Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about How to "Increase graininess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degassing method of ink-jet ink, production method of ink-jet ink and ink-jet printer

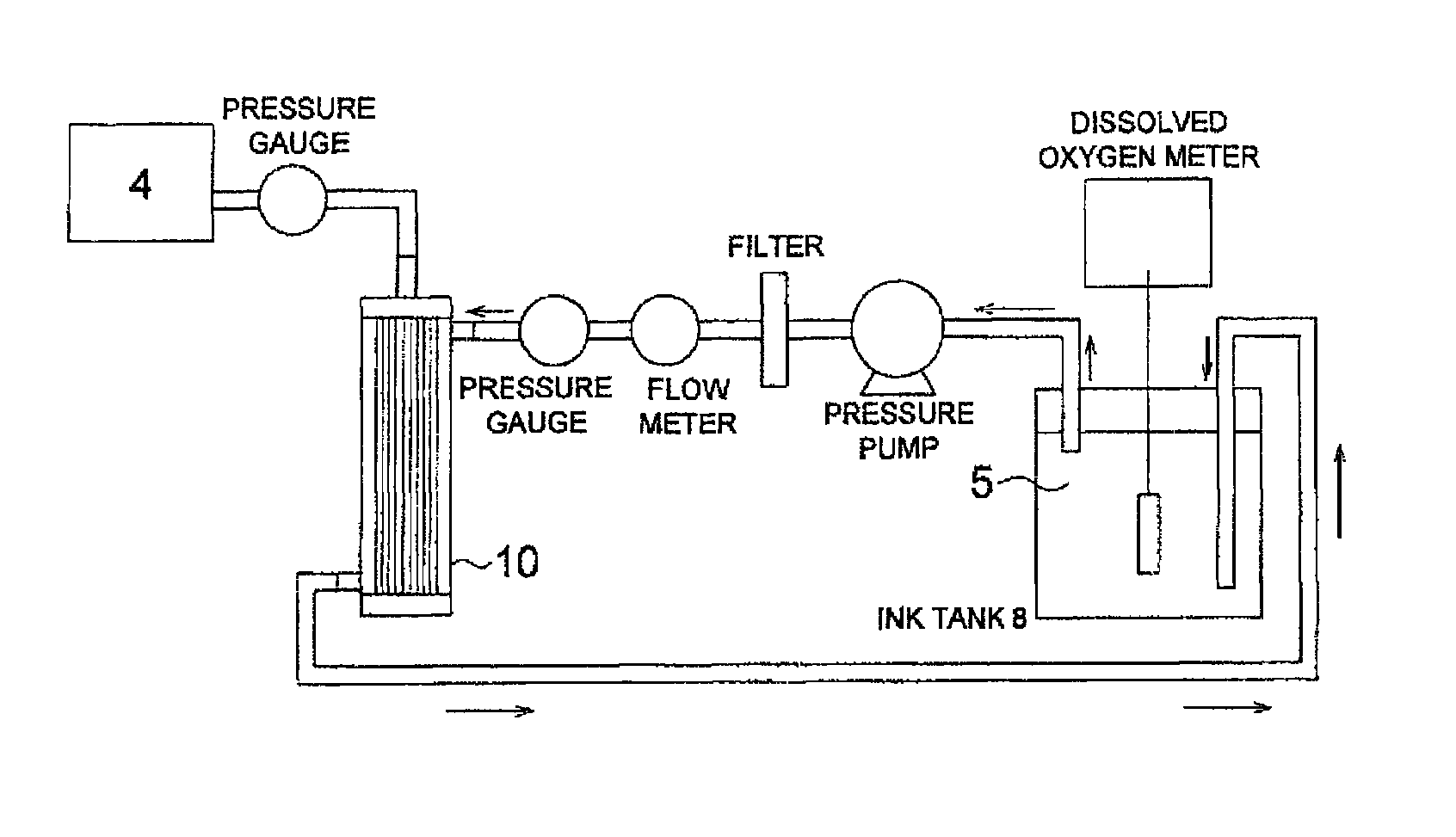

A degassing method of an ink-jet ink comprising at least a pigment, and having a viscosity of not less than 10 mPa·second and not more than 50 mPa·second at 25° C., comprising the step of: carrying out degassing employing an external refluxing type hollow fiber degassing module under a condition of a pressure loss of the hollow fiber degassing module during degassing being less than 0.1 MPa.

Owner:KONICA MINOLTA INC

Toner and developer, and image forming apparatus, image forming method and process cartridge

ActiveUS20080118855A1Far from smear and pollutionHigh qualityDevelopersPropylene glycolAliphatic alcohol

Provided is a toner that comprises a binder resin, a releasing agent, and a colorant, wherein the mass average particle diameter of the toner is 3 μm to 8 μm, the content of particles having a particle diameter of no more than 5 μm is from 60% by number to 90% by number, the binder resin comprises a polyester resin (A) having a softening temperature Tm(A) from no lower than 120° C. to no higher than 160° C. and a polyester resin (B) having a softening temperature Tm(B) from no lower than 80° C. to lower than 120° C., and at least one of the polyester resins (A) and (B) is prepared by condensation polymerization between an alcohol component and a carboxylic acid component, and the alcohol component comprises divalent alcohol of 1,2-propanediol in a content of no less than 65% by mole and consists substantially of aliphatic alcohol; and also provided is a developer that comprises the toner and a carrier.

Owner:RICOH KK

Toner

ActiveUS10295921B2Excellent low temperature fixabilityIncrease graininessDevelopersDynamic viscoelasticityEngineering

Owner:CANON KK

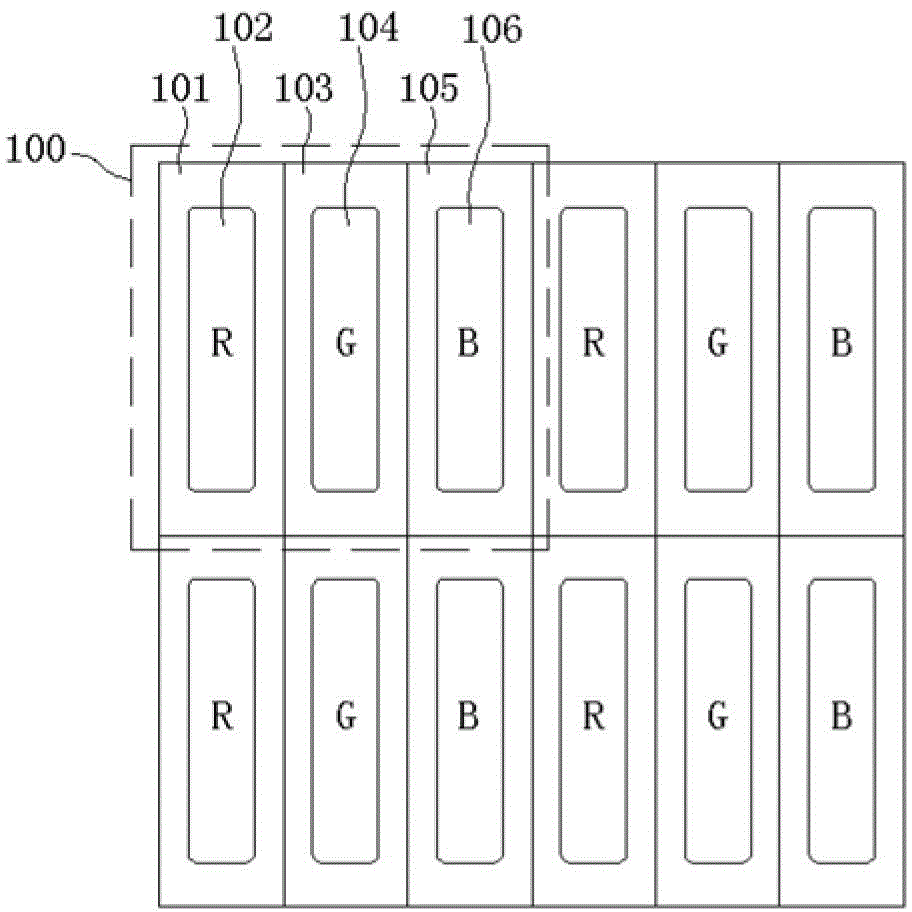

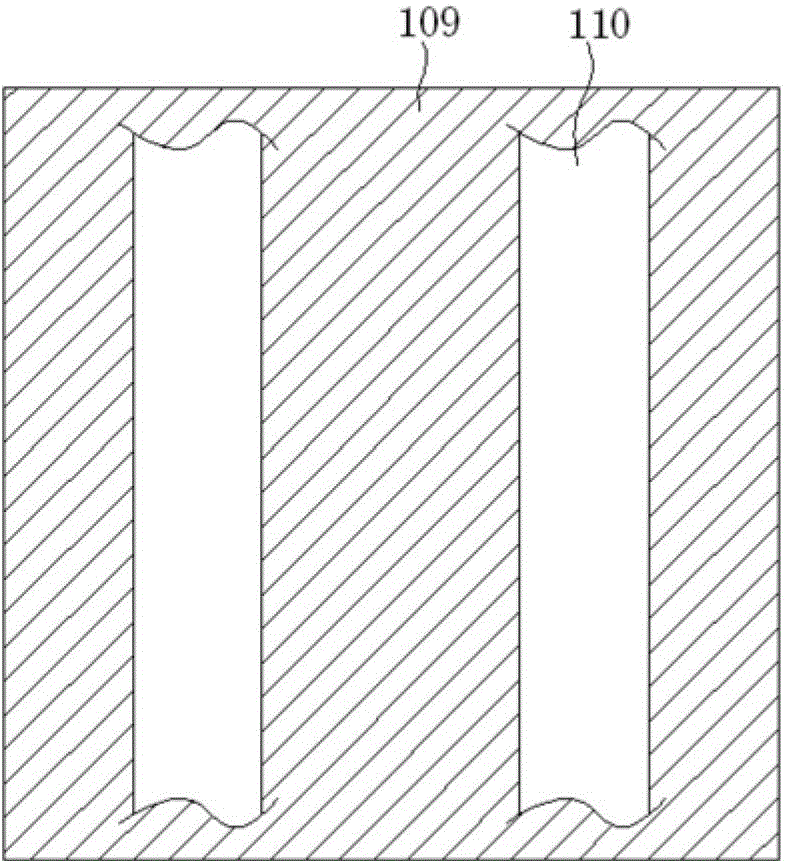

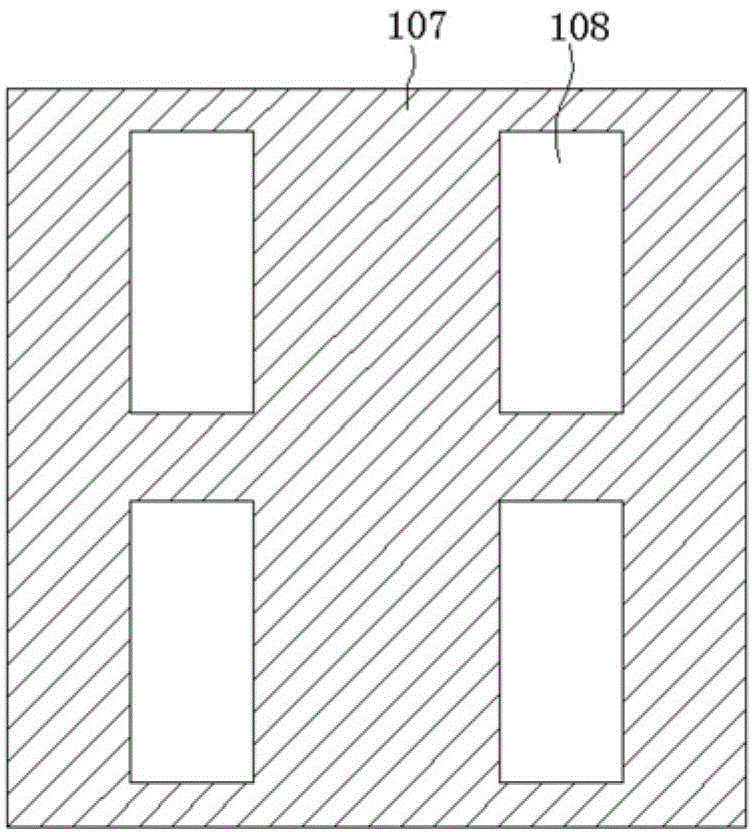

Pixel structure and organic light emitting display adopting same

ActiveCN104576696AIncrease widthReduce process difficultySolid-state devicesSemiconductor devicesDisplay deviceLower half

The invention discloses a pixel structure and an organic light emitting display adopting the same. The pixel structure comprises a plurality of pixel units, wherein each pixel unit takes a rhombus structure formed by an upper half part and a lower half part; the adjacent pixel units are arranged in a staggered manner; each pixel unit comprises a plurality of sub pixels; a first sub pixel forms one of the upper half part and the lower half part of the rhombus pixel unit; a second sub pixel and a third sub pixel are arranged side by side to form the other of the upper half part and the lower half part of the rhombus pixel unit together; pixels in the same color of the pixel units in the adjacent rows are arranged adjacently. By integrating the same sub pixels together, the width of the corresponding vapor deposition Mask hole diameter can be enlarged, the difficulty of the Mask technology can be reduced, and the display PPI (Pixel Per Inch) can be improved; meanwhile, because of the staggered arrangement manner of the pixel units in the adjacent rows, the adjacent edges of the second sub pixel and the third sub pixel with the first sub pixel can be longer, main light emitting of the pixel units can be relatively concentrated, and the light mixing effect is good.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

