a fixed mechanism

A fixing mechanism and first-line technology, applied in the direction of electrical components, etc., can solve the problems of different cable diameters, poor applicability of cable fixing fixtures, etc., to achieve good applicability, excellent shaping effect, and good fixing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

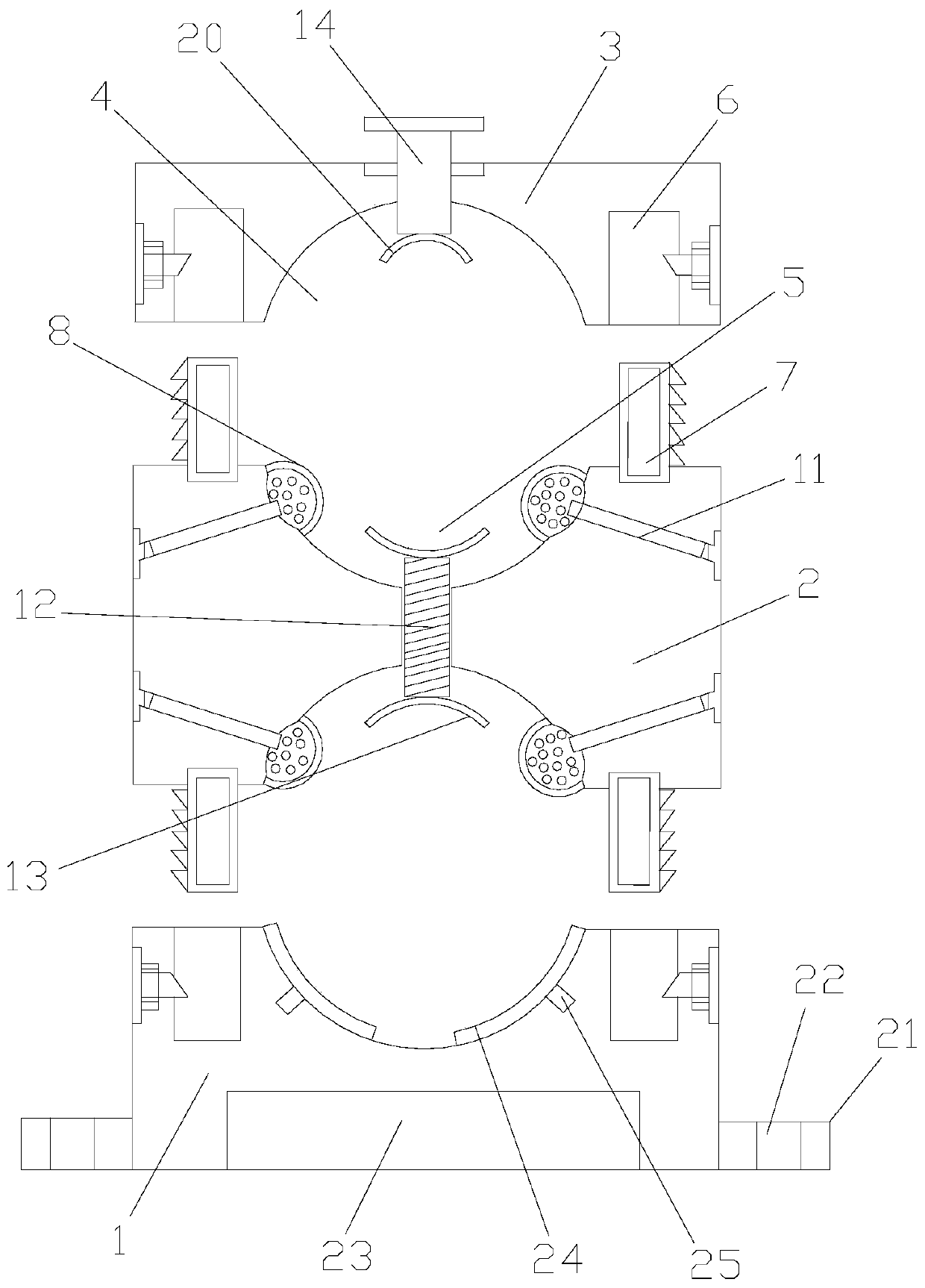

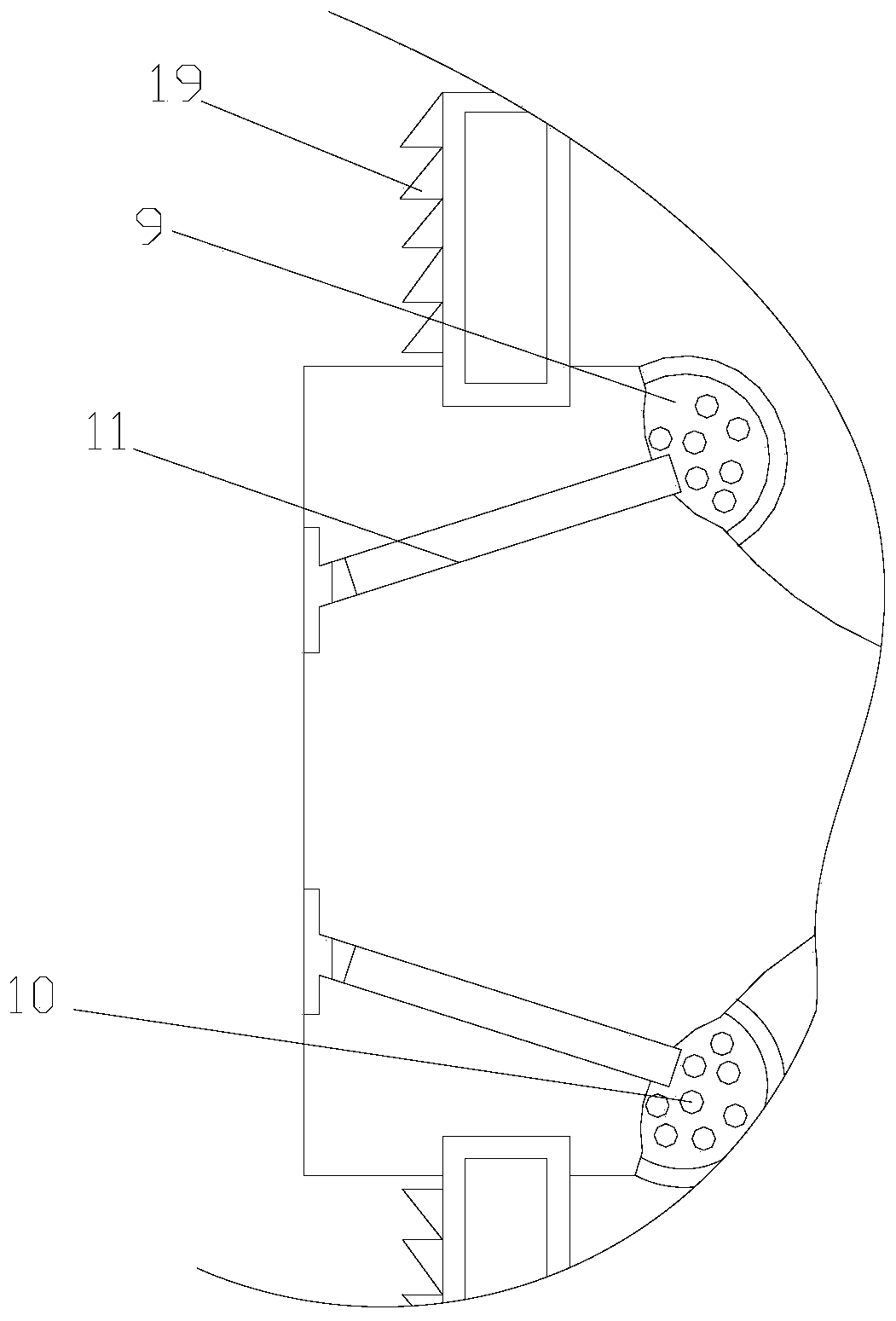

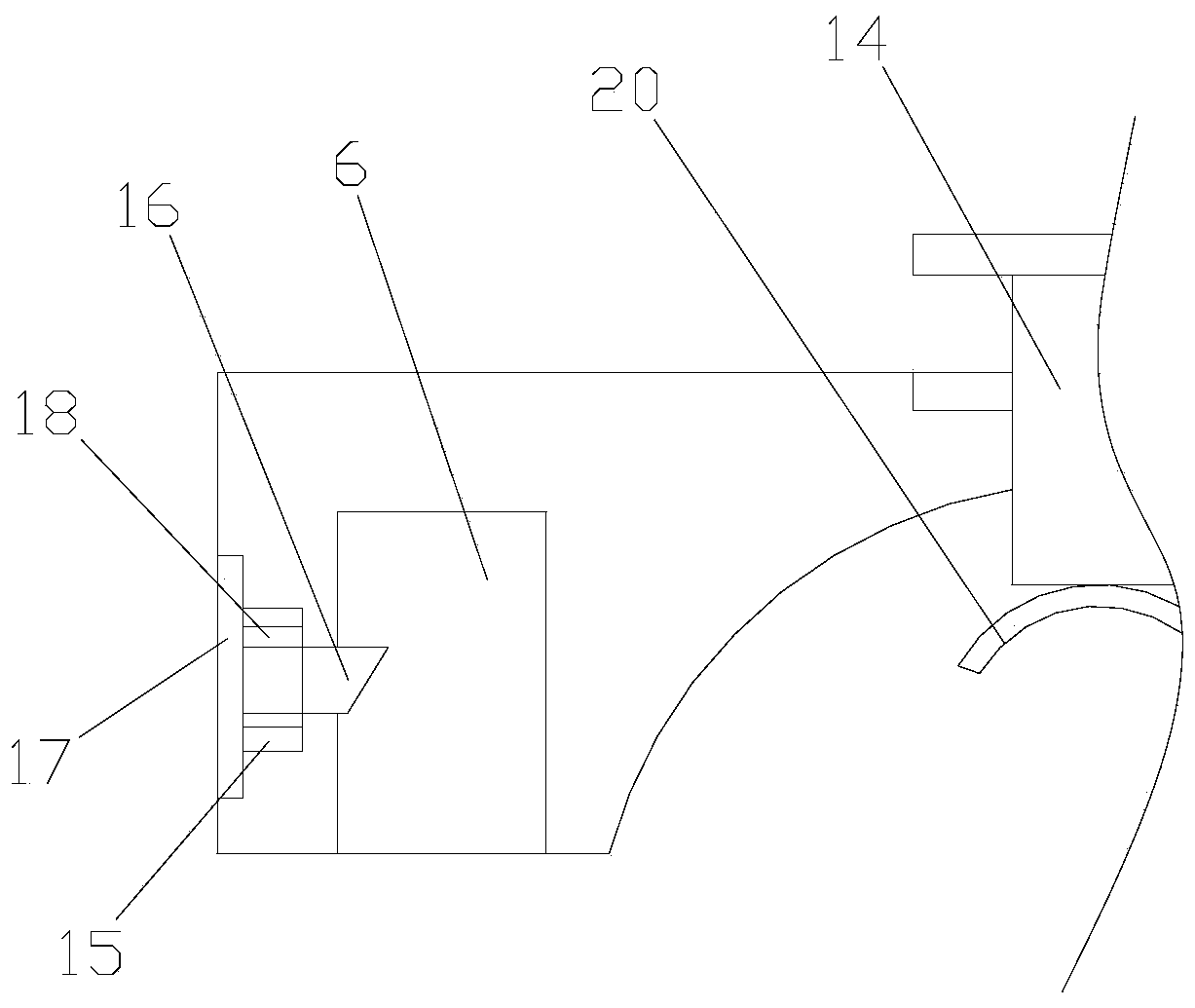

[0042] Such as Figure 1-3 As shown, a fixing mechanism includes a lower clamp 1, a middle clamp 2 and an upper clamp 3. The lower clamp 1 and the upper clamp 2 are each provided with a first wire slot 4, and the upper end surface and the lower clamp of the middle clamp 2 The end faces are all provided with a second wire groove 5 that is matched with the first wire