Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "With matte effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-face matt polyester film and preparation method thereof

InactiveCN101259771AGood matte effectHigh light transmittanceSynthetic resin layered productsPolyesterSurface layer

The invention discloses a single-side matt polyester film with a layered structure comprising at least a first film layer and a second film layer which are co-extruded, compounded with each other and arranged next to each other; the first film layer is arranged on the surface layer of the polyester film and is a matt layer, which contains 50 to 80 wt percent of the polyester, 20 to 50 wt percent of nylon polymer and 0 to 0.5 wt percent of crystal nucleating promoter; the second film layer is a highly transparent layer, the main component of which is the polyester. The invention also discloses a method for manufacturing the single-side matt polyester film. As the method does not require the aforehand special preparation of the matt master batch, the whole process is simple. The manufactured polyester film not only has favorable matt effect, but also has excellent transmittance and is in particular applicable to the use for printing, aluminum plating and compounding in the field of packaging.

Owner:WEIFANG FUWEI PLASTIC

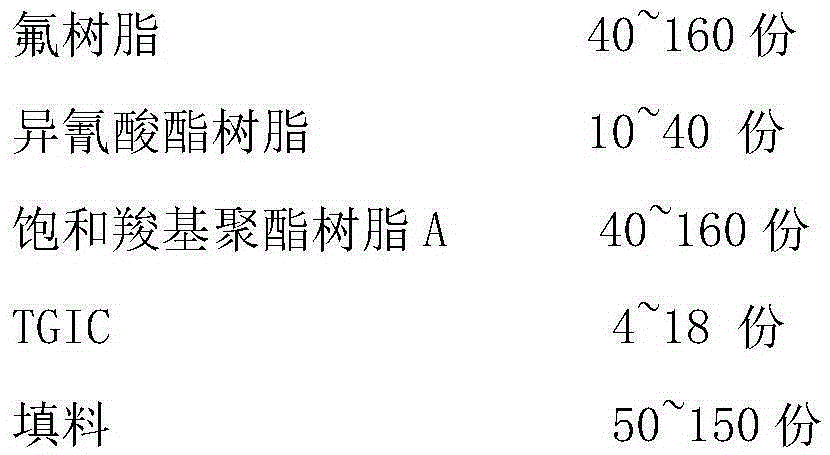

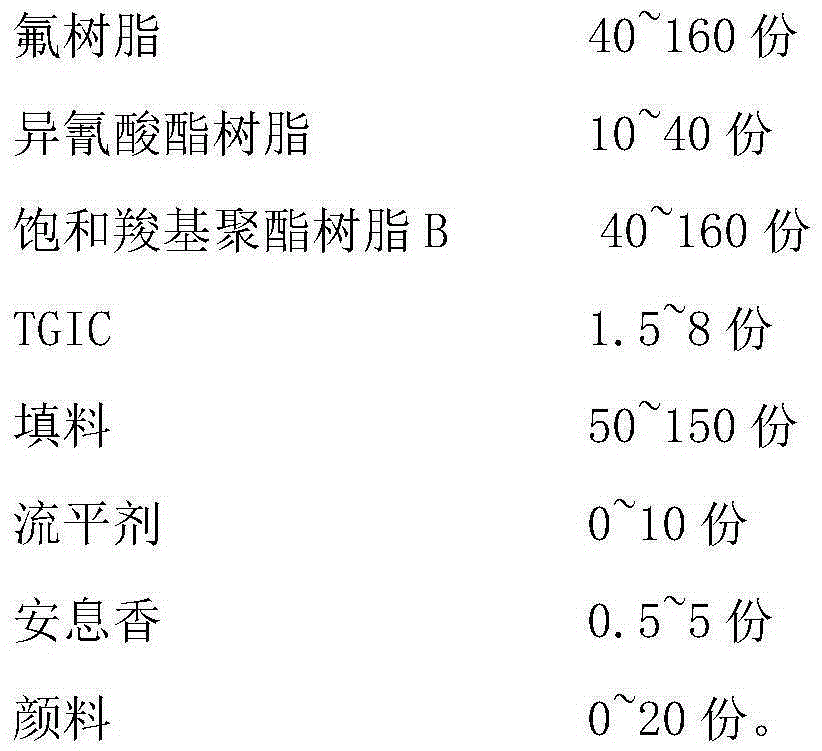

Extra-weather-resistant matt fluorocarbon-polyester composite powder coating and preparation method thereof

ActiveCN105419609AExtended service lifeEasy to preparePolyurea/polyurethane coatingsPowdery paintsFluorocarbon ResinsWeather resistance

The invention discloses an extra-weather-resistant matt fluorocarbon-polyester composite powder coating and a preparation method thereof. The powder coating is prepared from a component A and a component B in a ratio of 1:1-1:1.5 by means of dry mixing and grinding, wherein each of the component A and the component B contains a fluorocarbon resin and polyester resin dual-curing system. The extra-weather-resistant matt fluorocarbon-polyester composite powder coating has the advantages of simple technological formula, extra weather resistance, resistance to acid and alkali, capabilities of overcoming the shortcomings of poor adhesion and poor pigment filler wettability of a pure fluorocarbon powder coating and showing extra weather resistance by curing coats, long outdoor service life, low material use and maintenance integrated cost and the like.

Owner:GUANGZHOU KINTE IND

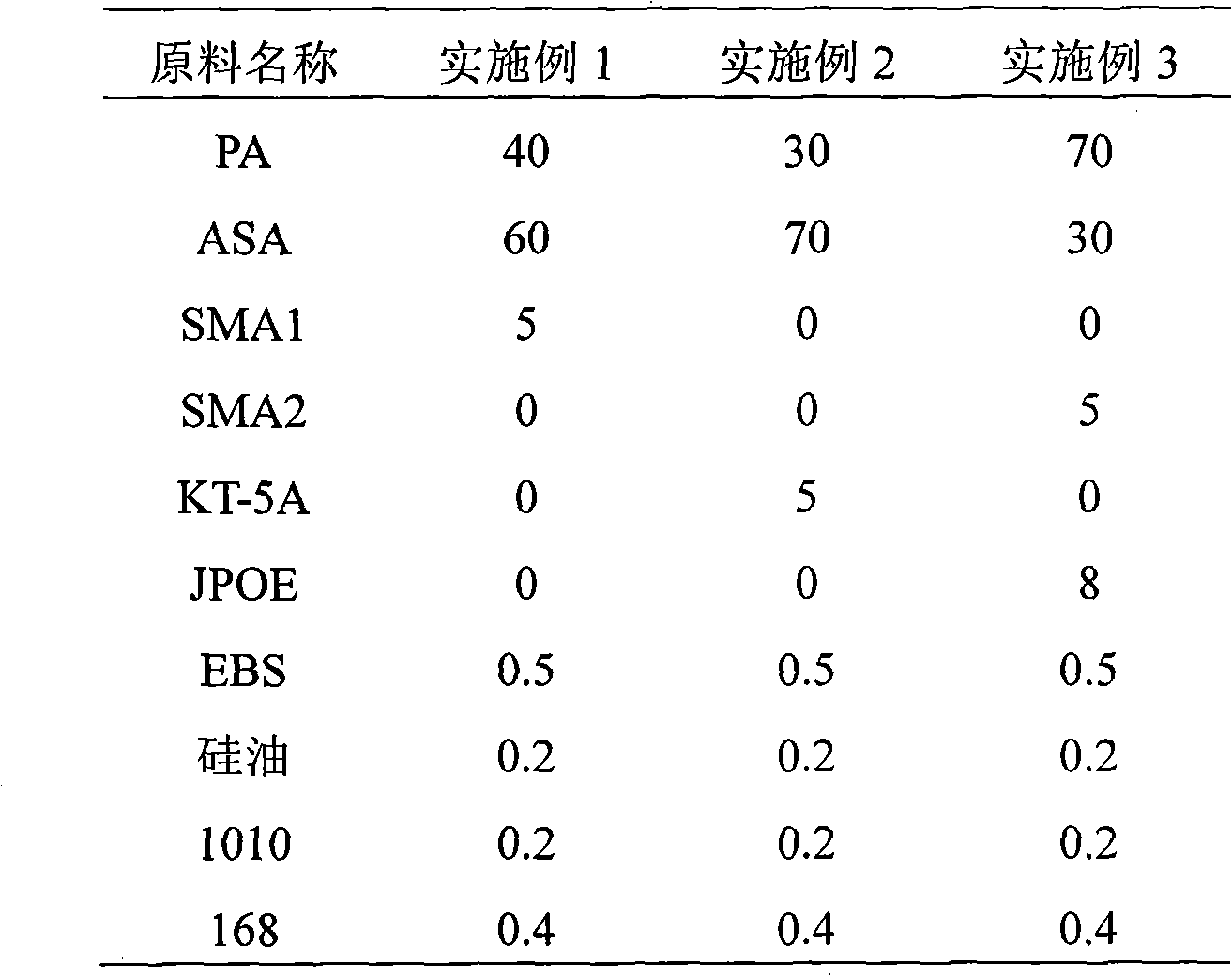

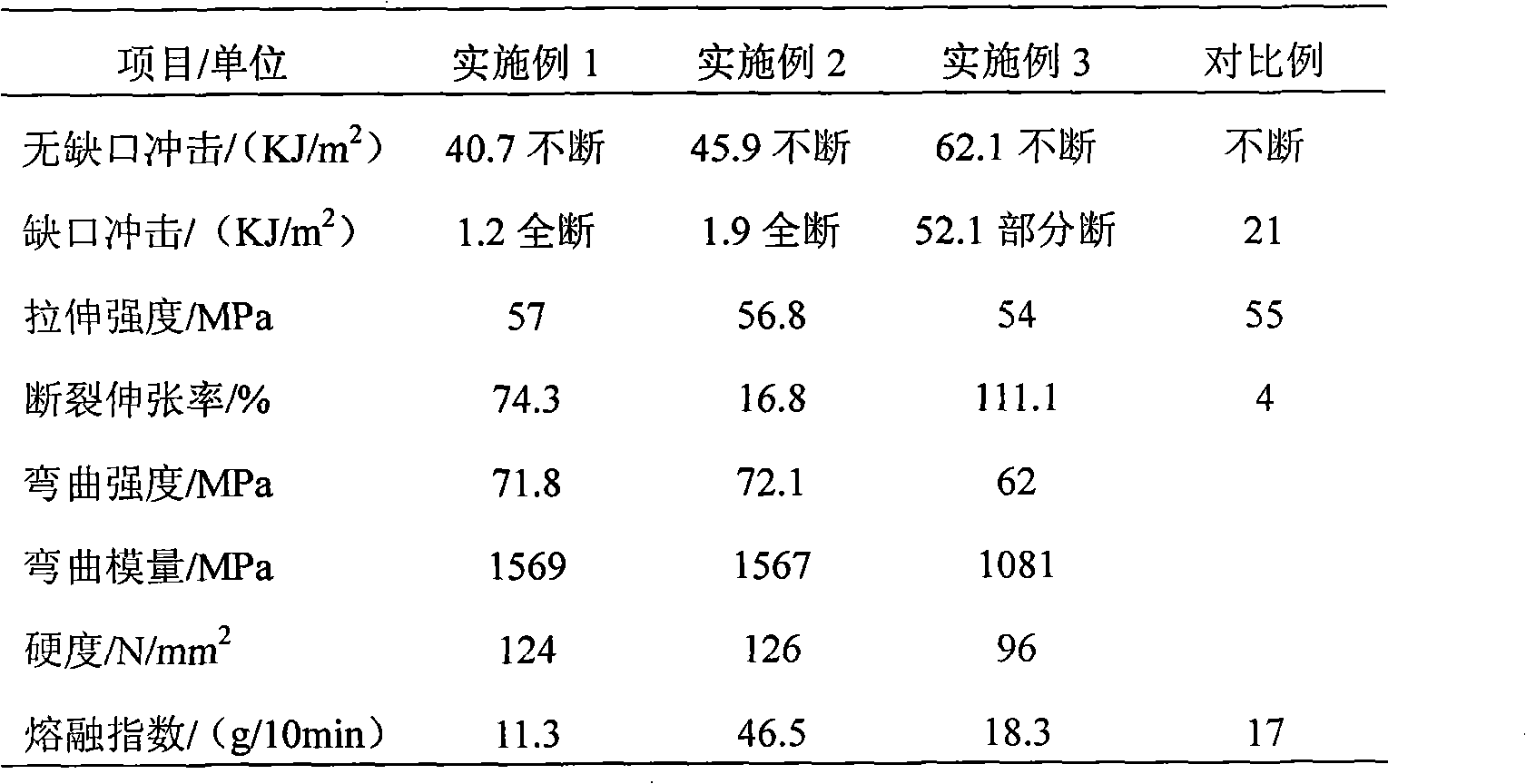

High notched impact PA/ASA alloy material and its preparation method

InactiveCN102337025AGood weather resistanceOutstanding notched impact performanceAlloyMechanical property

