Jet pump

A jet pump, annular technology, applied in the direction of jet pump, pump, jet device, etc., can solve the problem of incompatibility, and achieve the effect of high suction rate, small weight and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

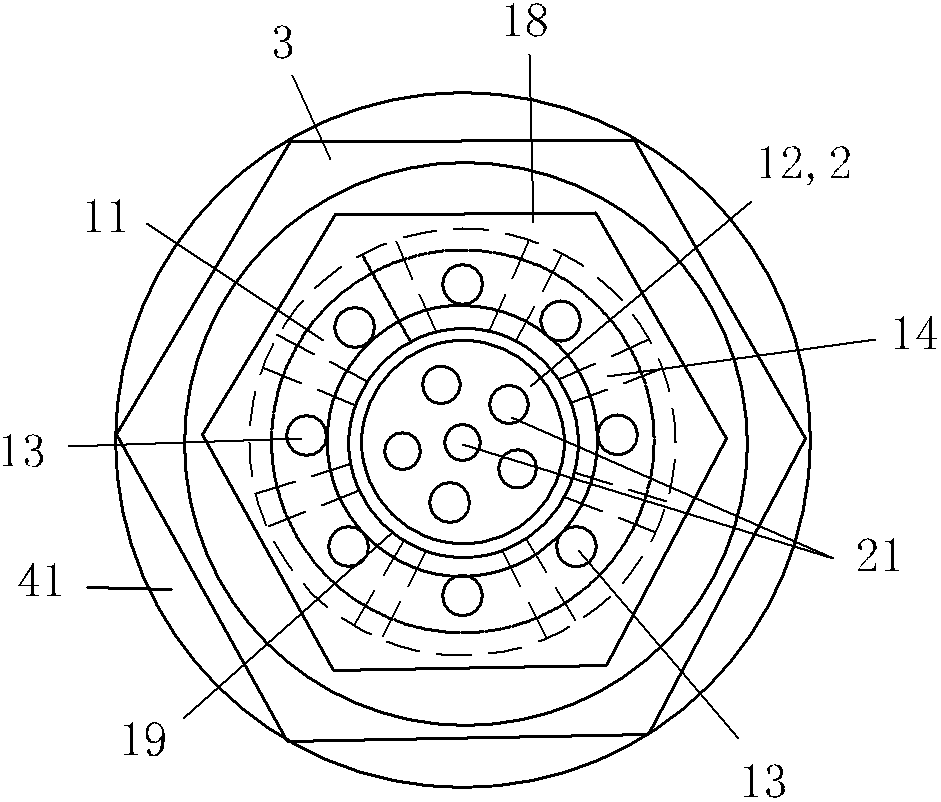

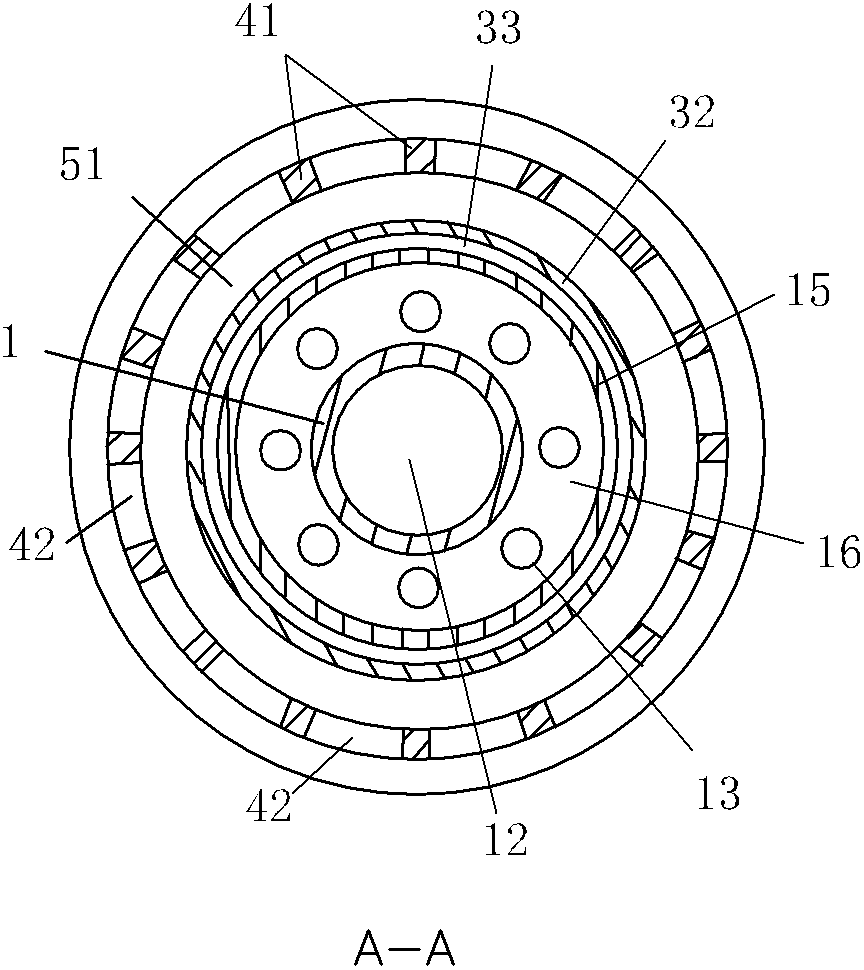

[0041] The structure of the first embodiment of jet pump of the present invention, as figure 1 shown. The jet pump consists of a central tube 1 , a central nozzle 2 , an intermediate sleeve 3 , an outer tube 4 and an outer tube extension 46 . figure 1 The upper part is the actual front, and the lower part is the actual rear.

[0042] The front end of the central pipe 1 is a pipe joint 19 with the smallest diameter, and the front part is an outer flange 18 with the largest diameter. The rear portion 15 of the outer flange 18 shrinks backward gradually and digs a groove 16 inward, and the rear portion 17 of the central pipe 1 continues to shrink gradually. Please see figure 2 A groove 11 is formed around the pipe joint 19 on the front end surface of the outer flange 18, and a plurality of longitudinal through holes 13 are evenly distributed, and these longitudinal through holes 13 run through the front and rear end faces of the outer flange 18 to reach the front of the groov...

Embodiment 2

[0054] The structure of the second embodiment of jet pump of the present invention, as Figure 4 shown. The jet pump consists of a central tube 10 , a central nozzle 20 , a middle sleeve 30 , an outer tube front sleeve 340 , and an outer tube main part 40 . Figure 4 The upper part is the actual front, and the lower part is the actual rear.

