Hydrophilic coating, preparation method and method for testing firmness of coating

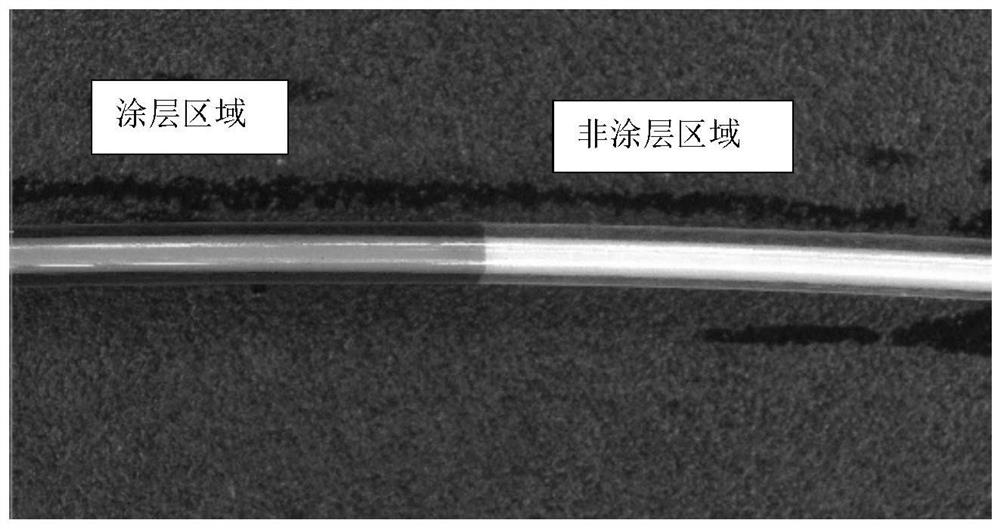

A technology of hydrophilic coating and hydrophilic polymer, which is applied in the preparation method and the test of the firmness of the coating. In the field of hydrophilic coating, it can solve the problem of insufficient firmness of the hydrophilic coating and the inability to maintain lubricity. Test method Incomplete and other problems, to achieve ideal effect, good lubricity, lubricity and wear resistance ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a kind of preparation method of hydrophilic coating, concrete steps are as follows:

[0044] In step 1, the catheter with an inner diameter of 1.7 mm and an outer diameter of 2.0 mm to be coated is subjected to plasma treatment, and the treatment gas is oxygen, and the treatment time is 5 minutes.

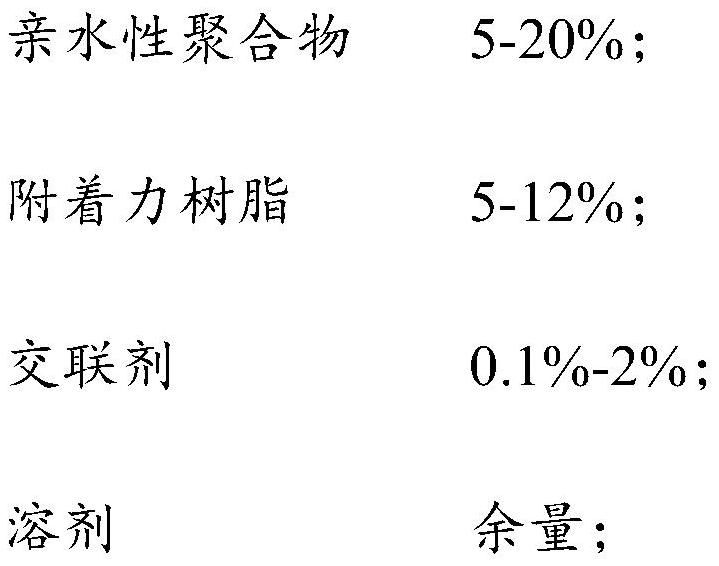

[0045] Step 2, prepare the hydrophilic coating solution according to the following ratio, including 100 g of the total mass of the hydrophilic coating solution, 10 g of polyacrylic acid acrylamide (molecular weight 4 million-5 million), DSM polyurethane emulsion NeoRez E-122 10g, CX-3000.3g, the balance is water.