The invention discloses a high notched impact PA / ASA alloy material and its preparation method. The high notched impact PA / ASA alloy material comprises the following components of: by weight, 30-90 parts of PA, 20-80 parts of ASA, 3-15 parts of a compatilizer, 3-20 parts of a flexibilizer, 0.2-0.5 part of a lubricant, 0.2-1 part of an anti-oxidant. The raw materials are weighed according to the above proportion and are mixed and extruded by a double screw extruder to prepare the PA / ASA alloy. Similar to PA / ABS, the prepared PA / ASA has good impact strength, good thermal stability and more excellent dimensional stability than PA. As ASA is used to replace ABS, PA / ASA has better weatherability and chemical resistance than PA / ABS. Due to self-lubricating property of PA, PA / ASA has better wear resistance than PC / ASA. The PA crystal material and the ASA amorphous material are mixed to possess good noise abatement and damping performance. The preparation method provided by the invention is used to greatly raise the notched impact strength of alloy without influencing processing performance and other mechanical properties, and is suitable for products which have high requirements on toughness. The product provided by the invention is an excellent substitutive material in the fields of automobile, electronics and electricity and the like.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Non-slip glaze, non-slip ceramic tile and preparation method thereof

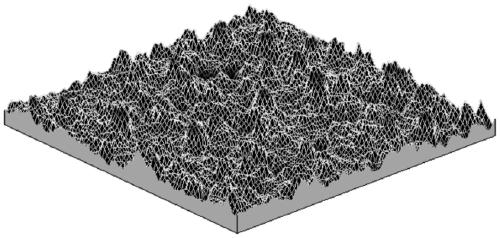

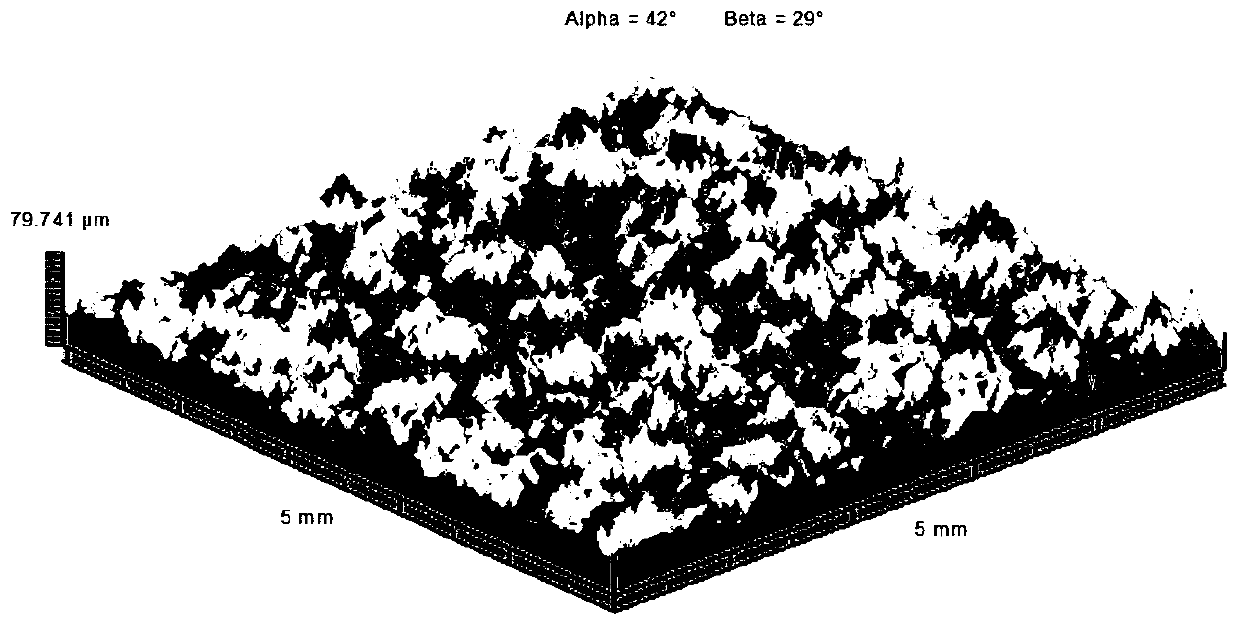

The invention discloses non-slip glaze, a non-slip ceramic tile and a preparation method thereof. The non-slip glaze is prepared from the following components in parts by weight: 40 to 65 parts of SiO2, 15 to 30 parts of Al2O3, 0.1 to 0.5 part of Fe2O3, 5 to 10 parts of CaO, 1 to 9 parts of MgO, 1 to 4 parts of K2O, 0.1 to 2 parts of Na2O, 0.5 to 1.5 parts of ZnO, 0.01 to 0.1 part of TiO2, 0.01 to0.1 part of B2O3, and 5 to 9 parts of BaO. Sharp convex peaks cannot be formed on the surface of the non-slip ceramic tile, the non-slip ceramic tile has a good non-slip function, the PTV value of the non-slip ceramic tile can be 36-65, the corresponding anti-slip grade can reach R10-R13, meanwhile, the non-slip ceramic tile has a matt effect, and the glossiness of the non-slip ceramic tile is averagely smaller than 3 degrees.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

Ceramic tile with bright and matte effects and preparation method thereof

ActiveCN109456035ARealize the artistic effect of combining bright and dumbImprove clarityClaywaresBrickMetallurgy

The invention discloses a preparation method of a ceramic tile with bright and matte effects. The preparation method comprises the following technology steps of (1) applying surface glaze to the ceramic tile blank, so as to obtain a surface glaze layer; (2) printing decoration pattern textures on the surface glaze layer in an ink jet way, and drying, so as to obtain a decoration pattern texture layer; (3) printing a low-temperature ceramic glue with pattern texture onto the decoration pattern texture layer in an ink jet way, so as to obtain a low-temperature ceramic glue layer; (4) spraying bright and matte dry particle glaze onto the low-temperature ceramic glue layer, and drying, so as to obtain a bright and matte dry particle layer; (5) firing at high temperature, so as to obtain a finished product. The preparation method has the advantages that under the synergistic function of the low-temperature ceramic glue and the bright and matte dry particle glaze, the tolerance rate of decoration pattern textures and glue pattern textures is high, so that while the bright and matte combination effect is realized on the decoration pattern texture layer, the bright and matte combination effect is also realized on the bright and matte dry particle layer at the surface of the ceramic tile, the controllability of the bright and matte effect of the whole ceramic tile is strong, and the definition of the decoration patterns is good. The invention also discloses the ceramic tile with the bright and matte effect prepared by the preparation method.

Owner:FOSHAN OCEANO CERAMICS

Formula of colored glaze with matt finishing effect

The invention provides a formula of colored glaze with the matt finishing effect. The formula of the colored glaze with the matt finishing effect is prepared from quartz sand, yellow sand, an oxidant, a clarifying agent, a coloring agent and a binder. The formula of the colored glaze with the matt finishing effect is characterized in that the usage amount of the clarifying agent is 30 to 50% of the usage amount of the oxidant, the usage amount of the coloring agent is 20 to 30% of the usage amount of the oxidant, the usage amount of the oxidant is 1 to 5% of the usage amount of the quartz sand, the usage amount of the binder is 10 to 15% of the usage amount of the yellow sand, and the usage amount of the yellow sand is 40 to 60% of the usage amount of the quartz sand; and the quartz sand and the yellow sand are 0.01 to 0.005mm in granularity. With the adoption of the colored glaze formula in the actual use, the prepared colored glaze is outstanding in performances, has the matt finishing effect and is nice in the appearance; and therefore, the formula is particularly applicable to the manufacturing of colored glaze artware.

Owner:太仓市科教新城琉璃艺术策划中心

Frosted anti-dazzle protective film and preparation method thereof

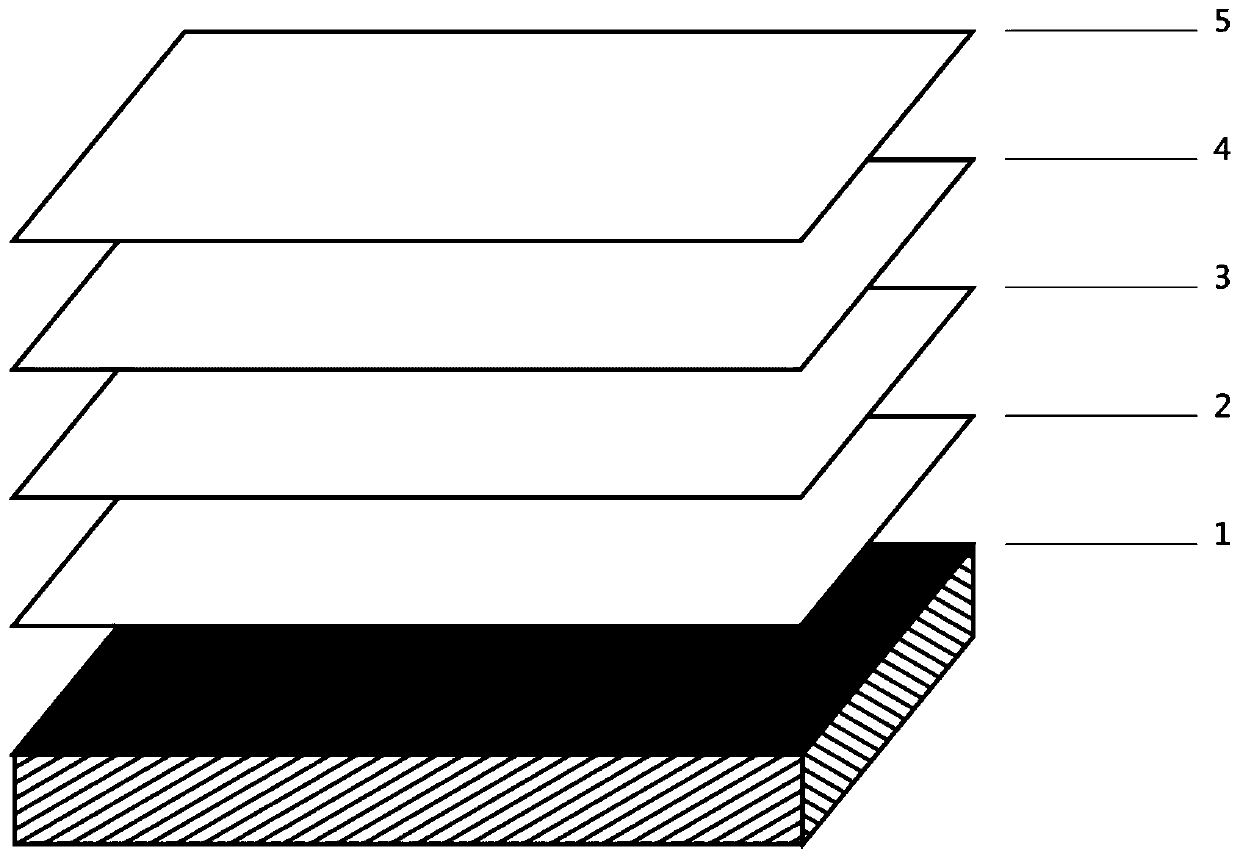

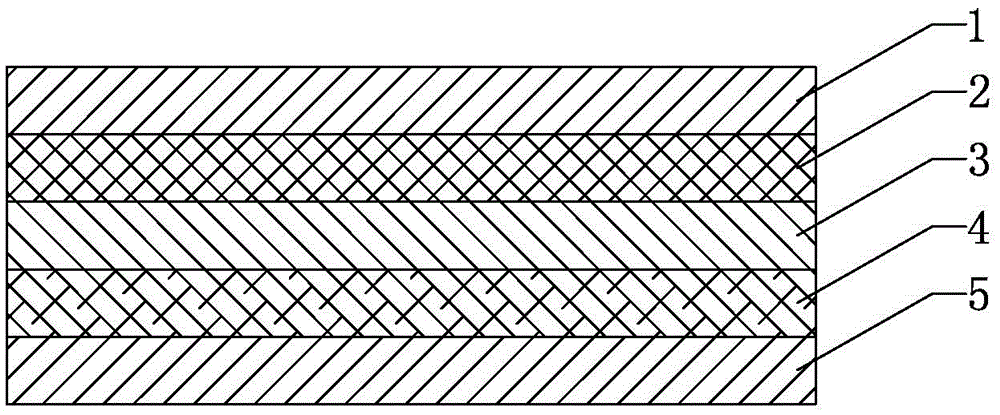

ActiveCN105623548AWith matte effectGood matte effectEster polymer adhesivesCoatingsTransmittanceAcrylic resin

The invention relates to the technical field of protective films, in particular to a frosted anti-dazzle protective film and a preparation method thereof. The frosted anti-dazzle protective film comprises a protective film layer, a frosted anti-dazzle coating layer, a base material layer, a bonding layer and a strippable film layer which are arranged in sequence from top to bottom, wherein the upper and lower surfaces of the frosted anti-dazzle coating layer are respectively adhered to the lower surface of the protective film layer and the upper surface of the base material layer; the upper and lower surfaces of the bonding layer are respectively adhered to the lower surface of the base material layer and the upper surface of the strippable film layer; the raw material of the frosted anti-dazzle coating layer adopts a mixture of a heat curing acrylic resin hardening liquid and a light curing acrylic resin hardening liquid with the ratio of the heat curing acrylic resin hardening liquid to the light curing acrylic resin hardening liquid being 1:(1-5). The frosted anti-dazzle protective film has a frosted effect and a good anti-dazzle effect, cannot produce problems of bright specks and turning white, can further improve light transmittance, guarantee the fidelity of images, and enhance the user experience.

