Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Ejection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

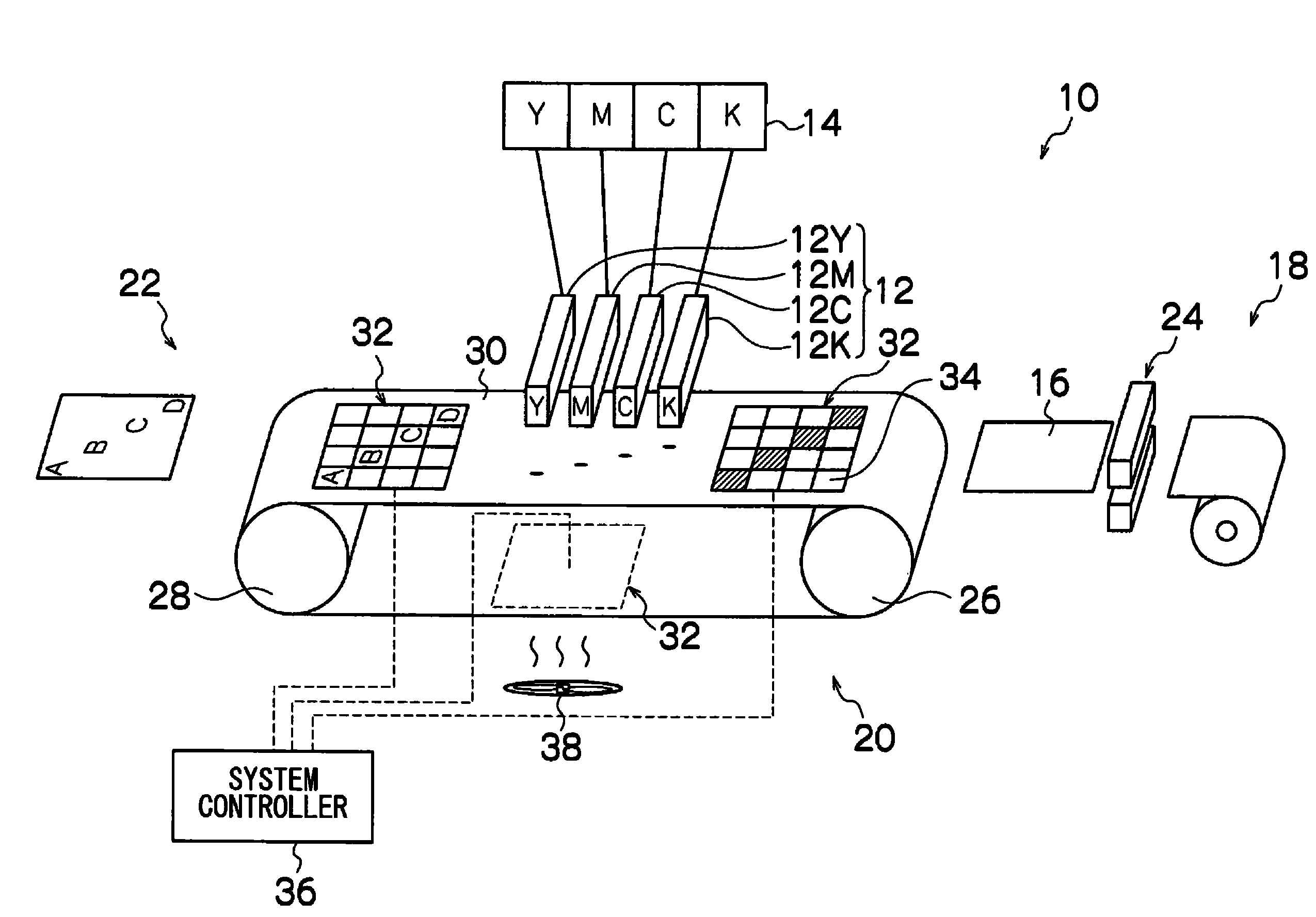

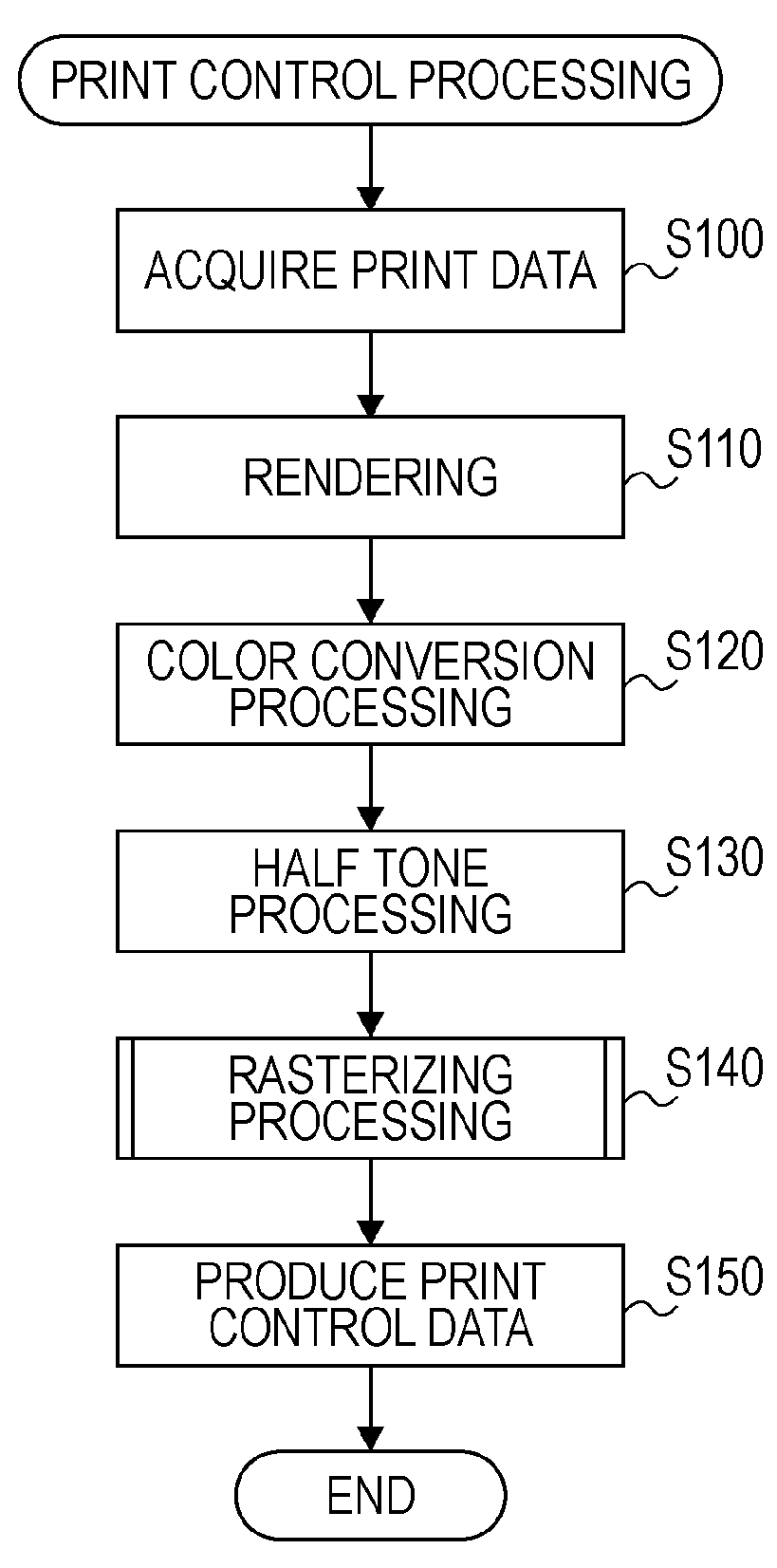

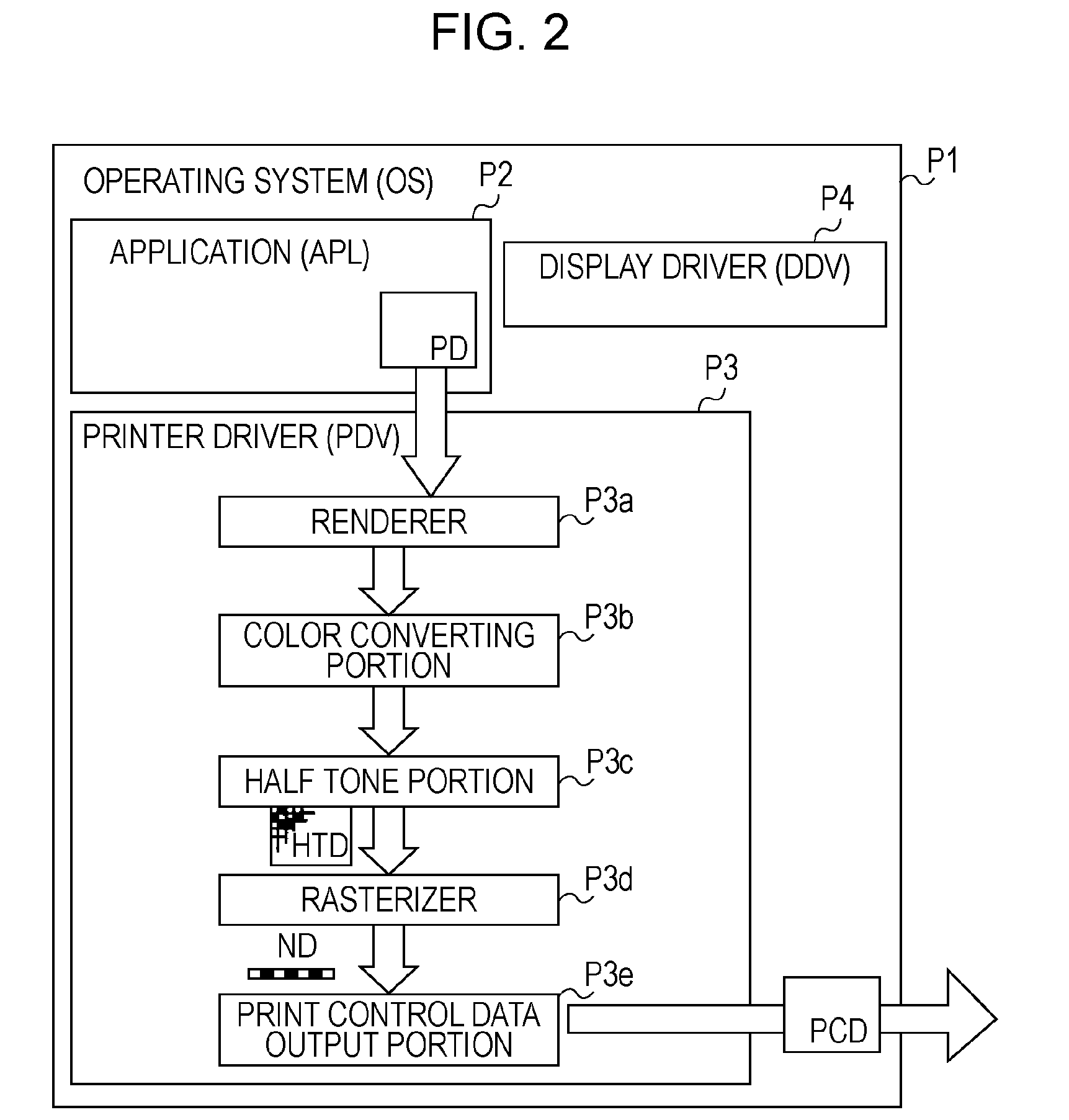

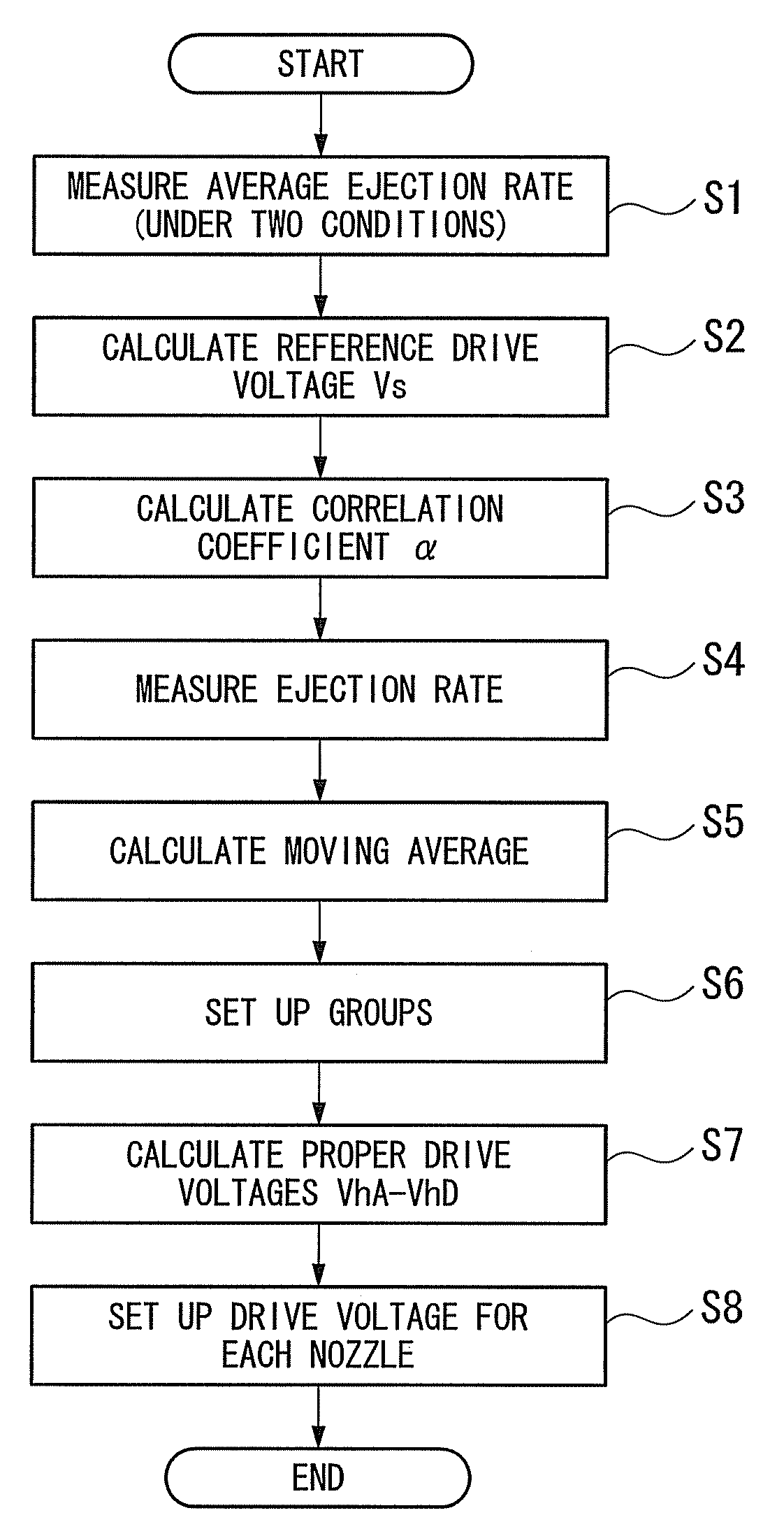

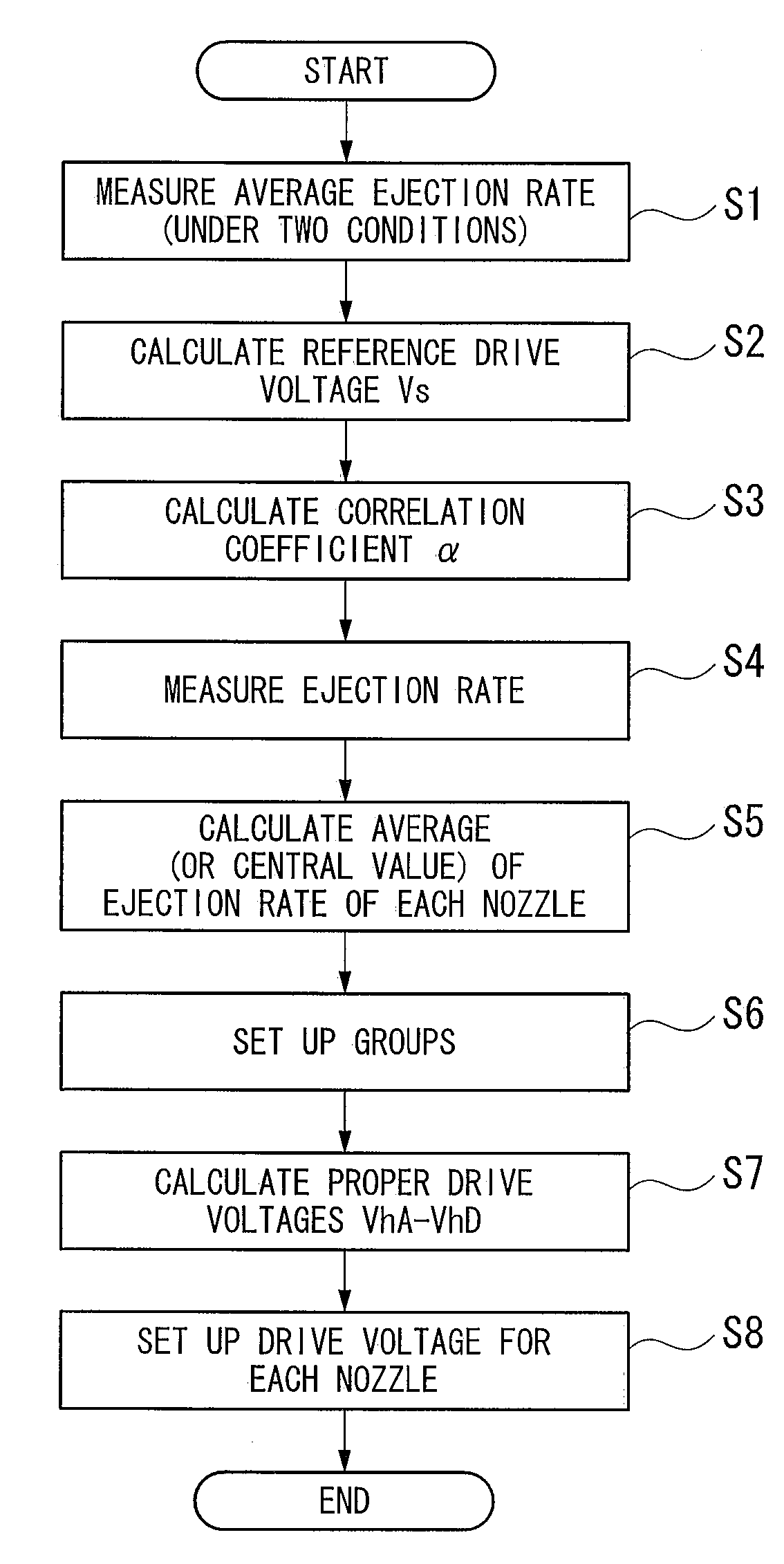

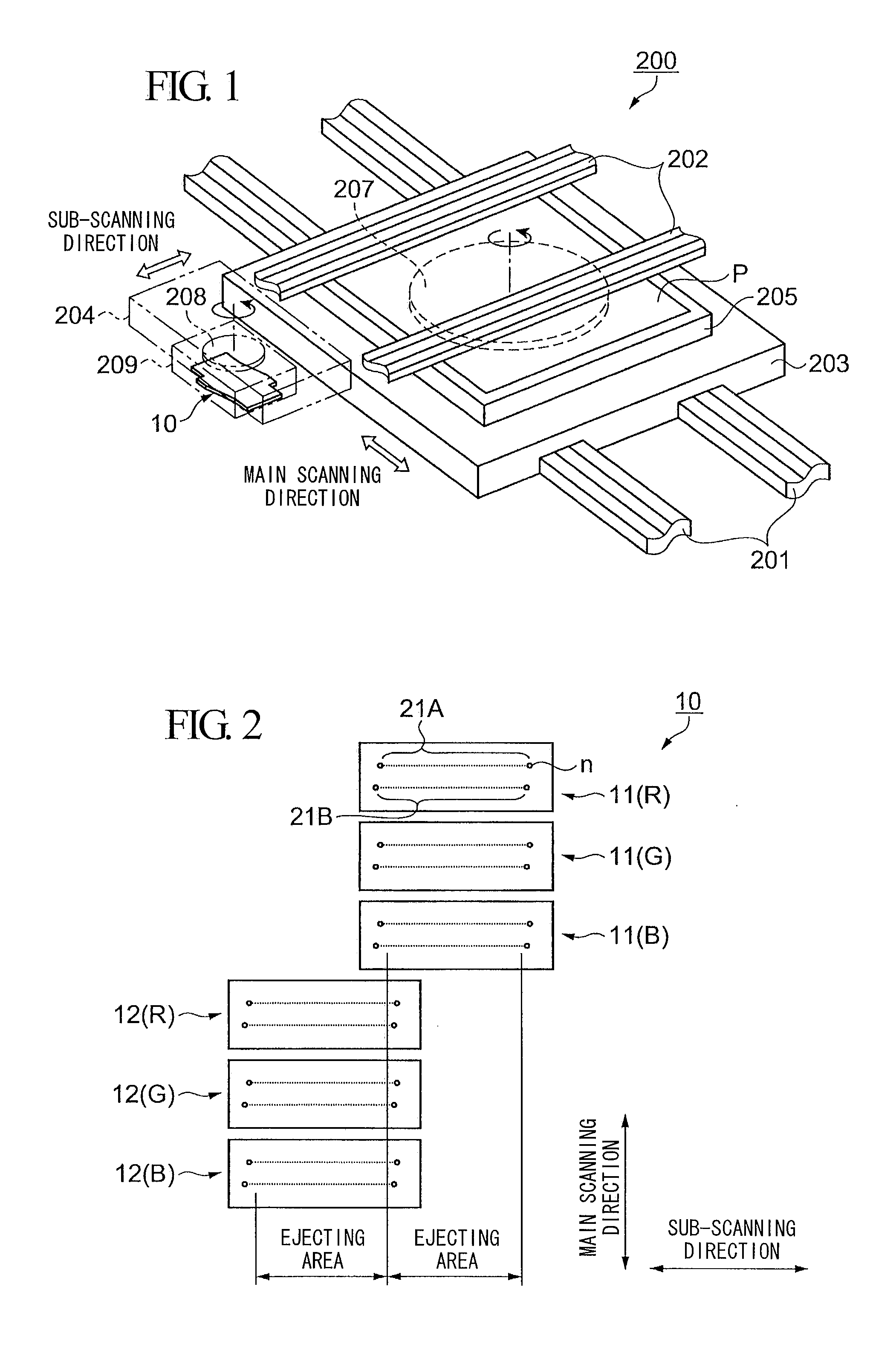

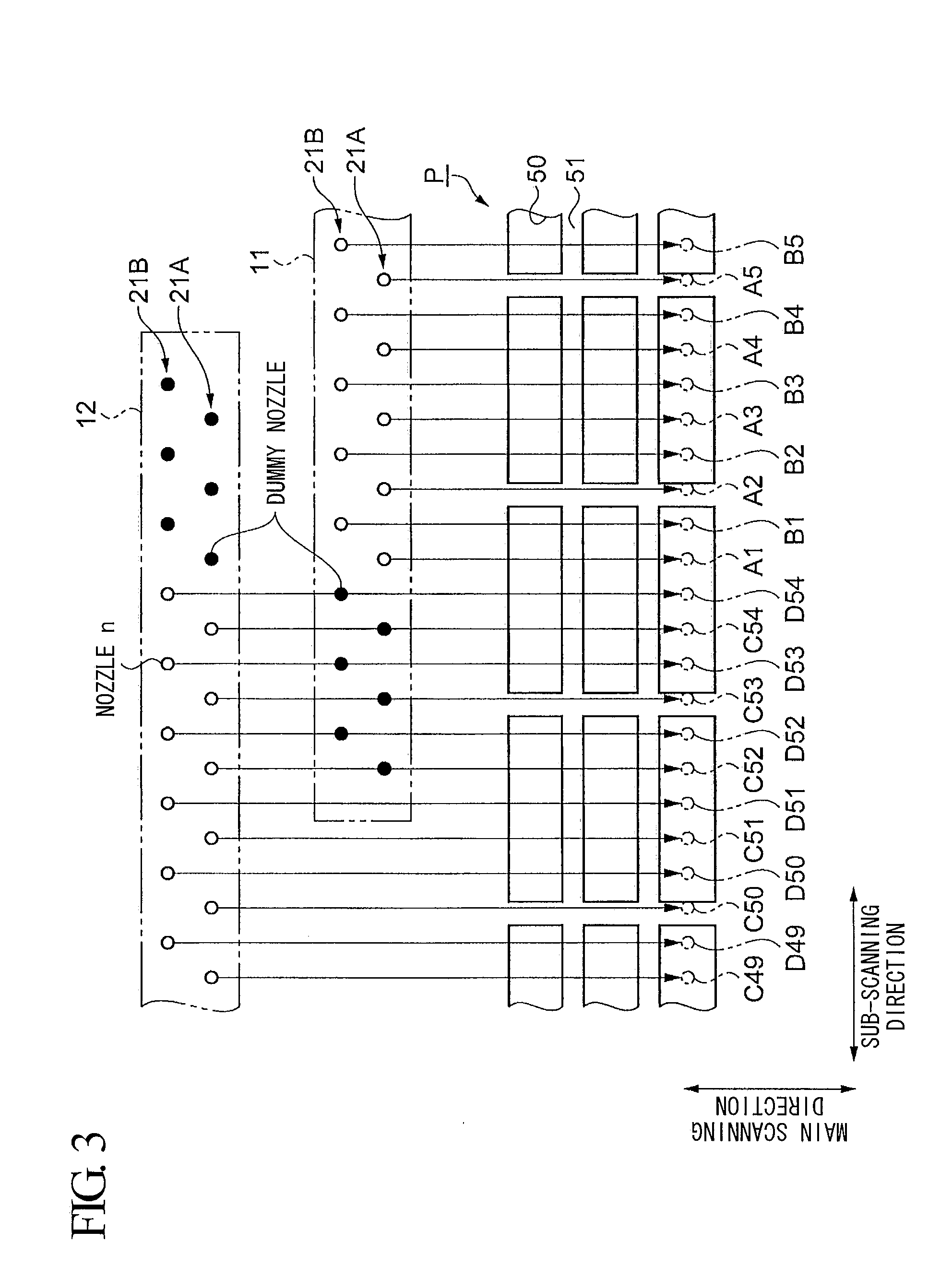

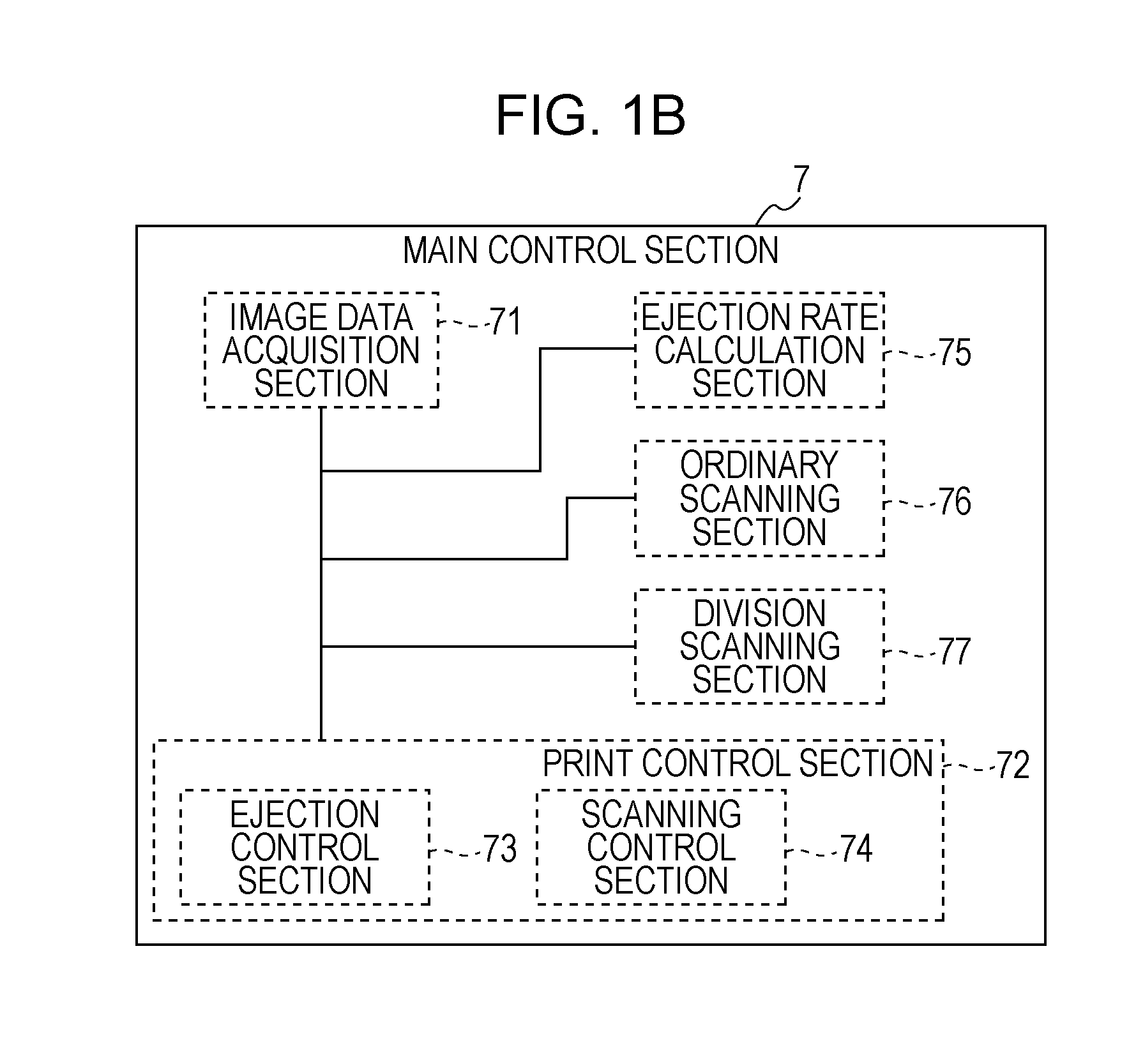

Method for setting up drive signal

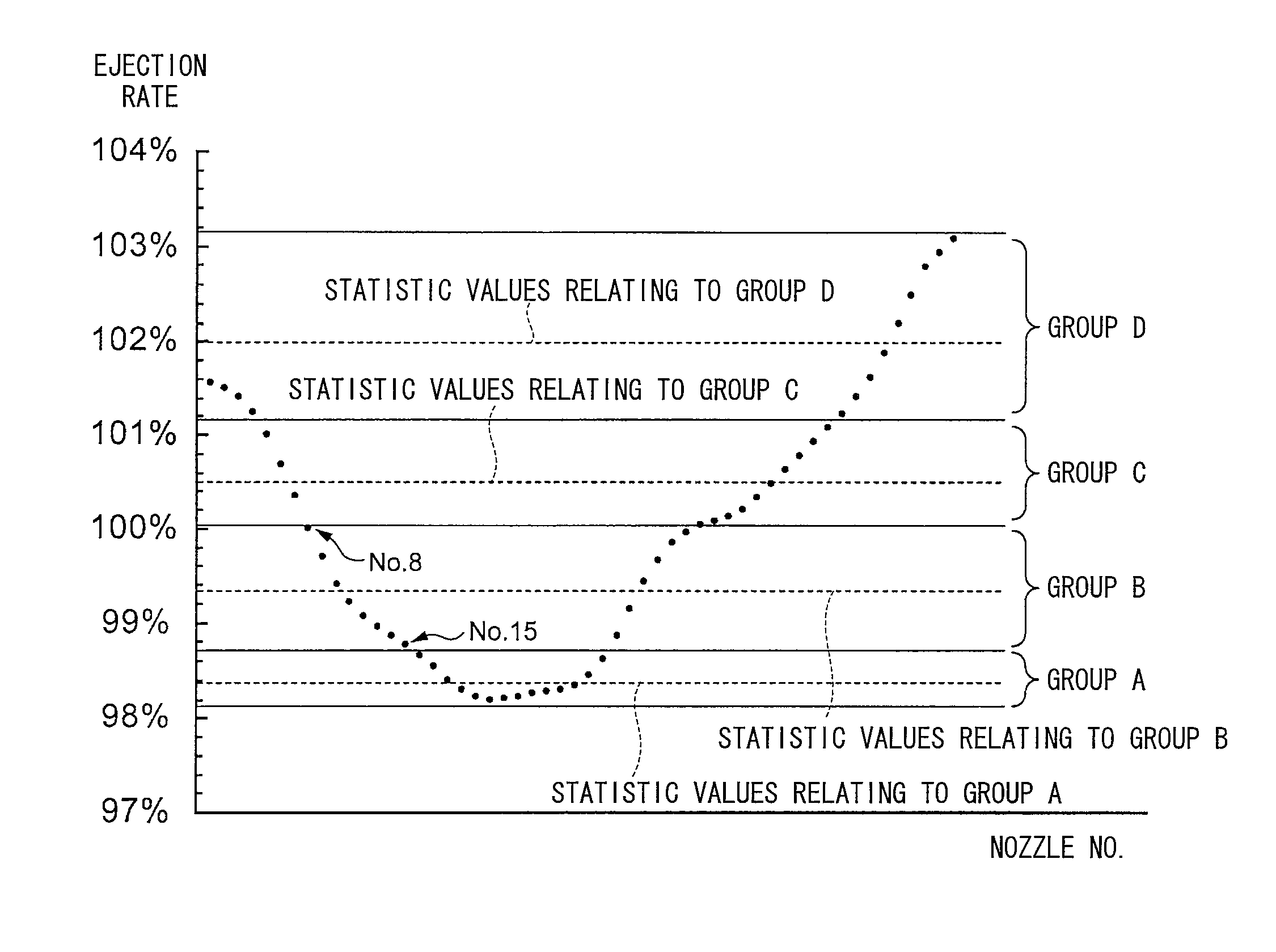

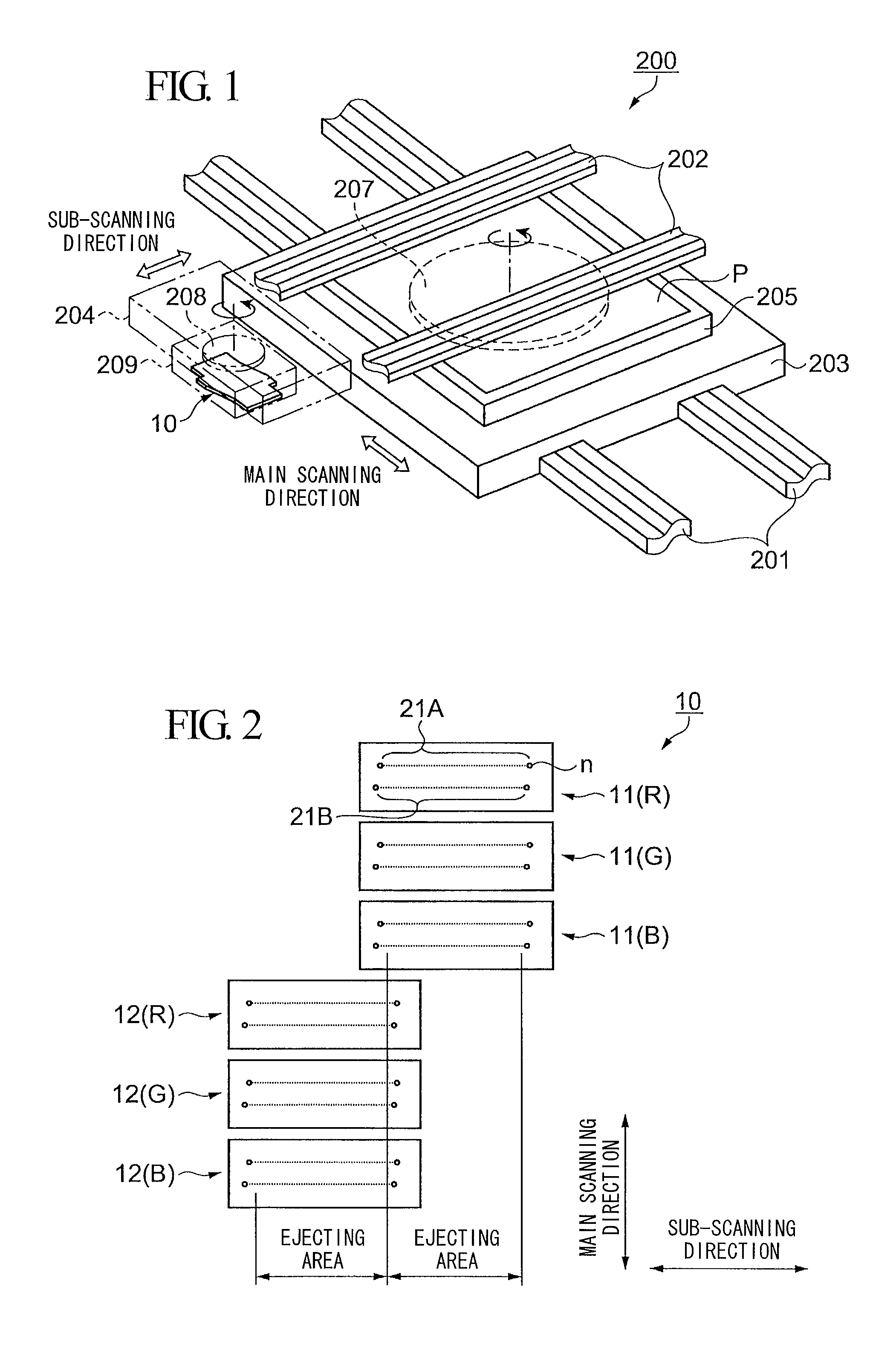

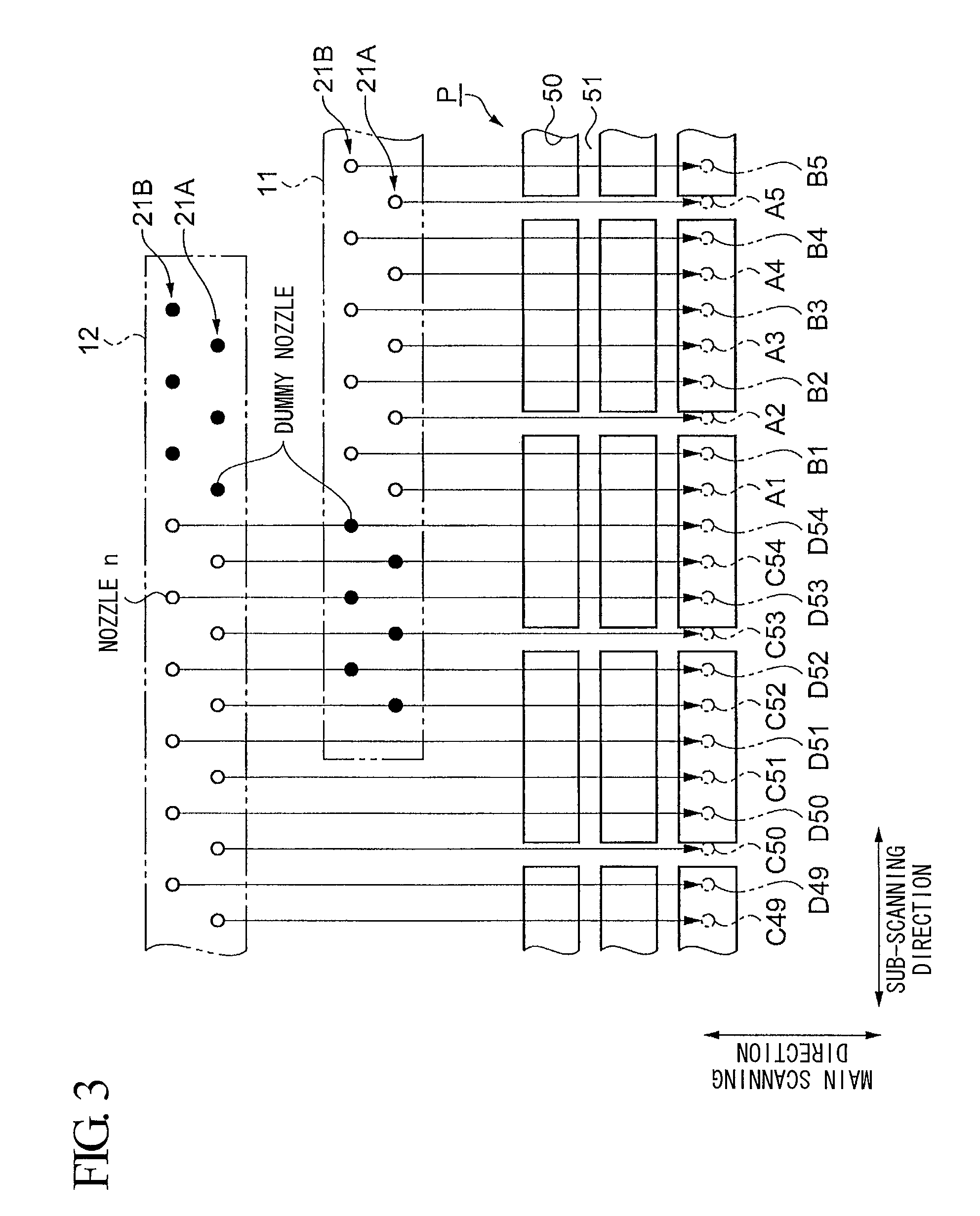

A method for setting up a condition for a drive signal in a liquid ejection head that includes a plurality of linearly-arranged nozzles and driving elements provided for each of the nozzles, includes: calculating an average value or a median value of ejection rates