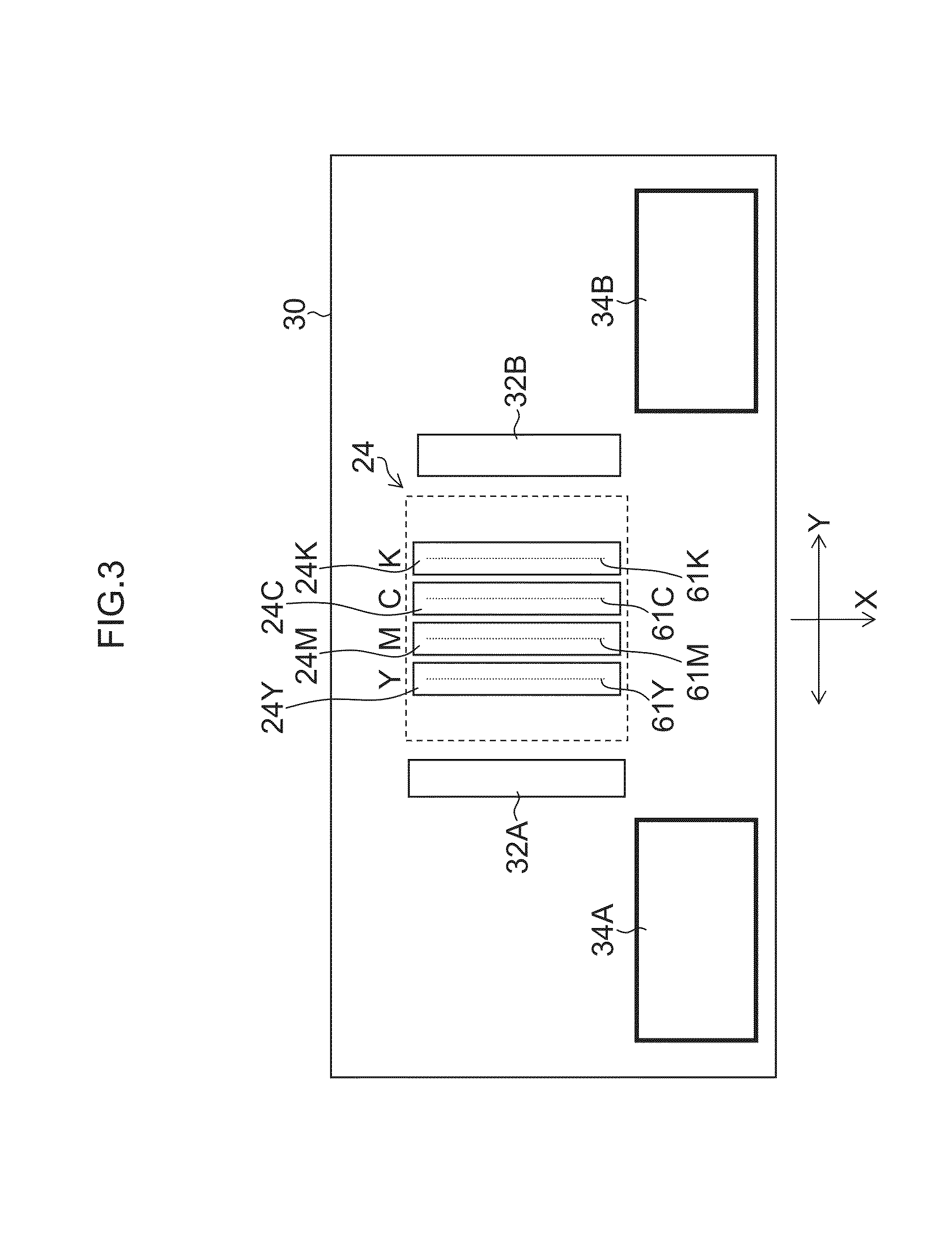

Developing apparatus for image forming apparatus

InactiveUS7103305B2Solve the lack of densityMaintain relatively stableElectrographic process apparatusDevelopersImage formationMechanical engineering

Owner:RICOH KK

Pixel driving method, pixel driving device and computer equipment

The invention relates to a pixel driving method, a pixel driving device and computer equipment. The pixel driving method comprises the steps that pixel signals of each color sub-pixel of each unit pixel in a pixel block are acquired, wherein each unit pixel comprises a red sub-pixel, a green sub-pixel and a blue sub-pixel; and then, according to the pixel signals of each color sub-pixel, signal judgment intervals and proportional norm values corresponding to the signal judgment intervals, a first type of gray scale signal is loaded to a part of the same color sub-pixels in the pixel block according to preset rules, and a second type of gray scale signal which is not equal to and has small difference with the first type of gray scale signal is correspondingly loaded to the remaining same color sub-pixels, so that graininess feeling when the pixel block displays is improved.

Owner:HKC CORP LTD

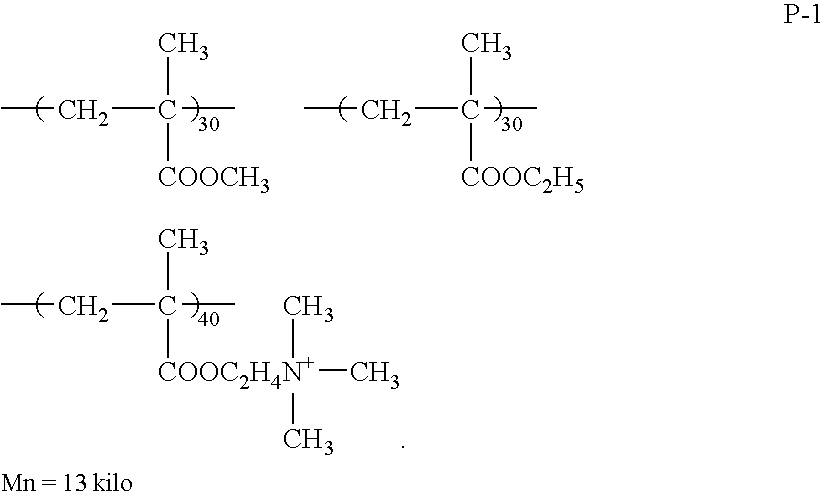

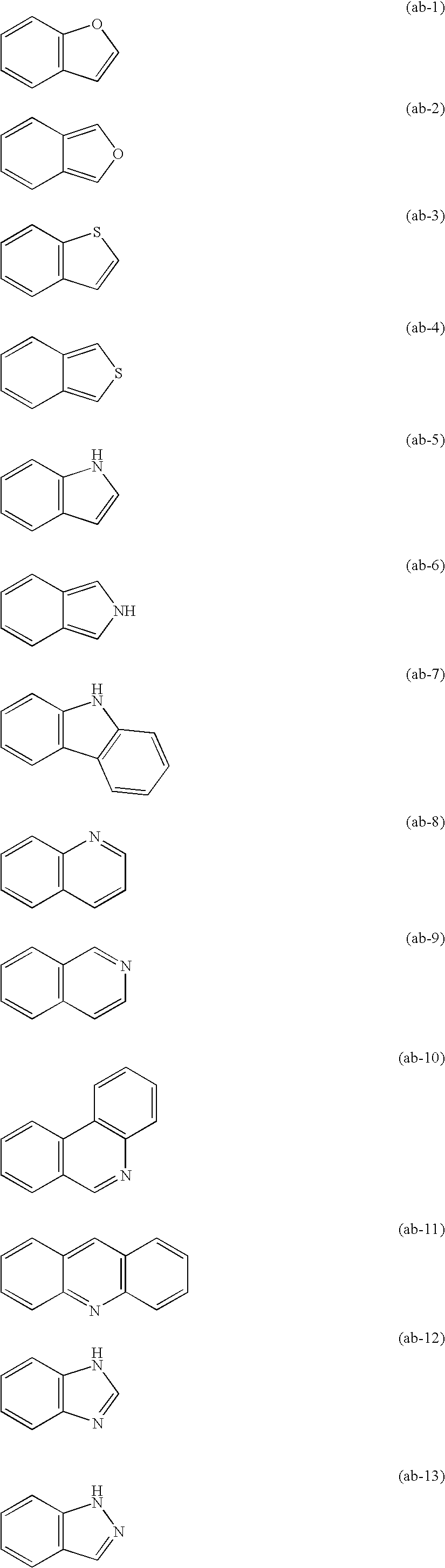

Ink jet recording method, and ink jet recording apparatus

InactiveUS8389600B2Graininess in the image occurs particularly remarkablyGraininess of the image tends to be more remarkableMeasurement apparatus componentsDuplicating/marking methodsEngineeringSilicone oil

Provided are an ink jet ink set, an ink jet recording method, and an ink jet recording apparatus each of which can reduce the graininess of an image to be recorded and improve the water fastness of the image even in a recording medium such as plain paper. The ink jet ink set has a first ink and a second ink independently, and is used so that the first and second inks overlap each other at least partly upon application of the inks to a recording medium. The first ink contains at least a pigment and a silicone oil. The second ink contains at least a pigment and a graft polymer that includes at least a nonionic unit represented by the general formula (I) and a unit having a polysiloxane structure.

