Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Biocoating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-Independent, Surface-Modifying, Multifunctional Coatings and Applications Thereof

ActiveUS20080149566A1Prevent buildupOrganic chemistryWater contaminantsSubstrate surfaceSurface modified

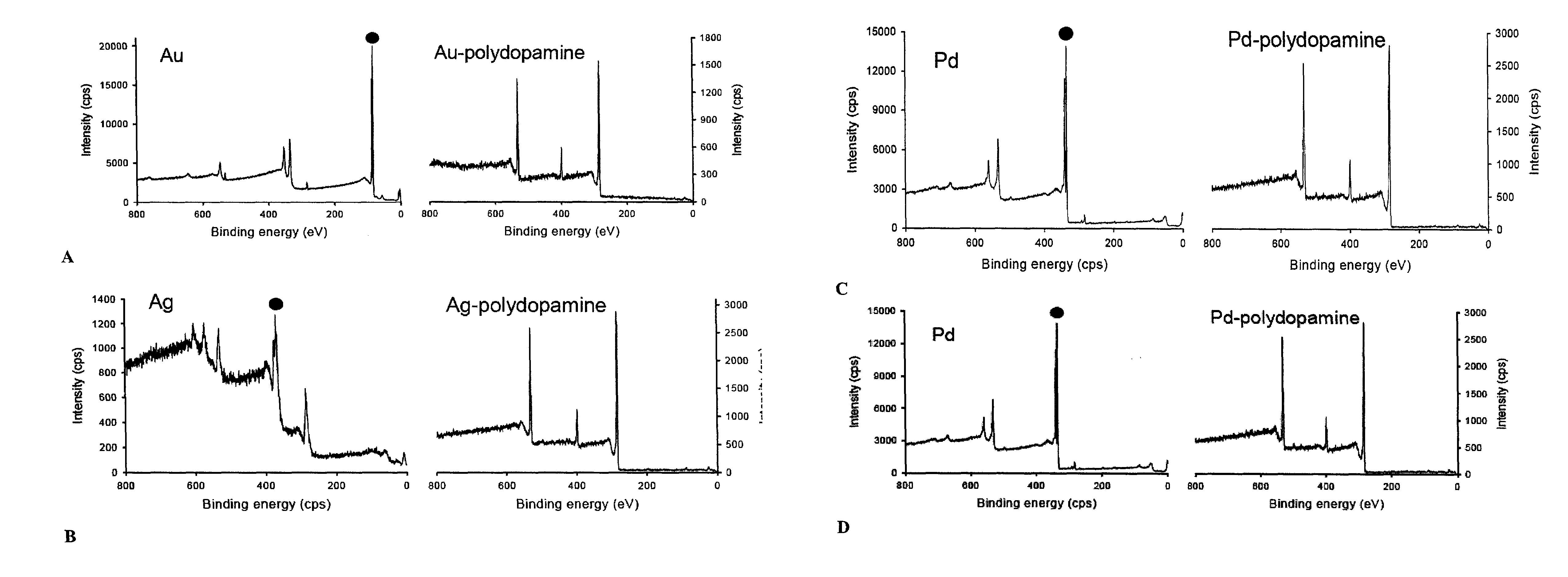

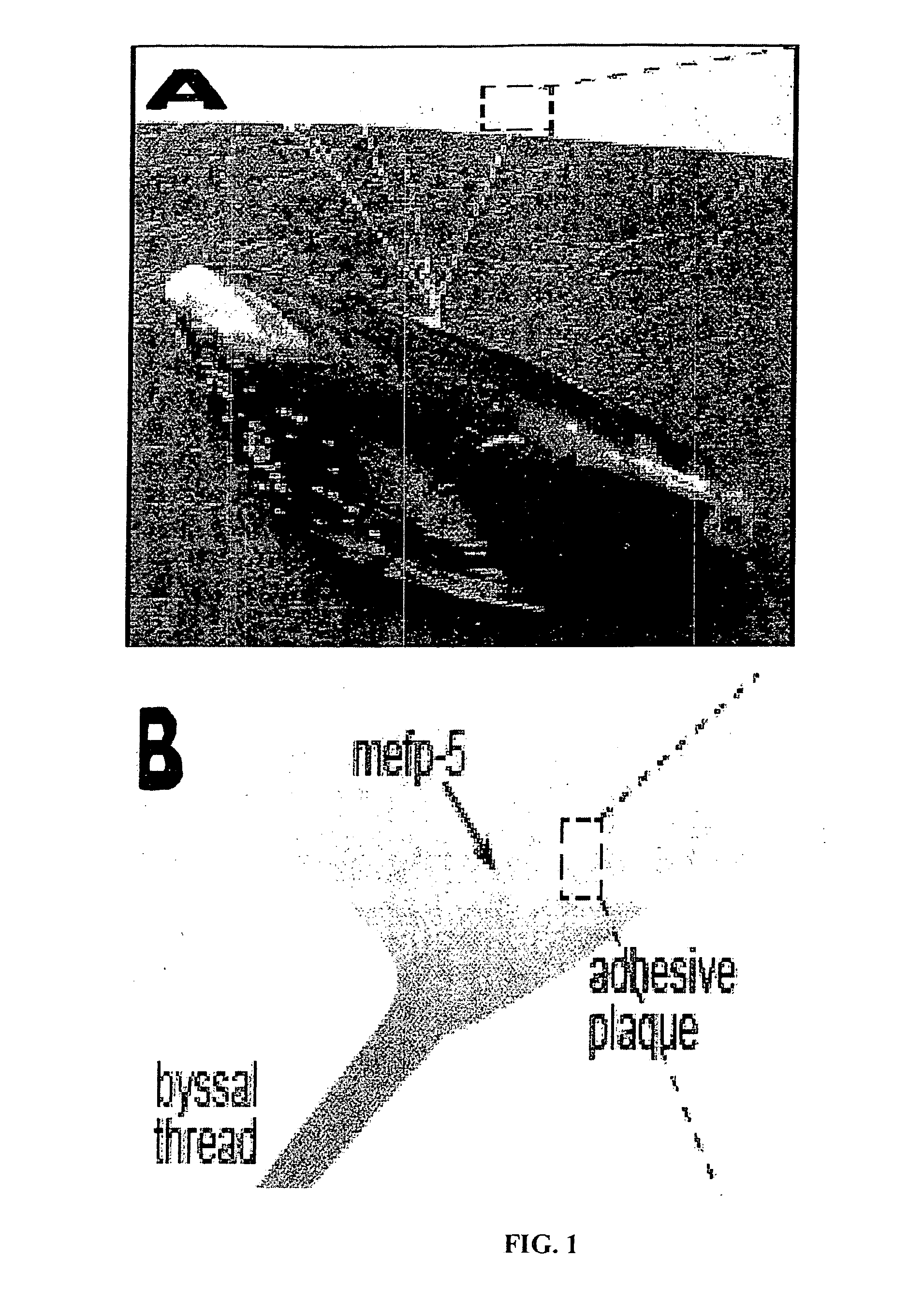

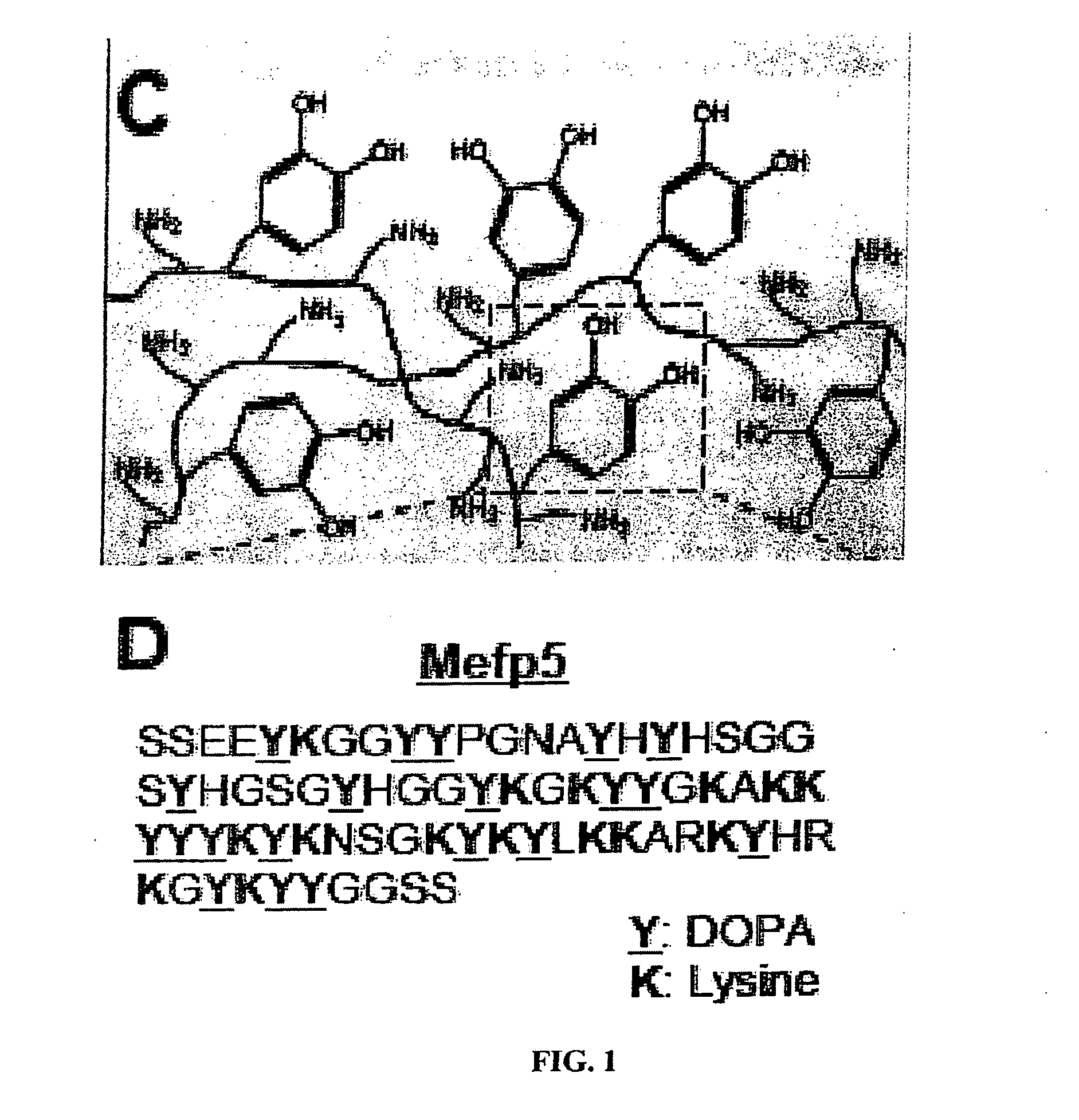

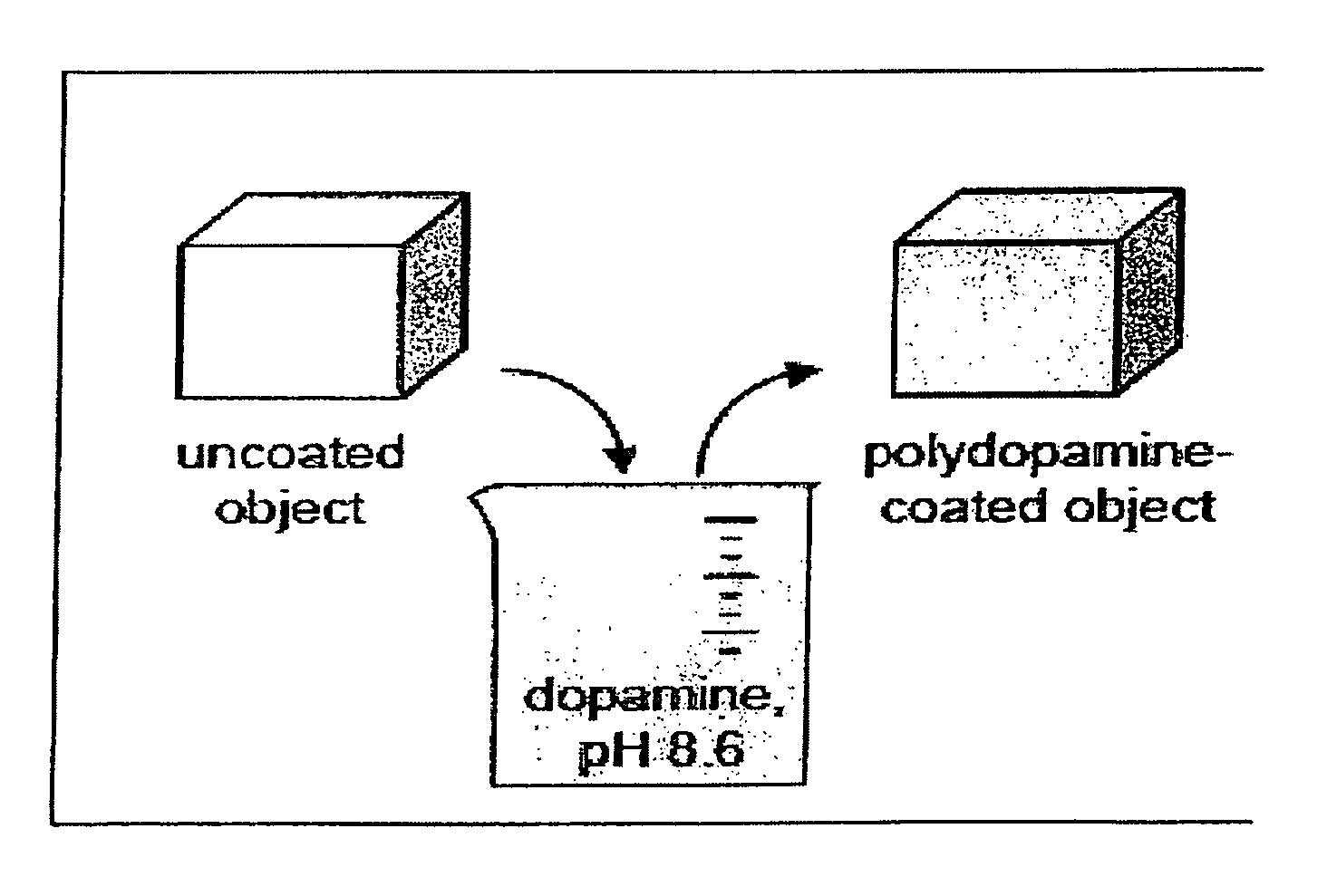

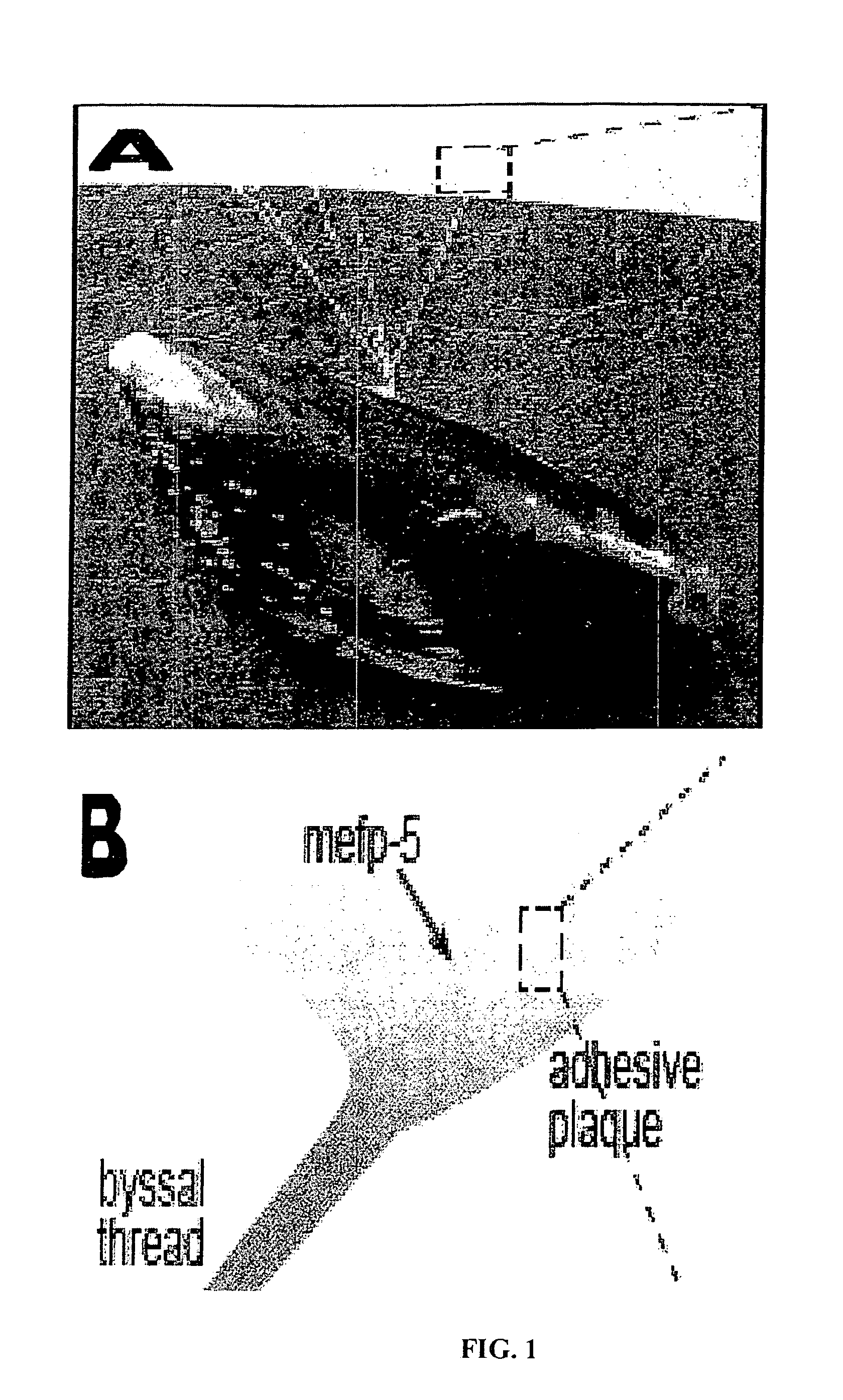

The present invention provides a surface-independent surface-modifying multifunctional biocoating and methods of application thereof. The method comprises contacting at least a portion of a substrate with an alkaline solution comprising a surface-modifying agent (SMA) such as dopamine so as to modify the substrate surface to include at least one reactive moiety. In another version of the invention, a secondary reactive moiety is applied to the SMA-treated substrate to yield a surface-modified substrate having a specific functionality.

Owner:NORTHWESTERN UNIV

Surface-independent, surface-modifying, multifunctional coatings and application thereof

The present invention provides a surface-independent surface-modifying multifunctional biocoating and methods of application thereof. The method comprises contacting at least a portion of a substrate with an alkaline solution comprising a surface-modifying agent (SMA) such as dopamine so as to modify the substrate surface to include at least one reactive moiety. In another version of the invention, a secondary reactive moiety is applied to the SMA-treated substrate to yield a surface-modified substrate having a specific functionality.