[0055] The front end of the center pipe 10 is a pipe joint 190 with the largest diameter, and the front and middle parts are outer flanges 110 with a medium diameter. A hexagonal cap 180 protruding outward is provided between the outer flange 110 and the pipe joint 190 . The front part of the outer flange 110 is provided with external threads. The rear portion 170 of the base pipe 10 is the smallest diameter straight pipe section. The inner hole 120 of the central pipe 10 is a stepped straight circular hole with a large front and a small rear, and penetrates from the front end surface of the pipe joint 190 to the rear end surface of t...

Embodiment 3

[0069] The structure of the third embodiment of the jet pump of the present invention, as Figure 9 shown. Figure 9 The upper part is the actual front, and the lower part is the actual rear. In the jet pump: the central tube is divided into a central tube front section 100 and a central tube rear section 200; the structure of the middle sleeve 300 is the same as that of the middle sleeve 3 in the first embodiment; the outer tube main body 400 and the outer tube extension 4600 The composed outer tube is provided with a large-diameter pipe section 4200, a first constricted cone pipe section 4300, a front transition pipe section 4400, an intermediate tapered pipe section 4500, a rear transition pipe section 46100, and a second tapered pipe section 46200 along the central axis from front to back. The rear straight pipe section 46300; the central nozzle 700 can adopt the structure of the central nozzle 2 or the central nozzle 20 in the above two embodiments.

[0070] The front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com