Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

469 results about "De wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

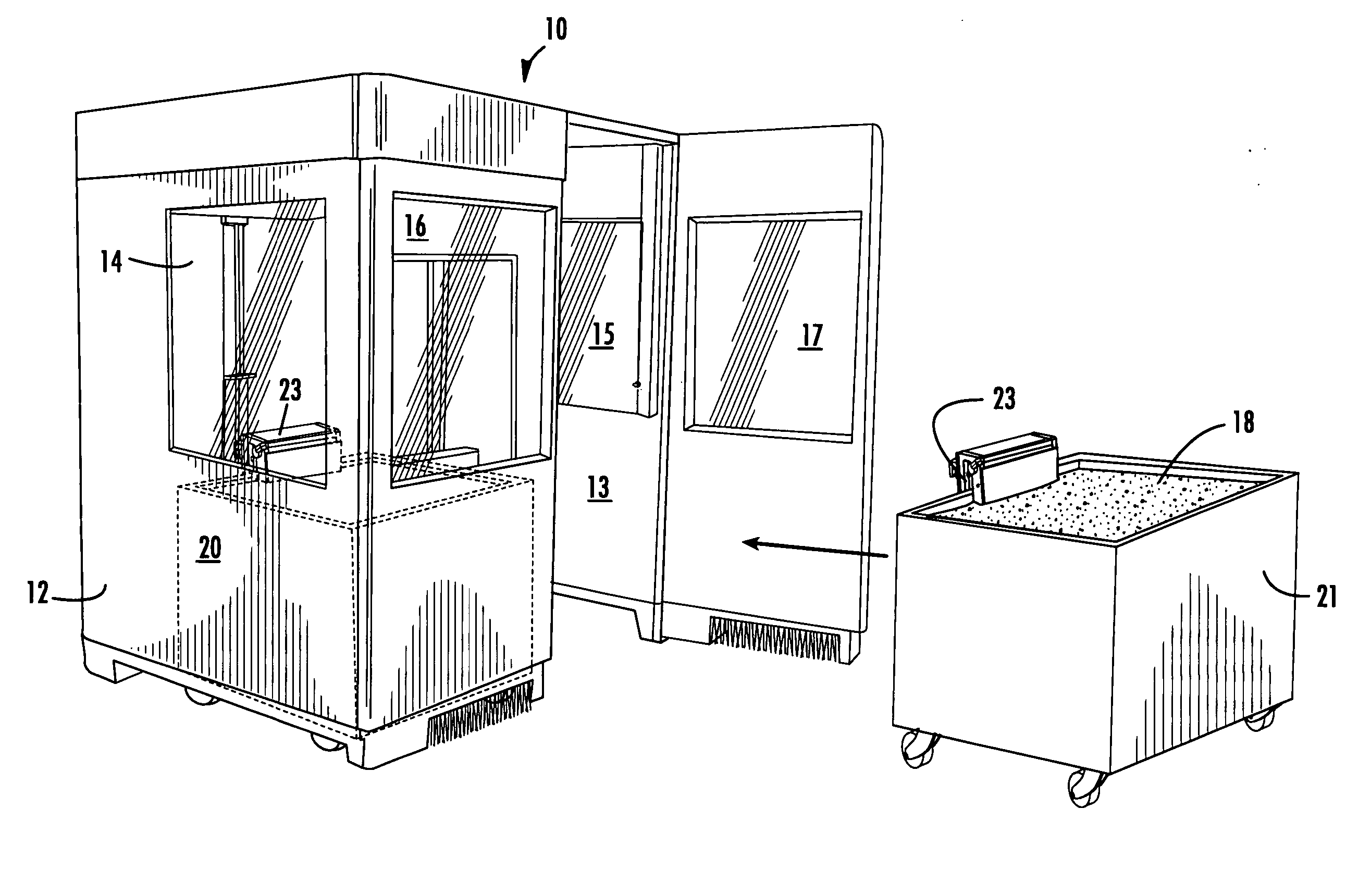

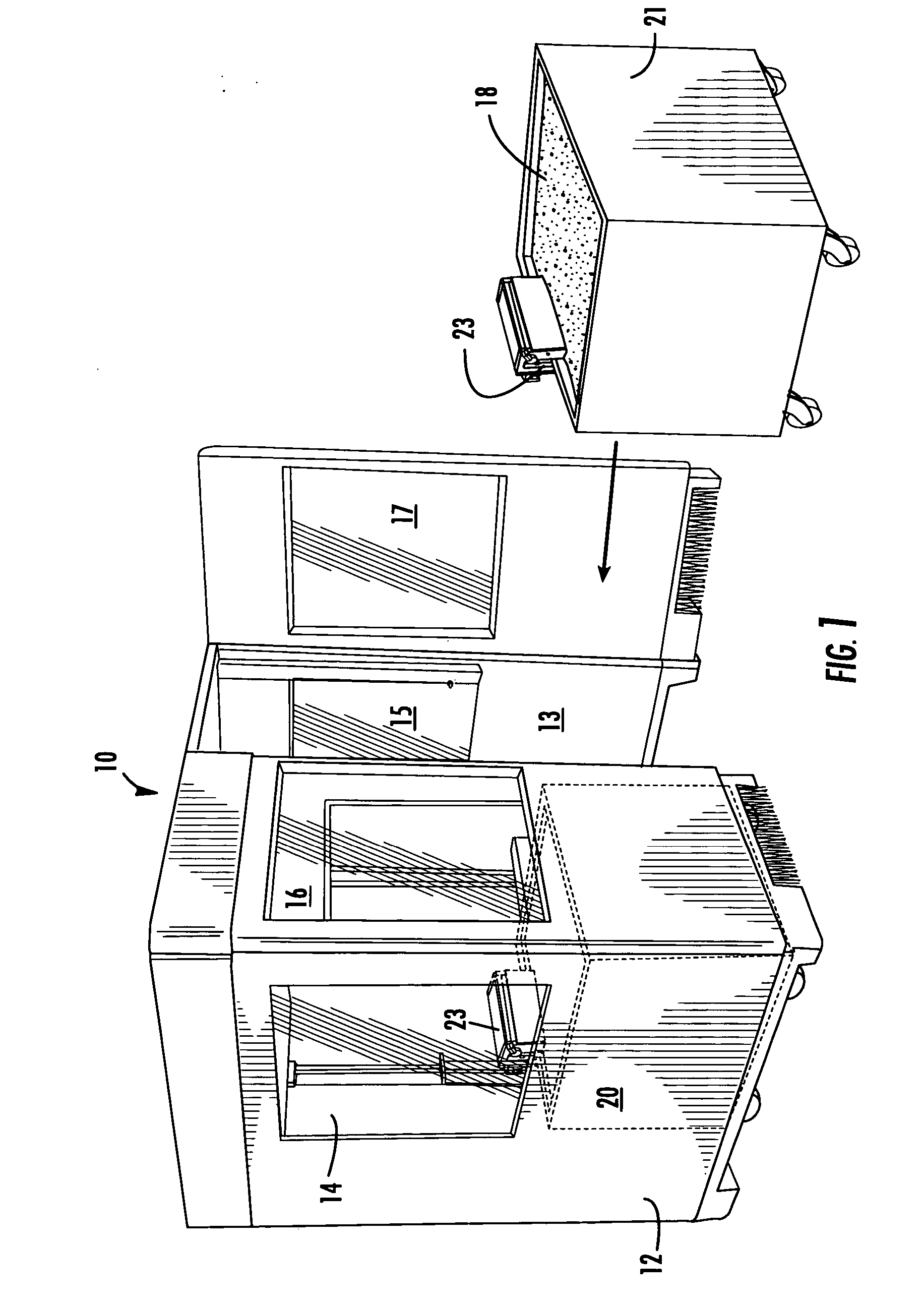

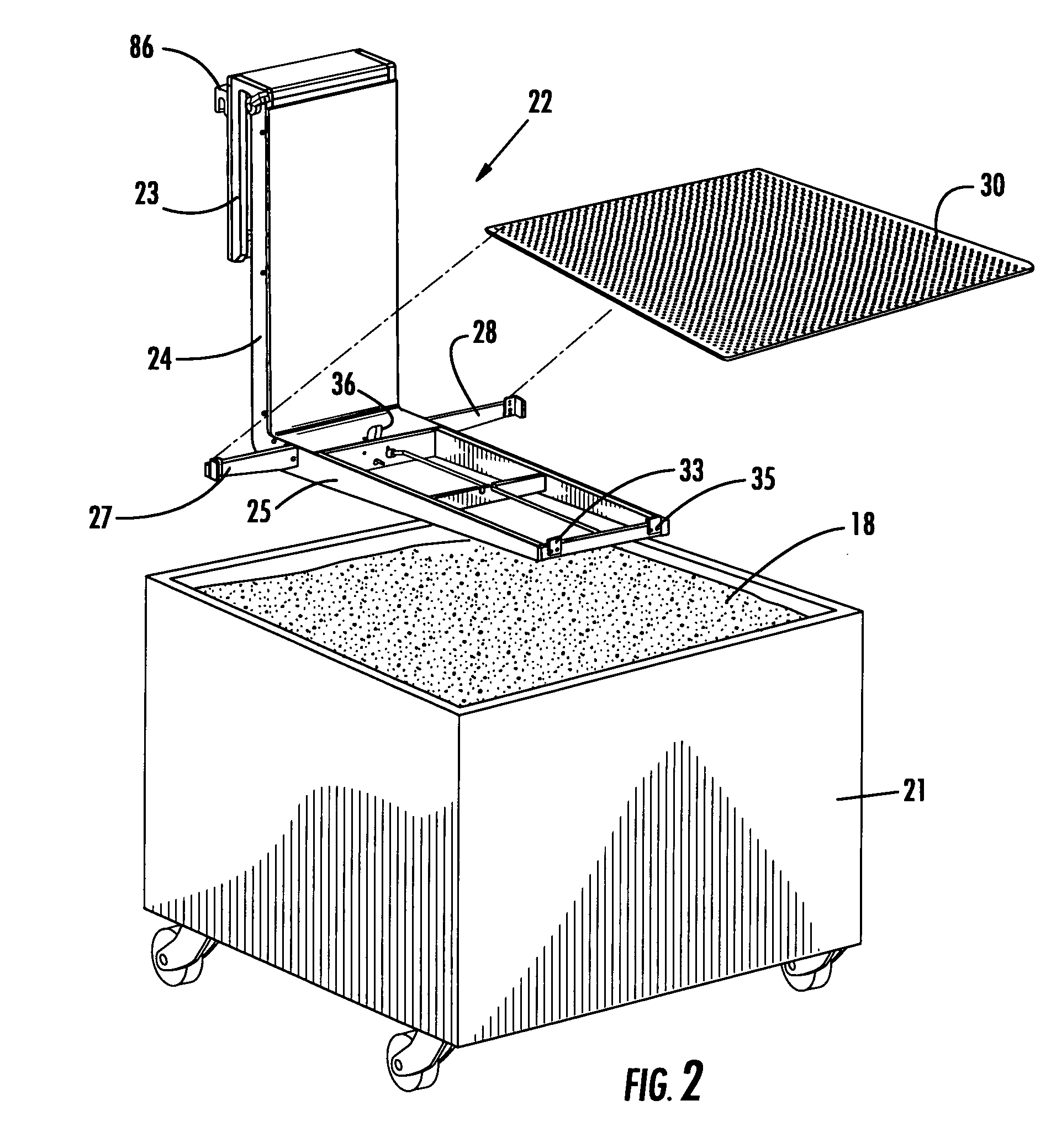

Rapid prototyping and manufacturing system and method

InactiveUS20070075461A1Simplify obtaining precisionShorten the timeManufacturing platforms/substratesAuxillary shaping apparatusElectrical resistance and conductanceEngineering

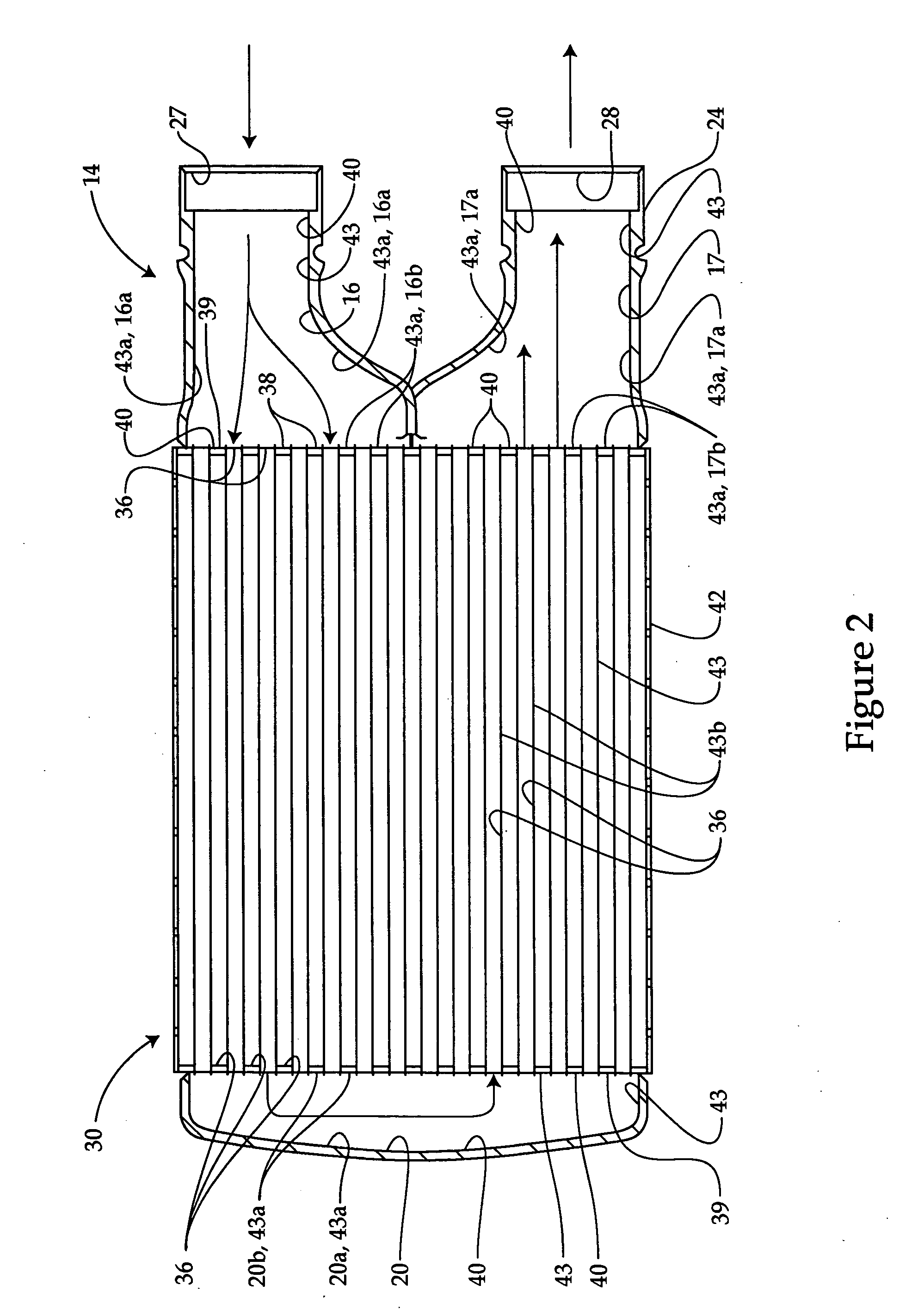

A stereolithography apparatus having a resin vat with computer controlled heating elements responsive to thermistors for controlled preheating of the resin vat, an elevator assembly for supporting and releasably retaining a build platform removably attached to the stereolithography apparatus frame such that elevator forks supporting the build platform can be released into the vat and removed from the stereolithography apparatus with the vat, and a recoater blade that can be removed and accurately installed by hand, thus providing that all wetted components can be quickly and efficiently removed and installed and enabling rapid changeover from spent resin to fresh resin and minimizing apparatus downtime between stereolithography operations.