groove 4, the lower clamp 1 and the upper clamp 3 are both provided with sockets 6, and the upper and lower end surfaces of the middle clamp 2 are both provided with The insertion rod 7 is matched with the insertion hole 6 and the insertion rod 7 is engaged with the insertion hole 6, an arc-shaped recess (not shown) is formed on the groove wall of the second wire groove 5, and the groove of the second wire groove 5 The wall is provided with a silicone sheet 8 for covering the depression. The silicone sheet 8 is glued to the groove wall of the second wire groove 5. A storage cavity 9 is formed between the silicone she...

Embodiment 2

[0050] Such as Figure 1-3 As shown, a fixing mechanism includes a lower clamp 1, a middle clamp 2 and an upper clamp 3. The lower clamp 1 and the upper clamp 2 are each provided with a first wire slot 4, and the upper end surface and the lower clamp of the middle clamp 2 The end faces are all provided with a second wire groove 5 that is matched with the first wire groove 4, the lower clamp 1 and the upper clamp 3 are both provided with sockets 6, and the upper and lower end surfaces of the middle clamp 2 are both provided with The insertion rod 7 is matched with the insertion hole 6 and the insertion rod 7 is engaged with the insertion hole 6, an arc-shaped recess (not shown) is formed on the groove wall of the second wire groove 5, and the groove of the second wire groove 5 The wall is provided with a silicone sheet 8 for covering the depression, the silicone sheet 8 is bonded to the groove wall of the second wire groove 5, and a storage cavity 9 is formed between the silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com