Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "With tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

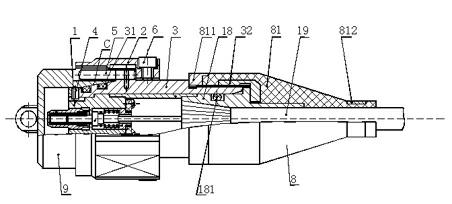

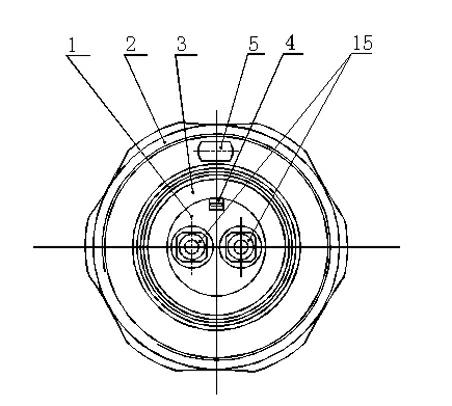

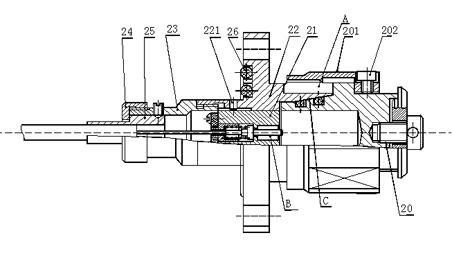

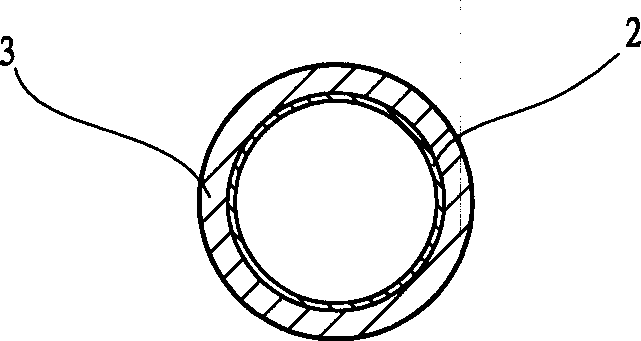

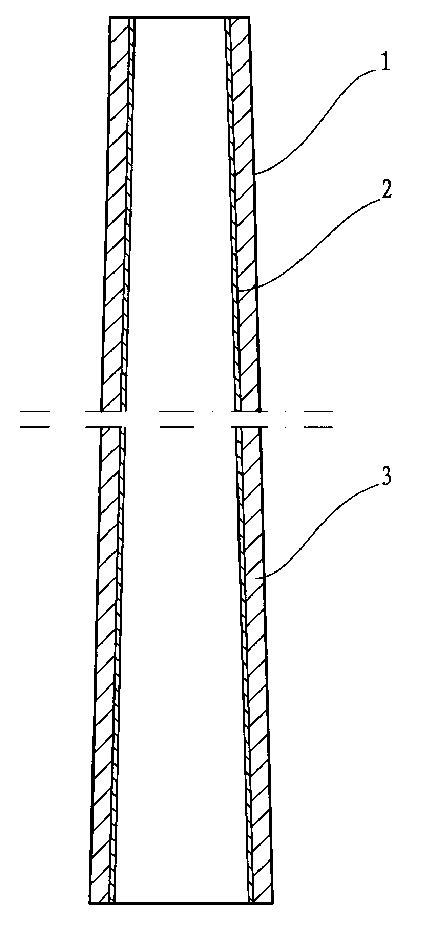

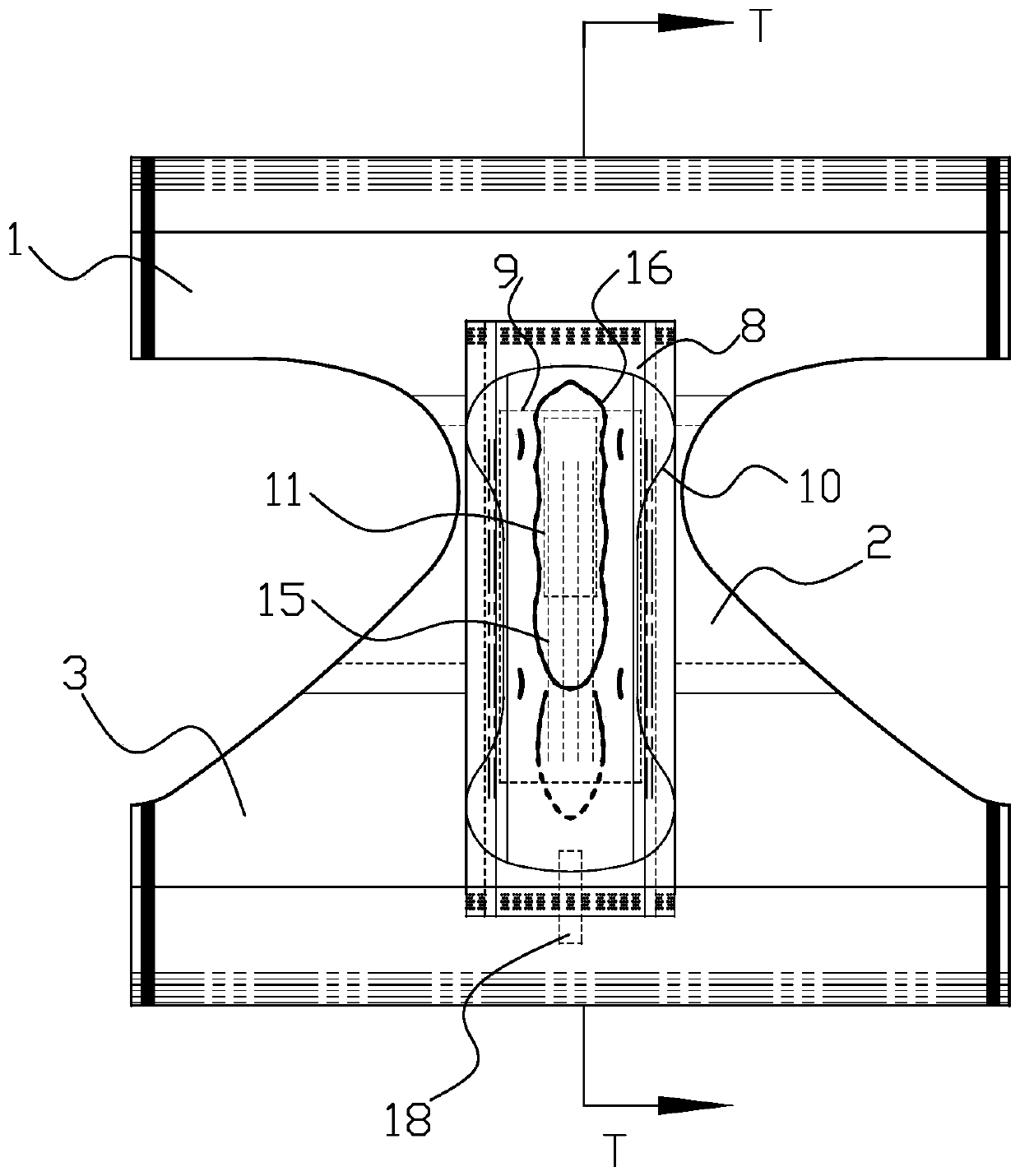

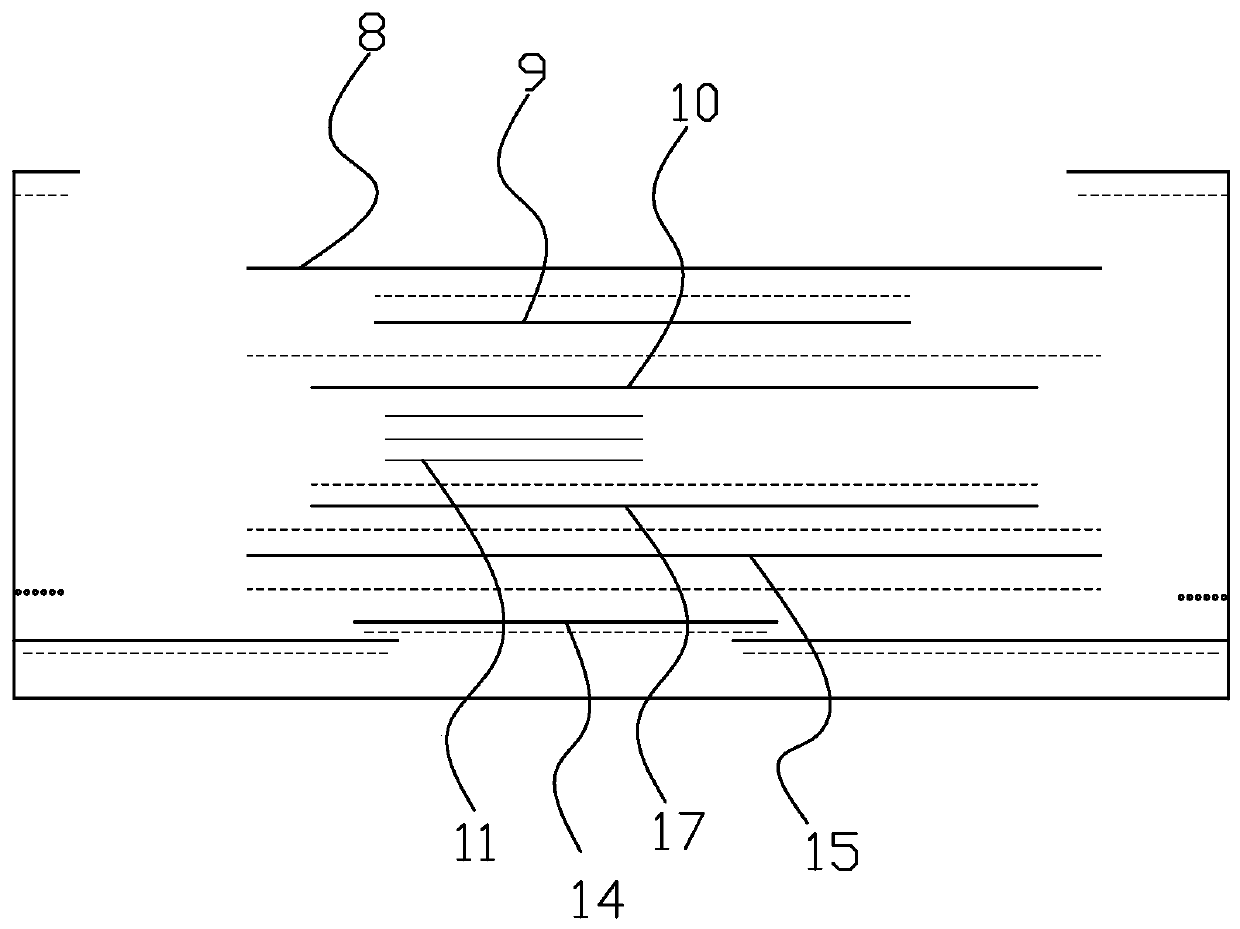

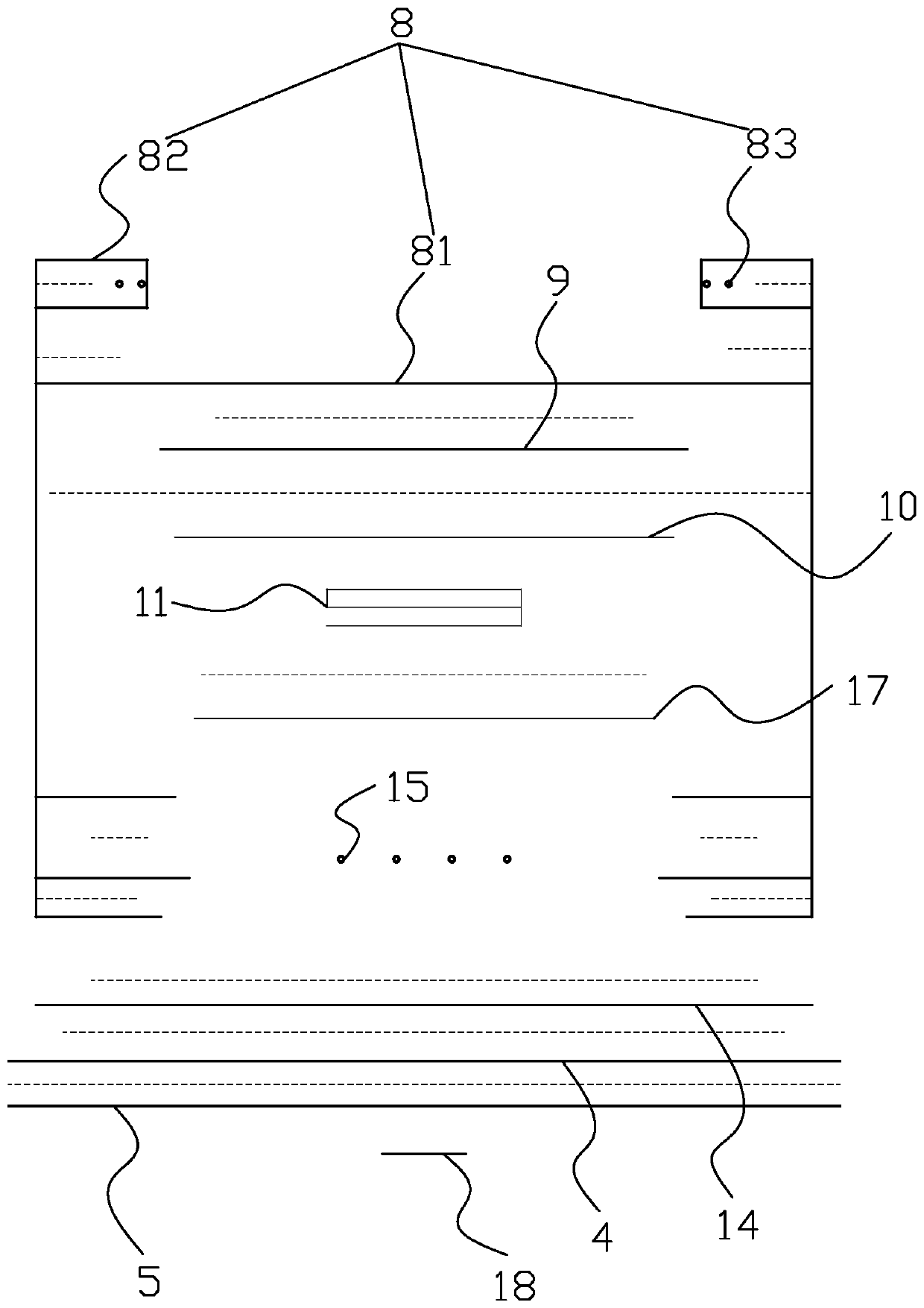

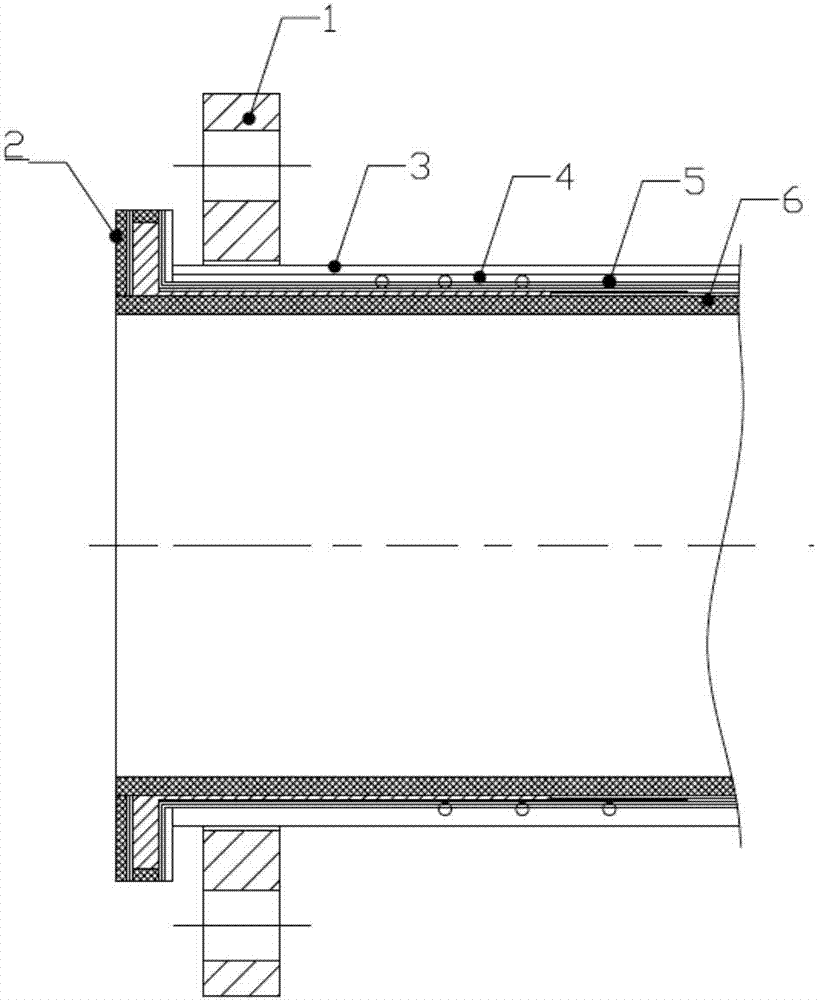

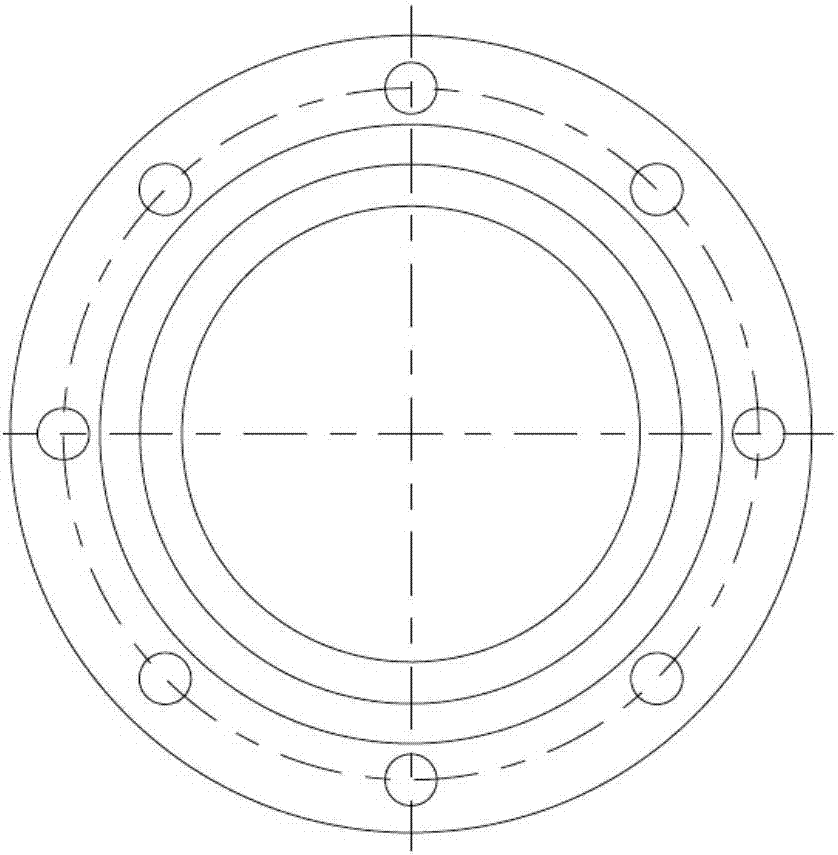

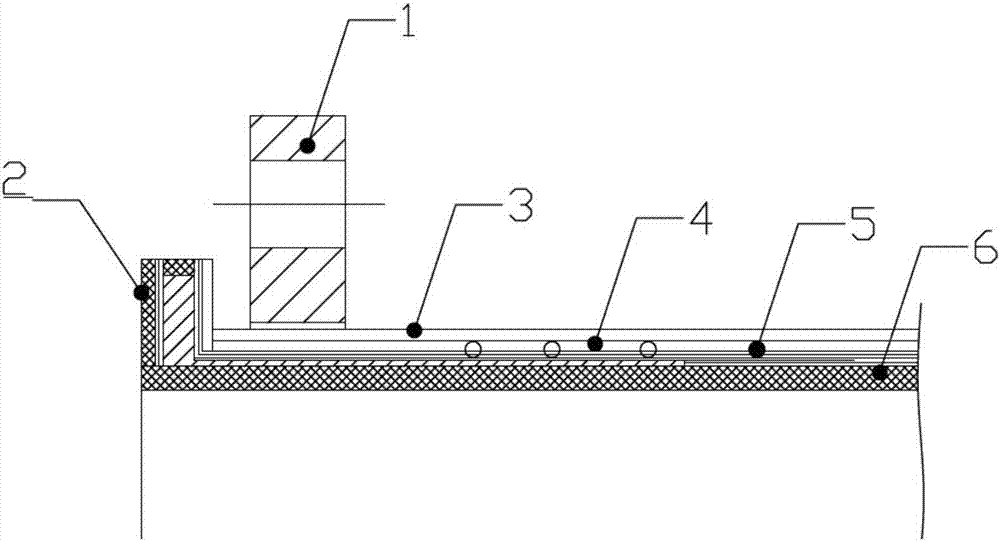

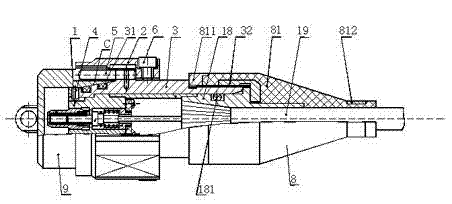

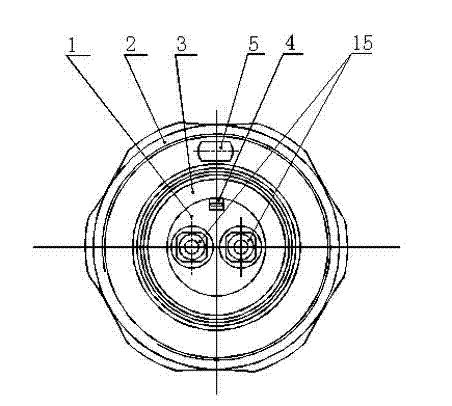

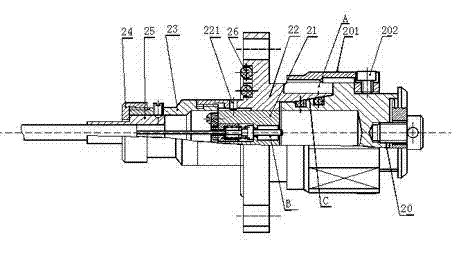

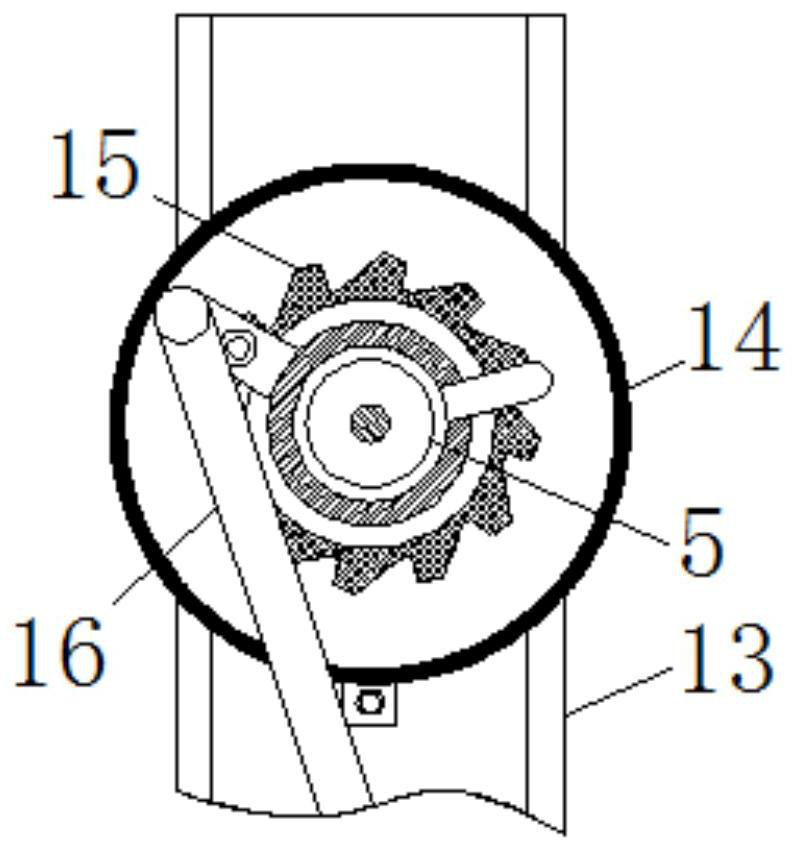

Underwater optical cable connector

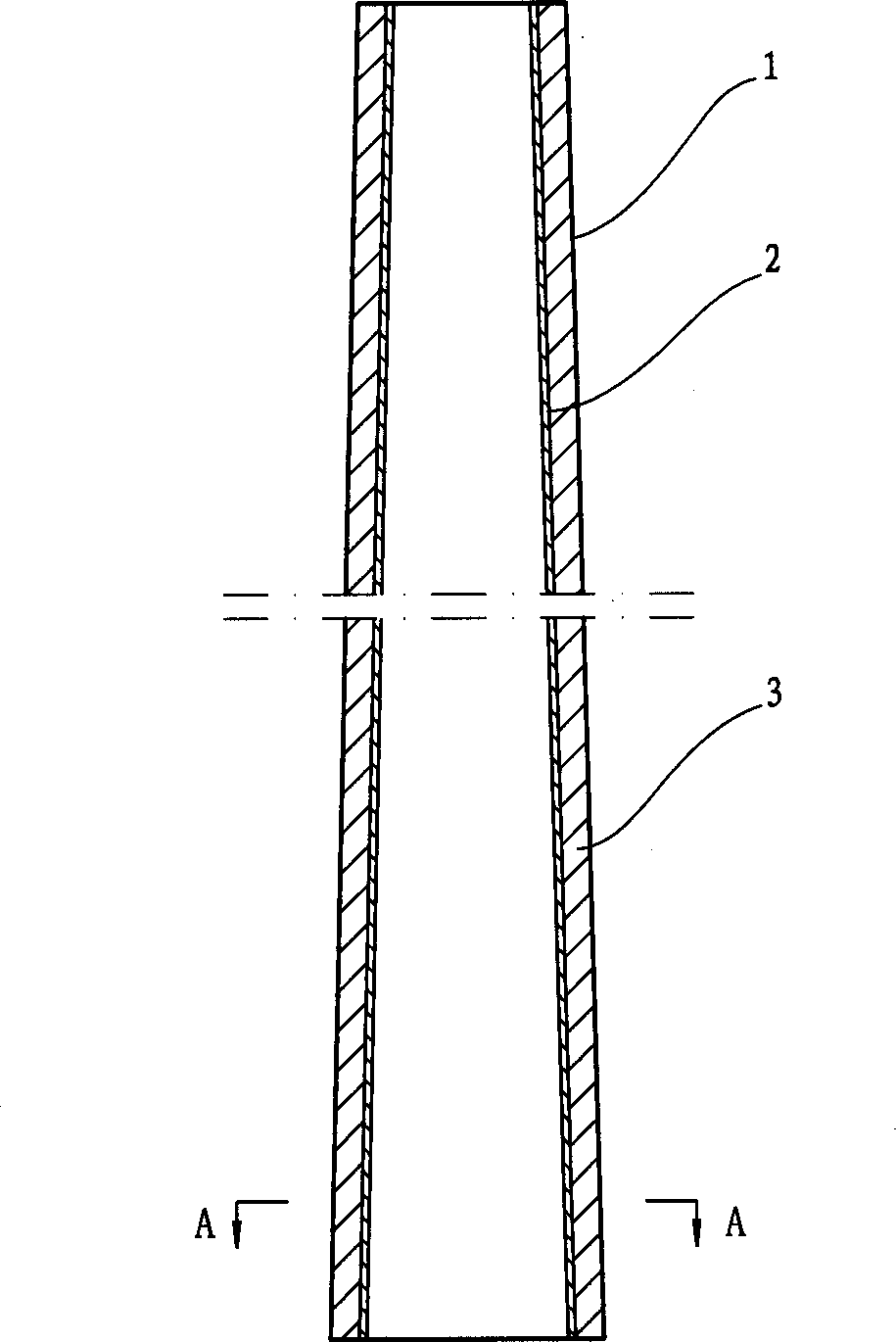