Owner:CANON KK

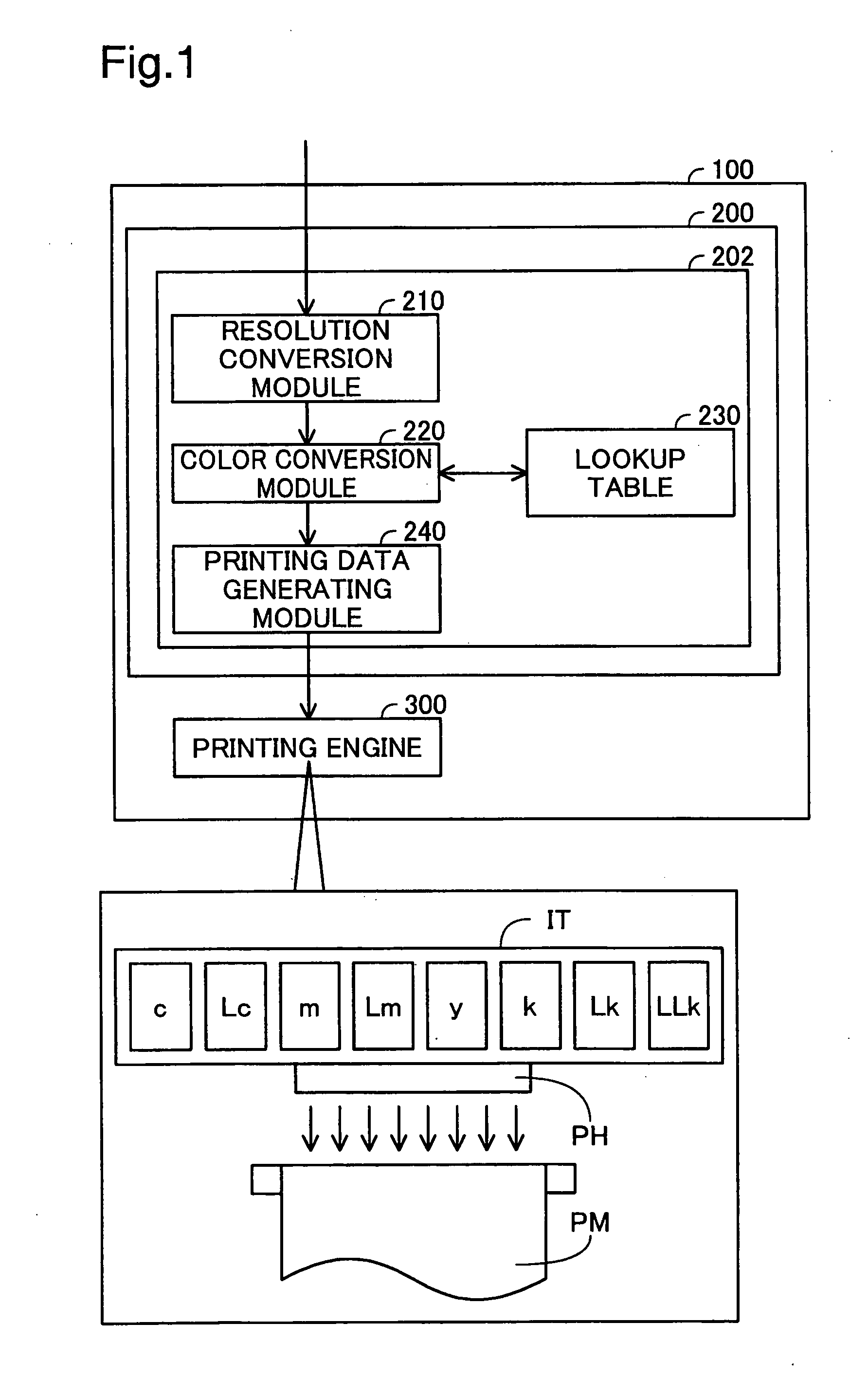

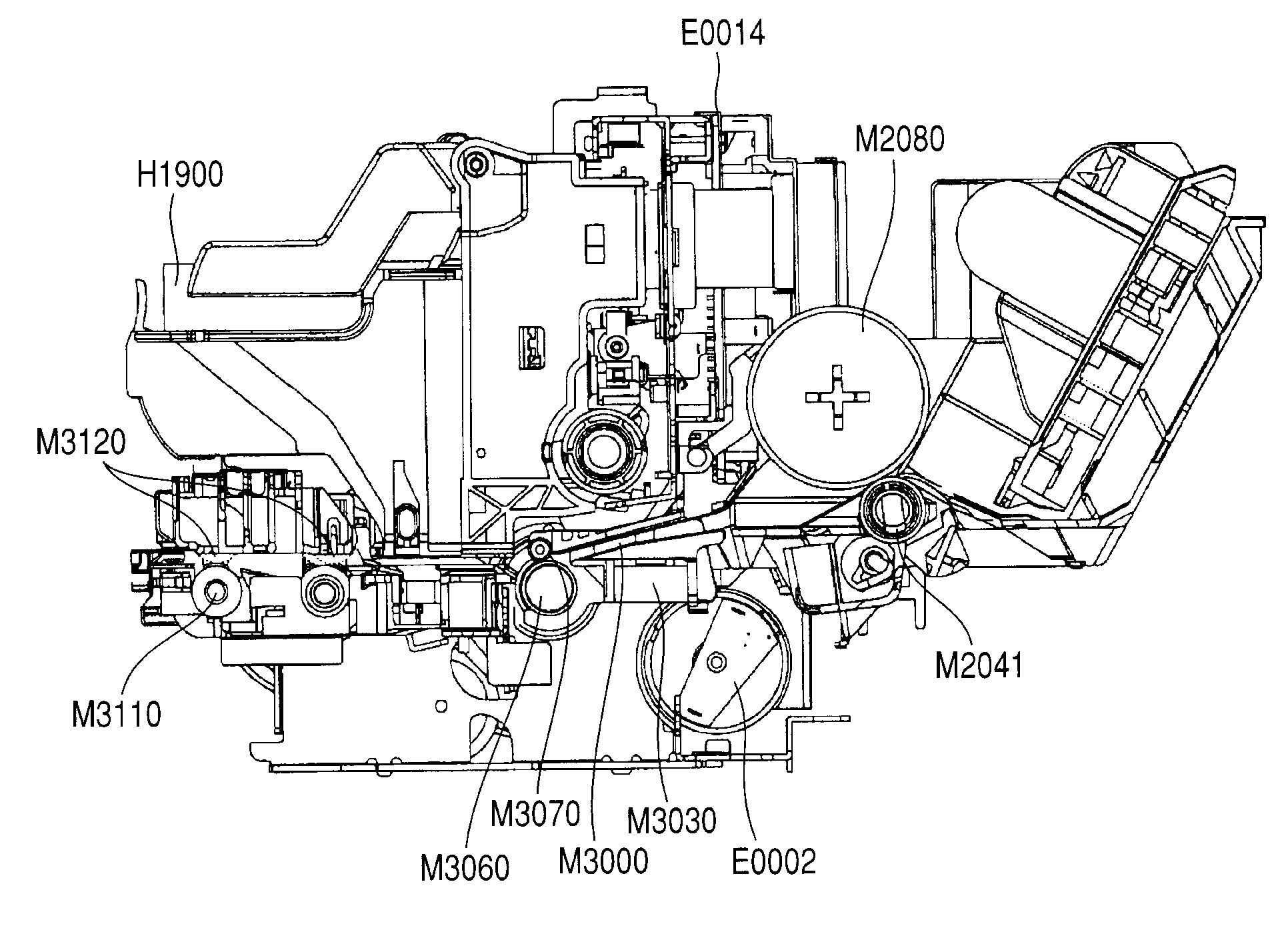

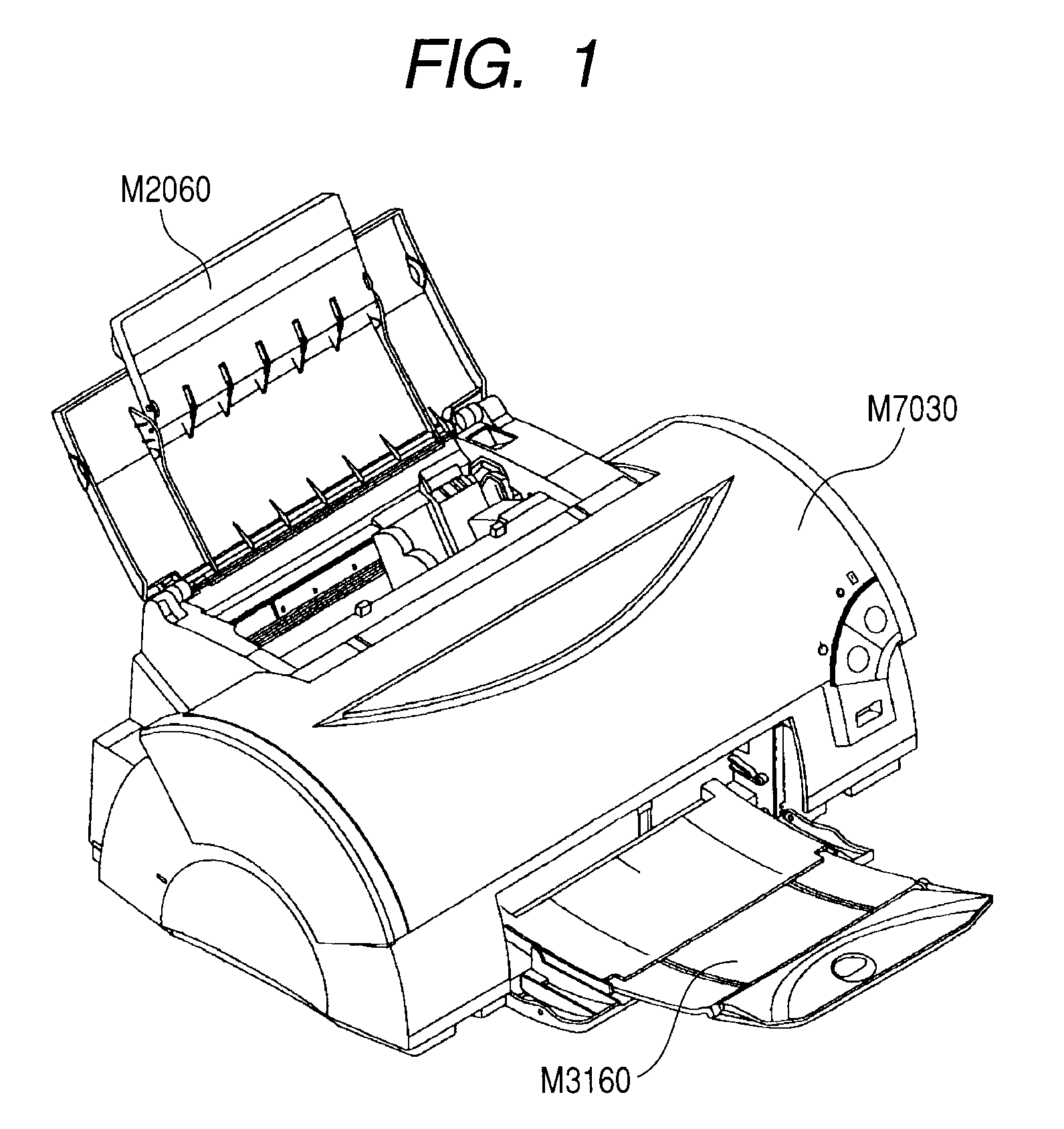

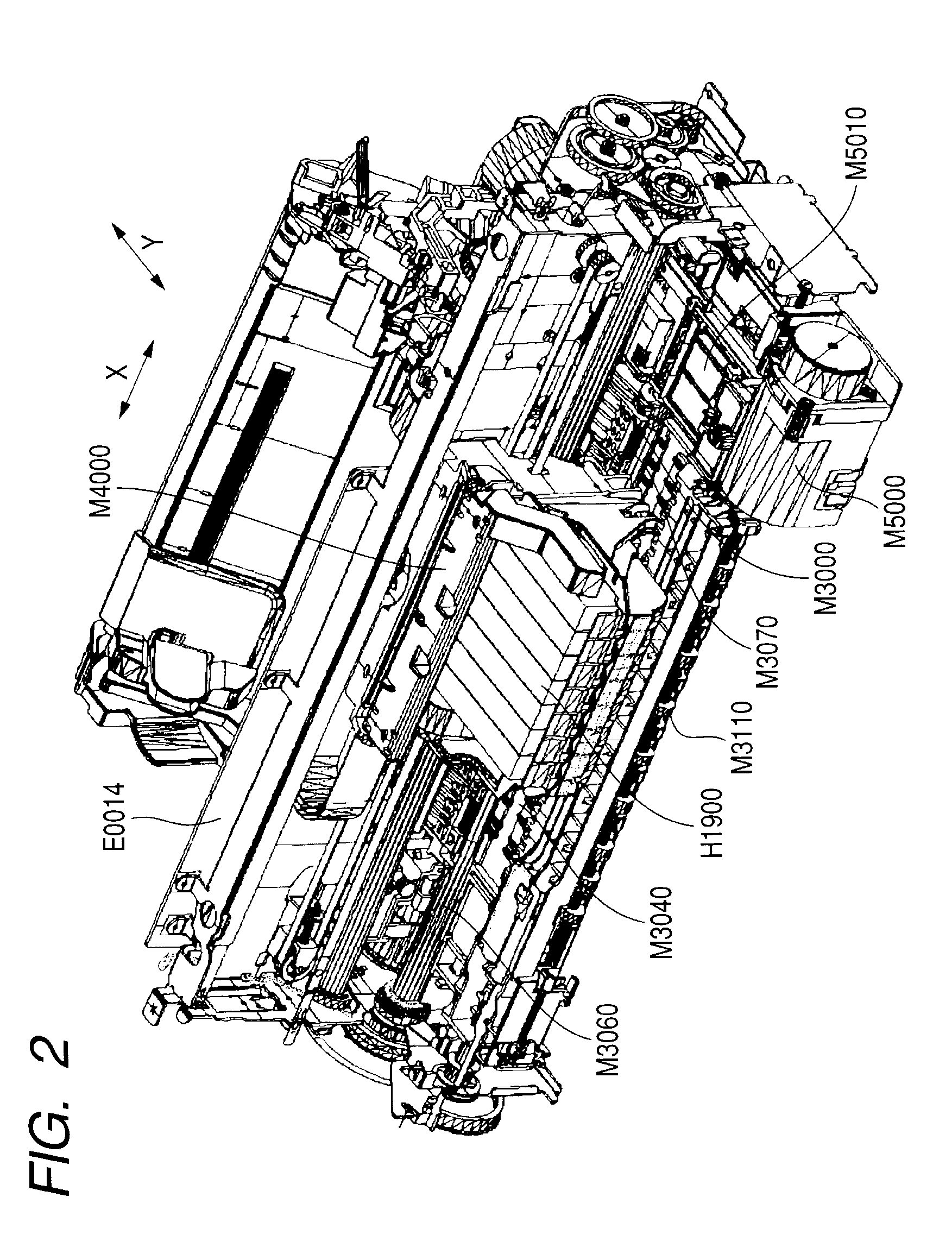

Printing apparatus and printing method

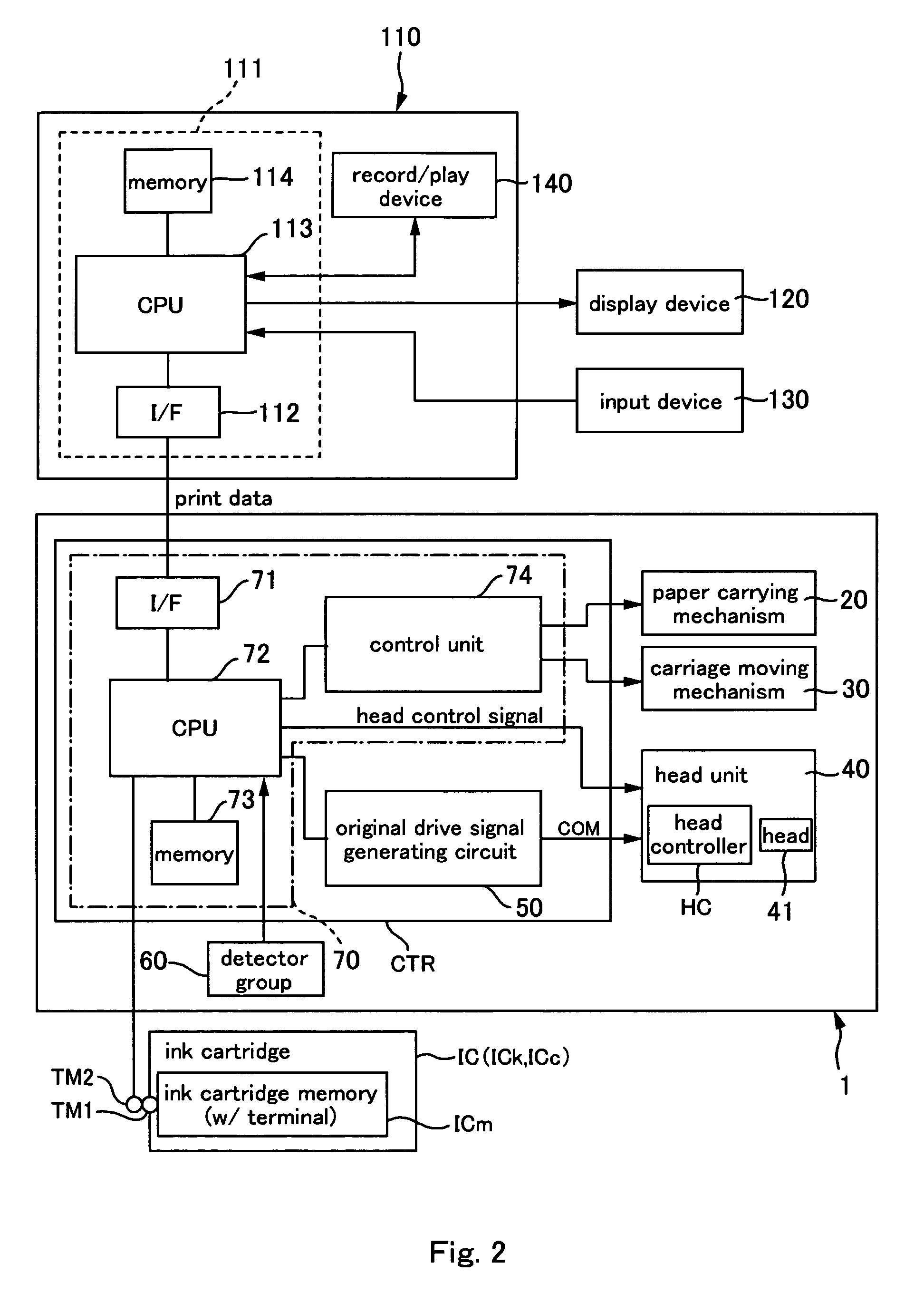

ActiveUS20070182974A1Improve graininessIncrease graininessDigitally marking record carriersVisual representation by matrix printersEngineeringHue

In printing of multi-level darkness / lightness of a certain color, which is performed with a dark ink and a light ink of the certain color, graininess is improved. A printing method includes generating a plurality of types of drive signals, and ejecting the dark ink and the light ink from a head, an amount of each ink varying for each dot tone value. In generation of a plurality of the types of the drive signals, a plurality of the types of drive signals are generated, where a waveform section that is for the dark ink of the certain color and that corresponds to a minimum dot tone value in ejection of ink is different from a waveform section that is for the light ink of the certain color and that corresponds to the minimum dot tone value, and where a waveform section that is for the dark ink of the certain color and that corresponds to a maximum dot tone value is different from a waveform section that is for the light ink of the certain color and that corresponds to the maximum dot tone value. In ejection of the dark ink and the light ink from the head, a drive signal that is generated based on a type of the dot tone value designated according to a size of a to-be-formed dot and based on a type of the ink is applied to an element that is provided on the head and that performs an operation for ejecting ink.

Owner:SEIKO EPSON CORP

Developing apparatus for image forming apparatus

InactiveUS20050095037A1Solve the lack of densityMaintain relatively stableElectrographic process apparatusDevelopersMechanical engineeringEngineering

Owner:RICOH KK

Stuffing modifier, dumpling and preparation methods thereof

InactiveCN107594323AKeep the clumping performancePreserve tendernessFood coatingGellan gumMonoglyceride

The invention relates to the technical field of food processing and specifically relates to a stuffing modifier, a dumpling and preparation methods thereof. The modifier is prepared from gellan gum, calcium hydrophosphate, xanthan gum, composite phosphate, monoglyceride and corn starch, wherein the gellan gum and the calcium hydrophsphate interact with each other to form gel; thus, under the situation that diced meat is utilized as a stuffing raw material, stuffing huddling performance can be still well kept, and granular sensation of meat stuffing is enhanced; the composite phosphate, the corn starch and the monoglyceride are added to effectively improve