Frosted anti-dazzle protective film and preparation method thereof

A technology of protective film and protective film layer, applied in the direction of pressure-sensitive film/sheet, film/sheet-like adhesive, adhesive type, etc. haze, light spots and other problems, to achieve the effect of improving light transmittance, good anti-glare effect and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

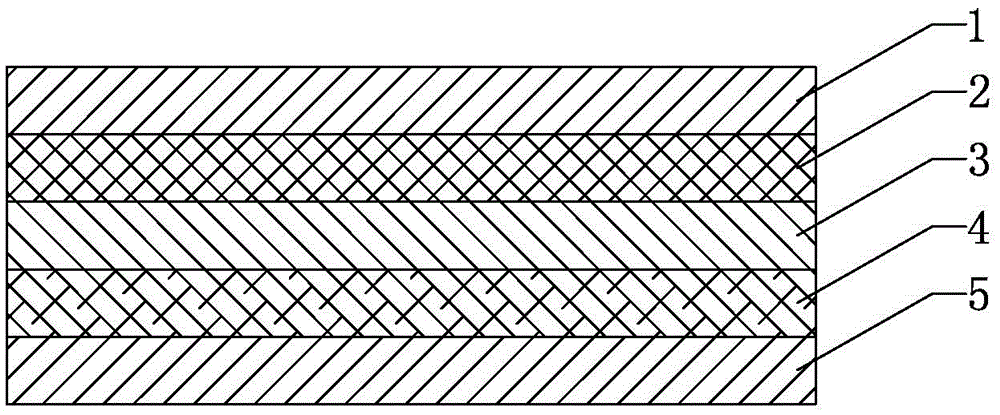

[0045] See figure 1 , a frosted anti-glare protective film, comprising a protective film layer 1, a frosted anti-glare coating 2, a substrate layer 3, an adhesive layer 4 and a peeling film layer 5 arranged sequentially from top to bottom, and the frosted anti-glare coating 2 The upper surface and the lower surface of the adhesive layer 4 are attached to the lower surface of the protective film layer 1 and the upper surface of the base material layer 3 respectively, and the upper surface and the lower surface of the adhesive layer 4 are respectively attached to the lower surface of the base material layer 3 and the release film layer 5. The upper surface fits.

[0046] The protective film layer 1 is a PE film; the upper surface of the frosted anti-glare coating 2 is provided with a textured structure; the substrate layer 3 is a PET film; the adhesive layer 4 is a pressure-sensitive adhesive coating; The peeling film layer 5 is a PET peeling film.

[0047] The thickness of th...

Embodiment 2

[0061] The difference between this embodiment and above-mentioned embodiment 1 is:

[0062] The thickness of the frosted anti-glare coating 2 is 3 μm; the thickness of the substrate layer 3 is 100 μm; the thickness of the adhesive layer 4 is 50 μm; the thickness of the release film layer 5 is 40 μm.

[0063] The raw material of the bonding layer 4 is pressure-sensitive adhesive, and the pressure-sensitive adhesive is liquid addition type reactive silica gel or liquid acrylic glue.

[0064] The raw material of the frosted anti-glare coating 2 is a mixture of thermosetting acrylic resin hardening solution and photocurable acrylic resin hardening solution in a weight ratio of 1:2; the thermosetting acrylic resin hardening solution is Wuxi Huixingxin The thermosetting anti-fog hardening solution 9511 produced by Material Co., Ltd.; the light-curable acrylic resin hardening solution is NOPCOCURE134 hardening solution produced by San Nopco.

[0065] A method for preparing a frosted...

Embodiment 3

[0076] The difference between this embodiment and above-mentioned embodiment 1 is:

[0077] The thickness of the frosted anti-glare coating 2 is 6 μm; the thickness of the substrate layer 3 is 120 μm; the thickness of the adhesive layer 4 is 100 μm; the thickness of the release film layer 5 is 50 μm.

[0078] The raw material of the bonding layer 4 is pressure-sensitive adhesive, and the pressure-sensitive adhesive is liquid addition type reactive silica gel or liquid acrylic glue.

[0079] The raw material of the frosted anti-glare coating 2 is a mixture of heat-curable acrylic resin hardening solution and light-curable acrylic resin hardening solution with a weight ratio of 1:3; the heat-curable acrylic resin hardening solution is Wuxi Huixingxin The thermosetting anti-fog hardening solution 9511 produced by Material Co., Ltd.; the light-curable acrylic resin hardening solution is NOPCOCURE134 hardening solution produced by San Nopco.

[0080] A method for preparing a frost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com