The invention relates to an optical cable connector, and provides an underwater optical cable connector, which is capable of meeting requirements on water tightness and tensile performance, and providing detachable and movable connection. The underwater optical cable connector is characterized in that mutually matched cone structures are arranged on a plug shell and a socket shell respectively sothat the plug shell and the socket shell can be in gapless sealing connection by means of insertion, a sealing connection structure is arranged between a plug and an optical cable, the space between the plug shell and a tensile taper sleeve is sealed by an 'O'-shaped sealing ring, and a sealing tail sleeve for sealing is formed in the space between the optical cable and a tail part of the whole plug by mean of integral die casting. The movable sealing connection structure is arranged between the plug and a socket of the underwater optical cable connector, the two shells are connected by cones, no gap is reserved between the inner cone and the outer cone, the space between the cones is sealed by the 'O'-shaped sealing ring, the inner cone and the outer cone are locked by a connecting nut, and the underwater optical cable connector is simple in structure, reliable in performance, extremely high in water pressure resistance and convenient in connection and detachment.

Owner:SHANGHAI FANGAO COMM TECH

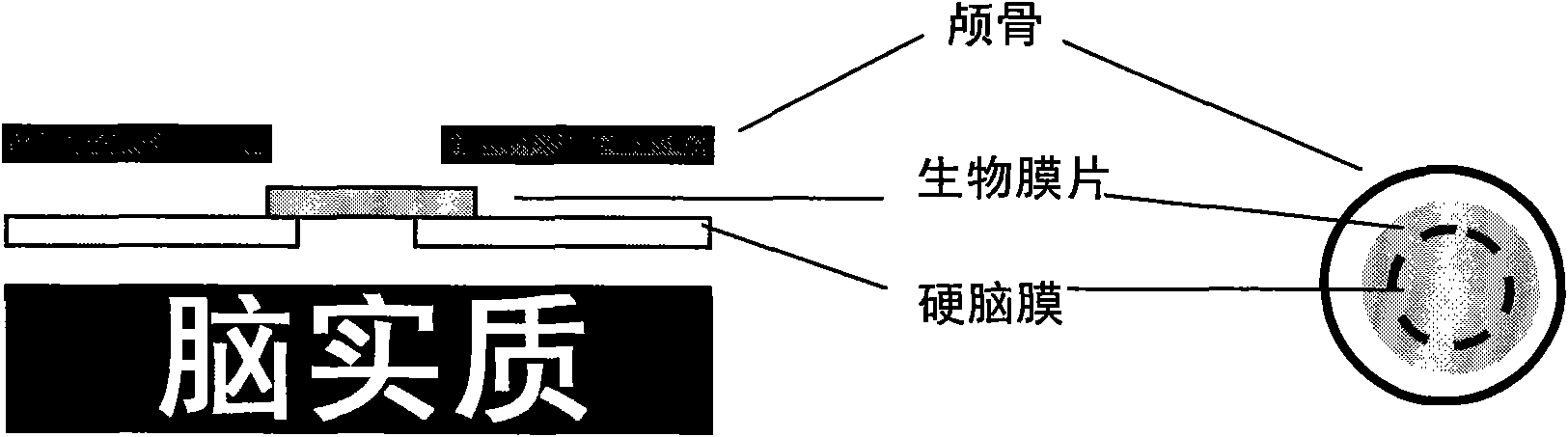

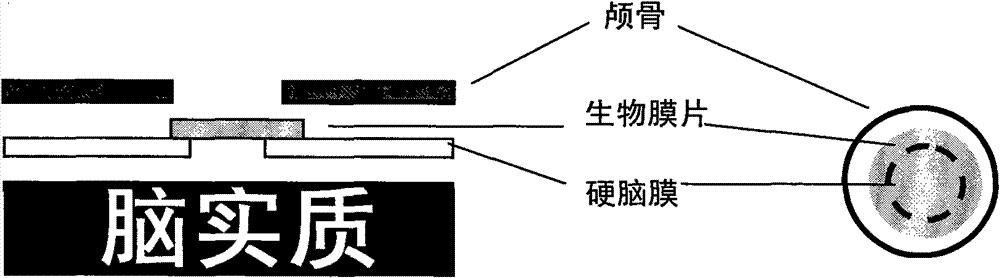

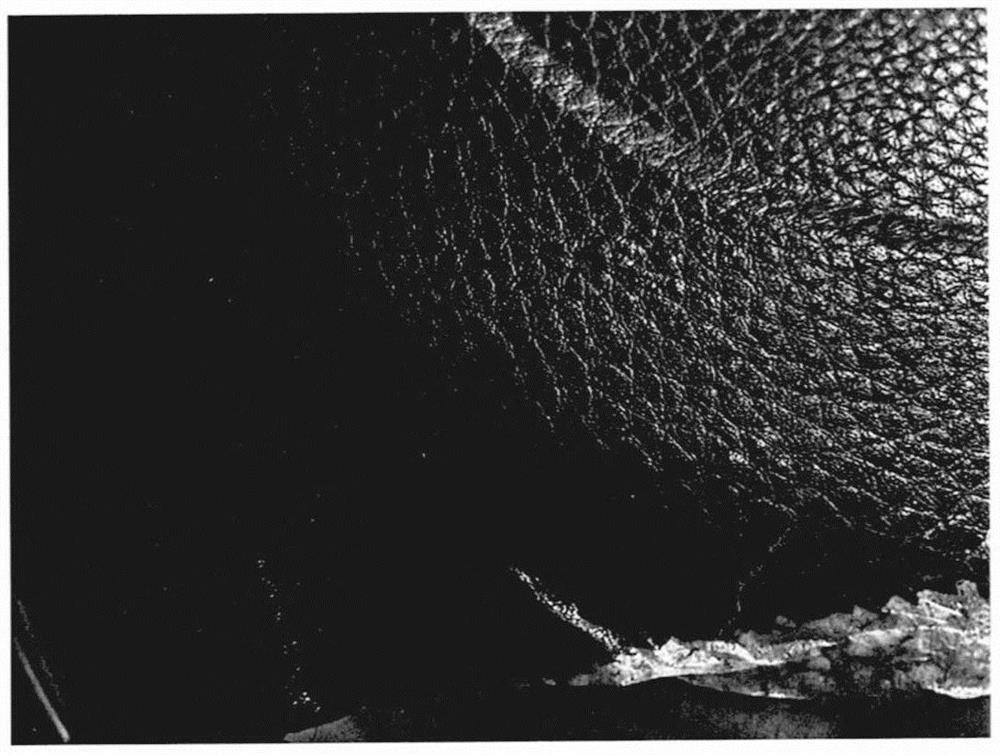

I-type medical collagen material keeping original specific triple helix structure of collagen, product and application thereof

The invention relates to an I-type medical collagen material keeping an original specific triple-helical structure of collagen, and an extraction method thereof, meninges / spinal meninges biomembrane made from the I-type medical collagen material, and a preparation process of the biomembrane, and application of the biomembrane to preparing meninges / spinal meninges tissue repair materials. The I-type medical collagen material keeping the original specific triple helix structure of collagen has the advantages of low immunogenicity, no foreign body reaction, good biocompatibility and controllabledegradation rate, the prepared meninges / spinal meninges biomembrane has certain stretching resistance strength, repairable and regenerative dura mater / spinal meninges tissue and tissue adhesion prevention / reduction, and the biomembrane is applicable to repair and regeneration of injured cerebral dura mater and spinal dura mater.