water binding capacity; thus, meat tenderness is kept, meat stuffing taste is prevented from being dry and skinny; meanwhile, product texture is improved, granular sensation is obvious when the meat stuffing is eaten, and the meat stuffing has elasticity; the xanthan gum is utilized as a thickener and can absorb moisture precipitatedfrom the meat stuffing, meat stuffing thickness is improved, and production operation is facilitated.

Owner:郑州研霖生物科技有限公司

Printing control apparatus and printing apparatus

InactiveUS20080216684A1Improve graininessIncrease brightnessPlaten pressesPrinting press partsControl equipmentEngineering

In an aspect, a first ink amount relating to the yellow ink is smaller than both a second ink amount relating to the cyan ink and a third ink amount relating to the magenta ink.In another aspect, a first total increase amount is larger than both a second total increase amount and a third total increase amount. The first total increase amount is a total increase amount of inks other than the yellow ink relating to a black yellow gradation. The second total increase amount is a total increase amount of inks other than the cyan ink relating to a black cyan gradation. The third total increase amount is a total increase amount of inks other than the magenta ink relating to a black magenta gradation.In another aspect, a first lowest brightness is lower than both a second lowest brightness and a third lowest brightness. The first lowest brightness is lowest brightness of color to be printed without using black ink on a black yellow gradation. The second lowest brightness is lowest brightness of color to be printed without using black ink on a black cyan gradation. The third lowest brightness is lowest brightness of color to be printed without using black ink on a black magenta gradation.

Owner:SEIKO EPSON CORP

Ink set, ink jet recording method, and ink jet recording apparatus

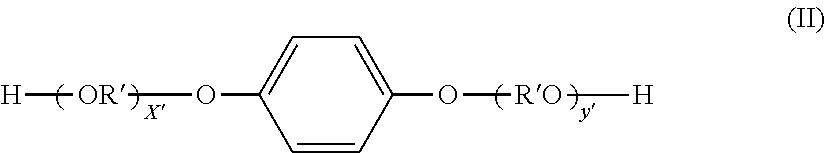

InactiveUS20100033523A1Long time intervalIncrease graininessMeasurement apparatus componentsDuplicating/marking methodsEngineeringSilicone oil

Provided are an ink jet ink set, an ink jet recording method, and an ink jet recording apparatus each of which can reduce the graininess of an image to be recorded and improve the water fastness of the image even in a recording medium such as plain paper. The ink jet ink set has a first ink and a second ink independently, and is used so that the first and second inks overlap each other at least partly upon application of the inks to a recording medium. The first ink contains at least a pigment and a silicone oil. The second ink contains at least a pigment and a graft polymer that includes at least a nonionic unit represented by the general formula (I) and a unit having a polysiloxane structure.

