Channel device for controlling magnetic liquid metal by utilizing electromagnetic field coupling

A liquid metal, coupled control technology, applied in magnetic liquids, magnetic objects, circuits, etc., can solve problems such as rare research on magnetic liquid metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

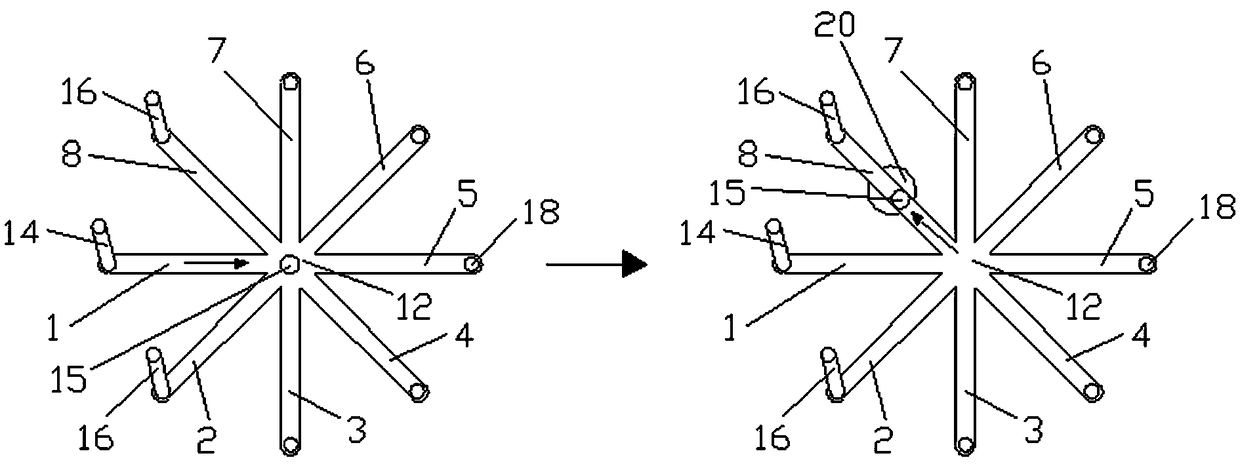

[0025] Such as figure 1 , figure 2 As shown, the channel device of magnetic liquid metal controlled by electromagnetic field coupling includes a power supply (not shown in the figure), a magnetic field element and eight channels. The power supply is used to form an electric field, and the magnetic field element is used to form a magnetic field. The eight channels are the first One channel 1, the second channel 2, the third channel 3, the fourth channel 4, the fifth channel 5, the sixth channel 6, the seventh channel 7 and the eighth channel 8, the first channel 1, the second channel 2, the The three passages 3, the fourth passage 4, the fifth passage 5, the sixth passage 6, the seventh passage 7 and the eighth passage 8 all intersect at a bifurcation 12, and the first passage 1, the second passage 2, and the third passage 3 , the fourth channel 4, the fifth channel 5, the sixth channel 6, the seventh channel 7 and the eighth channel 8 and the bifurcation 12 are all provided ...