Owner:JIANGSU ZHONGHAI HUA HE ENVIRONMENTAL PROTECTION CO LTD

Water-based matte oil-resistant synthetic leather and preparation method thereof

ActiveCN112760995AWith matte effectEasy to cleanTextiles and paperTextile/flexible product manufacturePolymer scienceSolvent free

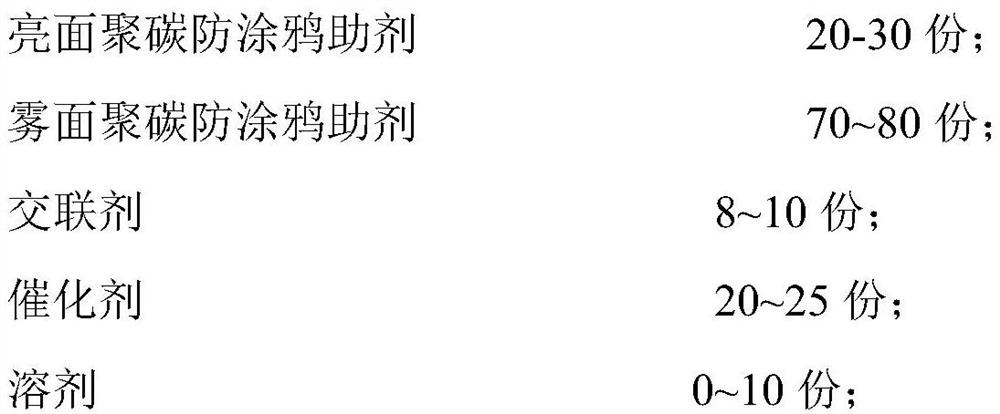

The invention relates to water-based matte oil-resistant synthetic leather and a preparation method thereof. The synthetic leather comprises a base cloth layer, a solvent-free bonding layer and a dry-method PU surface layer which are sequentially arranged, and the synthetic leather further comprises an oil-resistant surface treatment layer formed on the dry-method PU surface layer; the raw material formula of the oil-resistant surface treatment layer is prepared form the components in parts by weight: 20-30 parts of a bright-surface polycarbonate anti-doodling auxiliary agent; 70-80 parts of a matte polycarbonate anti-doodling auxiliary agent; 8-10 parts of a cross-linking agent; 20-25 parts of a catalyst; and 0-10 parts of a solvent. According to the water-based matte oil-resistant synthetic leather and the preparation method thereof, the water-based dry-method PU surface layer is subjected to surface treatment by adopting a specific surface treating agent, so that the synthetic leather not only has a matte effect, but also has oil-resistant and anti-doodling performance, particularly has excellent stain removal performance on stains of a ball-point pen and a marking pen, and is easy to clean.

Owner:马鞍山瑞高科技有限公司

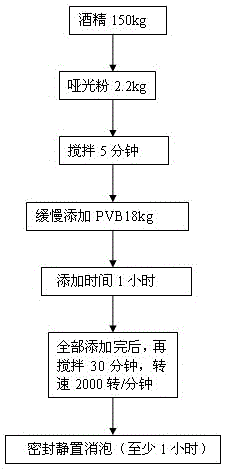

Polyethylene terephthalate (PET) film frosted glue

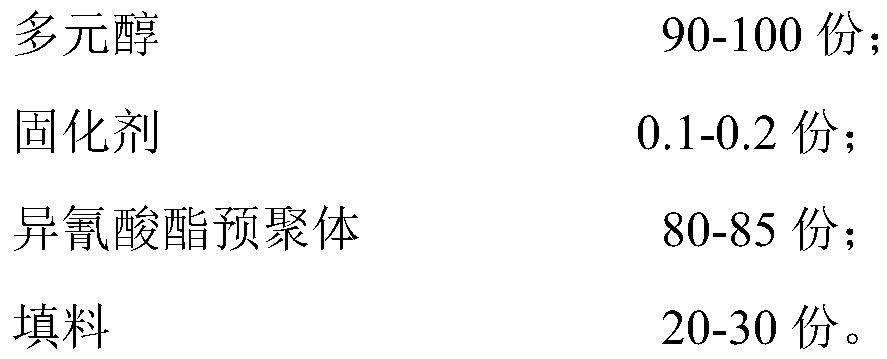

The invention provides a polyethylene terephthalate (PET) film frosted glue which comprises the components with the content: 18-22 parts of polyvinyl butyral (PVB), 1.6-2.4 parts of silica and 150-180 parts of silica, wherein 'part' represents unit mass. A preparation technology of the PET film frosted glue comprises the following steps of: (1) mixing the alcohol and the silica in proportion and evenly stirring the solution; (2) slowly adding the needed PVB into the solution obtained in the step (1), and evenly stirring; and (3) sealing, standing still and defoaming. The PET film frosted glue has the beneficial effects that after being spread onto a PET film, the PET film frosted glue can firmly attach on the surface of the PET film so as to lead the PET film to have frosting effect, the physical polishing process is omitted, and the cost can be reduced.

Owner:惠州艺都文化用品有限公司

Machining technology of hair clipper blade

The invention provides a machining technology of a hair clipper blade. The outer surface of the blade produced through the machining technology has the semigloss effect. The method comprises the stepsof A, punching, wherein a punching machine is used for punching steel, and a blade blank is formed; B, heat treatment, wherein the blank subjected to punching is subjected to heat treatment through amesh belt type heat treatment furnace; C, slope grinding, wherein the slope of the blank subjected to heat treatment is ground through a grinding machine; D, chamfering, wherein the edge of the ground blank is chamfered through an eddy type optical grinding machine via a triangular polishing block; E, outer surface grinding, wherein the outer surface of the chamfered blank is subjected to grinding through a hexagonal type rotation roller via cylindrical abrasive materials; F, smoothing, wherein the outer surface of the blank with the ground outer surface is subjected to grinding through the hexagonal type rotation roller via ceramic ball abrasive materials; and G, mirror surface polishing, wherein the front face and the reverse face of the blank subjected to smoothing are subjected to polishing through a plane polishing machine.

Owner:海宁市兴达刀剪有限公司

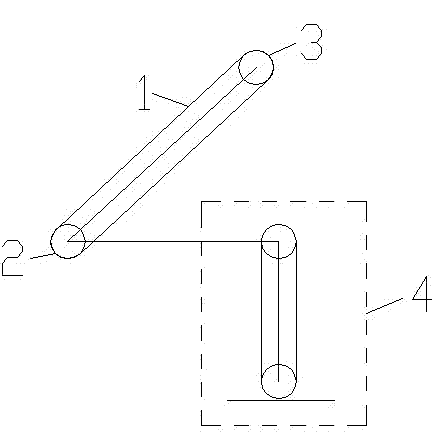

Wire-drawing ceramic processing device and processing method thereof

InactiveCN102825527AWith matte effectHigh hardnessBelt grinding machinesAbrasion apparatusHardnessToughness

The invention relates to the field of material surface treatment, and particularly relates to a wire-drawing ceramic processing device and a processing method thereof. The wire-drawing ceramic processing device comprises a driving device, a first driving wheel in transmission connection with the driving device, a polishing strip and a second driving wheel connected with the first driving wheel through the polishing strip, wherein the polishing strip is provided with a grinding structure used for grinding the surface of a ceramic product. The wire-drawing ceramic processing device overcomes the defects of polished products and causes the finished surface of the product to have matte effect, the surface of the processed material has the same texture with plastic and also has metal texture, no fingerprint is left on the product when the product is contacted with fingerprints, and the product is high in hardness and good in toughness and can resist wear, corrosion and oxidization.

Owner:CHAOZHOU THREE CIRCLE GRP

Method for machining frosted ceramic

The invention relates to the field of material surface treatment and particularly relates to a method for machining frosted ceramic. The method for machining the frosted ceramic comprises the following steps of: A, preparing sand blasting equipment and a sand blasting material; and B, feeding the sand blasting material into the sand blasting equipment; and transmitting the sand blasting material to an air vent by compressed air, so that the sand blasting material impacts the surface of a ceramic product at a high speed. With the adoption of the method, the defects of a product capable of being lighted can be overcome, so that the machined surface of the product has the frosted effect. The surface of the machined material has the sense similar to plastics, and further has the sense of metal. Furthermore, no fingerprints are formed after the product is in contact with fingerprints of a hand. And the machined product has the advantages of high rigidity, good toughness, abrasion resistance, erosion resistance and oxidation resistance.

Owner:CHAOZHOU THREE CIRCLE GRP

Skin-core polypropylene composite plastic high imitation rattan and preparation method thereof

InactiveCN109535460AWith matte effectWith tensile strengthCoatingsPolypropylene compositesFolding endurance

The invention discloses a skin-core polypropylene composite plastic high imitation rattan and a preparation method thereof. The high imitation rattan is prepared by the steps of: a. mixing a polypropylene matrix, a toughening agent, a compatilizer, a physical foaming agent, an antioxidant and a pigment, then conducting melt extrusion and foaming to obtain a foamed polypropylene rattan-imitating substrate; b. adding a soluble pore-forming agent, straw glue and inorganic whisker into an organic solvent to prepare a viscous outer wall solution; and c. impregnating the rattan-imitating substrate in the outer wall solution, then conducting washing and drying curing, thus obtaining the skin-core polypropylene composite plastic high imitation rattan. The method has the beneficial effects that: the high imitation rattan prepared by the method provided by the invention has a rough and matt surface, has appearance, texture and density similar to those of natural rattan, also has soft texture like natural rattan, completely achieves the performance of natural rattan, at the same time has high tensile strength and folding endurance, good mechanical properties and good durability, thus having wide application range.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