Owner:许和平

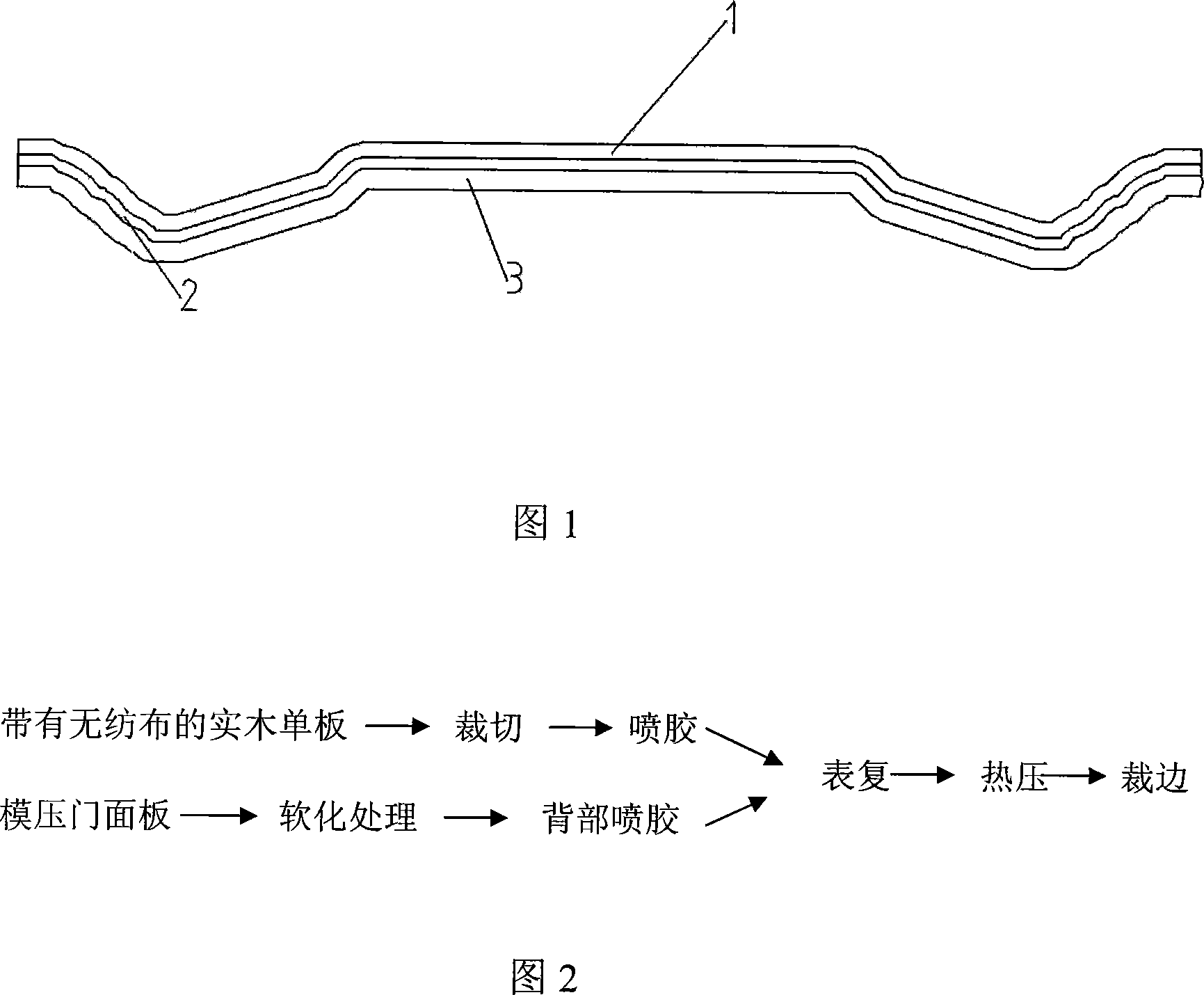

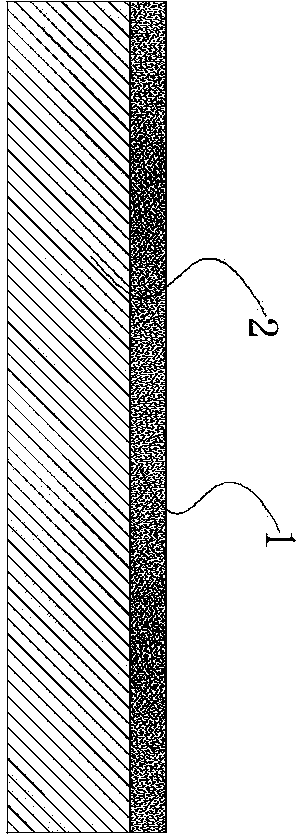

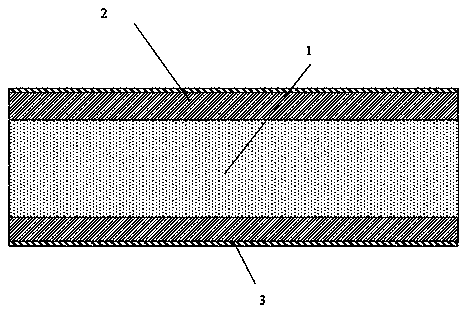

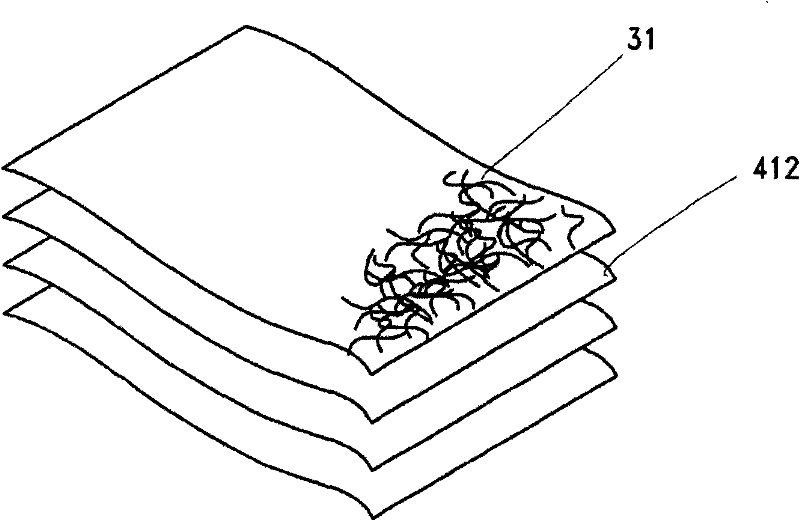

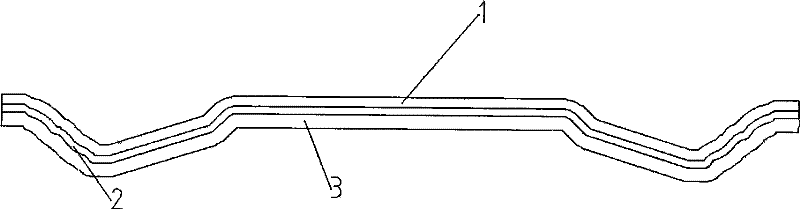

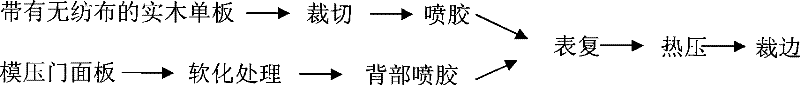

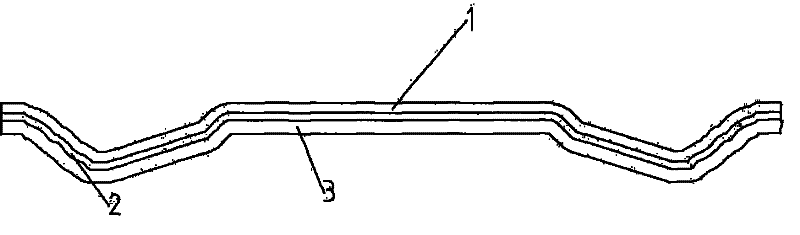

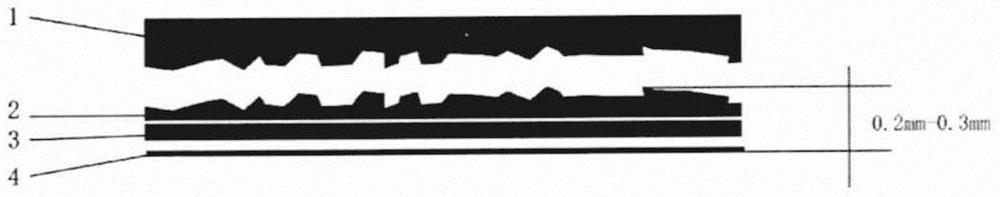

Solid wood composite coining door panel and production technology thereof

InactiveCN101116977AHigh tensile strengthSuitable for industrial scale productionWood veneer joiningSolid woodNonwoven fabric

The invention discloses a solid wood composite molded door board, belonging to a three-layer composite structure. The structure material of the first layer is natural solid wood single board or technical wood single board, the structure of the second layer is non-woven cloth and the structure of the third layer is molded door board (fiberboard). The invention also provided the manufacturing technique which is applicable to industrialized scale production and has stable quality. The invention overcomes the disadvantage of the solid wood single board which has no transverse pulling resistance strength without any material backing and is easy to break transversely; the solid wood composite molded door is a right integration of the solid wood composite door and the molded door, which not only has the advantages of the solid wood composite door that the wood surface texture true and natural, but also has the advantages of the molded door which does not craze or deform.