Owner:3D SYST INC

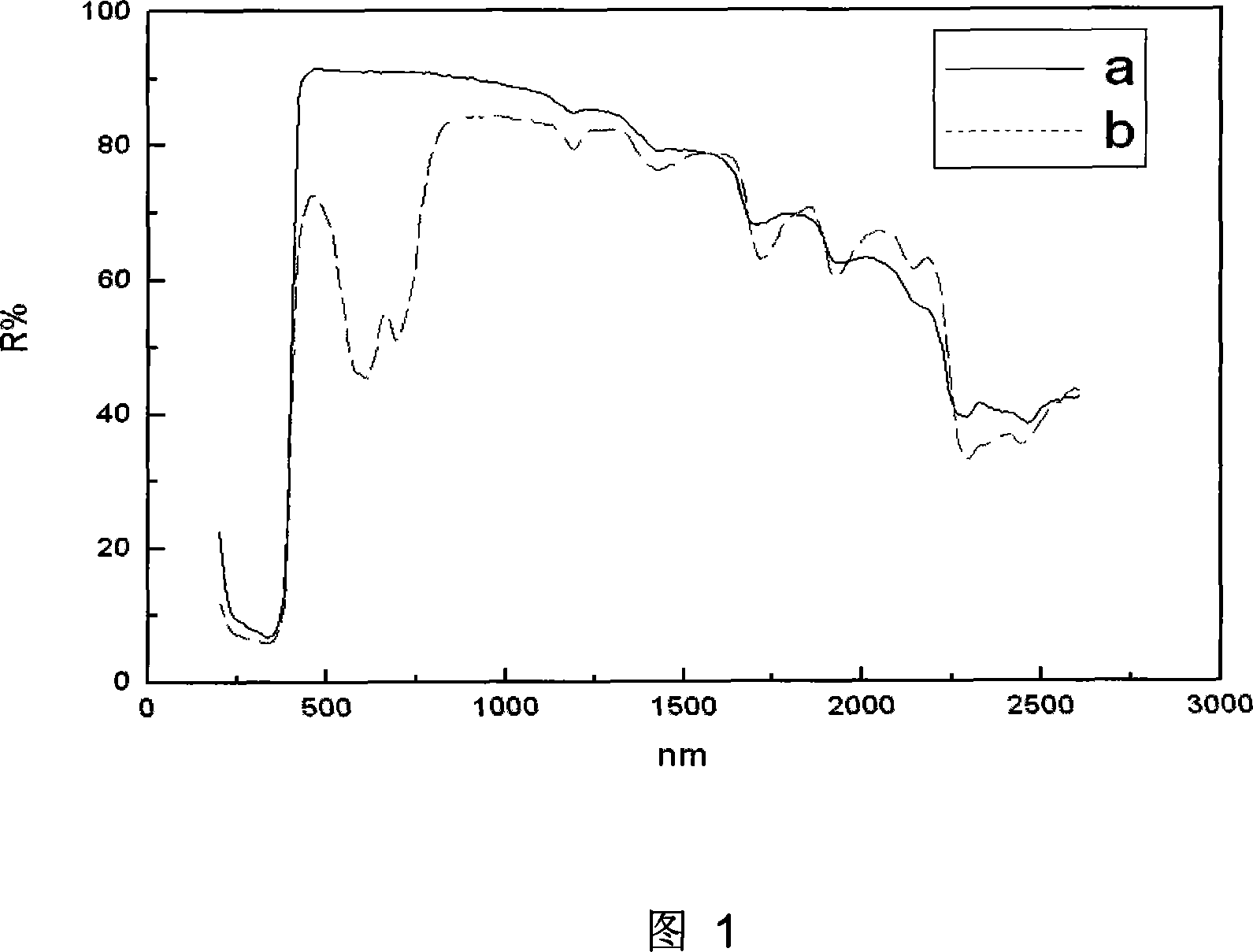

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

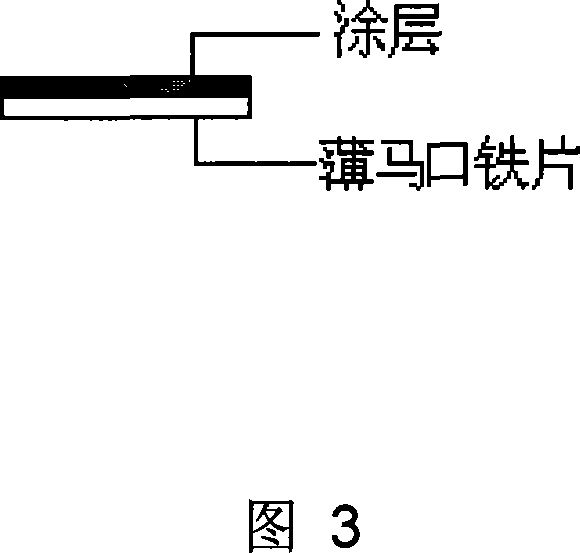

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

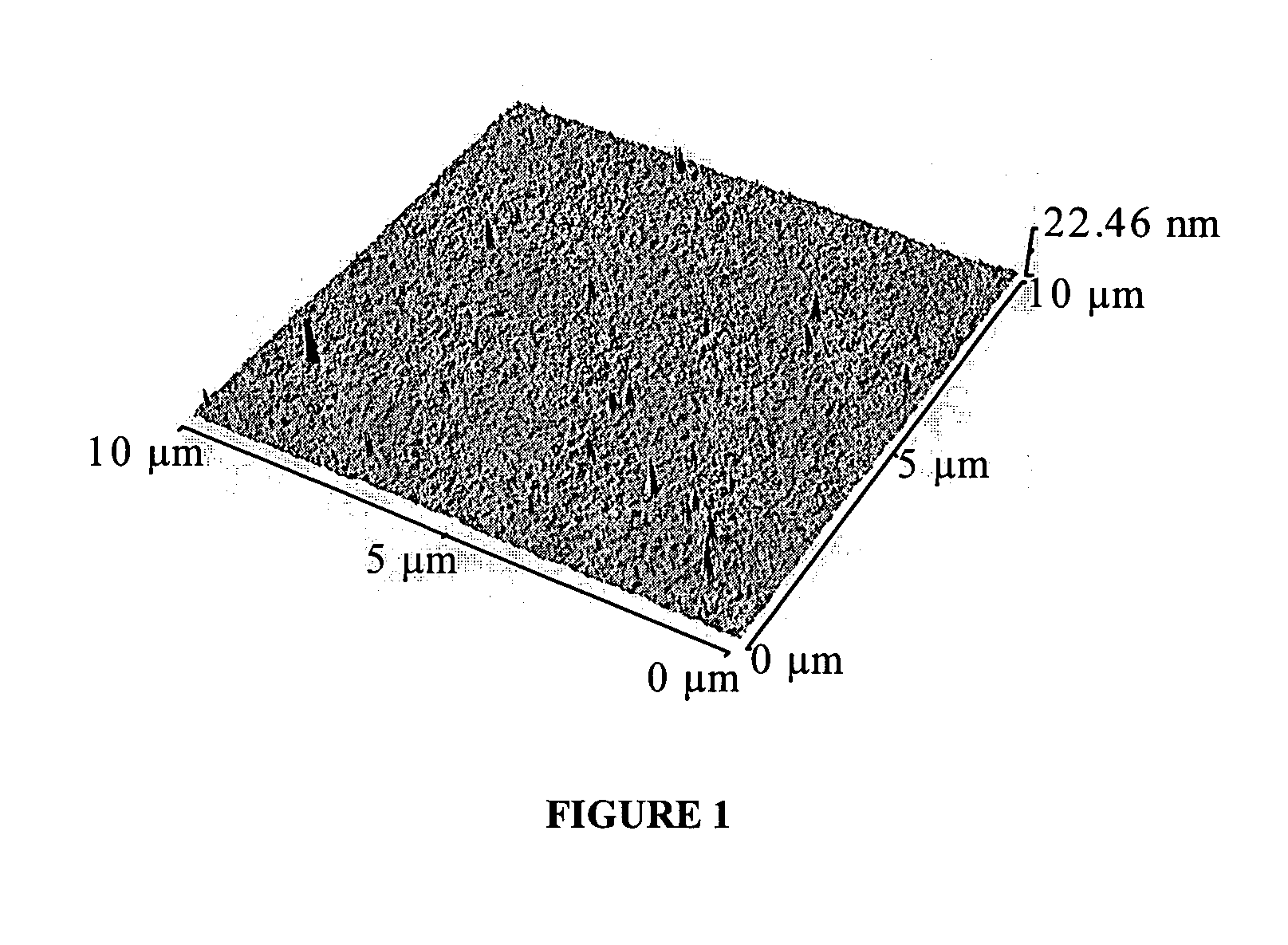

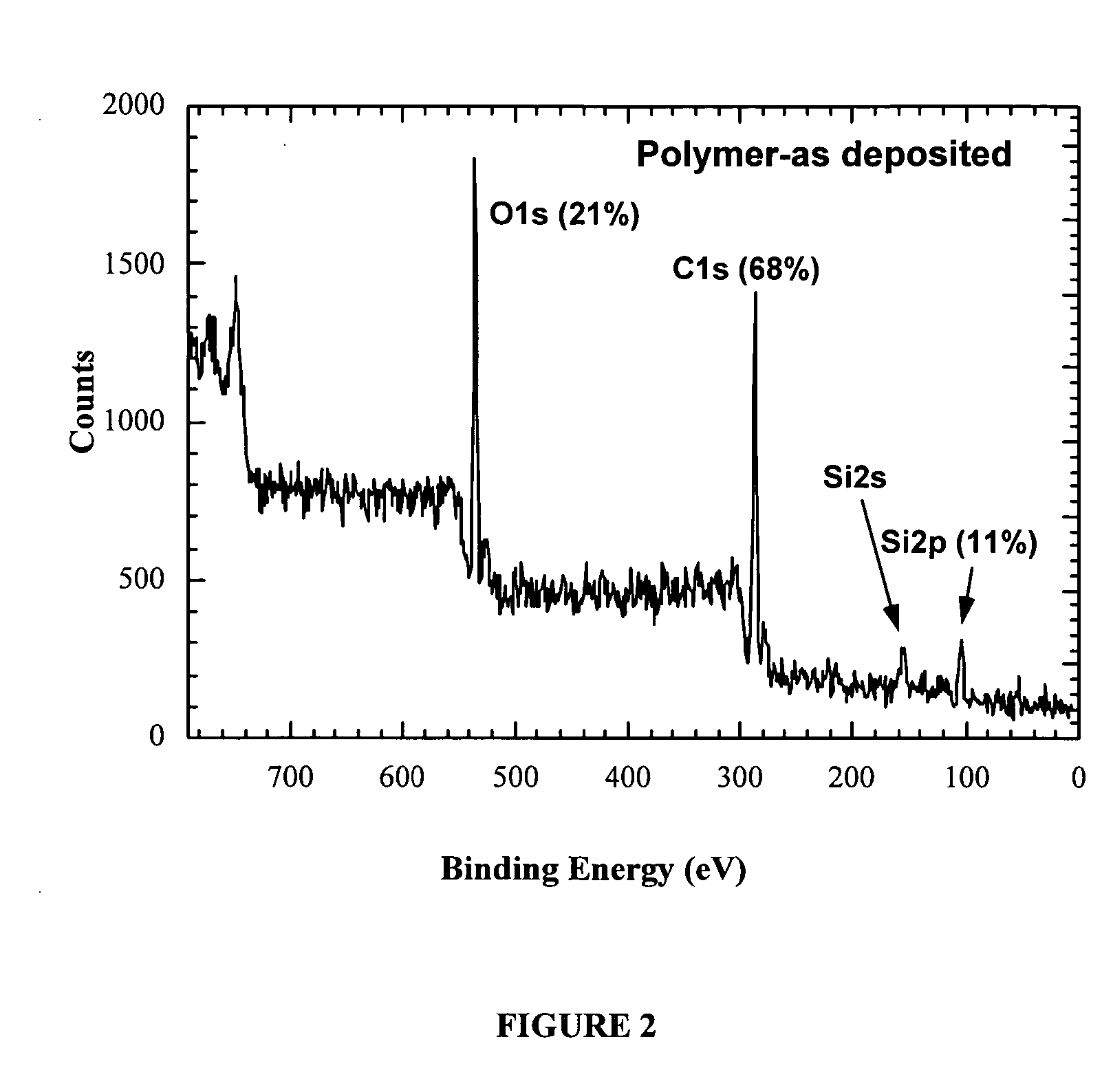

Chemical treatment of material surfaces

InactiveUS20050239295A1Lower contact angleImprove adhesionPrinted circuit assemblingSemiconductor/solid-state device manufacturingChemical treatmentSemiconductor structure

A method for treating the surfaces of materials to improve wettability and adhesion of subsequently deposited polymer layers is disclosed. Suitable materials for practice of the method include polymeric materials and silicon-containing materials is disclosed. The method involves contacting at least a portion of the surface of the material with an aqueous solution of sulfuric acid or phosphoric acid, followed by rinsing with water. After the acid treatment, the contact angle of the surface decreases, and subsequently deposited polymer coatings easily wet the material's surface and exhibit enhanced adhesion. The method may be used to fabricate useful structures, such as semiconductor structures, optical waveguide structures, and coated articles.

Owner:POLYSET +1

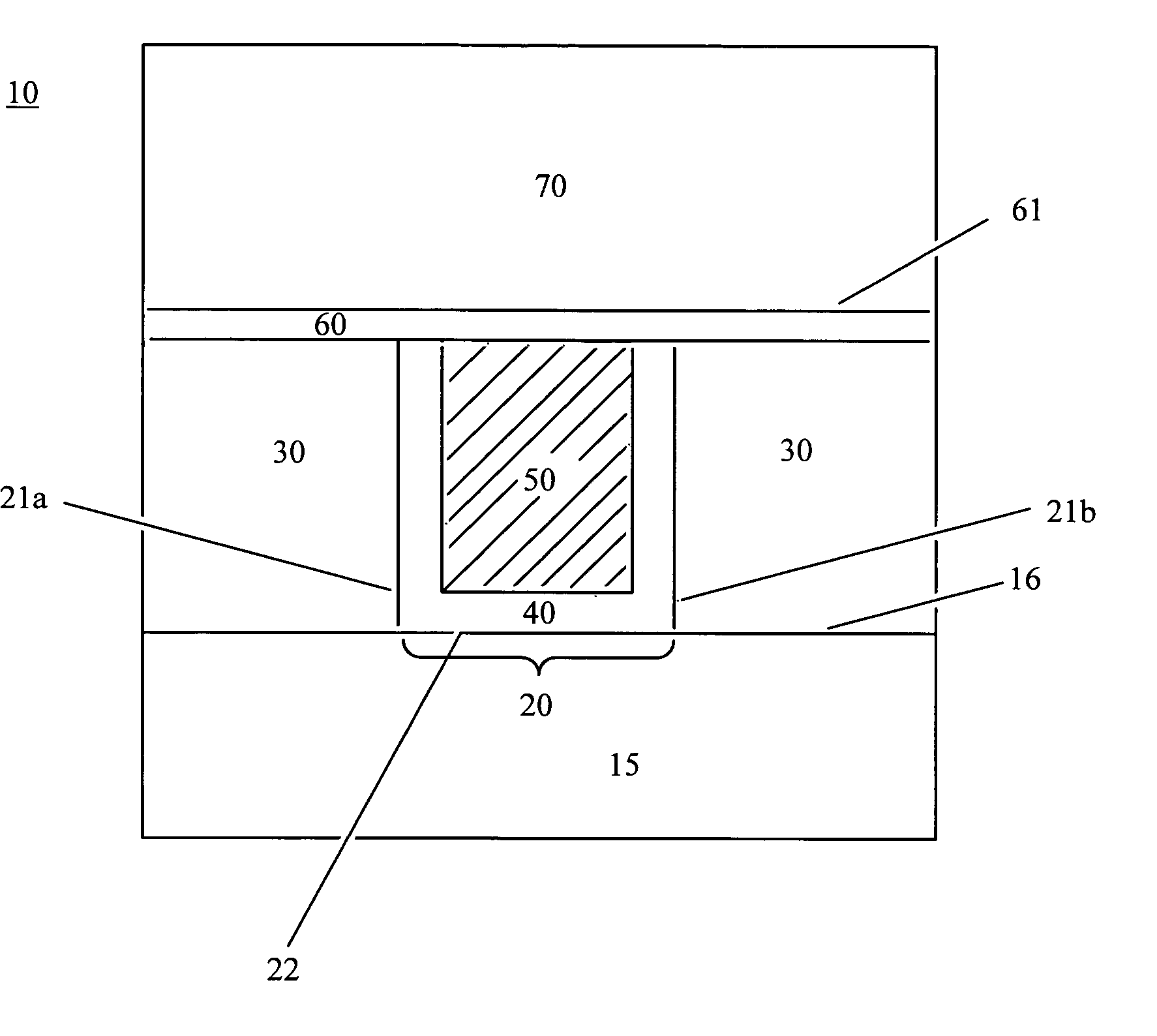

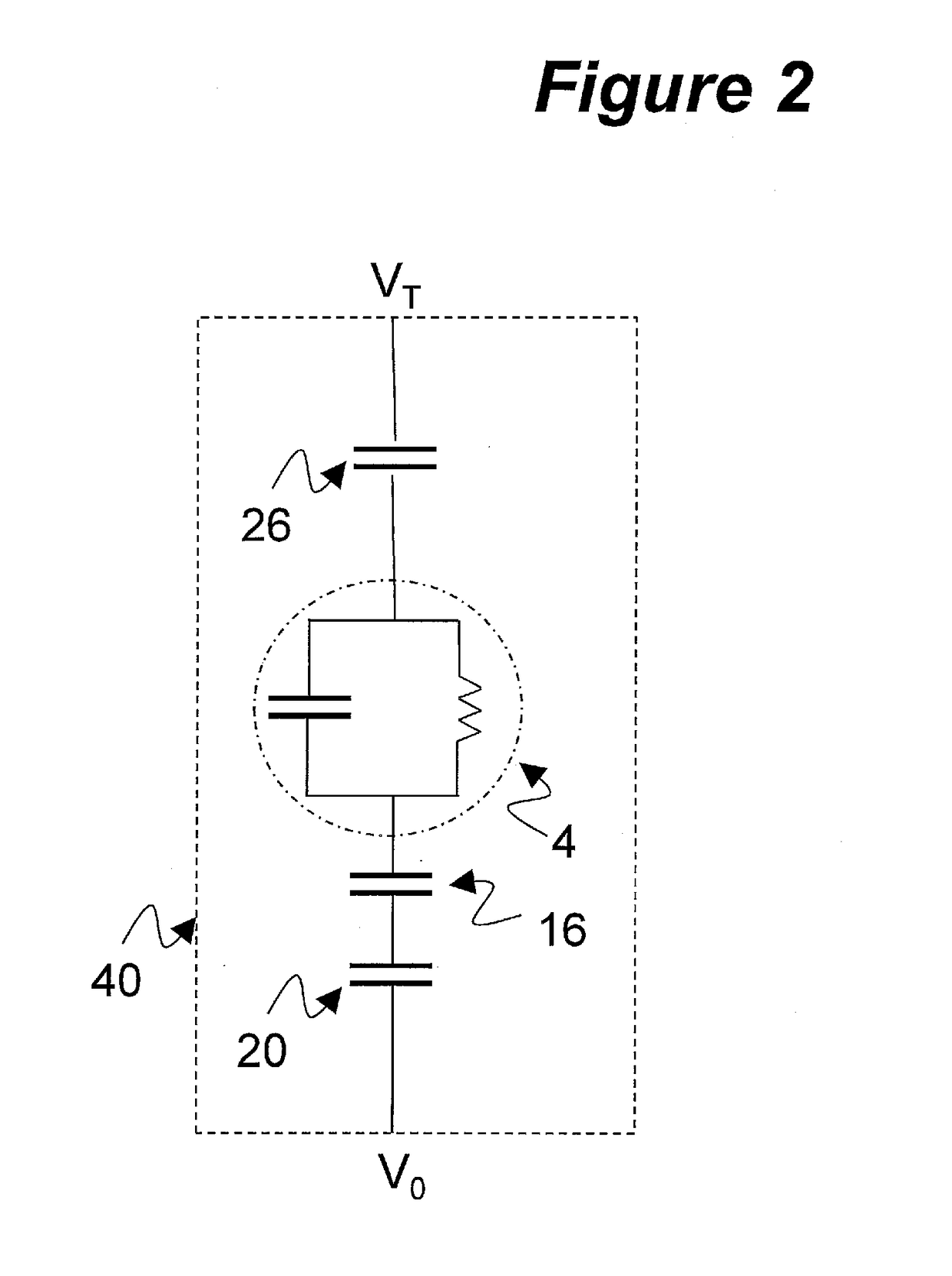

A method of driving an active matrix electro-wetting on dielectric device and an active matrix electro-wetting on dielectric device

ActiveUS20180078934A1Minimizes physical sizeMinimizing size of whole arrayCellsStatic indicating devicesDielectricElectricity

A method of driving an active matrix electro-wetting on dielectric (AM-EWOD) device comprises (i) setting a reference electrode to a first reference voltage; (ii) writing a set of data to array element electrodes of array elements of the device; and (iii) either (a) maintaining the voltages written to the array element electrodes until a time t0 or (b) re-writing the set of data N−1 times (where N≧2). The reference electrode is then set to a second reference voltage different from the first reference voltage, and features (i) to (iii) are repeated. When the data are first written, there is a delay between the time when the voltage on the reference electrode is transitioned and the time when a given array element is next written with data. Feature (iii) allows the time for which the correct data values are held to be increased relative to the time for which incorrect data values may possibly be held, so that the time for which an element may be in an incorrect state can be made insignificant in terms of its effect on unwantedly perturbing droplet operations.

Owner:SHARP LIFE SCI EU LTD

Wet wipe having a stratified wetting composition therein and process for preparing same

InactiveUS20080145664A1Maximize useEconomical and less-expensiveCosmetic preparationsLighting and heating apparatusFiberEmulsion

The present invention generally relates to a wet wipe or sheet that is suitable for contacting the skin and that has a stratified wetting composition therein. More specifically, the present invention related to a wet wipe, which may optionally be an ion-triggerable, water-disintegratable wipe, wherein the organic phase, and more particularly one or more components of the organic phase, of the wetting composition is concentrated near the surface of the wipe, and the aqueous phase of the wetting composition is concentrated in the bulk of the wipe. The present invention is further directed to a number of processes for preparing such a wet wipe. For example, in one embodiment an emulsified wetting composition is applied to a fibrous substrate of the wet wipe, and then treated to destabilize the emulsion. In an alternative embodiment, an emulsified wetting composition may be destabilized prior to it being applied to the fibrous substrate. As a result of the destabilization, the emulsion undergoes phase separation after being applied to the fibrous substrate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Black pigment ink for ink-jet printer and method for preparing the same

The invention provides a black ink for ink-jet printers, which comprises 10-30% of carbon black, 0.1-1.25% of amphiprotic polymerized substance, 0.1-1.5% of levelling agent, 10-30% of wetting agent, 0.05%-0.5% of defoaming agent and deionized water, 20-33% of carbon black dispersion liquid, 0.05-2% of surface active agent, 5-50% of humectant, 0.1-2% of pH regulator, 0.5-2% of drier, 0.1-0.5% of preservative agent, 0.1-0.5% of mold preventive, 0.01-0.5% of chelating agent, 0.1-2% of resin and deionized water.

