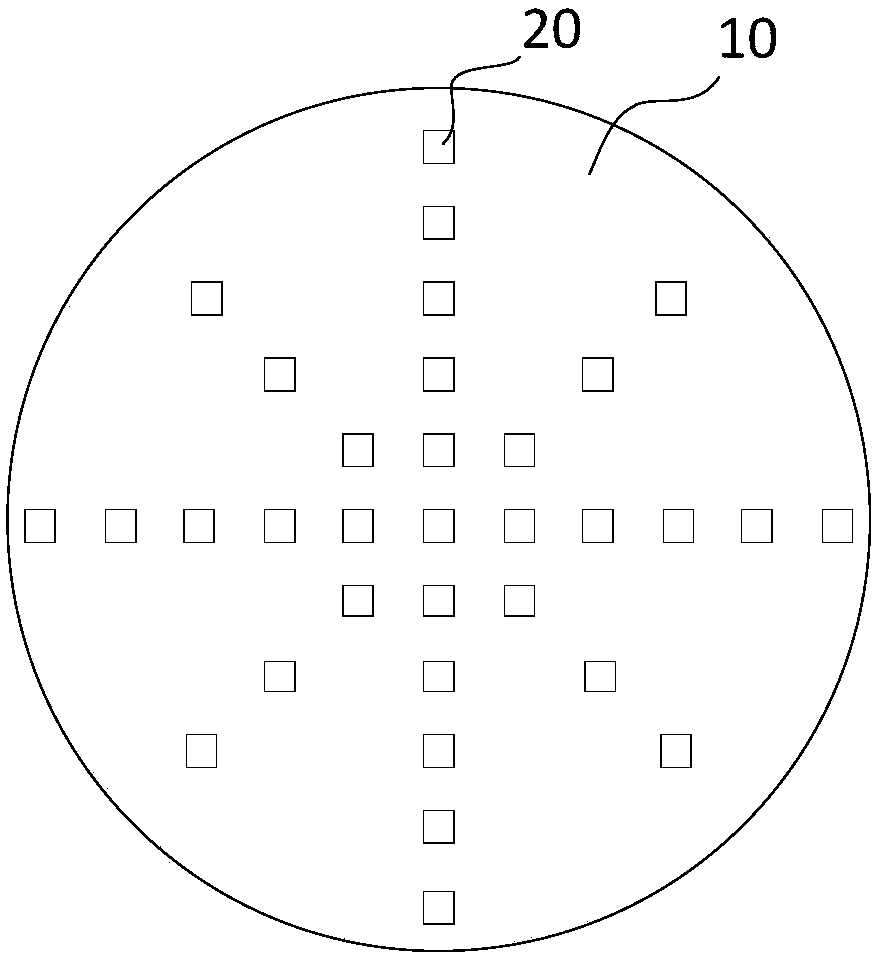

Liquid metal reconfigurable antenna and reconfiguration method thereof

ActiveCN110828980AContinuously adjustable antenna shapeContinuous and reliable workSimultaneous aerial operationsRadiating elements structural formsReconfigurable antennaElastic substrate

The invention relates to the technical field of antennas and discloses a liquid metal reconfigurable antenna and a reconfiguration method thereof. The antenna comprises an antenna unit and a deformation mechanism; the antenna unit comprises an elastic substrate and an elastic packaging layer; the elastic substrate bears liquid metal; the elastic packaging layer covers the outer side of the liquidmetal and is used for packaging the liquid metal; the deformation mechanism is used for enabling the antenna unit to generate one or more kinds of stretching deformation, twisting deformation or expansion deformation; and the antenna unit is provided with a feeder line joint for connecting the liquid metal and the feeder line. According to the invention, the liquid metal is packaged in the elasticpackaging part to form the antenna unit with the variable form, then the deformation mechanism is used for enabling the antenna unit to generate one or more kinds of stretching deformation, twistingdeformation or expansion deformation, and adjustment of parameters such as the frequency and the polarization mode of the liquid metal reconfigurable antenna is achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Fixing mechanism