for each nozzle relating to a supply of the drive signal under a plurality of conditions; classifying the plurality of nozzles into a plurality of groups based on the average value or the median value of the ejection rates; calculating a proper condition for the drive signal corresponding to each group based on a statistical value of the ejection rate relating to the group; and selecting one proper condition among proper conditions corresponding to the groups so as to set the selected proper condition for each nozzle.

Owner:KATEEVA

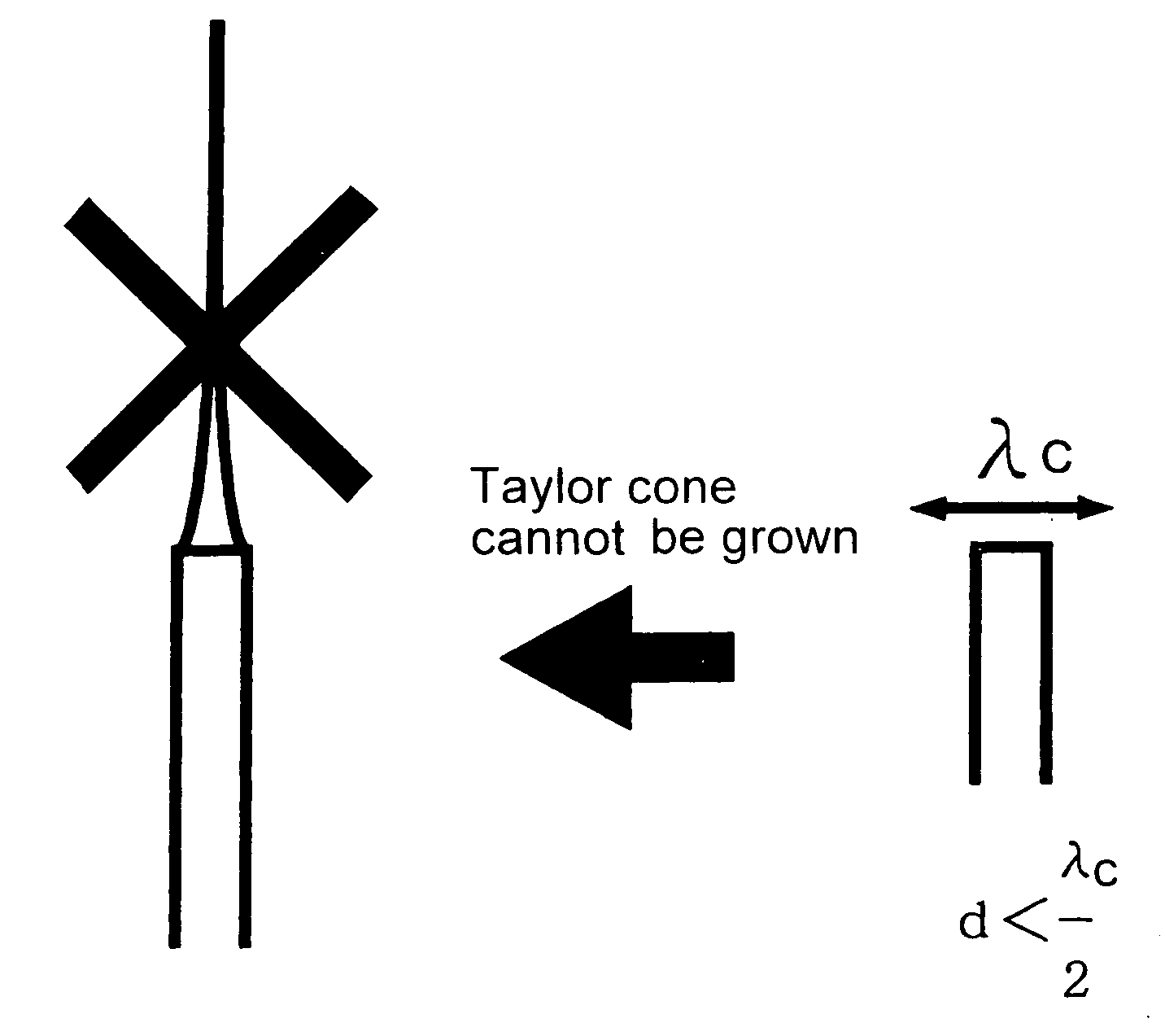

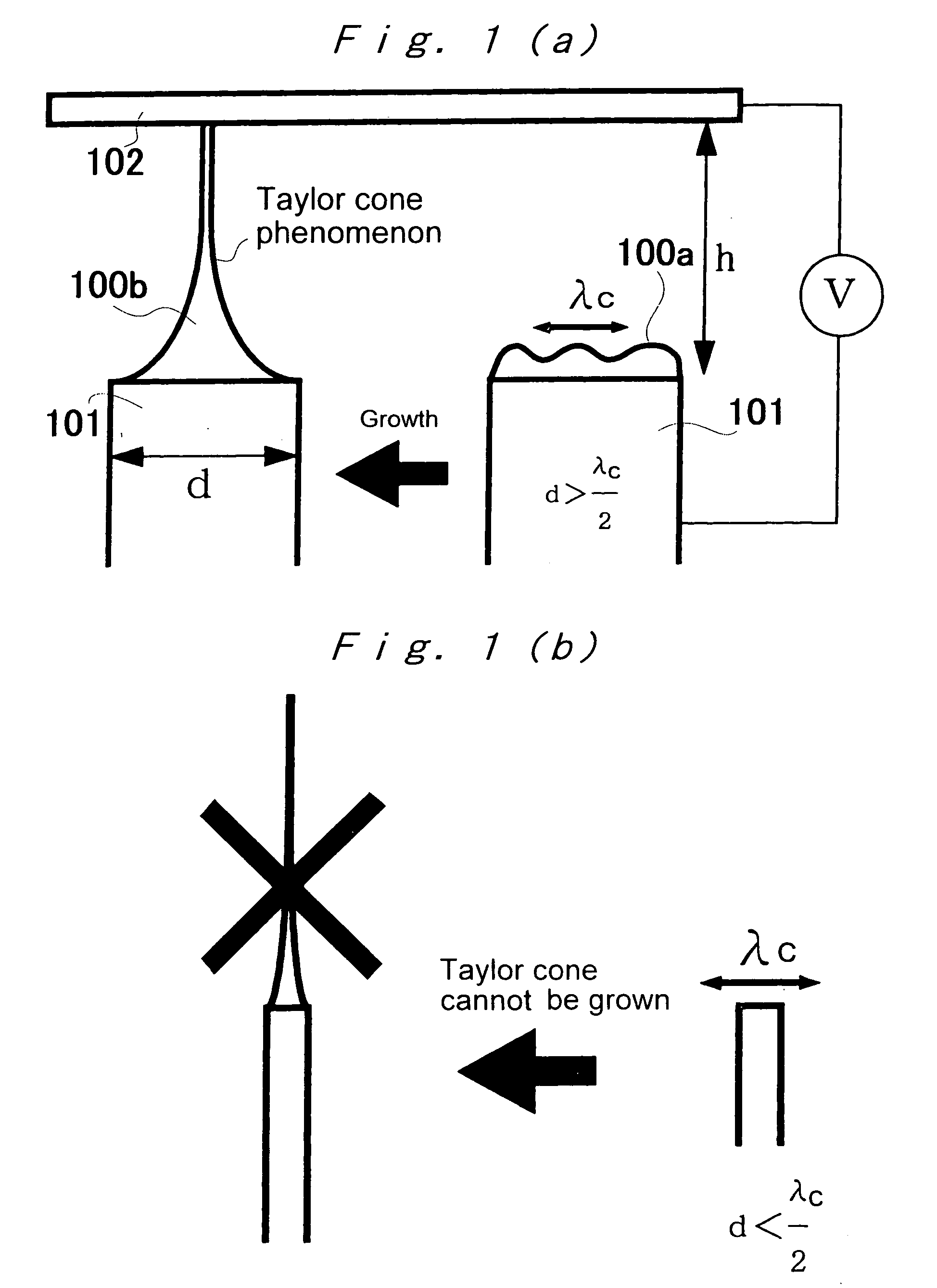

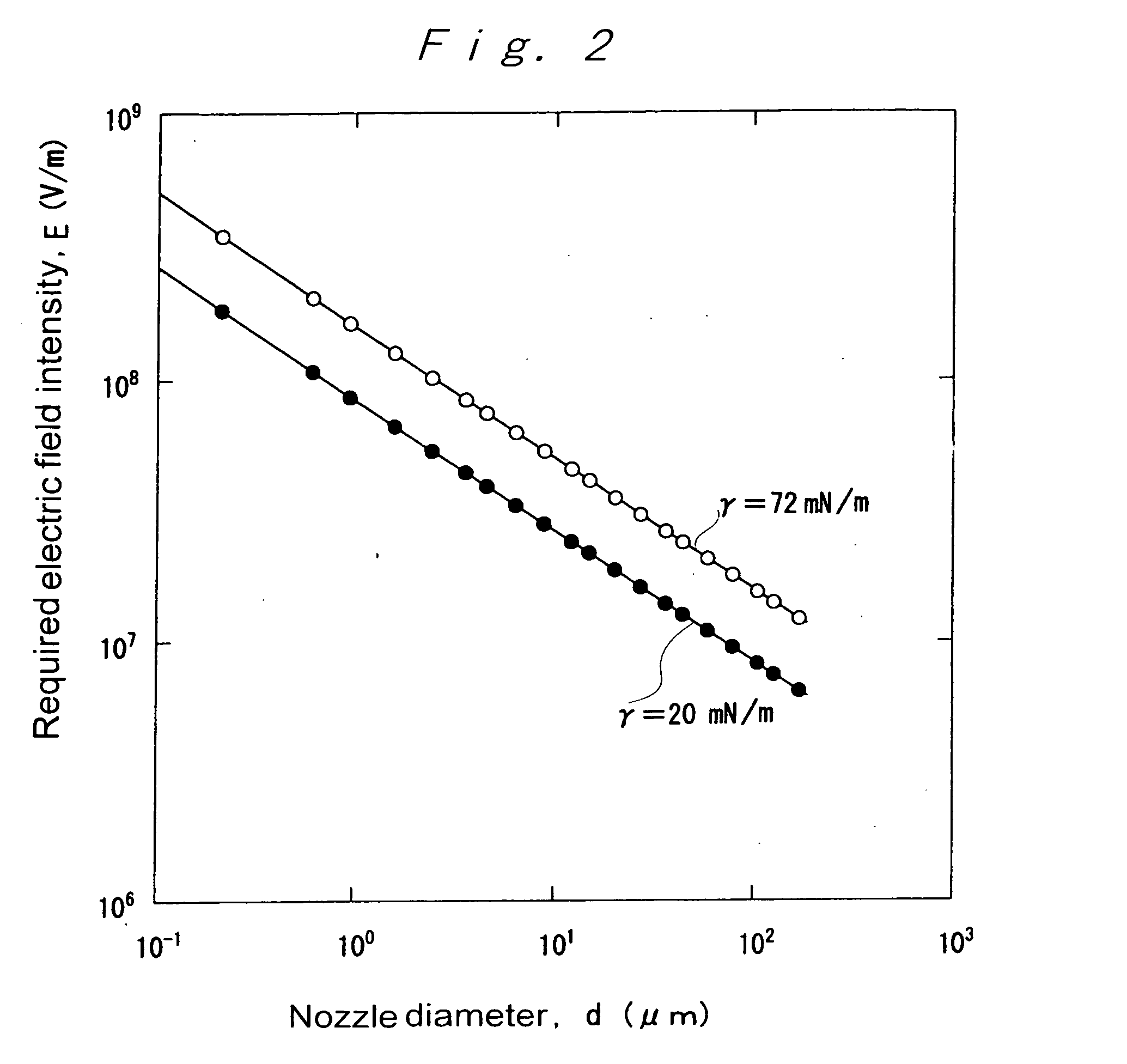

Ultrafine fluid jet apparatus

ActiveUS20050116069A1Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEvaporation

An ultrafine fluid jet apparatus comprising a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