Owner:CANON KK

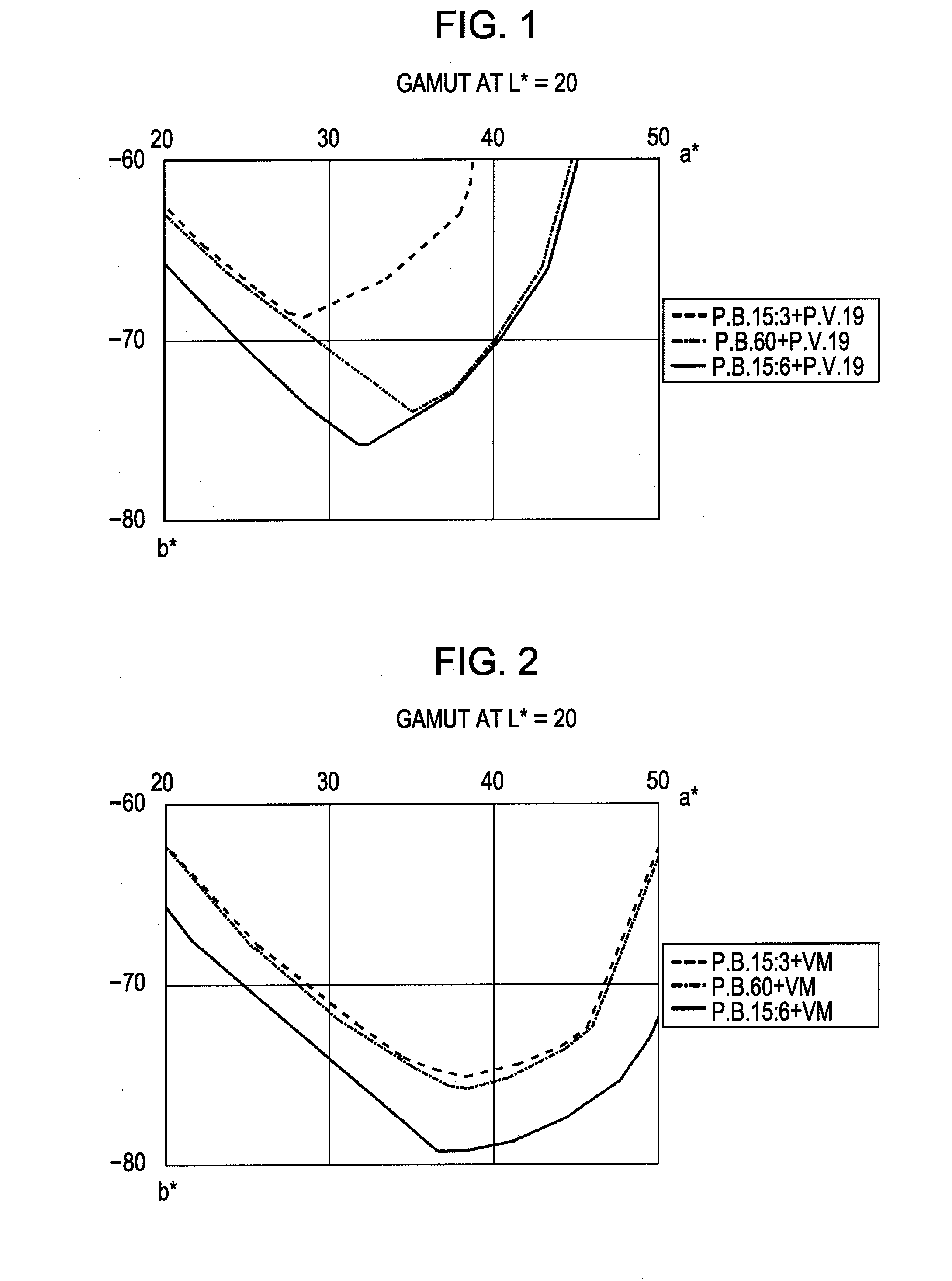

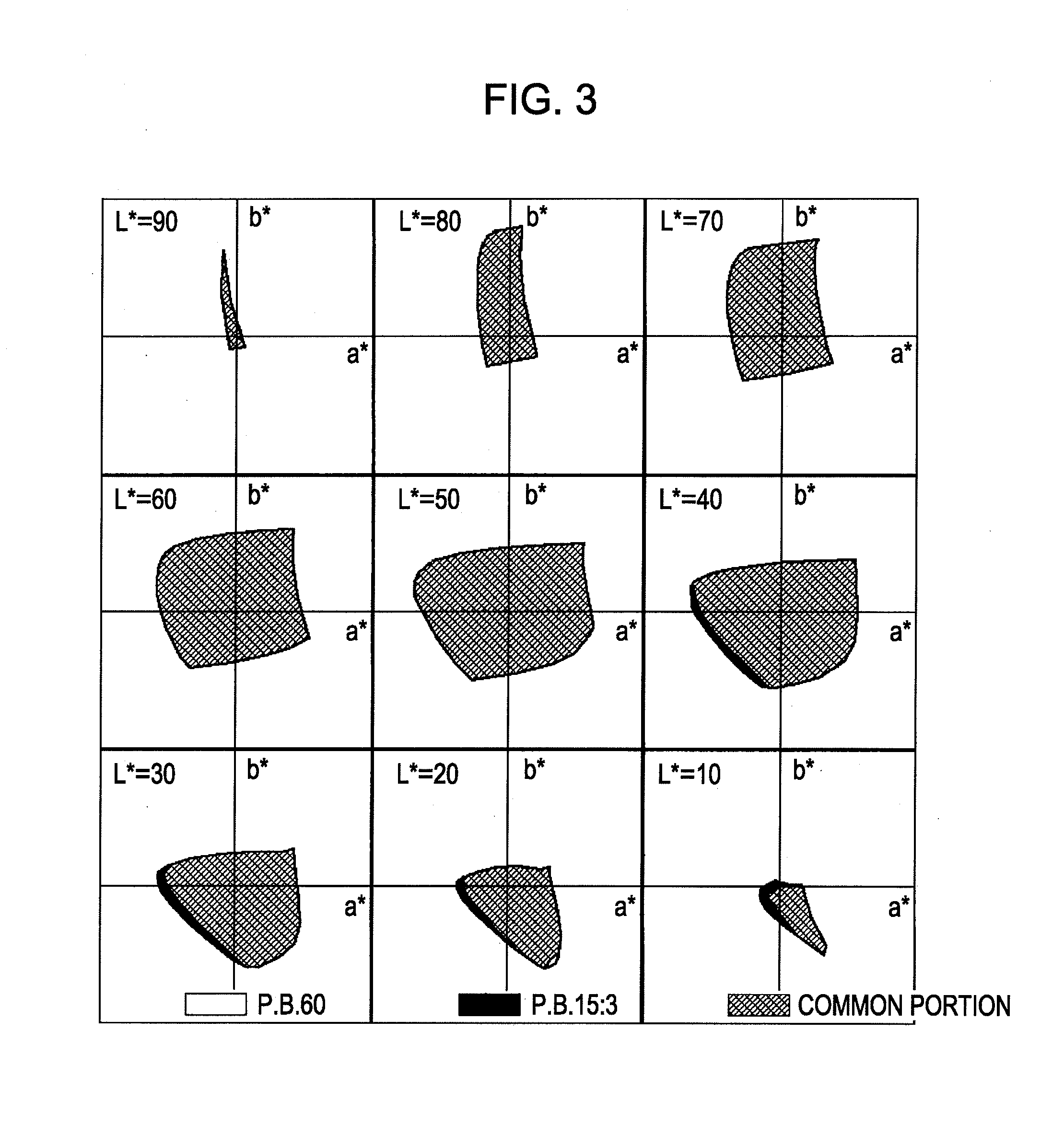

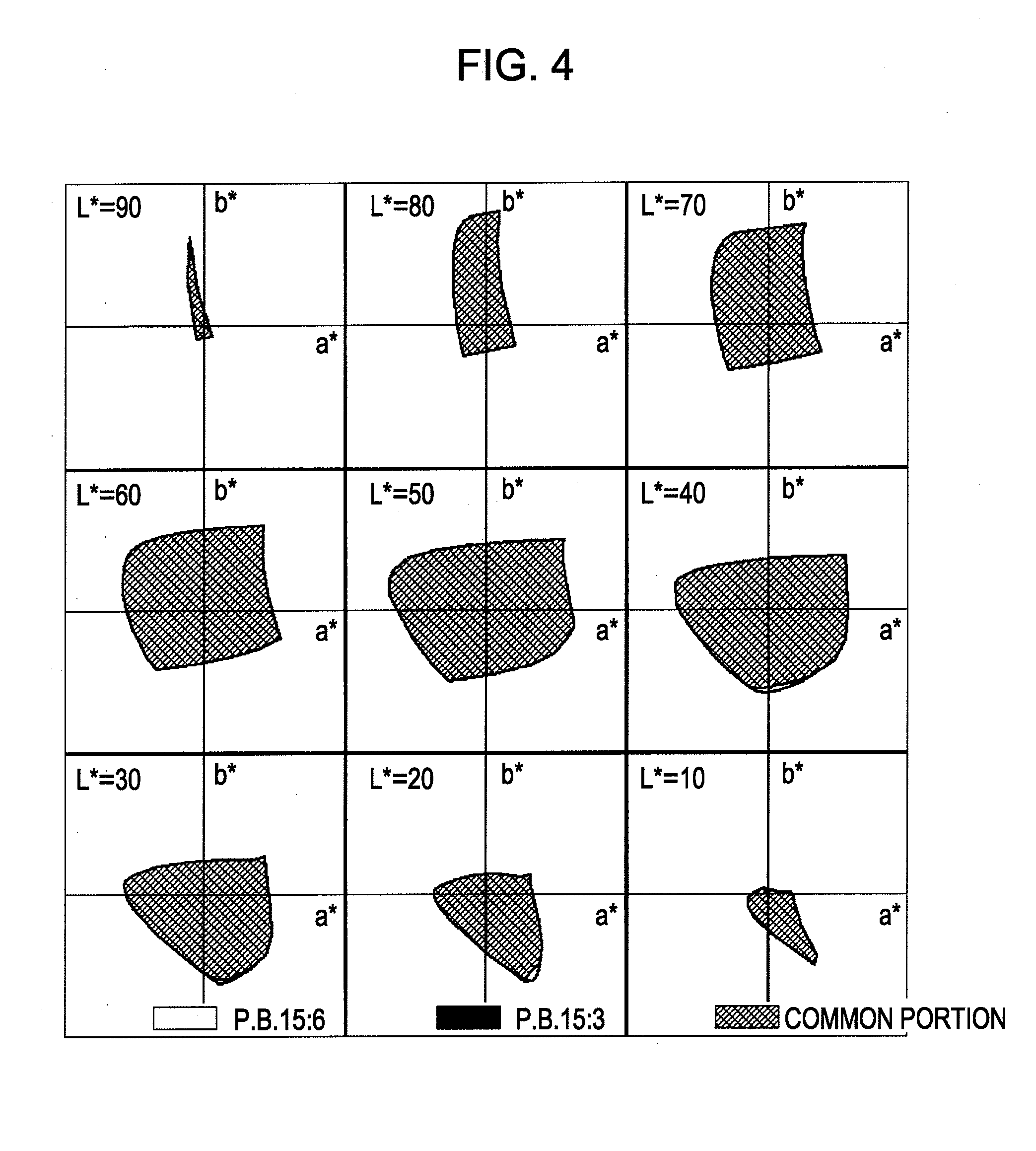

Ink set, recording apparatus, and recording method

InactiveUS20100212543A1Increase graininessHigh color reproductionMeasurement apparatus componentsDuplicating/marking methodsSolid solutionMagenta

An ink set includes a cyan ink composition containing C. I. Pigment Blue 15:6 as a pigment; a magenta ink composition containing a quinacridone pigment selected from the group consisting of C. I. Pigment Violet 19, C. I. Pigment Red 122, C. I. Pigment Red 202, and C. I. Pigment Red 209 or a quinacridone solid solution pigment composed of at least two selected from the group; a yellow ink composition containing a pigment selected from the group consisting of C. I. Pigment Yellow 74, C. I. Pigment Yellow 213, and C. I. Pigment Yellow 185; a light magenta ink composition containing a quinacridone pigment selected from the group consisting of C. I. Pigment Violet 19, C. I. Pigment Red 122, C. I. Pigment Red 202, and C. I. Pigment Red 209 or a quinacridone solid solution pigment composed of at least two selected from the group at a pigment concentration lower than that of the magenta ink composition; and a light cyan ink composition containing C. I. Pigment Blue 15:3 as a pigment at a pigment concentration lower than that of the cyan ink composition.