The invention discloses a fixing mechanism. The fixing mechanism comprises a lower fixture, a middle fixture and an upper fixture, wherein each of the lower fixture and the upper fixture is provided with a first cable tray, each of the upper end surface and the lower end surface of the middle fixture is provided with a second cable tray matched with the first cable tray, each of the lower fixtureand the upper fixture is provided with an insert hole, each of the upper end surface and the lower end surface of the middle fixture is provided with an insert rod matched with the insert hole, the insert rod and the insert hole are fitted, the wall of the second cable tray is provided with an arc concave, the wall of the second cable tray is provided with a silicon rubber sheet covering the concave, the silicon rubber sheet and the wall of the second cable tray are bonded, a storage cavity is formed between the silicon rubber sheet and the arc concave, the storage cavity is filled with liquidmetal, the middle fixture is provided with an insert hole, the insert hole is communicated with the storage cavity, an electric heating tube is inserted into the insert hole, and the tail of the electric heating tube is inserted into the storage cavity. The fixing mechanism has high applicability.

Owner:无锡林亿机械制造有限公司

Wearable electronic circuit, DIY manufacturing method thereof and DIY kit

PendingCN111465190AEasy to makeMeet individual needsPrinted circuit assemblingConductive pattern formationLiquid stateWearable Electronic Device

The invention provides a wearable electronic circuit, a DIY manufacturing method thereof and a DIY kit, and relates to the technical field of electronic circuits. The wearable electronic circuit provided by the invention comprises a liquid metal circuit, a power supply, at least one element and a packaging layer, wherein the liquid metal circuit is located on the skin; the power supply and the atleast one element are connected with the liquid metal circuit, and the power supply, the liquid metal circuit and the at least one element form a closed loop; and the packaging layer covers the liquidmetal circuit, the power supply and the at least one element. According to the technical scheme, the wearable electronic circuit can be simply manufactured, the operability is high, and the personalized requirement of a user for the wearable electronic device can be met.

Owner:BEIJING DREAM INK TECH CO LTD

Method for preparing copper-aluminum-silicon alloy powder by using ultrasonic gas atomization and application of method

InactiveCN107737939AUnique structureImprove conductivityCell electrodesSecondary cellsMolten stateSilicon alloy

The invention discloses a method for preparing copper-aluminum-silicon alloy powder by using ultrasonic gas atomization and application of the method, and belongs to the technical field of preparationof anode materials for lithium batteries. The method provides a copper-aluminum-silicon alloy anode nanomaterial for preparing the high-performance lithium batteries by using an ultrasonic gas atomization method and application of the method. According to the technical scheme, the method comprises the following steps that firstly, a tundish system of an atomization device is started, and the inner diameter of a tundish discharging spout is phi 6-14 mm; secondly, the tapping temperature of a copper-aluminum-silicon alloy in a molten state is adjusted to be 1300-1700 DEG C; and thirdly, liquidmetal is poured into a tundish, the flow rate of supersonic airflow is adjusted to be 2-2.5 mach. the pulse frequency of the supersonic airflow is 80-100 KHz, airflow pressure is 10-50 Mpa, and powdermaking through ultrasonic gas atomization is conducted. The method for preparing the copper-aluminum-silicon alloy powder by using ultrasonic gas atomization can be widely applied to the field of preparation of the anode materials for the lithium batteries.

Owner:산시우테하이머뉴매테리얼스테크놀러지컴퍼니리미티드

A heat dissipation device based on liquid metal multiphase fluid

ActiveCN109686710BIncrease the critical heat flux valueGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesHeat flowLiquid state

The invention provides a heat sink based on a liquid metal multiphase fluid. The heat sink comprises a cooling medium container, a liquid metal container, a pipeline mixer, a heat exchange device, a cooling device and a separation device, the cooling medium container is filled with a cooling medium, the liquid metal container contains a liquid metal, and the cooling medium is mixed with the liquidmetal and then introduced into the heat exchange device to cool and dissipate heat source components. The heat sink mixes the liquid metal with another cooling medium to flow to achieve heat dissipation, and the liquid metal has a lower vapor pressure and a high boiling point, and can maintain a liquid state in a wide operating temperature range when used as a coolant; under the low pumping powerconsumption, the internal circulation of the liquid-liquid two-phase flow can effectively improve the heat transfer coefficient, the liquid metal can always perform single relative flow heat exchange, thereby improving the working critical heat flow density value of a heat dissipation system, the reliability of the heat dissipation system is ensured, and the ability of the system to withstand thermal shock is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

A flexible dielectric elastomer composite material based on nano liquid metal and its preparation method

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com