Owner:NORTHWESTERN UNIV

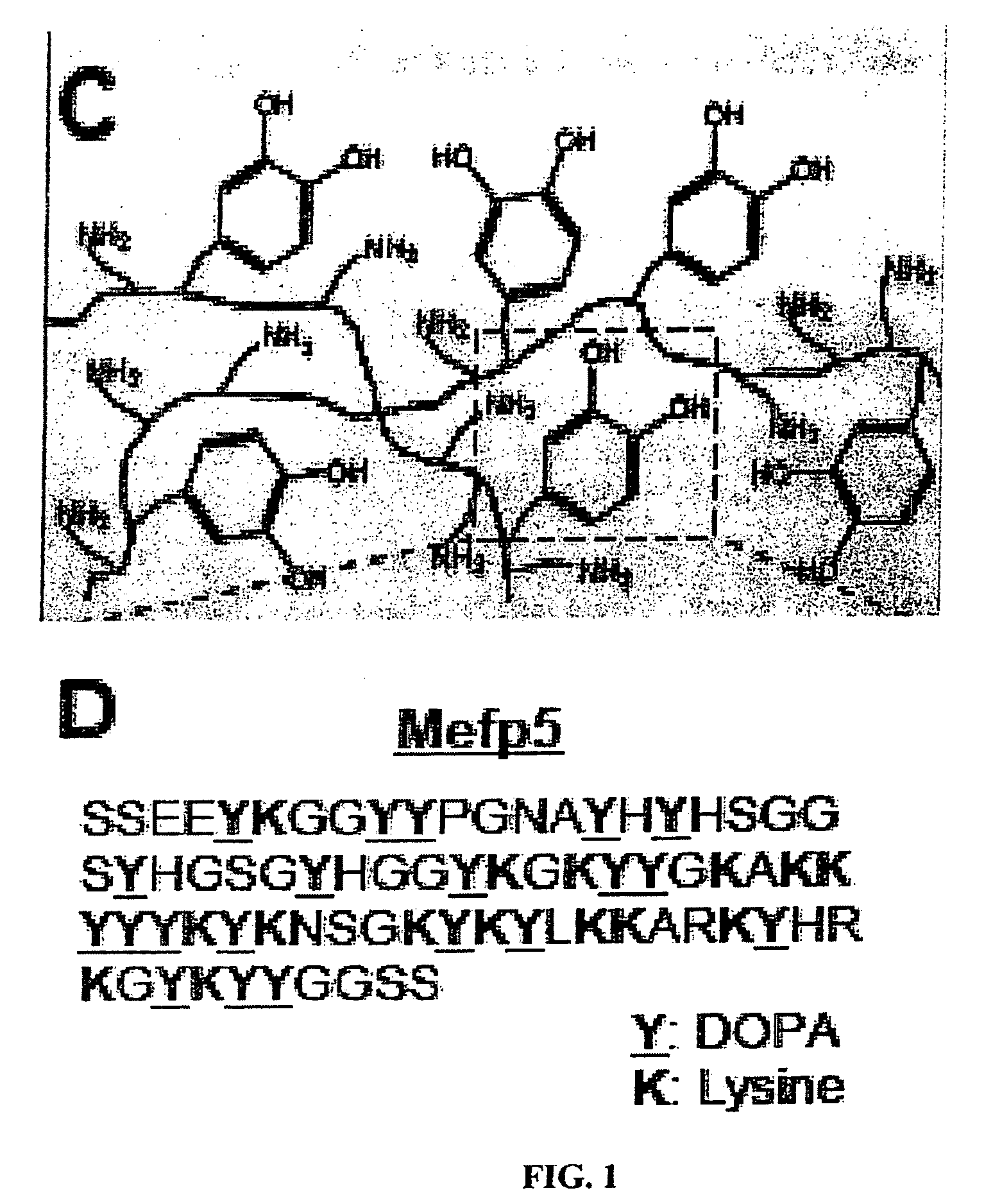

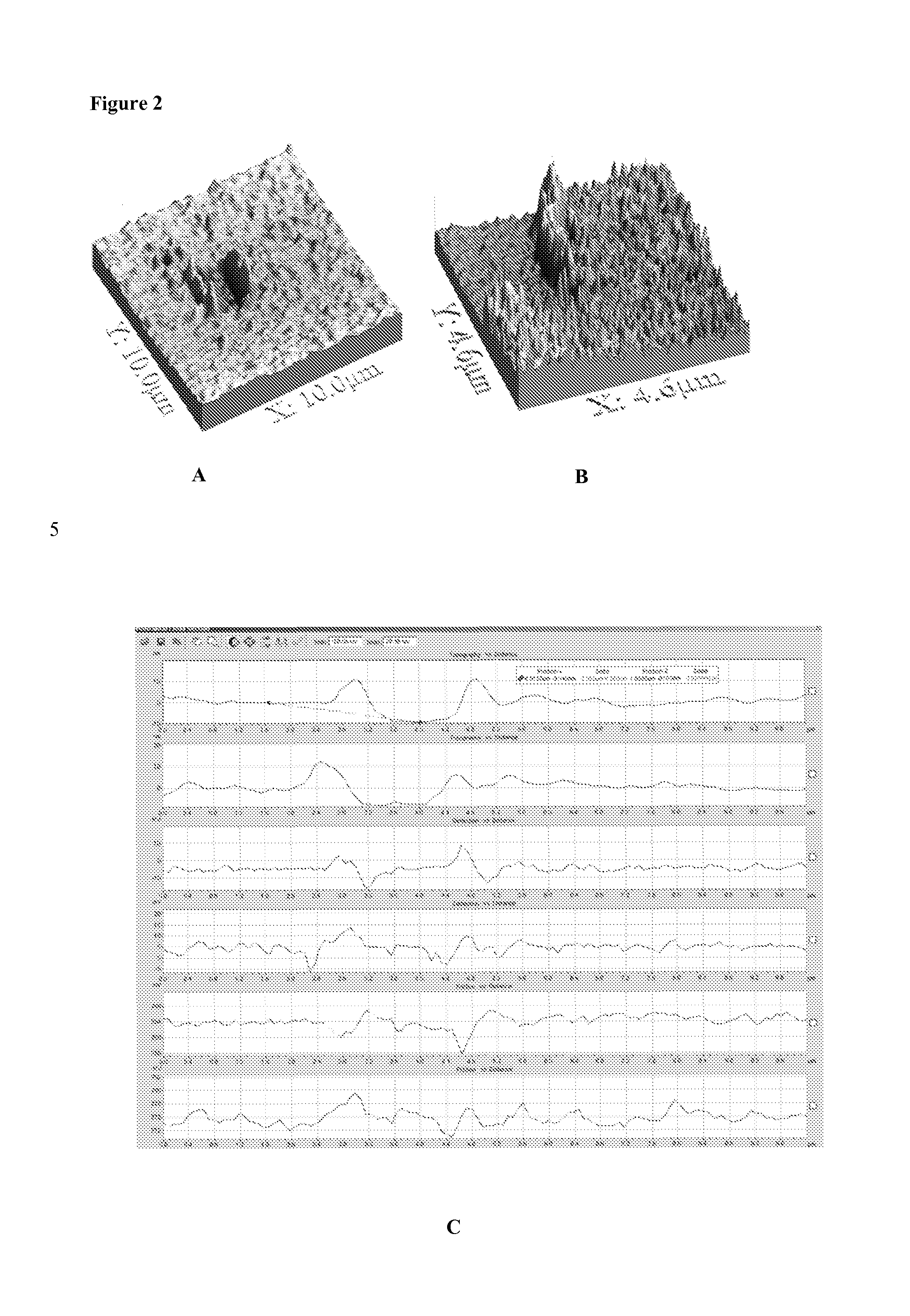

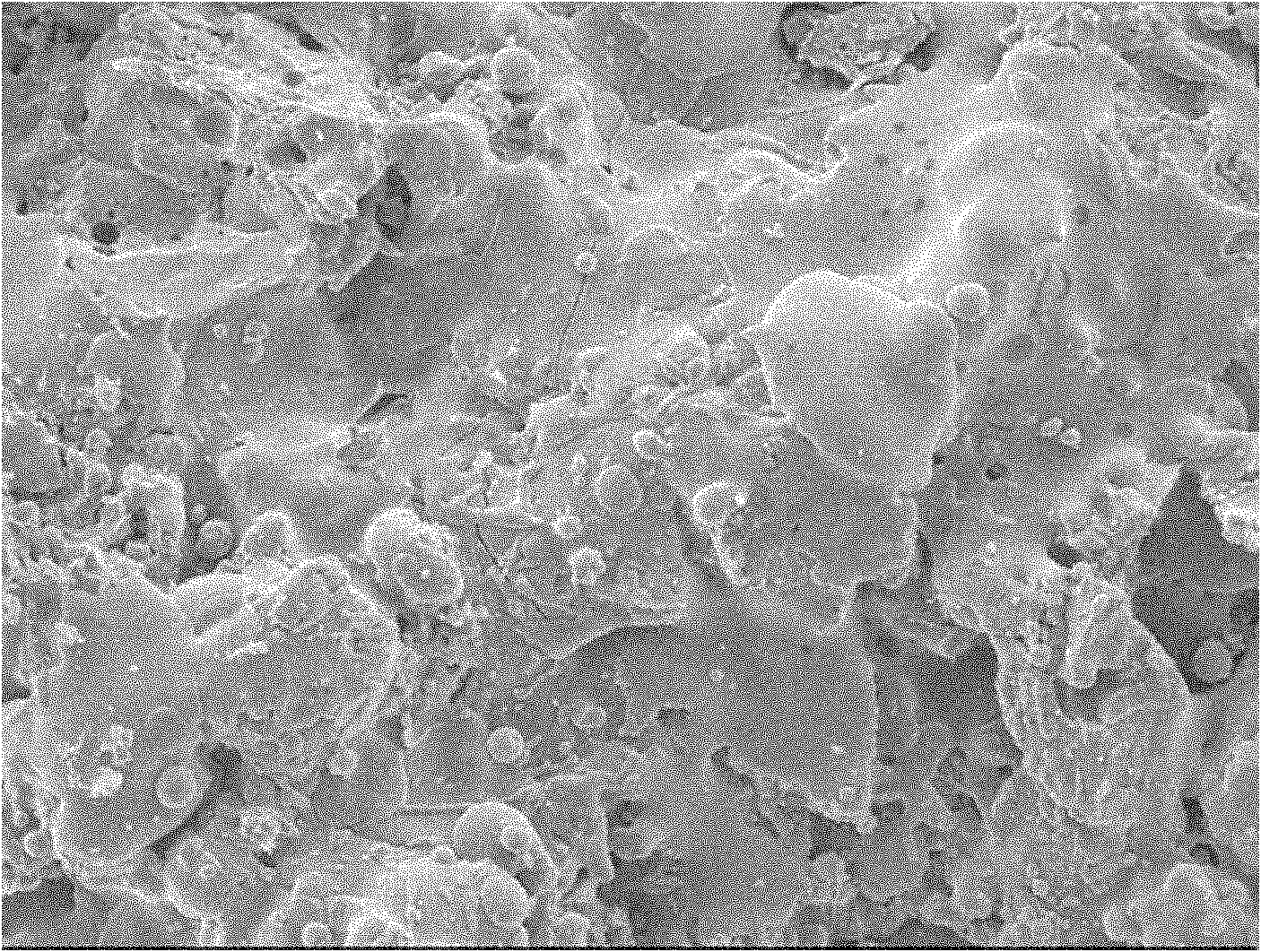

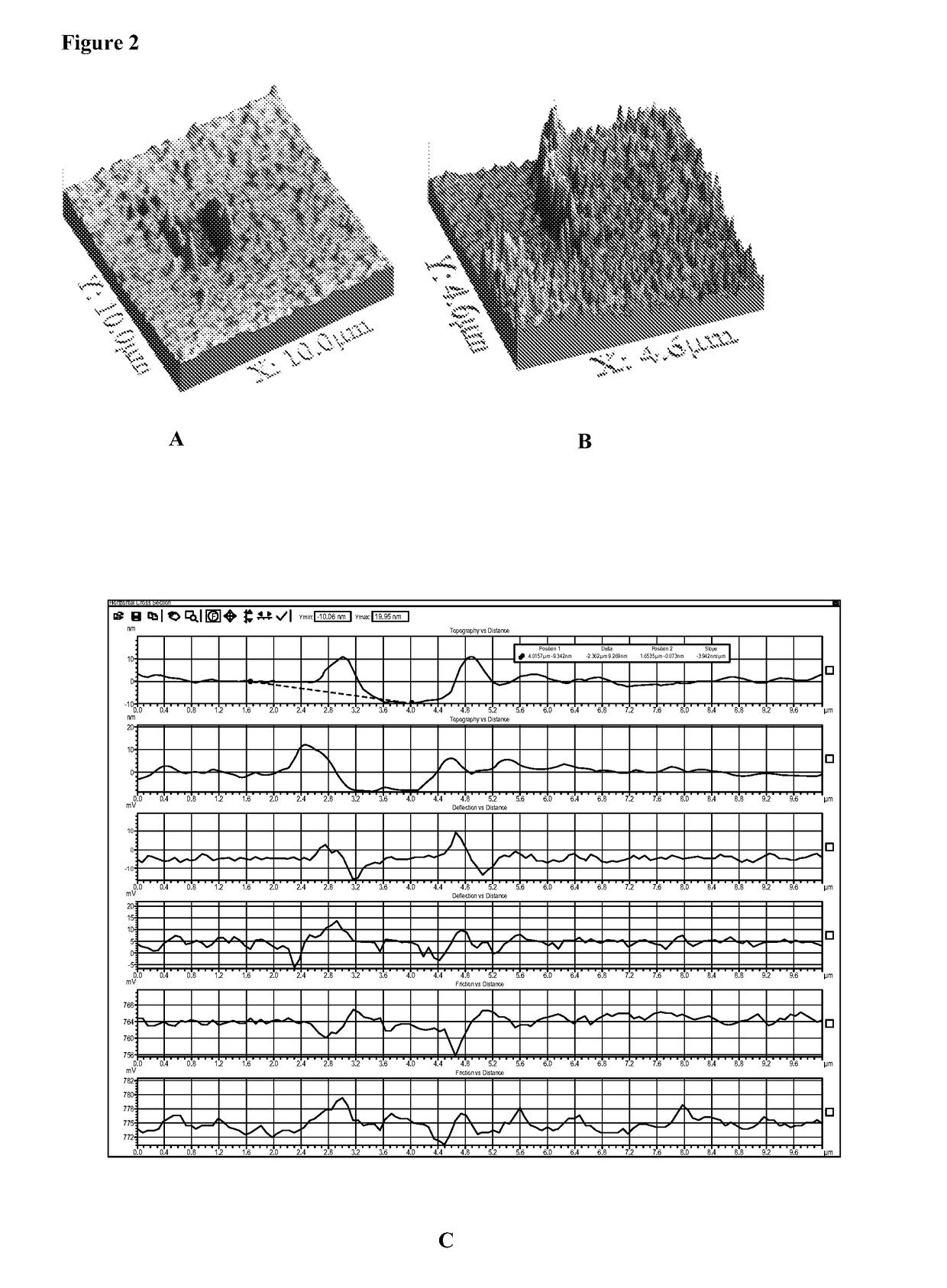

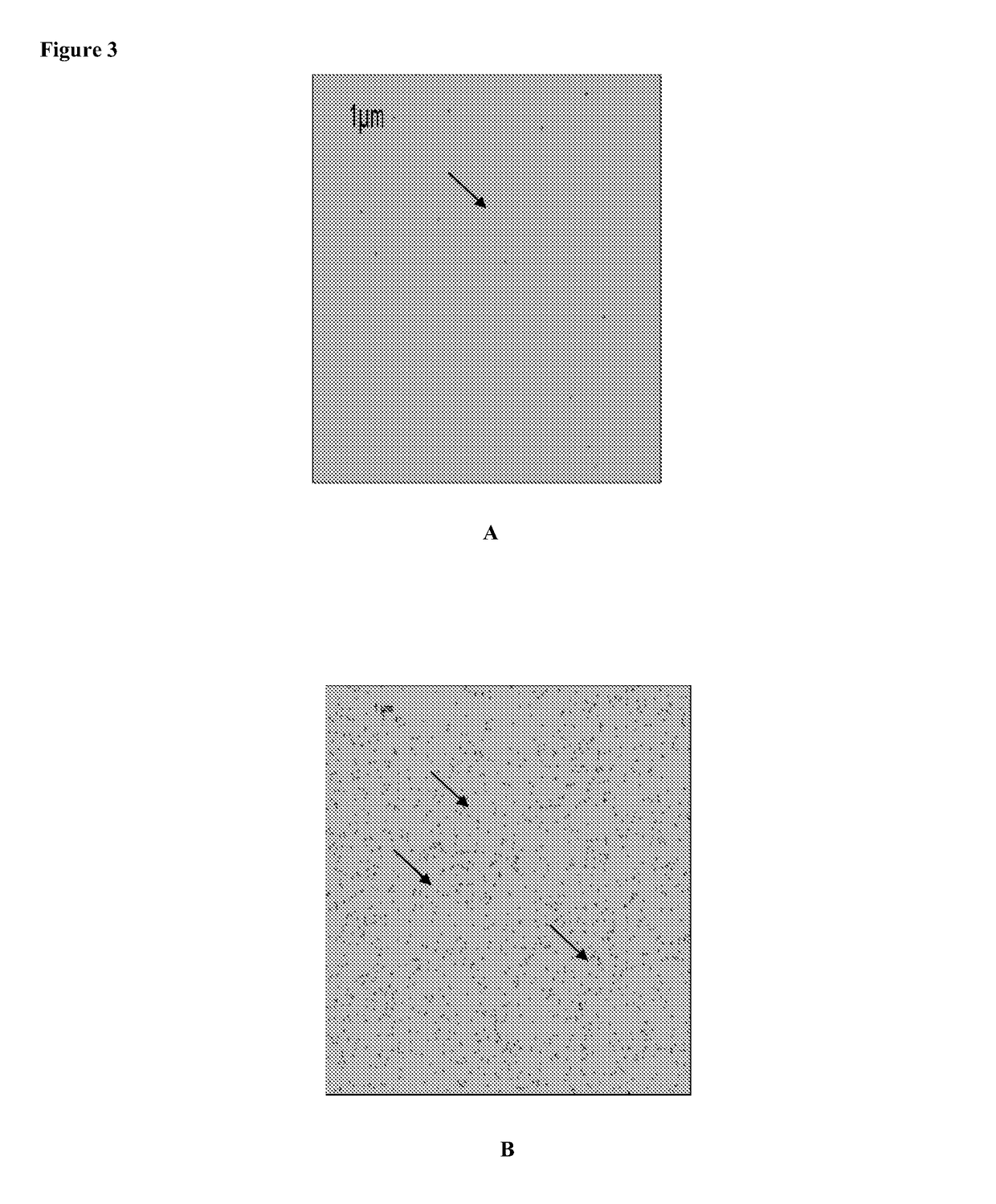

Biocoated piezoelectric biosensor platform for point-of-care diagnostic use

ActiveUS20150111765A1Rapid diagnosisSimple manufacturing processBioreactor/fermenter combinationsAnalysing fluids using sonic/ultrasonic/infrasonic wavesPoint of careChemical adsorption

Biosensor components (chips) are described based on direct biocoating processes that result in the tenacious and stable, noncovalent (believed to be chemisorptive) binding of anchor substances such as avidin(s) other proteins having specific binding partners or oligo- or poly-nucleotides onto any piezo-electrically active crystal surface. The resulting platform technology can be developed for a variety of biosensors with specific applications in biological assays. The table mono layers of the anchor substances forms reactive layers, ready to bind a capture reagent such as a biot-inylated antibody for capture and detection of analytes in biologic fluid samples. Although the processes described herein can be performed on any type of piezoelectric material in any number of configurations, some embodiments are directed to a biosensor with the foregoing biocoating onto a particular acoustic plate mode biosensor and where the interdigitated transducers (IDTs) are present on the opposite side of the crystal's biocoated film.

Owner:AVIANA MOLECULAR TECH

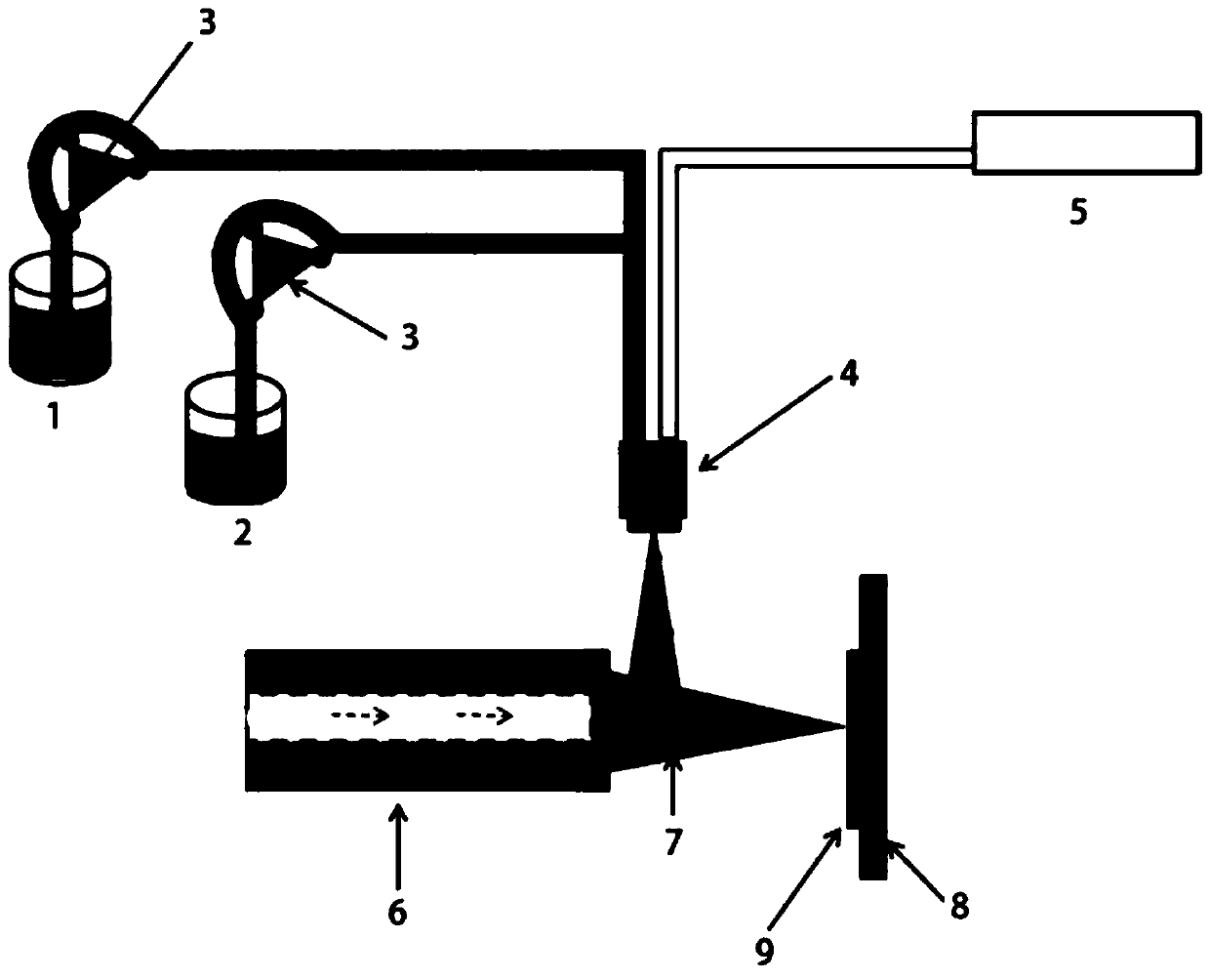

Nano hydroxyapatite coating and preparation method thereof and electrostatic atomization device

InactiveCN101703798AImprove mechanical propertiesImprove biological activityLiquid spraying plantsCoatingsApatiteNano hydroxyapatite

The invention provides a nano hydroxyapatite coating and a preparation method thereof and an electrostatic atomization device, belonging to the technical field of medical biological coating. The coating has the following components in weight percent: 10-30% of silk fibroin and 70-90% of nano hydroxyapatite. The preparation method is as follows: firstly carrying out degumming process and dissolving process to obtain the silk dissolving liquid; preparing into the suspending liquid of silk fibroin-nano hydroxyapatite composite precipitate; washing to neutrality by deionized water to prepare intoprecursor solution; and adopting the electrostatic atomization sedimentation method to lead the precursor solution to be coated on the substrate in atomizing form to prepare into nano hydroxyapatite composite material biological coating. The invention can prepare the silk fibroin / nano hydroxyapatite coating with compact accumulation and no cracks, and the shape thereof can be controlled.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Anti-degradation antibacterial biological coating, and preparation method and application thereof