Owner:大连思创信息材料有限公司

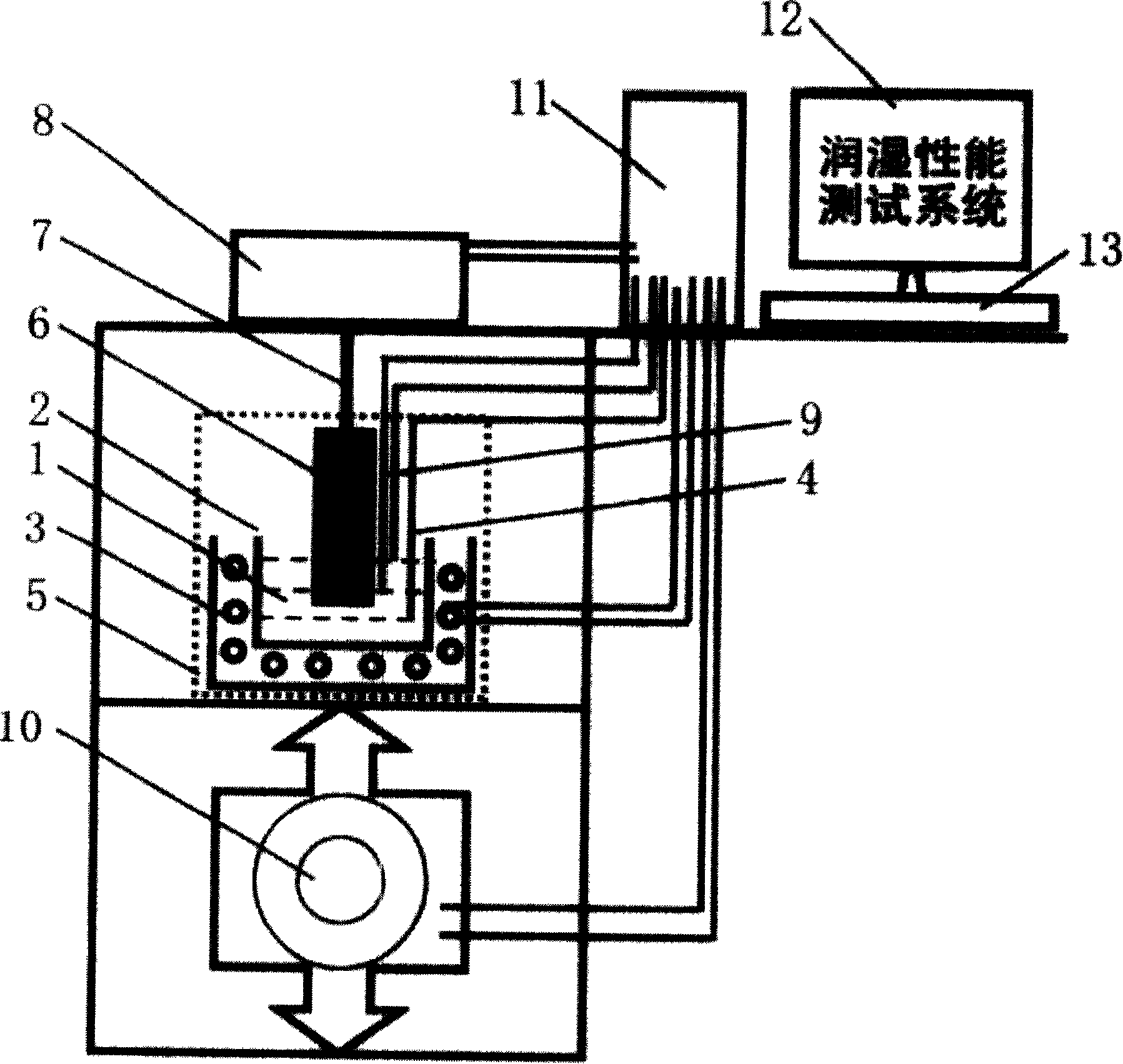

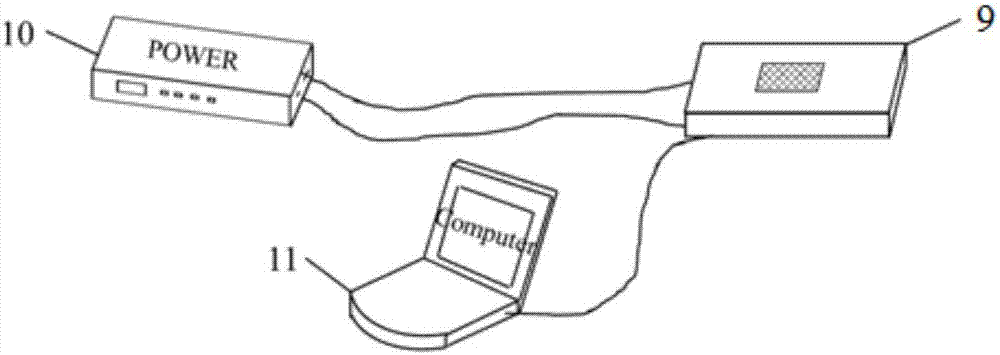

Dynamic testing method and system for wetting property

The invention provides a method for dynamically testing wettability and the testing system thereof, relates to a method for testing the wettablity of the solder, metal, ceramic, composite materials and fiber and the testing system thereof and belongs to the material performance detecting method and the detecting equipment thereof technical field, which comprises the wetability dynamic testing method, wetability dynamic testing software, an automatically controlled system (computer), a heating (cooling) system, a suspension system, a force testing balance system and a height adjusting hoist system. The method for dynamically testing wettability and the testing system thereof provided by the invention is capable of performing dynamic evaluation on the wetability of solder, the weldability of metals, ceramic and composite materials and the wetability of fiber to solution, and is capable of measuring the total wetting time.

Owner:廖树帜

Composition for providing a non-wettable coating, articles coated therewith, and methods for preparing the same

A heat-settable composition for a coating which is hydrophobic, oleophobic and resistant to abrasion, wherein the coating contains a hydrolyzate obtained from a solution of:one or more epoxidized alkoxysilane having alkoxy groups which are directly linked to the silicon atom;a hydrolyzable, non-epoxidized silane;colloidal silica;a catalyst which promotes cleavage of an epoxy bond; andat least one fluorinated hydrolyzable alkylsilane; and the use of the heat-settable composition in the preparation of a coated substrate of organic glass or mineral glass material, coated with a coating obtained from the heat-settable composition, with the substrate preferably being a pane (comprised of glass or a polymeric material) or an ophthalmic lens.

Owner:SAINT-GOBAIN GLASS FRANCE

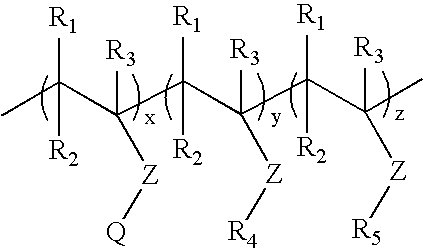

Method for Chemically Modifying the Internal Region of a Hair Shaft

InactiveUS20120180807A1Low variabilitySimplification of processCosmetic preparationsHair removalMonomer compositionMedicine

A method for chemically modifying the internal region of a hair shaft. The method comprises applying an oxidising formulation to the hair; de-wetting the hair; applying a monomer composition to the hair, wherein the monomer composition comprises an ethylenic monomer having a molecular weight of 500 g / mole or less and a cosmetically acceptable carrier. Also a kit which comprises: application instructions comprising the method; and the monomer composition.

Owner:THE PROCTER & GAMBLE COMPANY

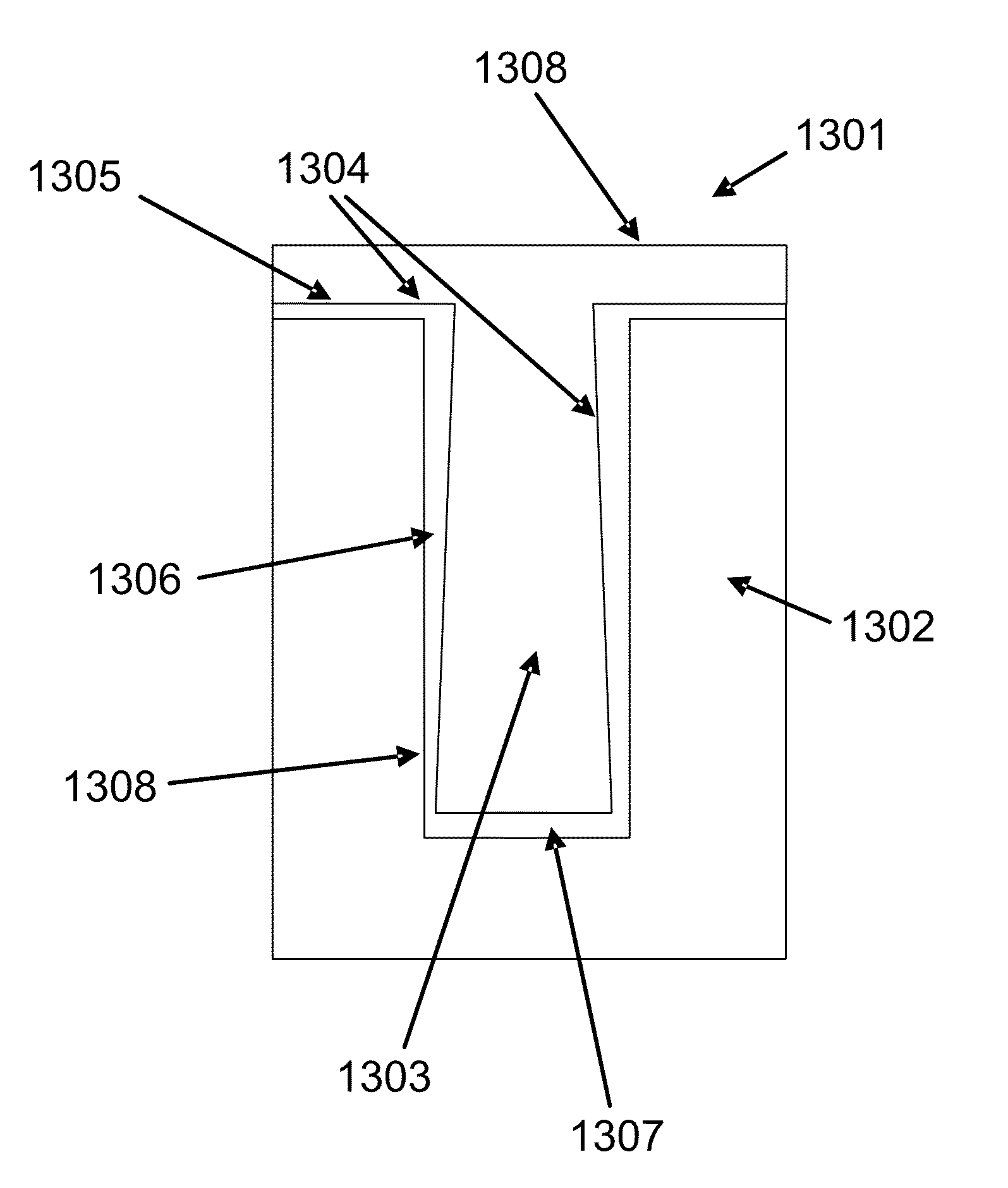

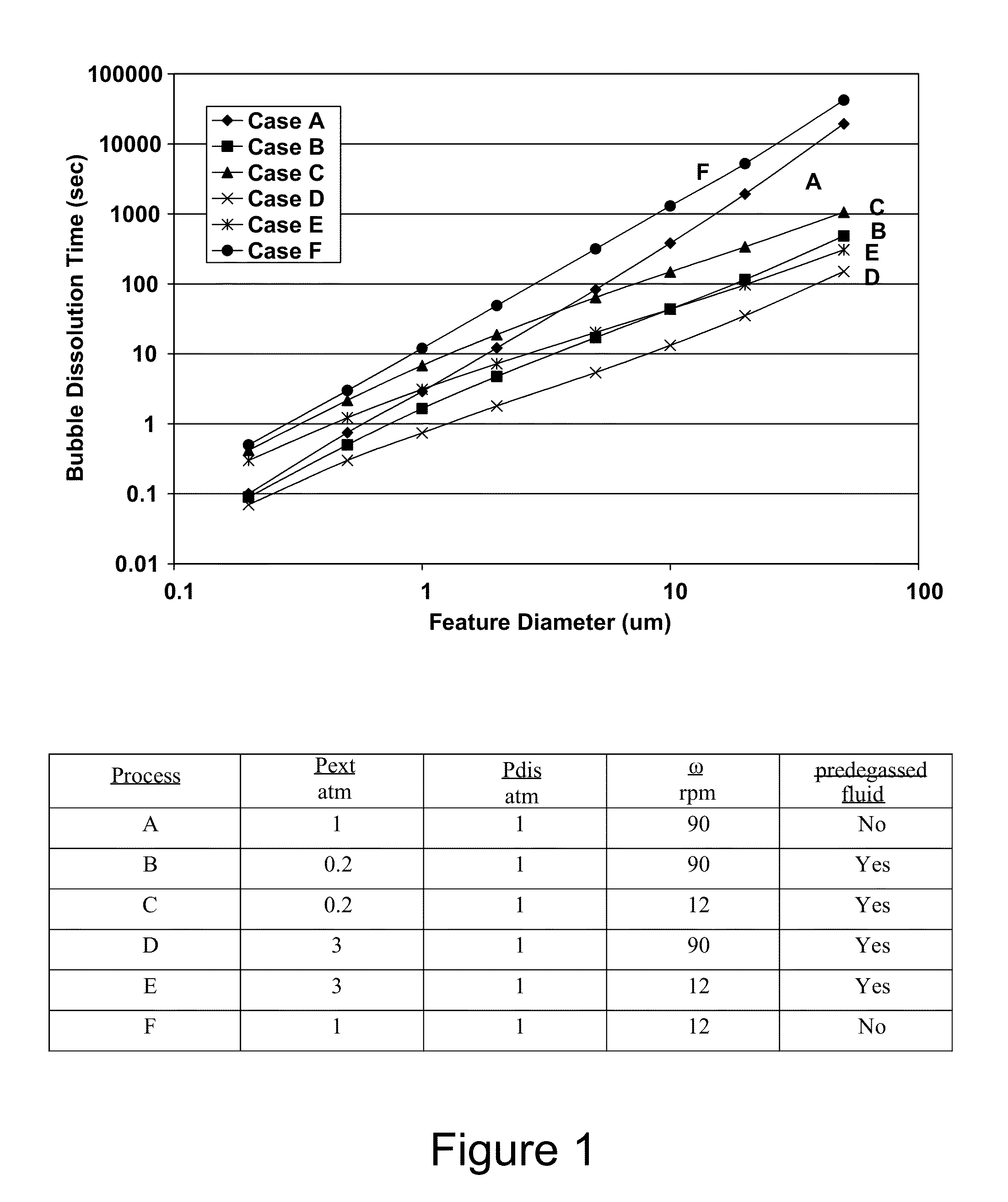

Wetting pretreatment for enhanced damascene metal filling

Disclosed are pre-wetting apparatus designs and methods. These apparatus designs and methods are used to pre-wet a wafer prior to plating a metal on the surface of the wafer. Disclosed compositions of the pre-wetting fluid prevent corrosion of a seed layer on the wafer and also improve the filling rates of features on the wafer.

Owner:NOVELLUS SYSTEMS

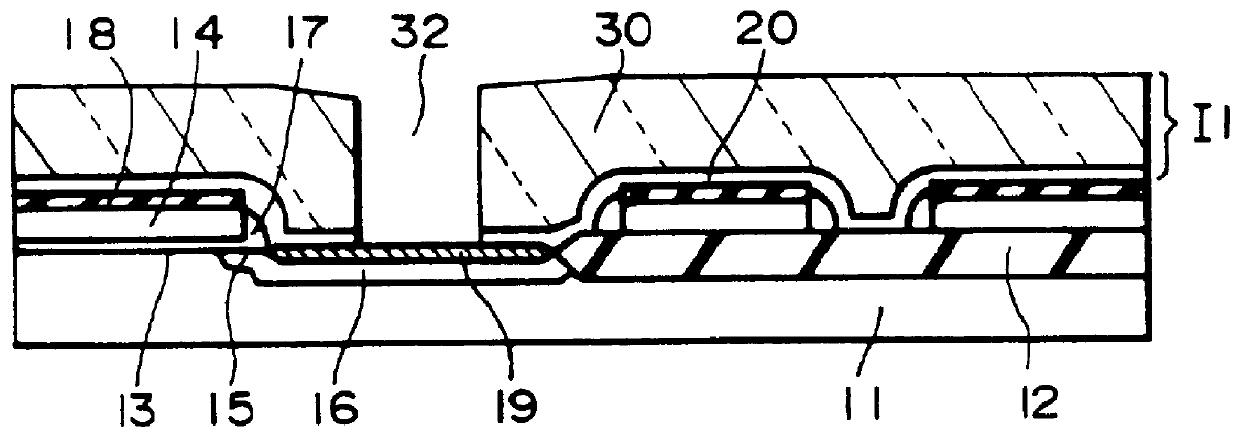

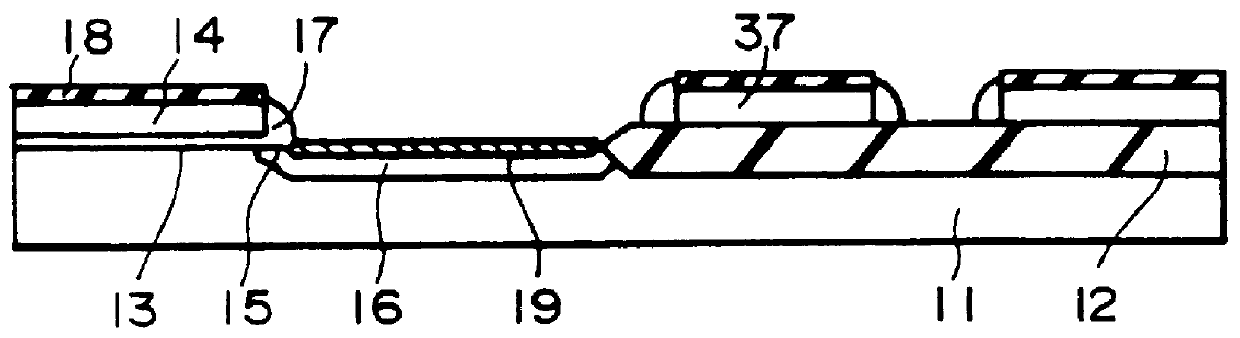

Semiconductor device and method of fabricating the same

InactiveUS6107182ASuppress generationReduce in quantitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingDielectricSemiconductor

A semiconductor device having a contact structure that can exhibit superlative step coverage without causing voids or wiring discontinuities, using aluminum or aluminum alloys as a conductive substance for via-holes. A method of fabricating the semiconductor device comprises, for at least one layer of wiring regions above the first wiring region on a semiconductor substrate, the following steps (a) to (f): (a) a step of forming a via-hole in a second interlayer dielectric formed above the first wiring region on a semiconductor substrate; (b) a degassing step for removing gaseous components included within the interlayer dielectric by a heat treatment under reduced pressure and at the substrate temperature of 300 DEG C. to 550 DEG C.; (c) a step of forming a wetting layer on the surface of the interlayer dielectric and the via-hole; (d) a step of cooling the substrate to a temperature of no more than 100 DEG C.; (e) a step of forming a first aluminum layer comprising one of aluminum and an alloy in which aluminum is the main component on the wetting layer at a temperature of no more than 200 DEG C.; and (f) a step of forming a second aluminum layer comprising one of aluminum and an alloy in which aluminum is the main component on the first aluminum layer at a temperature of at least 300 DEG C.