Embodiment 2

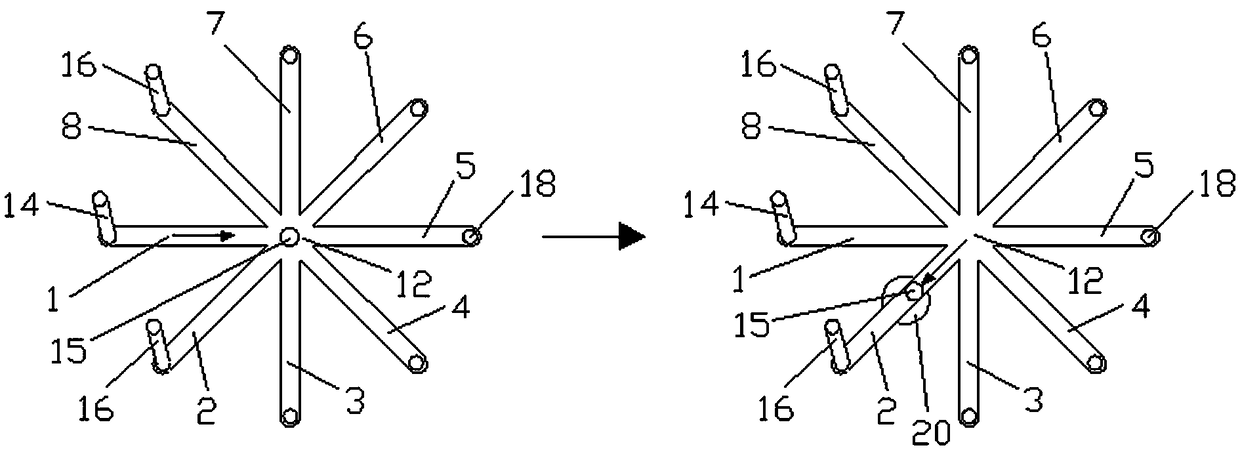

[0034] Such as image 3 As shown, the difference between the second embodiment and the first embodiment is that the second electrode 16 arranged in the eighth channel 8 is changed to be arranged in the seventh channel 7, and the distance between the second channel 2 and the seventh channel 7 is 135 °, under the action of the magnet 20, the magnetic liquid metal 15 can advance along the seventh channel 7.

Embodiment 3

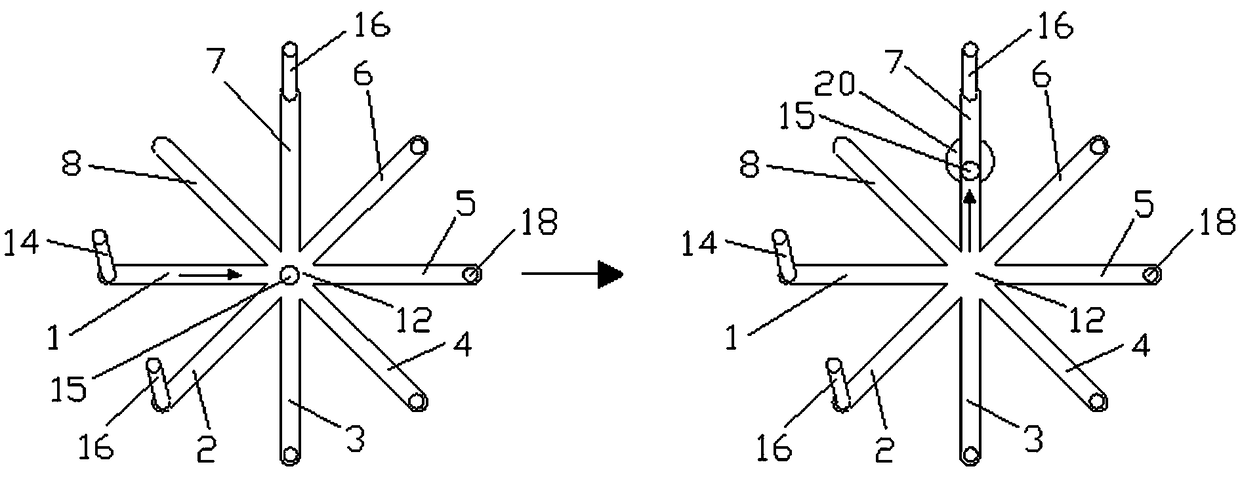

[0036] Such as Figure 4 As shown, the difference between the third embodiment and the first embodiment is that the second electrode 16 arranged in the eighth channel 8 is changed to be arranged in the sixth channel 6, and the distance between the second channel 2 and the sixth channel 6 is 180 °, under the action of the magnet 20, the magnetic liquid metal 15 can advance along the sixth channel 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com