Recyclable heart stent

A heart stent and main body technology, which is applied in the field of recyclable heart stents, can solve the problems of inflammatory reaction, non-recyclable heart stent, stimulation of blood vessels, etc., achieve fast curing speed, flexible solid-liquid phase transition, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

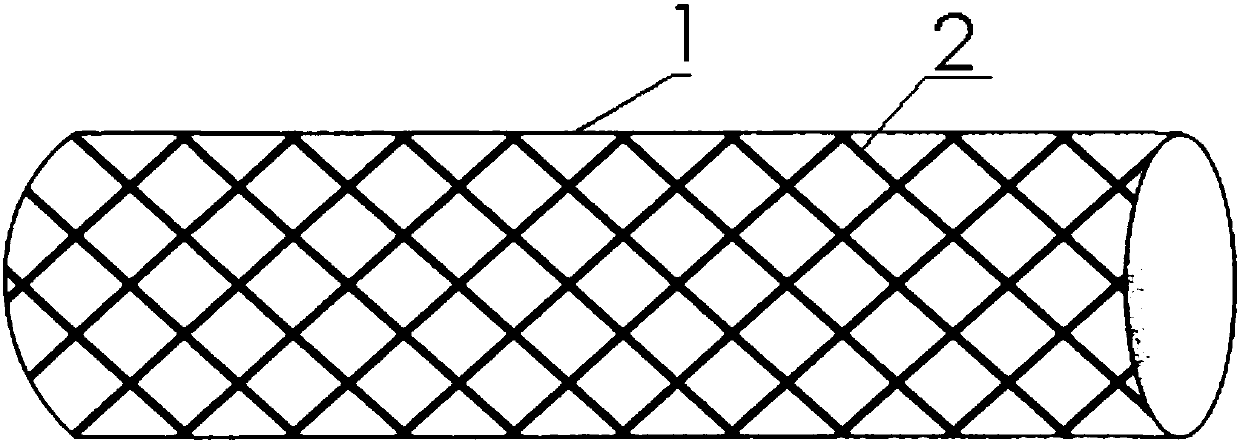

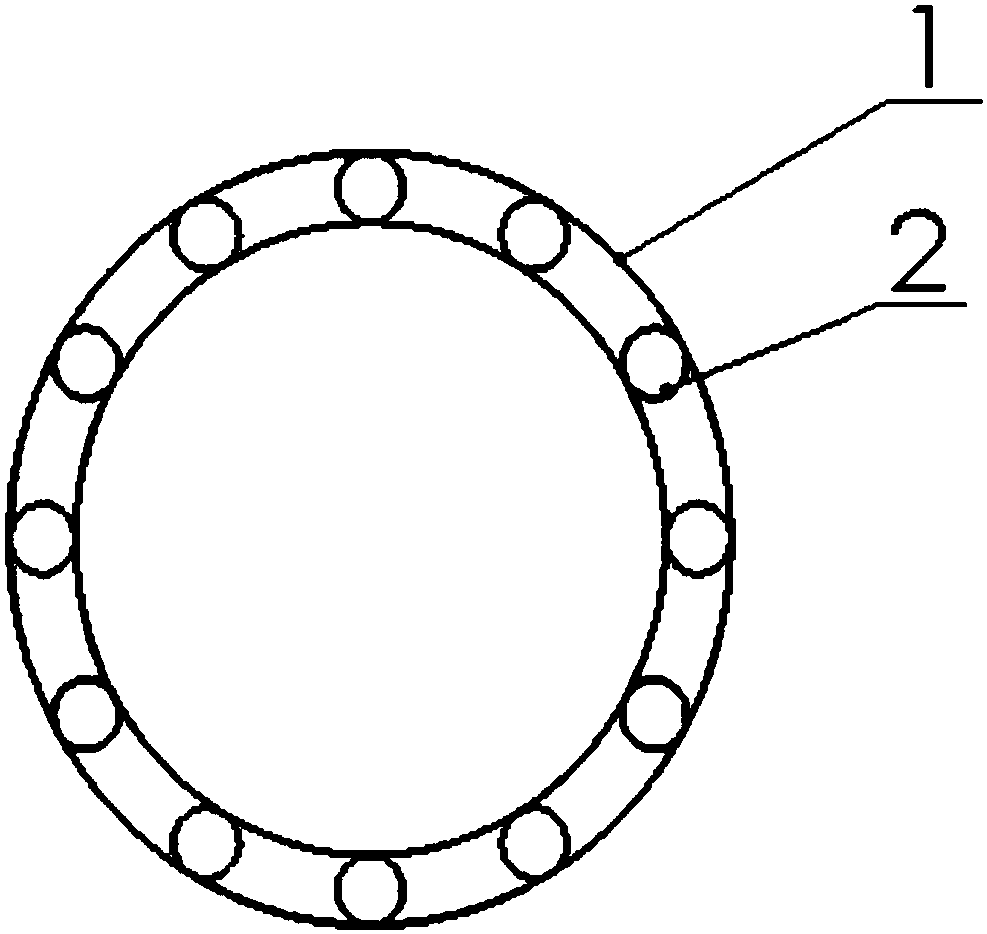

[0033] like figure 1 , 2 As shown, a recyclable cardiac stent provided in this embodiment includes a stent main body and a heating device. The stent main body is made of solidified liquid metal, and the surface of the stent main body is coated with a drug film, and the heating device is used for heating the stent main body.

