Method for improving the wetting of surface of solid substrate by liquid metal

A liquid metal, solid substrate technology, applied in metal material coating process, chemical/physical/physicochemical process of energy application, coating, etc., can solve unsatisfactory problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The use of ultrasound is sought in different industrial applications: at high power, ultrasound can eg be used in cleaning applications. At low power, they are often used for non-destructive inspection applications in materials or structures.

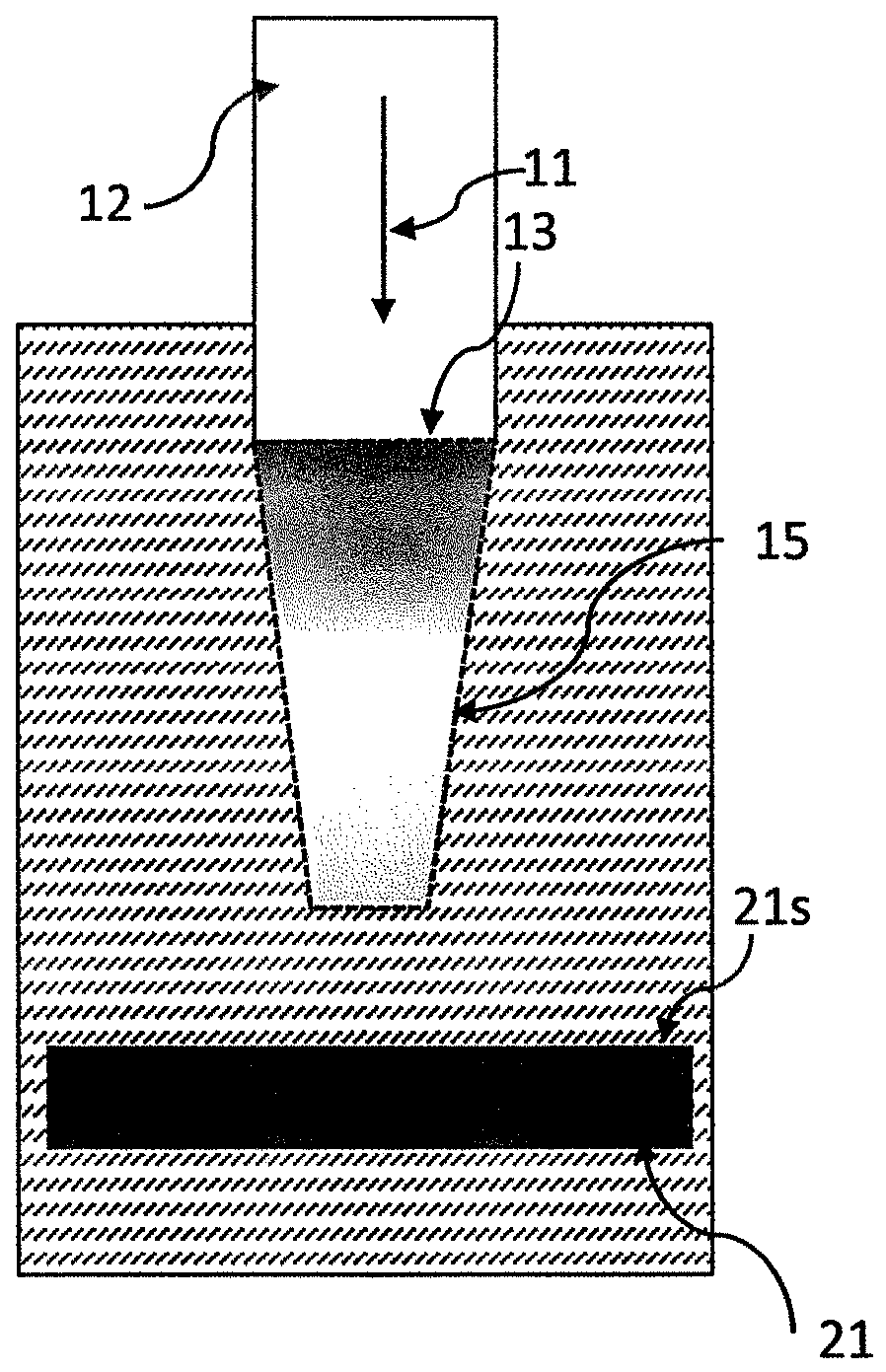

[0036] The present invention is based on the advantageous application of power ultrasound to increase the wetting of the surface of a solid substrate by liquid metal. In fact, the inventors have found that the application of high power ultrasound to a metal or ceramic substrate immersed in a molten pool formed by liquid metal results in increased wetting of the substrate surface by the liquid metal.