Method for setting up drive signal

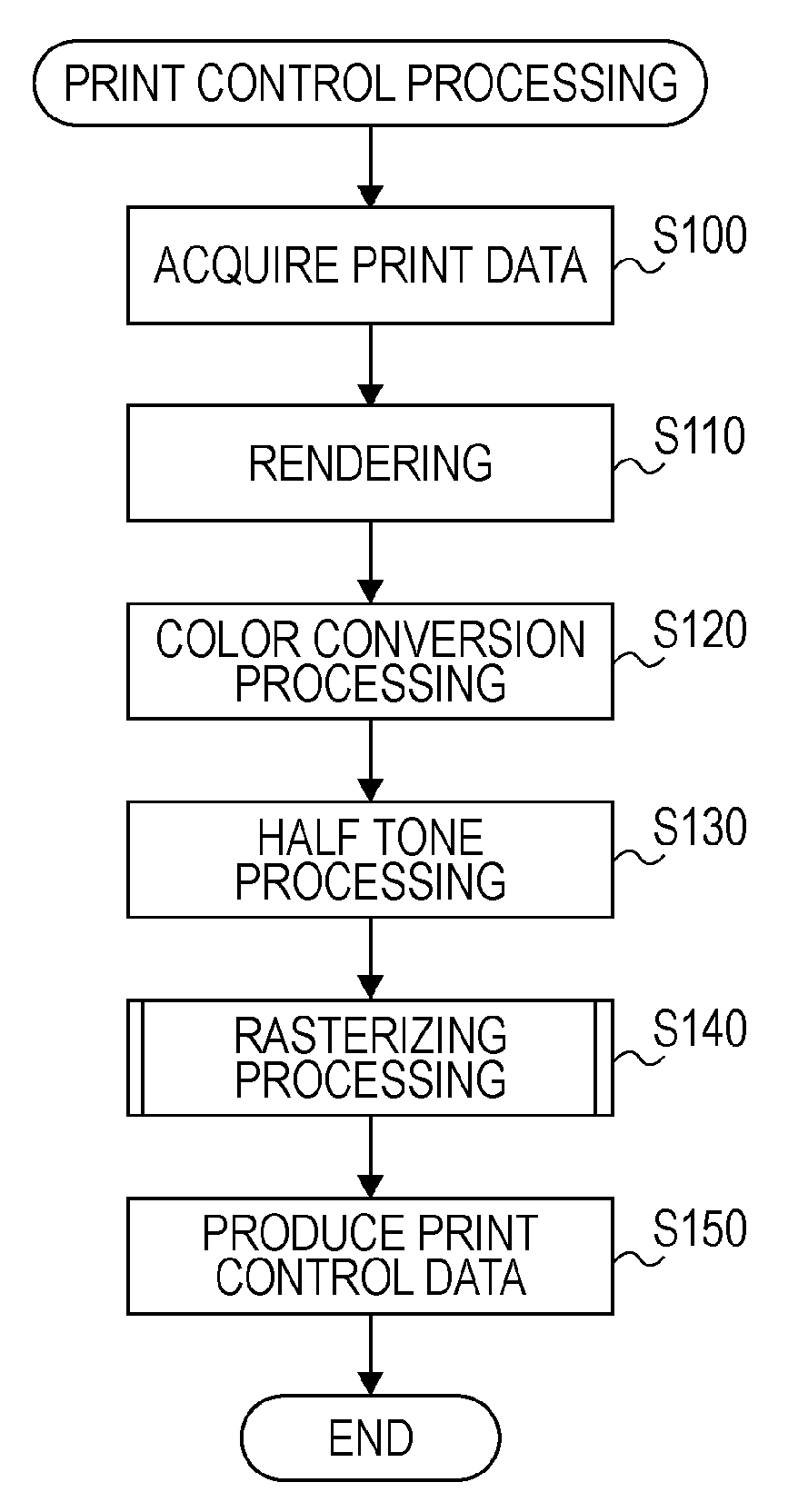

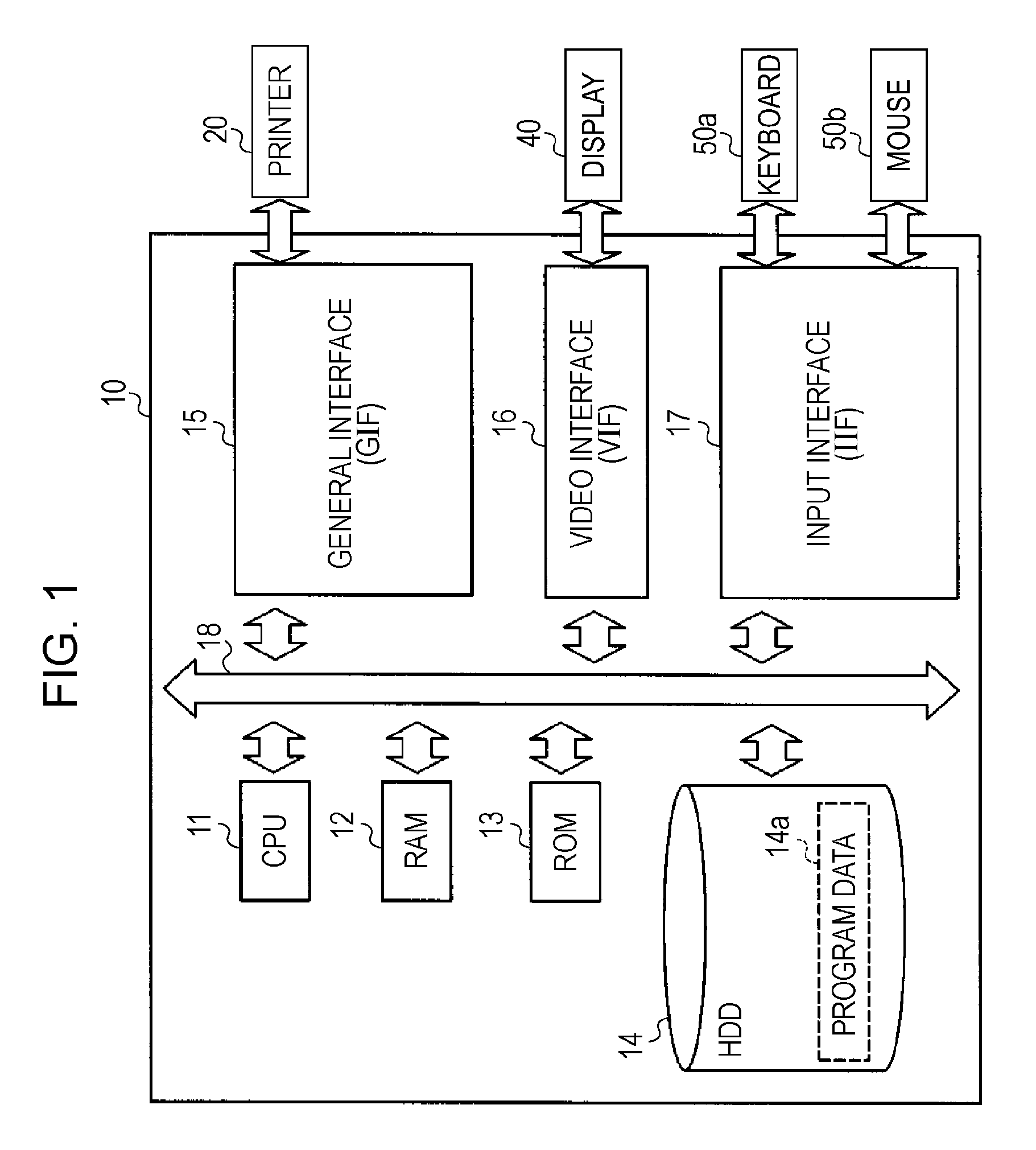

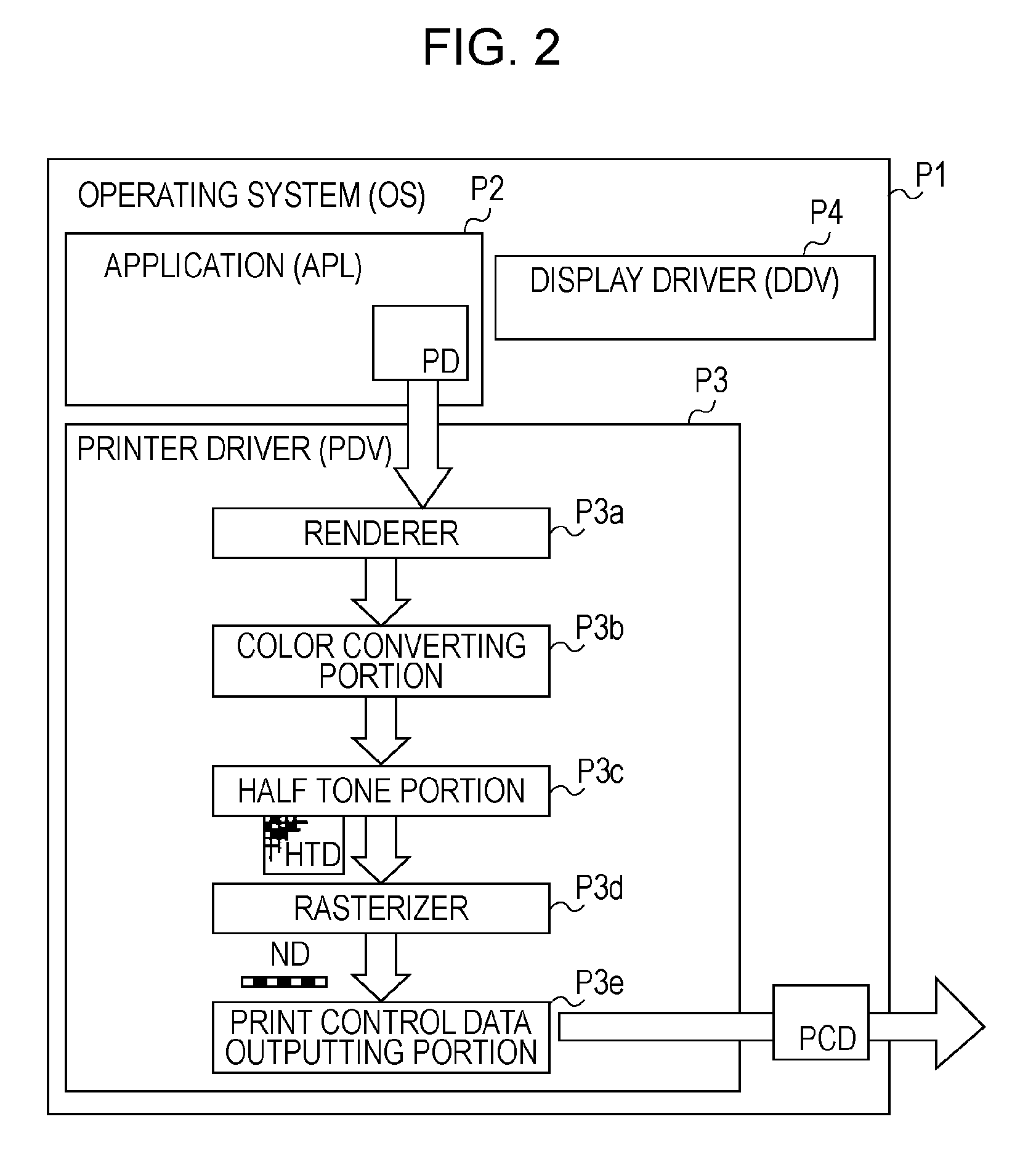

ActiveUS8123324B2Easy to set upConcentrate moreInking apparatusOther printing apparatusMoving averageSpray nozzle

A method for setting up a condition for a drive signal in a liquid ejection head that includes a plurality of linearly-arranged nozzles and driving elements provided for each of the nozzles, includes: calculating an ejection rate for each nozzle relating to a supply of the drive signal under a predetermined condition by using a moving average; classifying the plurality of nozzles into a plurality of groups based on the ejection rate calculated by using the moving average of each nozzle; calculating a proper condition for the drive signal corresponding to each group based on a statistical value of the ejection rate relating to the group; and selecting one proper condition among proper conditions corresponding to the groups so as to set the selected proper condition for each nozzle.

Owner:KATEEVA

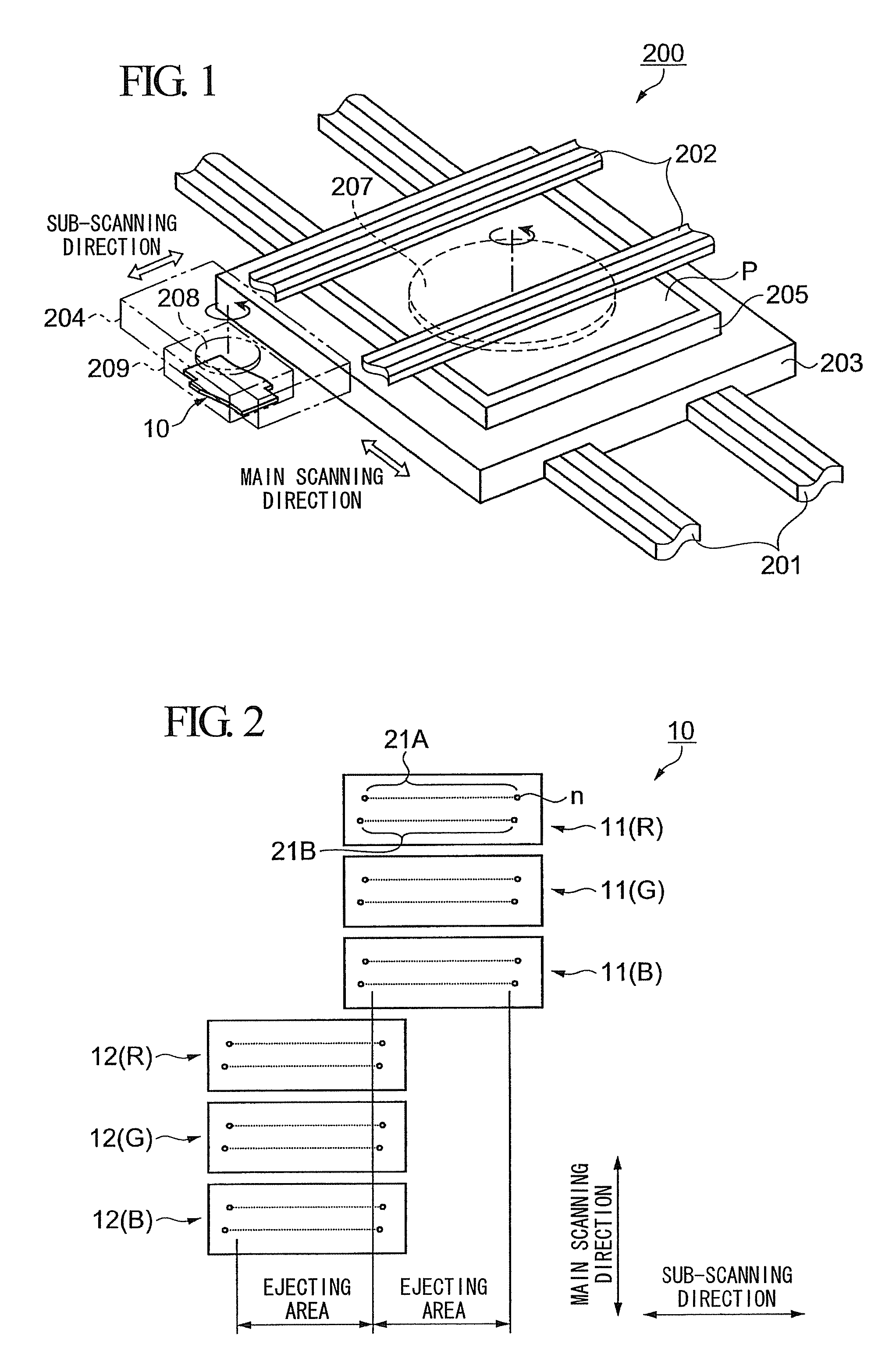

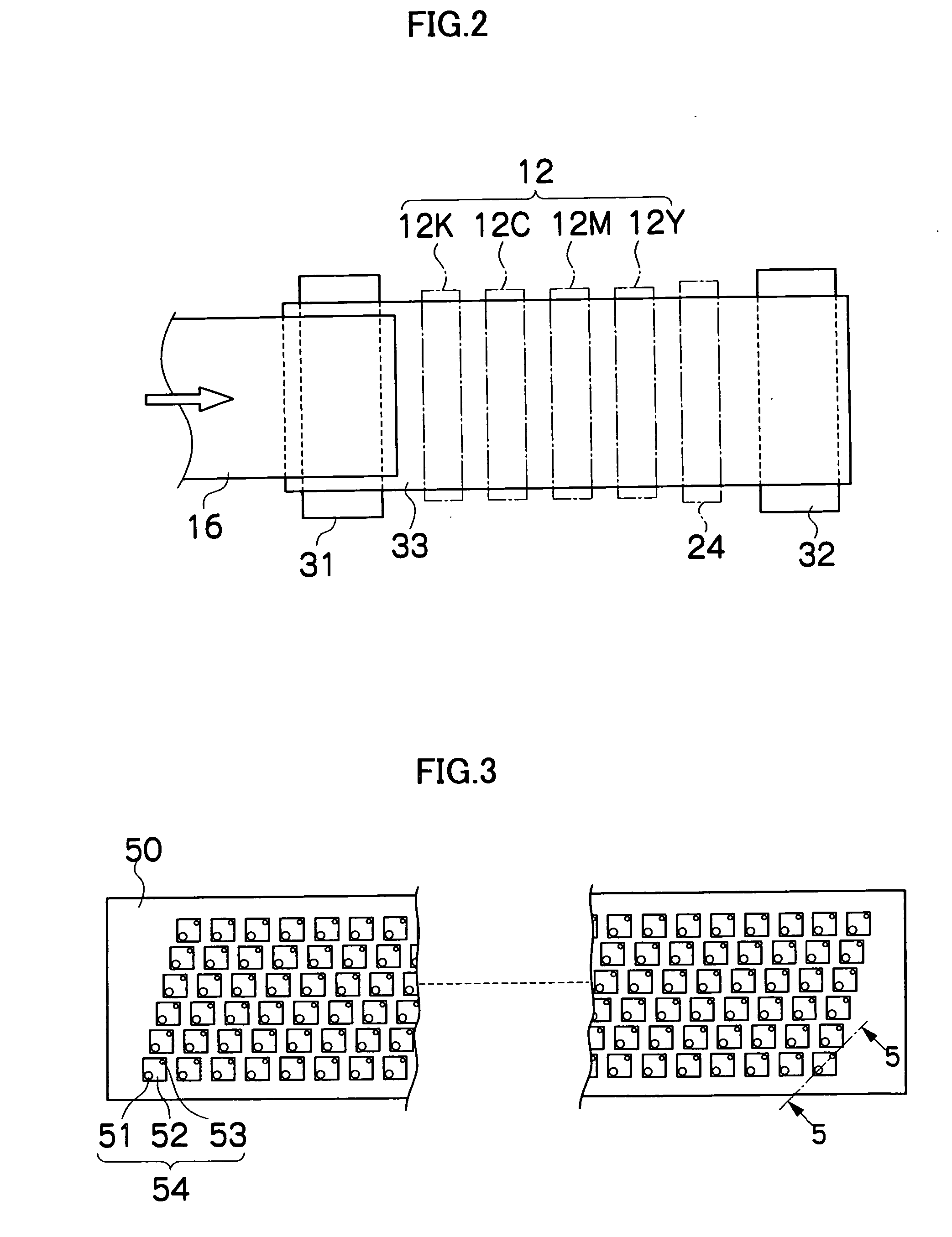

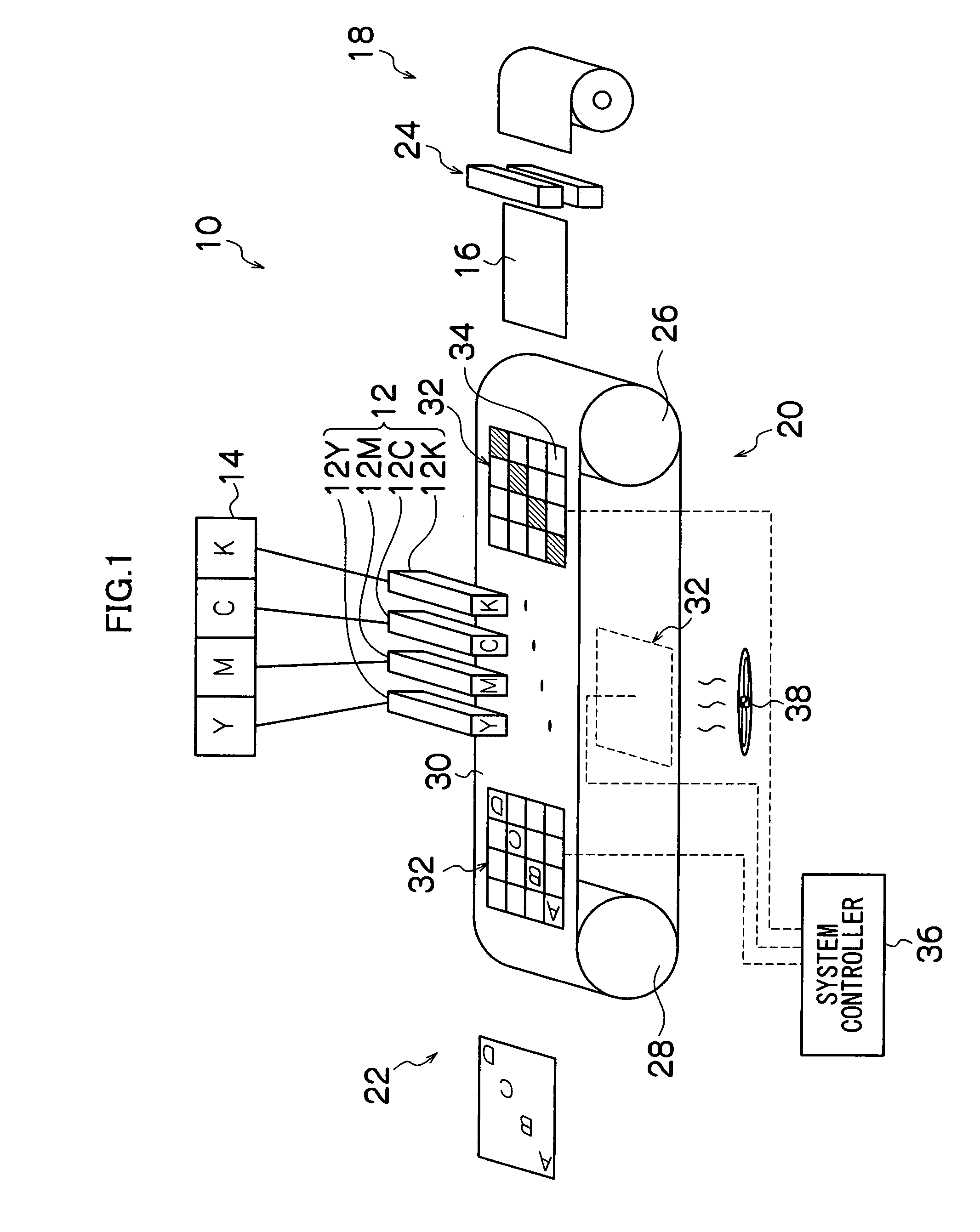

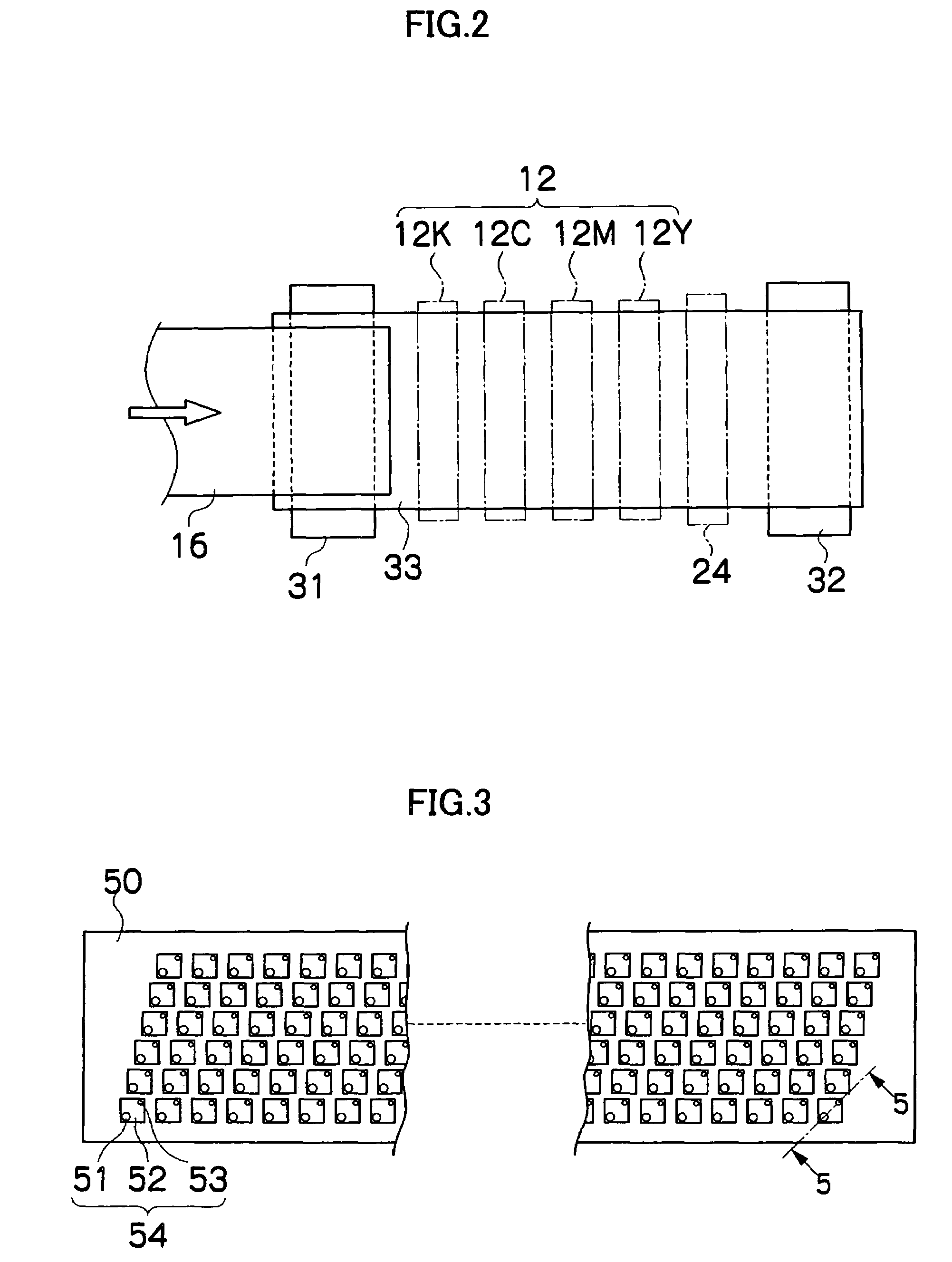

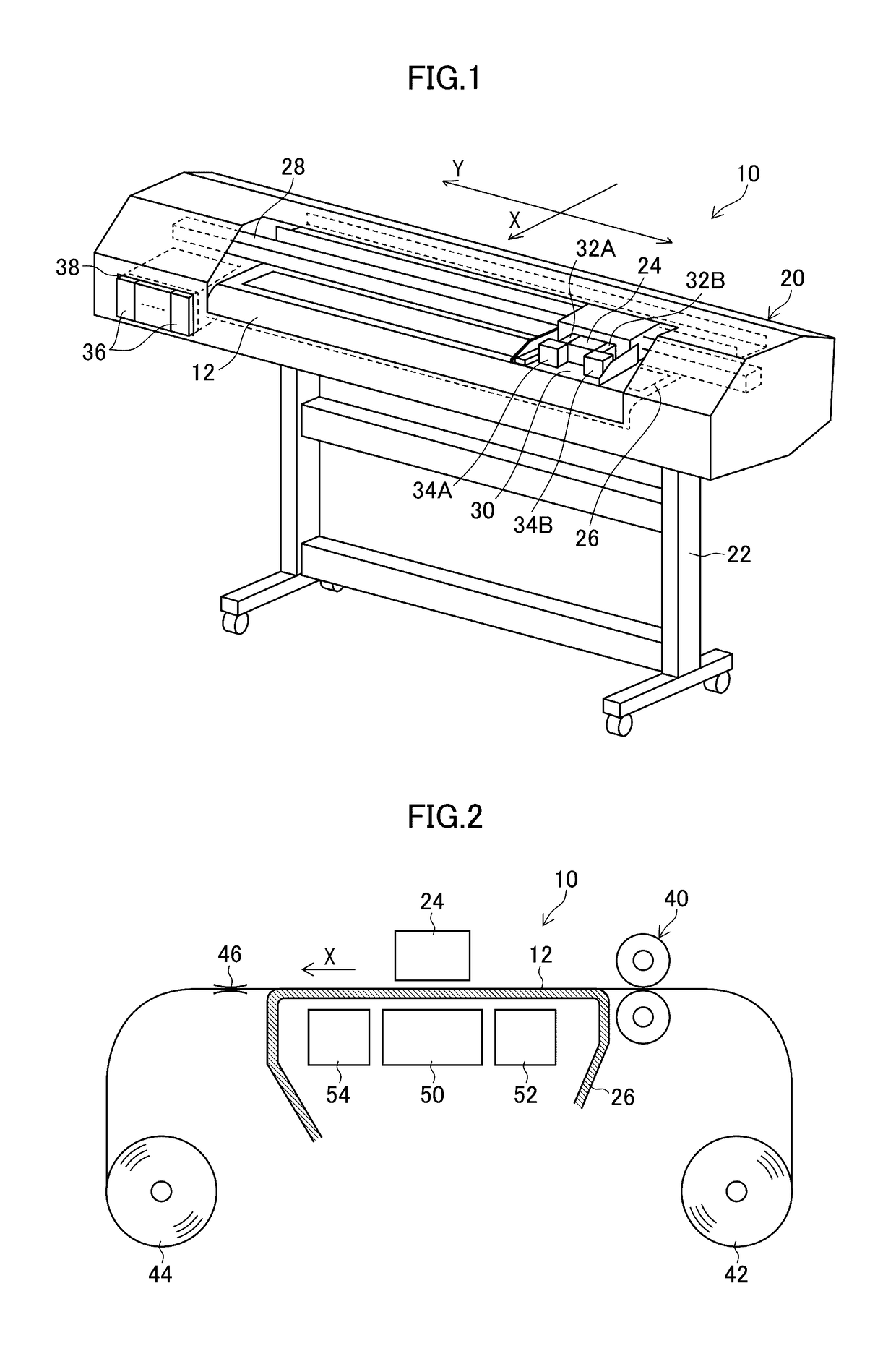

Image recording method and image recording apparatus

InactiveUS20060214960A1Eliminate unevennessReduce unevennessVisual presentationOther printing apparatusImage recordingEjection rate

The image recording apparatus records an image by ejecting ink onto a recording medium from a print head having a plurality of nozzles while moving the print head and the recording medium relatively to each other. The image recording apparatus comprises: a memory device which stores reference density characteristics obtained by measuring a prescribed test pattern formed on the recording medium by means of the nozzles; a density characteristic acquiring device which acquires density characteristics of print areas corresponding to the nozzles; a compensation device which compensates a droplet ejection rate signal of each of the nozzles so that the density characteristics acquired by the density characteristic acquiring device coincide with the reference density characteristics; and a quantization device which quantizes each droplet ejection rate signal compensated by the compensation device.