[0046] In step 3, the hydrophilic coating solution is applied to the surface of the catheter by dipping, the rising and falling speeds are both 1mm / s, and the soaking time is 20s. Allow to dry for 1 hour after coating.

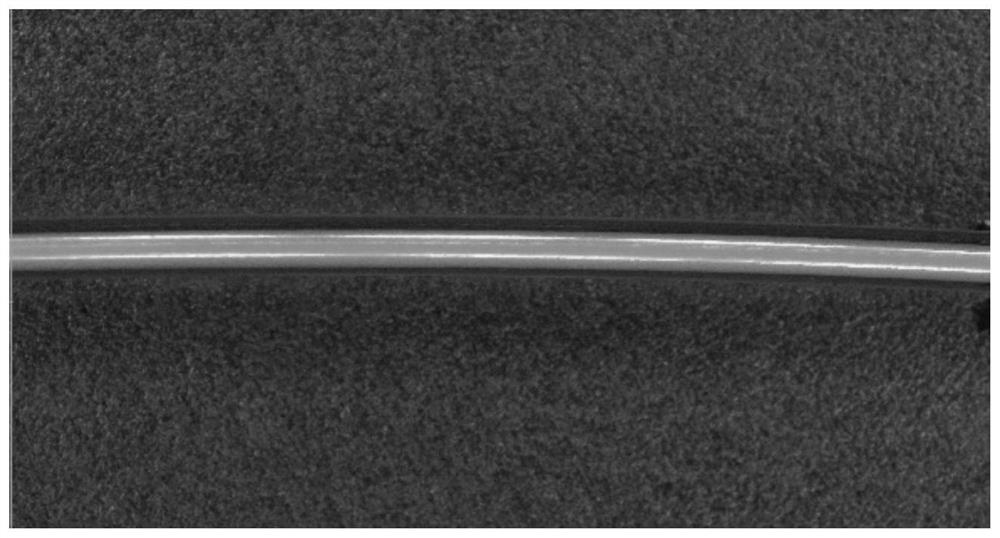

[0047] In step 4, heat and cure in an oven, and cure at 70° C. for 1 hour to obtain a hydrophilic coating with ...

Embodiment 2

[0049] The present embodiment provides a kind of preparation method of hydrophilic coating, concrete steps are as follows:

[0050] In step 1, the pipe with an inner diameter of 1.7mm and an outer diameter of 2.0mm made of Pebax7233 is subjected to plasma treatment, the treatment gas is oxygen, and the treatment time is 5 minutes.

[0051] Step 2, prepare the hydrophilic coating solution according to the following ratio, including 100 g of the total mass of the hydrophilic coating solution, 10 g of polyacrylic acid acrylamide (molecular weight 4 million-5 million), DSM polyurethane emulsion NeoRez E-122 10g, CX-3000.3g, the balance is water.

[0052] Step 3: Apply the hydrophilic coating solution to the surface of the catheter by dipping, the ascent and descent speeds are 1mm / s, the soaking time is 20s, and dry for 1 hour after the coating is completed.

[0053] In step 4, heat and cure in an oven, and cure at 70° C. for 1 hour to obtain a hydrophilic coating with a thickness o...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of hydrophilic coating, concrete steps are as follows:

[0056] Embodiment 3 is a variation of Embodiment 1, in order to achieve better lubricating performance and surface adhesion. Adjust the ratio of two kinds of polyacrylic acid acrylamide and acrylic acid modified polyurethane solution, apply in two steps, and then cure.

[0057] In step 1, the catheter with an inner diameter of 1.7 mm and an outer diameter of 2.0 mm to be coated is subjected to plasma treatment, and the treatment gas is oxygen, and the treatment time is 5 minutes.

[0058] In step 2, the hydrophilic coating solution is prepared according to the following proportions, and the proportions are mass ratios. The ratios of the two coats were different, with the first coat having a higher proportion of adhesion resin and the second coat of a higher proportion of hydrophilic polymer. In order to make the final lubricity and wear resistance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com