Owner:SEIKO EPSON CORP

Ultrafine fluid jet apparatus

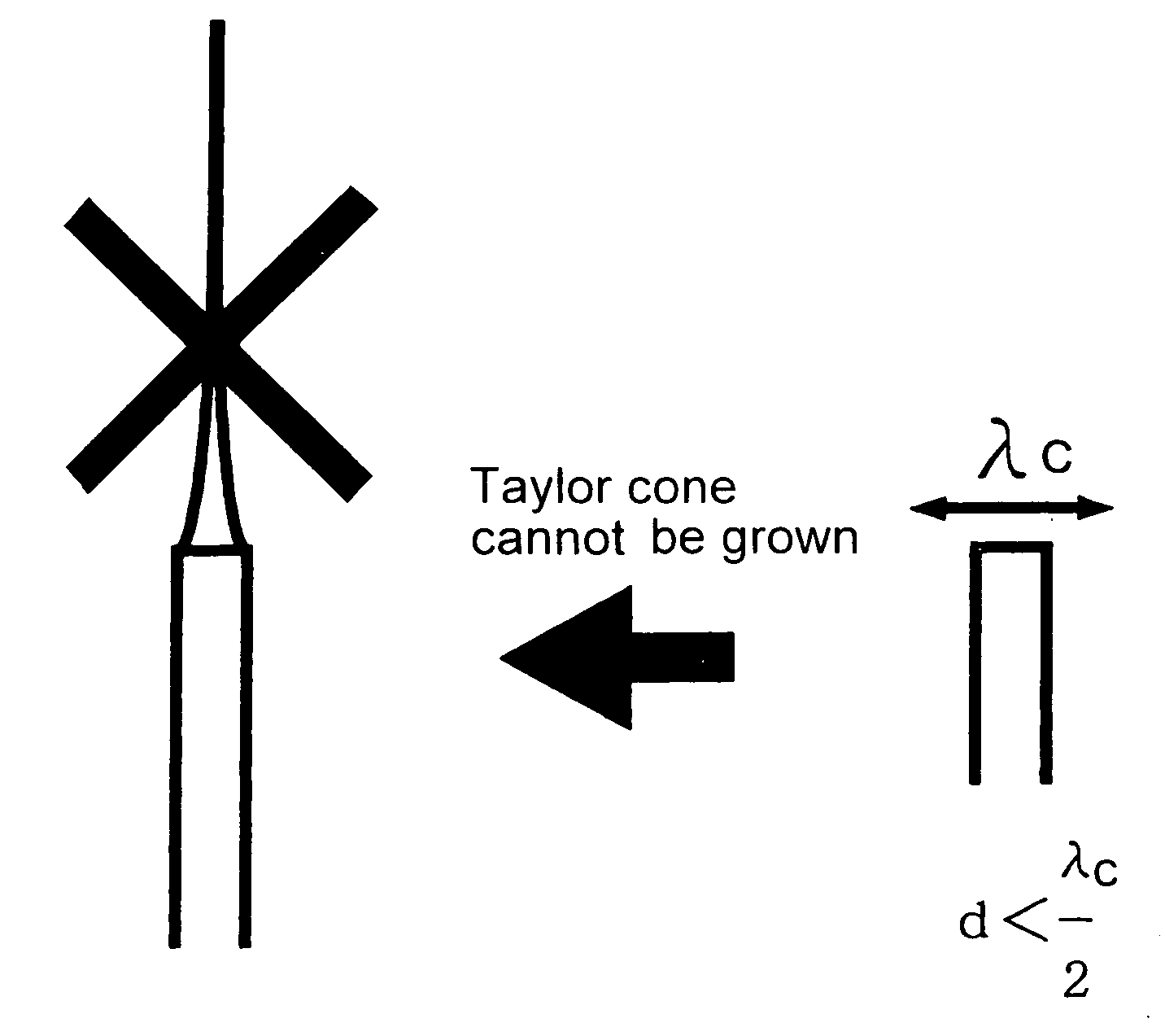

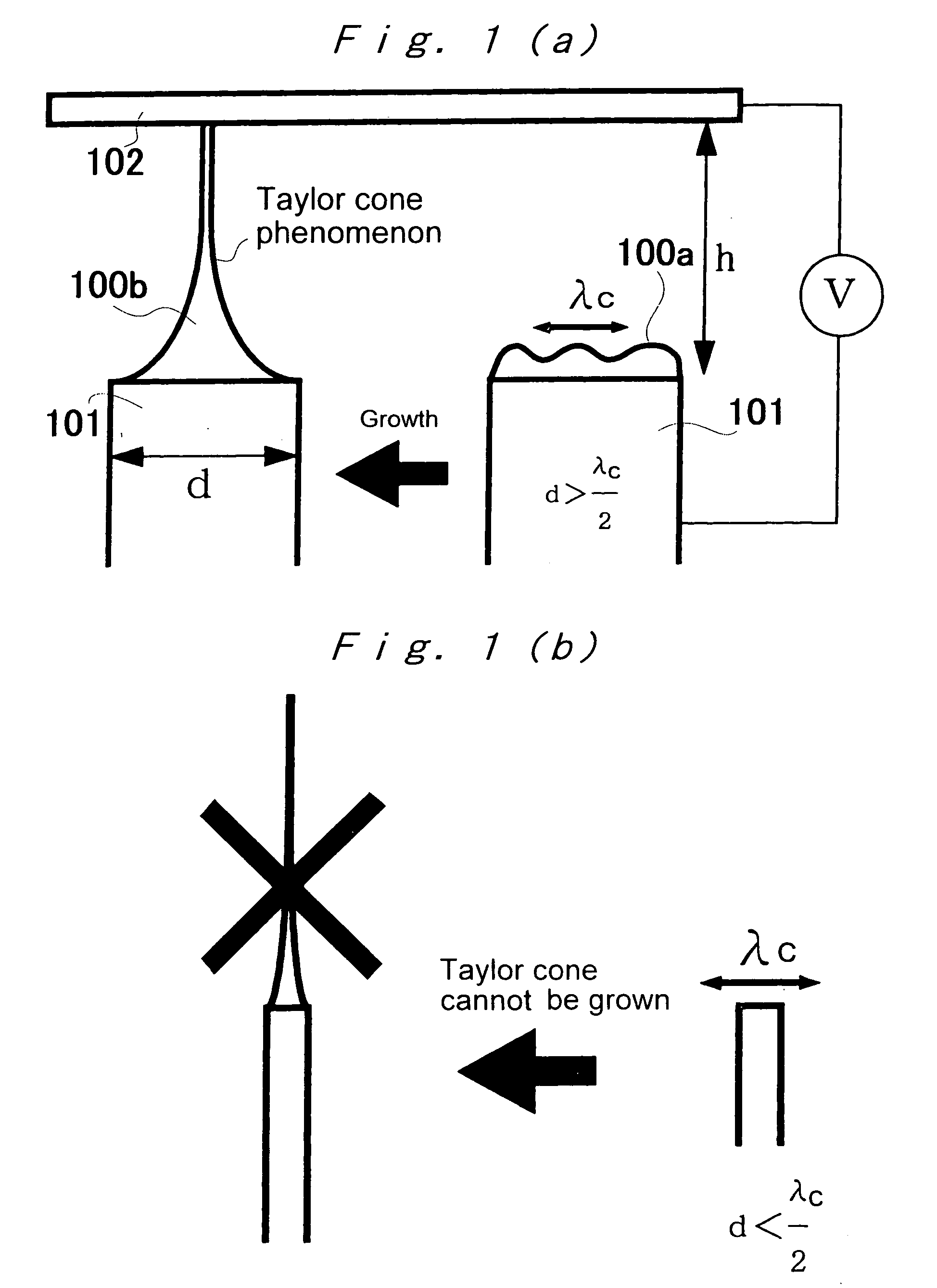

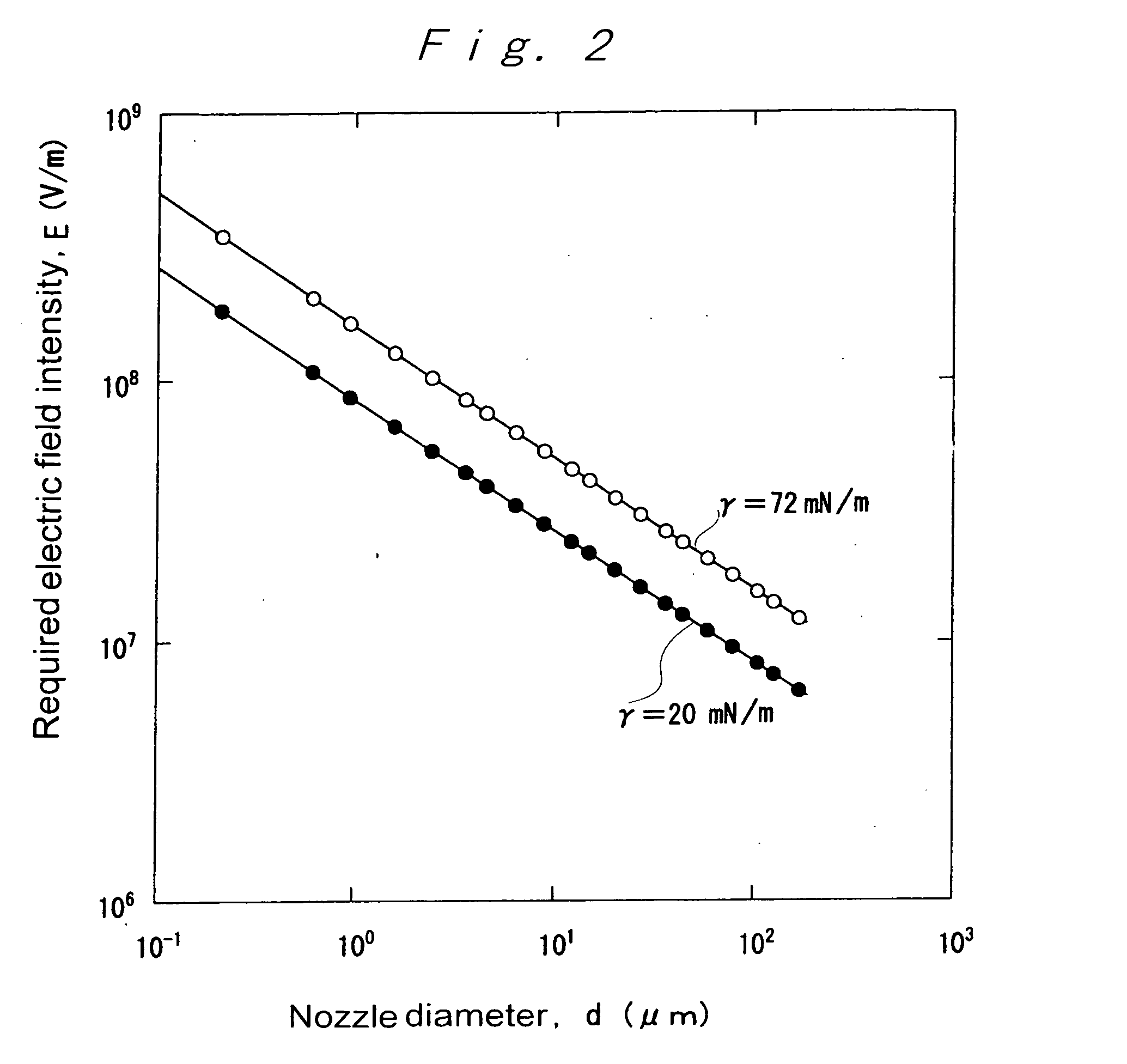

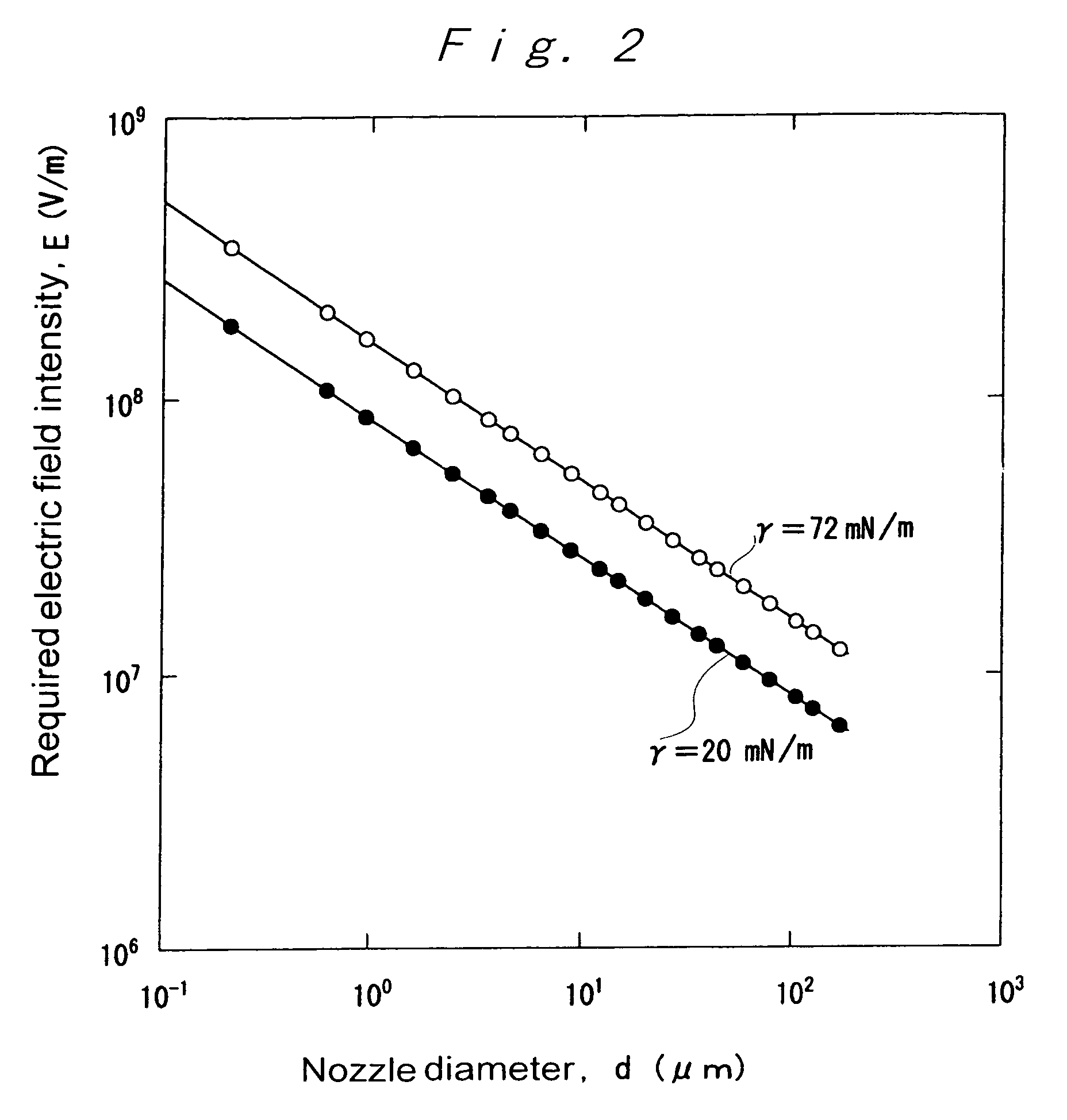

ActiveUS20050116069A1Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEvaporation

An ultrafine fluid jet apparatus comprising a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

Arrangement and method for degassing small-high aspect ratio drilled holes prior to wet chemical processing

InactiveUS6626196B2Electrostatic cleaningLiquid/solution decomposition chemical coatingCopper platingEngineering

An arrangement and method for the degassing small high-aspect ratio drilled holes or vias which are present in panels such as printed circuit boards prior to wet chemical processing, including copper plating of the vias, in order to remove any air or gas bubbles from the vias tending to inhibit the reliable plating thereof. This is carried out through the utilization of an ultrasonic prewetting in a liquid bath preceding cleaning for the electroless plating process, thereby enabling all of the vias or holes to be degassed; in effect, having air removed and the vias or holes filled with liquid; thereby allowing subsequent process cleansing solutions to easily flow into the respective holes or vias in order to facilitate the electroless copper plating process.