Owner:SEIKO EPSON CORP

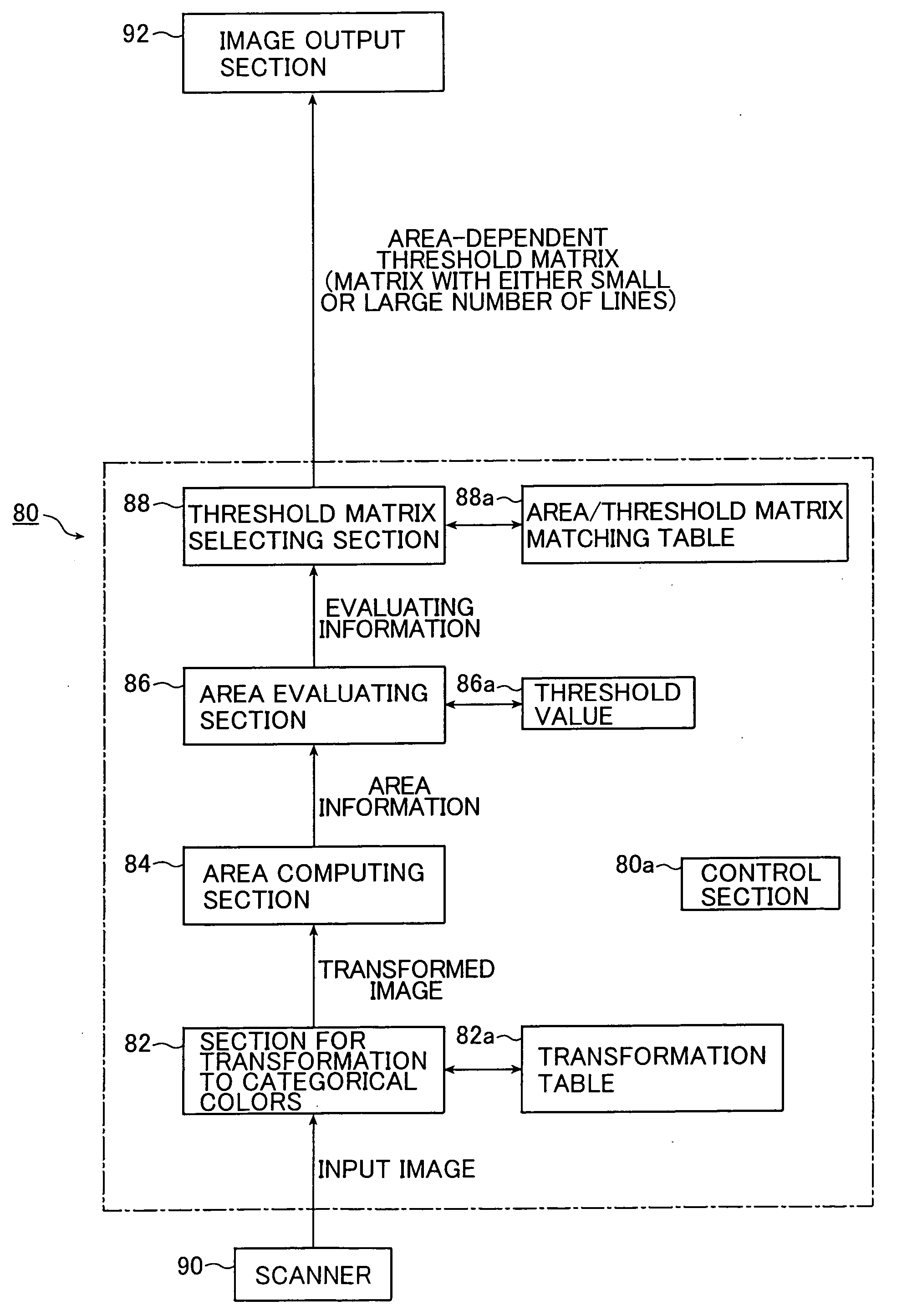

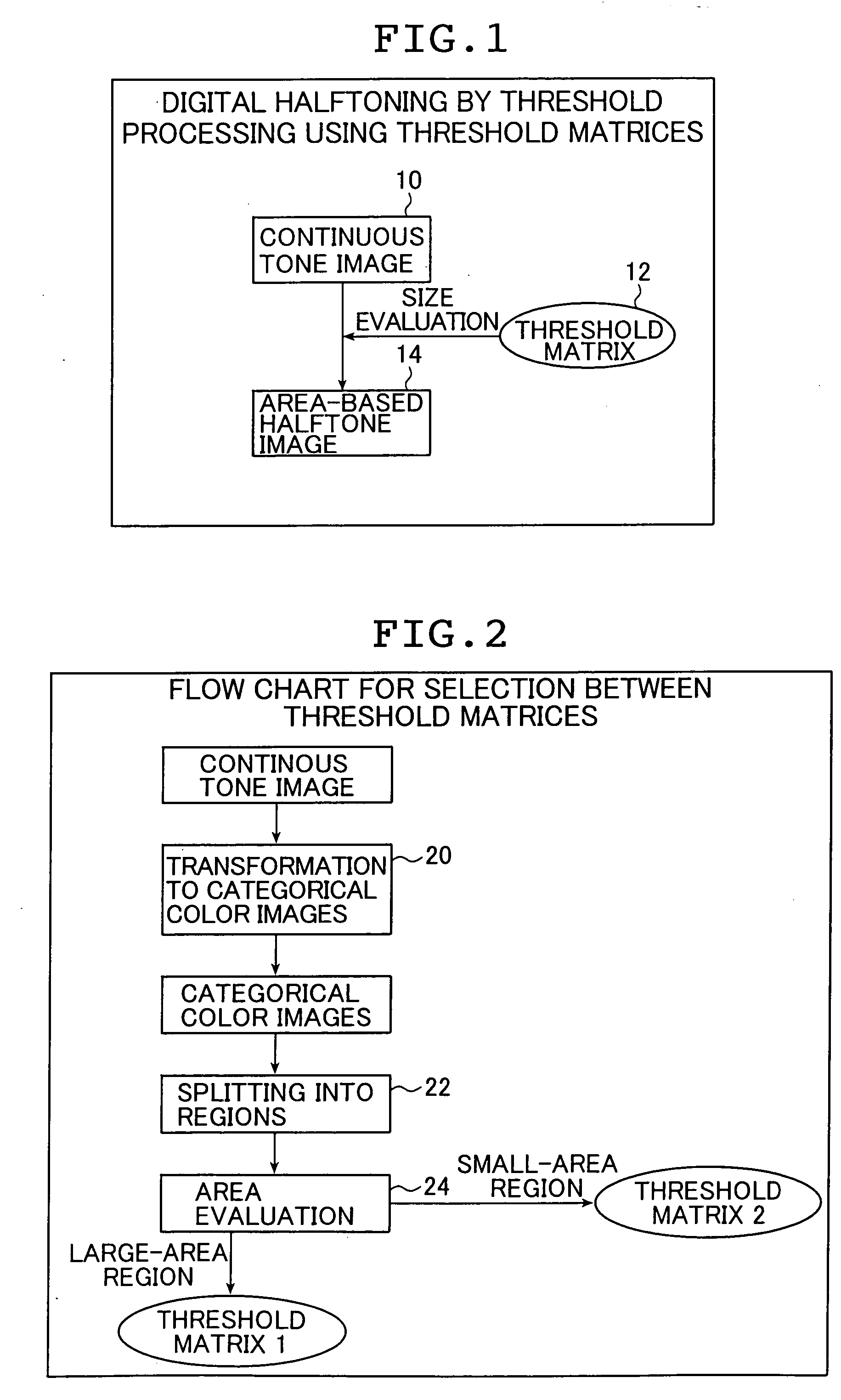

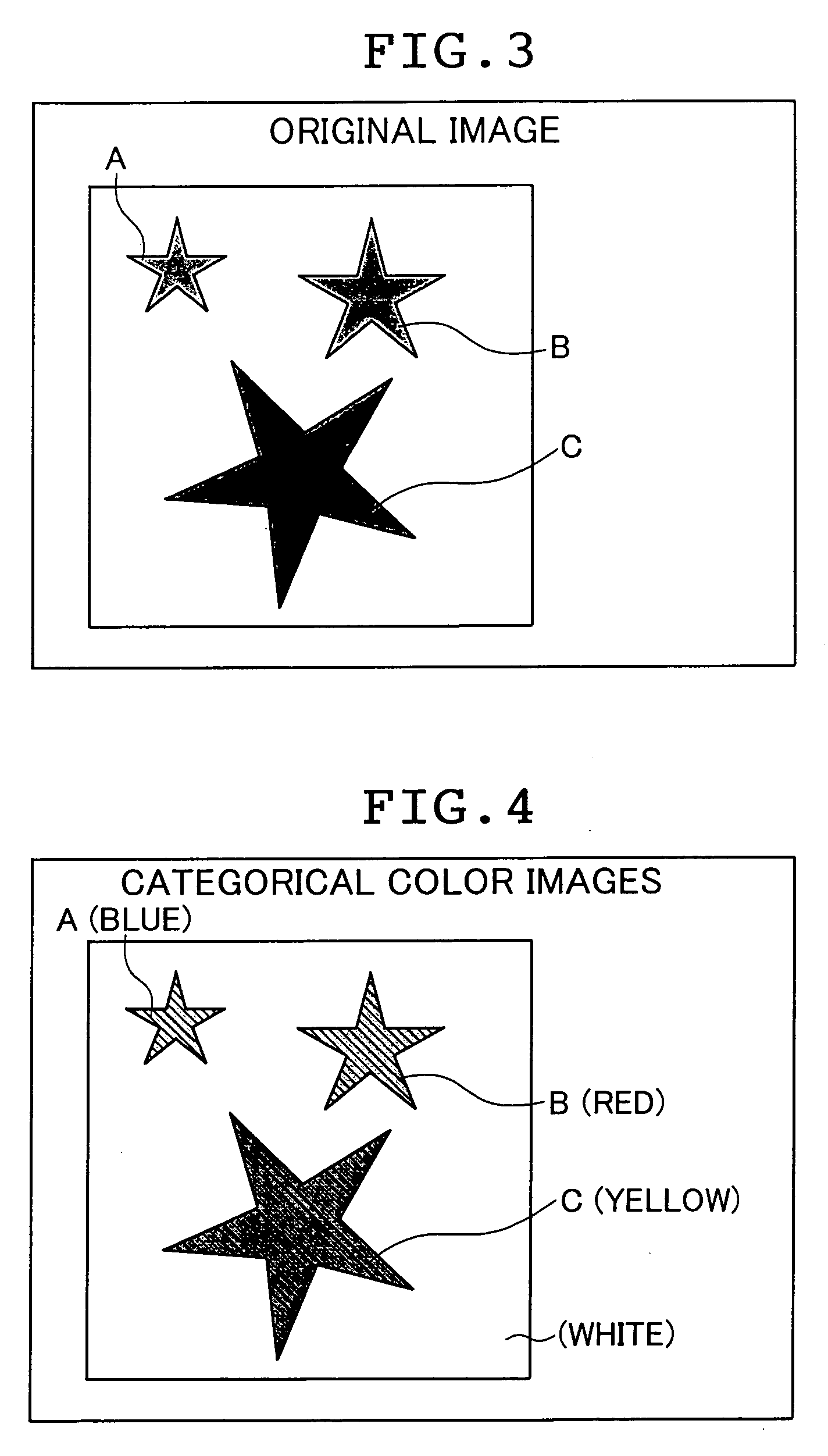

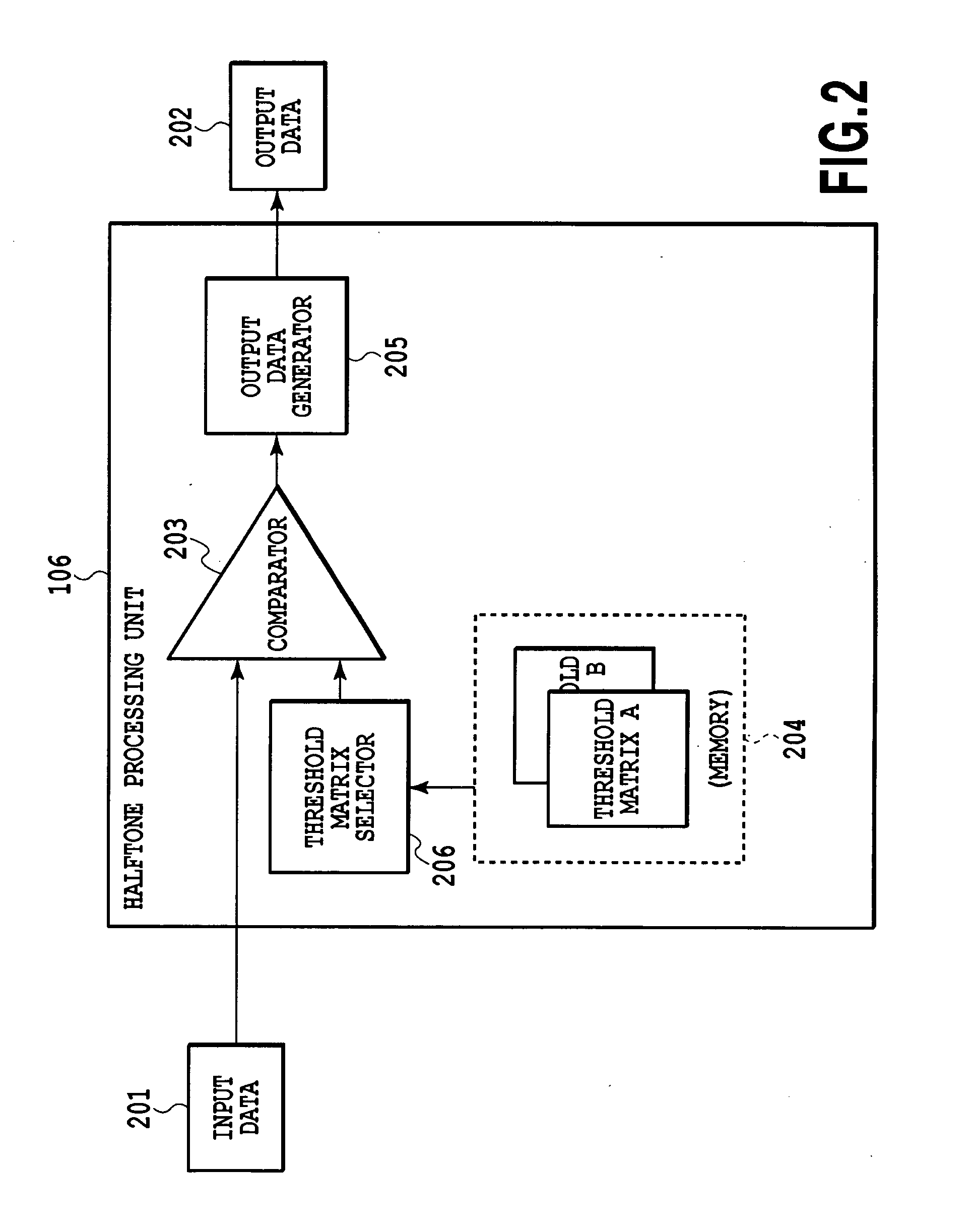

Method and apparatus for processing images

InactiveUS20050195443A1Less conspicuousIncrease graininessVisual presentationPictoral communicationImaging processingContinuous tone

The image processing method and apparatus use a digital half-toning technique. The method and apparatus split a continuous tone image into split regions, compute an area size of each of the split regions and select an optimum halftone best suited to each of the split regions depending on the thus computed area size of each of the split regions. The program implements the above image processing method by control with a computer. The above program is written to the recording medium and can be read with the computer from the recording medium.

Owner:FUJIFILM HLDG CORP +1

Processes for producing Bi12MO20 precursors, Bi12MO20 particles, and photo-conductor layers

InactiveUS20060051287A1Uniform compositionHigh puritySolid-state devicesTitanium compoundsElectrical conductorMaterials science

A mixed solution of a bismuth salt and a metal alkoxide is mixed together with an aqueous alkali solution, and a Bi12MO20 precursor, in which M represents at least one kind of element selected from the group consisting of Ge, Si, and Ti, is thereby obtained. The Bi12MO20 precursor is subjected to molding processing, the thus molded Bi12MO20 precursor is subjected to firing processing, and a photo-conductor layer is thereby produced. Alternatively, the Bi12MO20 precursor is subjected to heating processing in an alkaline liquid phase or to firing processing, and Bi12MO20 particles are thereby obtained. A photo-conductor layer is produced by use of the thus obtained Bi12MO20 particles.

Owner:FUJIFILM CORP +1

Method for creating dot arrangements or threshold matrices, an image processing apparatus, and a storage medium

ActiveUS20150286905A1Increase graininessImprove robustnessDigitally marking record carriersDigital computer detailsEvaluation resultPattern recognition

An image that is robust against position shift and that has improved graininess is formed. In the embodiments, a halftone processor creates a first dot arrangement and a second dot arrangement from related weighting functions and weighting maps (S1508, S1509), evaluates the image quality when the first dot arrangement and the second dot arrangement are overlapped and combined (S1511, S1512), updates the weightings for only pixels where a dot is arranged in case where the evaluation results in the evaluating step are not within a specified range (S1513), obtains a first dot arrangement and a second dot arrangement that were recreated based on the updated weightings (S1508, S1509), and repeats steps S1508 to S1514 until it is determined that the change in image quality due to position shift when the recreated first and second dot arrangements are overlapped and combined is within a specified range.

Owner:CANON KK

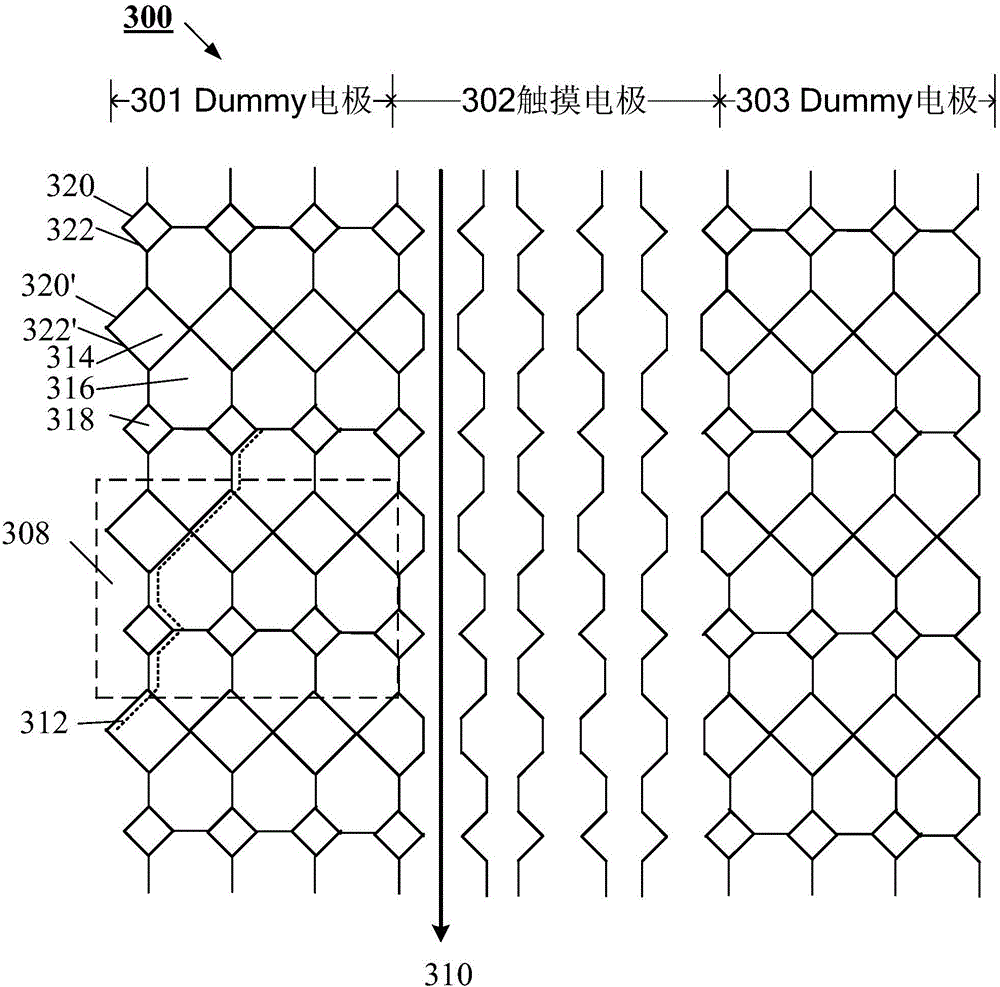

Electrode structure and manufacturing method thereof, touch panel and touch display device

ActiveCN106020527AImprove experienceIncrease graininessInput/output processes for data processingElectricityDisplay device

The invention discloses an electrode structure. The electrode structure includes: a plurality of first electrodes for sending an electrical signal; and a plurality of second electrodes which do not send the electrical signal; the first electrodes and the second electrodes are in mutual electrical isolation; the second electrodes and the first electrodes are arranged alternatively; each second electrode includes a plurality of electrically-isolated electrodes; some isolated edges which are not perpendicular to an extension direction of the first electrodes, of the plurality of electrically-isolated electrodes can be connected into an inclined connection line relative to the extension direction. In addition, the invention discloses a manufacturing method of the electrode structure, a touch panel, and a touch display device. The electrode structure can effectively improve the granular sensation, has a good shadow elimination effect, and can improve the user experience.