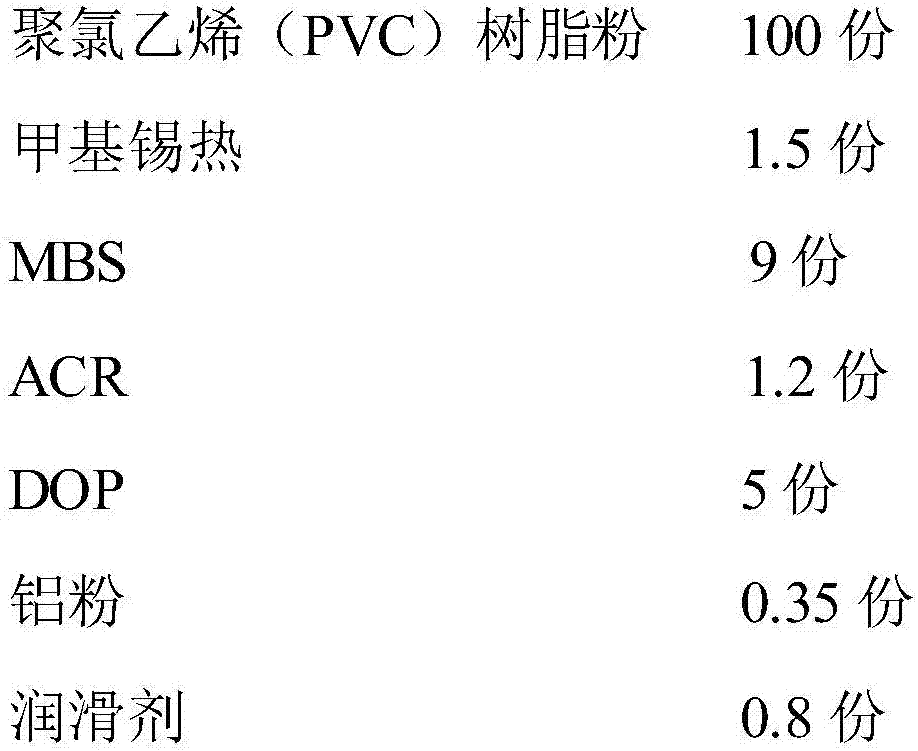

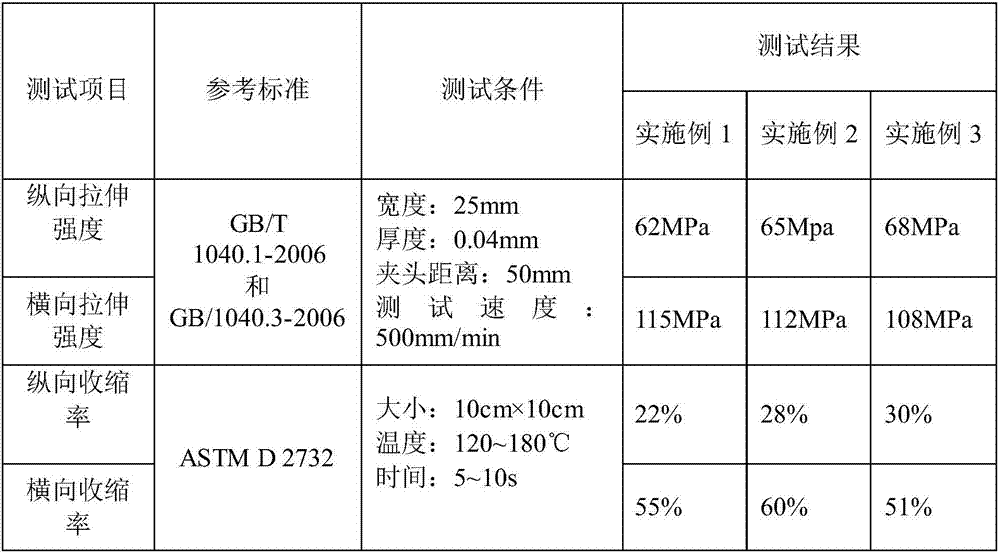

Modified film for packaging alcohol and drink and preparation method of modified film

The invention relates to the field of plastic making and in particular to a modified film for packaging alcohols and drinks and a preparation method of the modified film. The modified film for packaging alcohols and drinks comprises the following components in parts by weight: 100 parts of polyvinyl chloride resin powder, 1.5 parts of a stabilizer, 9 parts of a reinforcing agent, 1.2 parts of processing aids, 5 parts of a plasticizer, 0.35 part of aluminum powder and 0.8 part of a lubricating agent. Due to synergism of different components of the modified film for packaging alcohols and drinks, the obtained film can be shrunk, is good in sealing property, relatively uniform in longitudinal and transverse shrinkage rate, low in cost and low in price. The modified film prepared by using thepreparation method provided by the invention has a dull polish effect and a metallic color, and can meet market requirements.

Owner:上海冠宝印刷科技有限公司

Method for manufacturing tempered glass

InactiveCN106830697APrevent burstAvoid deformationGlass tempering apparatusScreen printingHeating furnace

The invention discloses a method for manufacturing tempered glass. The method is characterized by being processed in steps of defouling, bur picking, screen printing, sintering, heating, heat preserving, cooling, machine shaping and chemical tempering, and the glass well subjected to screen printing in the sintering step is placed in a heating furnace in a manner that front and rear surfaces are not exposed to heating-furnace panels. With the method, the situation that the surfaces of the tampered glass are exposed to the heating-furnace panels resulting in glass blowout or deformation due to temperature concentration in a traditional process is avoided, the glass can be heated evenly when sintered in the heating furnace by means of heating in suspension, and evenness in glass glazing is further improved.

Owner:曾志明

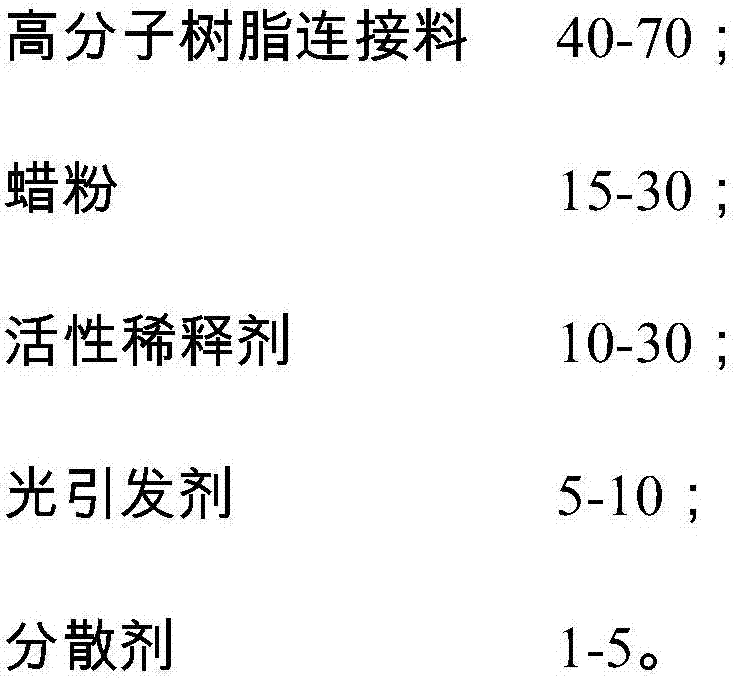

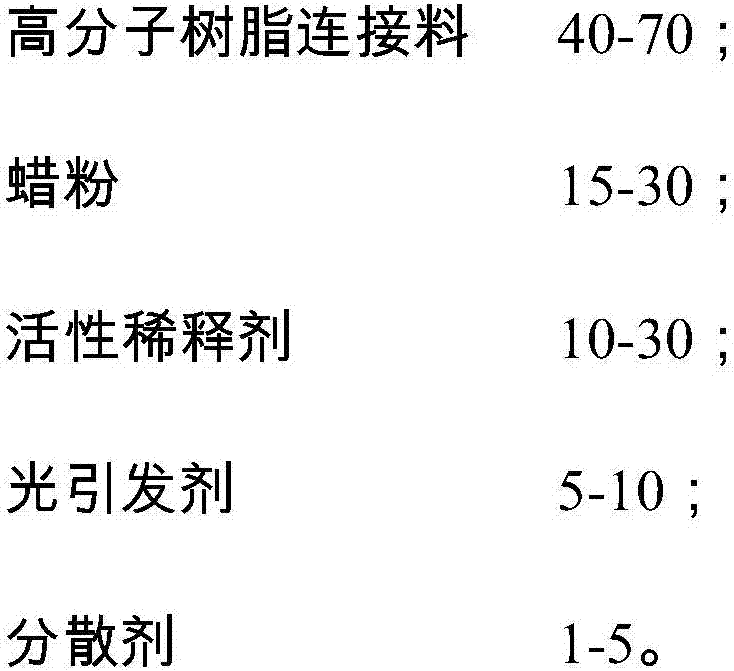

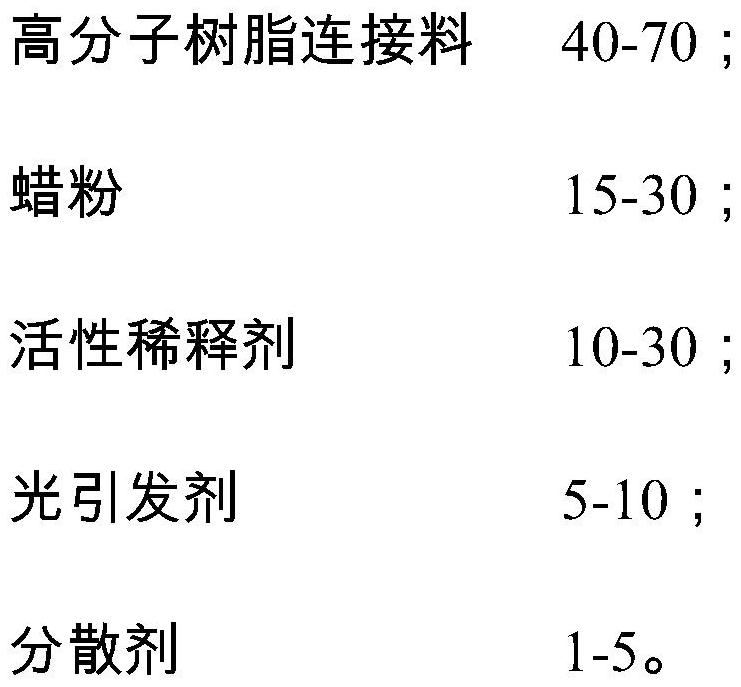

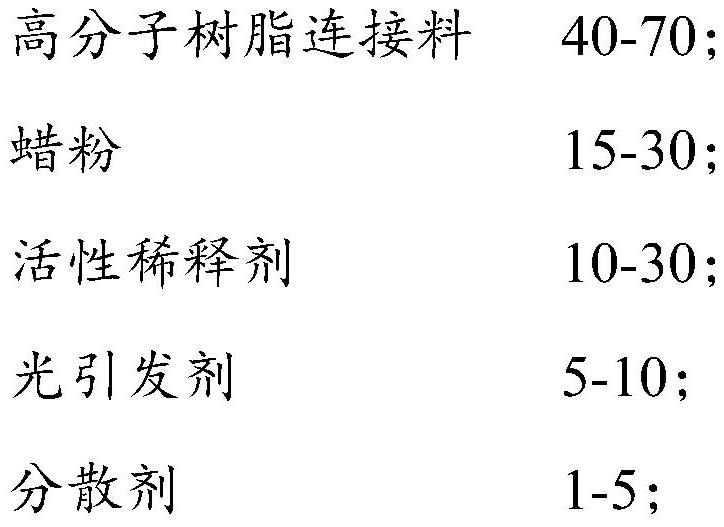

UV offset printing frosted ink, and preparation method thereof

The invention discloses a UV offset printing frosted ink, and a preparation method thereof. the UV offset printing frosted ink is composed of, by weight, 40 to 70 parts of a high molecular resin binder, 15 to 30 parts of wax powder, 10 to 30 parts of an active diluents, 5 to 10 parts of a photoinitiator, and 1 to 5 parts of a dispersant. The UV offset printing frosted ink contains no volatile solvent; the VOC content is capable of satisfying requirements in tobacco industry environmental protection standards; screen printing steps are reduced; production efficiency is increased; production cost is reduced; printing printability is excellent; and excellent offset printing effect is achieved.