Owner:GOOGLE LLC

Micro-fluidic chip based on SERS detection, preparation method and application thereof

ActiveCN105854964AHigh sensitivityHigh repetitionRaman scatteringLaboratory glasswaresMicro fluidicMicrofluidic chip

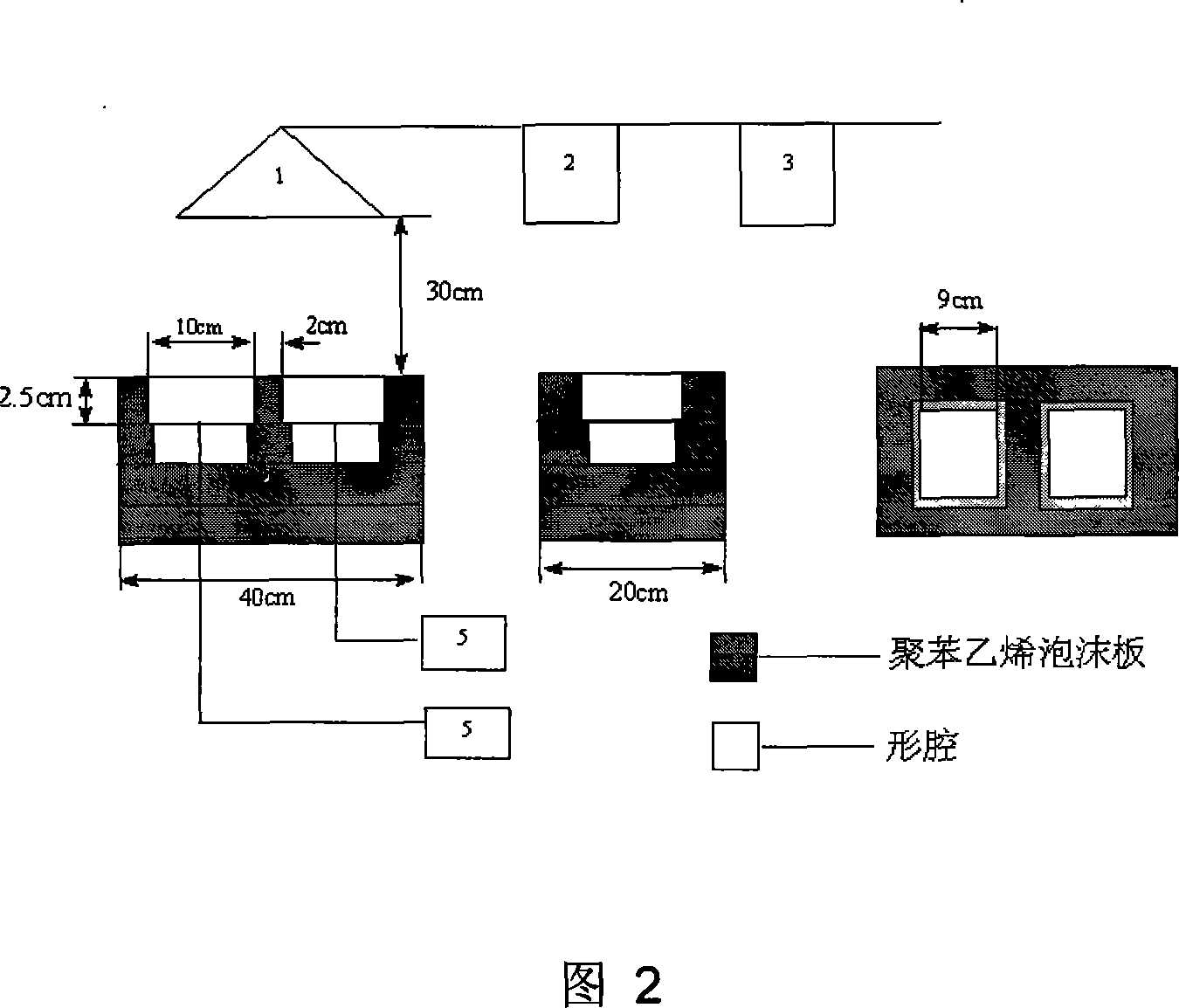

The invention relates to a micro-fluidic chip based on SERS detection, a preparation method and an application thereof. The preparation method comprises the steps of preparing a super-hydrophobic titanium dioxide solution, preparing a substrate with a super-hydrophobic layer and preparing a chip, wherein the chip comprises the substrate and a T-shaped runner arranged on the surface of the substrate; the interior of the runner is super-hydrophilic and the exterior of the runner is super-hydrophobic; two ends of a cross runner of the T-shaped runner are used as two runner inlets; a detection area is arranged at the tail end of a vertical runner; super-hydrophobic micro-patterns are distributed in the cross runner of the T-shaped runner; the micro-patterns are divided into a plurality of areas from two ends to the center; the intervals of the super-hydrophobic patterns in each area are equal to each other; the pattern interval gradient between area and area along the direction from two ends to the center is increased; a wetting gradient from lyophobic state to hydrophilic state is formed in the cross runner from two ends to the center; the vertical runner is designed as a wedge-shaped runner. The micro-fluidic chip based on SERS detection has the beneficial effects that the surface wetting gradient and the wedge-shaped structure runner are combined for realizing the automatic transportation of drop to the detection area and the cost of micro-fluid driving is greatly reduced.

Owner:ZHEJIANG UNIV OF TECH +1

Ultrafine fluid jet apparatus

ActiveUS7434912B2Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEngineering

An ultrafine fluid jet apparatus including a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

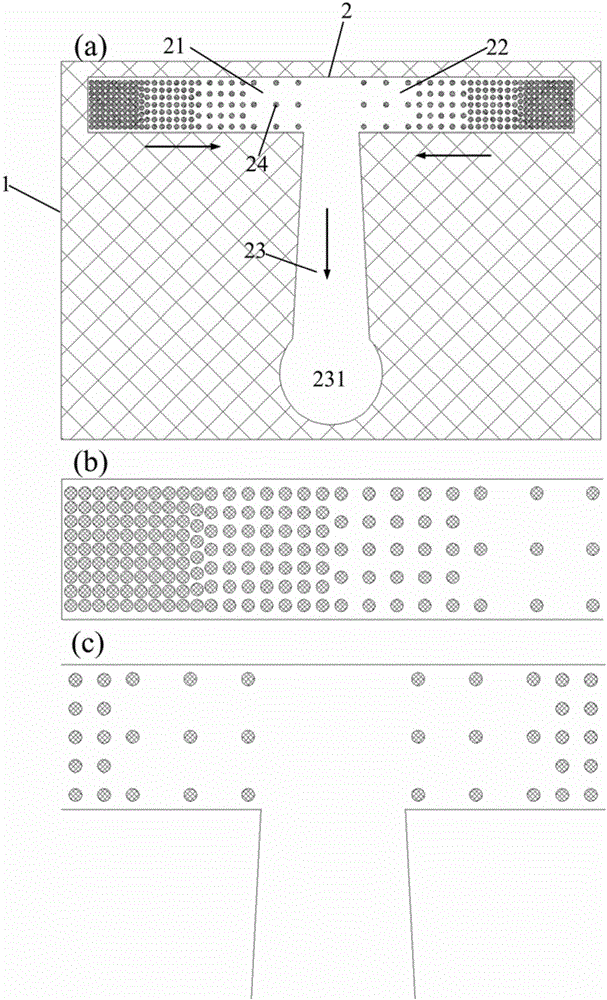

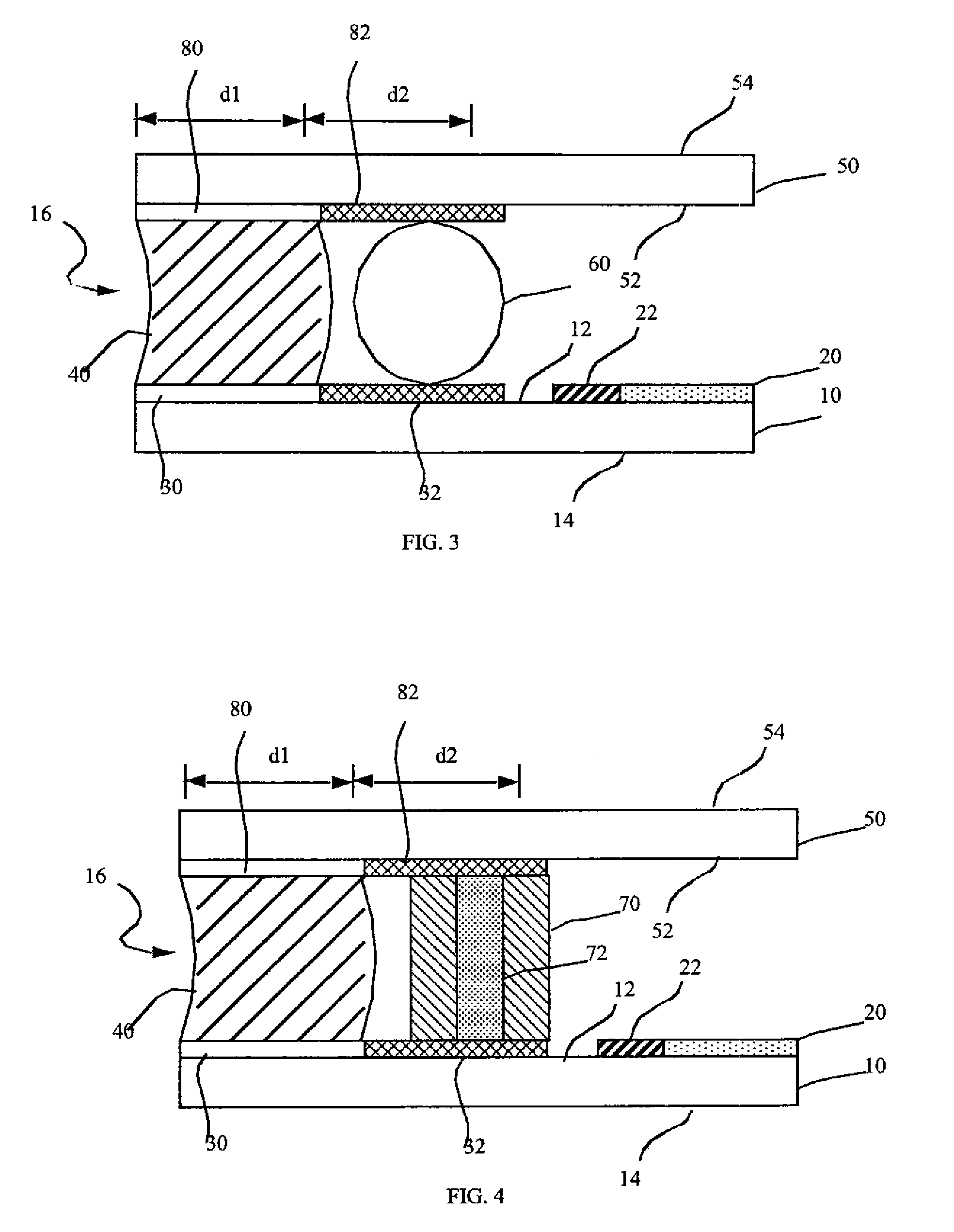

Liquid drop mixing unit based on electro-wetting digital micro-fluid chip

InactiveCN102836653AHigh-speed automatic transport mixingEasy to integrateFlow mixersMixing methodsElectricityFluidics

The invention belongs to the technical field of digital micro-fluidics, and in particular relates to a liquid drop mixing unit based on an electro-wetting digital micro-fluid chip. The mixing unit comprises three parts consisting of an inlet zone, a mixing zone and an outlet zone; the fast, high-efficiency, automatic and reliable mixing of the liquid drops can be realized via the special bidirectional driving electrode and closed-loop electrode arrangement and simplified electrode connection mode. The liquid drop mixing unit has the advantages of novel design, easiness in control, high reliability, excellent practicability, high automation degree, and the like, so that the liquid drop mixing unit can be widely used in various digital micro-fluid chips.

Owner:FUDAN UNIV

Apparatus adapted for membrane-mediated electropolishing

InactiveUS7566385B2Generates virtually no waste productEfficient processingCellsSemiconductor/solid-state device manufacturingElectrolysisElectrical battery

This invention provides a membrane-mediated electropolishing apparatus for polishing and / or planarizing metal work-pieces. The work-piece is wetted with a low-conductivity fluid. The wetted work-piece is contacted with a first side of a charge-selective ion-conducting membrane, wherein the second side contacts a conductive electrolyte solution in electrical contact with a electrode. Current flow between the electrode and the work-piece electropolishes metal from the work-piece. This invention also provides a half-cell adapted for use in membrane-mediated electropolishing having a fully or partially enclosed volume, a conductive electrolyte which partially or essentially fills the enclosed volume, an electrode which is in contact with the electrolyte, and a charge-selective ion-conducting membrane which seals one surface of the enclosed volume, cavity or vessel in such a way that the internal surface of said membrane contacts the electrolyte solution or gel and the external surface is accessible to contact the work-piece.

Owner:EI DU PONT DE NEMOURS & CO

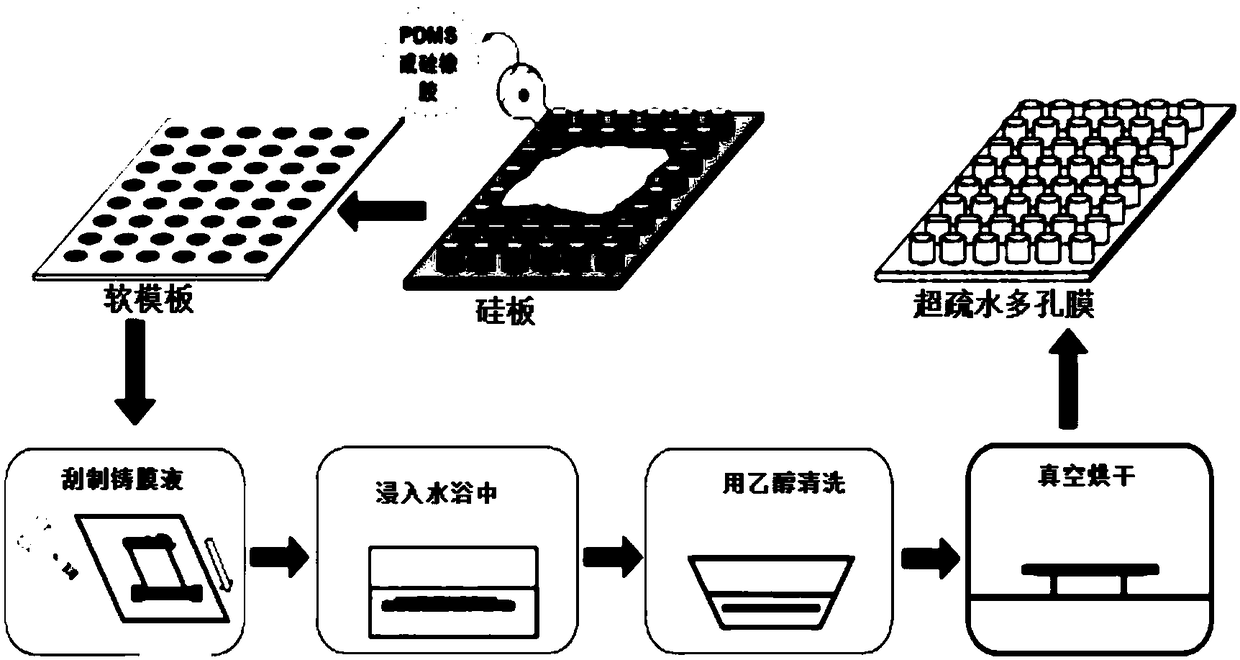

Super-hydrophobic porous membrane as well as preparation method and application thereof

InactiveCN108421418AImprove hydrophobicitySimple preparation processDistillationSalt resistanceWater baths

The invention discloses a super-hydrophobic porous membrane as well as a preparation method thereof. A micro molding technology and a phase separation technology are combined, a membrane scraping bottom plate on which a membrane casting solution is scraped is placed in a water bath at the preset temperature for phase separation membrane formation, a formed membrane material is stripped, and the super-hydrophobic porous membrane is obtained. The membrane scraping bottom plate is a grooved soft template produced with a reverse mold process, the super-hydrophobic porous membrane produced throughthe grooved soft template comprises micron-size surface bulges which are consistent in size and arranged regularly, and the distance between adjacent surface bulges is micron-sized. The surface morphology of the membrane material is reconstructed, the super-hydrophobic porous membrane with multiple scales is prepared while additional modifiers are not added, and the super-hydrophobic porous membrane can be applied to a membrane distillation technology, has the advantages of high hydrophobicity, pollution resistance, wetting resistance and the like and thus has high salt resistance, and a novelmembrane production technology is provided for industrialization of membrane distillation and is low in cost and prone to mass production.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