InactiveCN101972490AImprove biological activityGood biocompatibilityMolten spray coatingProsthesisBiocompatibility TestingTitanium

The invention discloses an anti-degradation antibacterial biological coating, which is formed by spraying hardystonite powder on the surface of a pure titanium or titanium alloy matrix. By using a plasma spraying process, the coating is prepared by spraying the hardystonite powder on the surface of the processed pure titanium or titanium alloy matrix. The biological coating provided by the invention has superior bioactivity and biocompatibility, anti-degradation performance and antibacterial performance, solves the problems in the prior art and promotes the repairing of hard tissues and development of the substitutional material field; and the preparation method of the invention has the advantages of high efficiency, high repeatability, suitability for scale production and the like and is easy to operate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

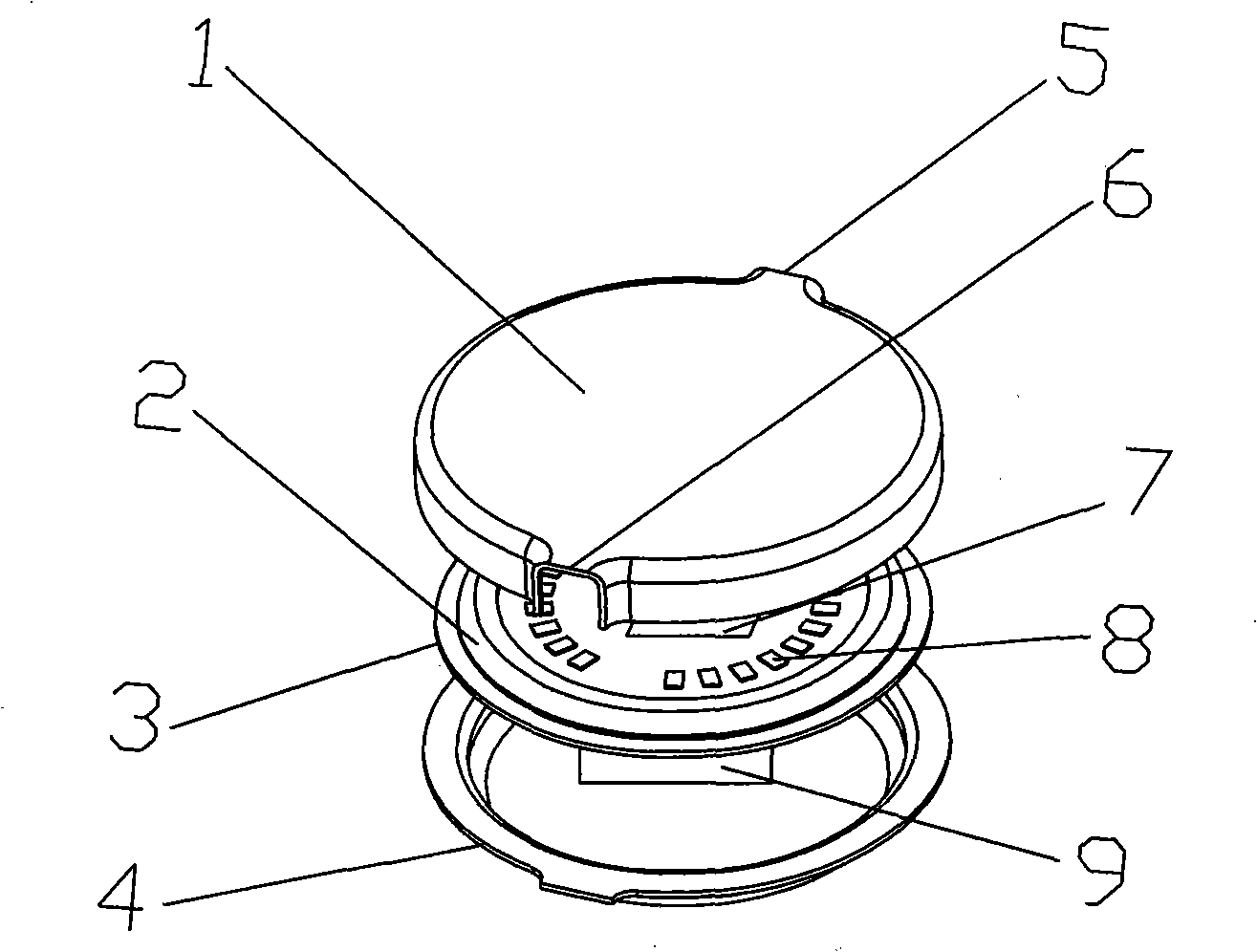

Sealing structure of artificial cochlea implant and sealing process thereof

InactiveCN101297781AImprove reliabilityImprove securityElectrotherapyEar treatmentArtificial cochlea implantBiochemical engineering

The invention discloses a sealing structure of an artificial cochlear implant and a packaging technology thereof, the sealing structure comprises: a circuit and a chip, which is characterized in that the circuit is arranged on a circular thin-sheet base plate, a welding ring and a contact point which is electrically connected with the circuit are arranged on the base plate, a connecting ring is annular and fixedly connected with the base plate; the chip is welded on the circuit; an upper end cover and a lower end cover are arranged outside the base plate, the upper end cover, the lower end cover and the welding ring are fixedly connected to form a sealing outer shell; the packaging technology specifically comprises that: the circuit, the welding ring and the base plate are sintered to a whole body by ceramics; the welding chip uses a biological coating layer to carry out the first packaging; the upper end cover and the lower end cover are produced to carry out the second packaging of the implant; and a biological silicon rubber is used for carrying out the third packaging of the upper end cover and the lower end cover. The sealing structure has simple structure, compared with the prior art, the reliability and the safety of the implant can be greatly improved, which can have great strength and toughness, prevent the collision and the seepage and ensure long-term normal work of the implant circuit in the human body.