Owner:FUJIFILM CORP

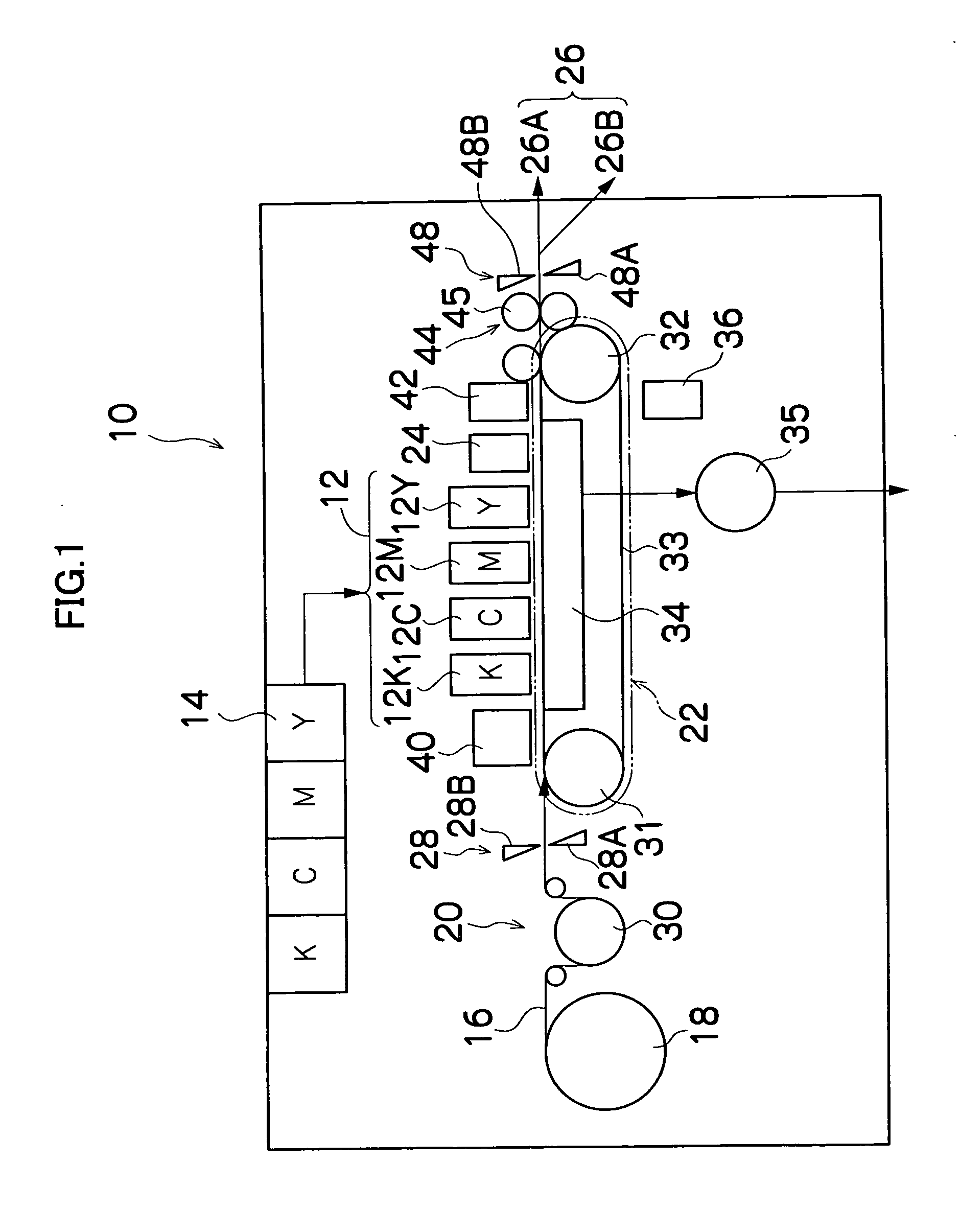

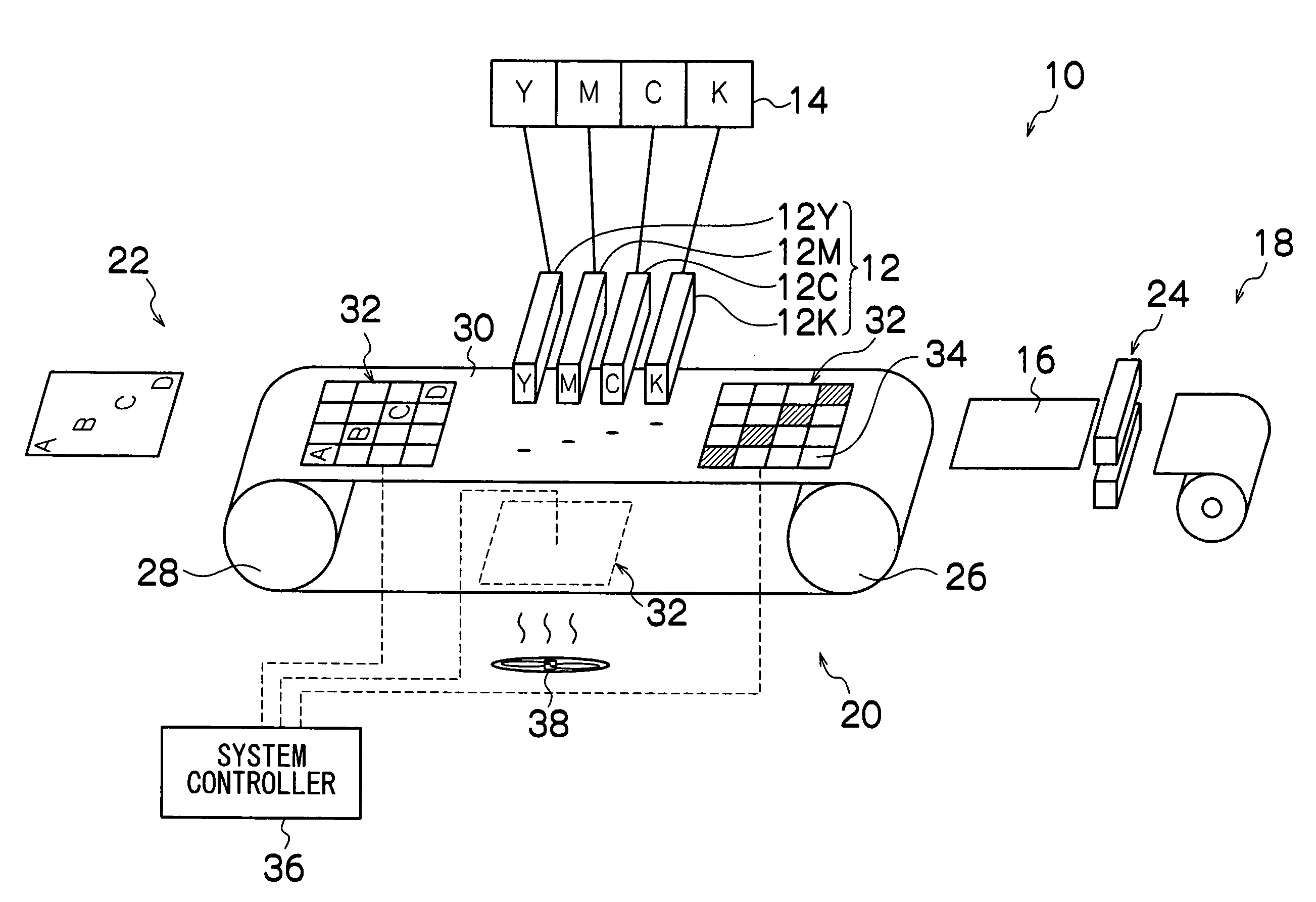

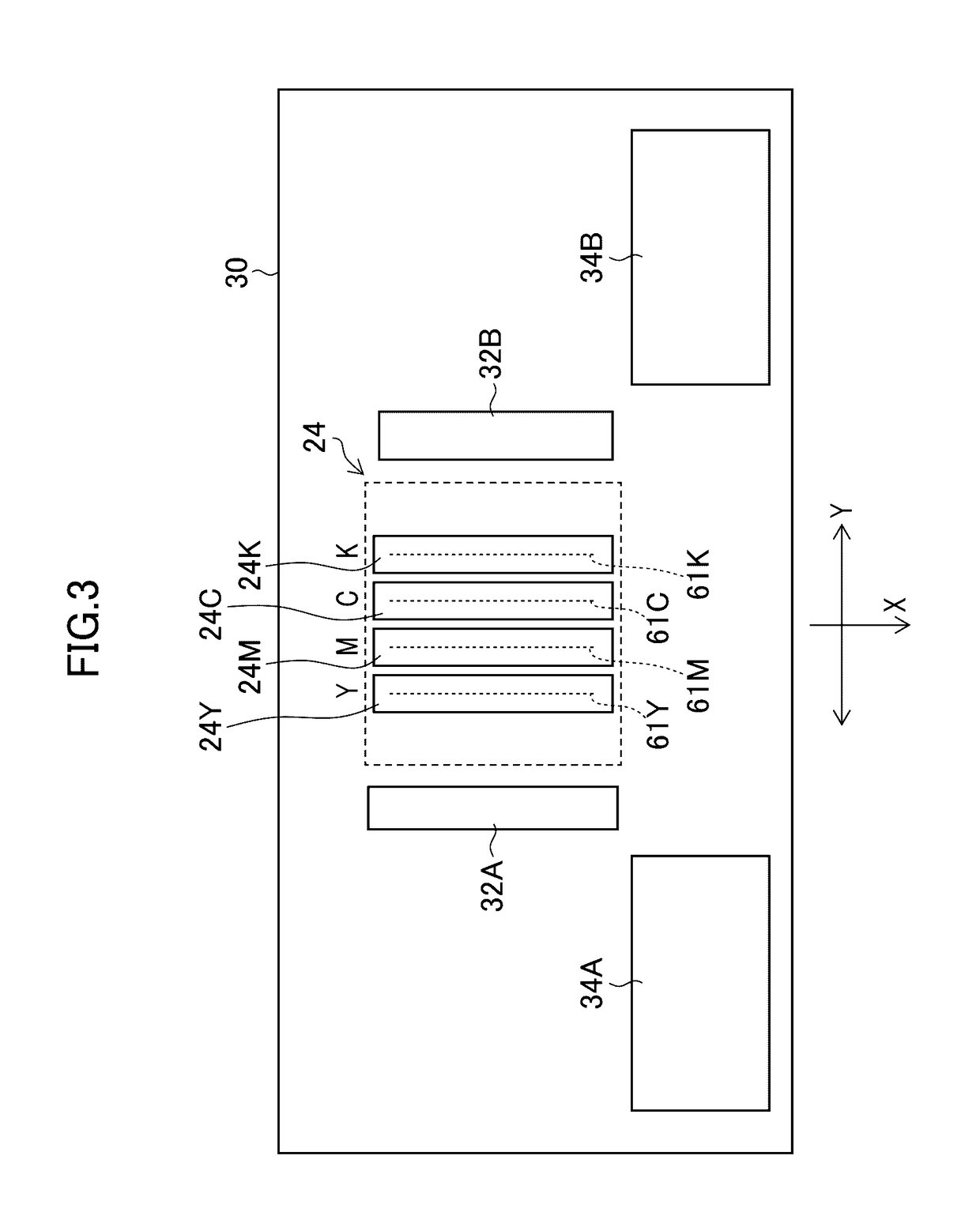

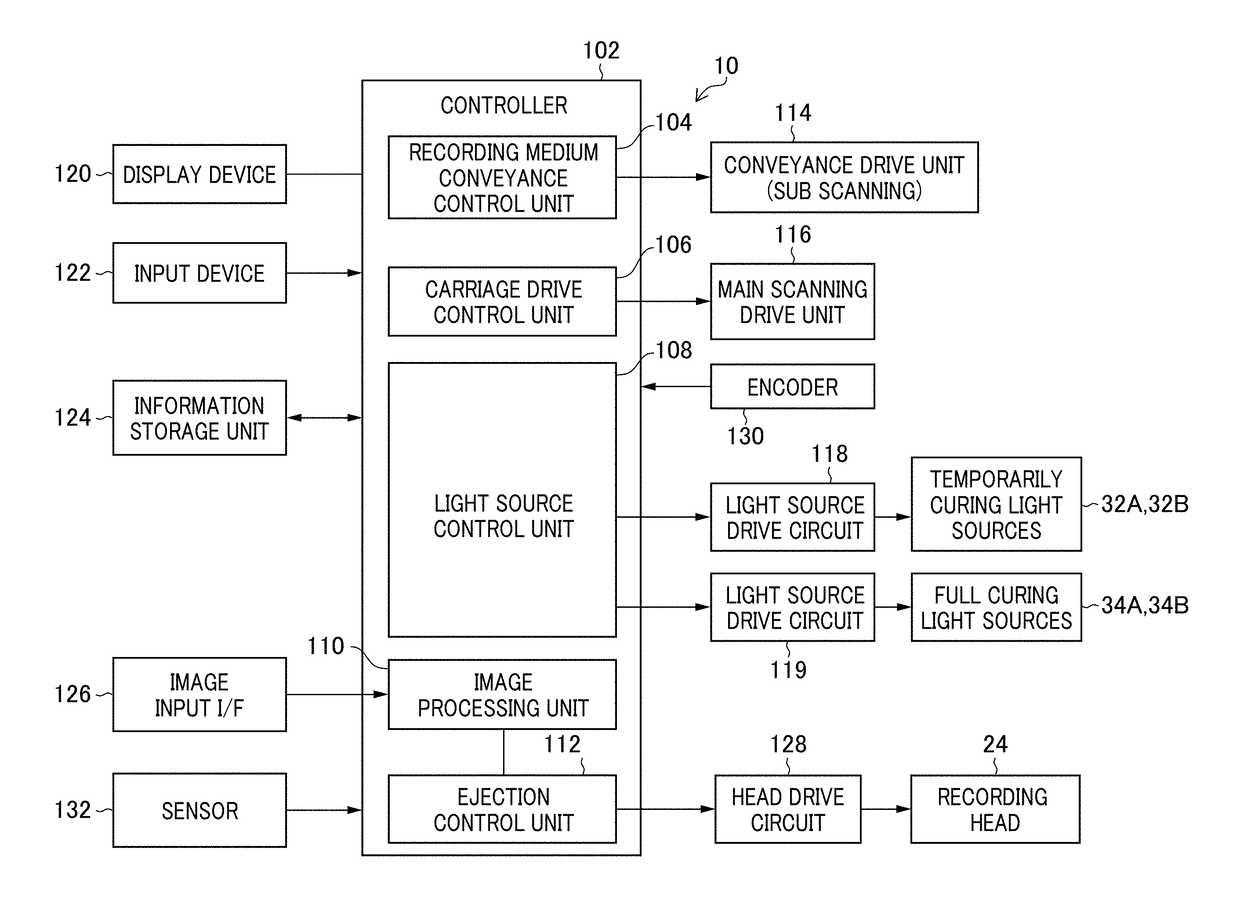

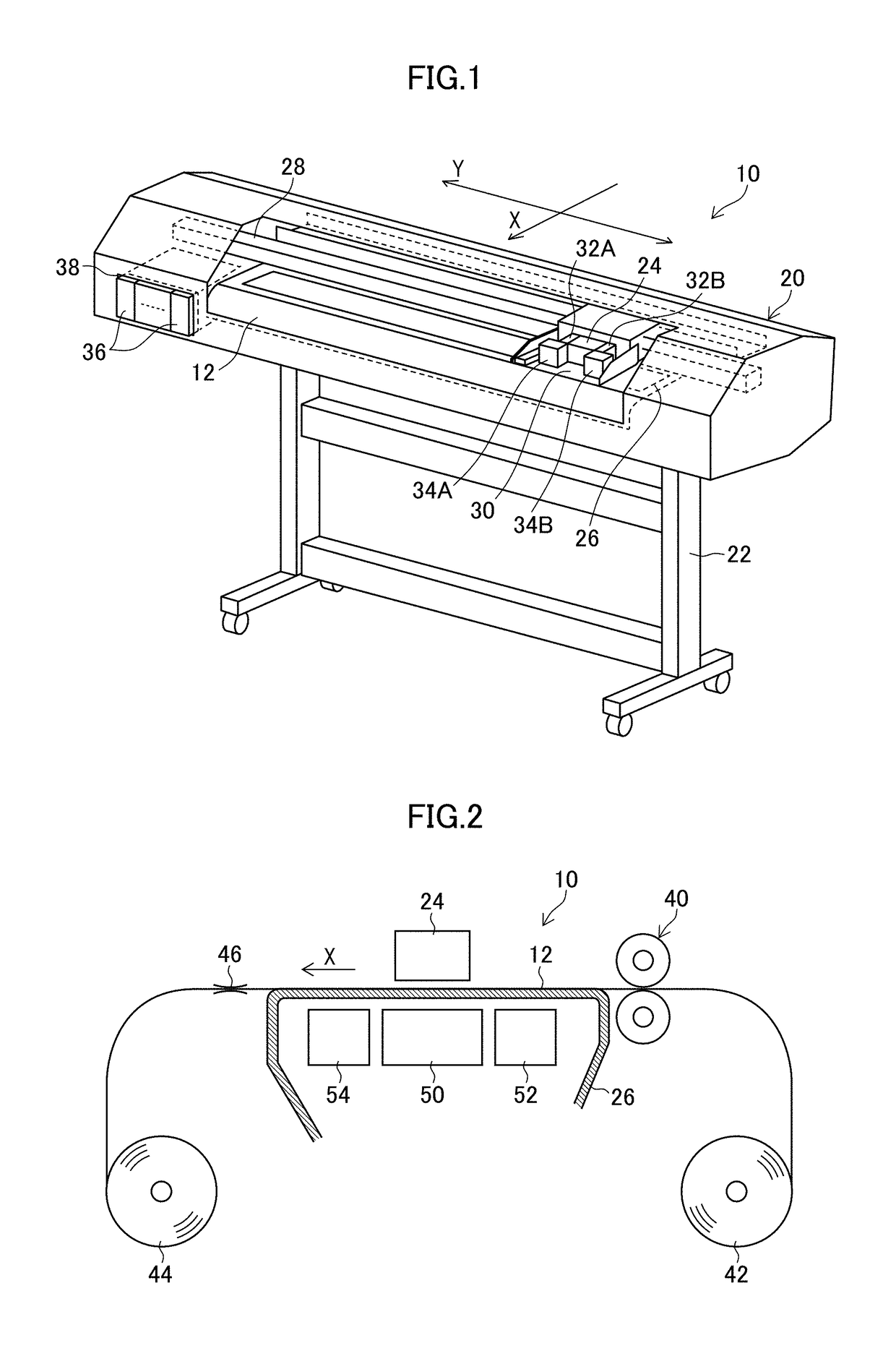

Image forming apparatus and image forming method

InactiveUS20080018690A1Prevent thermal deformationUniform temperature distributionOther printing apparatusData controlImage formation

An image forming apparatus has: an ejection head which ejects droplets of liquid toward a recording medium in accordance with image data; a hold device which holds the recording medium; a conveyance device which conveys the recording medium relatively to the ejection head while the recording medium is held by the hold device; a heating device which is provided with the hold device and is capable of heating a part of the recording medium selectively; and a control device which controls the heating device in accordance with the image data so that, before the droplets of the liquid are ejected by the ejection head, the recording medium is heated by the heating device in accordance with a heating pattern in which a first temperature not greater than an allowable temperature of the recording medium is set for a first region of the recording medium where a liquid ejection rate is not less than a first threshold value while a second temperature less than the first temperature is set for a second region of the recording medium where the liquid ejection rate is not greater than a second threshold value not greater than the first threshold value.

Owner:FUJIFILM CORP

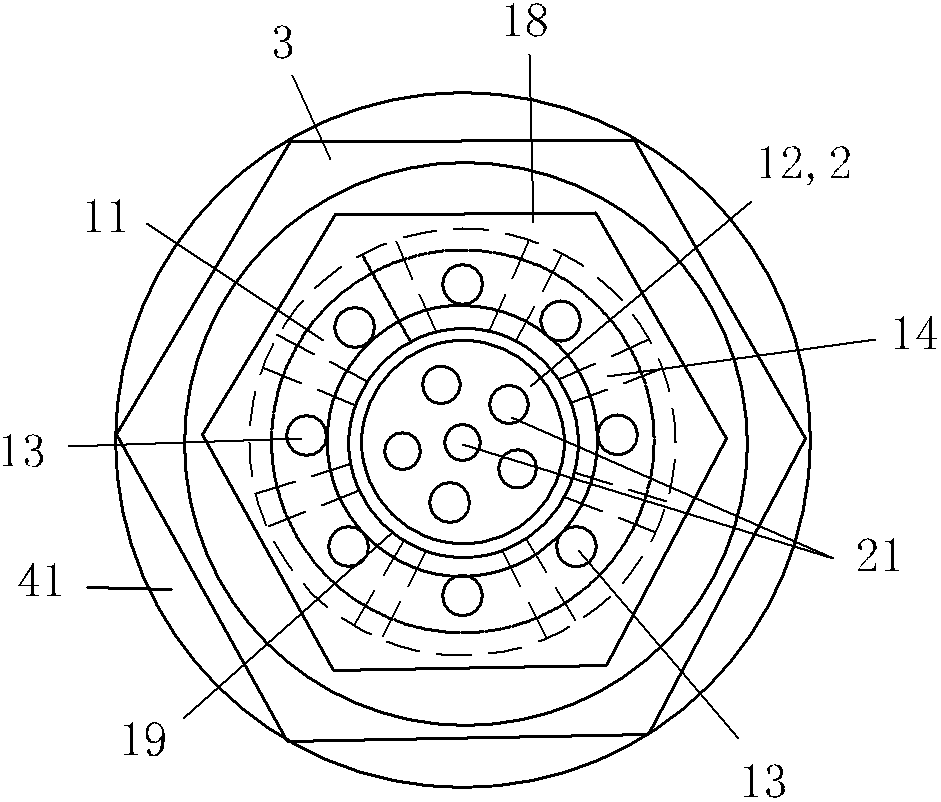

Jet pump

InactiveCN102705272AIncrease volley rateShorten the lengthJet pumpsSpray nozzlesMixed flowEjection rate

The invention discloses a jet pump and relates to mixed flow elements of fluid. An annular ejector of the jet pump is coaxially and serially arranged at the front end of a central ejector; the annular ejector comprises an annular nozzle, an annular mixing chamber and an annular mixing pipe; the central ejector comprises a central nozzle, a central mixing chamber and a central mixing pipe; a primary fluid inlet is laterally communicated with the annular nozzle and is directly communicated with the central nozzle at the tail end of a central pipe; a secondary fluid inlet is communicated with a side wall of the annular mixing chamber; one part of primary fluid is ejected to be introduced into secondary fluid of the annular mixing chamber through the annular nozzle and is mixed in the annular mixing pipe, and annular mixed flow is output; and the other part of primary fluid is jetted to an outlet of the central mixing pipe through the central nozzle and is ejected to enter the annular mixed flow in the central mixing chamber, and the primary fluid and the annular mixed flow are subjected to secondary mixing in the central mixing pipe and are output, so that suction of high-pressure primary fluid and mixed flow delivery of low-pressure secondary fluid are finished. The jet pump which is formed by sleeving and connecting two ejectors in series is small in axial size and high in ejection rate and output pressure.

Owner:韩铁夫

Method for determining color correction parameter for recording apparatus

ActiveUS20120194833A1Color variation can be suppressedIncrease productivityDigitally marking record carriersDigital computer detailsProduction rateComputer hardware

From a cost and productivity perspective, the recording and color-measurement of a test pattern to determine whether it is necessary to execute calibration places a heavy burden on a user. The present invention determines the need for processing to generate a color correction parameter without recording a test pattern. More specifically, the present invention determines whether it is necessary to execute color correction parameter generation processing based on an increase in a dot count since color correction parameter generation processing was previously executed, or a change in a ejection rate.

Owner:CANON KK

Image recording method and image recording apparatus

InactiveUS7524009B2Reduce unevennessEliminate unevennessVisual presentationOther printing apparatusImage recordingEjection rate

The image recording apparatus records an image by ejecting ink onto a recording medium from a print head having a plurality of nozzles while moving the print head and the recording medium relatively to each other. The image recording apparatus comprises: a memory device which stores reference density characteristics obtained by measuring a prescribed test pattern formed on the recording medium by means of the nozzles; a density characteristic acquiring device which acquires density characteristics of print areas corresponding to the nozzles; a compensation device which compensates a droplet ejection rate signal of each of the nozzles so that the density characteristics acquired by the density characteristic acquiring device coincide with the reference density characteristics; and a quantization device which quantizes each droplet ejection rate signal compensated by the compensation device.

Owner:FUJIFILM CORP

Dither mask generation method and device

The dither mask generation method includes: a process of setting a nozzle relative ejection rate which is a control target of the nozzle ejection rate and stipulates a relative using ratio of the individual nozzles; a process of setting a nozzle pattern indicating correspondence relation between individual pixels of the dither mask and the nozzles in charge of recording at respective pixel positions; a process of setting an upper limit to the nozzle ejection rates of the individual nozzles for each raster in a main scanning direction, regarding at least some thresholds; and a process of setting the thresholds to the pixels of the dither mask based on the nozzle relative ejection rate, the nozzle pattern and a limitation by the upper limit.

Owner:FUJIFILM CORP

Image forming apparatus and image forming method

InactiveUS7934824B2Easy to disassembleQuality improvementOther printing apparatusImage formationEngineering

An image forming apparatus has: an ejection head which ejects droplets of liquid toward a recording medium in accordance with image data; a hold device which holds the recording medium; a conveyance device which conveys the recording medium relatively to the ejection head while the recording medium is held by the hold device; a heating device which is provided with the hold device and is capable of heating a part of the recording medium selectively; and a control device which controls the heating device in accordance with the image data so that, before the droplets of the liquid are ejected by the ejection head, the recording medium is heated by the heating device in accordance with a heating pattern in which a first temperature not greater than an allowable temperature of the recording medium is set for a first region of the recording medium where a liquid ejection rate is not less than a first threshold value while a second temperature less than the first temperature is set for a second region of the recording medium where the liquid ejection rate is not greater than a second threshold value not greater than the first threshold value.