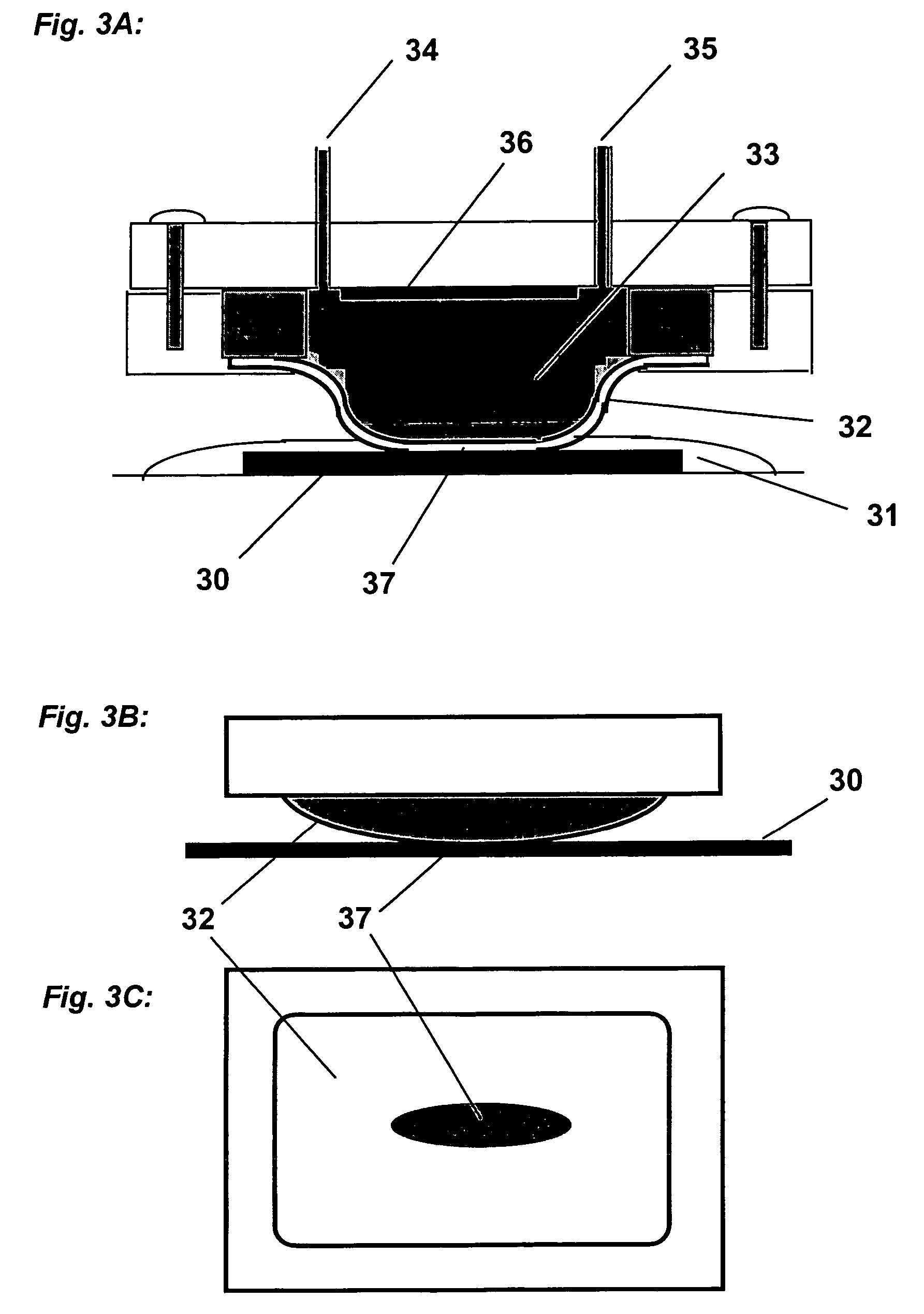

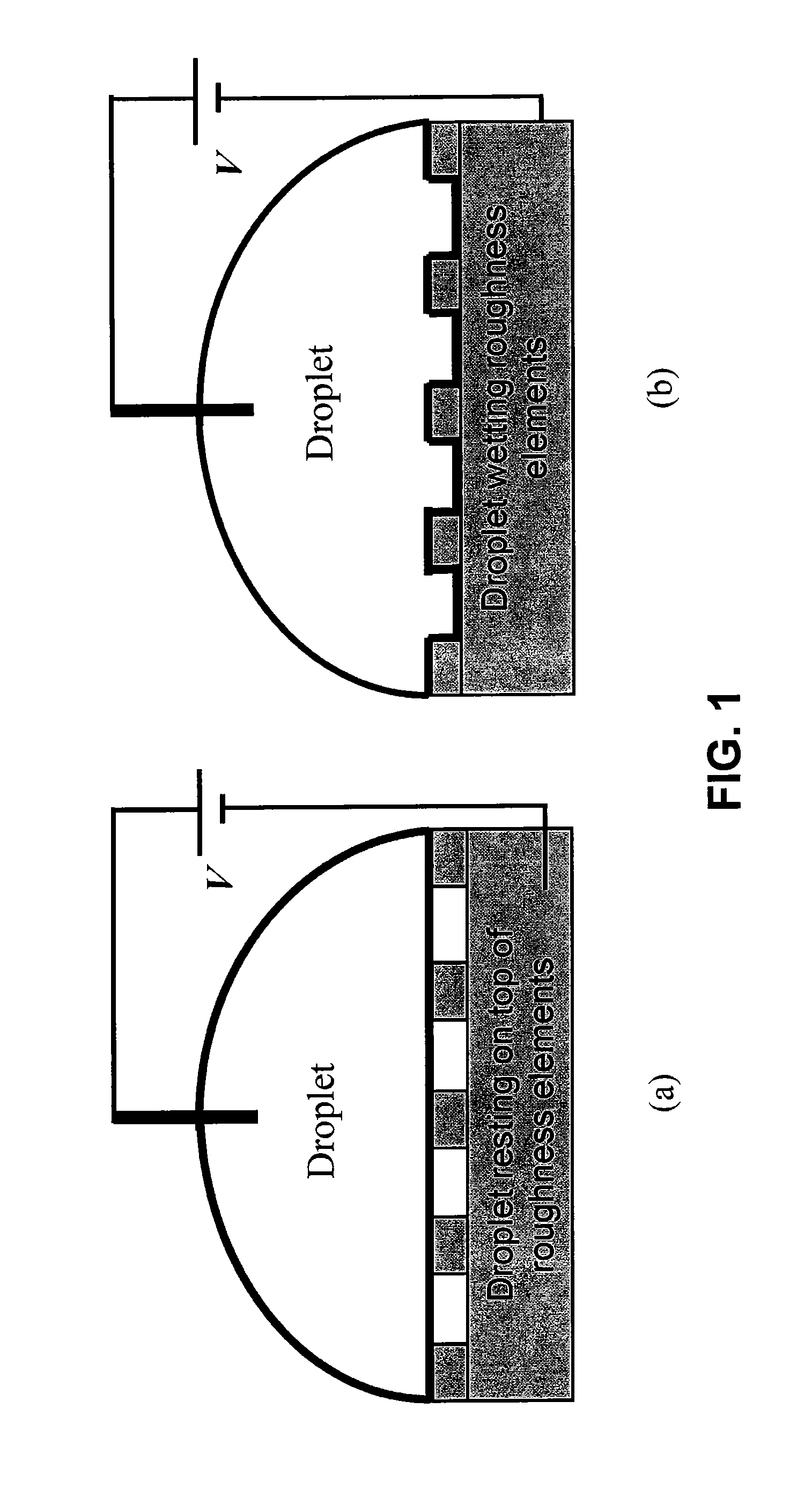

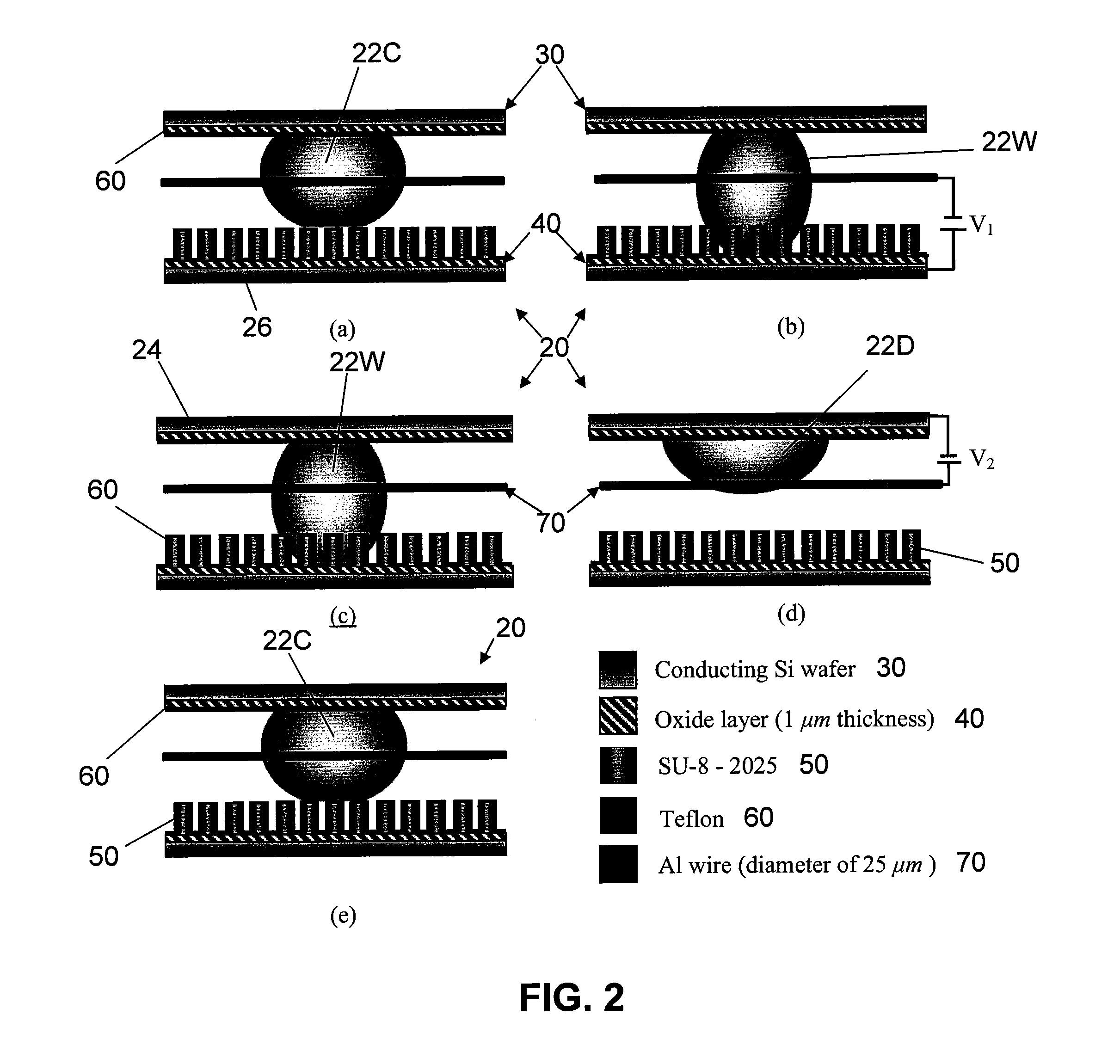

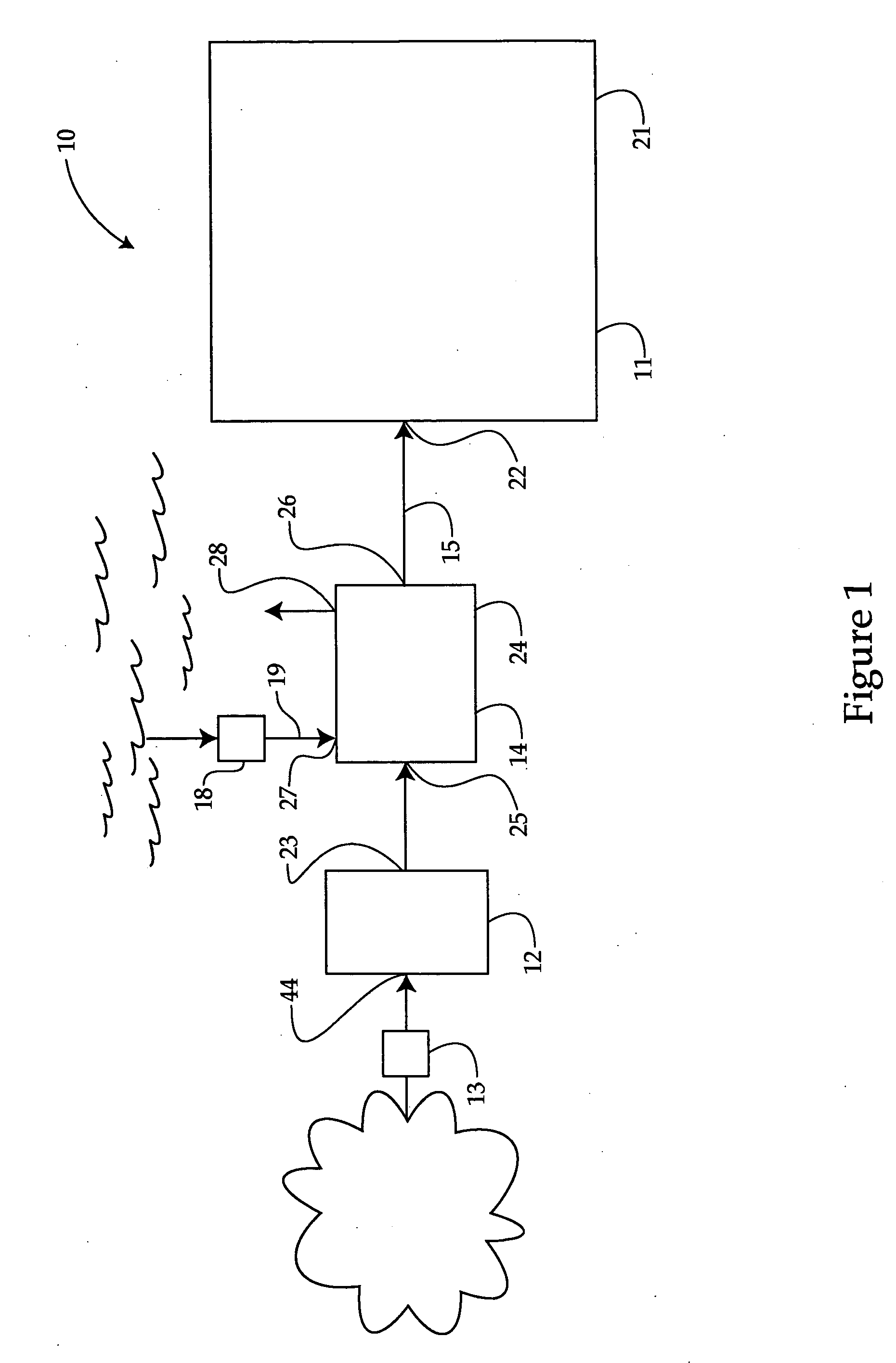

Controlled flow of a thin liquid film by electrowetting

InactiveUS20110303541A1Sludge treatmentVolume/mass flow measurementMechanical engineeringMaterials science

Owner:PURDUE RES FOUND INC

Method of producing metal to glass, metal to metal or metal to ceramic connections

A method of manufacturing metal to glass, metal to metal and metal to ceramic connections to be used in SOFC applications, said connections being produced as a mixture of a base glass powder and a metal oxide powder. As a result, the inherent properties of the glass used in the composite seals may be altered locally in the metal-coating interface by adding e.g. MgO in order to control the viscosity and wetting, and at the same time maintain the bulk properties such as high coefficient of thermal expansion of the basic glass towards the seal components.

Owner:DANMARKS TEKNISKE UNIV

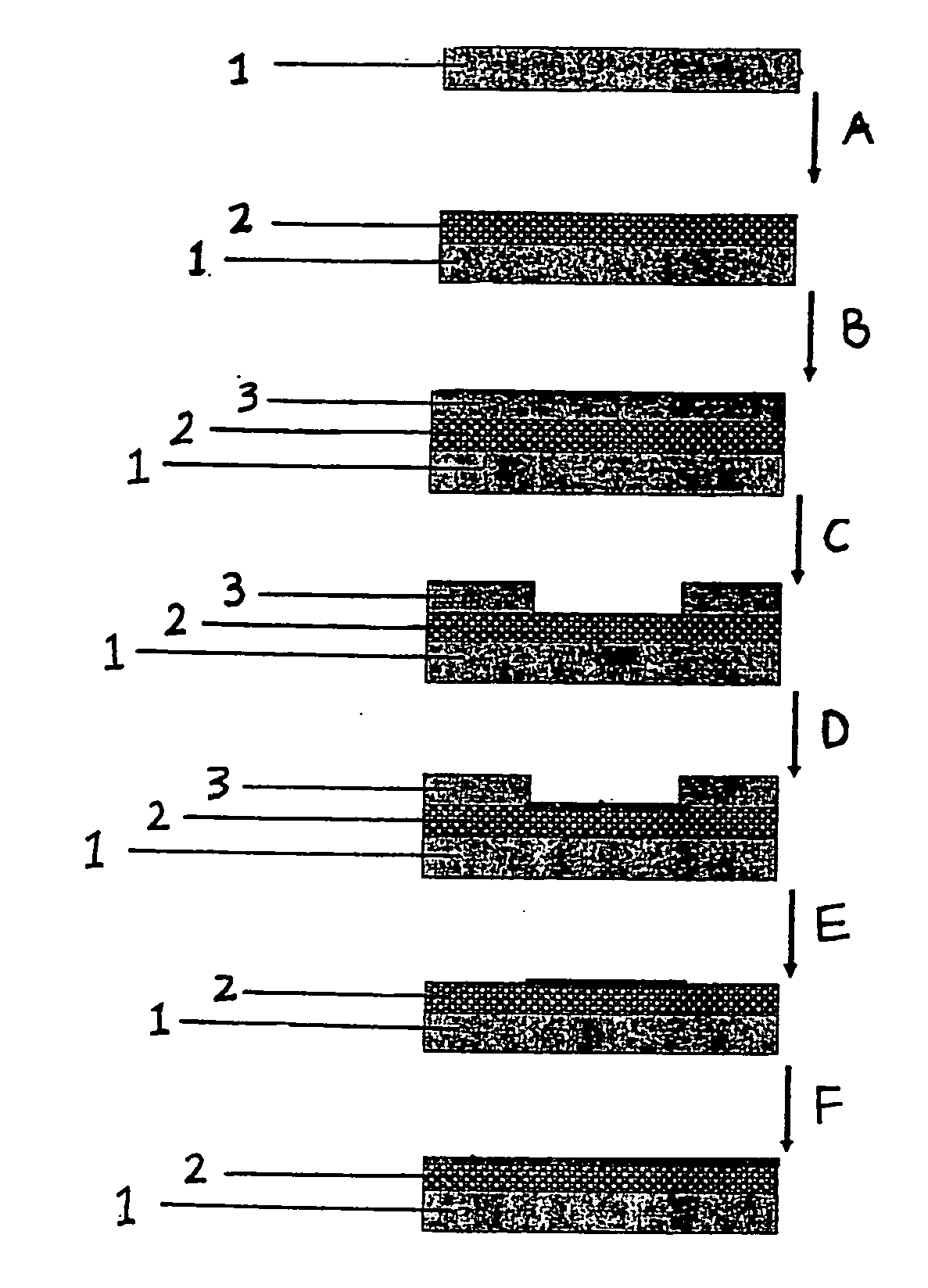

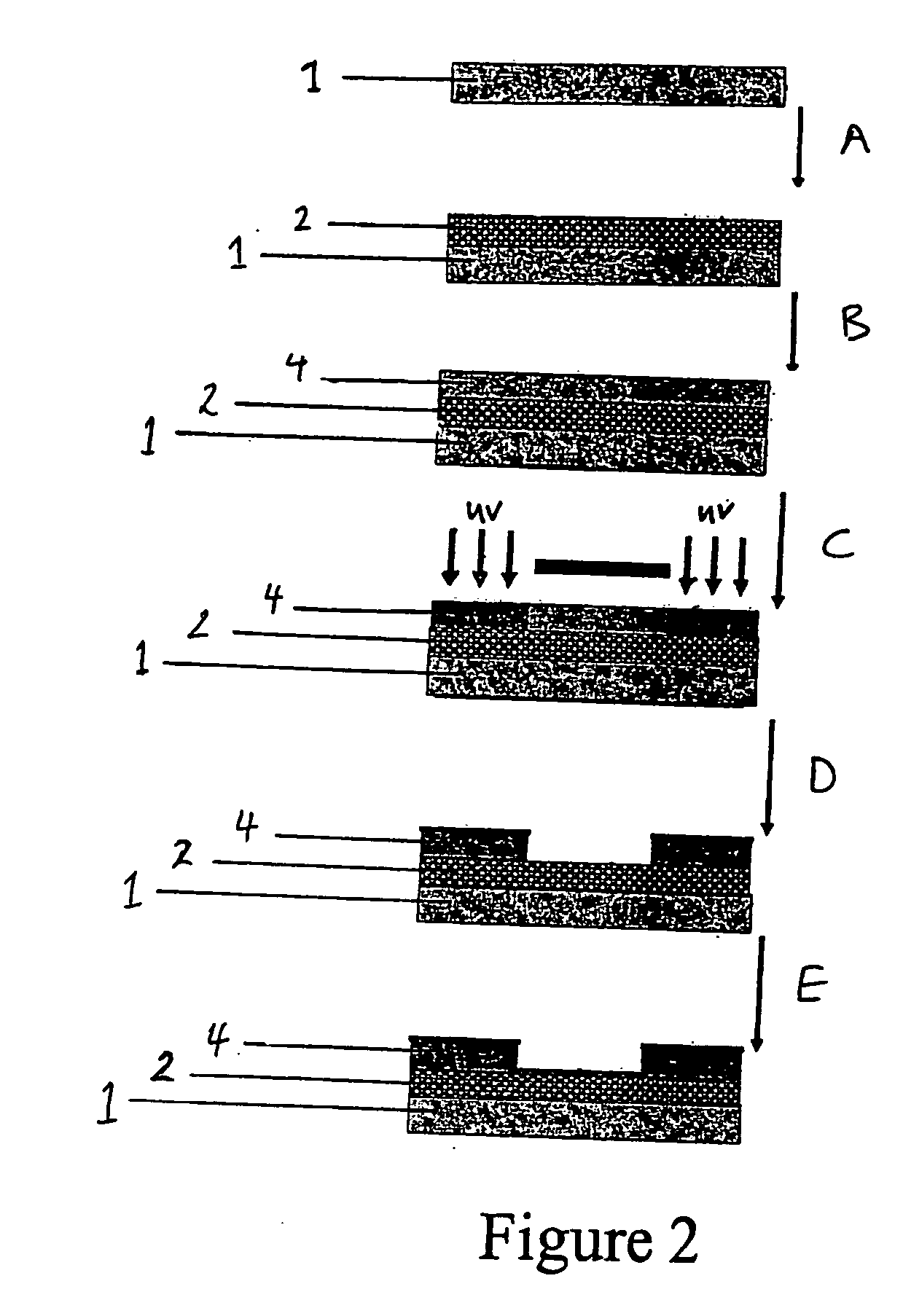

Method of producing a substrate having areas of different hydrophilicity and/or oleophilicity on the same surface

InactiveUS20070066078A1Wetting contrastSecure attachmentMaterial nanotechnologyFinal product manufactureElectronic componentInorganic materials

The present invention relates to flexible substrates having on their surface a wetting contrast. The wetting contrast comprises adjacent areas of different hydrophilicity and / or oleophilicity. The present invention further relates to methods of production of such substrates and to methods of producing microelectronic components wherein electronically functional material is deposited onto said substrates. According to a first aspect of the present invention, a method of producing a flexible substrate having a wetting contrast is provided. The method includes the step of forming a first area comprising an inorganic material on a flexible substrate precursor to form a substrate wherein the inorganic material is at least partially exposed at the substrate surface and the first area constitutes a pattern on the precursor surface.