Owner:SHANGHAI LISTENT MEDICAL TECH CO LTD

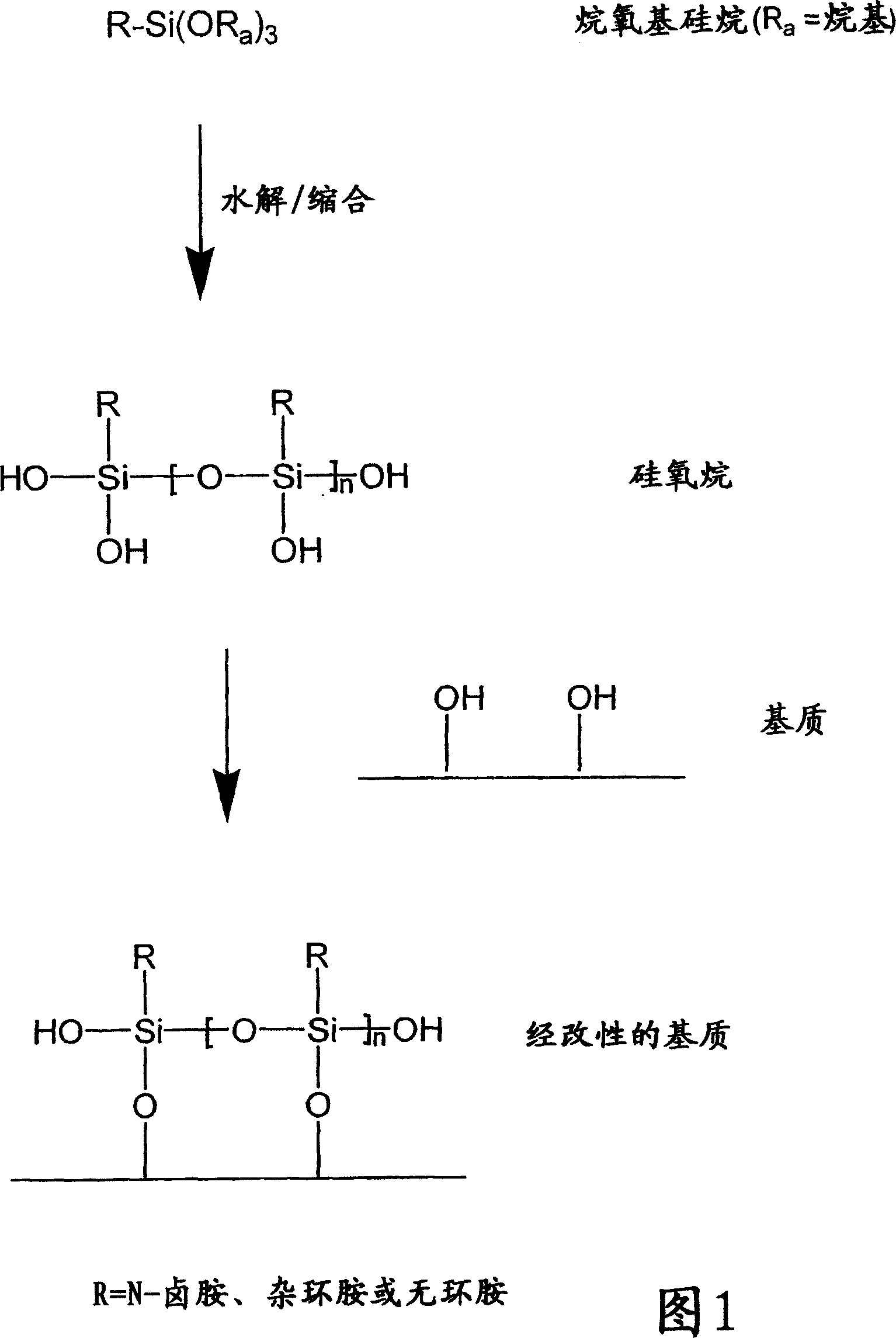

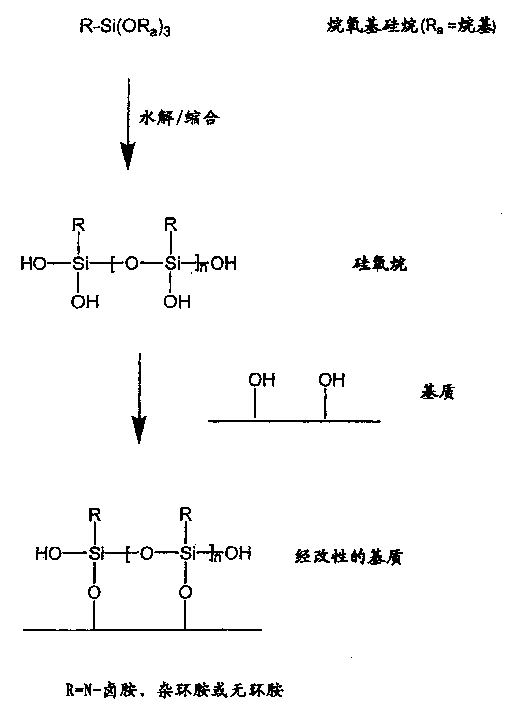

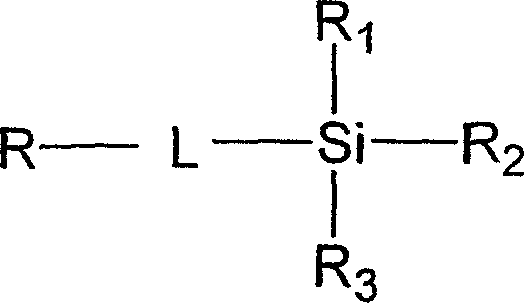

N-halamine siloxanes for use in biocidal coatings and materials

InactiveCN1675227AGroup 4/14 element organic compoundsThin material handlingCellulosePolymer science

Owner:AUBURN UNIV +1

Medical nano bio-coating and preparation process thereof

InactiveCN106540319AGood biocompatibilityHigh bonding strengthTissue regenerationCoatingsApatiteOsteoblast

The invention discloses a medical nano bio-coating and a preparation process thereof. The bio-coating is prepared through the following raw materials of nano-hydroxyapatite, tetracalcium phosphate, graphene quantum dots, strontium monophosphate, dopamine, calcium fluoride, magnesium fluoride, barium ditantalum hexaoxide, silver nitrate, gelatin, ammonium bicarbonate, polyethylene glycol, silk fibroin and phosphohumate. The bonding strength between the bio-coating provided by the invention and a substrate is high; meanwhile, the tenacity is improved, and the deficiency of large brittleness of traditional hydroxyapatite is overcome; and in addition, the bio-coating has good biocompatibility, capable of promoting adherency and growth of bone cells, increasing the repairing and healing rate and shortening the healing period, and good in application and popularization value.

Owner:SUZHOU AIBOMAIER NEW MATERIAL CO LTD

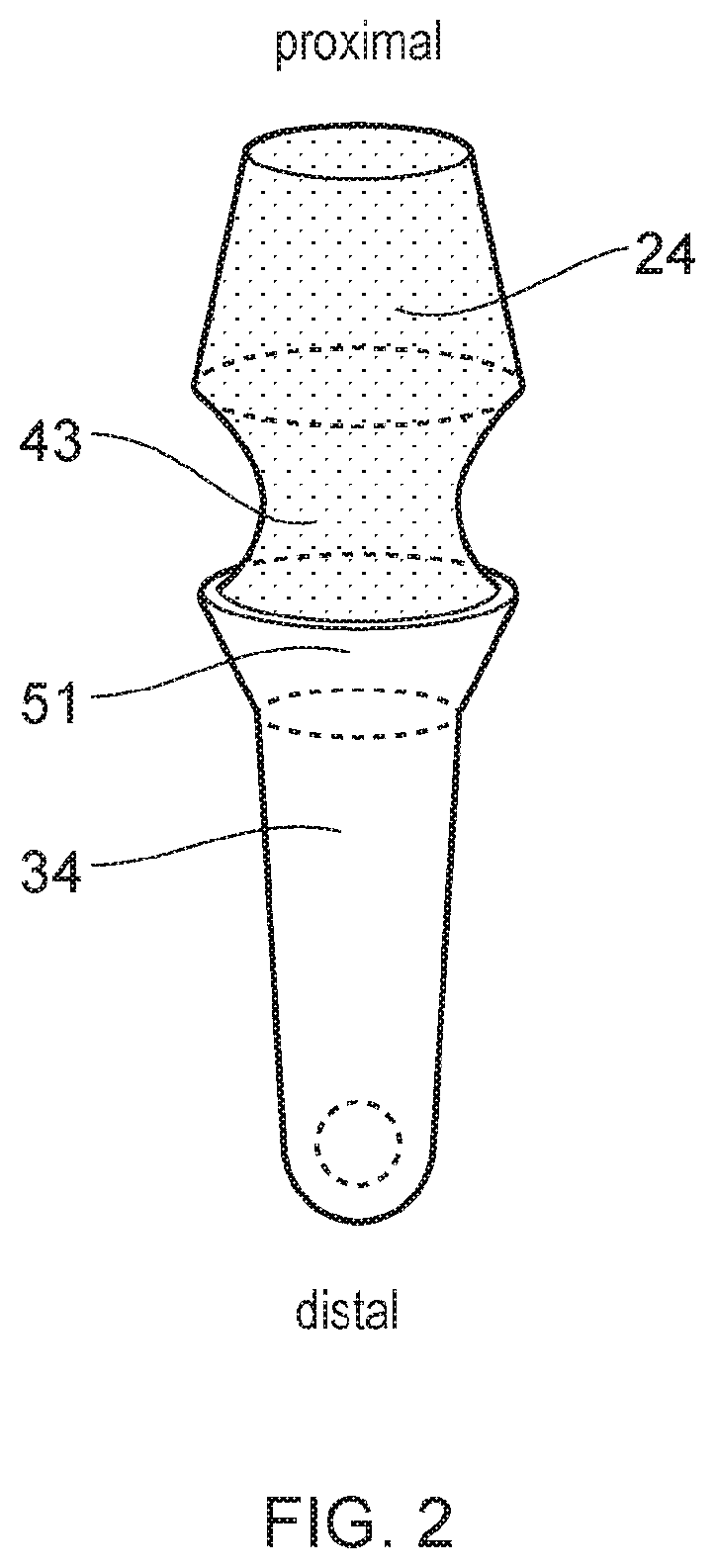

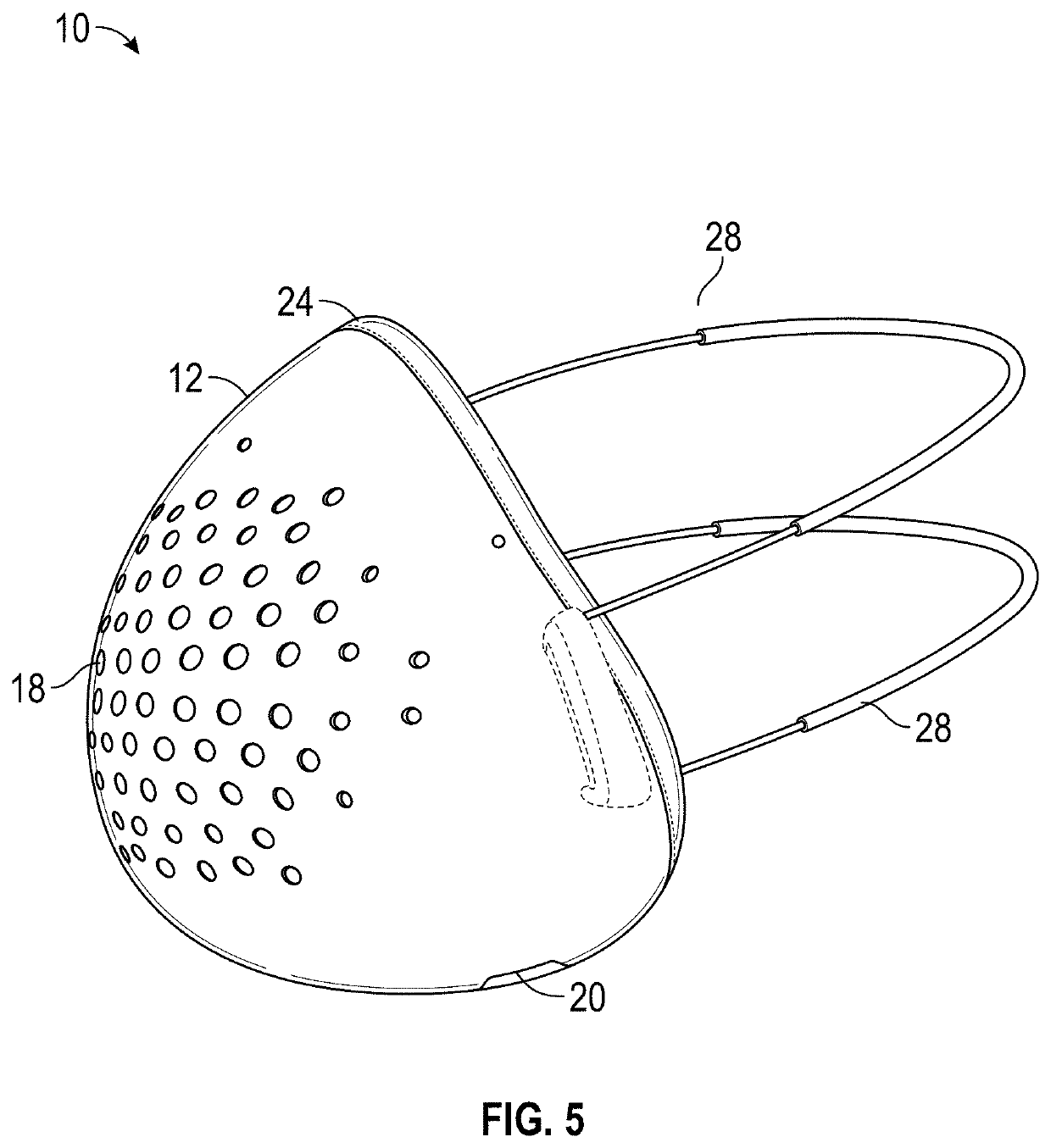

Implant

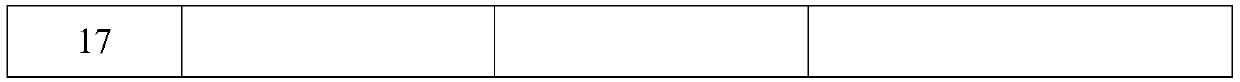

ActiveUS20200030065A1Improve long-term stabilityPromote osseointegrationDental implantsImpression capsRough surfaceAnatomy

