Diamond particle reinforced molten alloy thermal interface material and preparation method thereof

A technology of diamond particles and thermal interface materials, which is applied in the field of diamond particle-reinforced molten alloy thermal interface materials and its preparation, can solve the problems of high material cost, poor wettability, and large fluidity, and achieve simple equipment, easy operation, The effect of enhancing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

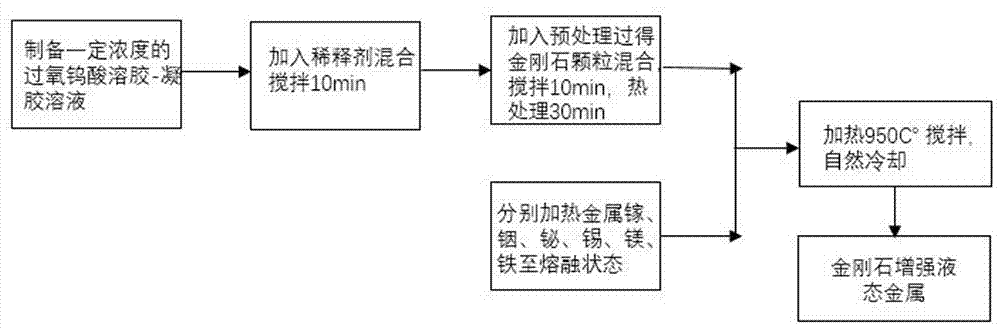

[0033] Adopt the following steps to realize the present invention:

[0034] (1) Slowly dissolve 4g of metal tungsten particles with a purity of 99.9% in 30% hydrogen peroxide solution, stir continuously, and keep the temperature at 15°C by soaking in a water bath. When the reaction was over, the solution became milky. Immerse the platinum piece in the solution to reduce excess hydrogen peroxide, then add 15ml of ethanol and 4ml of glacial acetic acid, and finally the solution was refluxed at 70°C for 12h until a stable peroxytungstic acid sol-gel was obtained, diluted by adding 10 parts agent to reduce the concentration of the peroxytungstic acid sol-gel;

[0035] (2) Put 40 parts of 100um diamond particles into distilled water and ultrasonically oscillate for 1 hour to remove impurities on the surface, then treat with 50% nitric acid, wash and dry with distilled water, and finally add the treated diamond particles to the Oxytungstic acid sol-gel, stirred for 10min, then fil...

Embodiment 2

[0039] Adopt the following steps to realize the present invention:

[0040] (1) Slowly dissolve 6g of metal tungsten particles with a purity of 99.9% in 30% hydrogen peroxide solution, stir continuously, and keep it at 15°C by soaking in a water bath. When the reaction was over, the solution became milky. Immerse the platinum piece in the solution to reduce excess hydrogen peroxide, then add 15ml of ethanol and 4ml of glacial acetic acid, and finally the solution was refluxed at 60°C for 10h until a stable peroxytungstic acid sol-gel was obtained, diluted by adding 15 parts agent to reduce the concentration of the peroxytungstic acid sol-gel;

[0041] (2) 50 parts of diamond particles with a particle size of 150um were first placed in distilled water for 1 hour to remove impurities on the surface, then treated with 60% nitric acid, washed with distilled water and dried, and finally the treated diamond particles were added to the Oxytungstic acid sol-gel, stirred for 10min, the...

Embodiment 3

[0045] Adopt the following steps to realize the present invention:

[0046] (1) Slowly dissolve 8g of metal tungsten particles with a purity of 99.9% in 30% hydrogen peroxide solution, stir continuously, and keep it at 15°C by soaking in a water bath. When the reaction was over, the solution became milky. Immerse the platinum piece in the solution to reduce excess hydrogen peroxide, then add 15ml of ethanol and 4ml of glacial acetic acid, and finally the solution was refluxed at 50°C for 10h until a stable peroxytungstic acid sol-gel was obtained, diluted by adding 20 parts agent to reduce the concentration of the peroxytungstic acid sol-gel;

[0047] (2) Put 60 parts of diamond particles with a particle size of 200um into distilled water and oscillate for 1 hour to remove impurities on the surface, then treat with 70% nitric acid, wash with distilled water and dry, and finally add the treated diamond particles to the Oxytungstic acid sol-gel, stirred for 10min, then filtere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com