Owner:深圳市深赛尔股份有限公司

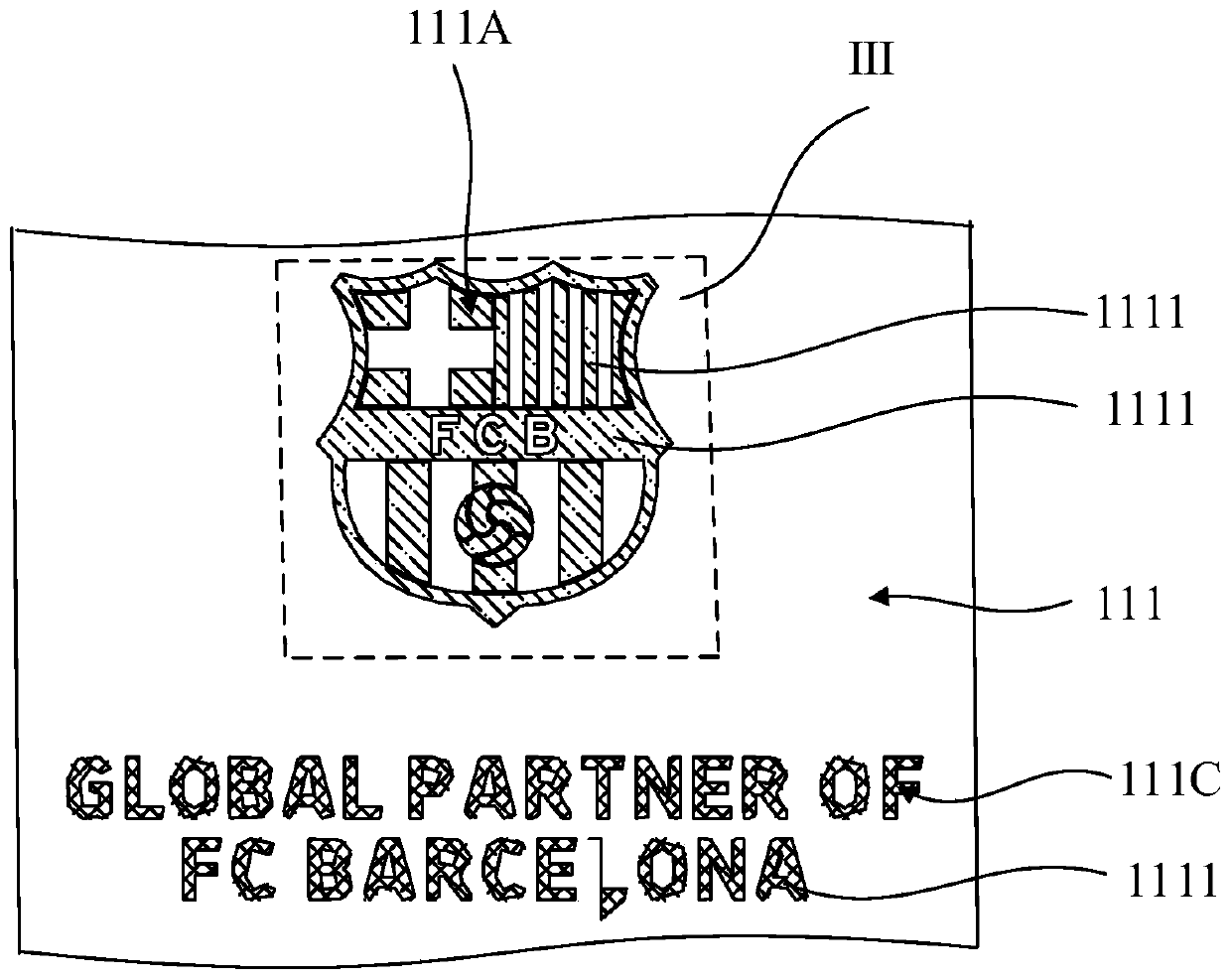

Shell assembly, preparation method thereof and electronic device

InactiveCN110381185AWith matte effectGlossySpecial ornamental structuresTelephone set constructionsEngineeringElectronic equipment

The invention relates to a shell assembly, a preparation method thereof and an electronic device. The shell assembly comprises a transparent substrate and a reflection unit, the transparent substrateis provided with a decorative surface, and a plurality of spaced rough areas are arranged on the decorative surface. The reflection unit is arranged on the decorative surface, covers each rough area and covers a gap between the adjacent rough areas. The shell assembly is rich in style.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Flame-retardant master batch for wigs and preparation method of flame-retardant master batch

InactiveCN110746751AReflective wavelength is differentGood matte effectFlame-proof filament manufactureConjugated synthetic polymer artificial filamentsPolymer sciencePowder mixture

The invention relates to a flame-retardant master batch for wigs and a preparation method of the flame-retardant master batch. The flame-retardant master batch for wigs comprises the following components in parts by mass: 100 parts of a resin, 65-70 parts of flame retardant, 60-70 parts of a matte powder mixture, 3-5 parts of a smoothing dispersant, 1-2 parts of a silane coupling agent, 0.4-0.5 part of an antioxidant and 0.4-0.5 part of an antistatic agent. The flame-retardant master batch for wigs, which is provided by the invention, is high in flame retardance efficiency, free of halogen, good in environment protection, good in liquidity, excellent in dispersion performance and low in cost, a wig prepared by the flame-retardant master batch is excellent in flame retardance performance and good in heat resistance and smoothness, and meanwhile has a matte effect, and in addition, the preparation method of the flame-retardant master batch for wigs, which is provided by the invention, issimple in process and applicable to mass production.

Owner:JIANGYIN SHENGSAI COLOR MASTERBATCH

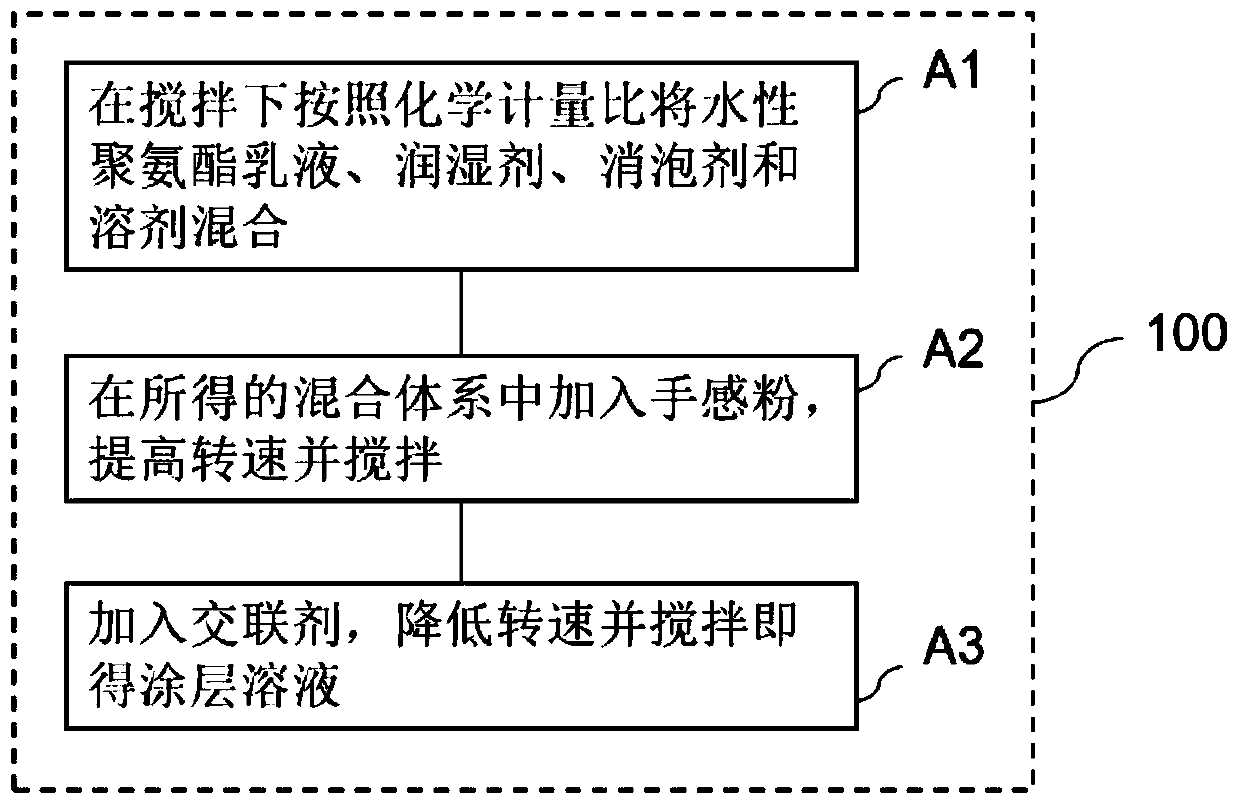

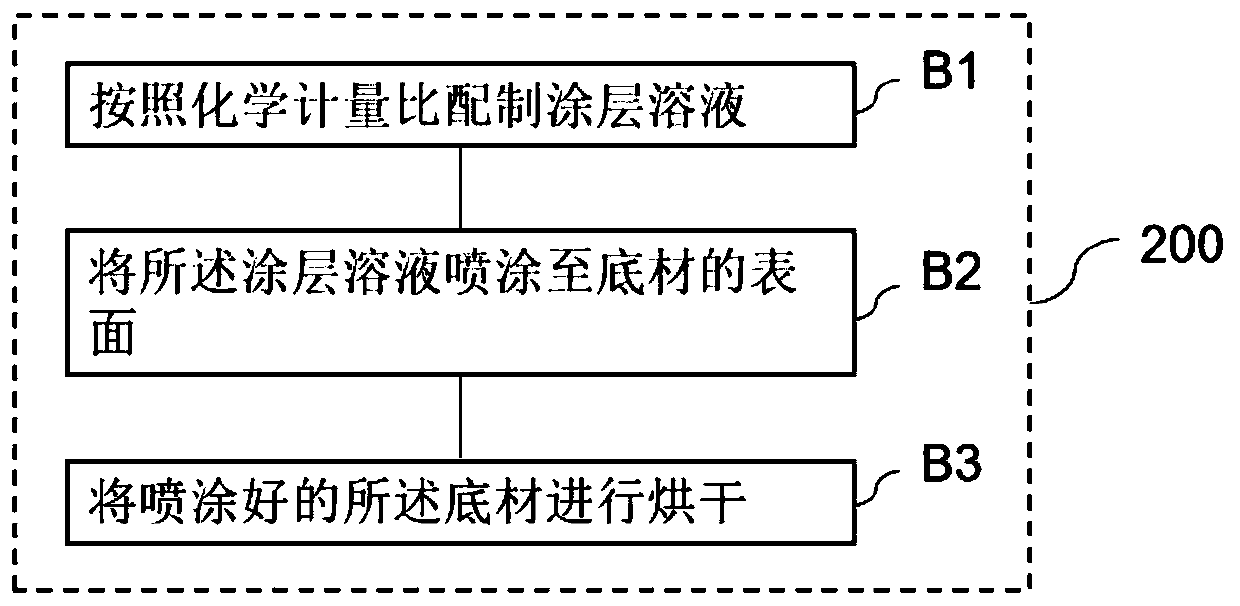

Coating formula, preparation method and coating method thereof

The invention discloses a coating formula, a preparation method and a coating method thereof. The coating formula comprises the following ingredients in percentage by weight: 45-50 percent of water-based polyurethane emulsion, 5 percent of handfeeling powder, 3-4 percent of a crosslinking agent, 0.5-1 percent of a defoaming agent, 0.5-1 percent of a wetting agent and 40-45 percent of a solvent. According to the coating formula, a coating can be formed on a base material, has the advantages of scratch resistance, matting performance, non-glare performance and the like, and has a certain velveteffect.

Owner:常州正邦数码科技有限公司

An anti-oxidation oil-absorbing drawing board

ActiveCN105421082BHas antioxidant propertiesDo not fadeFibre treatmentParaffin oilsOxidation resistant

An antioxidant ink-absorbing sketchpad is prepared according to the preparation procedures that firstly, 30-40 parts of yellow gum, 5-10 parts of chlorinated paraffin and 60-80 parts of water are added into a reaction kettle and stirred, the rotation speed of stirring is 1800-2000 r / min, and clean paste is obtained and sprayed to the surface of a base material; secondly, 70-80 parts of quartz sand, 70-80 parts of marble powder and 150-200 parts of deionzed water are mixed and stirred, the stirring speed is 3000-3500 r / min, 70-80 parts of acrylate, 70-80 parts of white glue, 20-30 parts of an adhering agent and 5-10 parts of a surfactant are added, stirred and mixed, the rotation speed of stirring is 2000-2500 r / min, surface paste is obtained, the base material obtained in the first step is coated with the surface paste through the shower coating technology, and then drying is performed. The antioxidant ink-absorbing sketchpad has oxidization resistance and will not become yellow or fade, and paintings can be preserved for a long time; surface tension of the sketchpad is balanced, the sketchpad has the dull polish effect and is high in ink absorbing performance, and drying of the paintings is fast.

