Method for packaging product by using liquid metal

A liquid metal, product packaging technology, applied in packaging, copying/marking methods, devices for coating liquid on the surface, etc., can solve problems such as poor product penetration, achieve excellent anti-corrosion and aging resistance, and the printing method is simple , the effect of increasing attractiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

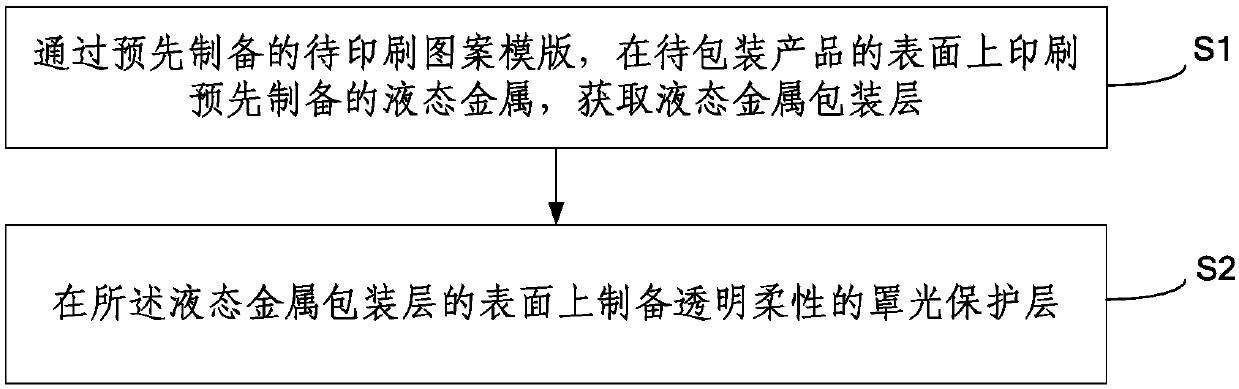

Method used

Image

Examples

Embodiment 1

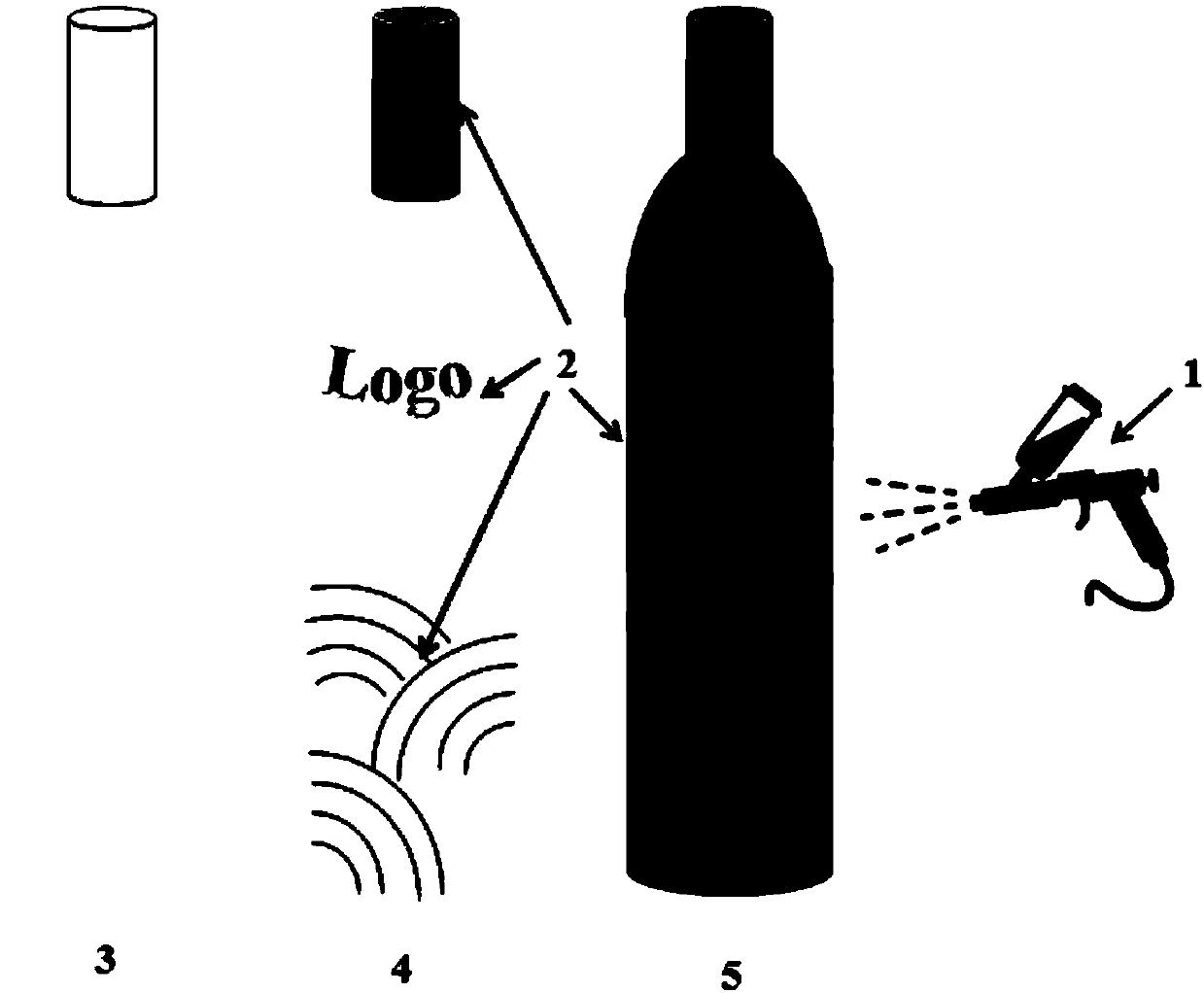

[0057] Example 1, figure 2 It is a schematic diagram of a packaged product of a method for product packaging using liquid metal provided by an embodiment of the present invention, such as figure 2 As shown in the figure, 1 is the spray gun with liquid metal; 2 is the packaging pattern, trademark, bottle cap, and the whole bottle printed by the liquid metal; 3 is the initial product to be packaged; 4 is the use of liquid metal The effect of product logo and decorative pattern after packaging; 5 is the effect of using liquid metal for large-area uniform packaging; the specific steps are as follows:

[0058] Step 1. Take a PET bottle with a smooth surface for packaging, take liquid metal with a higher purity (99.99%), and prepare a mask with different patterns and trademarks;

