Flexible conductor wire and molding technology thereof

A flexible conductive and forming technology, applied in metal/alloy conductors, cable/conductor manufacturing, rods/rods/wires/strip conductors, etc. The effect of preventing air bubbles, easy processing and forming, and ensuring electrical conductivity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention provides a flexible conductive wire body and a forming process thereof. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

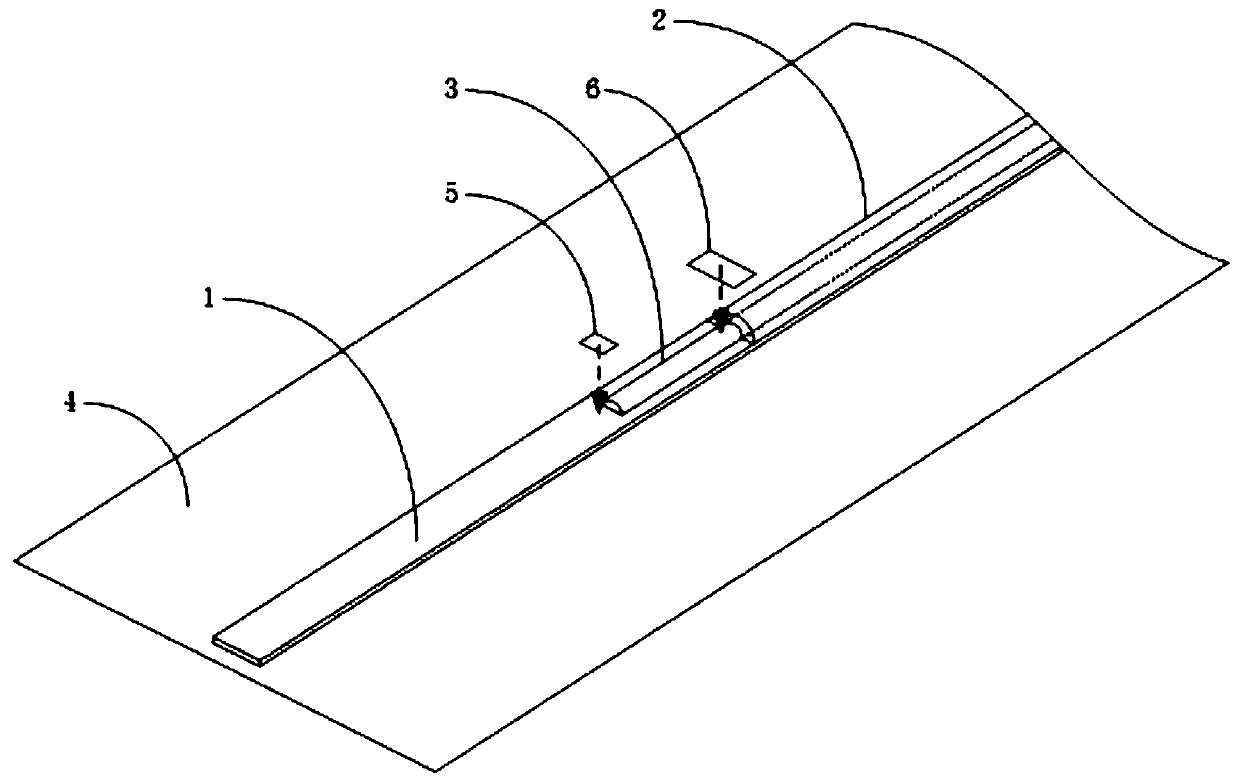

[0044] Flexible conductive wire body, such as figure 1 As shown, it is arranged on the surface of the fabric base 4, including a flexible base 1, a liquid metal 2, and a flexible package 3, wherein the flexible base 1 is bonded to the surface of the fabric base 4; the liquid metal 2 is arranged on the surface of the flexible base 1; the flexible package 3 The liquid metal 2 is connected to the flexible base 1; wherein, the flexible base 1 and / or the flexible wrapping 3 are flexible conductive materials.

[0045] The tubular hose loaded with liquid metal 2 is formed by the flexible base 1 and the flexible package 3. The tubular hose is washable and flexible, and the wall is not easy to break when bent and rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com