Hydroxyapatite nanorod biological coating and preparation method thereof

A hydroxyapatite and biological coating technology, which is applied in the fields of nano-drugs, coatings, nano-technology, etc., can solve the problems of preparing HA nano-rod biological coatings that have not been reported, and achieves improved biocompatibility and improved biological Compatibility, effect of reducing cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The method for preparing HA nanorod bio-coating on the surface of zinc and zinc alloy of the present invention includes the following steps:

[0035]Step 1: Use deionized water as the solvent and calcium acetate as the solute to form a solution with a calcium acetate concentration of 0.023-0.17mol / L, and place a polished round zinc or zinc alloy with a thickness of 2mm and a diameter of 10mm A hydrothermal treatment with a temperature of 90℃-130℃ and a time of 60-240min is carried out in the solution. For the convenience of description, the zinc or zinc alloy is recorded as the matrix, and a layer of zinc oxide nanorod coating is formed on the back of the matrix. That is, the side where the substrate is in contact with the reactor, and calcium acetate is used as a stabilizer to prevent the upper surface of the substrate from being corroded and still maintain its original morphology, and finally ZnO nanorods are grown on the back side.

[0036]Step 2: Use deionized water as solvent, ...

Embodiment 1

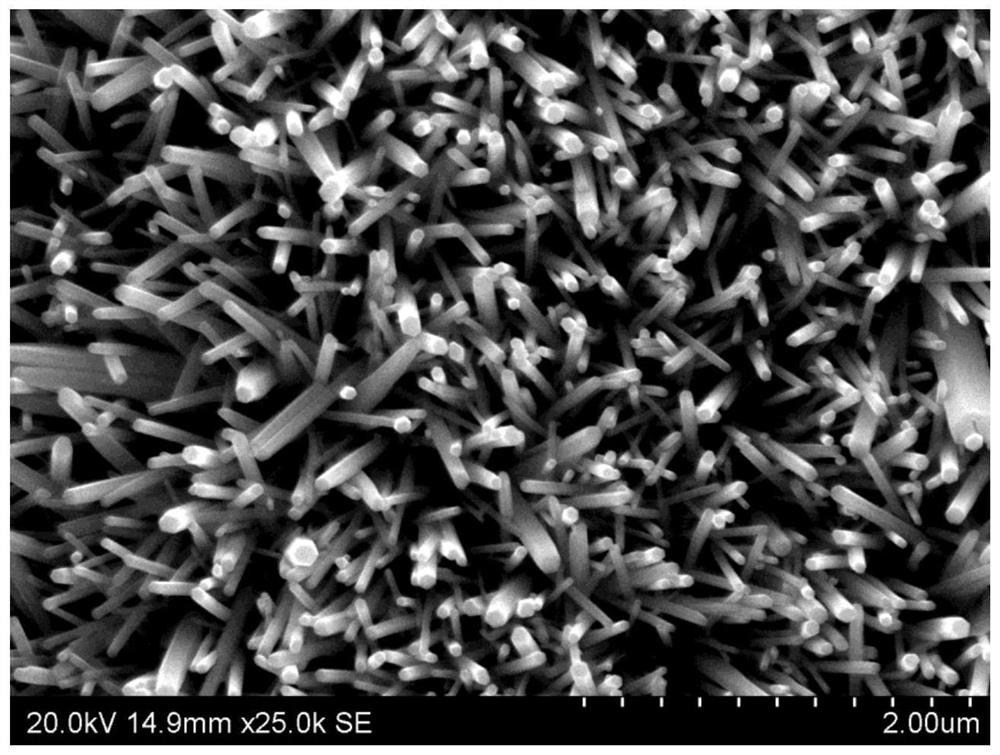

[0039]Step 1: Use deionized water as the solvent and calcium acetate as the solute. The calcium acetate concentration is 0.034mol / L to form a hydrothermal solution. The polished zinc flakes are placed in an aqueous solution for hydrothermal treatment. The reaction temperature is 110°C. The reaction time is 180 minutes to obtain the zinc oxide nanorod coating. Refer to the SEM photo of its surface microstructurefigure 1 , It can be seen that the surface is a uniform nanorod-like structure, please refer to the contact angle photofigure 2 , Through calculation, the surface contact angle is 18.3°, the XRD pattern can be referred toPicture 10, From the XRD peak, it can be known that the main phases are Zn and ZnO.