[0059] Step 2. Put the liquid metal into the spray gun, and cover the metal mask on the PET beverage bottle to perform liquid metal ultra-micro atomization inkjet printing, so that the printed pattern and trad...

Embodiment 2

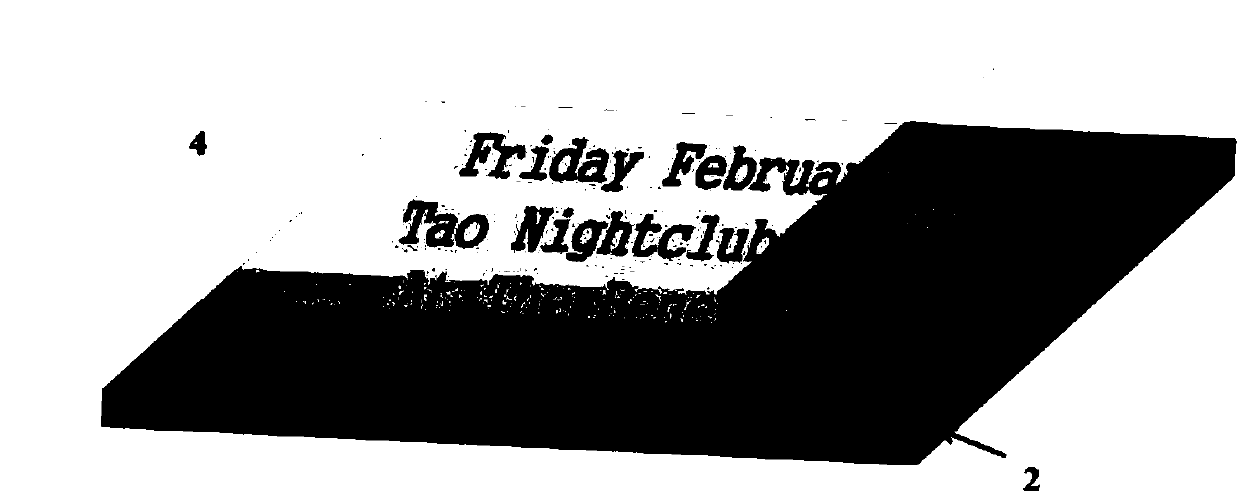

[0062] Example 2, image 3 The cross-sectional schematic diagram of the pattern structure of the method of using liquid metal for product packaging provided by the embodiment of the present invention, such as image 3 As shown in the figure, 2 is the product to be packaged; 3 is the packaging pattern printed by liquid metal; 4 is the transparent and flexible varnish or acrylate UV curing agent for packaging on the packaging surface. Specific steps are as follows:

[0063] Step 1. Prepare liquid metal with a higher melting point at room temperature, prepare hard paper business cards, and prepare silk screen with business card words and patterns;

[0064] Step 2: Use the screen printing method to print liquid metal on the business card, make the liquid metal form corresponding fonts and patterns, and use acrylic to cover the outer surface of the business card;

[0065] Step 3. The preparation of the business card packaged with liquid metal is completed.

[0066] Compared with the trad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com