Owner:沭阳凤凰画材有限公司

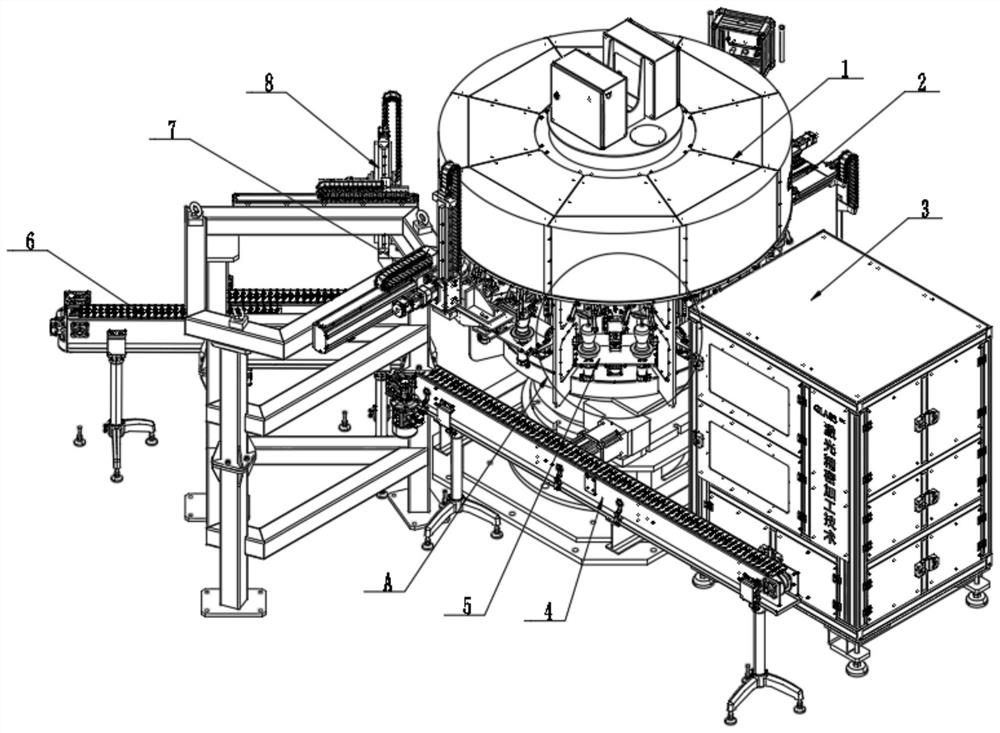

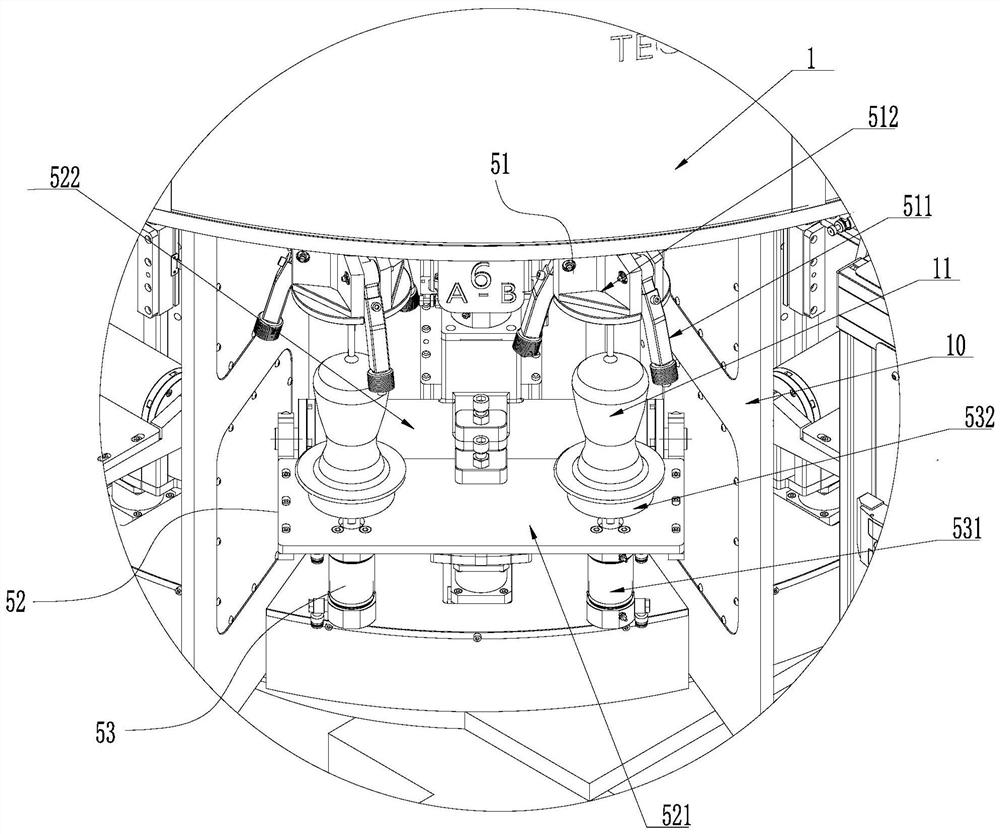

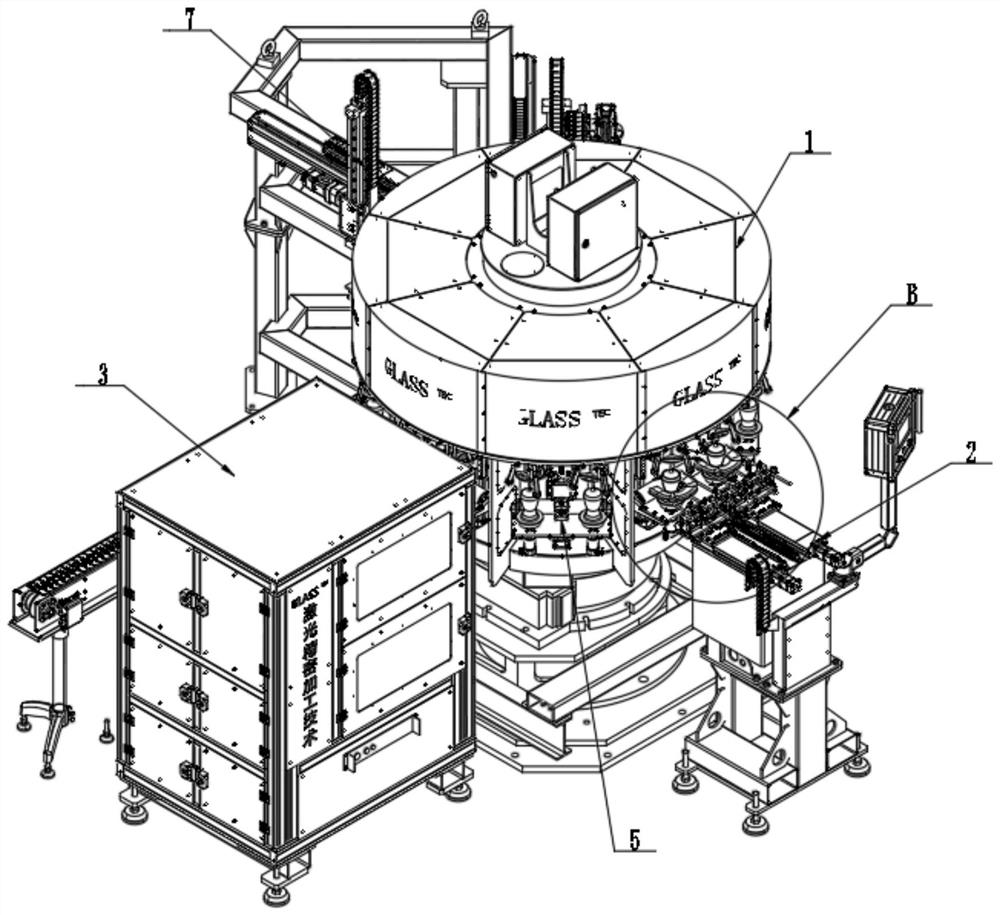

Glassware laser cutting equipment

PendingCN114393326AReduce generationHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesGlass vesselEngineering

The invention discloses laser cutting equipment for glassware. The laser cutting equipment for the glassware comprises a rotating disc body, a laser assembly and a flame explosion opening assembly. Wherein the rotating disc body can rotate around the axis of the rotating disc body, a plurality of cup body positioning devices are arranged on the rotating disc body in the circumferential direction of the rotating disc body, and the cup body positioning devices are used for fixing cup bodies and can drive the cup bodies to rotate around the axes of the cup bodies; the laser assembly and the flame explosion opening assembly are sequentially distributed in the rotating direction of the rotating disc body, the output end of the laser assembly corresponds to at least one cup body positioning device, and the output end of the flame explosion opening assembly corresponds to at least one cup body positioning device; the laser assembly is used for cutting the to-be-cut part of the cup body; the flame opening explosion assembly is used for heating the cutting position of the cup body so that the cup body can be separated from the material cap. The problems that in the related technology, when the glassware is cut, chippings, fragments and micro cracks are likely to be generated, so that the strength of the cutting edge is reduced, and the machining efficiency is low are solved.

Owner:山西大华玻璃智能制造有限公司

Preparation process of ultrathin foam cotton

InactiveCN110607138AImprove performanceAchieve uniformityNon-macromolecular adhesive additivesFilm/foil adhesivesSkin treatmentsSolvent

The invention discloses a preparation process of ultrathin foam, which comprises the following steps: A, foam production: firstly carrying out skinning treatment, carrying out glue transfer coating byusing a frosted PET film, baking the foam cotton in an oven at high temperature, drying the solvent, and directly rolling the foam cotton; B, direct coating of the produced foam leather: coating thefoamed glue on the foam cotton skin, and baking the foam cotton skin in an oven until the solvent is completely volatilized; C, taking out the dried foam cotton from the drying oven, and then compounding and rolling the foam with a double faced adhesive tape which is prepared in advance; D, aging rolled foam in a curing room, stripping off a frosted film on the foam leather and the foam are peeledand separately rolling the materials on a coating machine. The production process is simple, the cost is low, the quality is stable, meanwhile, the coating uniformity of the foam can be achieved, andthe produced foam is good in resilience, free of reverse adhesion, stable in foam performance and long in service life.

Owner:NANTONG KANGERLE MEDICAL MATERIALS CO LTD

A kind of modified hydroxyacrylic acid aqueous dispersion with matt effect and preparation method thereof

ActiveCN106957393BWith matte effectSolving Dispersion ProblemsCoatingsPolyethylene oxideAcrylic resin

The invention discloses a modified hydroxy acrylic acid aqueous dispersion with a honed effect and a preparation method thereof. The modified hydroxy acrylic acid aqueous dispersion is prepared from the following raw materials by weight percent: 20-35wt% of methyl methacrylate, 5-15wt% of isooctyl oleate, 3.1-6.2wt% of acrylic acid, 0.1-1wt% of polyethylene oxide, 5-10wt% of N,N-dimethylethanolamine, 3-5wt% of an organic solvent, 30-50wt% of deionized water, 2-4wt% of initiator and 1-2wt% of chain transfer agent. The preparation method comprises the following steps: polymerizing solution under the existence of polyethylene oxide, thereby preparing a hydroxy acrylic resin; adding N,N-dimethylethanolamine and adding water for diluting, thereby acquiring the modified hydroxy acrylic acid aqueous dispersion. After a curing agent is added for curing the product prepared according to the invention into a film, the polymer for forming the coating is crystal state and amorphous state coexisting system and the transparency of the coating is greatly reduced, so that the extinction effect is achieved and the modified hydroxy acrylic acid aqueous dispersion can be used as a honed finishing coat.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