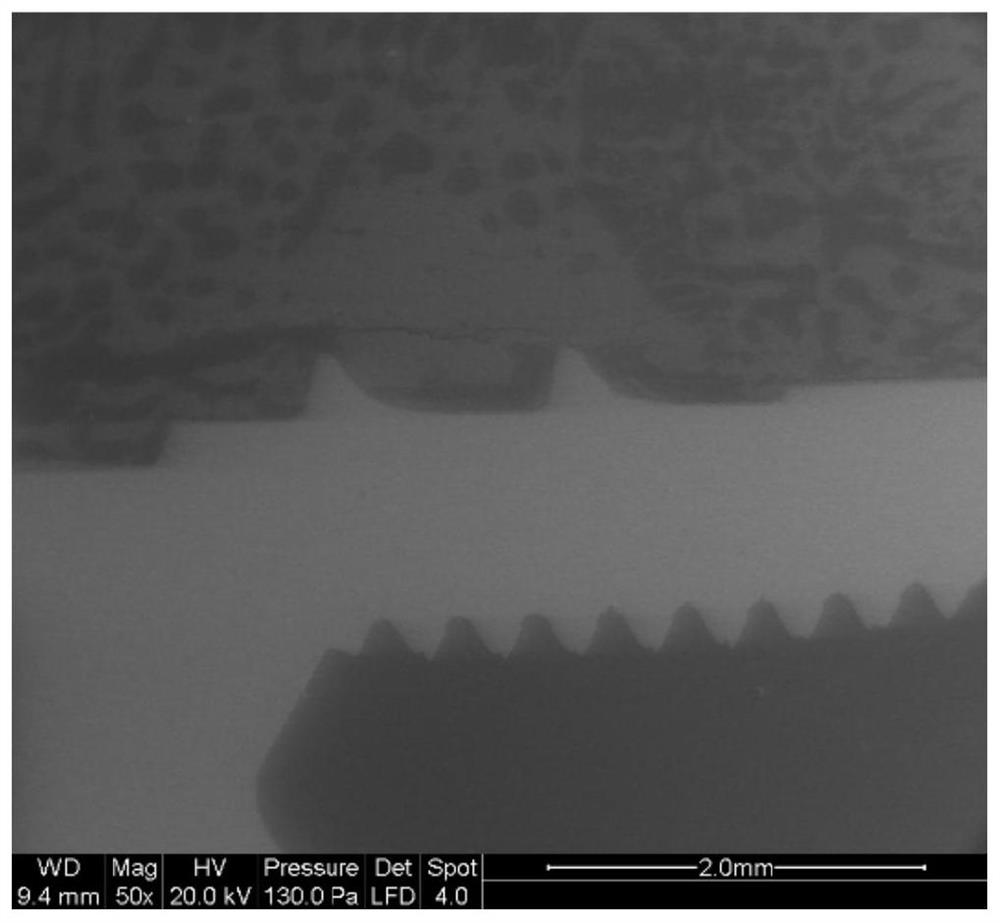

There is described an implant comprising: (a) a bone engaging portion positioned at the distal end of the implant, said bone engaging portion comprising: a longitudinally extending distal portion; and an adjoining region positioned at the proximal end of the longitudinally extending distal portion; (b) a transmucosal portion positioned at the proximal end of the adjoining region; and (c) an abutment portion positioned at the proximal end of the transmucosal portion, wherein the exterior surface of the longitudinally extending distal portion comprises a conformal microscale cell structure and optionally, a non-biological coating; wherein the exterior surface of the abutment portion is polished, suitably, to a mirrored or super mirrored finish and / or wherein the exterior surface of the abutment portion has an Ra of between about 1 and about 3 um; wherein the exterior surface of the adjoining region comprises a roughened surface, suitably with an Ra of between about 5 and about 30 um; and wherein the exterior surface of the transmucosal portion comprises a plurality of micro holes.

Owner:CUDETI SAGL

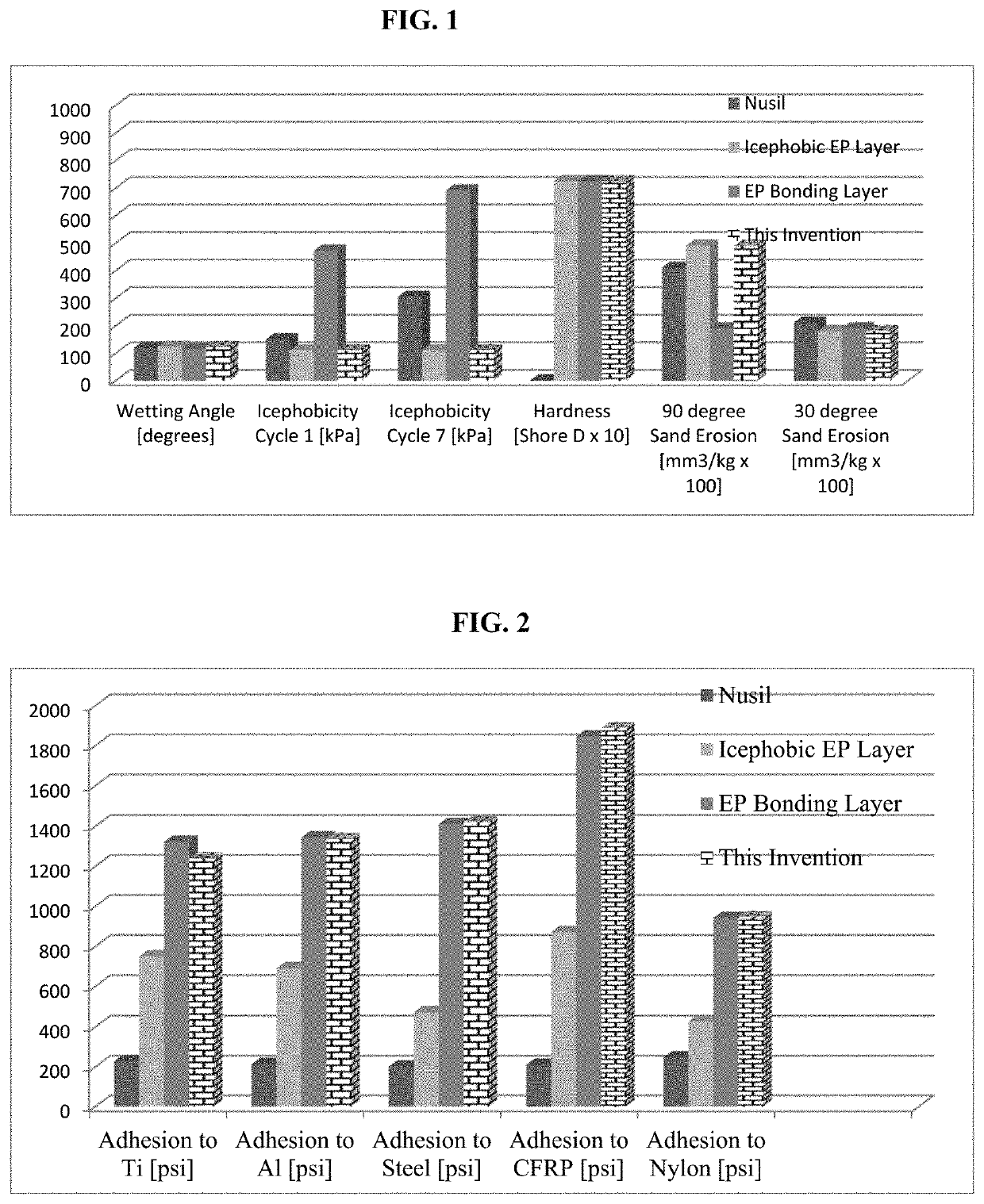

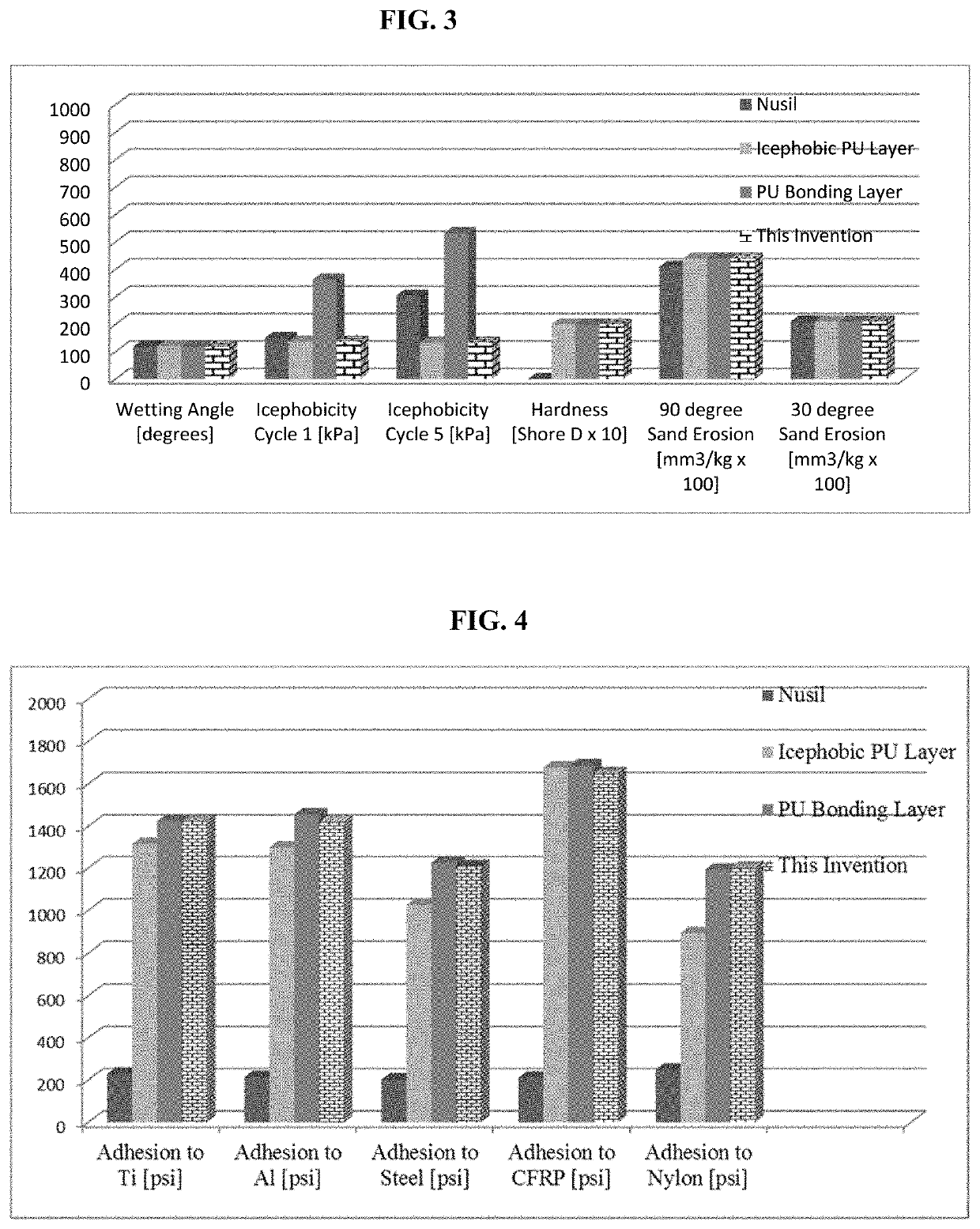

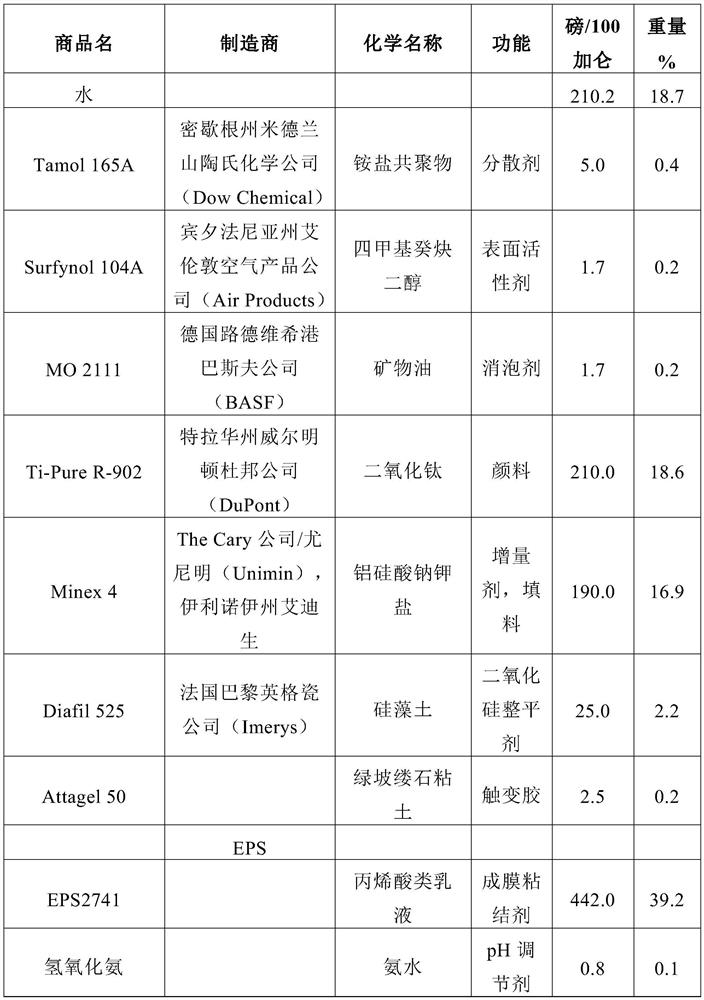

Articles comprising durable water repellent, icephobic and/or biocidal coatings

ActiveUS11312869B2Minimize adverse effectsQuick wearAntifouling/underwater paintsPaints with biocidesPolymer sciencePolymer resin

Articles including durable and icephobic and / or biocidal polymeric coatings are disclosed. The polymeric coatings can include a bonding layer which may contain a substantially fully cured polymeric resin providing excellent adhesion to metallic or polymer substrates. The polymeric coating further includes an outer surface layer which is smooth, hydrophobic, biocidal and icephobic and, in addition to a substantially fully cured resin, contains silicone comprising additives near the exposed outer surface. The anisotropic polymeric coatings are particularly suited for strong and lightweight parts required in aerospace, automotive and sporting goods applications. A process for making the articles is disclosed as well.

Owner:INTEGRAN TECH

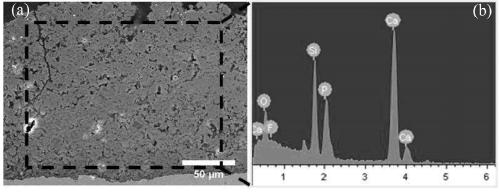

Method for preparing continuous gradient biological coating by utilizing suspension plasma spraying

ActiveCN111286691AReduce internal stressReduce sensitivityMolten spray coatingCalcium silicateFluorohydroxyapatite

The invention discloses a method for preparing a continuous gradient biological coating by utilizing suspension plasma spraying. A calcium silicate / fluorohydroxyapatite continuous gradient biologicalcoating is prepared on the surface of a titanium or titanium alloy matrix by utilizing a suspension plasma spraying method. The high bonding strength between a calcium silicate coating and the titanium matrix and the low solubility of fluorohydroxyapatite are utilized, solid phase components of a mixed solution are gradually changed by adjusting the liquid feeding rates of two suspensions, the continuous gradient coating is prepared on the surface of the titanium or titanium alloy matrix by adopting a suspension plasma spraying technology, namely, the calcium silicate is arranged at the bottomof the coating, the fluorohydroxyapatite is arranged at the top of the coating, gradient component transition is achieved between the top and the bottom, the internal stress of the coating can be greatly reduced through gradient design, and the sensitivity at an interface is reduced. The binding force between the calcium silicate / fluorohydroxyapatite gradient coating and the titanium matrix is obviously improved, the dissolution rate is obviously reduced, and the coating shows good biological activity and antibacterial activity.