Owner:桦甸市城市基础设施开发建设投资有限公司

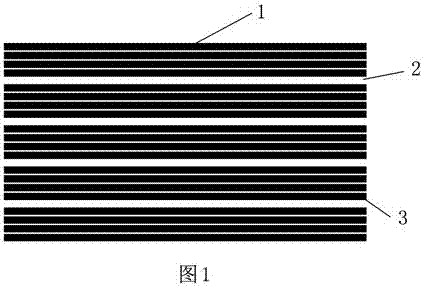

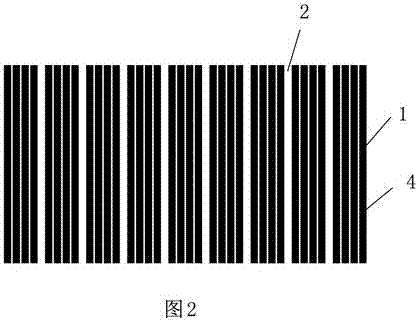

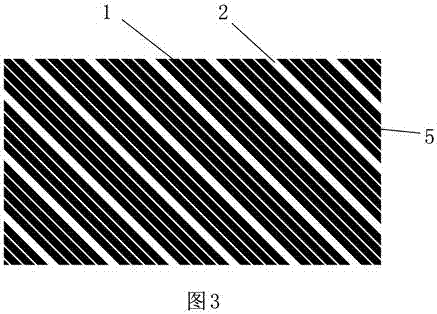

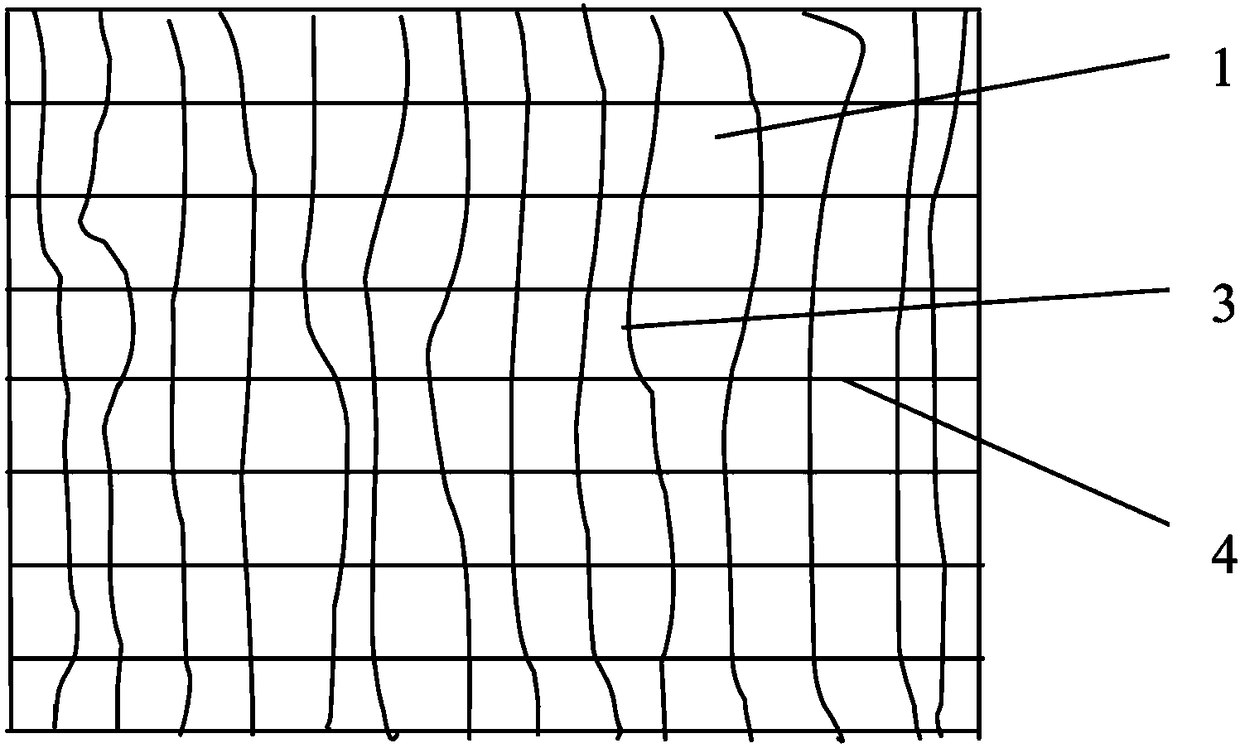

Non-woven fabric

PendingCN106988022AIncrease tow specific gravityWith tensile strengthNon-woven fabricsYarnEngineering

Disclosed is a non-woven fabric. The non-woven fabric is formed by bonding a plurality of layers. Each layer adopts a plurality of single set of densely-arranged tows, an empty gap position is arranged by a certain distance, short cut yarn is placed at the empty gap positions between the layers and the other parallel faces of a certain layer, warp direction and weft direction layers are adopted, left layers and right layers of diagonal lines between the weft and warp directions are adopted, and the non-woven fabric is formed by stacking and bonding the layers. According to the non-woven fabric, the tow specific gravity in the unit volume is increased, the diagonal directions between the weft and warp directions have the tensile strength, the shear force between the layers is increased, and the non-woven fabric is applicable to adopting fiber as reinforcing materials, plastics is the reinforcing material of the composite of the base material, the non-woven fabric is applicable to various purposes, and the non-woven fabric has the high tensile strength, high twisting power resistance, high interlayer shear force resistance and good softness.