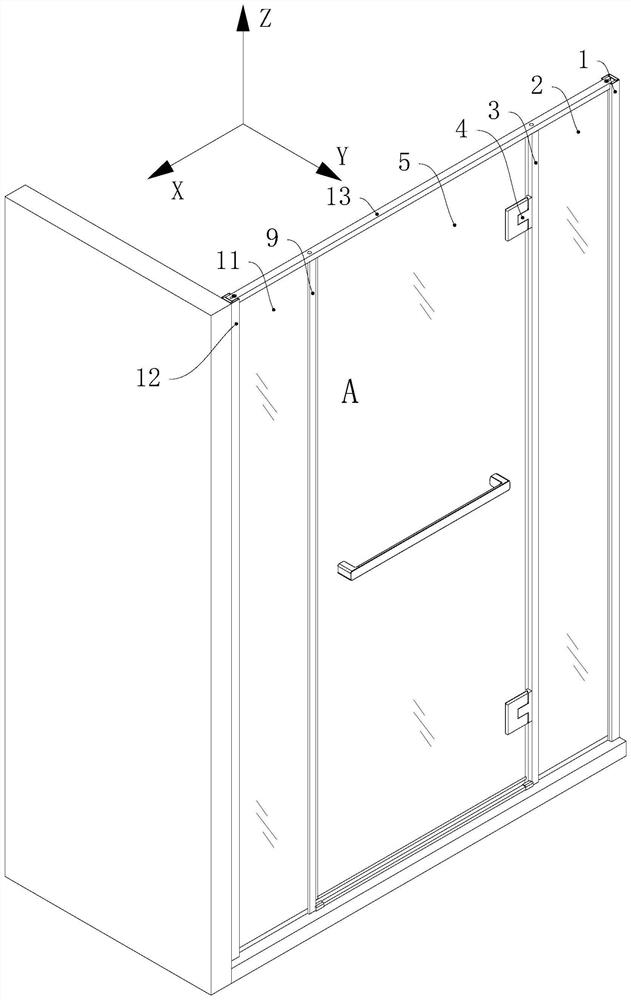

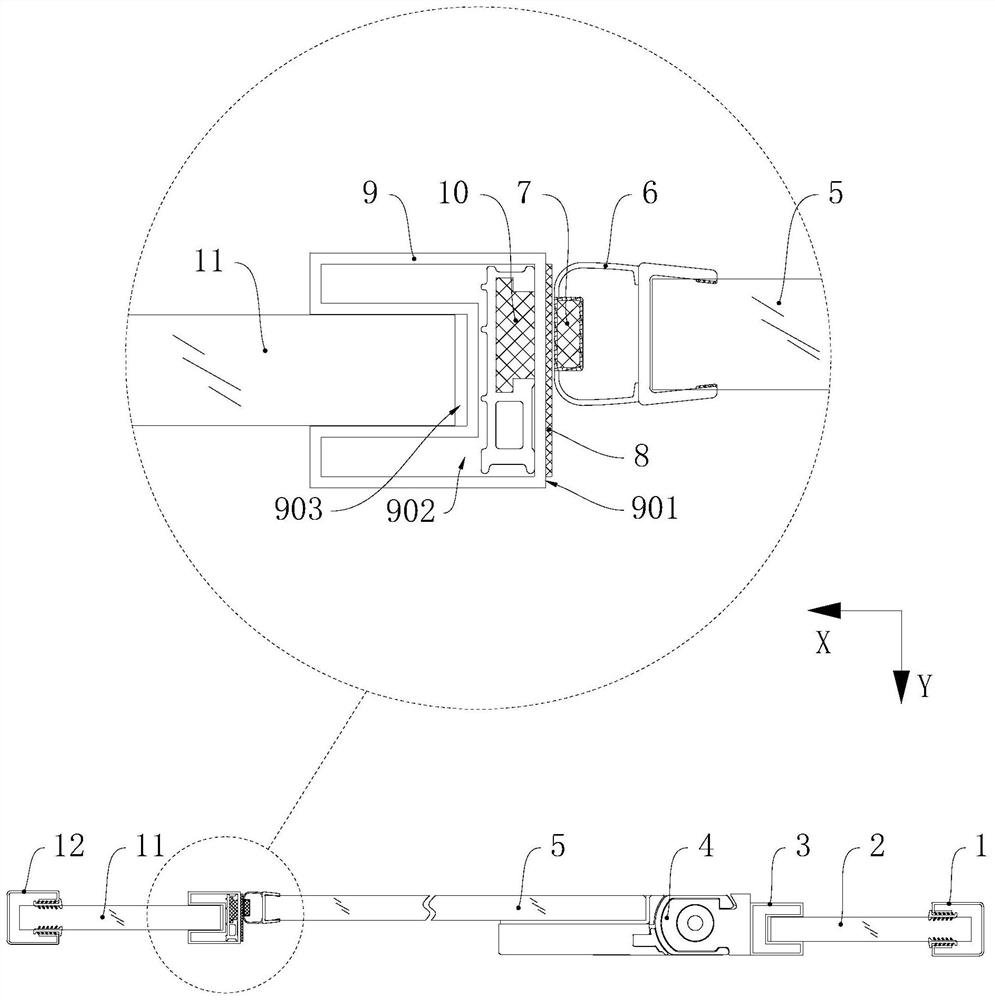

Shower door assembly

PendingCN112145033ASimple structureGood lookingWindow/door framesSealing arrangementsBathroom EquipmentStructural engineering

The invention relates to the field of bathroom equipment, and provides a shower door assembly. The shower door assembly comprises a first fixed base body, hinges, a movable door plate and a second fixed base body which are sequentially distributed in the first horizontal direction. The movable door plate is rotatably connected with the first fixed base body through the hinges; a vertical frame isof a tubular structure extending in the vertical direction, a first magnetic attraction part is fixed in a tubular cavity of the vertical frame, and the vertical frame is provided with a combination face with the normal direction in the first horizontal direction and facing the movable door plate; a waterproof rubber part is fixed to the movable door plate, and a second magnetic attraction part isfixed into the waterproof rubber part; and a protective film is stuck on the combination face. When the shower door assembly is in a closed state, the thickness of the movable door plate is in the second horizontal direction, the second horizontal direction is perpendicular to the first horizontal direction, and the waterproof rubber part is forced to make sealing contact with the protective filmthrough attraction force between the first magnetic attraction part and the second magnetic attraction part. According to the shower door assembly, excessive collision noise cannot be generated whenthe door is closed, and the combination surface is not prone to being scratched.

Owner:IDEAL SANITARY WARE CO LTD

A kind of processing method of frosted ceramics

ActiveCN102825550BWith matte effectHigh hardnessBlast gunsAbrasive feedersMachined surfaceProduct processing

Owner:CHAOZHOU THREE CIRCLE GRP

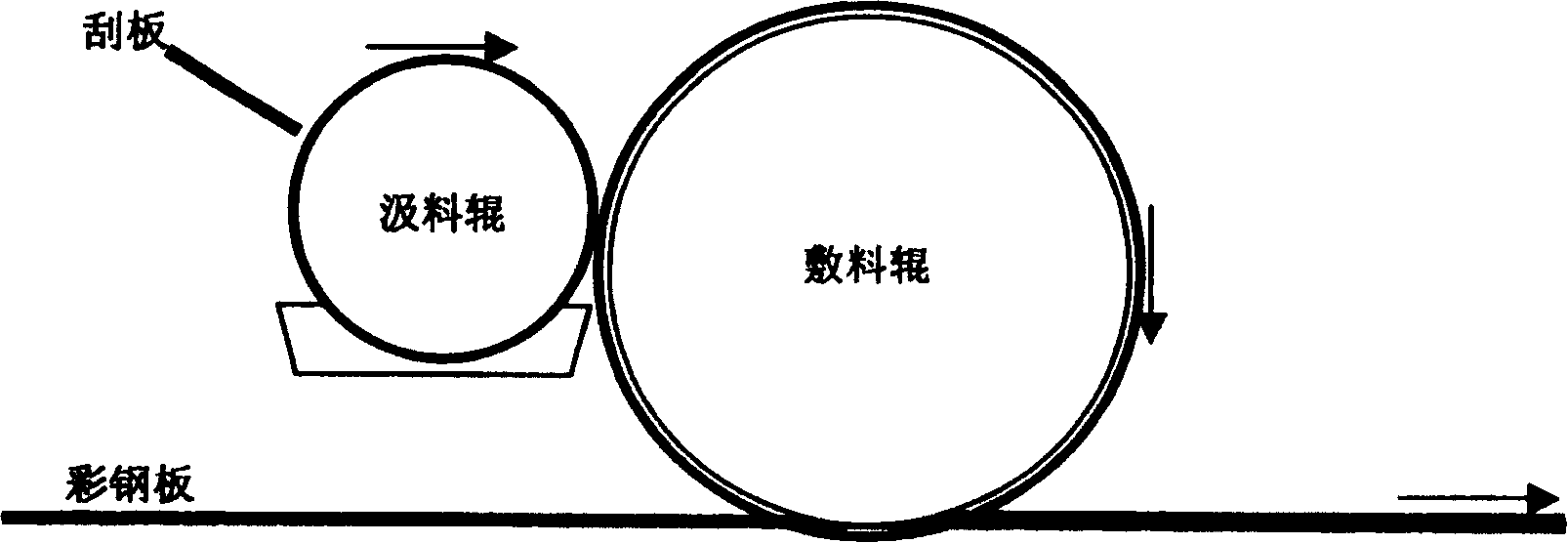

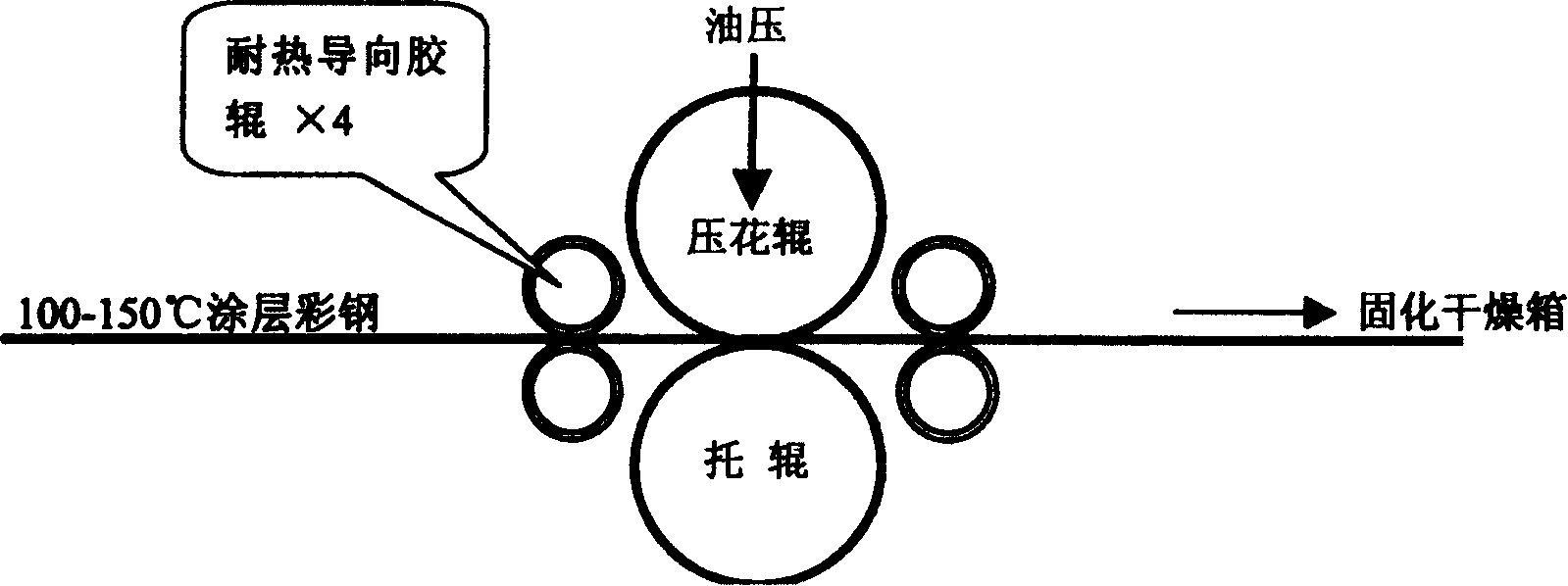

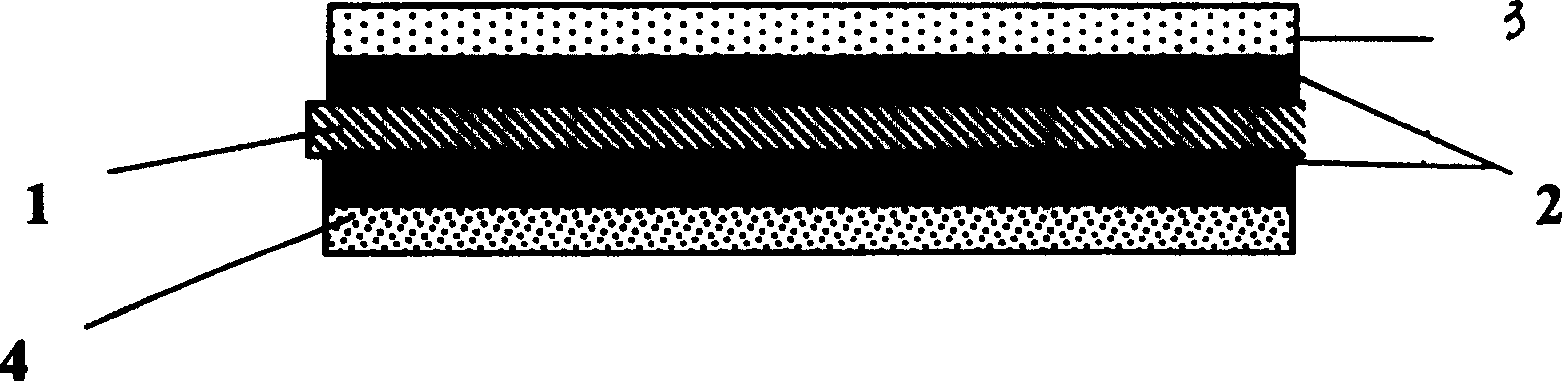

Method for continuous production of sub-brightness abbatre coloured steel-plate

InactiveCN100382898CAdjust content ratioWith matte effectLiquid surface applicatorsDecorative surface effectsCold airSheet steel

A technology for continuously producing the dull multi-color steel sheet with concave-convex pattern includes such steps as continuously feeding steel sheet, reversely coating the dull surface paint, baking the surface solvent by hot air, blowing cold air to make its surface become non-adhesive, embossing by embossing roller to form concave-convex pattern, baking by hot air to solidify the paint, thermotransfer printing, with thermotransfer film and hot rubber drum, cooling by cold air, and removing used film.