Owner:INNER MONGOLIA UNIV OF TECH

Biological coating based on cyclomatrix-type polyphosphazene and preparing method thereof

InactiveCN105255362ASimple preparation conditionsAdjustable propertiesAnti-corrosive paintsFunctional monomerPolyphosphazene

The invention provides a biological coating based on cyclomatrix-type polyphosphazene and a preparing method thereof. Phosphonitrilic chloride trimer and a polyfunctional group functional monomer containing an amino group and a hydroxyl group are dissolved into organic solvent, then a material to be modified is placed into a solution, an acid-binding agent is added, and the cross-linking reaction is carried out to obtain the coating modified by cyclomatrix-type polyphosphazene. The polyphosphazene coating technology is a method which is easy to realize and improves traditional macromolecule biocompatibility and corrosion resistance of metal alloy equipment, and the method is expected to play a role in the field of clinical medicine and biological scaffolds.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of zirconium oxide implant biological coating and zirconium oxide implant

ActiveCN112274692AStable structureHigh matrix bond strengthDental implantsPharmaceutical delivery mechanismSand blastingBiocompatibility

The invention relates to a preparation method of a zirconium oxide implant biological coating. The method comprises the following steps: carrying out sand blasting roughening treatment on the surfaceof a pretreated zirconium oxide implant by adopting a sand blasting machine to obtain a zirconium oxide implant with a rough surface; placing the zirconia implant part with the rough surface in micron-sized zirconia suspension liquid, performing soaking for a first preset time, then taking out the implant, and then placing the zirconia implant in a sintering furnace to be sintered to obtain a zirconia implant with the surface of a concave-convex porous structure; and spraying zirconium dioxide particles to the surface of the zirconium oxide implant with the surface of a concave-convex porous structure through a supersonic plasma spraying method so as to obtain the biological coating with a micro-nano structure. The biological coating prepared by adopting the preparation method is of the micro-nano structure, and the micro-nano structure can effectively promote the attachment growth of bone cells, so that the finally prepared biological coating of the zirconium oxide implant has highermatrix bonding strength, not only has a stable structure, but also has excellent mechanical strength and biocompatibility.

Owner:JIAXING JINGYIN BIOTECHNOLOGY CO LTD

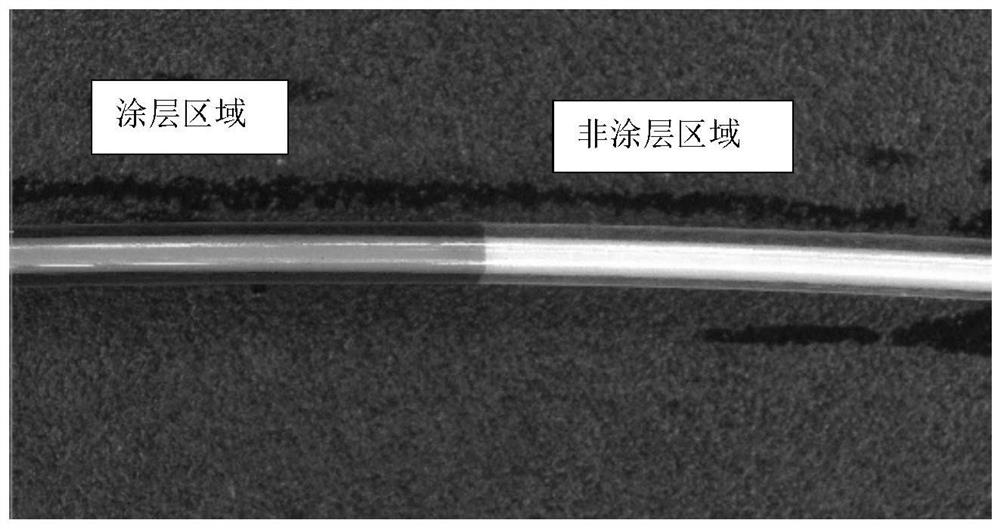

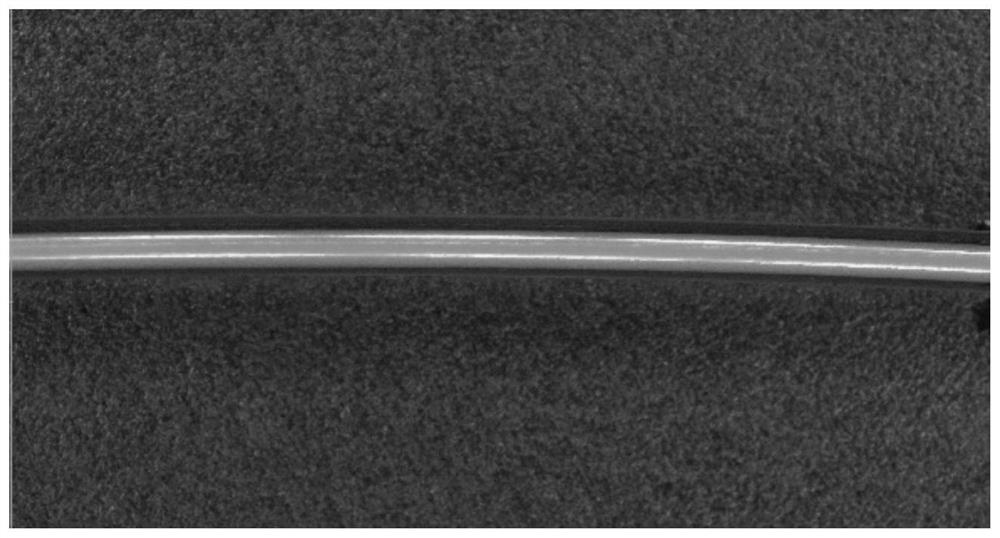

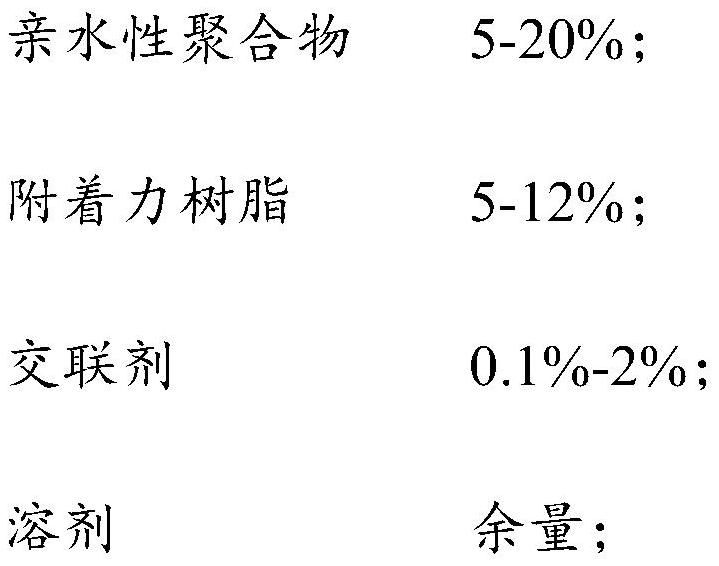

Hydrophilic coating, preparation method and method for testing firmness of coating

InactiveCN113354993AGood substrate adhesionReduce stimulationPretreated surfacesUsing mechanical meansHuman bodyHydrophilic coating

The invention belongs to the technical field of medical biological coatings, and particularly relates to a hydrophilic coating, a preparation method and a method for testing the firmness of the coating. The coating comprises the following raw materials in percentage by mass: 5-20% of a hydrophilic polymer; 5-12% of adhesive force resin; 0.1%-2% of a cross-linking agent; and the balance solvent, wherein the mass average molecular weight of the hydrophilic polymer is 3 to 6 million. Through cooperation of all the components, the prepared hydrophilic coating has good surface lubricating performance and base material adhesive force, puncture resistance of instruments can be reduced, stimulation to human tissue and mucosa is reduced, pain of patients is reduced, and meanwhile particle impurities introduced into human body fluid are reduced.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Preparation method of biological coating with strong binding force on surface of carbon/carbon composite material

ActiveCN111265713AImprove cohesionImprove biological activityTissue regenerationCoatingsCarbon compositesFiber

The invention relates to a preparation method of a strong-binding-force biological coating on the surface of a carbon / carbon composite material. The method comprises the following steps: firstly, directionally arranging carbon fibers in an orthogonal direction on the surface of the carbon / carbon composite material; firstly, preparing carbon fibers, then introducing hydroxyapatite nanobelts into pore structures of the carbon fibers by virtue of a titration method, then introducing the hydroxyapatite nanobelts again by virtue of resin, and in addition, attaching the resin to the surfaces of thehydroxyapatite nanobelts and filling gaps with the resin, so as to finally form the biological coating composed of the orthogonally arranged carbon fibers, hydroxyapatite nanobelts and resin. The maximum value of the interface bonding force between the prepared biological coating and the carbon / carbon composite material is 19.80 MPa, and the interface bonding force is improved by 37.8% compared with the maximum value of the interface bonding force reported in the background technology.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method for medical metal-based biocoating

ActiveCN106283160AHigh bonding strengthReduce consumptionElectrolytic coatingsPharmaceutical delivery mechanismActivated sludgeApatite

The invention discloses a preparation method for a medical metal-based biocoating, and belongs to the field of metal coating material synthesis. According to the method, the surface of magnesium alloy is cleaned and degreased with acetone, after honey is coated, the magnesium alloy is soaked in seawater and secondary sedimentation tank activated sludge, and microorganisms and algae in seawater and sludge are catalyzed to invade into the surface of the magnesium alloy for growth corrosion through sunlight exposure; and after drying sintering, components which is rich in hydroxyl and facilitates crystallization of hydroxylapatite are formed on the surface of the magnesium alloy, in the electrophoretic deposition process, a substrate and the coating are chemically bonded, the interface bonding strength is greatly improved, and finally the medical metal-based biocoating is obtained through sintering. The biocoating is uniform in thickness, high in bonding force with the substrate and not prone to loosening and peeling off in the using process, and the service life is greatly prolonged.

Owner:东阳市特意新材料科技有限公司

Telecommunication base station biocoating

InactiveCN103666271ALow thermal conductivityStable physical and chemical propertiesCellulose coatingsLignin material coatingsCelluloseCooking & baking

The invention discloses a telecommunication base station biocoating. The biocoating is characterized in that the biocoating comprises, by weight, 35-52 parts of a plastic base material, 9-16 parts of elm chip, 19-20 parts of camphor wood chip, 6-12 parts of Chinese oak wood chip, 7-13 parts of trumpet shell powder, 6-7 parts of oyster shell powder, 10-29 parts of an interpenetrating network emulsion, 3-8 parts of an inorganic thickening agent, 4-8 parts of a flexibilizer, 5-13 parts of a fire retardant, 9-18 parts of mica powder having a laminated structure, 1-6 parts of nanometer calcium carbonate, 2-8 parts of ethylene-acrylate, 3-5 parts of high density polyethylene, 4-6 parts of talcum powder, 6-7 parts of liquid paraffin, 1-2 parts of cellulose, 1-2 parts of a foaming agent, 3-6 parts of pore-closed bead, and 1-2 parts of fly ash. The biocoating has the advantages of excellent heat insulation performance, low heat conduction coefficient, stable physical and chemical performances, ageing resistance and high temperature cracking resistance, can be used as a coating, and can also be put in a die to form a sheet after strickling, heating and baking.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

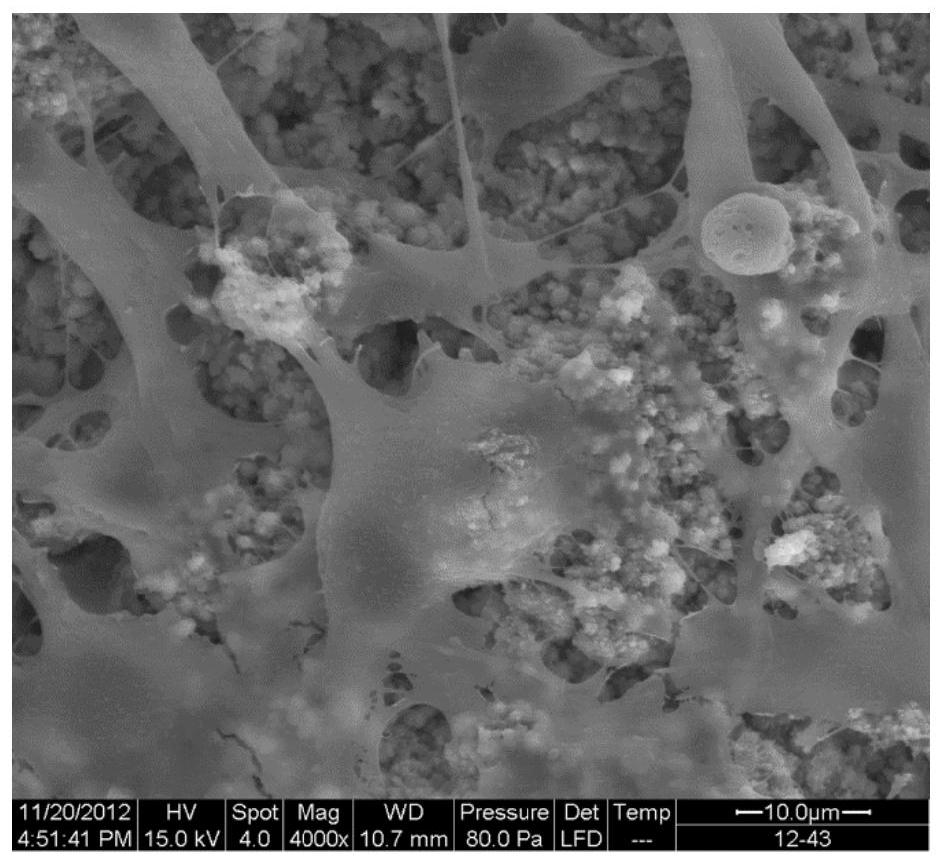

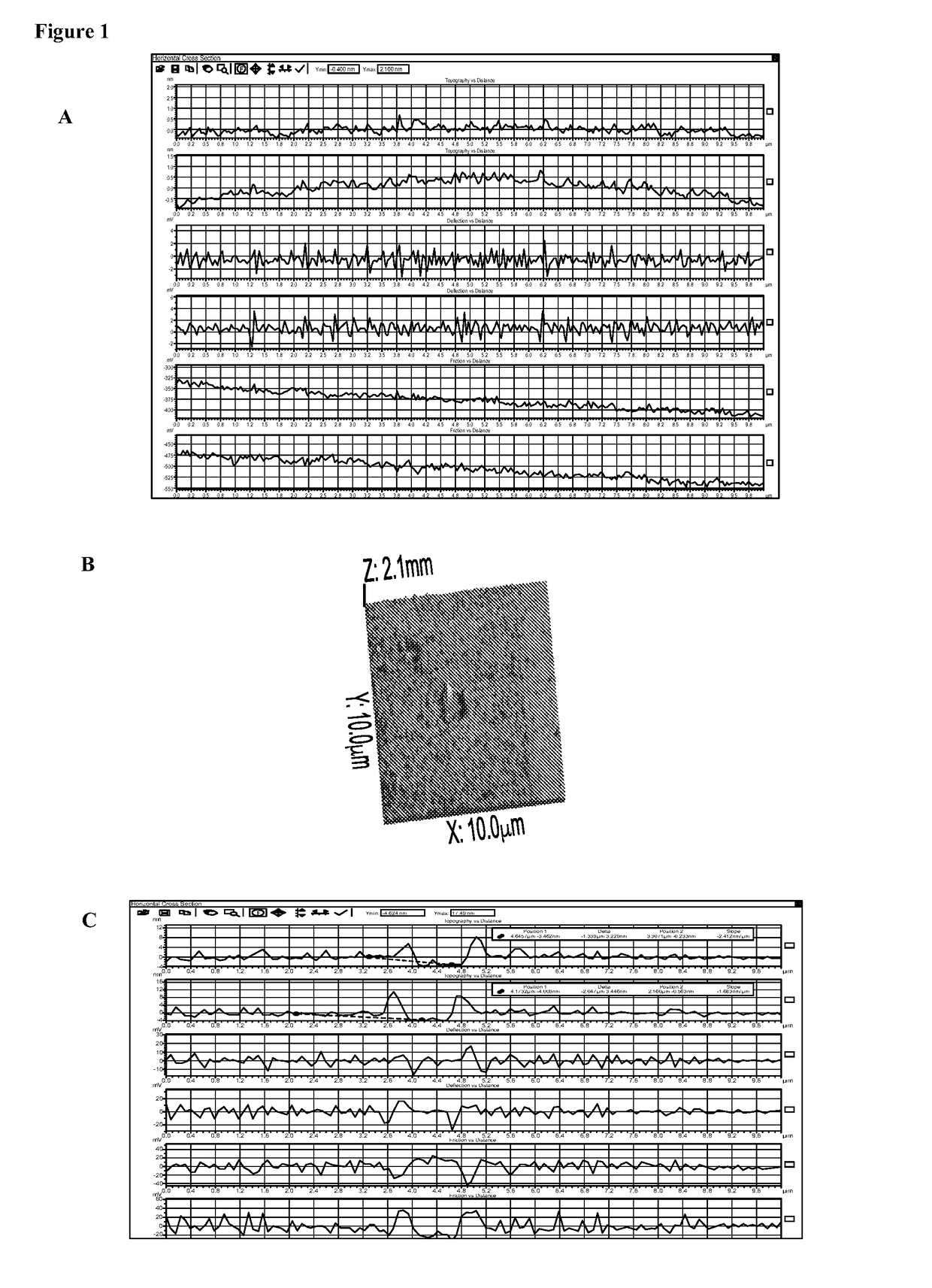

Titanium alloy bone implant adopting bio-coating structure and preparation method of titanium alloy bone implant