Owner:FUJIFILM CORP

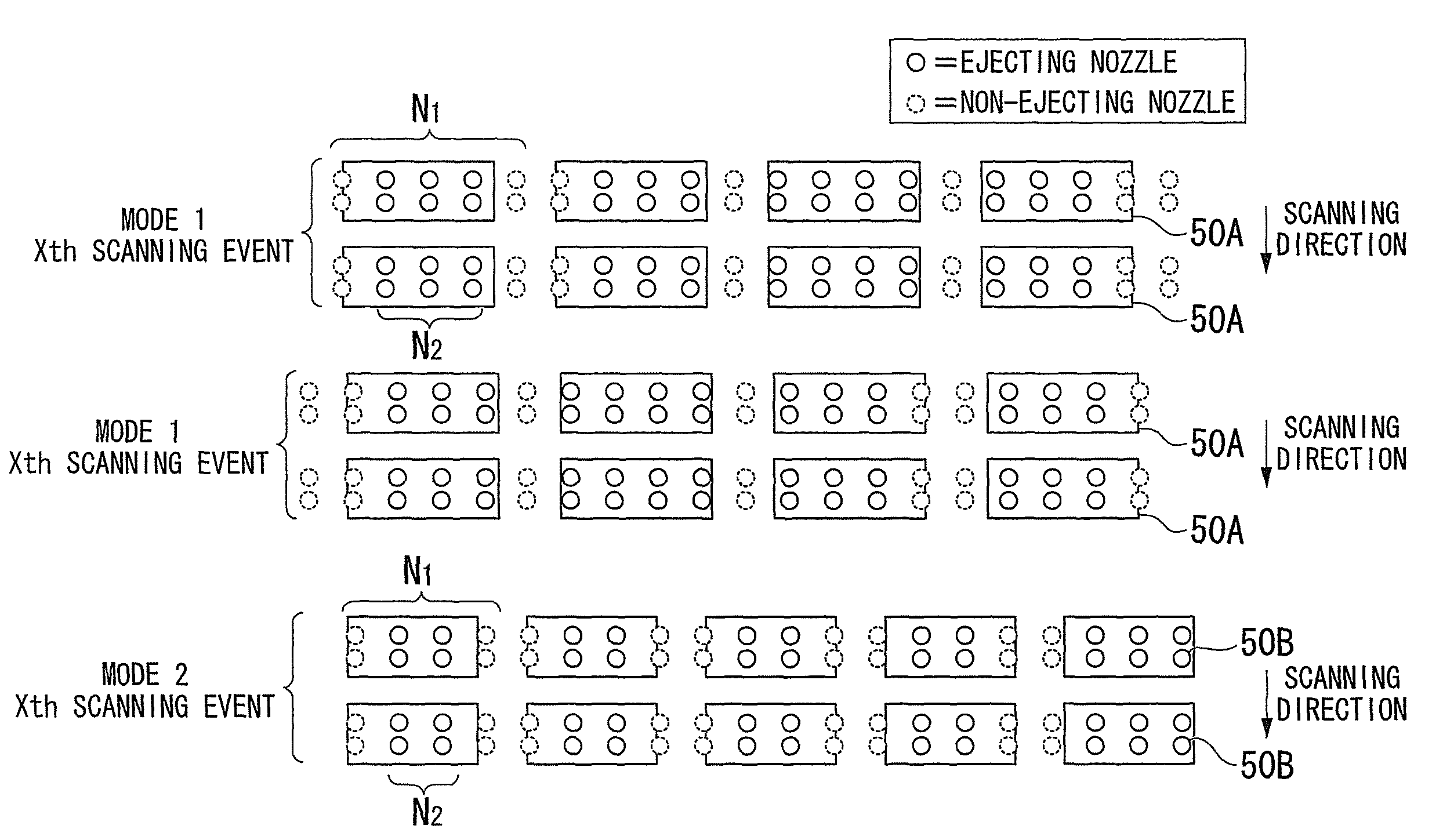

Liquid ejection control device, method, and program

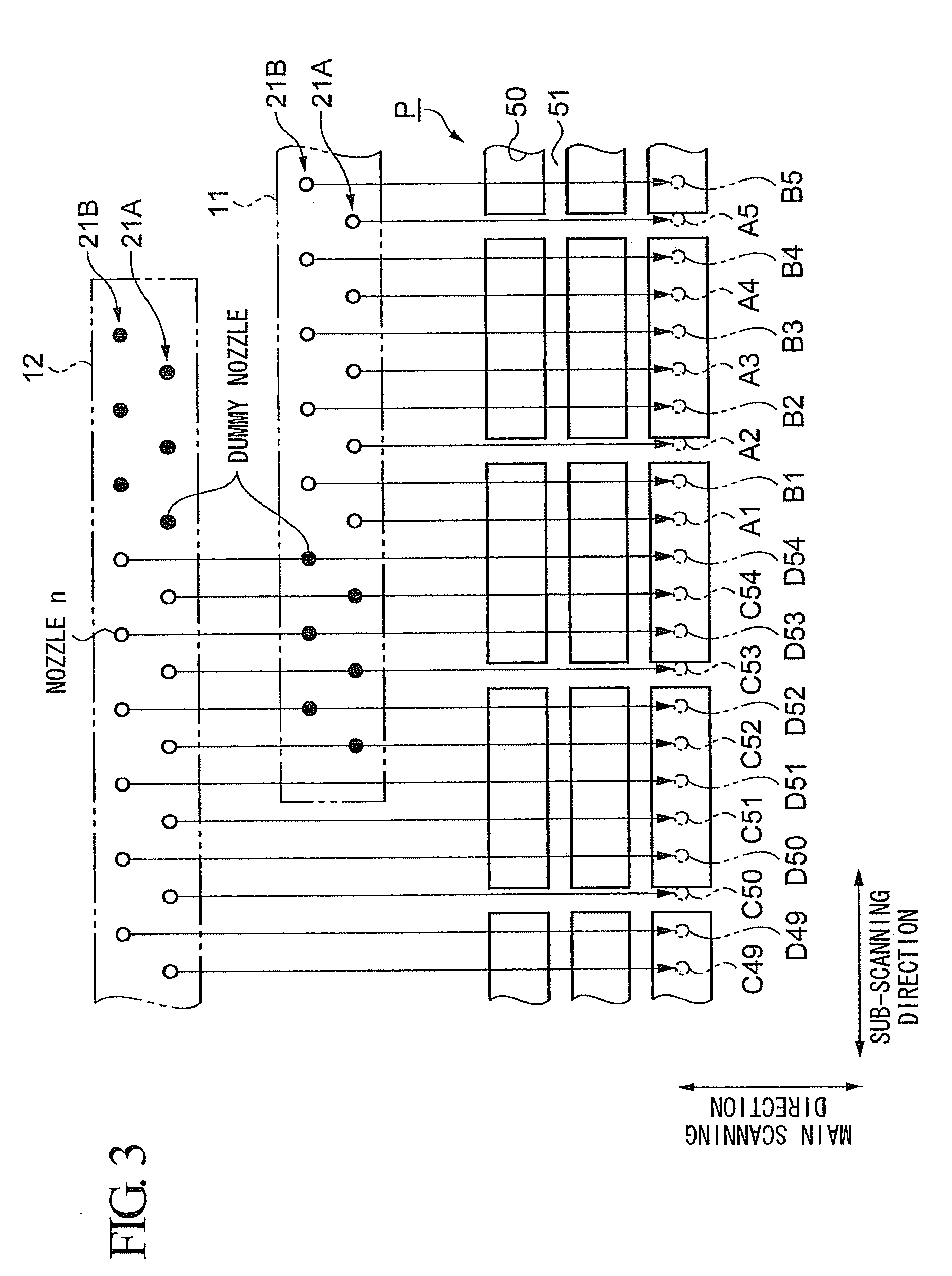

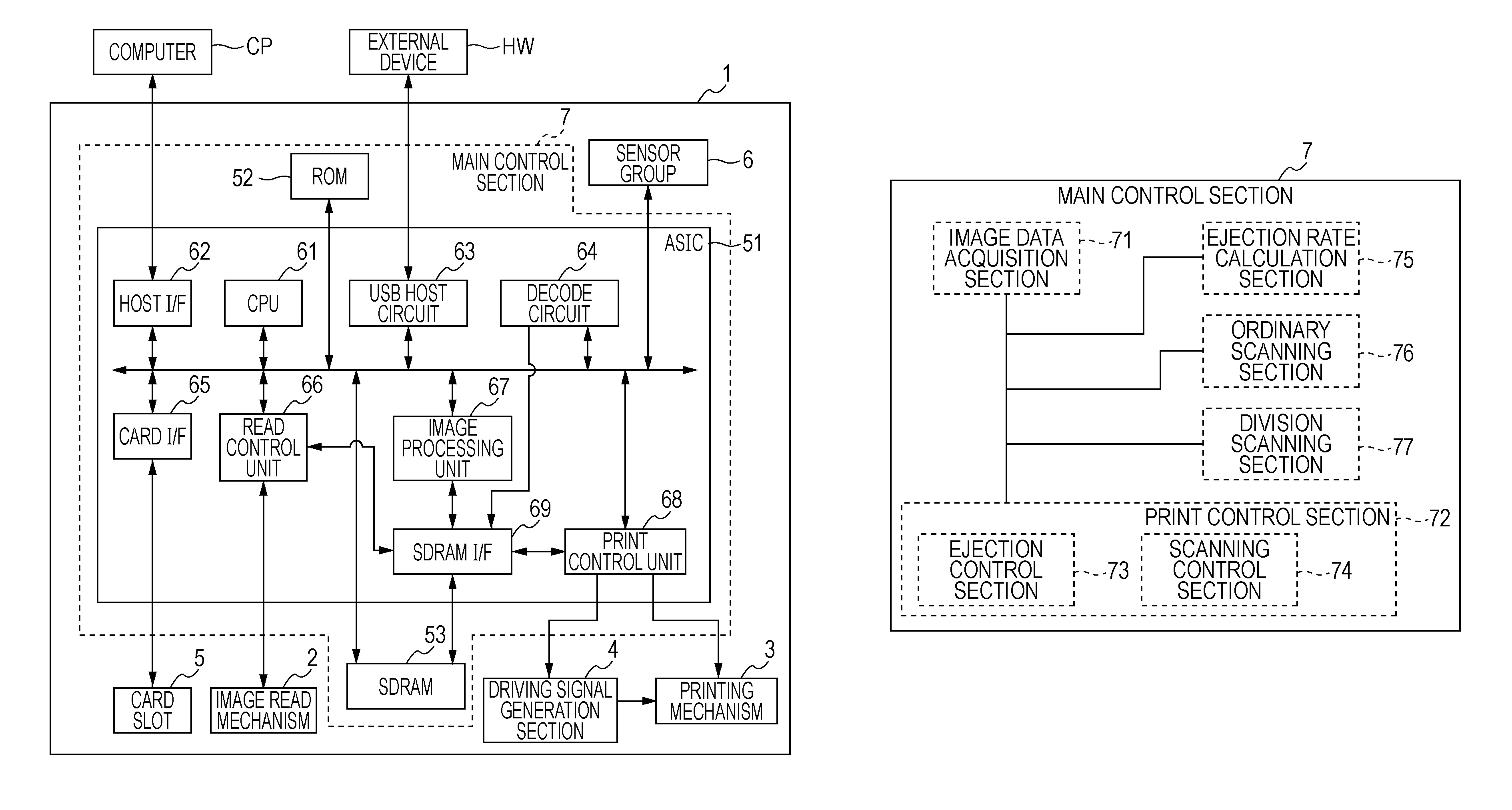

A liquid ejection control device, which makes an ejection object medium and an ejection nozzle column which ejects liquid relatively primarily scan in a primary scan direction which intersects the nozzle ejection column and makes the ejection object medium and the ejection nozzle column relatively subordinately scan in a subordinate scan direction which almost perpendicularly intersects the primary scan direction, includes an ejection control unit which controls ejections of ejection nozzles in a manner such that ejection rates of the ejection nozzles are asymmetric with respect to positions of the ejection nozzles, when a rate of an ejection, which is charged by a predetermined ejection nozzle, to a primary scan line at the same position in the subordinate scan direction is called an ejection rate.

Owner:SEIKO EPSON CORP

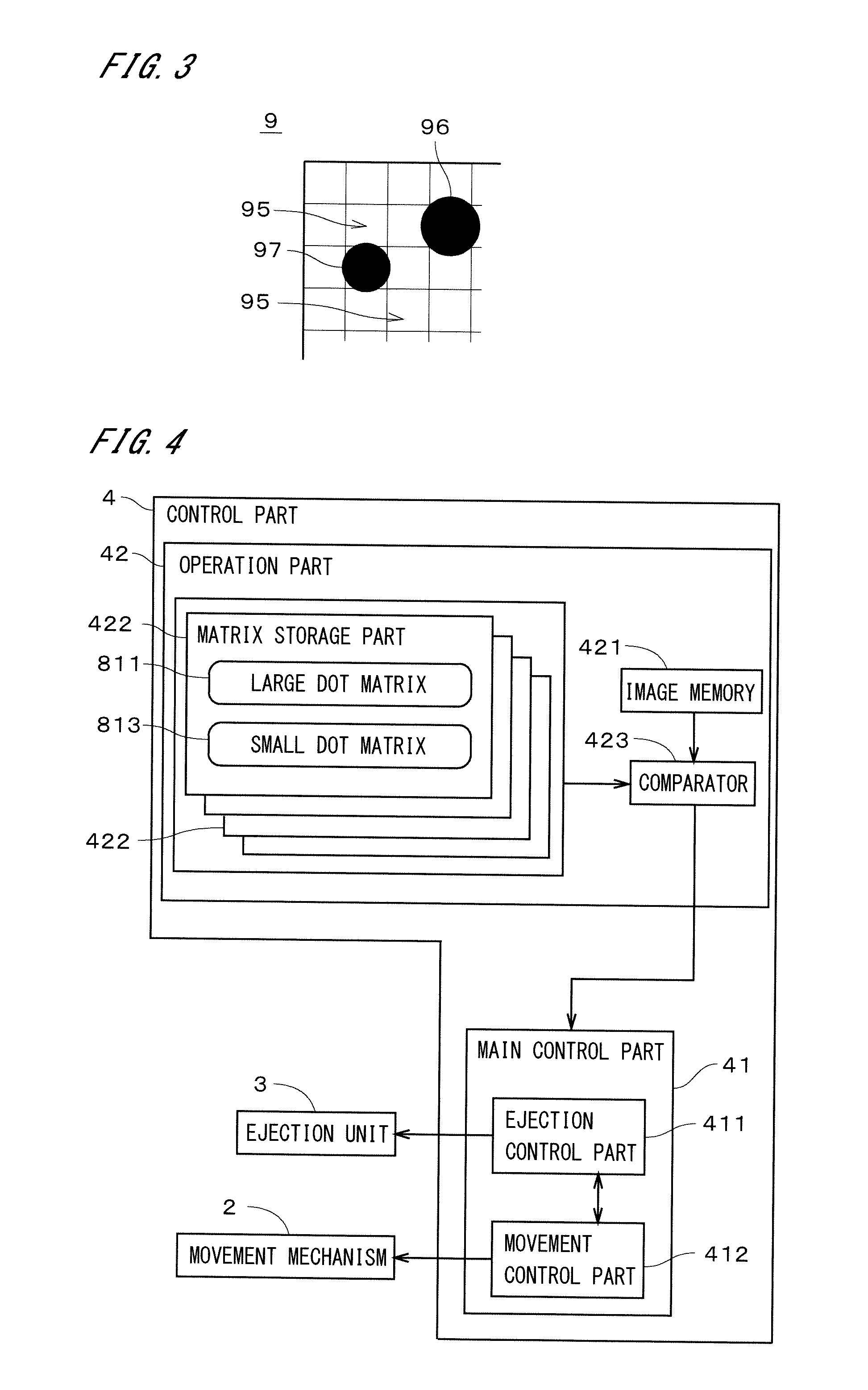

Method for setting up drive signal

ActiveUS20090201326A1Easy to set upConcentrate moreInking apparatusOther printing apparatusMoving averageEjection rate

A method for setting up a condition for a drive signal in a liquid ejection head that includes a plurality of linearly-arranged nozzles and driving elements provided for each of the nozzles, includes: calculating an ejection rate for each nozzle relating to a supply of the drive signal under a predetermined condition by using a moving average; classifying the plurality of nozzles into a plurality of groups based on the ejection rate calculated by using the moving average of each nozzle; calculating a proper condition for the drive signal corresponding to each group based on a statistical value of the ejection rate relating to the group; and selecting one proper condition among proper conditions corresponding to the groups so as to set the selected proper condition for each nozzle.

