Fluid-handling apparatus with corrosion-erosion coating and method of making same

a technology of corrosive corrosion and coating, which is applied in the direction of coatings, lighting and heating apparatus, corrosion prevention, etc., can solve the problems of affecting the performance of the cooling devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example coating 2

[0024] Example coating 2 includes a copper-nickel alloy that includes approximately 70% copper and approximately 30% nickel. Those skilled in the art will appreciate that example coating 2 is a commercially available alloy, specifically alloy 71600, often referred to as 70-30% copper-nickel. Similar to example coating 1, in addition to the copper and nickel, example coating 2 includes other alloying metals, including iron and manganese. Example coating 2 is harder than the corrosion-erosion prone surfaces 43a upon which the coating 40 is applied. Example coating 3 includes a 60% copper—40% nickel alloy. Example coating 3 is not a standard copper alloy, but rather a powder commercially available for physical disposition spray applications. Although coating 3 could include other minor alloying metals like those used in example 1 and example 2, coating 3 is illustrated as including 60% copper and 40% nickel. Although the coatings in examples 2 and 3 will protect the corrosion-erosion p...

example coating 4

[0025] Example coating 4 includes a 85-15% copper nickel alloy. Similar to example coatings 1-3, example coating 4 includes copper to transfer the heat between the air and the sea water, and nickel to resist impingement, thereby, providing corrosion and erosion resistance. Moreover, example coating 4 includes minor alloying metals and is commercially available as alloy 72200.

example coating 5

[0026] Example coating 5 includes an aluminum-bronze alloy that includes 14% or less aluminum, 2% or less manganese, 6% or less nickel, and 5% or less iron. The remaining concentration would include copper and / or other minor alloying elements. Those skilled in the art will appreciate that the example coating 5 could includes standard aluminum-bronze alloys commercially available could be used. Example coating 5 is a commercially available aluminum bronze alloy, being alloy 63000. The aluminum aids in corrosion resistance while the iron and nickel aids in impingement resistance. As with the other coatings 40a-c, example coating 5 preferably includes manganese and iron.

