High-temperature heat exchanger for liquid metaland heat exchange system

A liquid metal and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of liquid metal corrosion, shortening the service life of heat exchangers, etc. The effect of prolonging the service life and improving the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

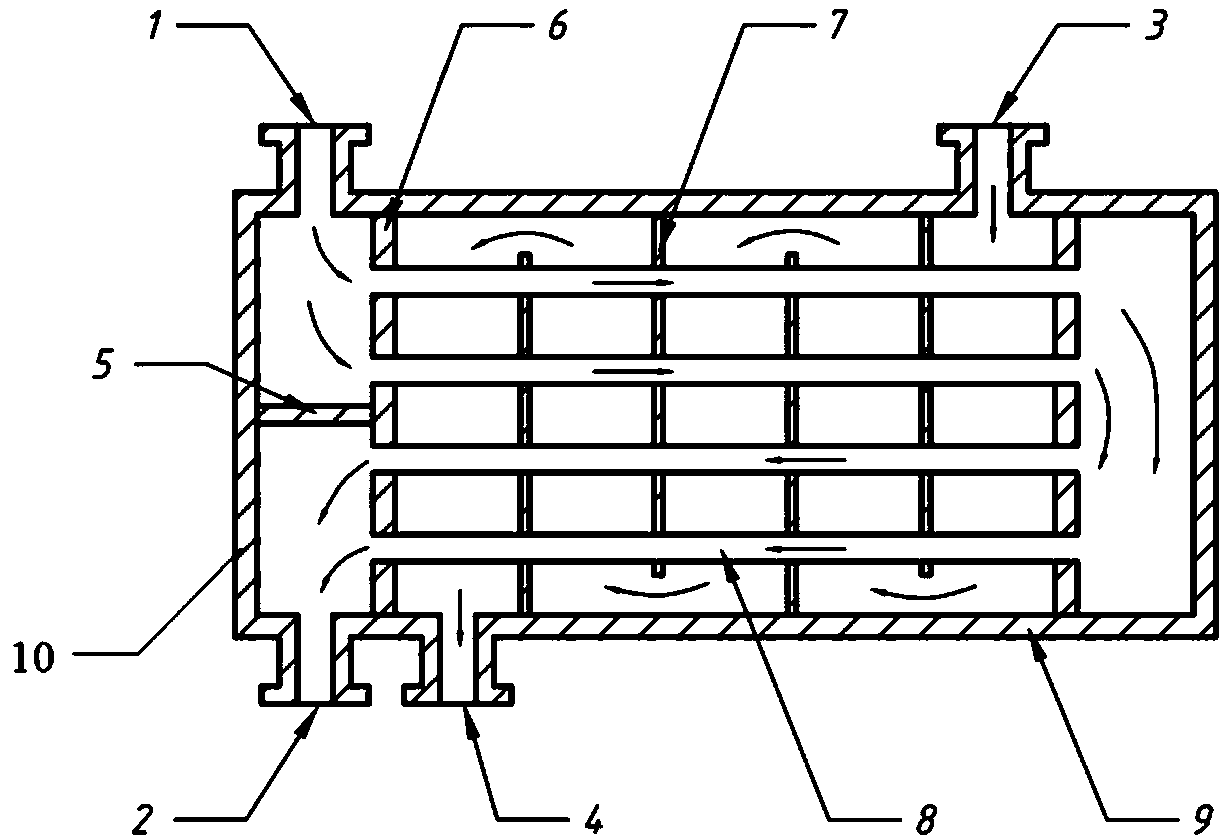

[0033] Such as figure 1 As shown, the present invention provides a high temperature heat exchanger for liquid metal, the heat exchanger includes a shell 9 and two tube boxes 10 respectively arranged at both ends of the shell 9, the tube box 10 is connected to the tube plate 6 and The shell 9 is connected; the shell 9 is provided with a plurality of heat exchange tubes 8, and the two ends of the heat exchange tubes 8 protrude from the corresponding tube sheets 6 to form a channel for the flow of liquid metal together with the two tube boxes 10 , that is to say, the two ends of the heat exchange tube 8 communicate with two tube boxes 10 respectively; the side wall of the shell 9 is provided with a shell-side inlet 3 and a shell-side outlet 4, and the tube box 10 is provided with a tube-side inlet 1 And the tube side outlet 2; the tube box 10 and the heat exchange tube 8 are made of refractory metal alloy.

[0034] When in use: if the liquid metal flowing into the heat exchanger...