ActiveCN107519531AImprove adhesionPromote proliferationPharmaceutical delivery mechanismTissue regenerationBone implantAlloy coating

The invention discloses a titanium alloy bone implant adopting a bio-coating structure and a preparation method of the titanium alloy bone implant. The titanium alloy bone implant comprises a titanium alloy matrix, a porous metal powder coating and a bio-coating, wherein the porous metal powder coating is uniformly distributed on the surface of the titanium alloy matrix and the bio-coating is uniformly distributed on the surface of the porous metal powder coating. The porous metal powder coating and the bio-coating are designed on the implant, multiple pores are formed in the surface of the implant by the aid of the porous metal alloy coating, the bio-coating enters the pores during coating to form closer connection between coatings, the frozen bio-coating forms tiny pores, the bio-coating is made of a resistance-free and easy-to-absorb material, thus, adhesion, proliferation and differentiation of cells are facilitated, regenerated cell tissue can be tightly combined with the porous titanium alloy coating after the bio-coating is completely degraded, the adhesion of regenerated tissue and the implant can be improved, and rejection reactions can be reduced.

Owner:张阳

Articles comprising durable water repellent, icephobic and/or biocidal coatings

ActiveUS20210017399A1Minimize adverse effectsQuick wearAntifouling/underwater paintsPaints with biocidesPolymer sciencePolymer resin

Articles including durable and icephobic and / or biocidal polymeric coatings are disclosed. The polymeric coatings can include a bonding layer which may contain a substantially fully cured polymeric resin providing excellent adhesion to metallic or polymer substrates. The polymeric coating further includes an outer surface layer which is smooth, hydrophobic, biocidal and icephobic and, in addition to a substantially fully cured resin, contains silicone comprising additives near the exposed outer surface. The anisotropic polymeric coatings are particularly suited for strong and lightweight parts required in aerospace, automotive and sporting goods applications. A process for making the articles is disclosed as well.

Owner:INTEGRAN TECH

New biological modification method of surface of crystalline silicon

InactiveCN101787567AGood biocompatibilityImprove bindingAfter-treatment detailsSimulated body fluidApatite

The invention discloses a new biological modification method of the surface of crystalline silicon. The method comprises the following steps: firstly dissolving an alkaline reagent in water to prepare an alkaline solution, and soaking the crystalline silicon in the prepared alkaline solution until the surface of the crystalline silicon forms a thin silicate colloid layer; then directly putting the crystalline silicon soaked by the alkaline solution in a simulated body fluid prepared in advance and soaking to form an osseous apatite bioactivity layer on the surface of the thin silicate colloid layer by inducement; and finally, repeatedly rinsing the prepared crystalline silicon with the thin silicate colloid layer and the osseous apatite bioactivity layer with water, and then drying to form a compound biological coating using the silicate as a transition layer and the osseous apatite as an outer layer on the surface of the crystalline silicon, namely a silicon-based silicate-osseous apatite compound biological coating is ultimately formed. The method has the advantages of convenient operation and low cost. Besides, the obtained biological coating on the surface of the crystalline silicon has favorable biological compatibility, and is difficult to fall off.

Owner:HUNAN UNIV

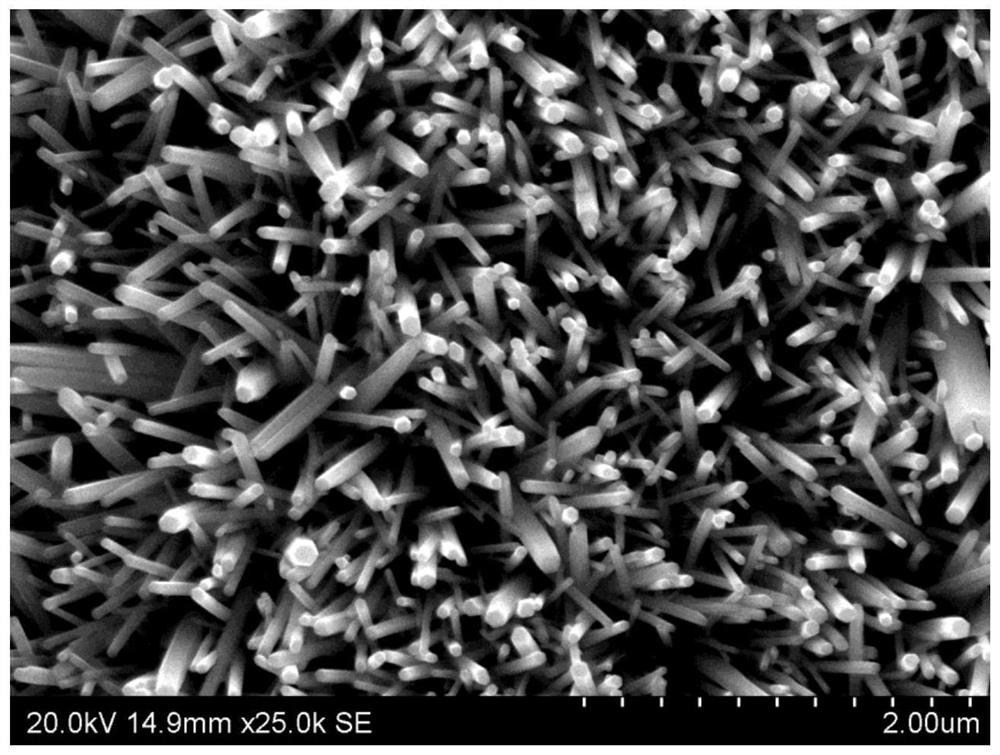

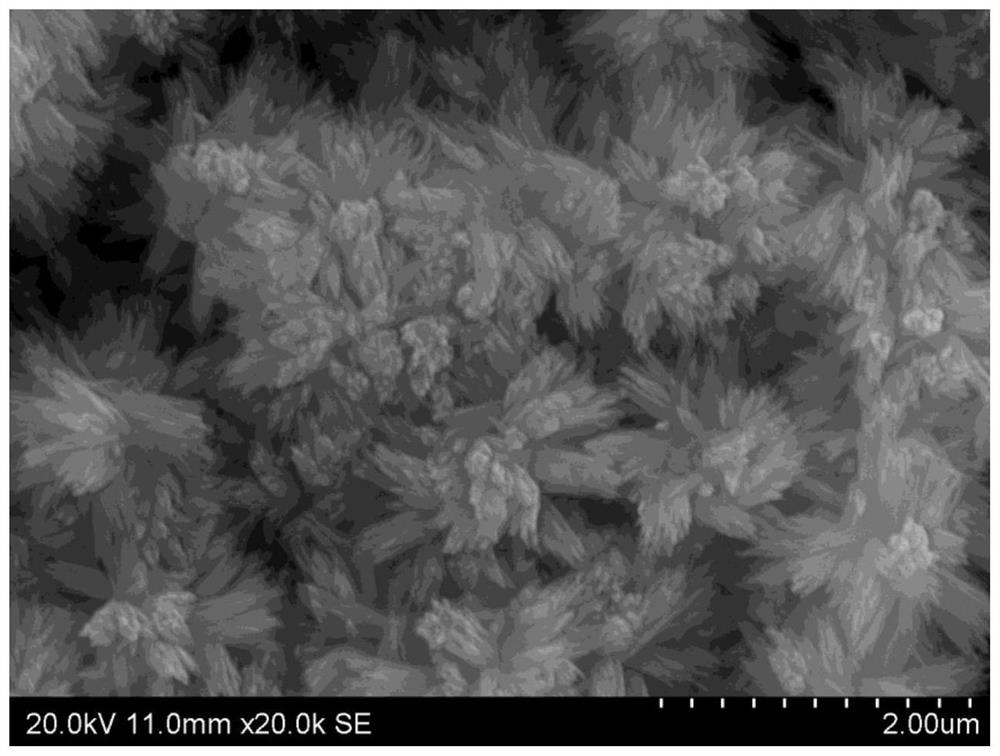

Hydroxyapatite nanorod biological coating and preparation method thereof

ActiveCN112226767AImprove biological activityHigh bonding strengthMaterial nanotechnologyNanomedicinePhosphateZinc alloys

The invention relates to a hydroxyapatite nanorod biological coating and a preparation method thereof. The method comprises the steps: step 1, placing zinc or a zinc alloy in an aqueous solution of calcium acetate to be subjected to a hydrothermal reaction, and placing the aqueous solution of calcium acetate in a reaction kettle, wherein zinc or the zinc alloy is in contact with the bottom of thereaction kettle, and a zinc oxide nanorod coating is formed on the surface, in contact with the bottom of the reaction kettle, of the zinc or zinc alloy; adding an aqueous solution of NaOH into an aqueous solution of calcium salt and phosphate to form a mixed system A to enable the mixed system A to be alkaline, and putting the aqueous solution of calcium salt and phosphate into the reaction kettle; and step 2, placing the zinc or zinc alloy obtained in the step 1 in the mixed system A, placing the zinc oxide nanorod coating upward, performing hydrothermal treatment at 70-180 DEG C to form a hydroxyapatite nanorod biological coating which is firm in combination and good in biological activity on the surface of the zinc oxide nanorod coating. The hydroxyapatite nanorod biological coating isof great significance in development of the zinc alloy in repairing and replacing hard tissues and applying an implant.

Owner:XI AN JIAOTONG UNIV

Medical magnesium-based alloy material and preparation method thereof

InactiveCN110639057AAvoid surface crackingHigh affinityTissue regenerationCoatingsFiberHydroxylapatite

The invention discloses a medical magnesium-based alloy material and a preparation method thereof. The medical magnesium-based alloy material comprises an alloy matrix and a biological coating. The alloy matrix comprises the following components in percentage by weight: 2.2-3.2% of Cu, 0.6-1.2% of Fe, 1.2-1.6% of Sb, 0.4-0.8% of Ta, 1.2-3.2% of Ca, 0.6-1.2% of V, 0.2-0.4% of Mo, 1.2-1.4% of Ag, 2.2-3.2% of P, 0.3-0.7% of Si, 0.02-0.04% of F, 0.1-0.3% of S, 5.2-6.4% of nano-hydroxyapatite, and the balance of Mg. The surface of the alloy matrix is polished to smooth the unsmooth surface caused by the nano-hydroxyapatite floating on the surface layer of the alloy matrix, and the polishing thickness is 1-3 [mu]m. The main materials of the biological coating are collagenous fibers and chitin. According to the invention, metal elements Cu, Fe and Sb are added, inorganic elements P, Si, F and S are jointly added, the nano-hydroxyapatite is added, the surface is polished, and then the surfaceis coated with the biological coating, so that the strength and biocompatibility of the alloy material are improved.

Owner:长沙凯泽工程设计有限公司

Biocoated piezoelectric biosensor platform for point-of-care diagnostic use

ActiveUS10161934B2Rapid diagnosisSimple manufacturing processAnalysing fluids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationPoint of careChemical adsorption

Biosensor components (chips) are described based on direct biocoating processes that result in the tenacious and stable, noncovalent (believed to be chemisorptive) binding of anchor substances such as avidin(s) other proteins having specific binding partners or oligo- or poly-nucleotides onto any piezo-electrically active crystal surface. The resulting platform technology can be developed for a variety of biosensors with specific applications in biological assays. The table mono layers of the anchor substances forms reactive layers, ready to bind a capture reagent such as a biot-inylated antibody for capture and detection of analytes in biologic fluid samples. Although the processes described herein can be performed on any type of piezoelectric material in any number of configurations, some embodiments are directed to a biosensor with the foregoing biocoating onto a particular acoustic plate mode biosensor and where the interdigitated transducers (IDTs) are present on the opposite side of the crystal's biocoated film.

Owner:AVIANA MOLECULAR TECH

Method for preparing tantalum biological coating on surfaces of magnesium and magnesium alloy

PendingCN114381778ANon-cytotoxicImprove bindingAnodisationVacuum evaporation coatingElectrolytic agentMicro arc oxidation

The invention discloses a method for preparing a tantalum bio-coating on the surface of magnesium and magnesium alloy, which is characterized by comprising the following preparation steps: 1) preparing a porous micro-arc oxidation ceramic coating on the surface of magnesium / magnesium alloy: suspending and immersing the magnesium / magnesium alloy into an electrolyte as an anode, taking a stainless steel electrolytic bath as a cathode, and performing micro-arc oxidation in a constant-voltage mode to prepare a porous micro-arc oxidation ceramic coating on the surface of the magnesium / magnesium alloy; the specific parameters are as follows: the voltage is 350-450 V, the power supply frequency is 800-1200 Hz, the positive and negative duty ratio is 30-50%, the treatment time is 2-10 min, and the electrolyte system comprises 0.5-2 g / L of tantalum powder, 2-5 g / L of sodium hexametaphosphate and 5-10 g / L of potassium fluoride; and 2) carrying out double glow plasma tantalum plating on the surface of the porous micro-arc oxidation ceramic coating to form a tantalum diffusion plating layer. According to the method, appropriate electrolyte components and micro-arc oxidation parameters are selected, the melting point of the ceramic coating prepared through micro-arc oxidation on the surface of the magnesium alloy can reach 1000-1500 DEG C, the increased surface temperature can provide a higher working temperature interval for double-glow ion tantalum plating, and therefore the coating thickness and the coating quality of double-glow ion tantalum plating are improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

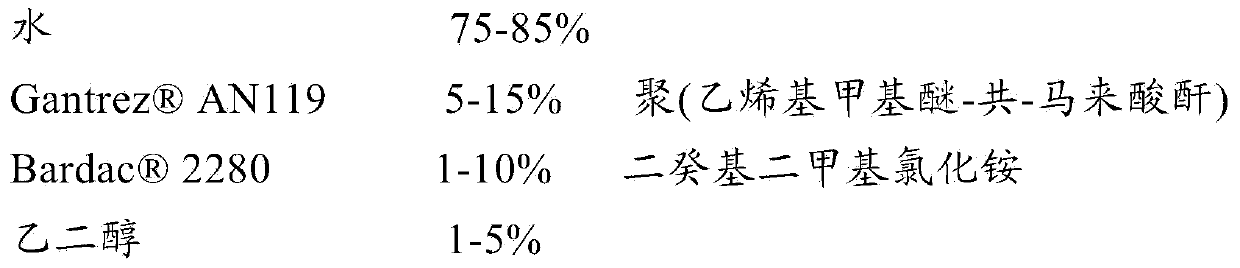

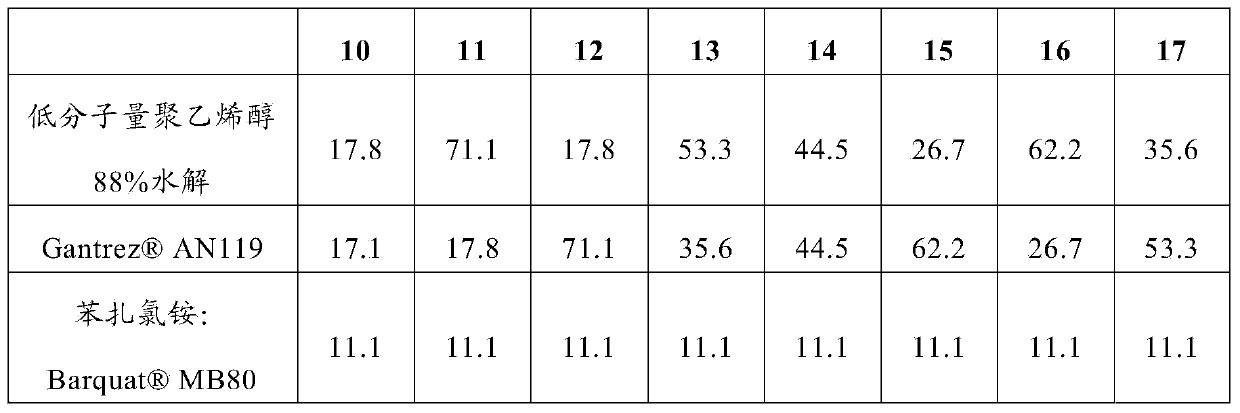

Biocidal coating

The invention relates to a biocidal composition comprising a carboxyl functional polymer and biocidal quaternary ammonium ions. The polymer is a copolymer comprising maleic acid monomer units and / or anions thereof and vinyl ether comonomer units. The composition may be in the form of a film on a surface or in the form of a solution.