Owner:JIANGSU HAILU TECH

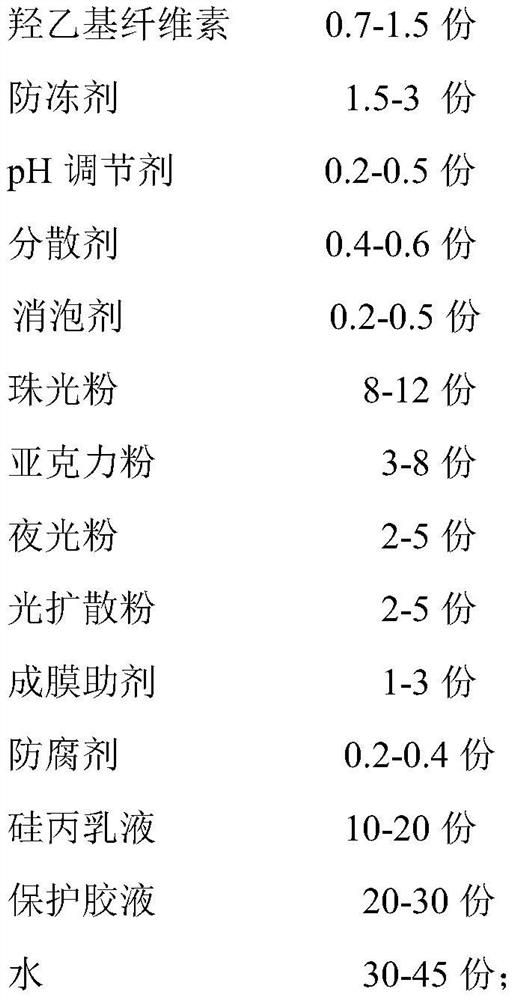

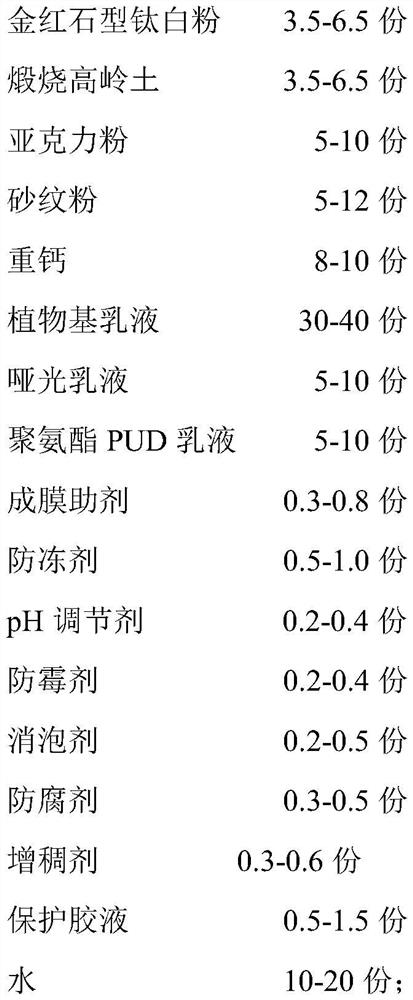

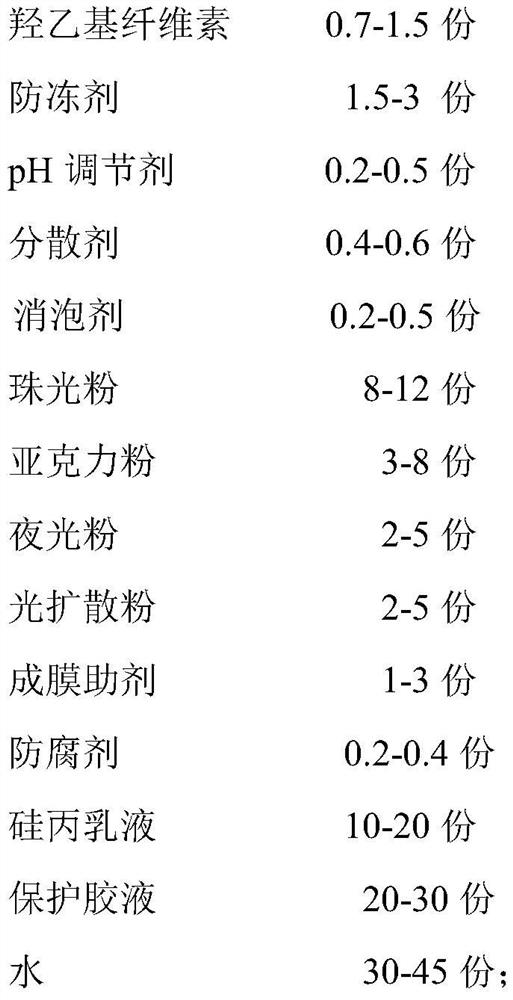

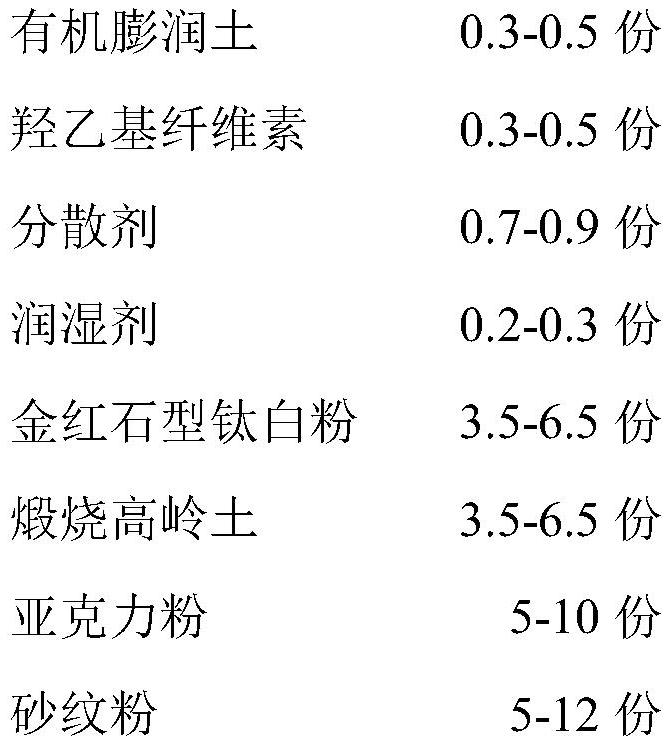

Colorful plant-based aldehyde-removing mildew-proof interior wall paint and preparation method thereof

ActiveCN113980526BEasy constructionNo unevennessAntifouling/underwater paintsLuminescent paintsPolymer scienceEmulsion

The invention relates to a colorful plant-based aldehyde-removing and mildew-proof interior wall paint and a preparation method thereof, which comprises the following dispersed phase and continuous phase latex paint, and the mass fraction ratio of the dispersed phase and the continuous phase latex paint is 5-40:60 -95; Wherein, described dispersed phase comprises following base paint and protective colloid, the mass and number ratio of described basic paint and protective colloid is 1:1.5-2.5. This invention overcomes the disadvantages of the existing water-based multi-color coatings when used on the interior wall, such as the need for overlay, easy to cause visual fatigue, and unsuitable for large-scale construction. Particles are added to the continuous phase based on interior wall latex paint, and combined with protective glue, light diffusion powder, acrylic powder, sand grain powder, plant-based emulsion, polyurethane PUD emulsion and other preferred raw materials, the paint film is smooth and smooth. It has the advantages of frosted feeling, no need for overlay, high hardness of paint film, can cover fine cracks, good wall art effect, energy saving and environmental protection.

Owner:河南三棵树新材料科技有限公司

A kind of UV offset printing matte ink and preparation method thereof

ActiveCN107189540BFully consider printabilityGuaranteed matte effectInksScreen printingOrganic chemistry

The invention discloses a UV offset printing frosted ink, and a preparation method thereof. the UV offset printing frosted ink is composed of, by weight, 40 to 70 parts of a high molecular resin binder, 15 to 30 parts of wax powder, 10 to 30 parts of an active diluents, 5 to 10 parts of a photoinitiator, and 1 to 5 parts of a dispersant. The UV offset printing frosted ink contains no volatile solvent; the VOC content is capable of satisfying requirements in tobacco industry environmental protection standards; screen printing steps are reduced; production efficiency is increased; production cost is reduced; printing printability is excellent; and excellent offset printing effect is achieved.

Owner:深圳市深赛尔股份有限公司

Colorful plant-based formaldehyde-removing mildew-proof interior wall coating material and preparation method thereof

ActiveCN113980526AEasy constructionNo unevennessAntifouling/underwater paintsLuminescent paintsPolymer scienceMildew

The invention relates to a colorful plant-based formaldehyde-removing mildew-proof interior wall coating material and a preparation method thereof. The colorful plant-based formaldehyde-removing mildew-proof interior wall coating material comprises a dispersed phase and a continuous phase latex paint, wherein a mass part ratio of the dispersed phase to the continuous phase latex paint is (5-40): (60-95), wherein the dispersed phase comprises a base paint and a protection glue solution, and a mass part ratio of the base paint to the protection glue solution is 1: (1.5-2.5). According to the invention, the defects that when an existing water-based colorful coating material is used on an interior wall, a cover surface is needed, visual fatigue is easily caused, large-area construction is not suitable, and the like are overcome; and pearl powder and noctilucent powder serve as color point particles in water-in-water colorful, are added into a continuous phase with interior wall latex paint as a base, and are cooperated with a protection glue solution, light diffusion powder, acrylic powder, sand texture powder, plant-based emulsion, polyurethane (PUD) emulsion and other preferable raw materials, so that the coating material has the advantages of flat and smooth paint film, frosted feeling, no need of cover surface, high paint film hardness, capability of covering fine cracks, good wall artistic effect, energy saving and environmental protection.

Owner:河南三棵树新材料科技有限公司

PET film frosting glue

The invention provides a polyethylene terephthalate (PET) film frosted glue which comprises the components with the content: 18-22 parts of polyvinyl butyral (PVB), 1.6-2.4 parts of silica and 150-180 parts of silica, wherein 'part' represents unit mass. A preparation technology of the PET film frosted glue comprises the following steps of: (1) mixing the alcohol and the silica in proportion and evenly stirring the solution; (2) slowly adding the needed PVB into the solution obtained in the step (1), and evenly stirring; and (3) sealing, standing still and defoaming. The PET film frosted glue has the beneficial effects that after being spread onto a PET film, the PET film frosted glue can firmly attach on the surface of the PET film so as to lead the PET film to have frosting effect, the physical polishing process is omitted, and the cost can be reduced.

Owner:惠州艺都文化用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com