[0040]Step 2: Use deionized water as the solvent, EDTA-Ca and diammonium hydrogen phosphate as solutes, where the concentration of EDTA-Ca is 0.167 mol / L, the concentration of diammonium phosphate is 0.1 mol / L, and the NaOH solution of 10mom / L is used Adjust the pH of the soluti...

Embodiment 2

[0042]Step 1: Use deionized water as the solvent and calcium acetate as the solute. The calcium acetate concentration is 0.034mol / L to form a hydrothermal solution. The polished zinc flakes are placed in an aqueous solution for hydrothermal treatment. The reaction temperature is 110°C. The reaction time is 180 minutes to obtain the zinc oxide nanorod coating.

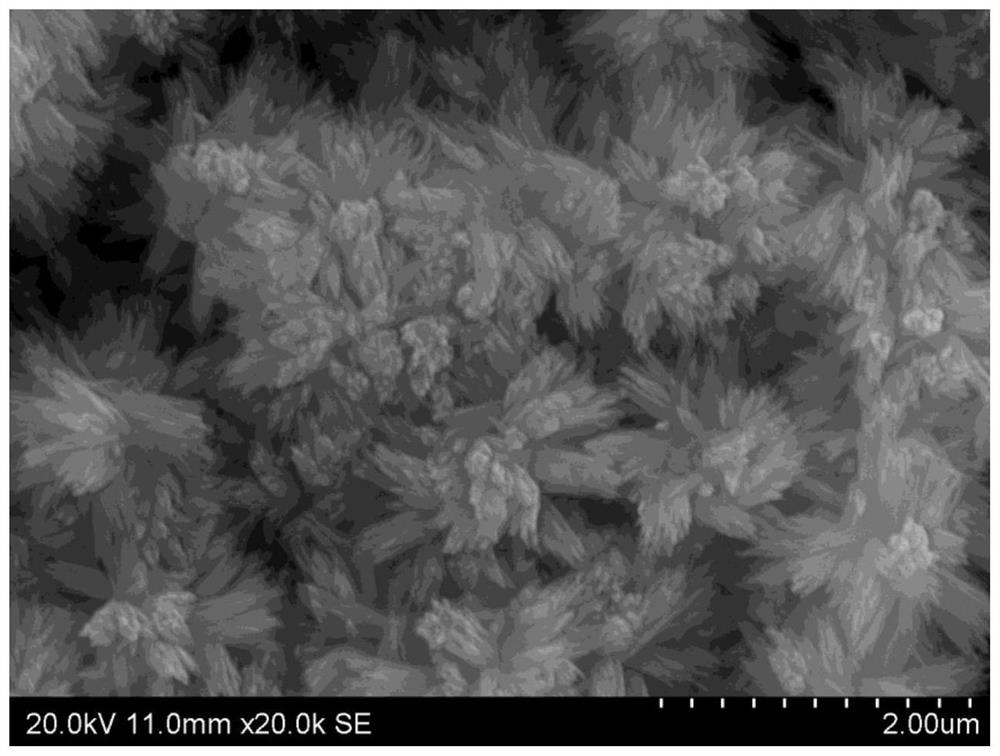

[0043]Step 2: Use deionized water as the solvent, EDTA-Ca and diammonium hydrogen phosphate as solutes, where the concentration of EDTA-Ca is 0.167 mol / L, the concentration of diammonium phosphate is 0.1 mol / L, and the NaOH solution of 10mom / L is used Adjust the pH of the solution to 12.70 to form a second-step hydrothermal solution. Place the zinc alloy with zinc oxide nanorods in the solution for the second-step hydrothermal reaction. The reaction temperature is 110°C and the reaction time is 60min. The reaction is over Then, HA nanorod coating was obtained on the surface of the zinc alloy. Refer to the SEM photo of its surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com