Owner:SEIKO EPSON CORP

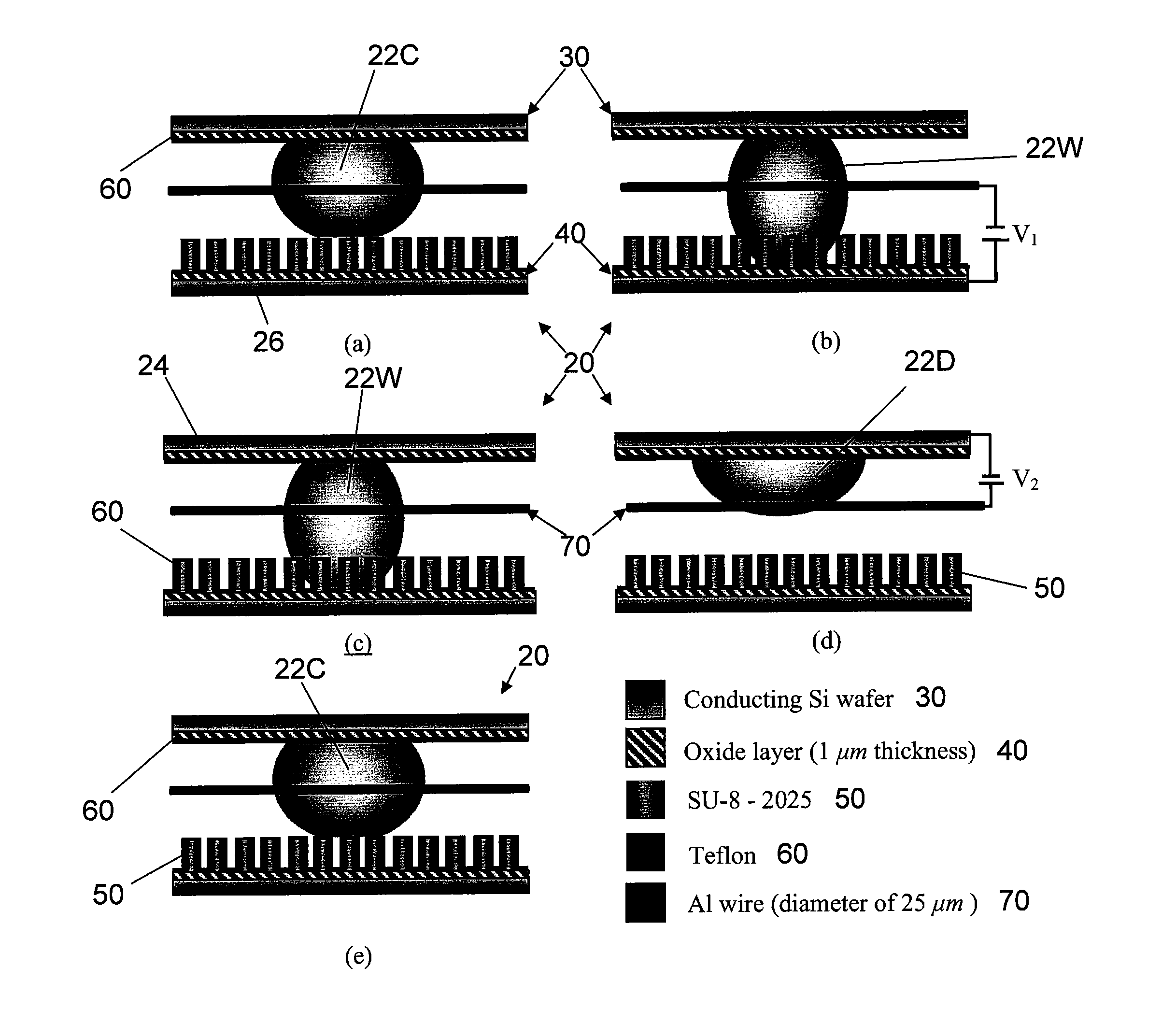

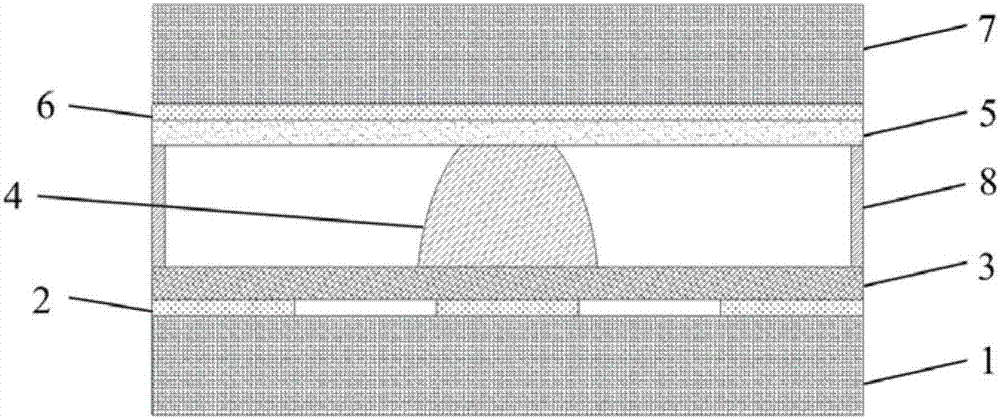

Programmable control micro-fluidic chip based on liquid-liquid electrowetting effect

PendingCN107335490AReduce production processEasy to makeChemical/physical/physico-chemical microreactorsLaboratory glasswaresThin membranePolymer thin films

The invention provides a programmable control micro-fluidic chip based on a liquid-liquid electrowetting effect. The programmable control micro-fluidic chip comprises a lower substrate, a drive electrode array, a lower substrate hydrophobic insulating layer, at least one liquid drop, an upper substrate hydrophobic layer, a conductive layer and an upper substrate from bottom to top, wherein cofferdams are added to the peripheries of the upper substrate and the lower substrate to form a closed cavity. The hydrophobic insulating layer is formed by a porous polymer film and a liquid capable of improving electric wettability and has the advantages of being good in electric wetting reversibility, reusable and resistant to voltage breakdown, high temperature and chemical reagents, the effect of the hydrophobic insulating layer is not affected after long-time storage, so that the service life of a device is prolonged, the efficiency of the device is improved, and the application range of the device is broadened; besides, the pressing mode of the drive electrode array can be programmed, therefore, operation processes such as rapid movement, combination, reaction and the like of different liquid drops are executed in different positions according to preset parameters.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

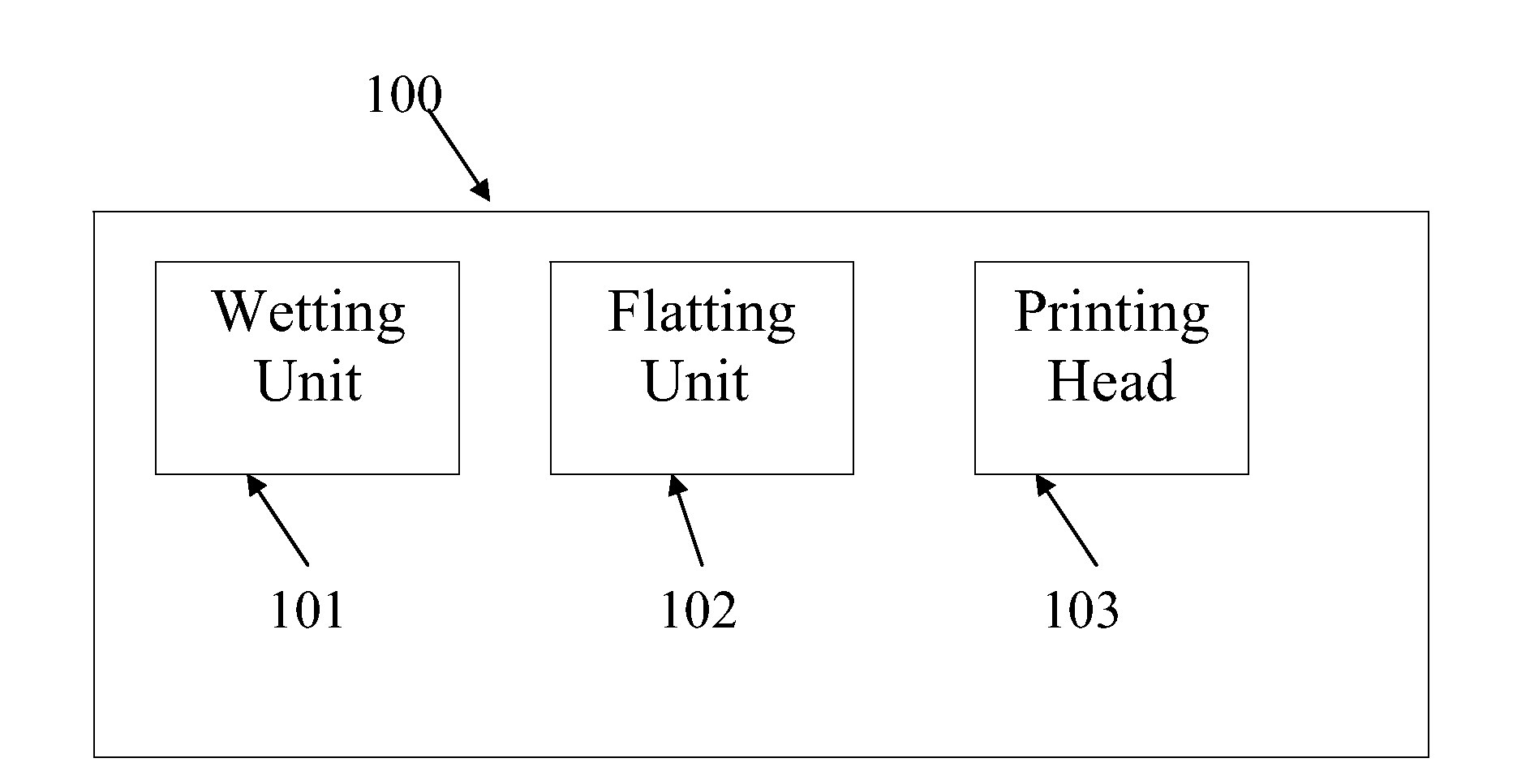

Digital printing device with improved pre-printing textile surface treatment

InactiveUS20110032319A1Smoother plane for printingEliminate needInking apparatusInksFiberTextile printer

A digital printing machine prints textiles. The machine comprises a wetting unit for wetting fabric to be printed prior to printing, a printing head for printing on said fabric and a flattening unit located between the wetting unit and the printing head for exerting pressure on the fabric to flatten outwardly extending fibers of the fabric after wetting and before printing. The flattening provides a smoothed surface for digital printing.

Owner:KORNIT DIGITAL TECHNOLOGIES LTD

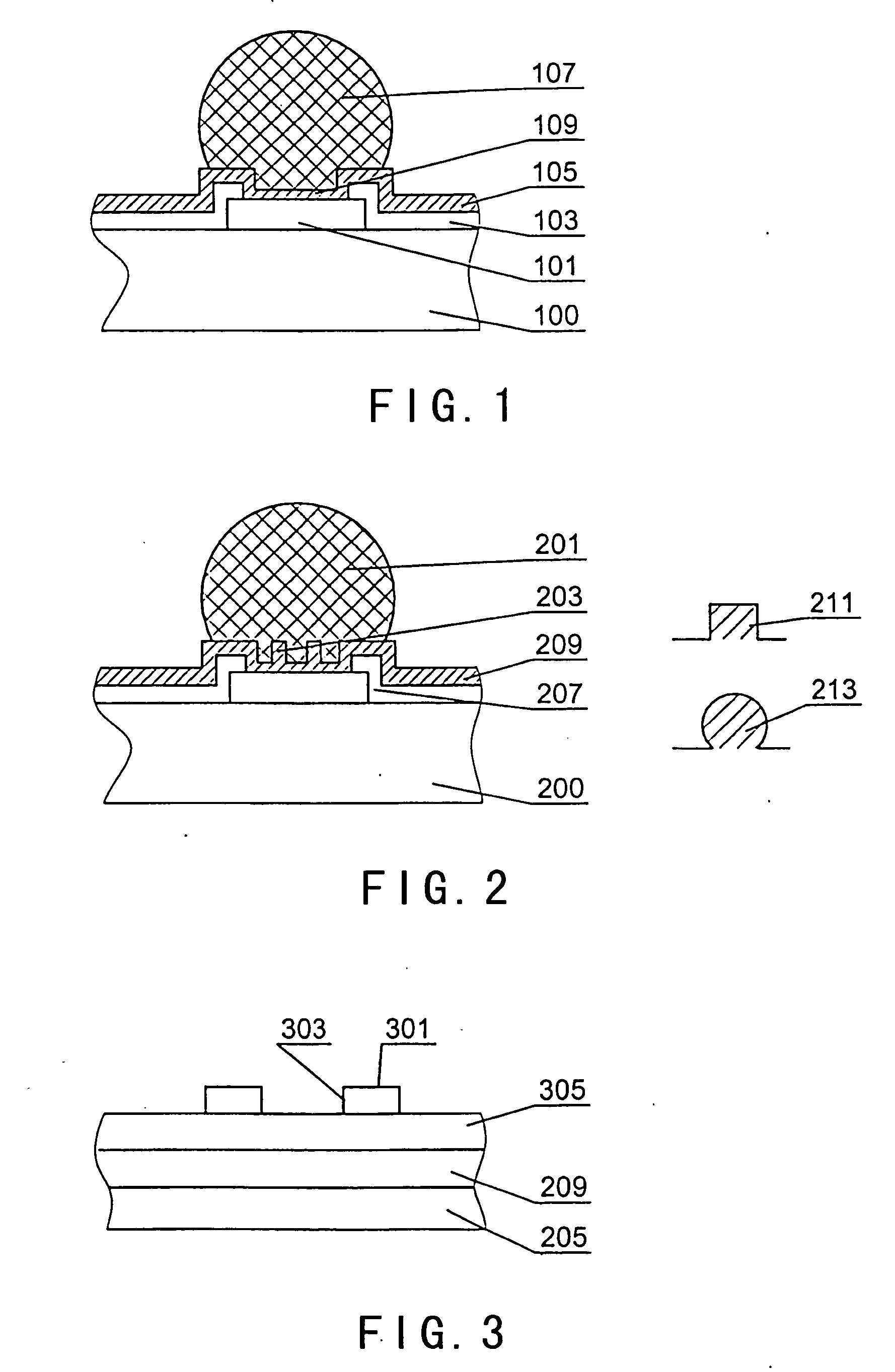

Method and device for manufacturing bonding pads for chip scale packaging

InactiveUS20050140027A1Easy to useHigh device yieldSemiconductor/solid-state device detailsSolid-state devicesWaferingSilicon on insulator

An integrated circuit chip and method of manufacture. The chip has a substrate, e.g., silicon, silicon on insulator, epitaxial wafer. The substrate has a plurality of chip structures. A plurality of bonding pads are disposed on the substrate. Each of the bonding pads is formed from an aluminum bearing material or other like material. A surface region is formed on each of the bonding pads. An under bump metal layer (“UBM”) is overlying the surface region. A wetting layer is formed overlying the under bump metal layer. The wetting layer comprises a plurality of protrusions extending out of the wetting layer and disposed spatially on the wetting layer. A bump layer is formed overlying the wetting layer and is mechanically coupling to the plurality of protrusions.