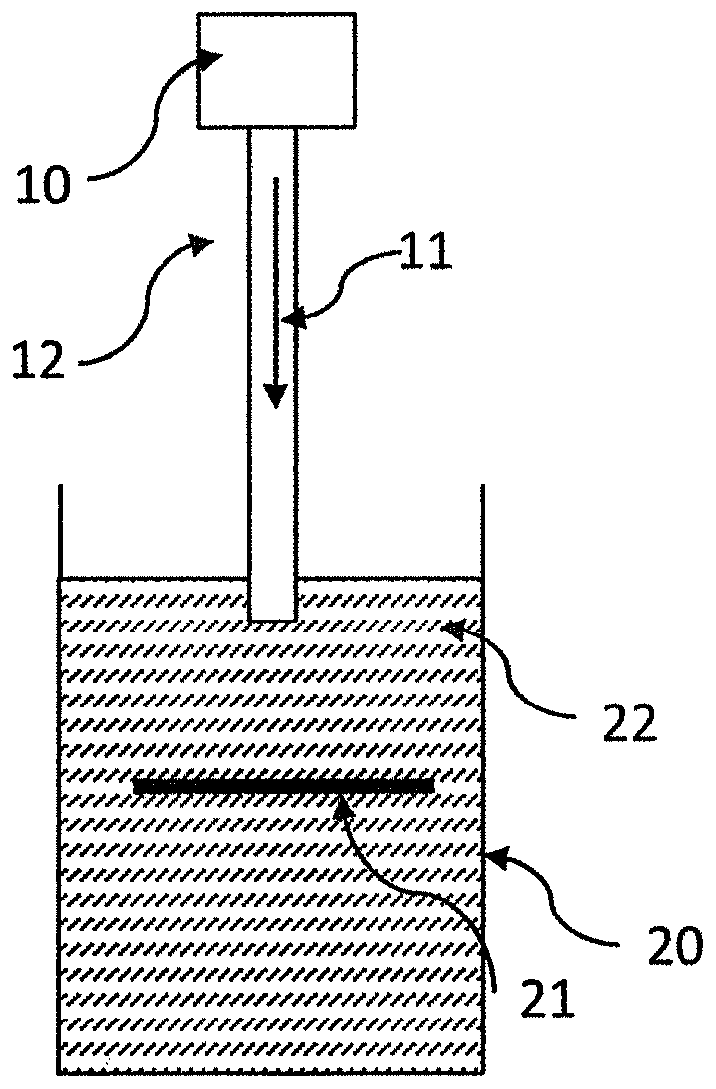

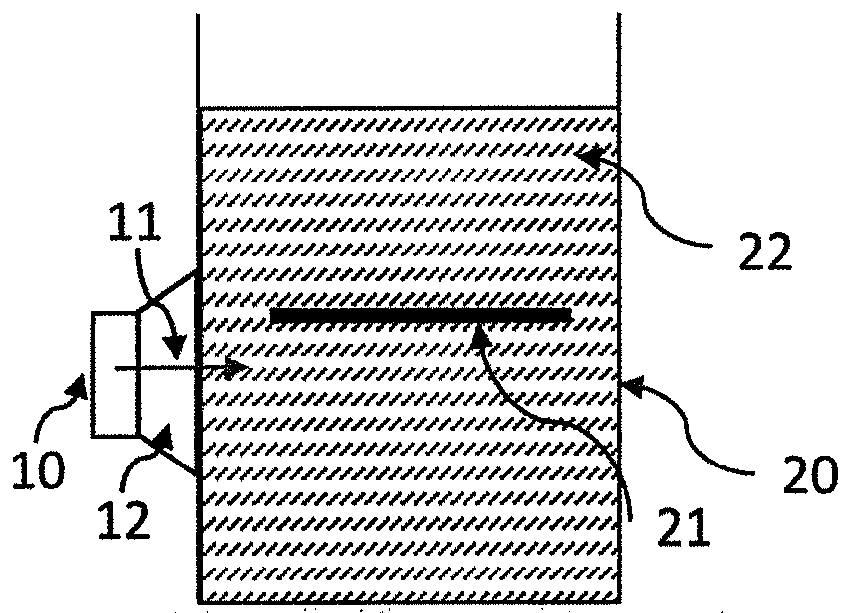

[0037] According to a first application, the invention is used to deposit a metal layer on a substrate. The first embodiment is in Figure 1A shown in . A solid substrate 21 formed of a first material, such as aluminum alloy or ceramic, is immersed into a molten pool of a second metal 22 in liquid state. In this embodiment, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com