Owner:BOE TECH GRP CO LTD +1

Color separation into a plurality of ink components including primary color ink and spot color ink

InactiveUS20090185208A1Reduce colorEnhance the imageDigitally marking record carriersDigital computer detailsHueCell separation

Utilizing an ink set that includes a plurality of chromatic primary color inks that, when used in combination, can reproduce achromatic color, and at least one spot color ink of hue different from any of the plurality of chromatic primary color inks. Color to be reproduced on a print medium according to any one input color is termed “reproduction color”, and the combination of ink quantities in the ink set for reproducing the reproduction color on the print medium is termed the “color separation ink quantity set.” The ink quantity of the spot color ink included in the color separation ink quantity set is adjusted in accordance with a lightness parameter value which is correlated to lightness of reproduction color, so as to reduce ink quantity at a rate of change greater than the rate of change of the lightness parameter in the direction of increasing brightness.

Owner:SEIKO EPSON CORP

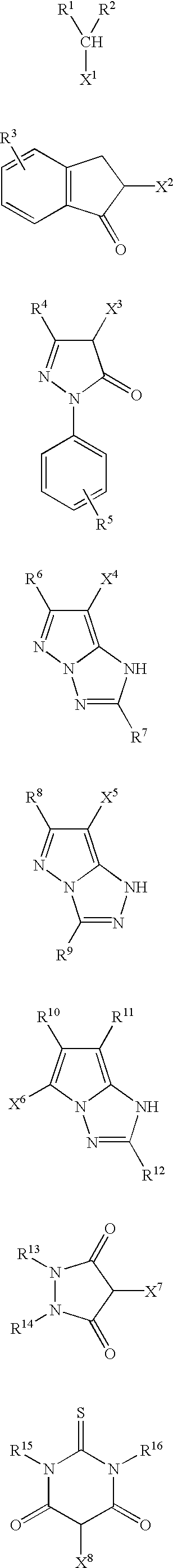

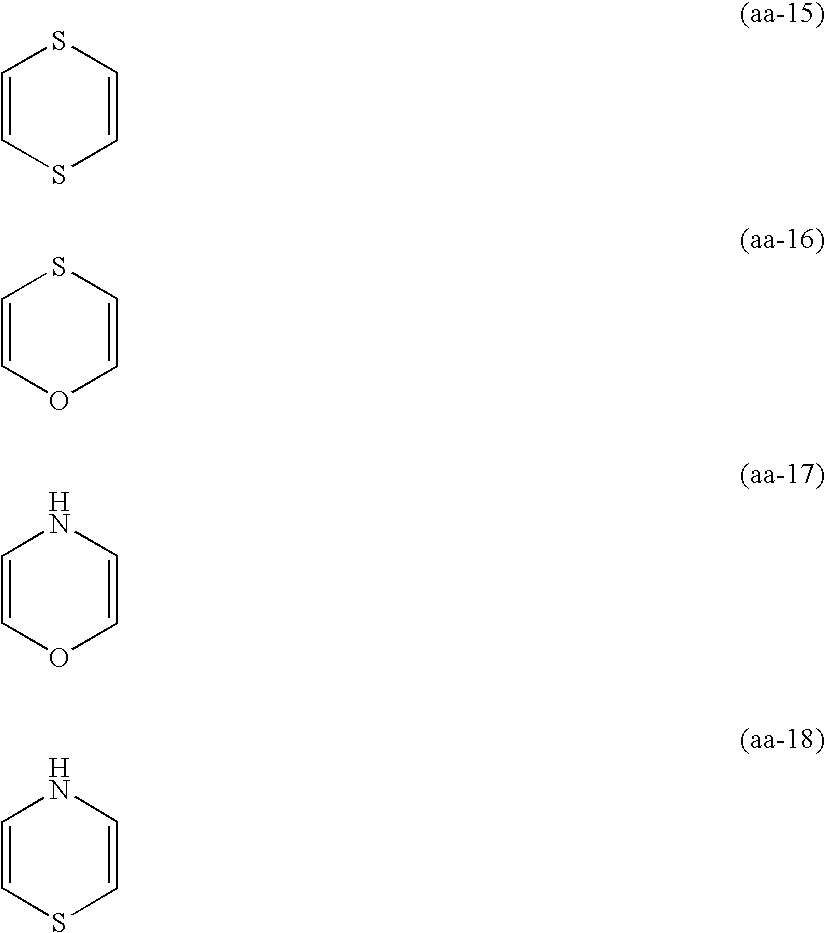

Photothermographic material and method for forming images

InactiveUS6649329B2High sensitivityIncrease graininessX-ray/infra-red processesRadiation applicationsSilver halidePhenol derivative

The present application relates to a photothermographic material comprising, on a side of a support, (a) a photosensitive silver halide, (b) a reducible silver salt, (c) a phenol derivative having the specific structure as reducing compound, (d) a binder, (e) a coupler compound, and (f) a compound represented by Q<1>-NHNH-V<6 >wherein Q<1 >is a 5- to 7-membered unsaturated ring and V<6 >is a carbamoyl group, etc.

Owner:FUJIFILM CORP

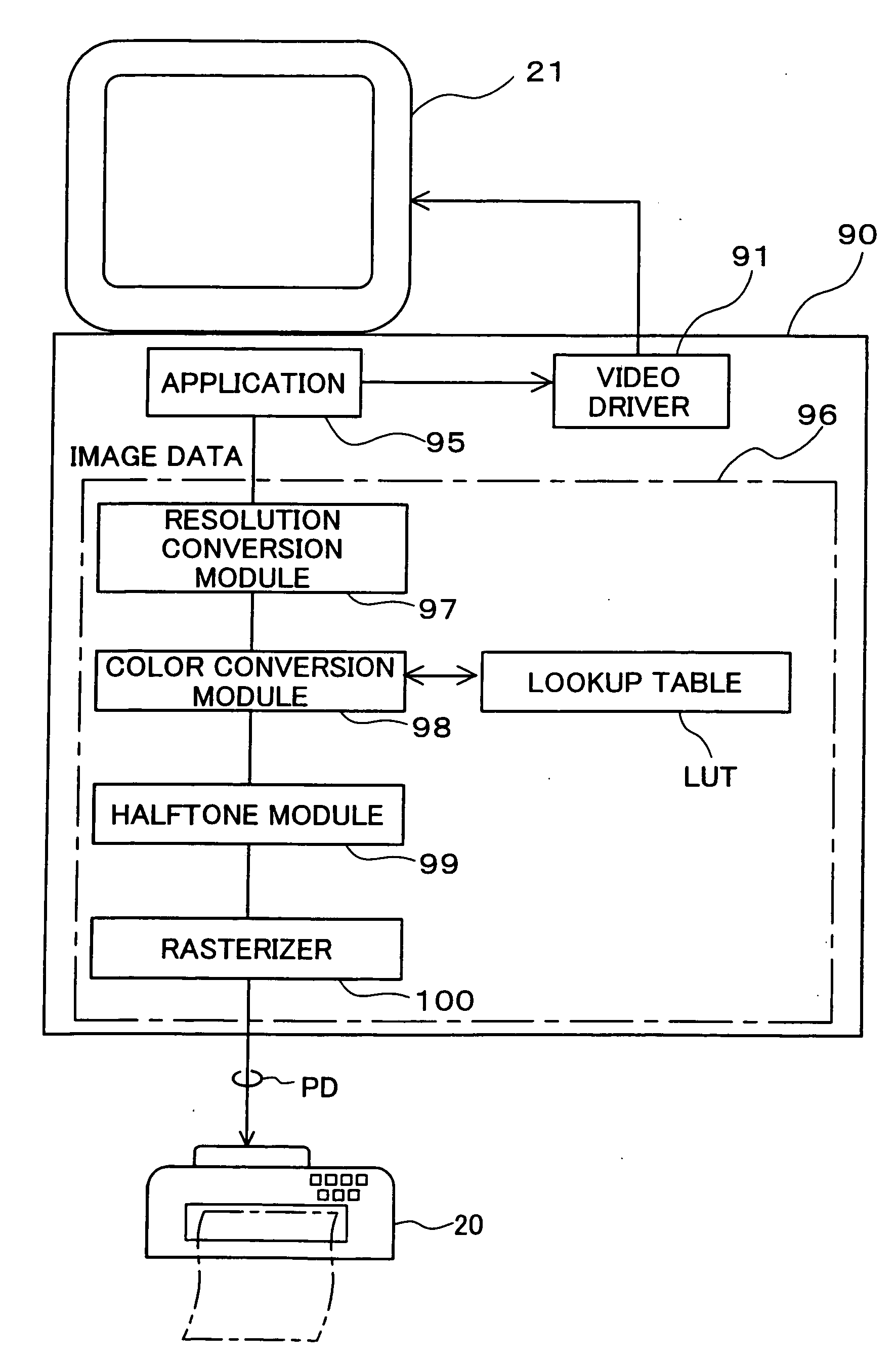

Image processing method and apparatus

InactiveUS7009737B2Good reproducibilityLow regionImage enhancementVisual presentationImaging processingError diffusion

A non-periodic dot output arrangement is taken in the low thickness region, and a periodic dot output arrangement is taken in the intermediate and high thickness region. In addition, error diffusion processing is made for all thickness regions. Small dots are produced in the non-periodic dot arrangement low-thickness region, and dot-concentrated-type dots are produced in the periodic dot arrangement intermediate-and-high-thickness region. Moreover, non-periodic dots are produced in the edge region of the image.