Owner:KATEEVA

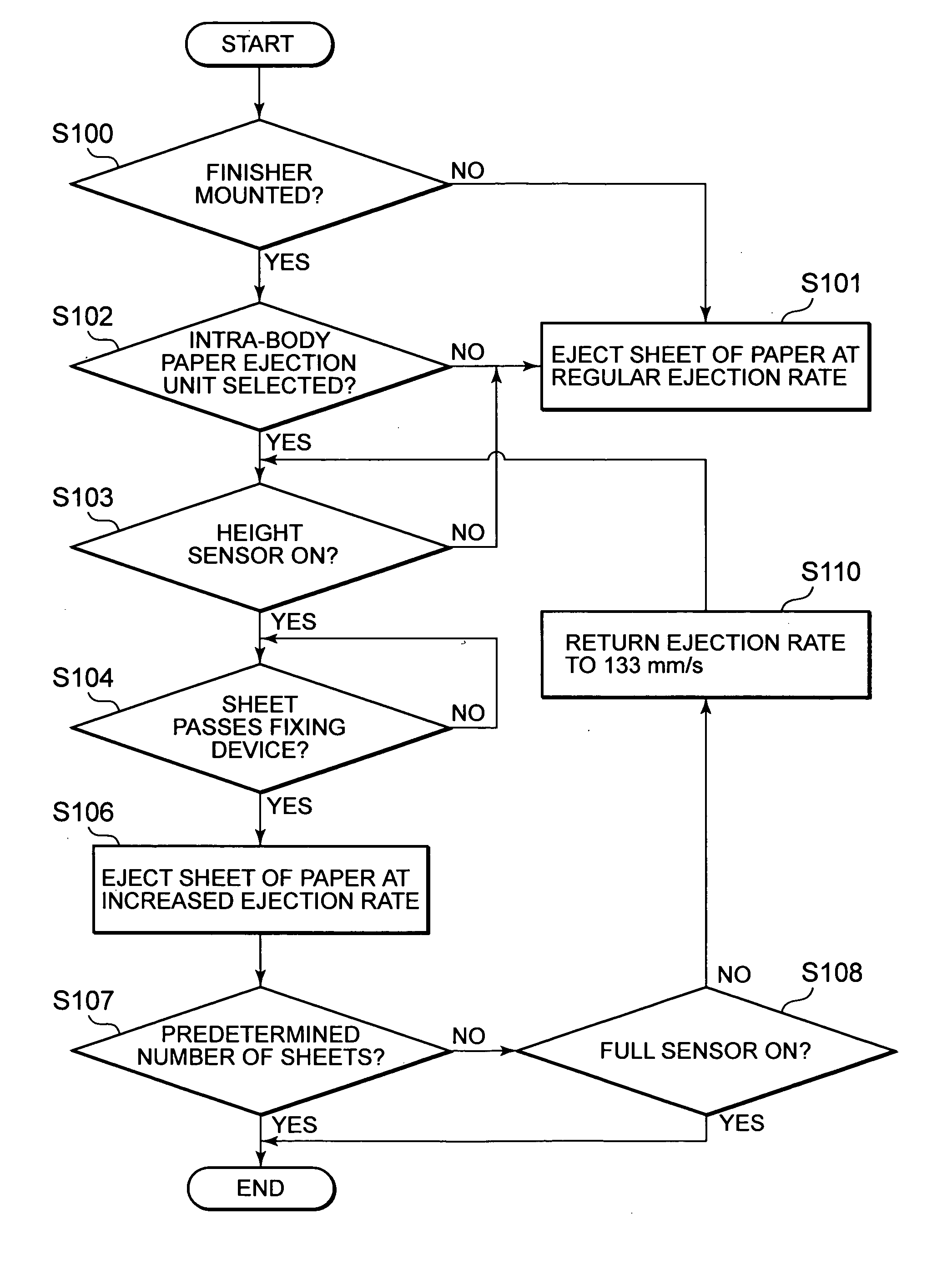

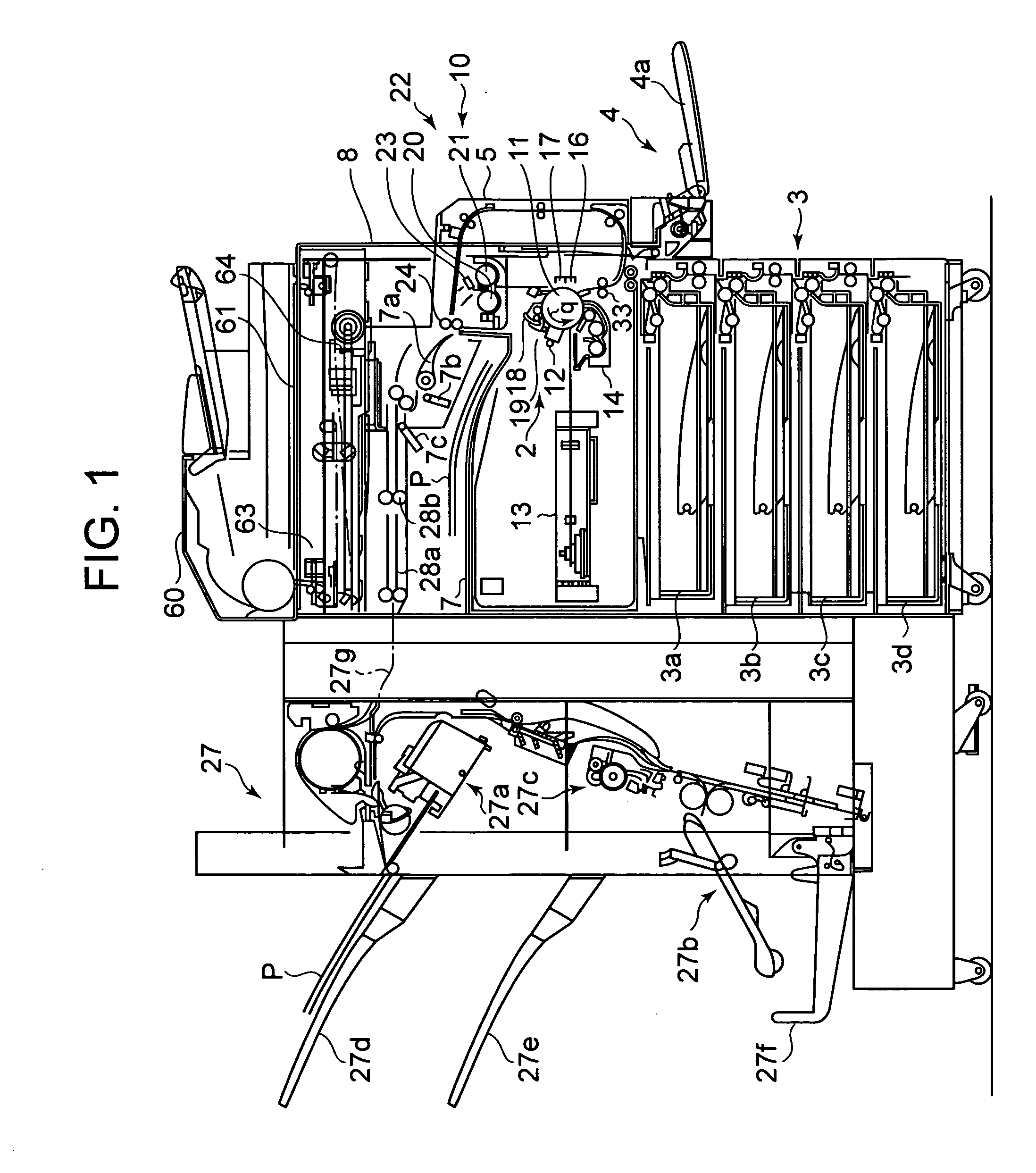

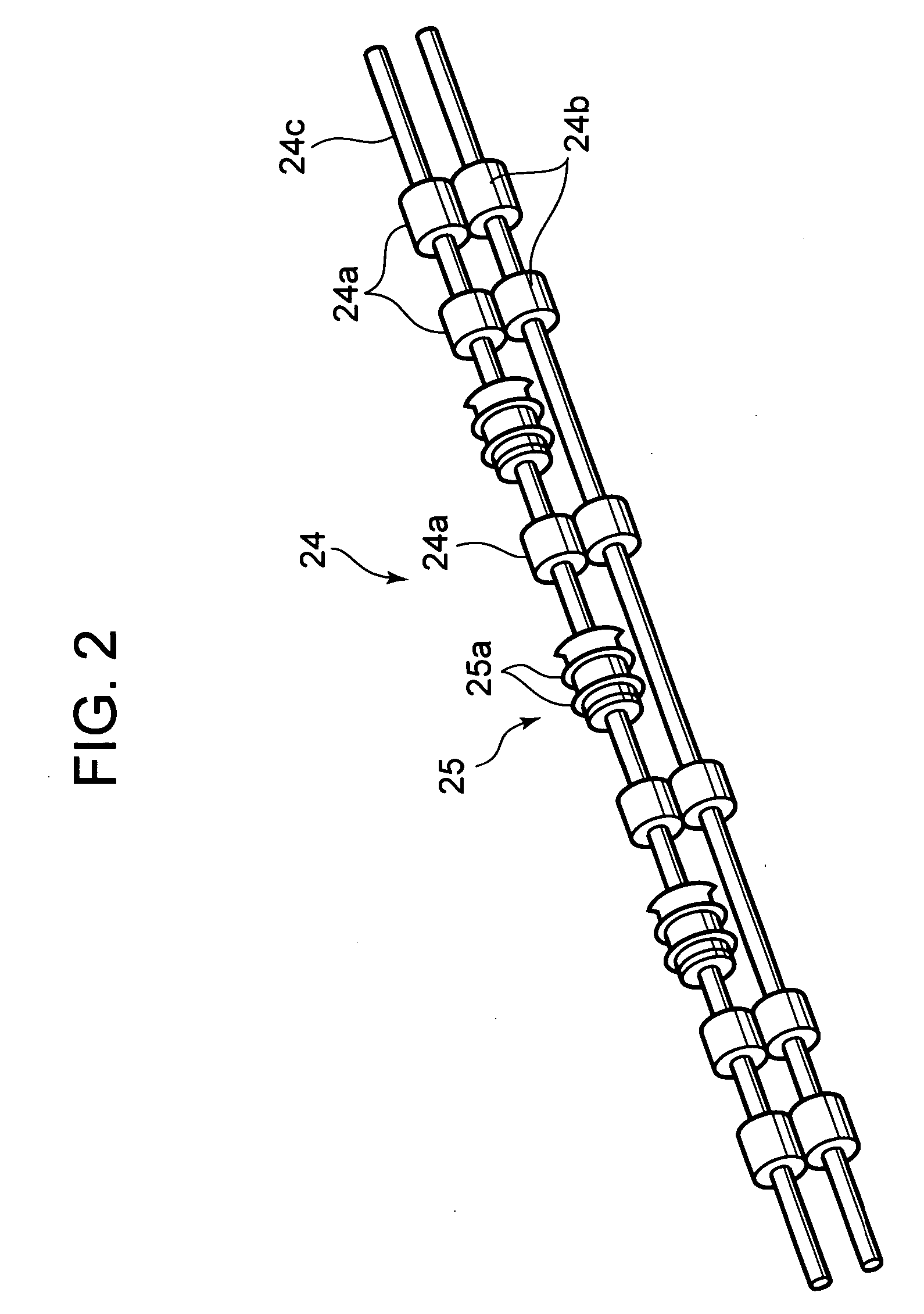

Image forming apparatus and paper ejection method of image forming apparatus

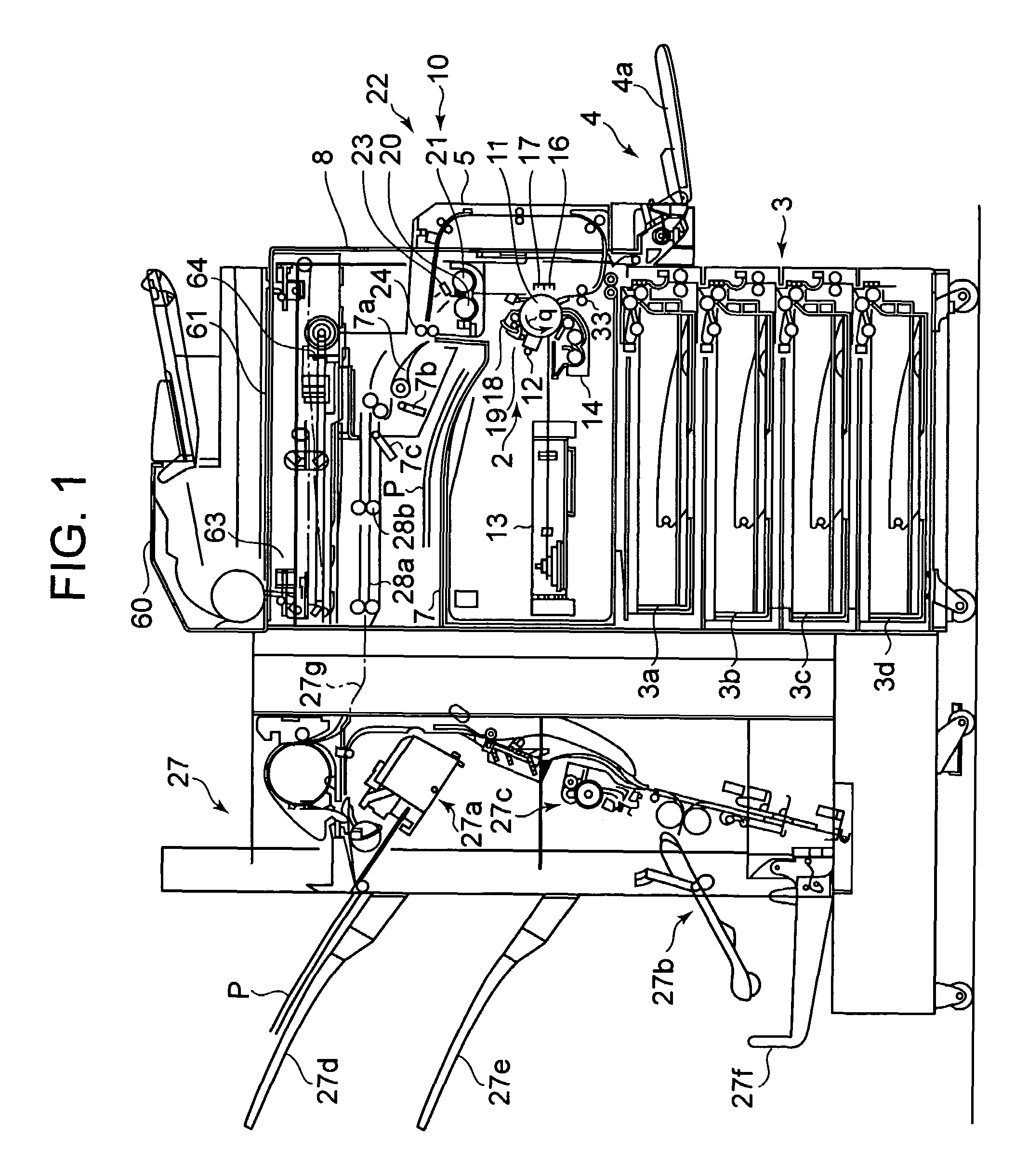

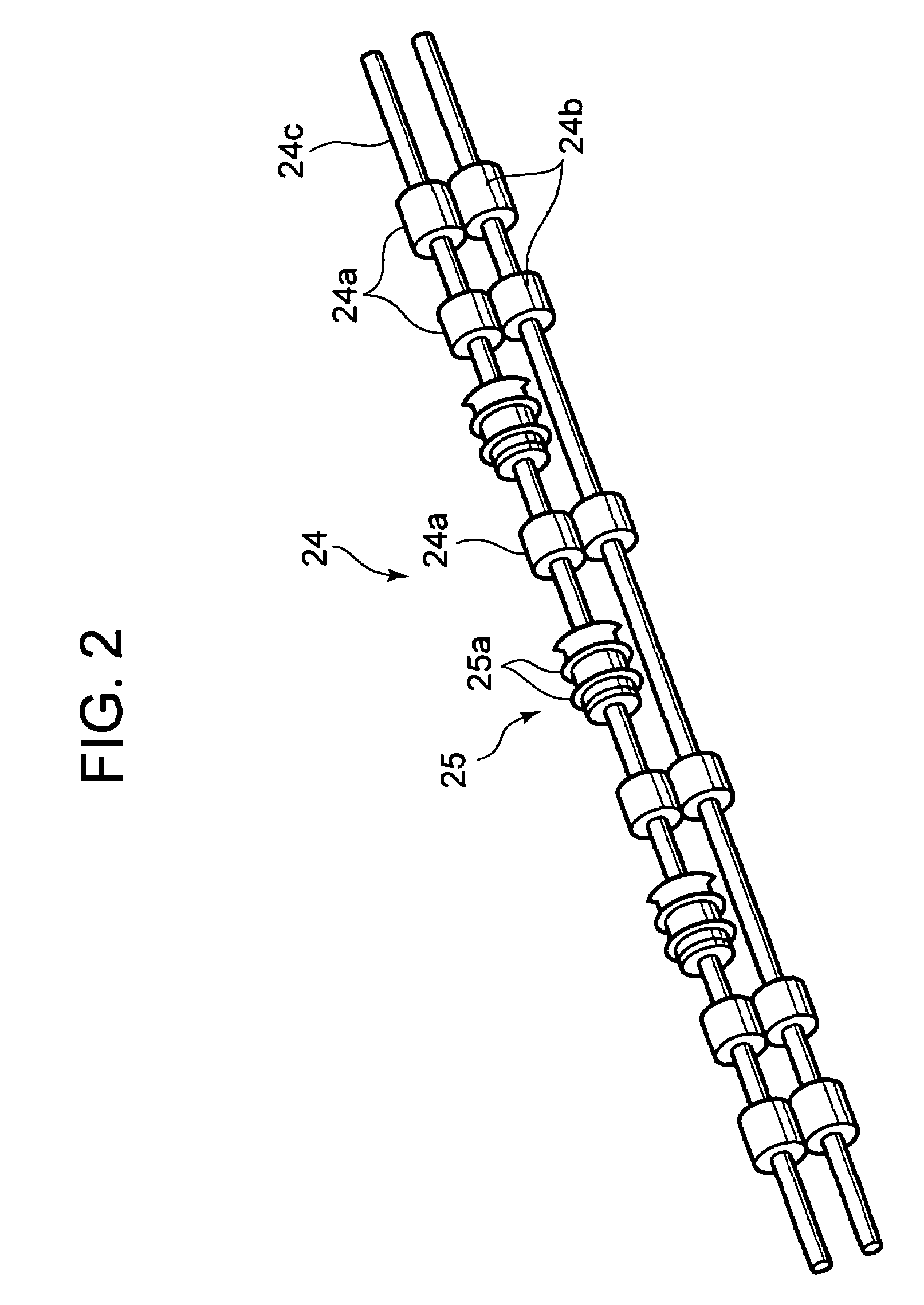

ActiveUS7426366B2Easy to transportElectrographic process apparatusImage formationPulp and paper industry

A drive unit for changing the driving rate of paper ejection rollers for ejecting sheets of paper after fixing is installed, and an image forming apparatus has an option, and when ejecting the sheets of paper to an intra-body paper ejection unit, after the sheets of paper pass a fixing device, the paper ejection rate of paper ejection rollers 24 is increased, and the ejection force of the sheets of paper P is increased, and paper jamming at the time of paper ejection to the intra-body paper ejection unit is prevented.

Owner:KK TOSHIBA +1

Ultra-low carbon IF steel complex deoxidation method

InactiveCN106544473AReduce the generation of inclusionsFacilitate the removal of inclusions floating upEjection rateOxygen content

The invention relates to an ultra-low carbon IF steel complex deoxidation method. The method includes the following steps that (1) after RH vacuum decarburization and degassing treatment are completed, the complex deoxidizer Si-Ca-Ba-Fe is added for preliminary deoxidation according to the weight percentage content requirement of silicon in finished product IF steel; and (2) after the Si-Ca-Ba-Fe is added, RH clean circulation lasts for 3-5min, the molten steel oxygen content is measured, and then aluminum particles are added for final deoxidation according to the molten steel oxygen content based on a conventional deoxidation technology. Compared with the prior art, the ultra-low carbon IF steel complex deoxidation method has the beneficial effects that (1) Al2O3 impurities in molten steel can be reduced, and floating elimination of the Al2O3 impurities is facilitated; (2) the composite deoxidation product mainly refers to a composite occluded foreign substance of BaO, CaO, Al2O3 and the like, the occluded foreign substance can float easily, the size is small, water gaps cannot be blocked, and smooth pouring is guaranteed; (3) the cleanliness of the molten steel is improved obviously, the quality of automobile body sheets and other products with high surface quality requirements is effectively improved, the included ejection rate is lowered, and the whole performance of IF steel is improved; and (4) operation is simple and easy to implement, and cost is low.

Owner:ANGANG STEEL CO LTD

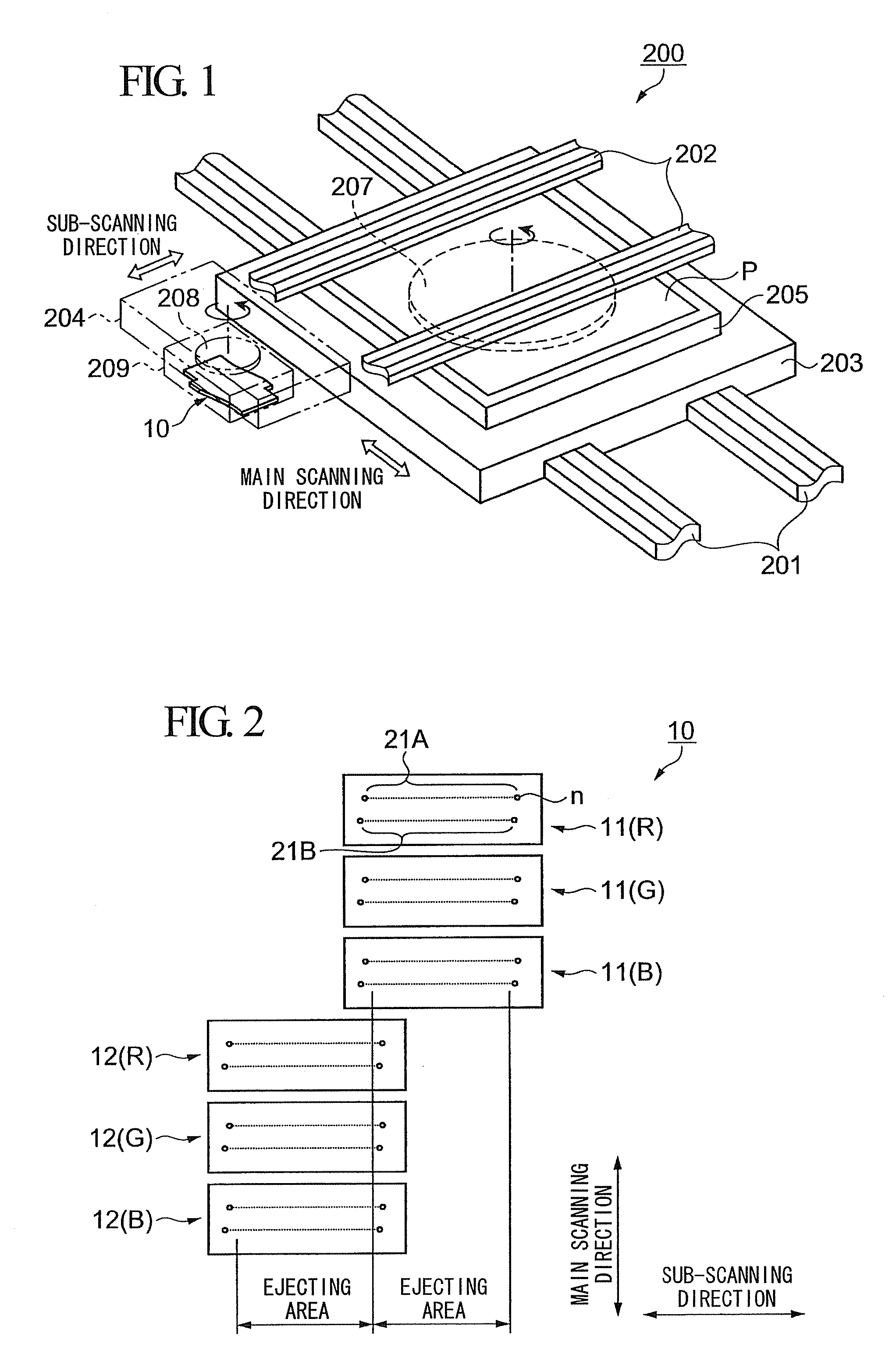

Liquid ejecting apparatus and liquid ejecting method

Owner:SEIKO EPSON CORP

Method for setting up drive signal

ActiveUS20090207201A1Easy to set upConcentrate moreOther printing apparatusEjection rateDriven element

A method for setting up a condition for a drive signal in a liquid ejection head that includes a plurality of linearly-arranged nozzles and driving elements provided for each of the nozzles, includes: calculating an average value or a median value of ejection rates for each nozzle relating to a supply of the drive signal under a plurality of conditions; classifying the plurality of nozzles into a plurality of groups based on the average value or the median value of the ejection rates; calculating a proper condition for the drive signal corresponding to each group based on a statistical value of the ejection rate relating to the group; and selecting one proper condition among proper conditions corresponding to the groups so as to set the selected proper condition for each nozzle.

Owner:KATEEVA

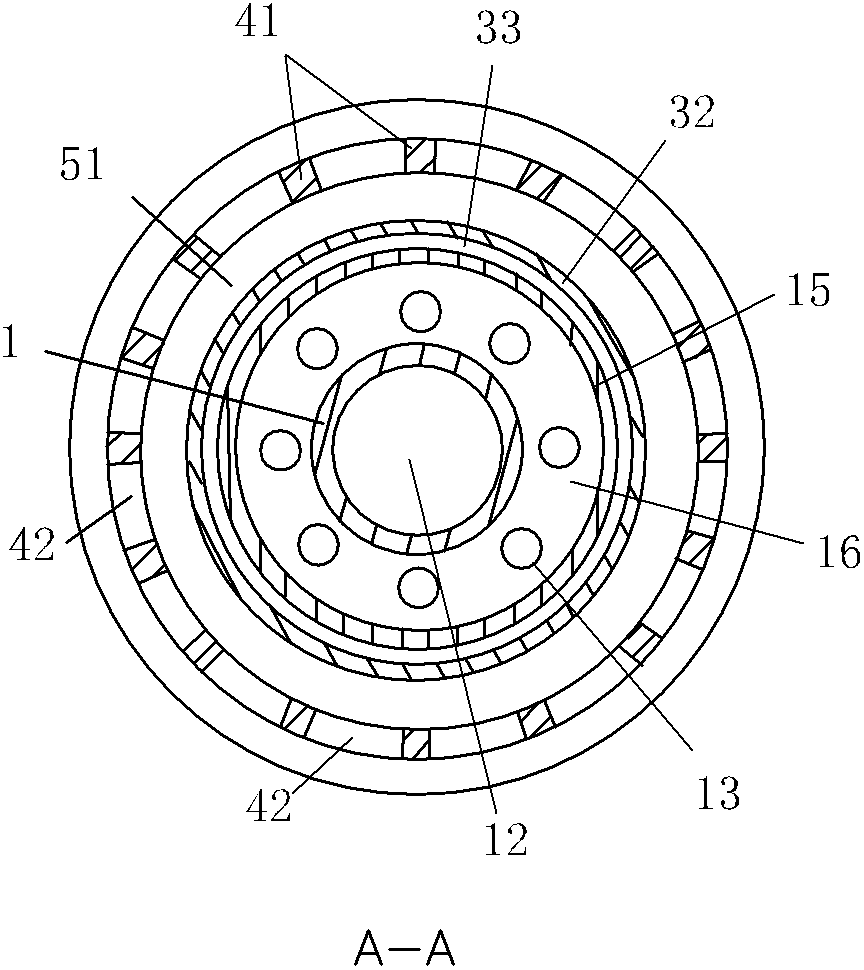

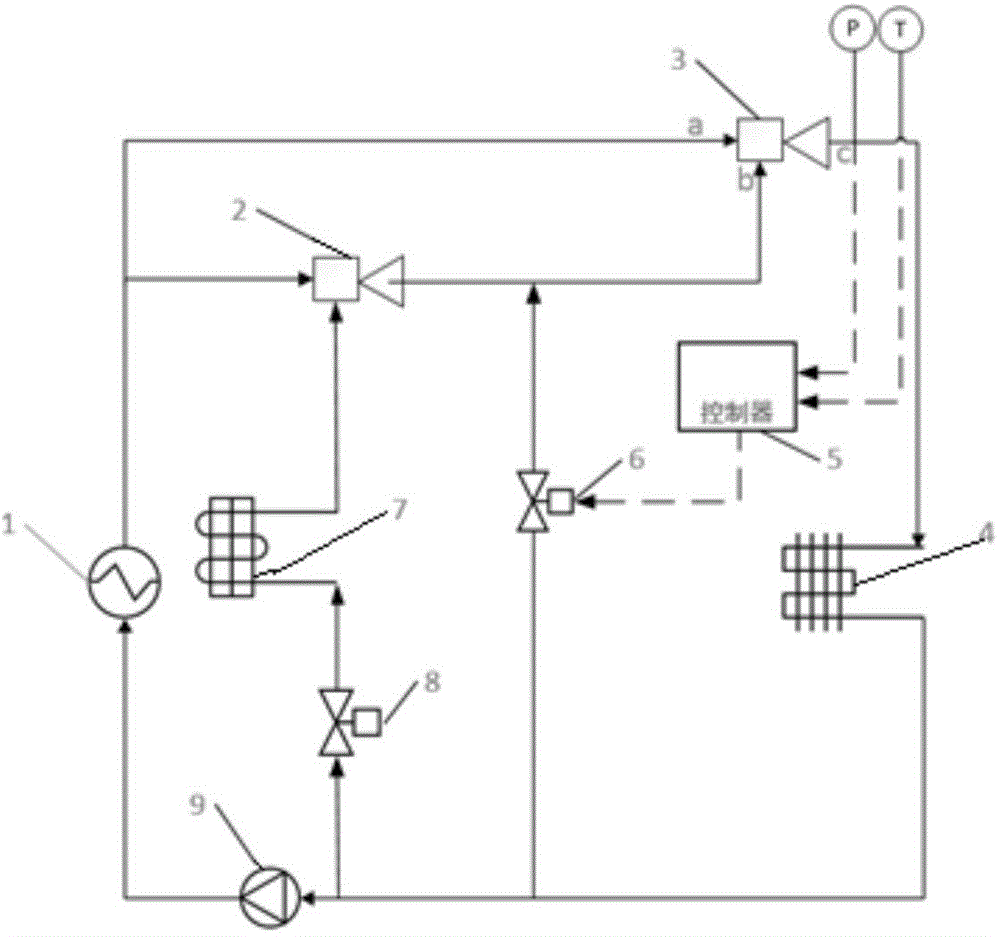

Improved two-stage ejection type refrigerating system

ActiveCN104406324ASave working gasSimple structureCompression machinesMachines using refrigerant evaporationEjection rateEngineering

The invention discloses an improved two-stage ejection type refrigerating system. The system comprises a condenser, wherein an output end of the condenser is divided into three ways, one way is connected with a first throttling valve, another way is connected with a pump, and the third way is sequentially connected with a second throttling valve, an evaporator and a first ejector; the output of a generator is divided into two ways, one way is connected with the first ejector, the other way is connected with a second ejector, and both the first ejector and the first throttling valve are connected with the second ejector. The system has the energy-saving effect, the required working gas volume from the generator is effectively decreased, the ejection rate is increased, the energy efficiency can be increased by about 10%, and the system is simple in structure, low in manufacturing cost and compact in structure.

Owner:SHANDONG UNIV

Method to increase the efficiency of polymer drag reduction for marine and industrial applications

ActiveUS8039055B2Effective drag-reducingGood curative effectWatercraft hull designFluid dynamicsEngineeringVolumetric Mass Density

A method for increasing the efficiency of additive drag reduction by establishing a drag-reducing viscoelastic coating on a surface. The method includes mixing a polymer into a concentrated solution that has approximately the same density as a fluid flowing over the surface, ejecting the mixture / solution into the flowing fluid in a manner such that a coating of polymer, which initially grows thicker with time, is adsorbed onto the surface, and reducing the ejection rate of the first fluid such that the coating of polymer then grows thinner with time. These steps may be repeated so that a desired minimum coating thickness is maintained over an extended period of time. The method reduces the polymer expenditure rate for a given drag reduction. Moreover, the produced viscoelastic coating impedes the attachment and growth of drag-producing natural organisms and may be applied without “down-time” (e.g., while underway).

Owner:CORTANA CORP

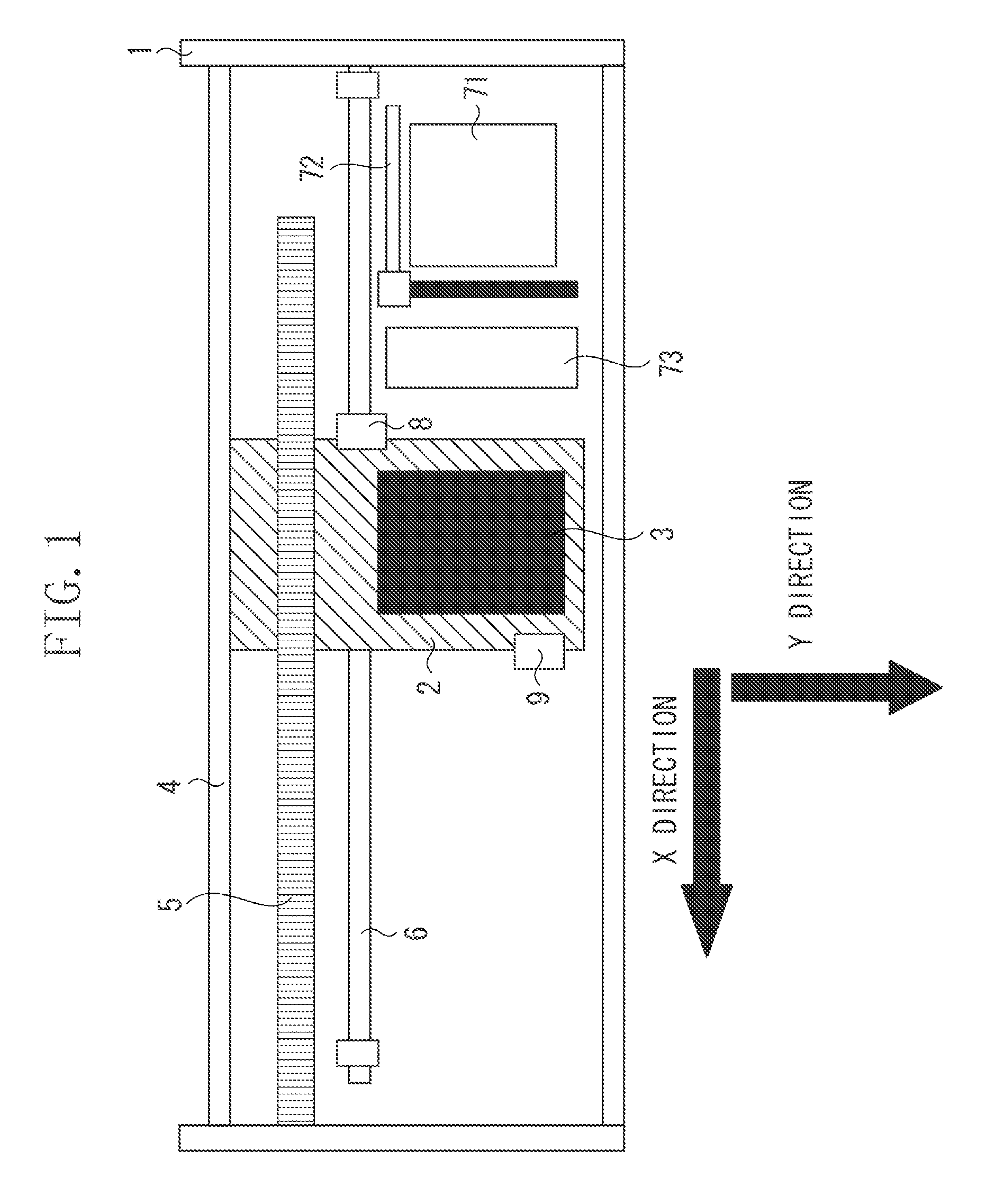

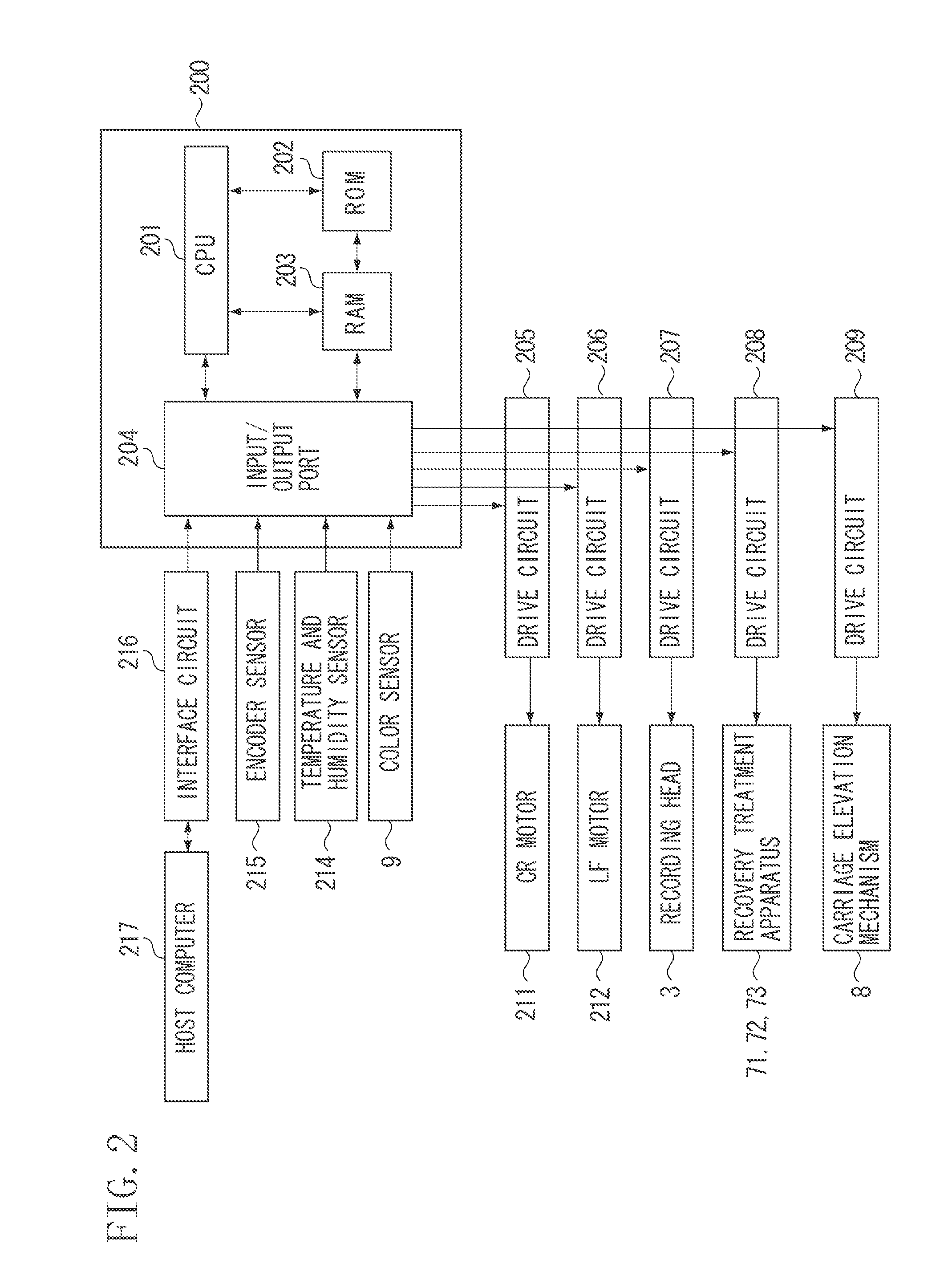

Image forming apparatus and paper ejection method of image forming apparatus

A drive unit for changing the driving rate of paper ejection rollers for ejecting sheets of paper after fixing is installed, and an image forming apparatus has an option, and when ejecting the sheets of paper to an intra-body paper ejection unit, after the sheets of paper pass a fixing device, the paper ejection rate of paper ejection rollers 24 is increased, and the ejection force of the sheets of paper P is increased, and paper jamming at the time of paper ejection to the intra-body paper ejection unit is prevented.