Owner:SEMICON MFG INT (SHANGHAI) CORP

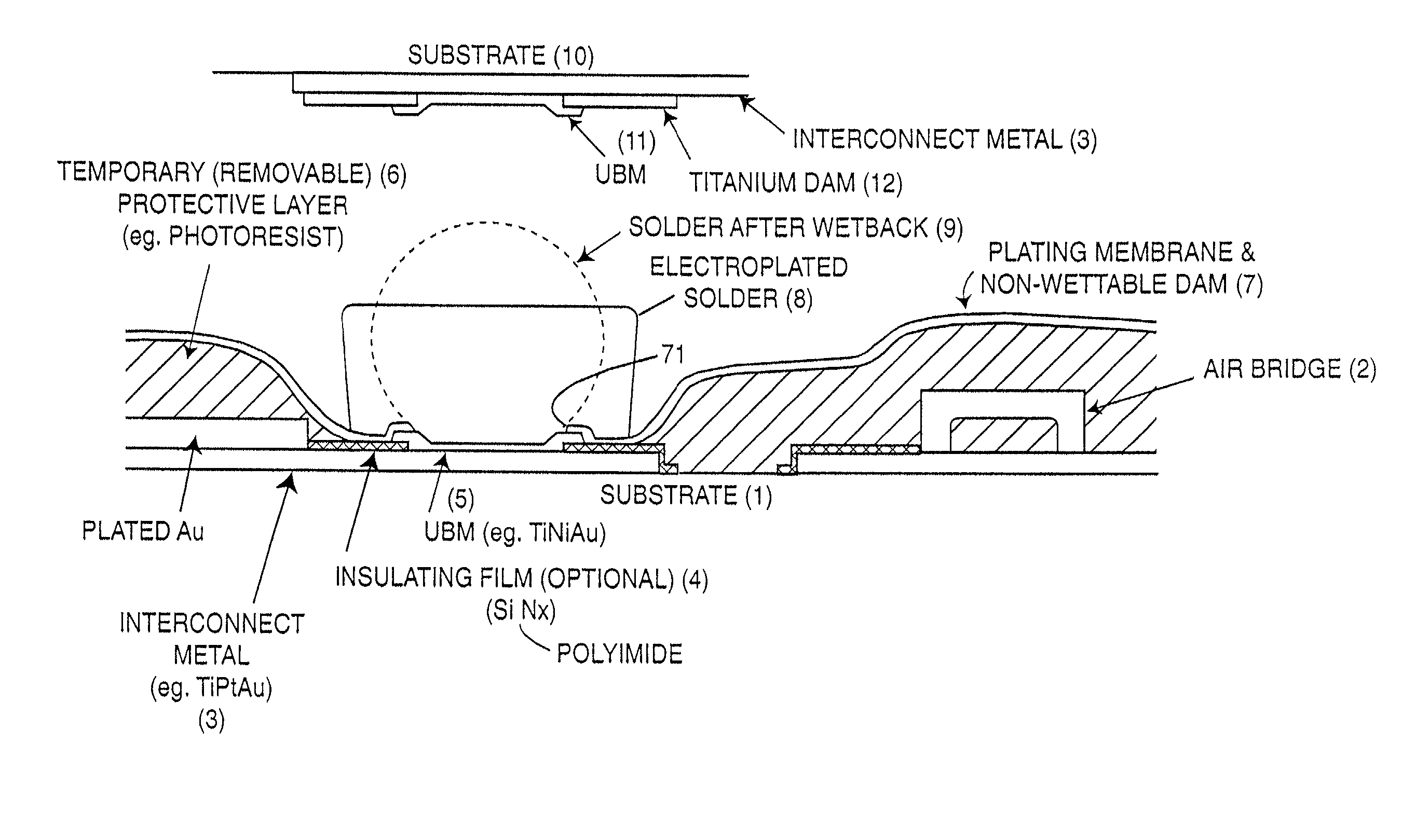

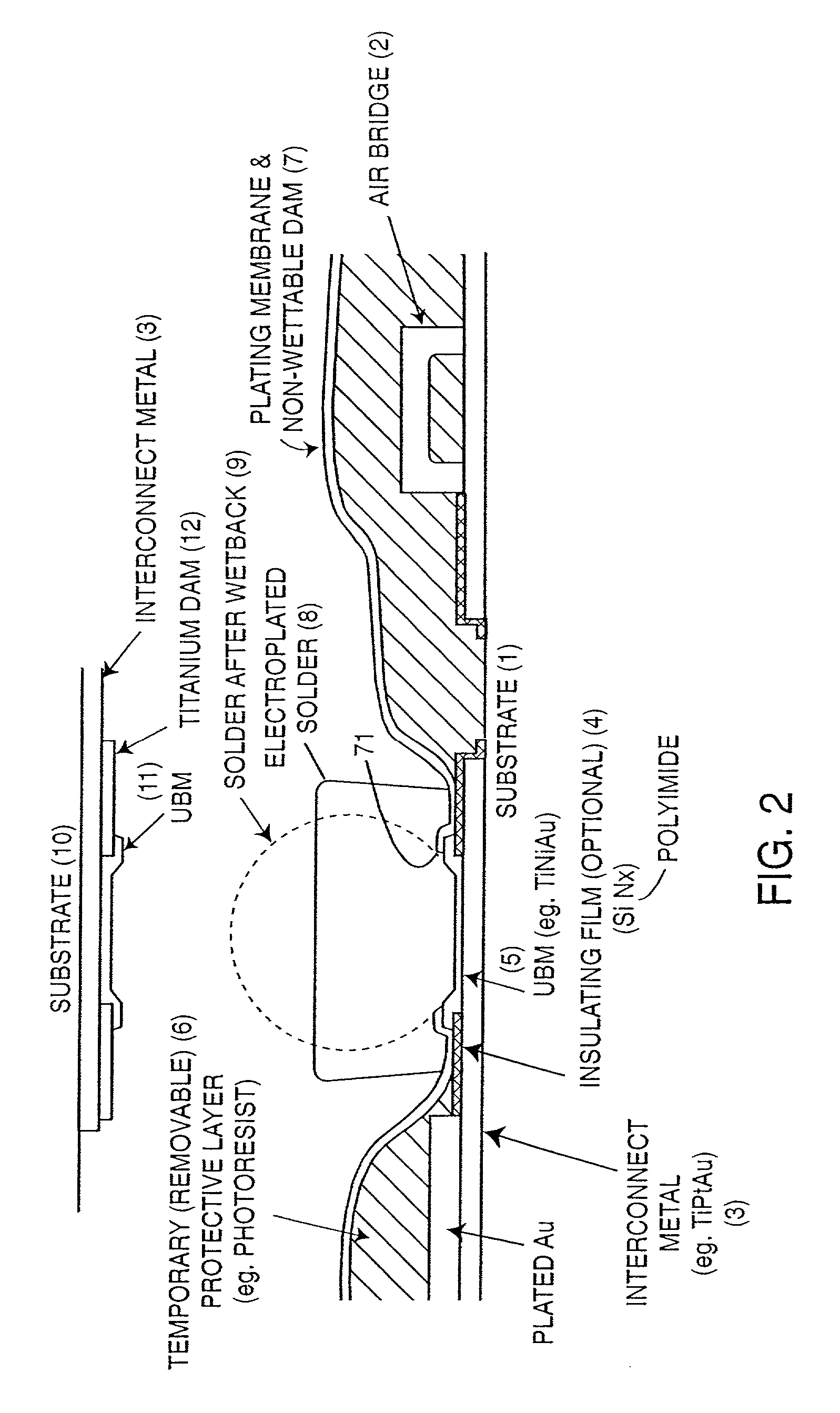

Precision electroplated solder bumps and method for manufacturing thereof

InactiveUS20020090805A1Avoid the needAlter its performancePrinted circuit assemblingSemiconductor/solid-state device detailsEvaporationSolvent

A method for fabrication of a solder bump, comprising applying preferably an insulating film, followed by applying a multilayer underbump metallization, a layer of a photoresist, and a thin layer of titanium on a substrate containing, preferably, III-V semiconductor circuits. The multilayer UBM pad, preferably comprising a 0.02 to 0.05 micrometer thick layer of titanium, a 0.5 to 1.0 micrometer thick layer of nickel and a 0.1 to 0.2 thick layer of gold. The protective film with the thickness of preferably 0.5 to 40 micrometer comprises a photoresist. After the solder has been electroplated, the protective film is removed, preferably by dry etching or with a solvent. The titanium film serves a dual function of being a membrane for electroplating of the solder and of being a non-wettable dam for wetting back of the plated solder. The titanium film with the thickness of 200 to 1,000 Angstroms is preferably deposited by evaporation. After the solder has been electroplated, much of the titanium film is removed, preferably by wet etching or dry etching, leaving only a band of titanium that surrounds the disk of solder. A multilayer solder bump structure for III-V semiconductor circuits manufactured using this method, comprising, preferably, an insulating film, a multilayer underbump metallization layer, and remnants of the thin titanium film.

Owner:HRL LAB

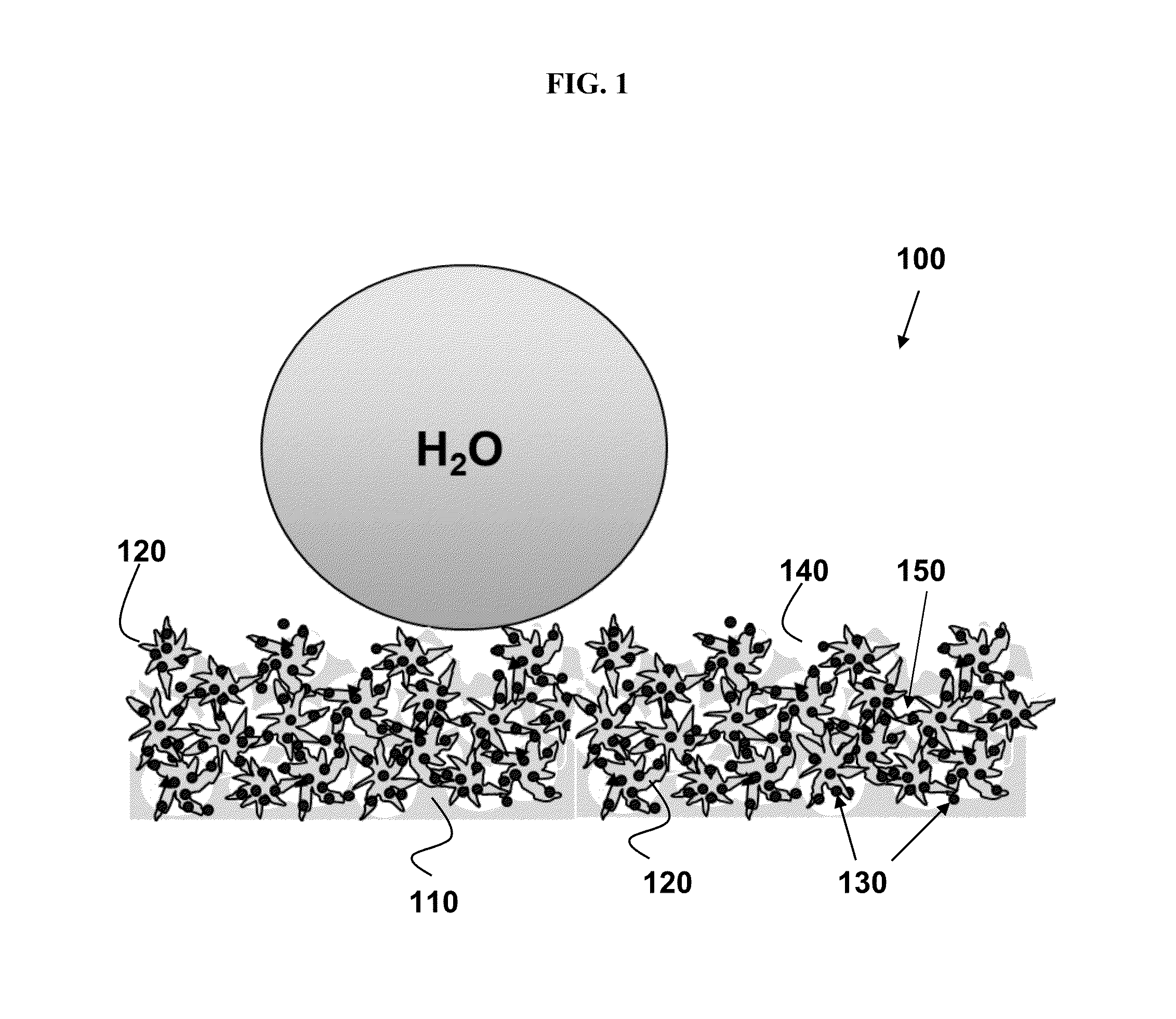

Transparent Anti-icing coatings

ActiveUS20150284614A1Prevent wettingOther chemical processesSynthetic resin layered productsEnvironmental resistanceNanoparticle

Transparent, impact-resistant, anti-icing coatings are disclosed. In some variations, a transparent anti-icing coating comprises: a continuous matrix of a hardened material; asymmetric templates that inhibit wetting of water, wherein the asymmetric templates have a length scale from about 10-300 nanometers; porous voids surrounding the asymmetric templates, wherein the porous voids have a length scale from about 15-500 nanometers; and nanoparticles that inhibit heterogeneous nucleation of water, wherein the nanoparticles have an average size from about 5-50 nanometers. Disclosed coatings have transparencies of 90% or higher light transmission. These coatings utilize lightweight and environmentally benign materials that can be rapidly formed into coatings. A uniform distribution of particles and asymmetric templates throughout the coating allows it to be abraded, yet retain its anti-icing function as well as transparency. Therefore if the surface is damaged during use, freshly exposed surface is identical to that which was removed, for extended lifetime.

Owner:HRL LAB

Fluid-handling apparatus with corrosion-erosion coating and method of making same

Inlet surfaces of a fluid-handling apparatus, such as a heat exchanger, are often prone to corrosion and erosion due to the high velocities of incoming fluid. The present disclosure includes a fluid-handling apparatus with a plurality of wetted surfaces of which a first portion is corrosion-erosion prone and a second portion is non-corrosion-erosion prone. The first portion is coated with a corrosion-erosion coating that is harder than the first portion. Less than all of the wetted surfaces are coated.

Owner:CATERPILLAR INC

Kit for the application of a fluid preparation

InactiveUS7874756B2Prevent leakageDampen the at least one porous area of the applicator substantially completelyLiquid surface applicatorsCleaning machinesEngineeringMechanical engineering

Kit for applying a fluid onto a surface and method using the kit. The kit includes a fluid having a yield point, a fluid container having at least one opening, and an applicator element having one or more porous areas for applying the fluid to a surface. The applicator element is located on the at least one opening of the container. The at least one porous area of the applicator element is in contact with the fluid. The fluid wets the at least one porous area of the applicator element but does not leak out of it as long as the porous area is not in contact with the surface. A porosity of the at least one porous area of the applicator element is related to the yield point of the fluid or vice versa.

Owner:BEIERSDORF AG

Hermetic seal

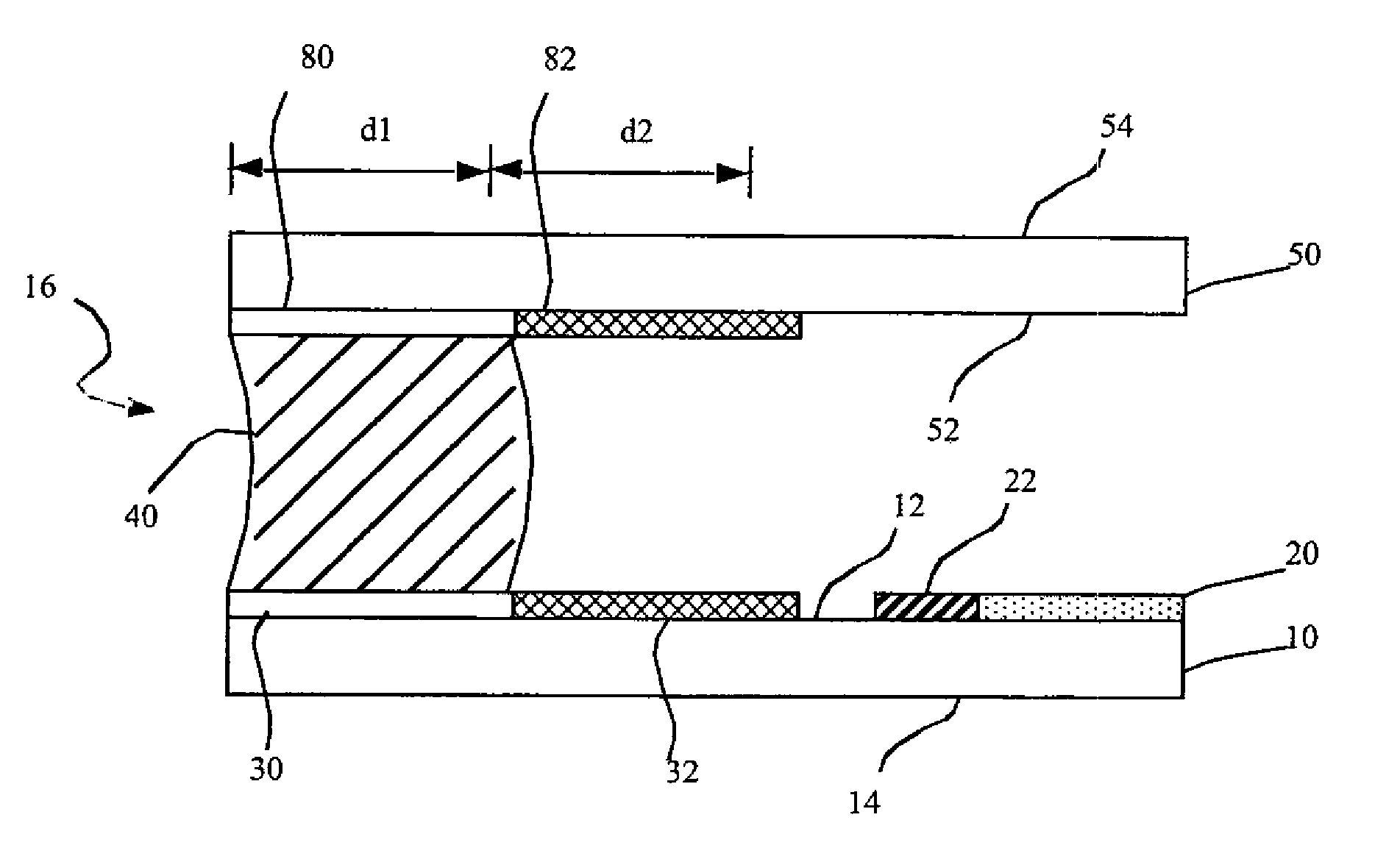

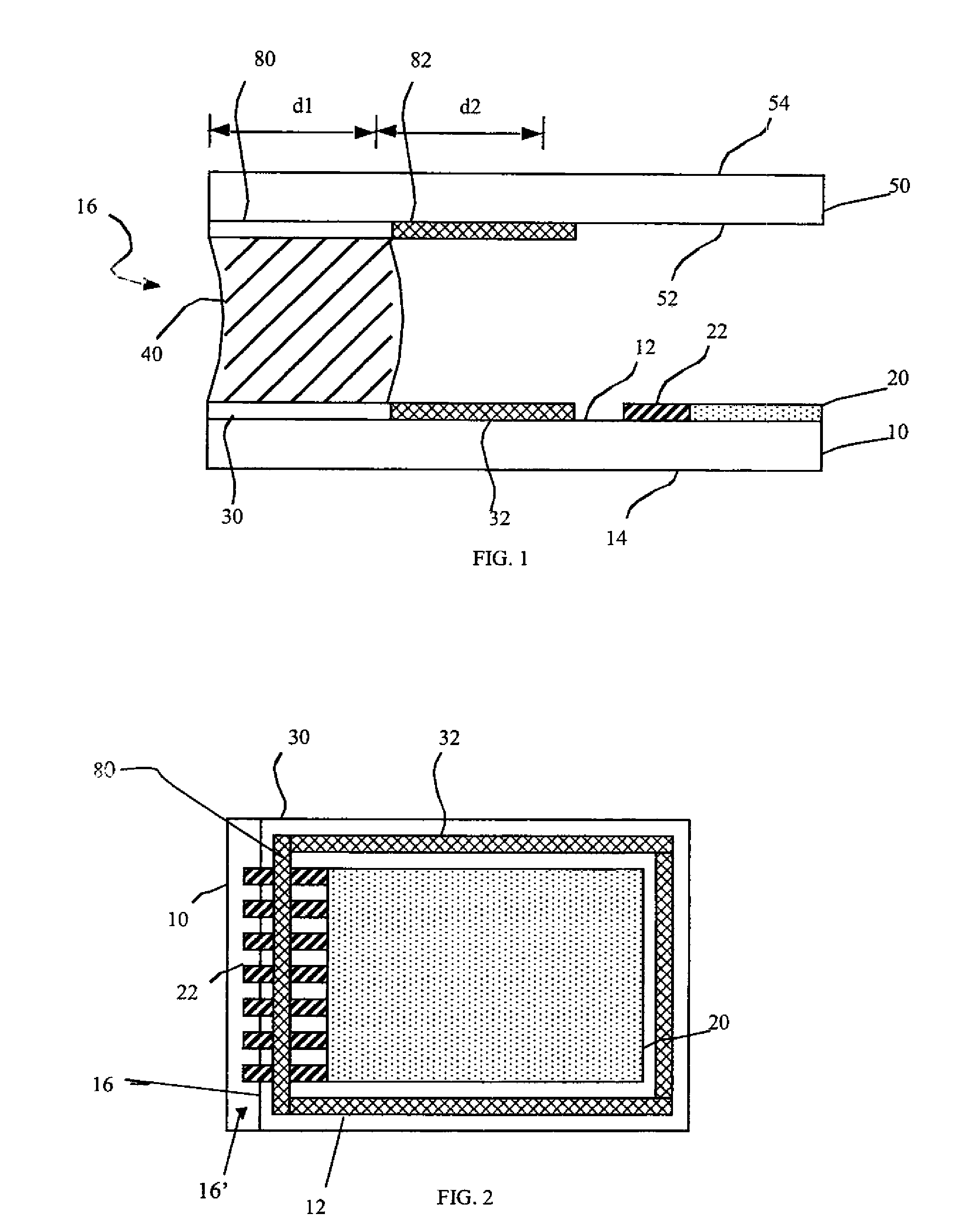

ActiveUS20100225231A1Lower Level RequirementsNarrow sealDischarge tube luminescnet screensSemiconductor/solid-state device detailsHermetic sealEngineering

Hermetic seal for a device includes a substrate. A first strip on the substrate has a first surface wettability and a second strip on the substrate has a second surface wettability different from the first surface wettability. The seal further includes a first cover strip having the first surface wettability spaced from the first substrate strip and a second cover strip having the second surface wettability spaced from the second substrate strip in contact with the first cover strip. A sealing member wets and adheres to the first substrate and cover strips but not the second substrate and cover strips.

Owner:GLOBAL OLED TECH

Water-based composite passivation solution for galvanized steel plate and preparation method of water-based composite passivation solution

InactiveCN104451641AImprove corrosion resistanceQuality improvementMetallic material coating processesWater basedChromium free

The invention relates to a water-based composite chromium-free passivation solution for a galvanized steel plate. The passivation solution contains 10-30g / L of sodium molybdate, 0-10g / L of sodium phosphate, 5-10g / L of organic phosphoric acid, 1-10g / L of fluotitanic acid, 5-15g / L of a silane coupling agent, 5-20g / L of sodium metasilicate, 0.1-1% of a wetting dispersant and the balance of deionized water. The passivation solution provided by the invention consists of an organic phosphoric acid-molybdate system in match with the modified hydrolysis type silane coupling agent and a nano-inorganic filler, does not contain a chromate and is in line with ROHS requirements; the passivation and drying curing time is short, the degree of stability is high, the quality of a film layer is good, the white rust area in a 72h salt fog test does not exceed 5%, the cost is relatively low, a passivation process device does not need to be changed, and continuous passivation can be realized by using a hexavalent chromium passivation device in early period.

Owner:北京蓝星清洗有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com