Owner:HANGZHOU YOUKAI BOAT CO LTD

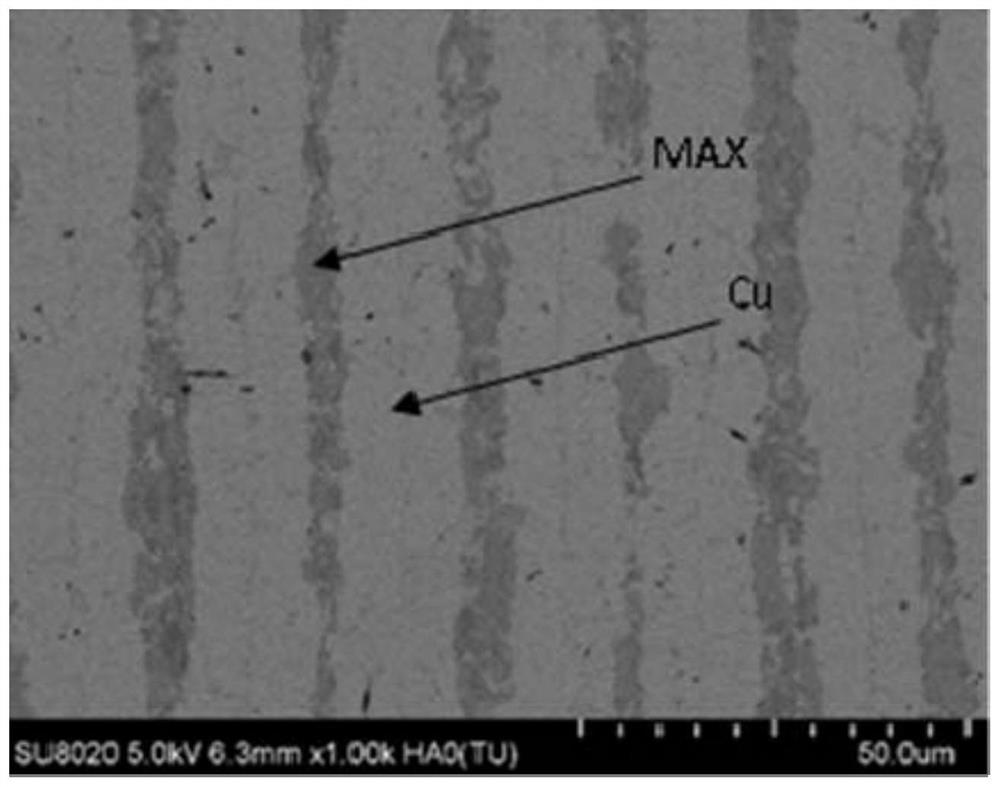

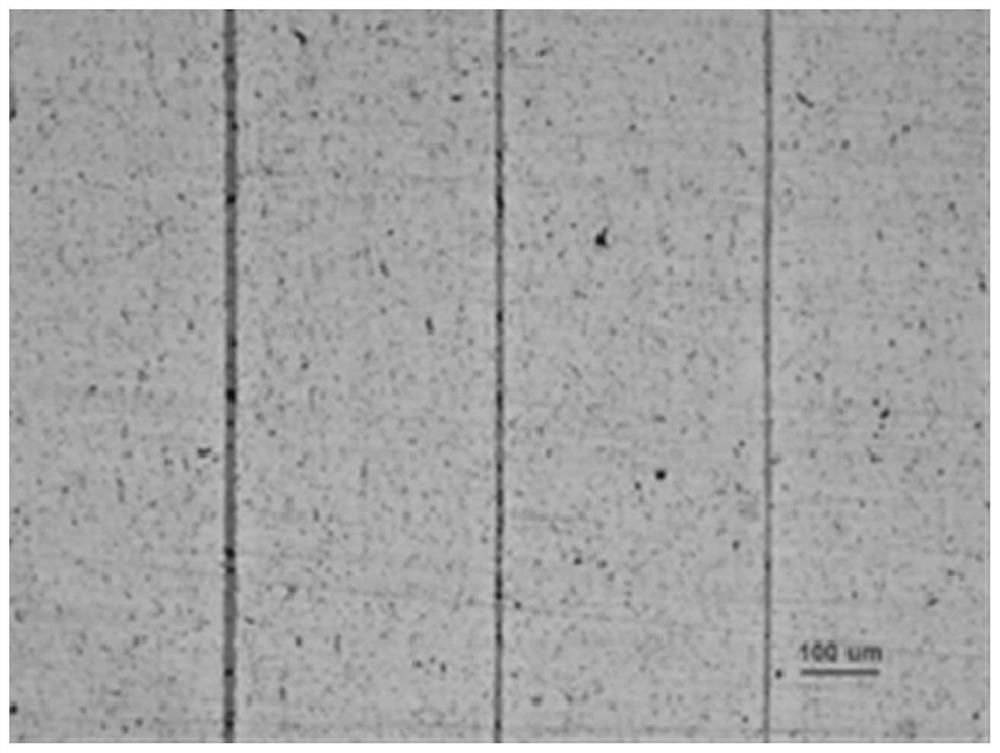

MAX phase ceramic-metal lamellar composite material, preparation method and purpose

ActiveCN109318547AImprove conductivityImprove mechanical propertiesLamination ancillary operationsProtective equipmentCeramic metalHeat treated

The invention relates to an MAX phase ceramic-metal lamellar composite material, a preparation method and a purpose. The MAX phase ceramic-metal lamellar composite material comprises n layers of superposition units, wherein each superposition unit comprises a metal foil layer and an MAX phase ceramic layer attached to the metal foil layer and n is equal to or greater than 2. Ti2AlC powder and metal foil are used as raw materials for the MAX phase ceramic-metal lamellar composite material; a preform is prepared by superposing the metal foil coated with MAX phase ceramic particles; and next, the preform is subjected to pressurization heat treatment, so that the MAX phase ceramic-metal lamellar composite material is obtained. The MAX phase ceramic-metal lamellar composite material is used inthe field of carrying tools, the field of power transmission and transformation or the field of military materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composite type environment protection wire pole and production techonlogy thereof

InactiveCN1333410AEliminate damageSave forest resourcesSolid waste managementLayered productsAdhesivePolypropylene

The production process of composite type environment-protecting electrical pole includes the following steps: firstly, laying, metal pipe or metal net roll on the conical core mould, packing the binding material made up by mixing rubber powder, polyethylene or / and polypropylene, fly ash, and adhesive according to a certain mixing ratio on the metal pipe or metal net, then press-moulding by means of pressing machine with 200-350 tons and forming mould of pole, removing conical core mould, drying so as to obtain the invented finished product. Said invention is simple in production process, has no secondary pollution, its product performance is stable, can resist high temp. and low temp., its product does not deform in -40-+70 deg.C, and can resist acid corrosino and alkali corrosion.

Owner:刘春江

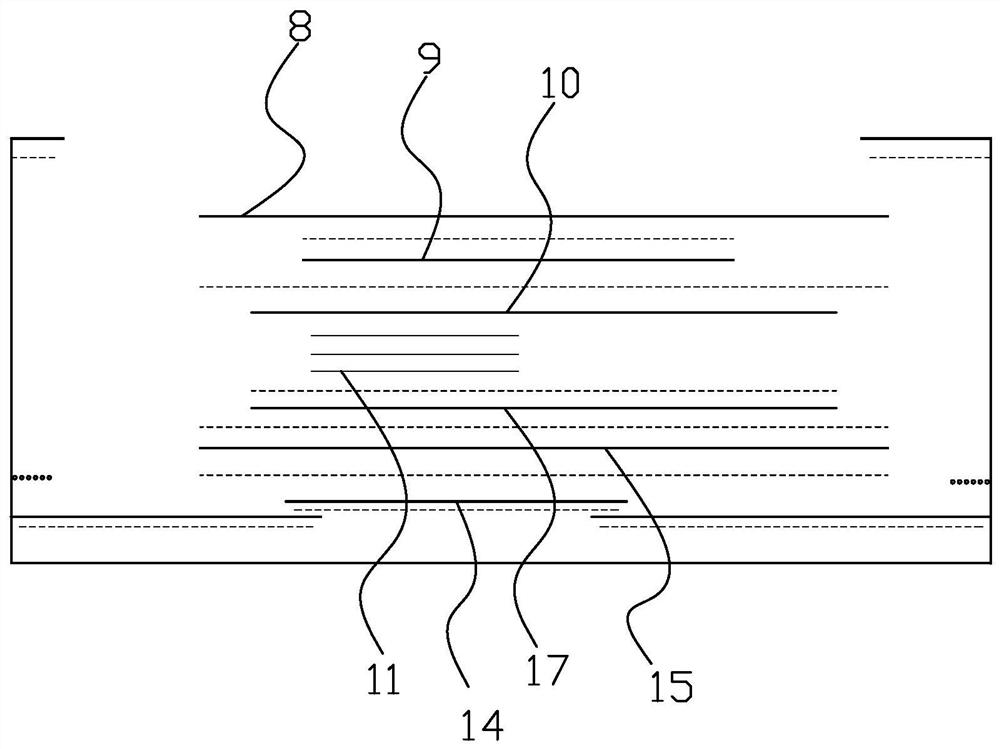

Preparation method for disposable pants-type sanitary articles

ActiveCN110946711AWith tensile strengthGuaranteed stabilityAbsorbent padsBaby linensComposite materialPolymer chemistry

The invention relates to the field of sanitary articles, provides a preparation method for a disposable pants-type sanitary article, solves the problems in the prior art that the pants-type sanitary article has a complex preparation technology and a high cost, and also solves the problems that a tightening feeling is generated since the outer clothing layer of the disposable pants-type sanitary article obtained by the preparation method in the prior art is poor in flexibility and uneven in elastic distribution. The preparation method comprises the steps of: preparing an outer clothing layer, preparing an absorption body, fixedly arranging the absorption body on the outer clothing layer, welding the outer clothing layer to obtain a pants-type structure, and carrying out slitting to obtain asingle product. The step of preparing the outer clothing layer comprises the following steps of: a: preparing elastic nonwoven cloth; b: sending the elastic nonwoven cloth prepared in the step a intoan activation system to be subjected to activation processing; and c: after the elastic nonwoven cloth prepared in the step b is slit along a longitudinal direction, and compounding the slit elasticnonwoven cloth and spunbond nonwoven cloth into a whole through hot melt adhesives or ultrasonic waves, wherein each piece of slit elastic nonwoven cloth to be independently is positioned on two longitudinal sides of the spunbond nonwoven cloth, so as to obtain the outer clothing layer.

Owner:FUJIAN HENGAN HLDG CO LTD +2

I-type medical collagen material keeping original specific triple helix structure of collagen, product and application thereof

The invention relates to an I-type medical collagen material keeping an original specific triple-helical structure of collagen, and an extraction method thereof, meninges / spinal meninges biomembrane made from the I-type medical collagen material, and a preparation process of the biomembrane, and application of the biomembrane to preparing meninges / spinal meninges tissue repair materials. The I-type medical collagen material keeping the original specific triple helix structure of collagen has the advantages of low immunogenicity, no foreign body reaction, good biocompatibility and controllabledegradation rate, the prepared meninges / spinal meninges biomembrane has certain stretching resistance strength, repairable and regenerative dura mater / spinal meninges tissue and tissue adhesion prevention / reduction, and the biomembrane is applicable to repair and regeneration of injured cerebral dura mater and spinal dura mater.