INDUSTRIAL APPLICABILITY

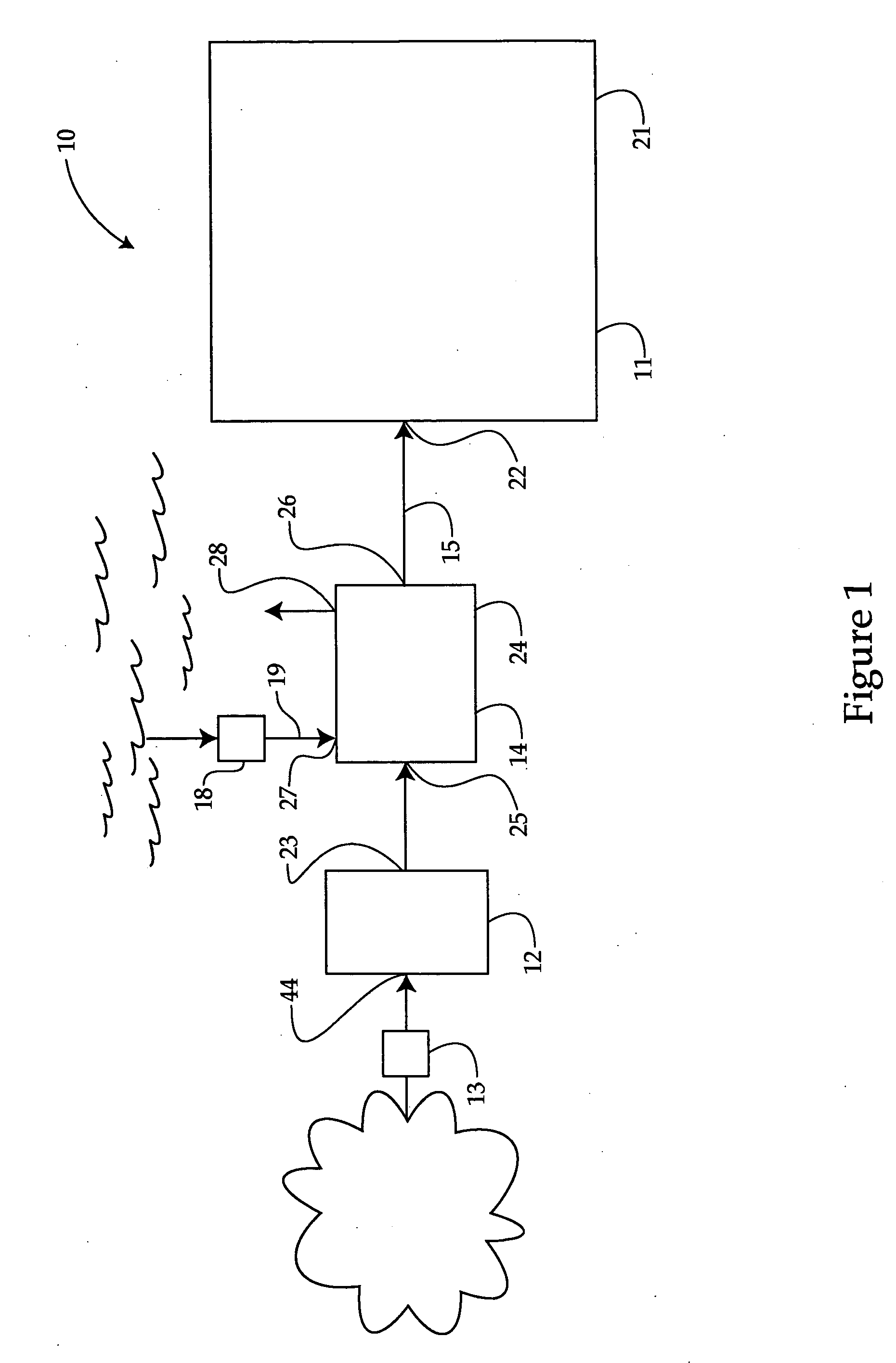

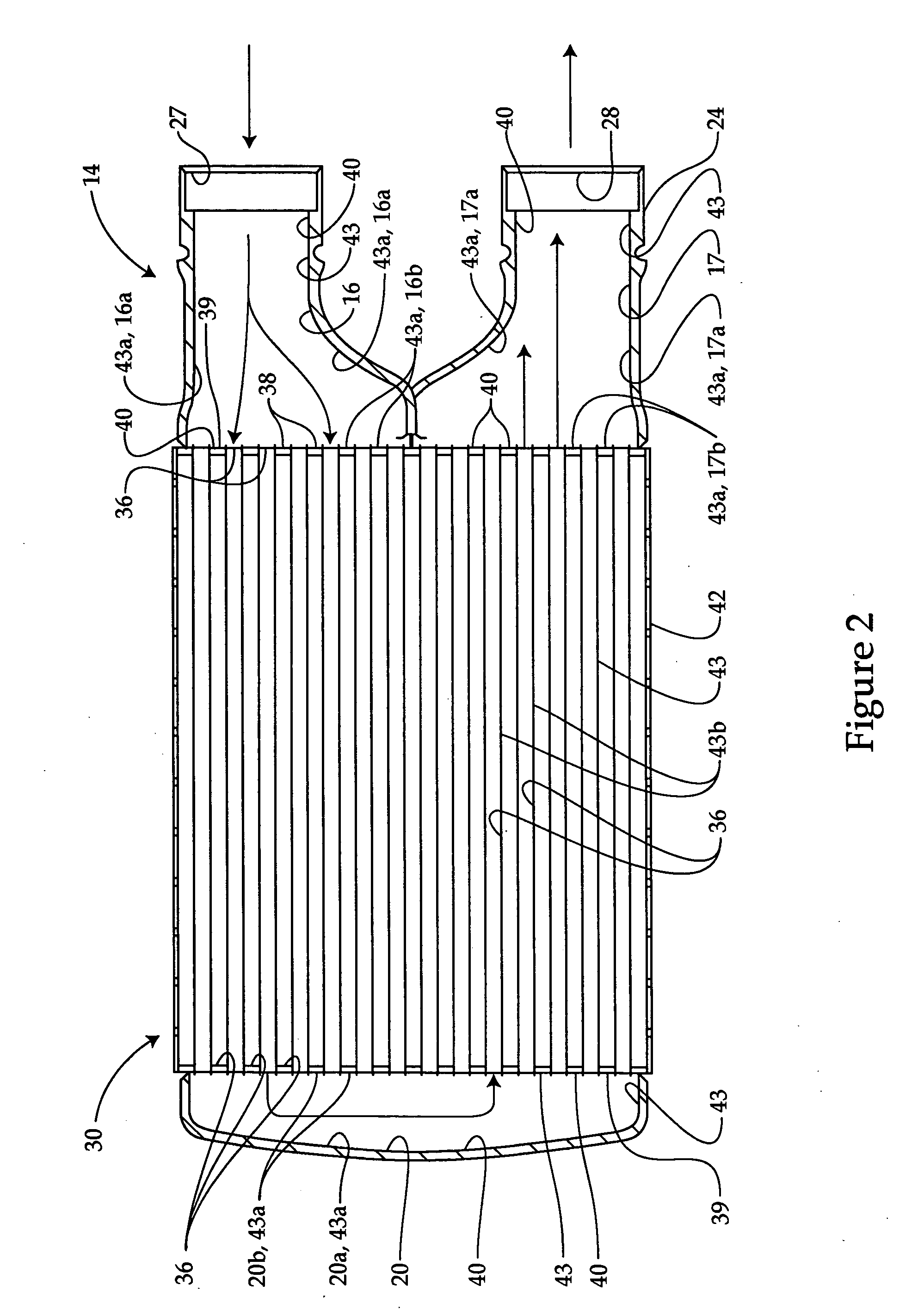

[0027] Referring to FIGS. 1-3, a method of making the heat exchanger 14 will be discussed. Although the heat exchanger 14 is part of the engine system 10 with marine application and is a “bar and plate” type heat exchanger, those skilled in the art should appreciate that the method of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com