[0034] The specific process will be described in further detail below.

[0035] The stent main body 2 coated with the drug film 1 reaches the vascular blockage site through cardiac stent interventional surgery; when the operation fails or there is a need to take out the stent main body 2, the heating device can be used to heat the position of the stent main body 2; reaching the melting point of liquid metal Finally, the stent body 2 changes from a solid state to a liquid state, and a catheter is used to suck out the liquid metal from the blood vessel to realize recovery.

[0036] Wherein, the heating device is an induction heating device, a microwave h...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

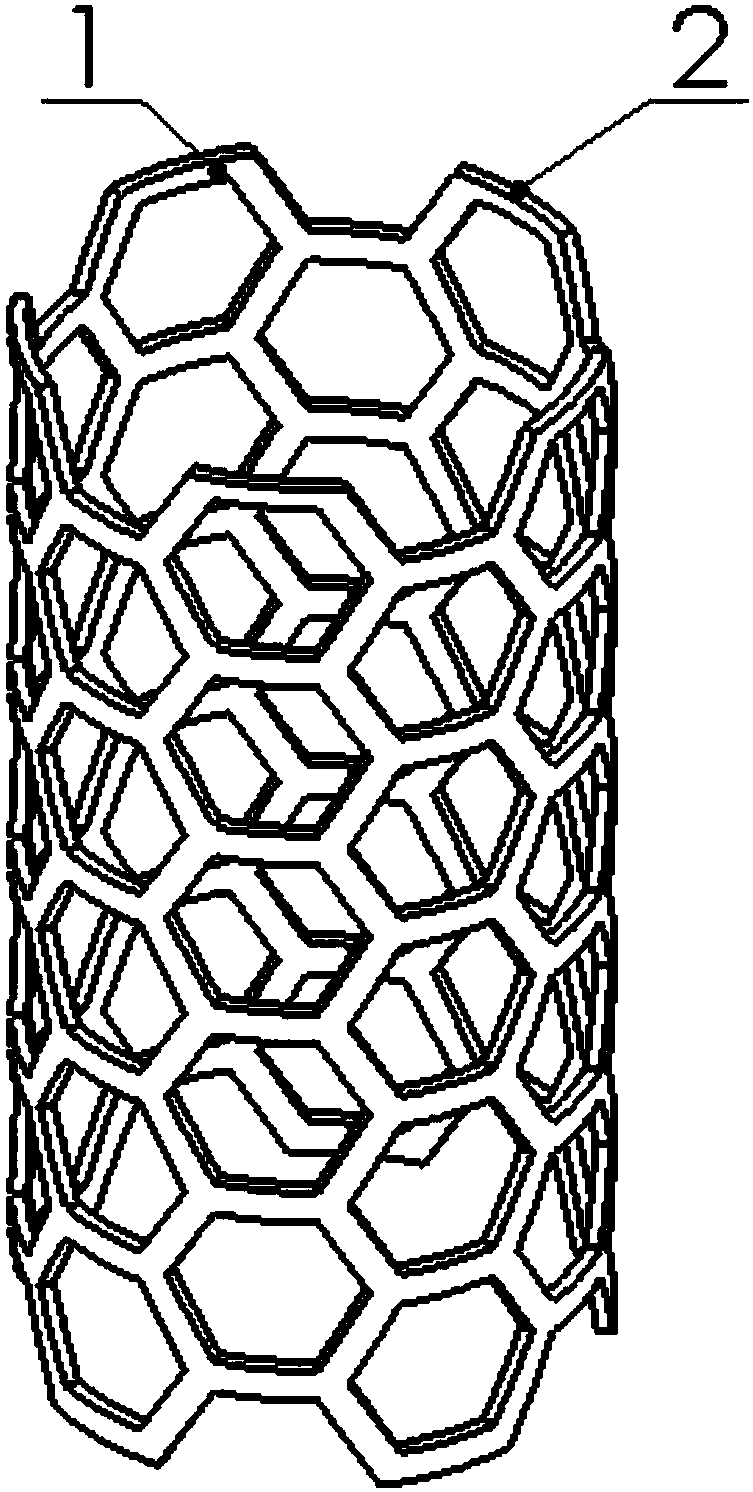

[0044] like image 3 , 4 As shown, in the recyclable heart stent provided by this embodiment, the main body 2 of the stent is an interconnected regular hexagonal network structure.

[0045] This embodiment provides a recyclable cardiac stent. The main body of the stent is an interconnected regular hexagonal network structure, so that the main body of the stent is fully in contact with the inner wall of the blood vessel, and the stress between the two is increased. The fixing ability is strong, it is not easy to shift, and the mechanical strength High, suitable for some parts that can bear a large load.

[0046] Biocompatibility means that a material elicits the appropriate response in a speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com