Dustproof emulsion pump mechanism

An emulsion pump and dust-proof technology, applied in the directions of closing, packaging, transportation and packaging, can solve the problems of inability to meet the needs of users, unstable ejection volume, and high production costs, and achieve convenient and fast connection, simple structure, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

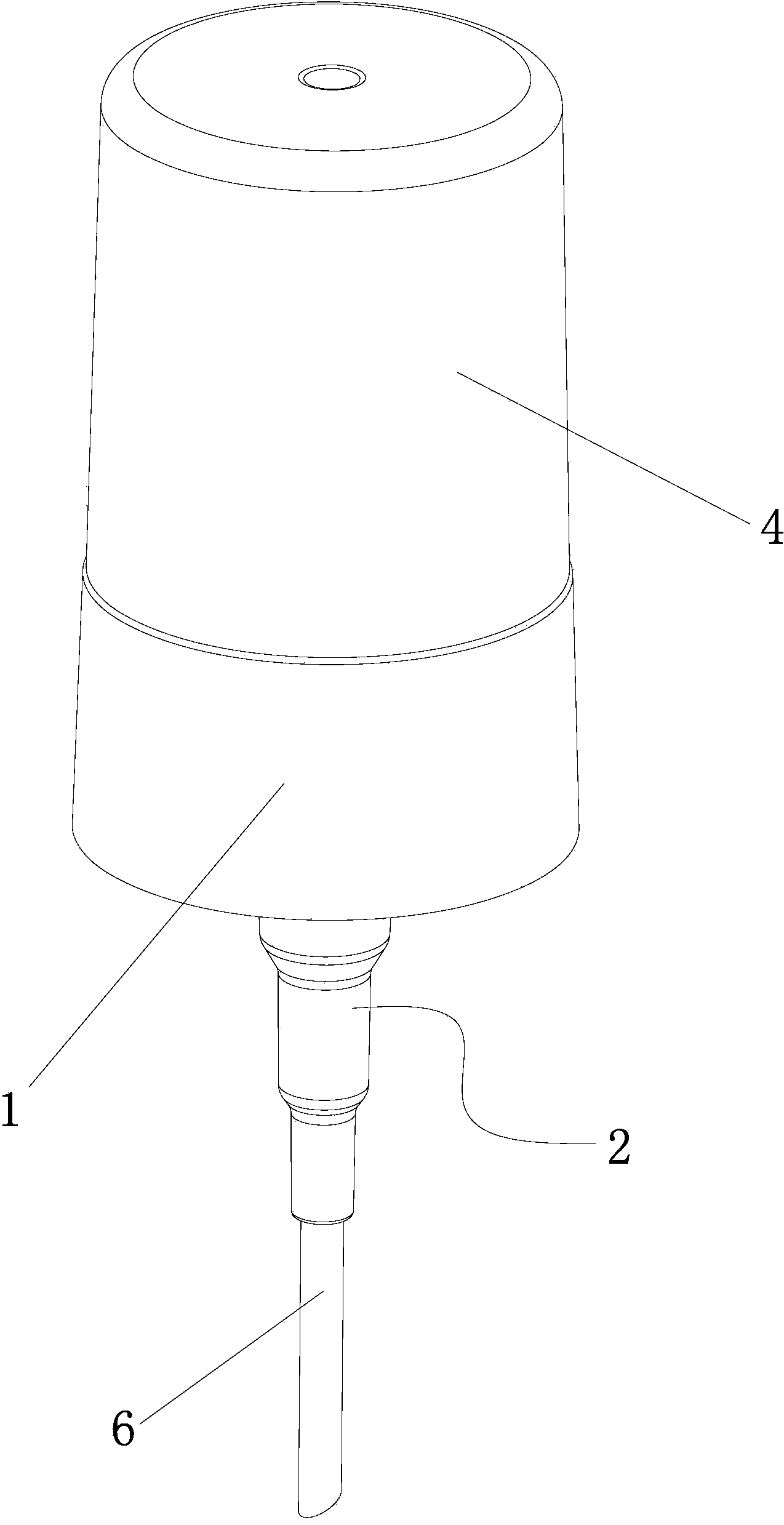

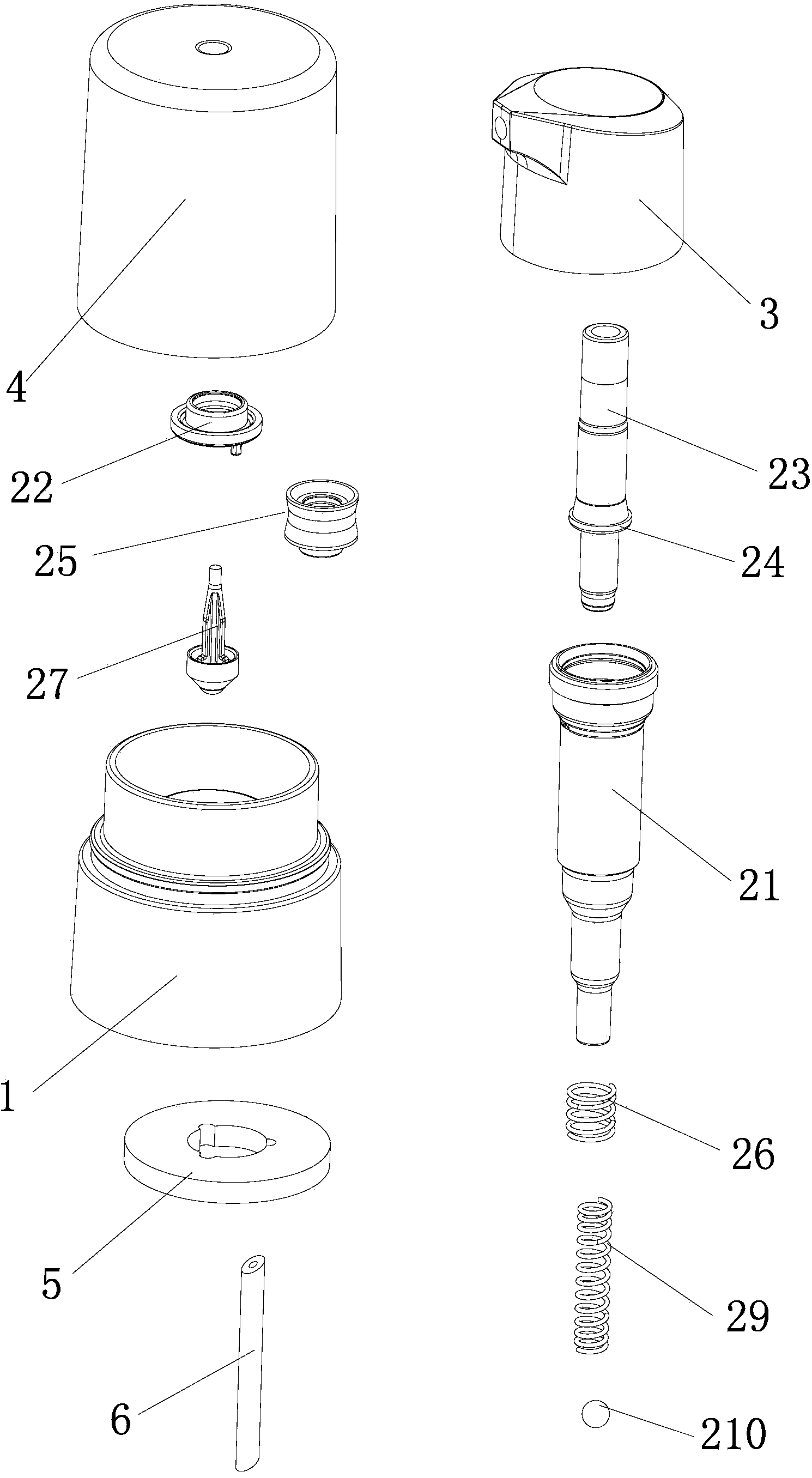