Owner:NOVAPHARM RES AUSTRALIA

A kind of copper-based metal anti-biological coating and preparation method thereof

ActiveCN113249610BImprove wear resistanceGood anti-fouling propertiesMolten spray coatingCopper oxideAlloy

The invention discloses a copper-based metal anti-biological coating, which comprises a copper-based alloy wire, and the copper-based alloy wire includes the following weight components: 50-78% of copper, 18-45% of zinc, 1.3-2.5% of lead, 0.2-1.9% of tin, 0.2-2.6% of aluminum, 0.2-1.3% of nickel, 0.1-3.3% of zirconium dioxide, and 0.1-0.8% of copper oxide. The preparation method is also included, including the following steps in sequence: S1: pretreatment of copper-based alloy wire; S2: pretreatment of the surface to be protected; S3: grinding the surface to be protected; S4: spraying. The coating of the present invention has good wear resistance, good anti-biological adhesion, superior anti-corrosion performance and stable performance; it is different from the anti-biological adhesion technology of TBT and toxic material coatings belonging to the same type, and belongs to the environment-friendly technology, which has a great impact on the marine environment. Small.

Owner:南京微米电子产业研究院有限公司

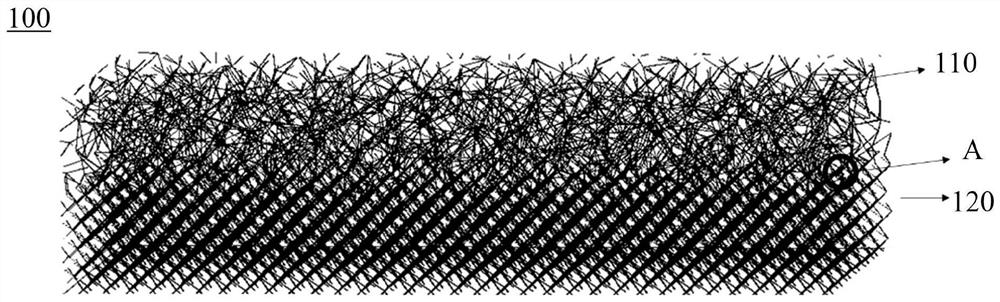

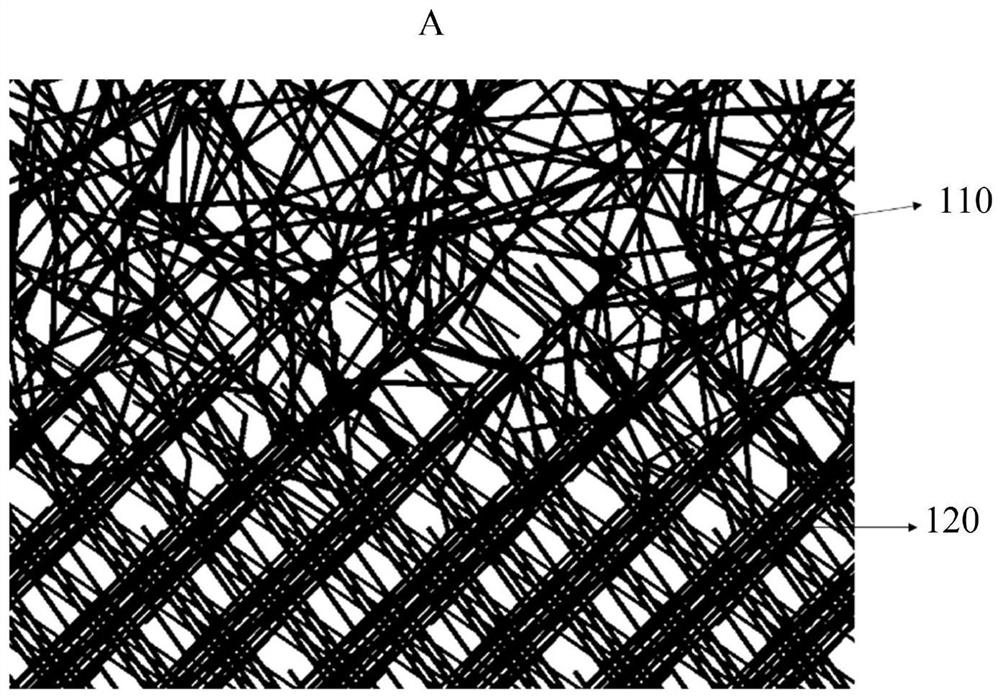

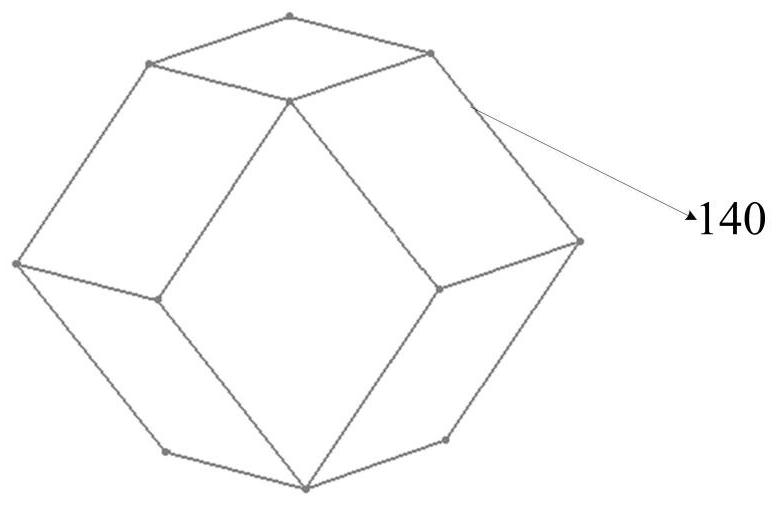

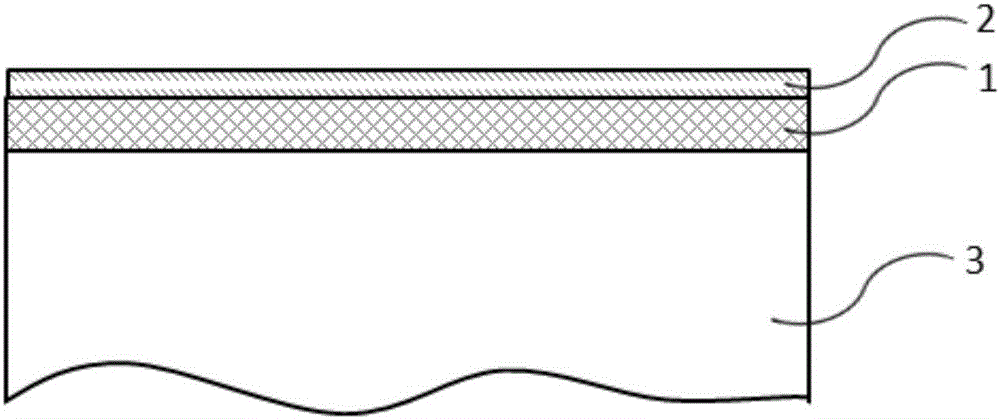

Biocoatings and Implants

ActiveCN111388156BPromote ingrowthImprove growth performanceStentsAdditive manufacturing apparatusBone tissueBone ingrowth

The present invention provides a biological coating and implant. The biological coating includes a surface layer, the surface layer includes a plurality of first monomers connected in a disordered manner, and a plurality of first monomers are formed between the first monomers and inside the first monomers. A through hole. Since the surface layer is arranged on the outermost side of the biological coating, and the surface layer includes a plurality of first monomers connected in a disordered manner, the first monomers and the first monomers A plurality of first through holes are formed inside the body, that is, a plurality of first monomers in the surface layer are connected in a disordered manner, so the plurality of first through holes in the surface layer can be in a disordered state, so that Facilitate the growth of corresponding bone tissue cells into the superficial layer, thereby improving bone ingrowth and long-term stability.

Owner:MICROPORT SINICA CO LTD

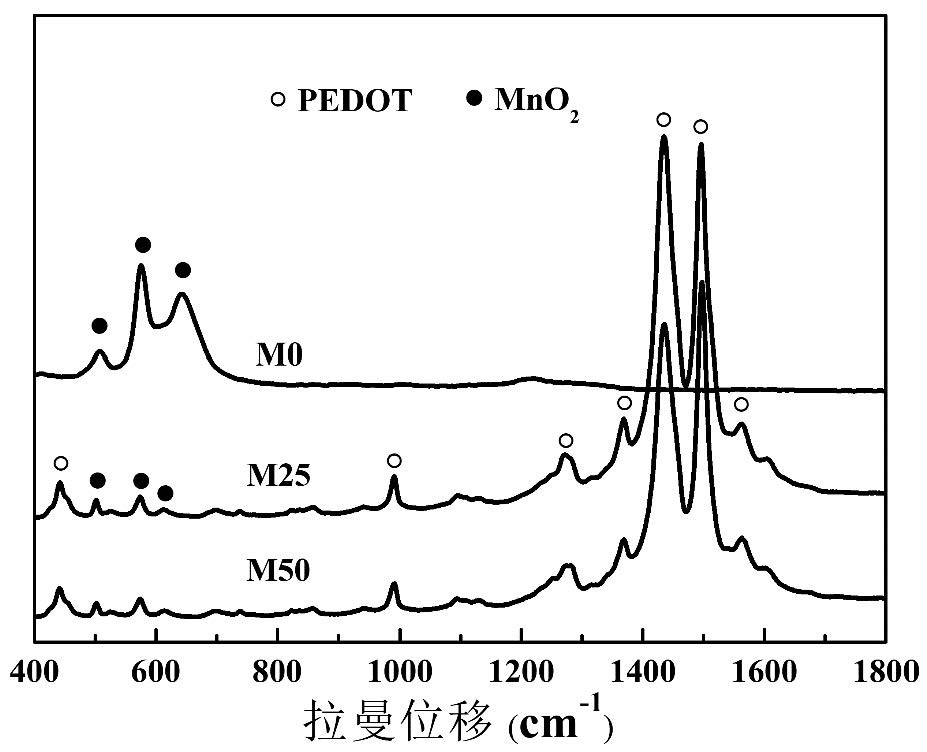

Manganese dioxide-poly(3,4-ethylenedioxythiophene) biocoating with osteogenic activity and its preparation method and application

ActiveCN113827770BGood bone activityGood osteogenesisPharmaceutical delivery mechanismTissue regenerationIn situ polymerizationPhysical chemistry

The invention discloses a manganese dioxide-poly(3,4-ethylenedioxythiophene) biological coating with osteopromoting activity and a preparation method and application thereof. The MnO 2 ‑PEDOT biocoating is achieved by in situ growth of MnO on the substrate surface 2 layer and in MnO 2 MnO with nanosheet structure and connected pore structure obtained by in situ polymerization of layer surface to generate PEDOT 2 ‑PEDOT biocoating.

Owner:江苏先进无机材料研究院

Biocidal coatings

A composition for forming a biocidal coating is provided. The composition has a log reduction of at least 2 and a CIEL*a*b* delta E*value less than about 30.

Owner:CORNING INC

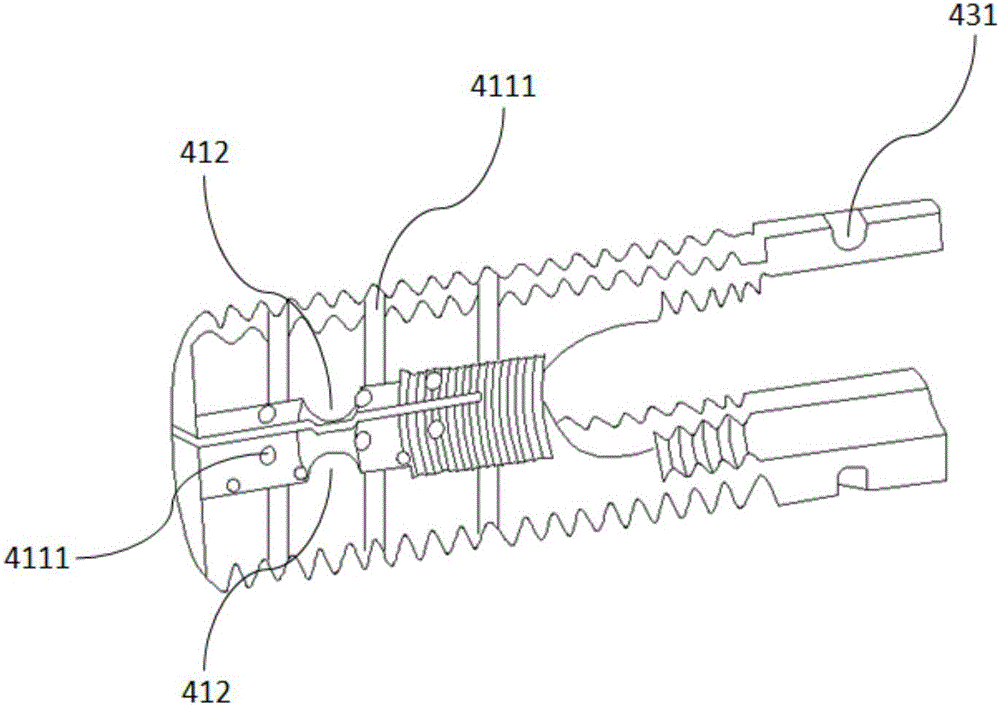

All-built-in expandable biocoating spine anterior internal fixation system

PendingCN106618706AGood tissue compatibilityInternal osteosythesisPharmaceutical delivery mechanismGraphene coatingMedicine

The invention provides an all built-in expandable biocoating spine anterior internal fixation system, relating to the technical field of medical devices. The all-built-in expandable biocoating spine anterior internal fixation system provided by the invention comprises a fastening nail, a nail core, a connecting rod and a plug screw, and a nano-hydroxyapatite-graphene coating and a nano-hydroxyapatite coating which are cooperated with each other coat the surfaces of the fastening nail, the nail core, the connecting rod and the plug screw, so that tissue compatibility of the fixation system is effectively promoted.

Owner:ZHUJIANG HOSPITAL SOUTHERN MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com