Owner:PANASONIC CORP

Toner

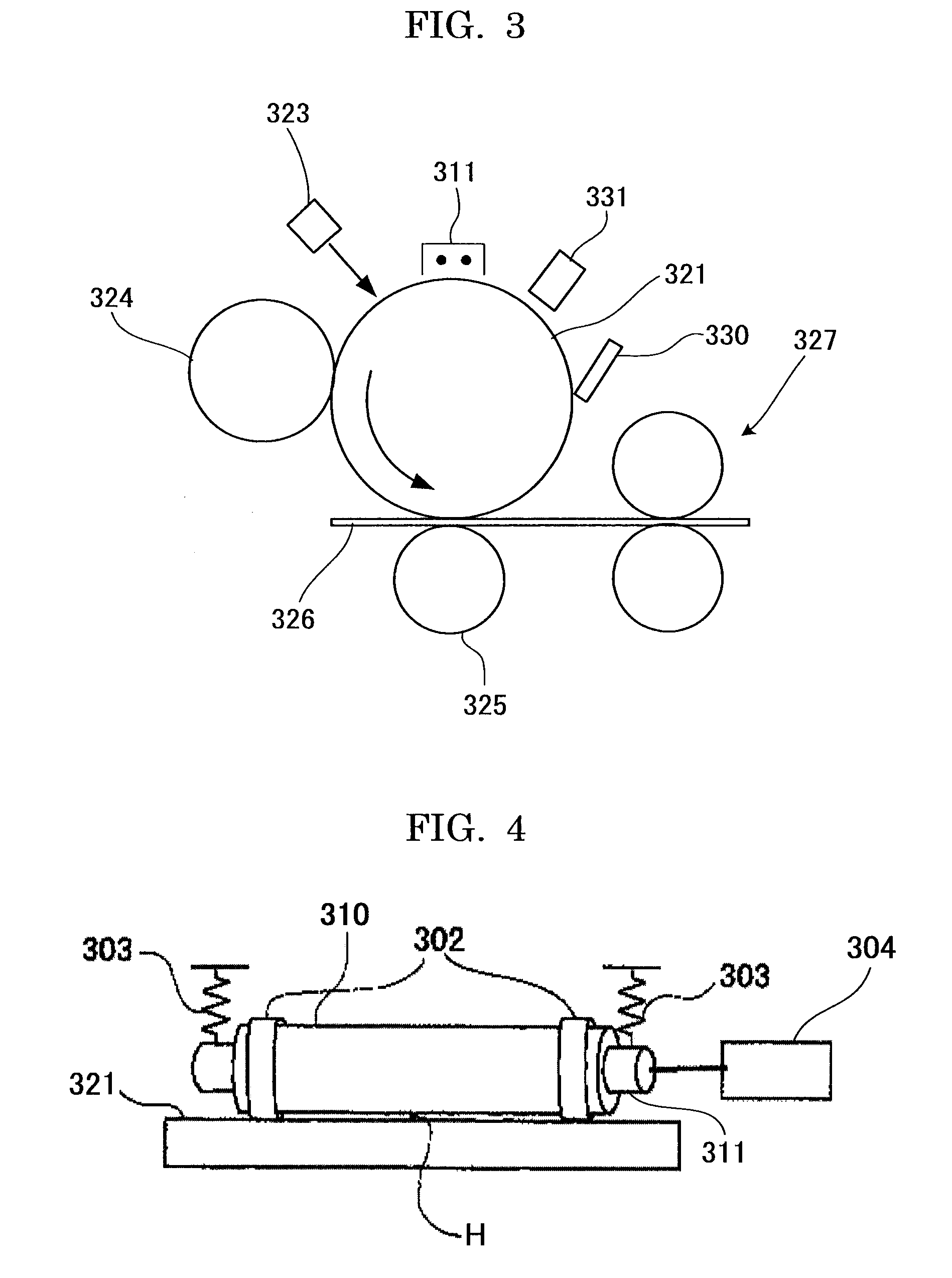

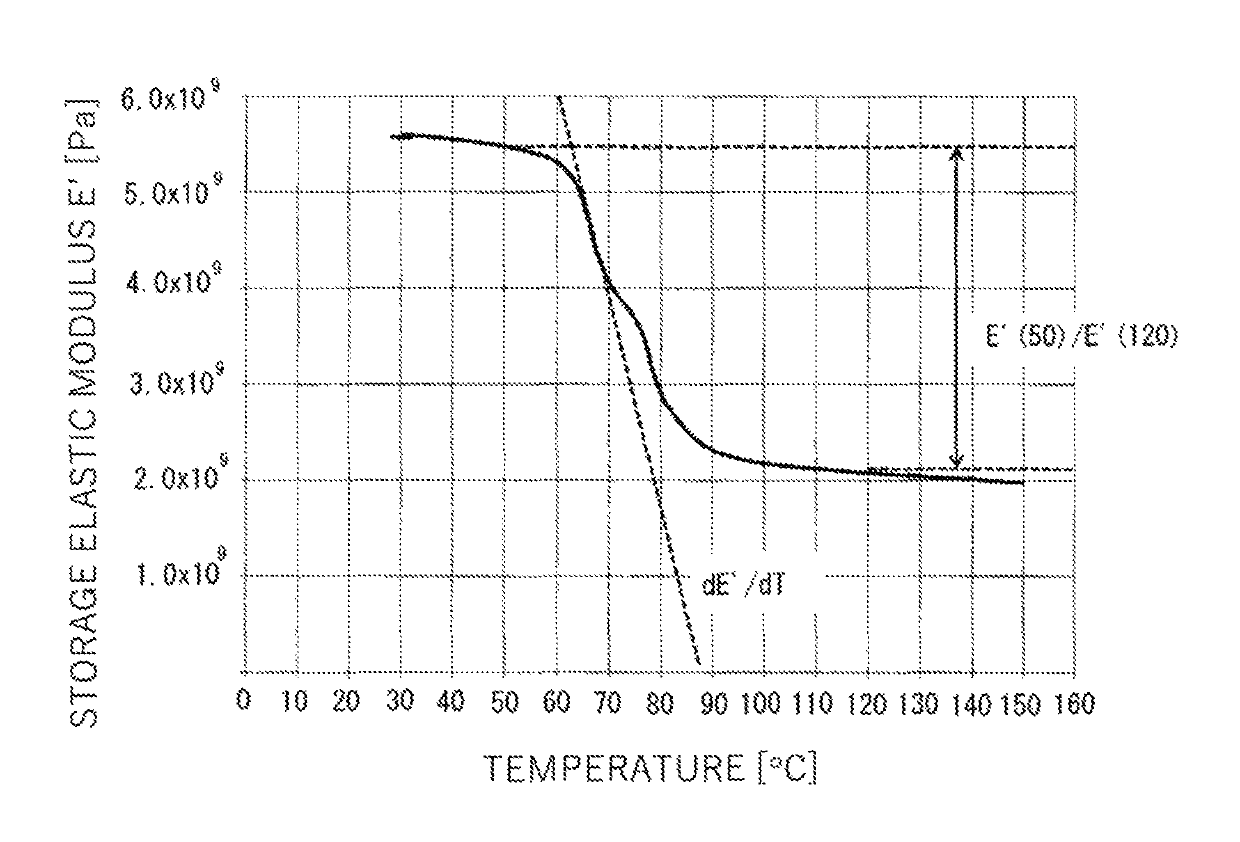

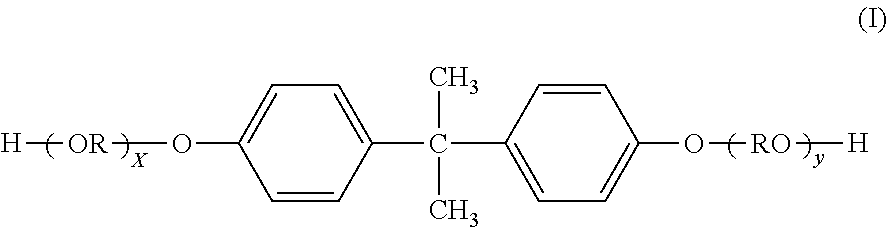

ActiveUS20180173126A1Excellent low-temperature fixabilityExcellent halftone image graininessDevelopersElastic modulusEngineering

A toner comprising a toner particle containing a resin and a colorant, wherein, with respect to a temperature-storage elastic modulus curve obtained by powder dynamic viscoelastic measurement on the toner, (I) the relative minimum values for the variation in the storage elastic modulus E′ with respect to temperature T in the temperature range of at least 30° C. and not more than 180° C. have a relative minimum value of equal to or less than −1.00×107 and the relative minimum value on the lowest temperature side is equal to or less than −1.00×108; (II) the storage elastic modulus E′ (50) of the toner at 50° C. is at least 1.00×109 and not more than 9.00×109; and (III) for a storage elastic modulus E′ (120) of the toner at 120° C., E′ (50) and E′ (120) satisfy 1.50≤[E′ (50)] / [E′ (120)]≤3.00.

Owner:CANON KK

Ink-jet ink production method and ink-jet recording method

ActiveUS20050217536A1Easy to demouldQuality improvementMeasurement apparatus componentsDuplicating/marking methodsFiberOrganic solvent

A method of producing an ink-jet ink containing the steps in the order named: (a) dispersing colorant particles, a dispersing agent, and a solvent mixture containing water and a water-soluble organic solvent so as to obtain a dispersion of the colorant particles; (b) filtering the dispersion of the colorant particles using a hollow fiber filter; and (c) applying ultrasonic degassing treatment to the filtered dispersion of the colorant particles to obtain the ink-jet ink, wherein a content of oxygen in the ink-jet ink is not more than 2 ppm based on the total weight of the ink-jet ink.

Owner:KONICA MINOLTA INC

Degassing method of ink-jet ink, production method of ink-jet ink and ink-jet printer

Owner:KONICA MINOLTA INC

Photothermographic material and method for forming images

InactiveUS20020055067A1High sensitivityIncrease graininessX-ray/infra-red processesRadiation applicationsSilver halidePhenol derivative

The present application relates to a photothermographic material comprising, on a side of a support, (a) a photosensitive silver halide, (b) a reducible silver salt, (c) a phenol derivative having the specific structure as reducing compound, (d) a binder, (e) a coupler compound, and (f) a compound represented by Q1-NHNH-V6 wherein Q1 is a 5- to 7-membered unsaturated ring and V6 is a carbamoyl group, etc.

Owner:FUJIFILM CORP

Inkjet recording method and inkjet recording apparatus

InactiveUS6926399B2Increase pressure appliedSize of apparatus becomes largeDuplicating/marking methodsCoatingsEngineeringOrganic solvent

An inkjet recording method having the steps of: ejecting ink containing pigment, water and an organic solvent onto an image receiving medium, wherein the image receiving medium has a support member having a non-solvent-permeable resin layer, and an ink image receiving layer having a solvent absorbing layer containing inorganic fine particles and a binder, and a surface portion layer containing resin fine particles, an inorganic pigment and a binder; and conducting a heating and pressing treatment onto the image receiving medium. The heating and pressing treatment satisfies conditions of following expressions:(T−TG)xt>2(T−TM)xt<3wherein, T represents a surface temperature (° C.) of the heating and pressing treatment; TG represents a glass transition temperature of the resin fine particles (° C.); t represents a time (second) of the treatment; and TM represents a melting temperature (° C.) of the non-solvent-permeable resin layer.

Owner:KONICA CORP

Dither mask generation method and device

ActiveUS20160167376A1Increase graininessGood dispersionVisual presentationPrintingEngineeringThresholding

The dither mask generation method includes: a nozzle ejection rate determination process of determining a nozzle ejection rate of each nozzle in a recording head; a corresponding nozzle specifying process of specifying the nozzle corresponding to individual pixels of a dither mask by making at least one nozzle in charge of recording at each pixel position correspond to the individual pixels of the dither mask; a nozzle ejection rate reflecting processing process of performing processing of reflecting the nozzle ejection rate on an evaluation index when individual thresholds of the dither mask are set; and a threshold setting process of setting the thresholds to the individual pixels of the dither mask on the basis of the evaluation index.

Owner:FUJIFILM CORP

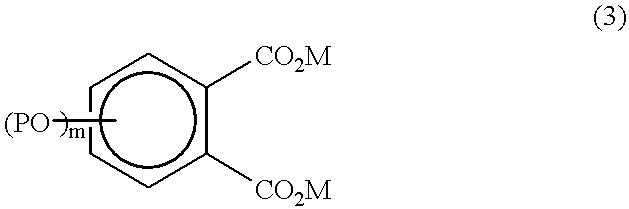

Silver halide color photosensitive material

InactiveUS20050214696A1Increase graininessSensitive highRadiation applicationsSilver halide emulsionsSilver halidePhotochemistry

A silver halide color photosensitive material comprising a support and, superimposed thereon, a blue-sensitive layer unit, a green-sensitive layer unit and a red-sensitive layer unit, each of these light-sensitive layer units composed of at least one silver halide emulsion layer, together with at least one nonphotosensitive layer, wherein at least one compound (A) and at least one compound (B) are contained, the compound (A) being a heterocyclic compound of less than 4.5 ClogP which when added, is capable of enhancing the sensitivity of the silver halide color photosensitive material as compared with that exhibited when not added, the compound (B) being a heterocyclic compound of 4.5 or greater ClogP which when added, is capable of enhancing the sensitivity of the silver halide color photosensitive material as compared with that exhibited when not added.

Owner:FUJIFILM HLDG CORP +1

Fish skin ham sausage preparation method using ictalurus punctatus skin

The present invention discloses a fish skin ham sausage preparation method using ictalurus punctatus skin and the preparation method which uses ictalurus punctatus skin and frozen hypophthalmichthys molitrix surimi as raw materials to prepare the fish skin ham. The preparation method is as follows: firstly thawing fish skin, dicing, marinating for the next step, and secondly thawing the frozen hypophthalmichthys molitrix surimi, adding accessory ingredients, chopping, and finally adding fish skin grains at a certain percentage, mixing evenly, vacuum pumping, and filling ham sausage, sterilizing, cooling and preparing finished products. The method maintains the original flavor of the fish meat sausage, at the same time improves taste and nutritional value enriches the variety of the ham sausage, and provides a new way for the use of ictalurus punctatus.

Owner:YIYANG YIHUA AQUATIC PRODS +1

Printing apparatus and printing method

InactiveUS7708363B2Increase graininessOther printing apparatusElectrical and Electronics engineeringColor tone

A printing apparatus includes a head and a drive signal generating section. The head has an element performing operation for ejecting ink and ejects a plurality of types of inks, an amount of each ink ejected by the head being different depending on a designated tone value. The drive signal generating section generates a drive signal having a waveform section for operating the element and generates a plurality of types of the drive signals for a specific tone value, the waveform section of each of the drive signals for the specific tone value being different depending on the types of inks.

Owner:SEIKO EPSON CORP

A water outlet device capable of forming a hollow water curtain

ActiveCN105983490BLarge bath areaIncrease graininessMovable spraying apparatusDomestic plumbingParticulatesWater flow

The invention discloses a water outlet device capable of forming a hollow water curtain, which comprises a hollow shell and a guide post inserted in the shell, an annular flow channel is formed between the shell and the guide post, the The casing is also provided with several arc-shaped water inlet grooves, which are arranged in a circular array around the annular flow channel. The inner ends of the arc-shaped water inlet grooves communicate with the annular flow channel, and the water flows along the arc. The water inlet groove flows into the annular channel to form a hollow annular water curtain with centrifugal force. When the tangential centrifugal force guided by the lower flow section of the water flow is greater than its surface tension, it will break open, so that the water flow will break apart into particles and disperse after maintaining a certain length of the water curtain. After dispersing, a certain range of continuous splashes will be formed. The bathing area is large, and the single granular water splash has a good grain feeling.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com