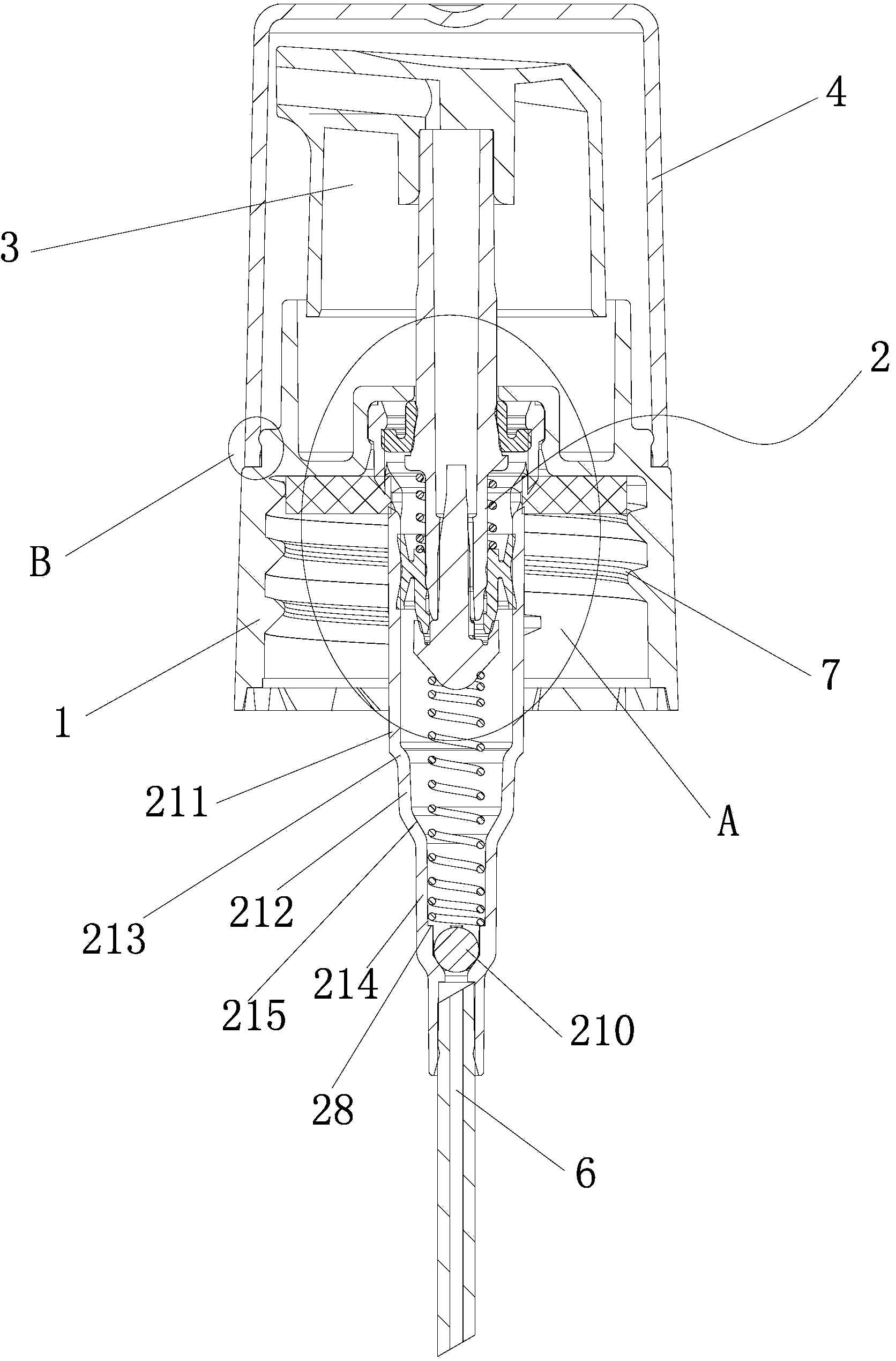

[0031] Such as Figures 1 to 3 The shown dust-proof lotion pump mechanism includes a combination cover 1, a pump body assembly 2 is arranged inside the combination cover 1, and a button capable of driving the pump body assembly 2 is arranged on the upper part of the pump body assembly 2 3. A protruding ring 11 is provided on the upper end surface of the combined cover 1, a large outer cover 4 is set on the protruding ring 11, and a connecting buckle 111 is provided on the lower part of the outer wall of the protruding ring 11. An annular connecting groove 41 is provided on the inner wall of the large outer cover 4 corresponding to the connecting buckle 111 , and the connecting buckle 111 is clamped in the annular connecting groove 41 .

[0032] The present invention has a simple structure, and a large outer cover 4 is arranged on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com