Owner:KK TOSHIBA +1

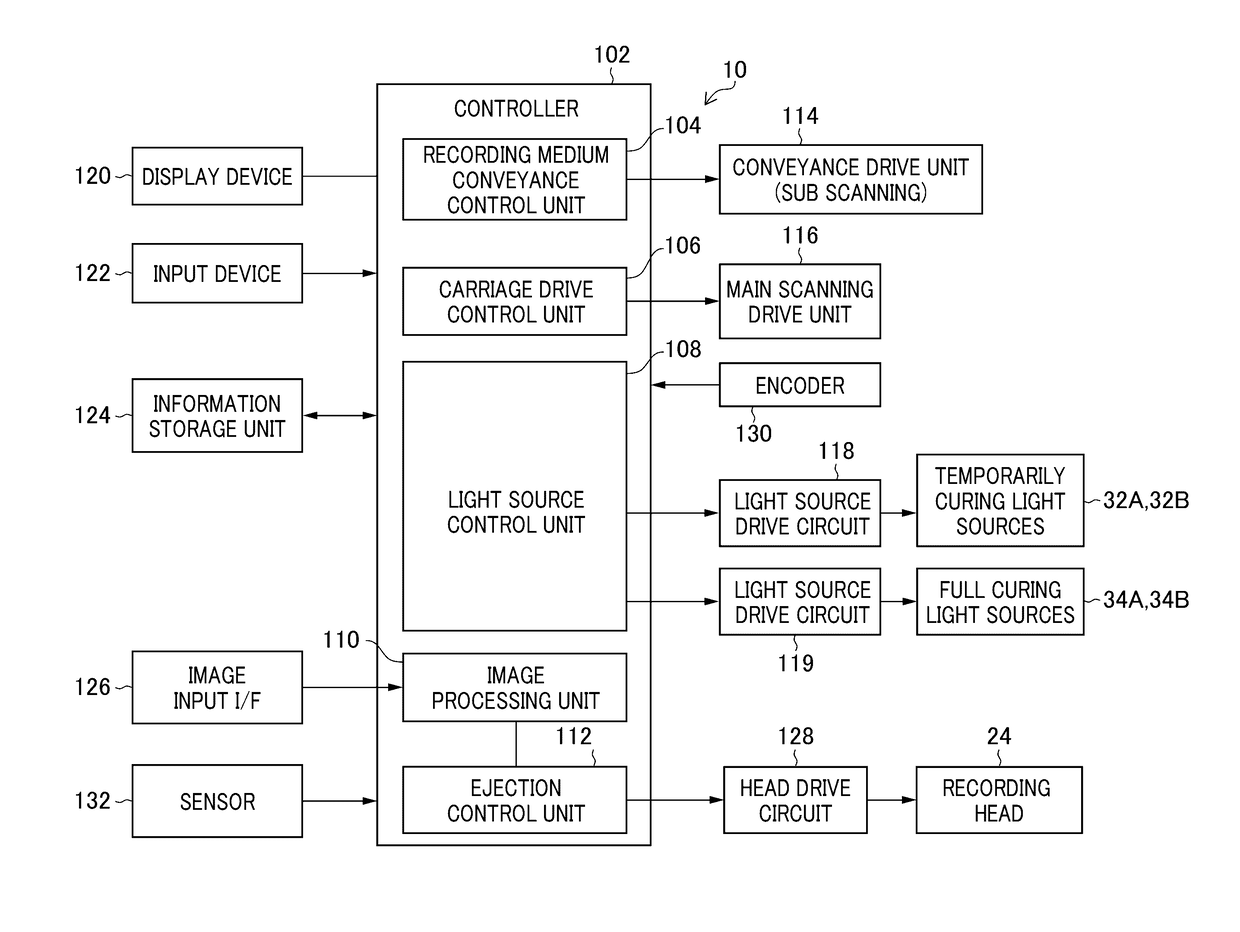

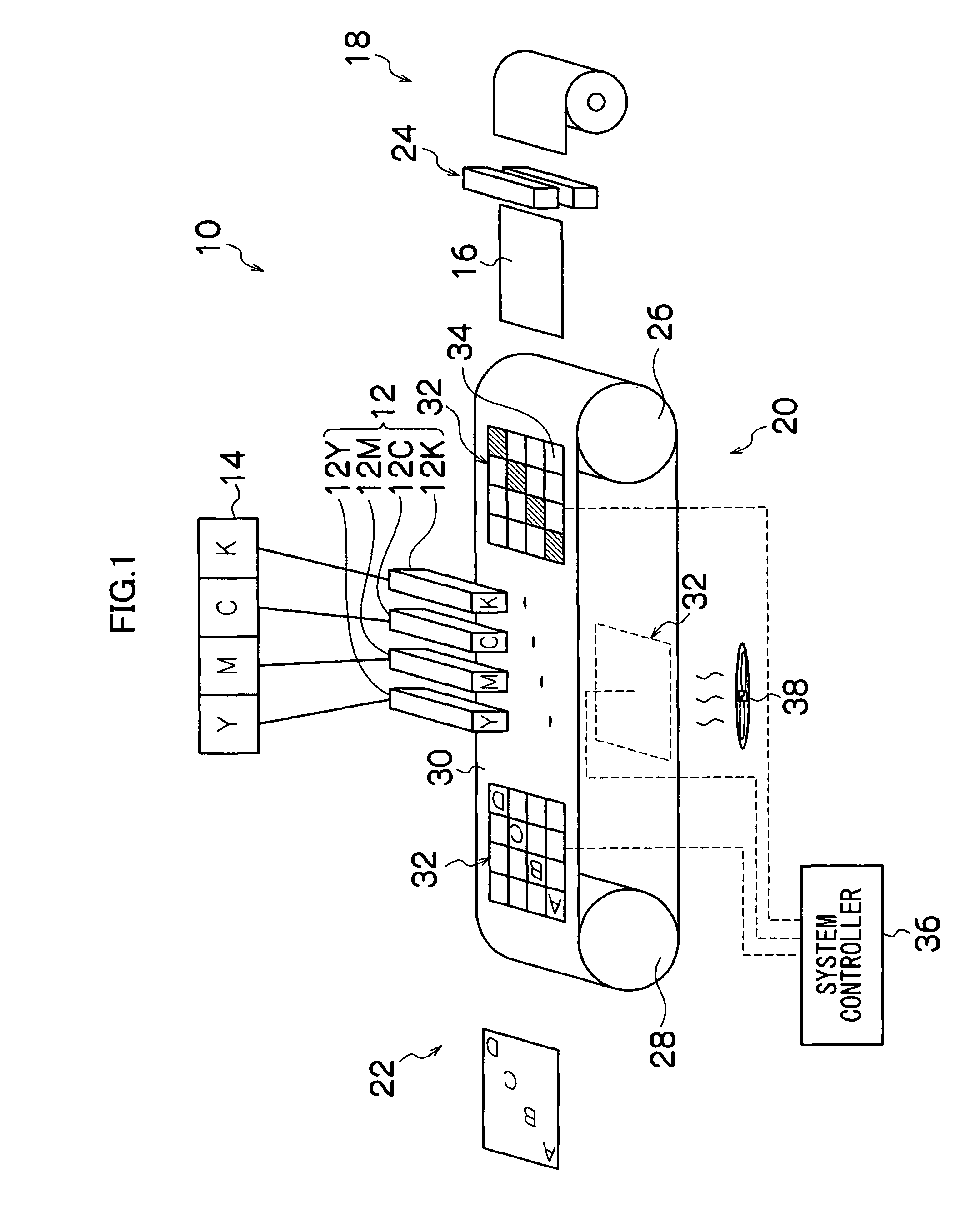

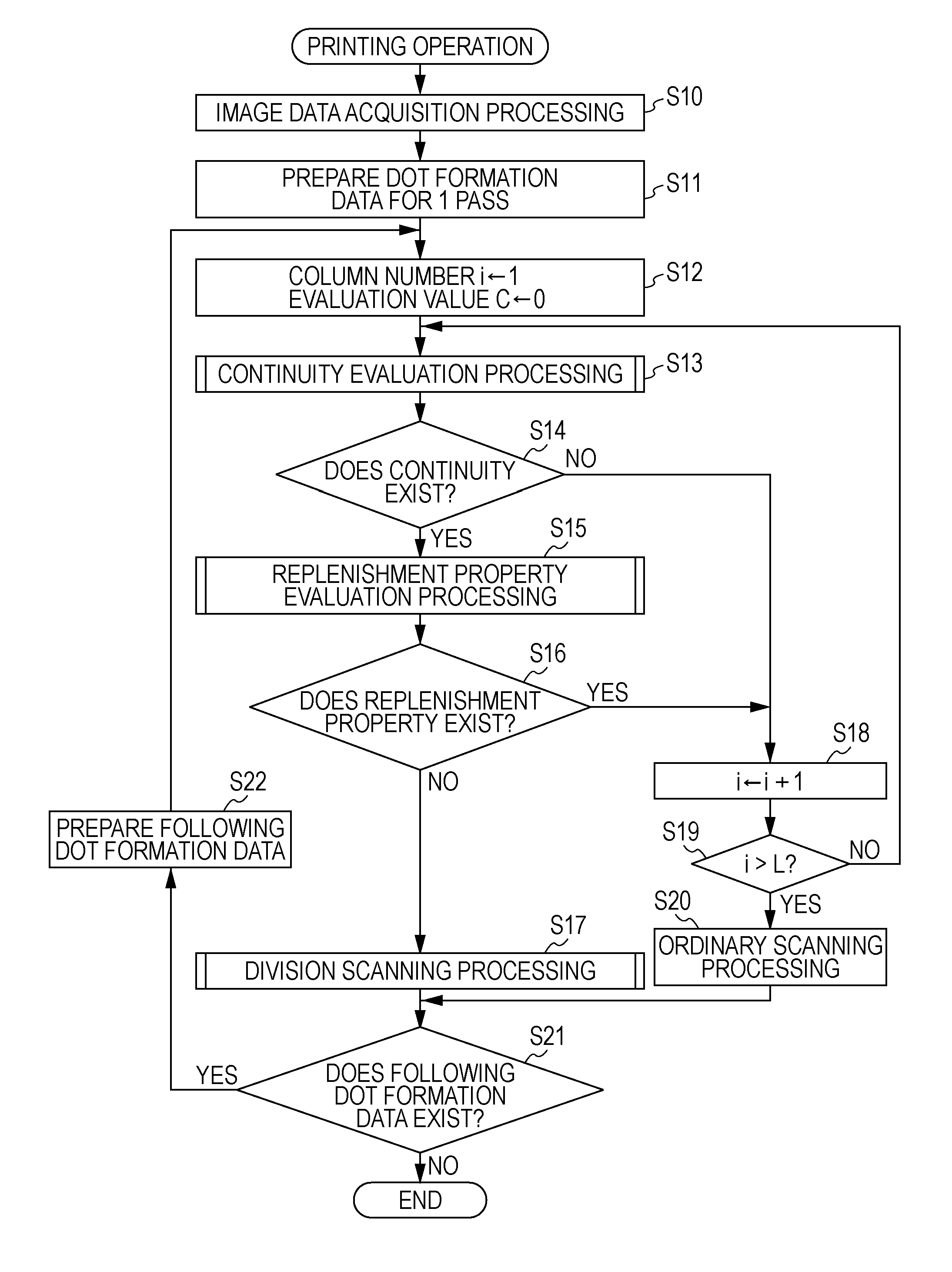

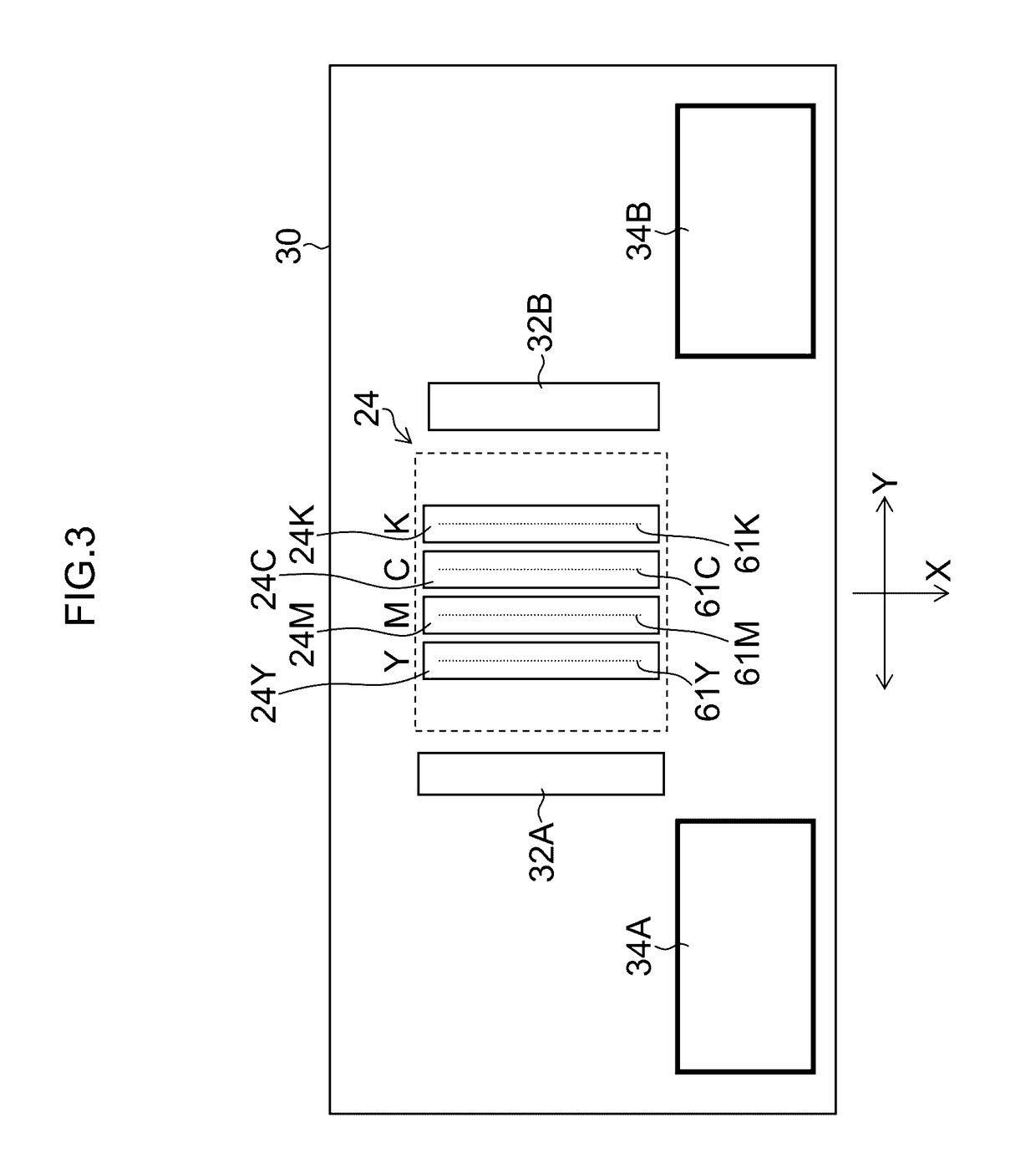

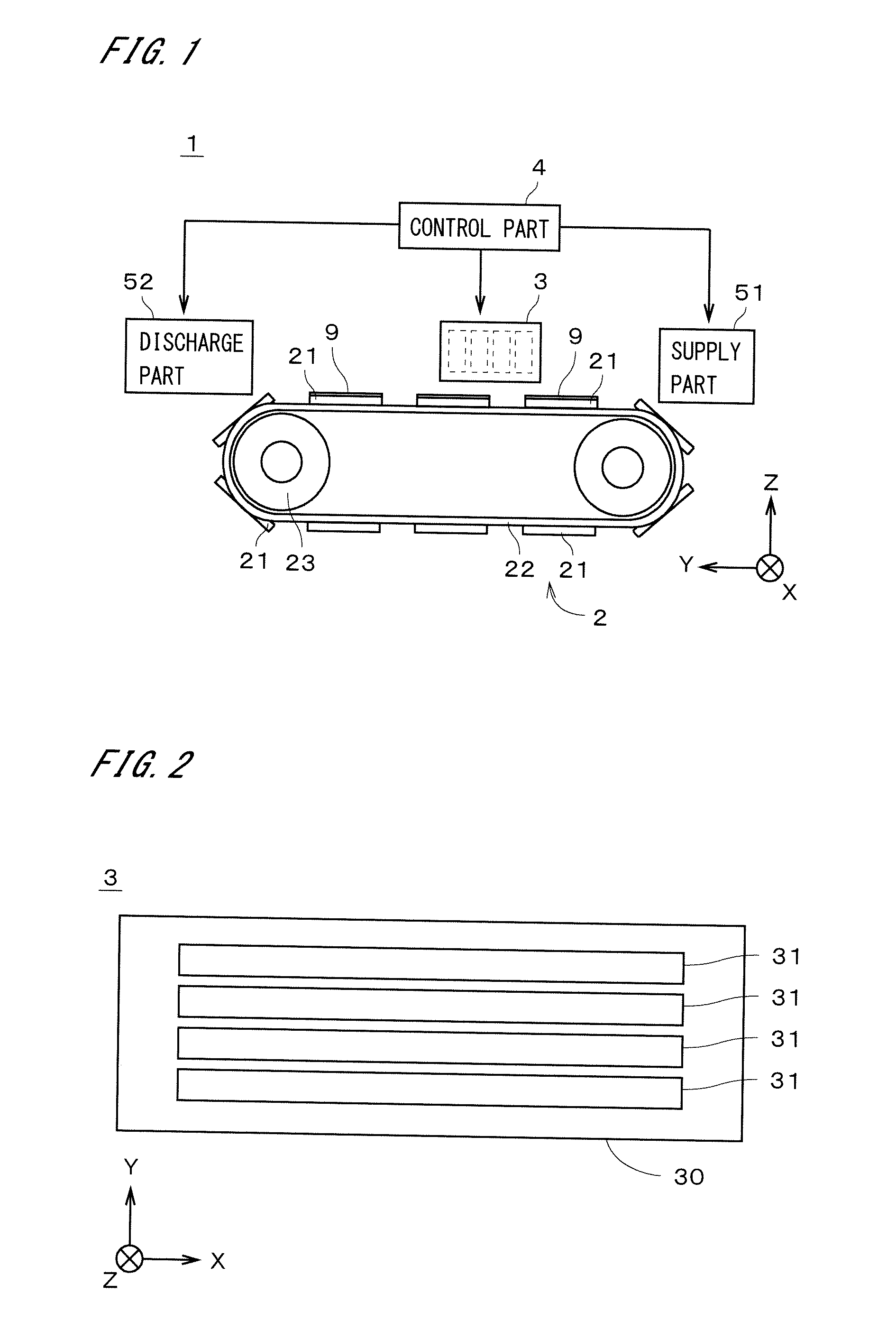

Liquid ejecting apparatus and liquid ejecting method

ActiveUS20100207981A1Excellent ejectionSuppresses poor ejectionOther printing apparatusHead movementsLiquid jet

A liquid ejecting apparatus includes a liquid ejecting head that ejects liquid from a nozzle. A head movement section moves the liquid ejecting head in a movement direction. A controller controls a movement ejection operation that ejects the liquid from the nozzle while moving the liquid ejecting head in the movement direction. If there is satisfied a decision condition that indicates that the ejection rate is excessive, the controller causes the number movement ejection operations related to a certain range to be larger than if the decision condition were not satisfied. With respect to second liquid being higher in viscosity than first liquid, the controller determines the number movement ejection operations related to the above-mentioned certain range by the above-mentioned decision condition determined as excess of the above-mentioned ejection rate at an ejection rate being smaller than that of the first liquid.

Owner:SEIKO EPSON CORP

Dither mask generation method and device

ActiveUS9682550B2Increase graininessGood dispersionVisual representation by matrix printersPrintingEjection rateComputer science

The dither mask generation method includes: a nozzle ejection rate determination process of determining a nozzle ejection rate of each nozzle in a recording head; a corresponding nozzle specifying process of specifying the nozzle corresponding to individual pixels of a dither mask by making at least one nozzle in charge of recording at each pixel position correspond to the individual pixels of the dither mask; a nozzle ejection rate reflecting processing process of performing processing of reflecting the nozzle ejection rate on an evaluation index when individual thresholds of the dither mask are set; and a threshold setting process of setting the thresholds to the individual pixels of the dither mask on the basis of the evaluation index.

Owner:FUJIFILM CORP

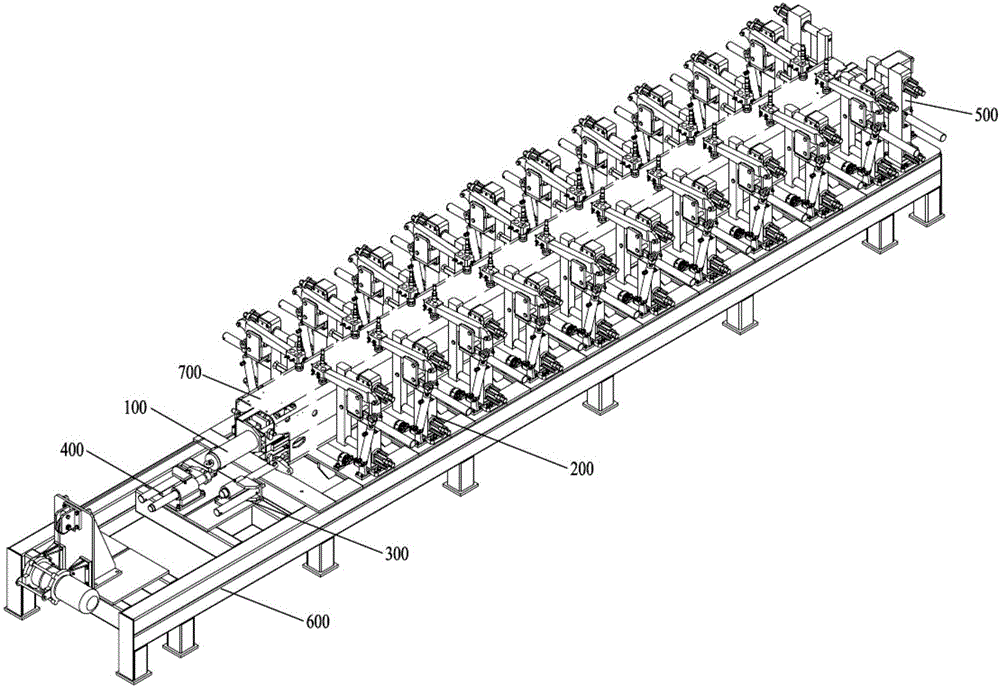

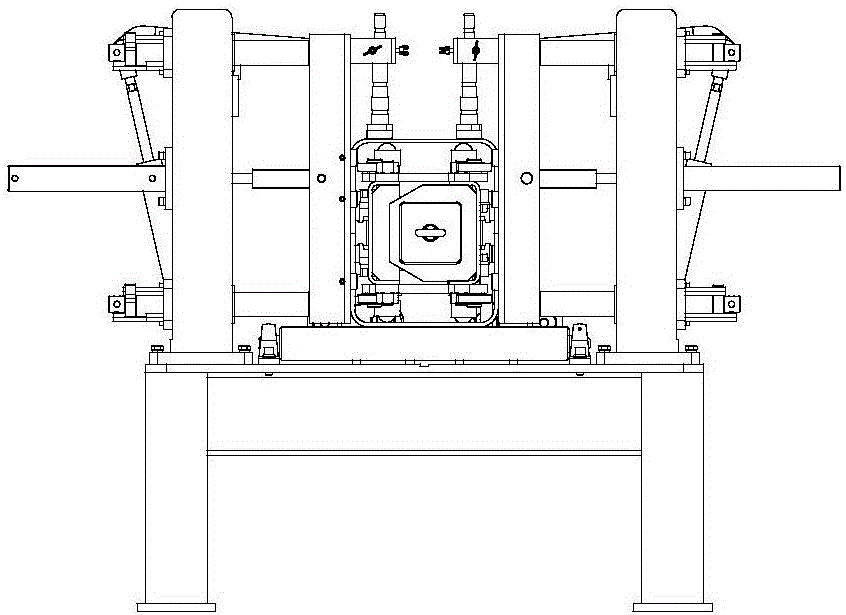

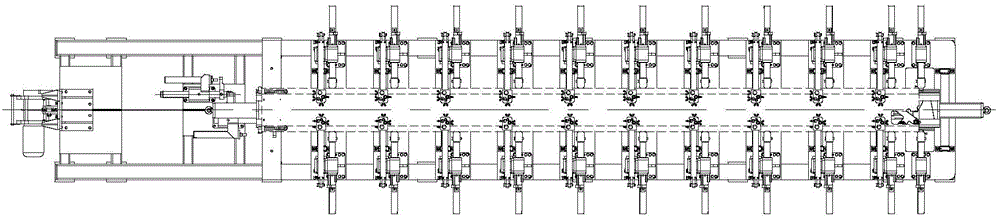

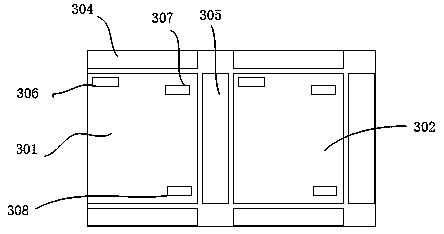

Bi-directional pressing device applicable to lap welding tooling for suspension arm cylinder

ActiveCN106271305AImprove machining accuracyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesHigh volume manufacturingEngineering

The invention discloses a bi-directional pressing device applicable to a lap welding tooling for a suspension arm cylinder. The bi-directional pressing device comprises a first pressing device used for applying pressing force to two half cylinder bodies forming the suspension arm cylinder in the first direction, and a second pressing device used for applying pressing force to the half cylinder bodies in the second direction, wherein the first pressing device and the second pressing device are connected; and the first direction is perpendicular to the second direction. According to the bi-directional pressing device applicable to the lap welding tooling for the suspension arm cylinder, during manufacturing of the suspension arm cylinder, the two half cylinder bodies can be accurately located, clamped and fixed, the processing accuracy and production efficiency of the suspension arm cylinder are improved, the stabilization for the quality of a suspension arm cylinder product is facilitated, the ejection rate is low, the requirement on skills of welding workers is reduced a lot, the labor intensity is reduced, and the bi-directional pressing device is applicable to large-batch production.