Embodiment 2

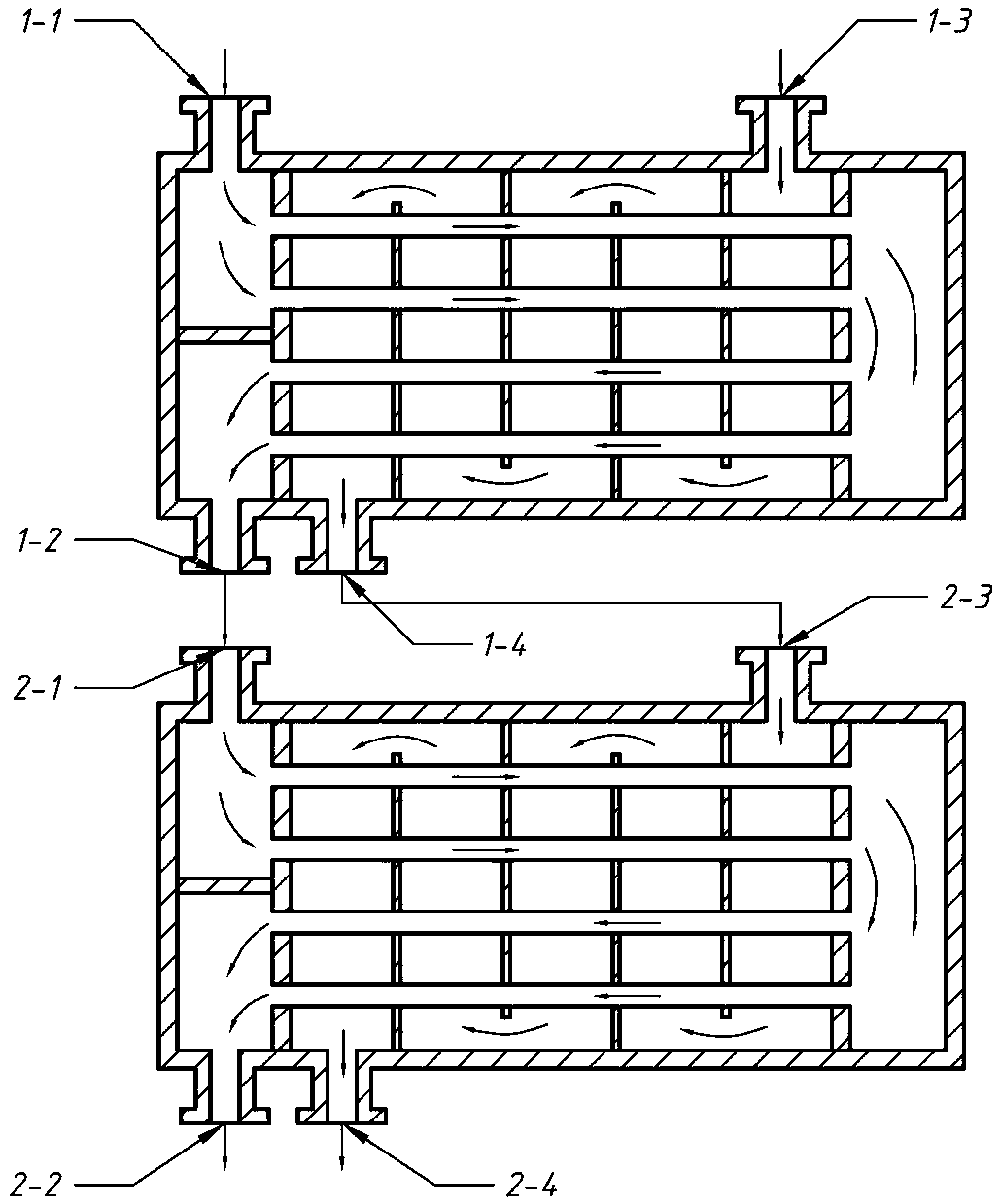

[0044] The present invention also provides a heat exchange system for liquid metal, the system includes a plurality of the above-mentioned heat exchangers for liquid metal, a plurality of heat exchangers for liquid metal are connected in series, that is to say , the tube-side outlet and shell-side outlet of one of the two adjacent liquid metal heat exchangers are connected to the tube-side inlet and shell-side outlet of the other liquid metal heat exchanger respectively. The shell side inlet is connected.

[0045] The following uses a heat exchange system including two heat exchangers for liquid metal as an example to illustrate how to use the heat exchange system:

[0046] Such as figure 2 As shown, one of the heat exchangers for liquid metal is the primary high-temperature heat exchanger, and the other heat exchanger for liquid metal is the final high-temperature heat exchanger. Among them, the tube-side outlet 1-2 of the primary high-temperature heat exchanger is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com