Owner:ANHUI CHANG YONG DE MACHINERY

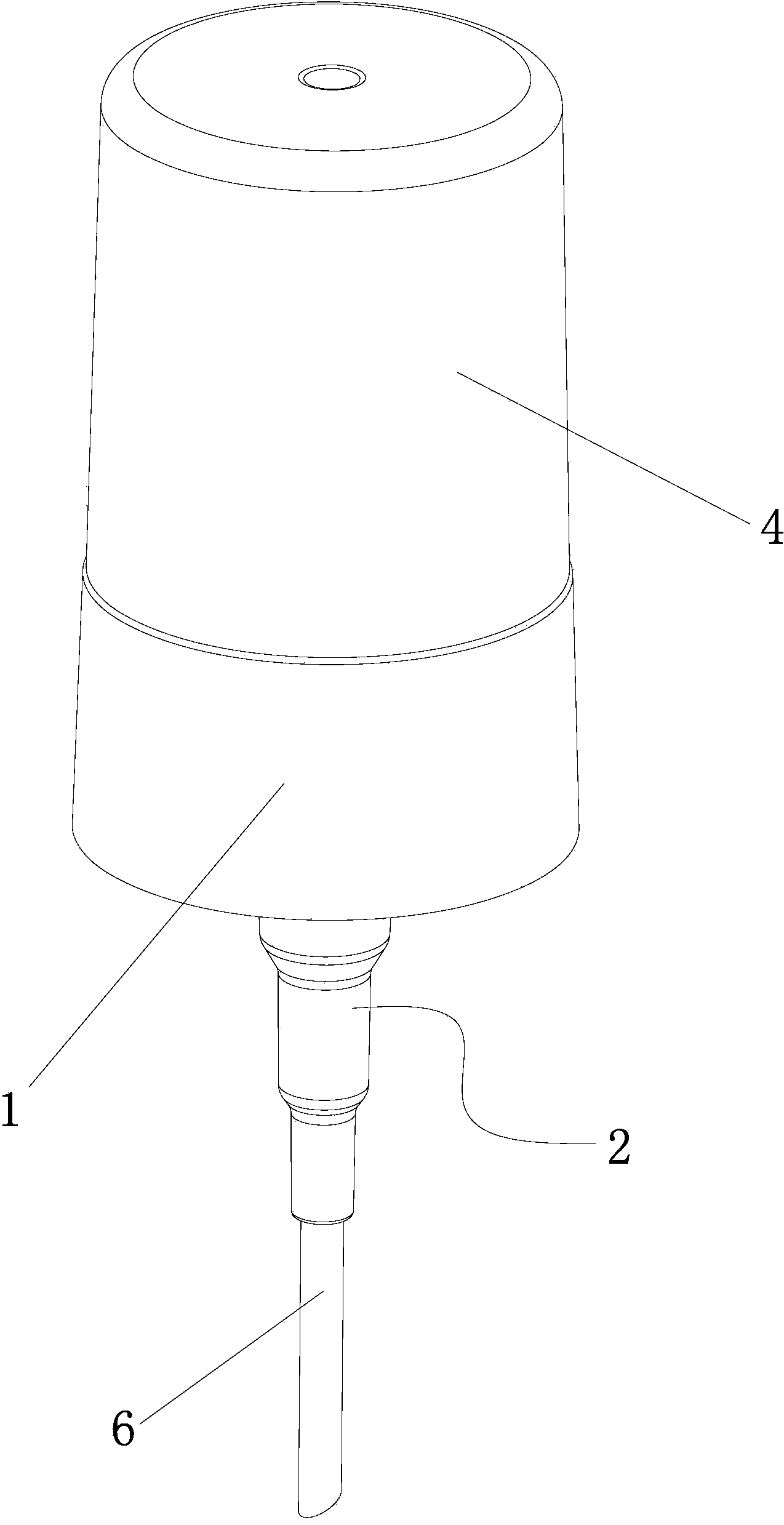

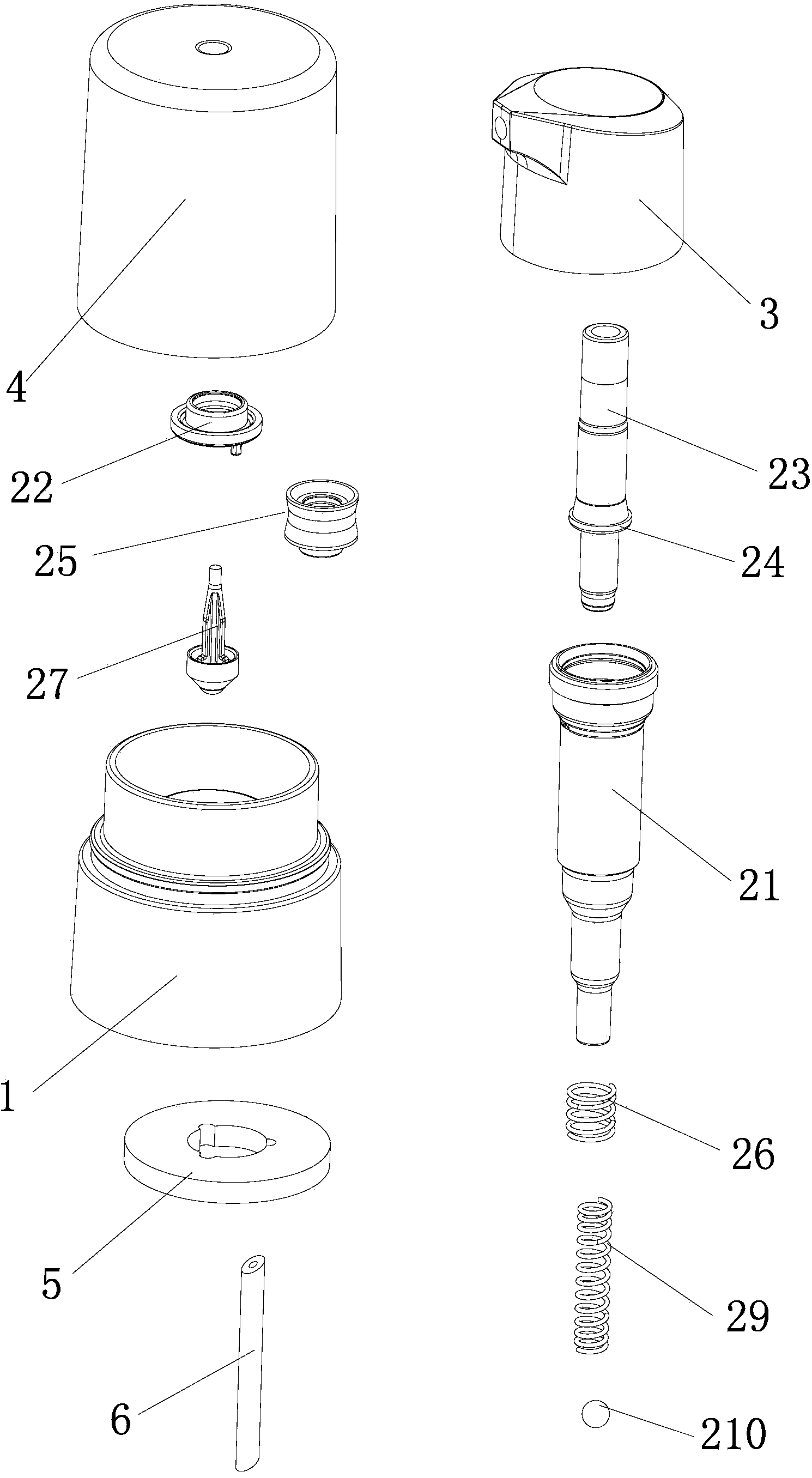

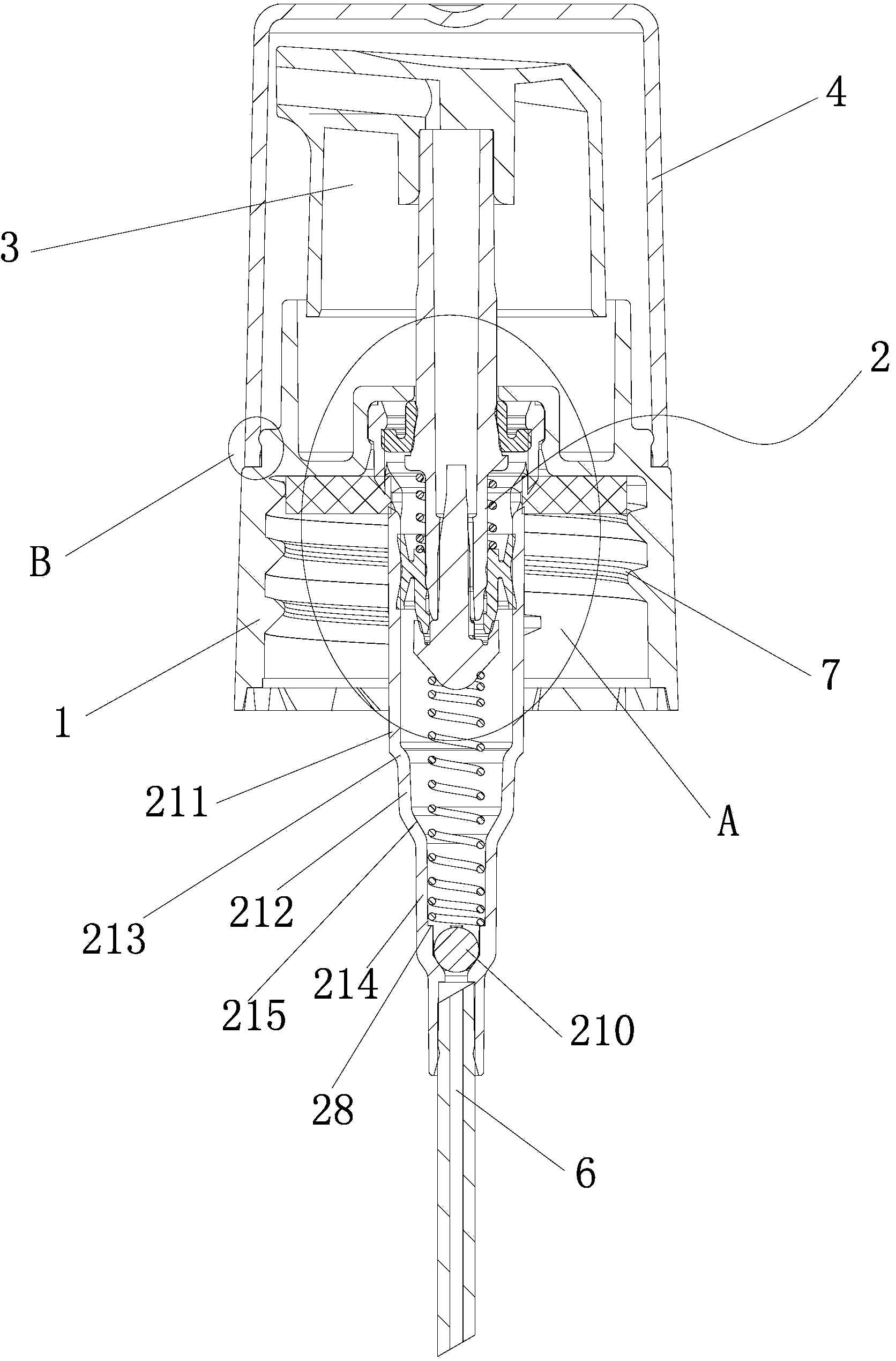

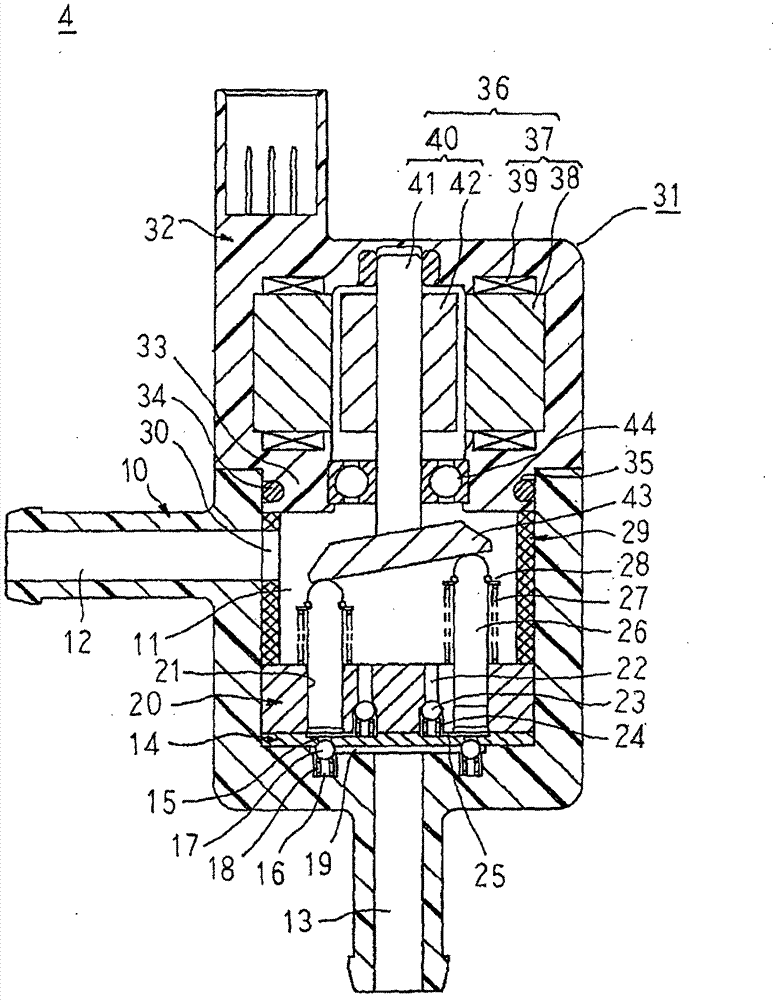

Dustproof emulsion pump mechanism

The invention discloses a dustproof emulsion pump mechanism. The dustproof emulsion pump mechanism comprises a combination cover and is characterized in that a pump body component is arranged in the combination cover; the upper portion of the pump body component is provided with a button capable of driving the pump body component to operate; the upper end face of the combination cover is provided with a convex ring; a large outer cover is sleeved on the convex ring; the lower portion of the outer wall of the convex ring is provided with a connecting button stand; an annular connecting trough is formed in the inner wall of the larger outer cover corresponding to the connecting button stand; the connecting button stand is clamped in the annular connecting trough. The invention aims to overcome the defects in the prior art and provides the dustproof emulsion pump mechanism, which is simple in structure, low in production cost, convenient to assembly and high in pumping speed and has relatively stable ejection rate.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

Method to increase the efficiency of polymer drag reduction for marine and industrial applications

ActiveUS20080254226A1Effective drag-reducingGood curative effectWatercraft hull designFluid dynamicsEngineeringEjection rate

A method for increasing the efficiency of additive drag reduction by establishing a drag-reducing viscoelastic coating on a surface. The method includes mixing a polymer into a concentrated solution that has approximately the same density as a fluid flowing over the surface, ejecting the mixture / solution into the flowing fluid in a manner such that a coating of polymer, which initially grows thicker with time, is adsorbed onto the surface, and reducing the ejection rate of the first fluid such that the coating of polymer then grows thinner with time. These steps may be repeated so that a desired minimum coating thickness is maintained over an extended period of time. The method reduces the polymer expenditure rate for a given drag reduction. Moreover, the produced viscoelastic coating impedes the attachment and growth of drag-producing natural organisms and may be applied without “down-time” (e.g., while underway).

Owner:CORTANA CORP

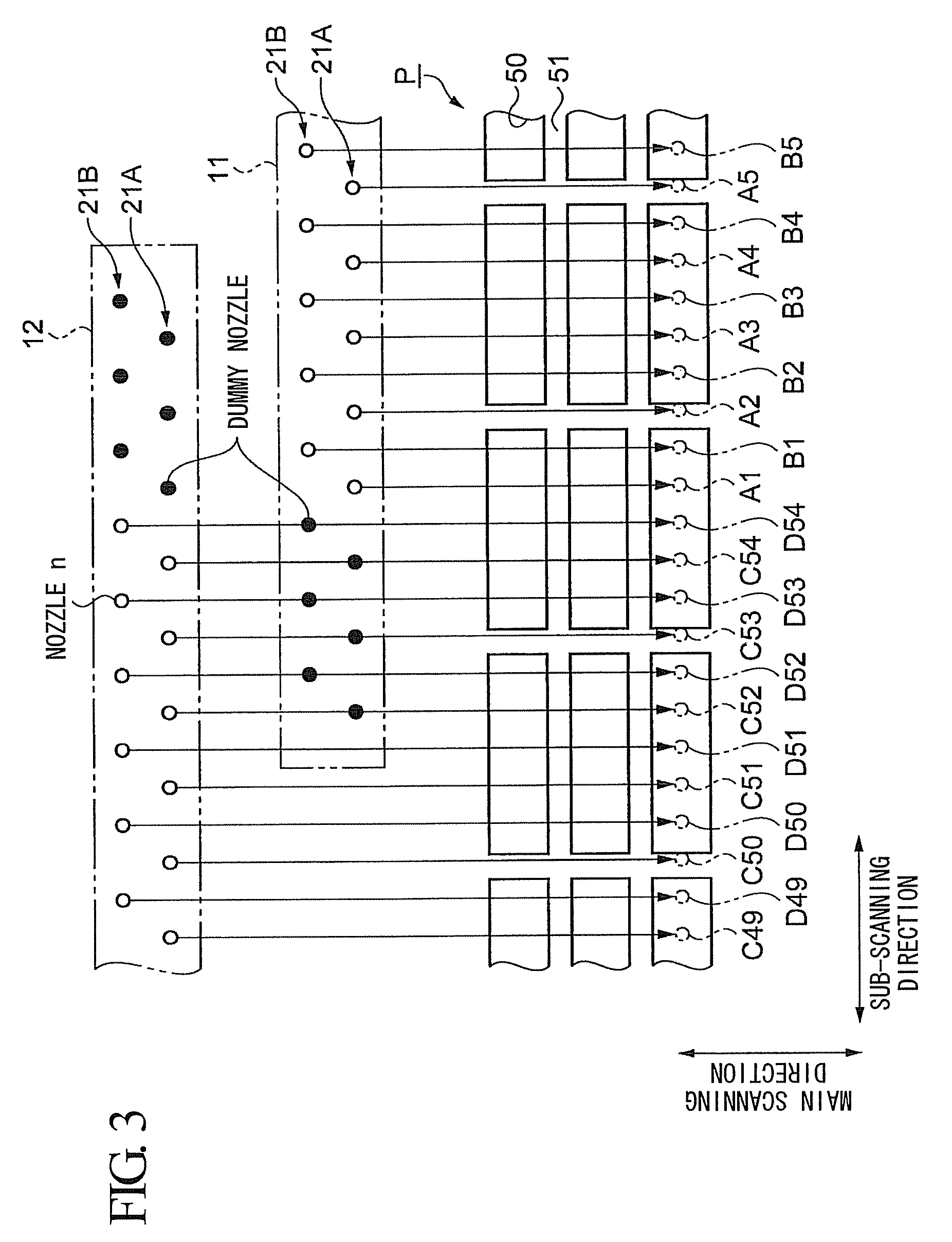

Liquid ejection control device, method, and program

InactiveUS20090179936A1Reduce negative impactReduced stabilitySpacing mechanismsScan lineEjection rate

A liquid ejection control device, which makes an ejection object medium and an ejection nozzle column which ejects liquid relatively scan in a primary scan direction which almost perpendicularly intersects the nozzle ejection column and makes the ejection object medium and the ejection nozzle column relatively scan in a subordinate scan direction which almost perpendicularly intersects the primary scan direction. The liquid ejection control device includes an ejection control unit controlling ejections of ejection nozzles such that ejection rates of the ejection nozzles vary according to positions of the ejection nozzles in the subordinate scan direction, the variation being set such that the ejection nozzles having a maximum ejection rate are dispersed in the subordinate scan direction, when a rate of an ejection, which is charged by a predetermined ejection nozzle, to a primary scan line at the same position in the subordinate scan direction is called an ejection rate.

Owner:SEIKO EPSON CORP

Online anti-interference NH3-N automatic monitor

InactiveCN108254318AIsolate interferenceAvoid interferenceMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsPeristaltic pumpEjection rate

The invention discloses an online anti-interference NH3-N automatic monitor which comprises a first three-way electromagnetic valve and an ammonia gas collector, wherein a peristaltic pump is arrangedabove one side of the first three-way electromagnetic valve; a metering device is arranged below one side of the peristaltic pump; a valve island is arranged below the metering device; an ejection bottle is arranged on one side, far away from the peristaltic pump, of the metering device; and an ejection tube is arranged above the ejection bottle. Due to adoption of the peristaltic pump, a semi-reflection semi-permeable mirror and the ammonia gas collector, interference of external environment air can be prevented, the ejection rate of the ejection bottle can be increased, the absorption rateof an absorption colorimetric bottle can be increased, a one-time measurement multi-result average value method can be achieved, the measurement stability and accuracy can be ensured, an ammonia-freegas can be provided for a reagent bottle vent hole, the ammonia-free gas can be also provided for the peristaltic pump, external environment interference can be avoided, and relatively good application prospects can be achieved.

Owner:江苏汇环环保科技有限公司

Dither mask generation method and device

The dither mask generation method includes: a process of setting a nozzle relative ejection rate which is a control target of the nozzle ejection rate and stipulates a relative using ratio of the individual nozzles; a process of setting a nozzle pattern indicating correspondence relation between individual pixels of the dither mask and the nozzles in charge of recording at respective pixel positions; a process of setting an upper limit to the nozzle ejection rates of the individual nozzles for each raster in a main scanning direction, regarding at least some thresholds; and a process of setting the thresholds to the pixels of the dither mask based on the nozzle relative ejection rate, the nozzle pattern and a limitation by the upper limit.

Owner:FUJIFILM CORP

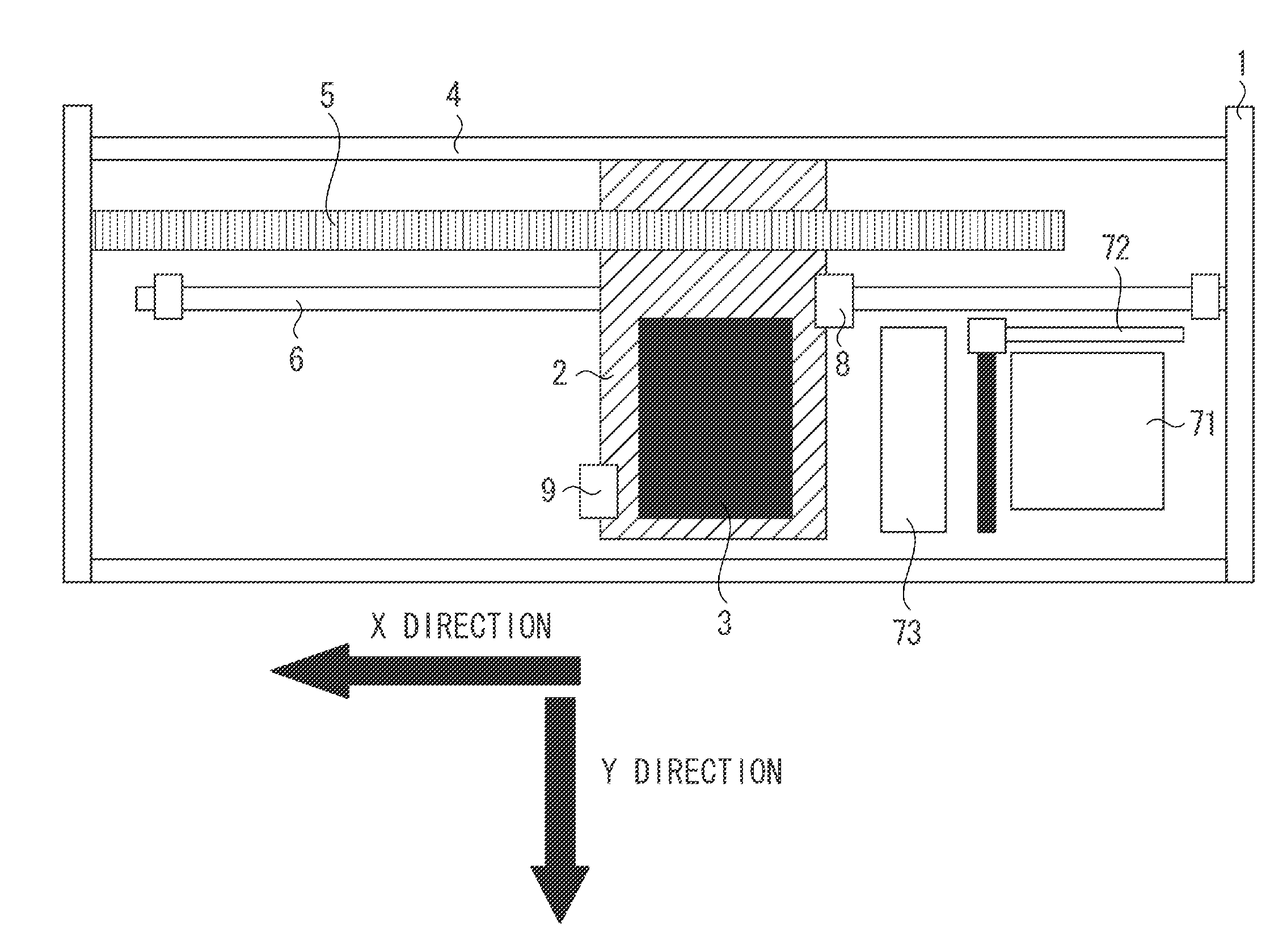

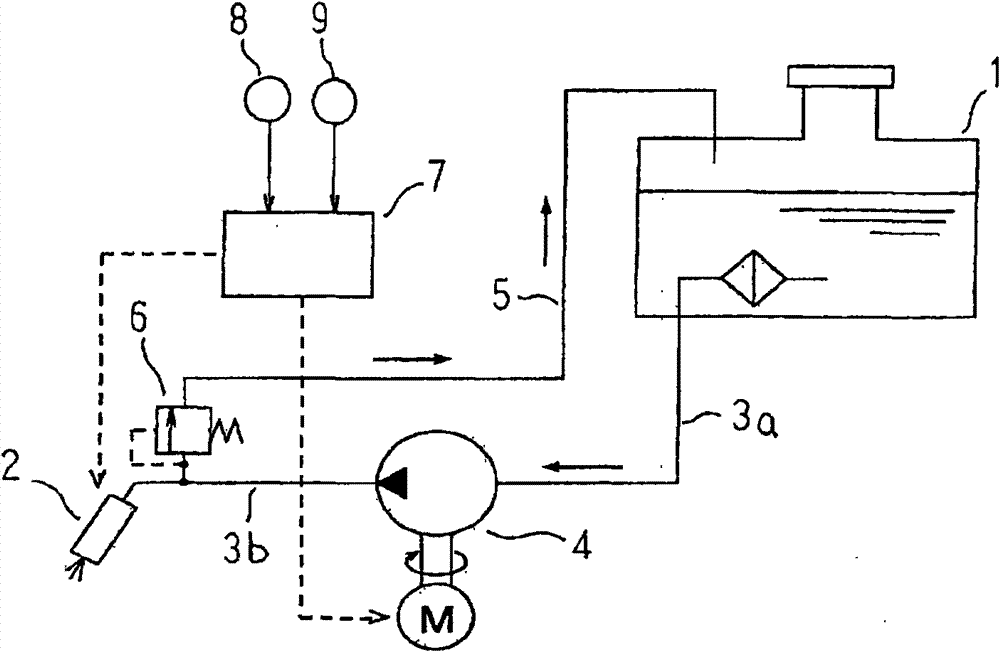

Fuel supply device

ActiveCN101737213BLow costSimplified piping layoutElectrical controlLow pressure fuel injectionEjection rateHigh pressure

The device has a pressure regulating device (6) i.e. poppet valve, provided such that fuel pressure is achieved within a high pressure line (3b). A fuel pump control unit (7) computes necessary fuel ejection rate while computing discharge flow rate that is added to necessary engine fuel rate. The engine fuel rate is computed based on engine operating condition that is detected by an air flow measuring device (8) and a crank angle sensor (9) to control engine rotating speed of a fuel pump (4) i.e. piston pump, for ejaculating the computed fuel ejection rate.

Owner:MITSUBISHI ELECTRIC CORP

Image recording apparatus and image recording method

InactiveUS20130257950A1InhibitionReducing degree instabilityOther printing apparatusPictoral communicationSmall dropletImage recording

In an image recording apparatus, only small ink droplets are ejected toward a recording medium in the range of tone values less than a second tone value. In the range of tone values greater than or equal to the second tone value and less than a first tone value, large and small droplets are ejected toward the recording medium. The first tone value is less than or equal to a 50% tone value, and the total ejection rate at the first tone value is less than 50%. In the range of tone values greater than or equal to the first tone value, only large droplets are ejected toward the recording medium. Thus, the occurrence of streaking can be suppressed while reducing the degree of instability of the landing positions of fine droplets of ink.

Owner:DAINIPPON SCREEN MTG CO LTD

A method for arranging semiconductor wafers to improve chip yield

ActiveCN107104063BImprove production rateIncrease profitSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsGeneration rateEjection rate

The invention discloses an arrangement method for improving chip generation rate of a semiconductor wafer. Blocks for placing chips are arranged in the semiconductor wafer. The arrangement method comprises the following steps of a, placing partial board or total board of PCM parameter testing information into an idle area of the chip board; and b, placing the board of alignment information and partial board, which is not placed into the chip, of the PCM parameter testing information into a scribing trough, thereby reducing the distance between chips in the block. Through the manner of the invention, the arrangement method for improving chip generation rate of the semiconductor wafer is advantageous in that through placing the board blocks for the PCM parameter testing information in partial process manufactures into an actual chip, purposes of reducing the area of the scribing troughs and reducing block area are realized, thereby placing more blocks on the same semiconductor wafer, improving utilization rate of the semiconductor wafer, and realizing cost of a single wafer. The arrangement method improves market competitiveness of a product to a certain extent.

Owner:JIANGSU BRMICO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com