Owner:许和平

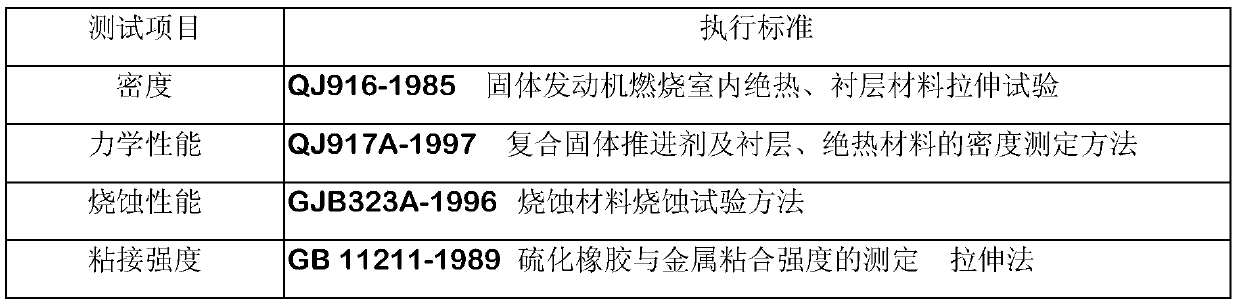

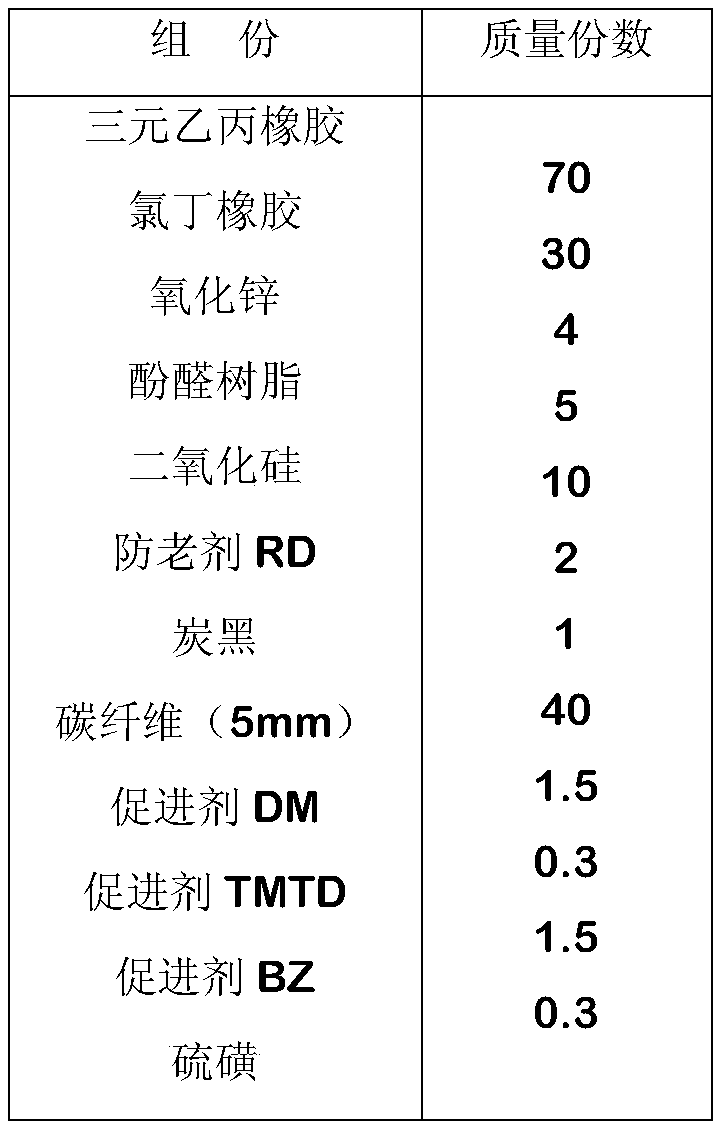

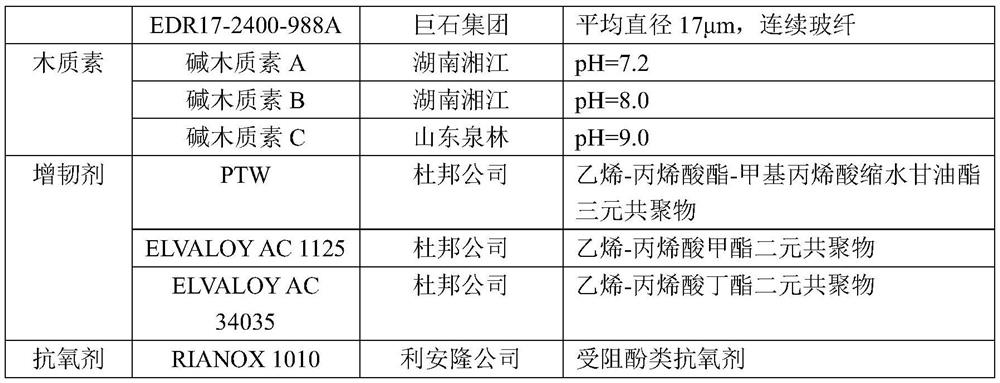

EPDM heat-insulation layer material, and preparation method and application thereof

InactiveCN109851924AGood process performanceImprove construction accuracyThermal insulationEPDM rubber

The invention relates to an EPDM heat-insulation layer material, and a preparation method and an application thereof, specifically to a windable EPDM heat-insulation layer material and a preparation method and an application for the windable EPDM heat-insulation layer material, belongs to the technical field of heat insulation of solid rocket motors, and specifically relates to an EPDM heat-insulation material which can be prepared into a raw adhesive tape, is applicable to a winding molding process and has excellent comprehensive performance. According to the invention, through addition of polar rubber into EPDM rubber for reinforcement, an unvulcanized heat-insulation layer material has certain tensile strength, and is easily prepared into a strip-shaped heat-insulation layer and wound into a disk, so continuous molding and mechanized operation can be realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

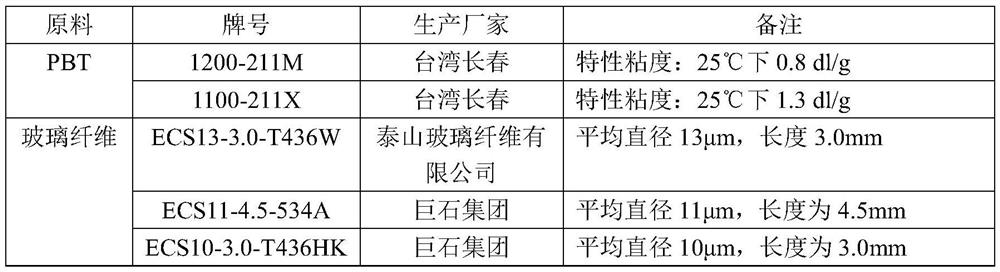

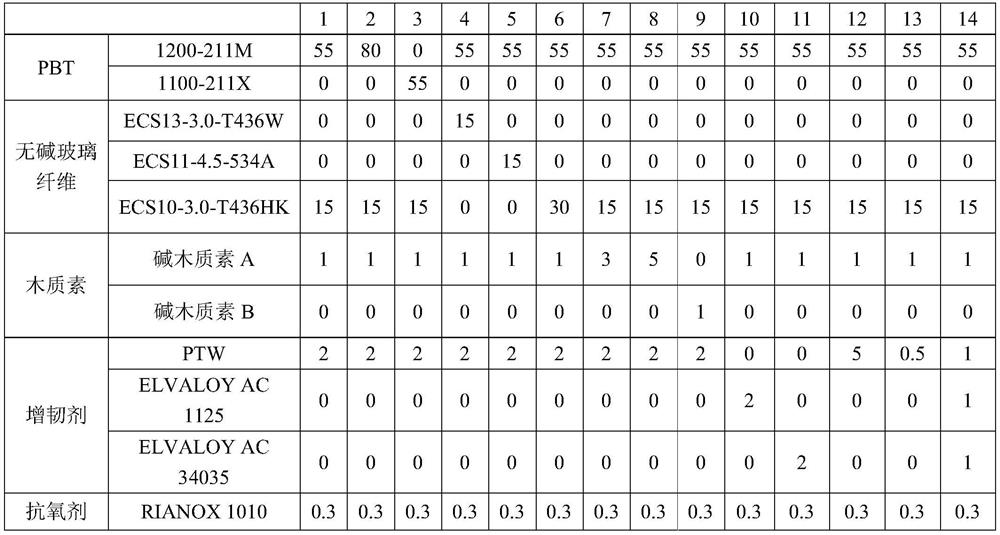

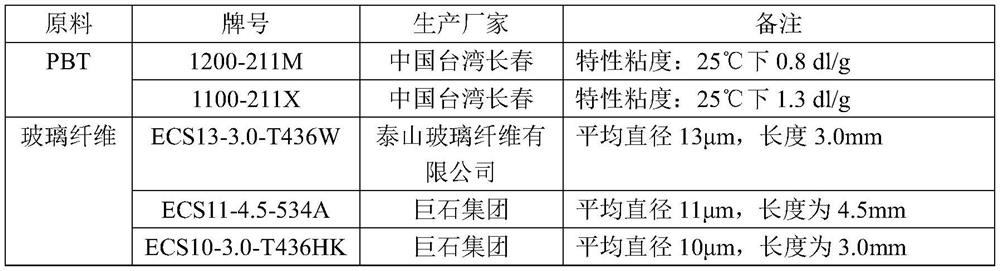

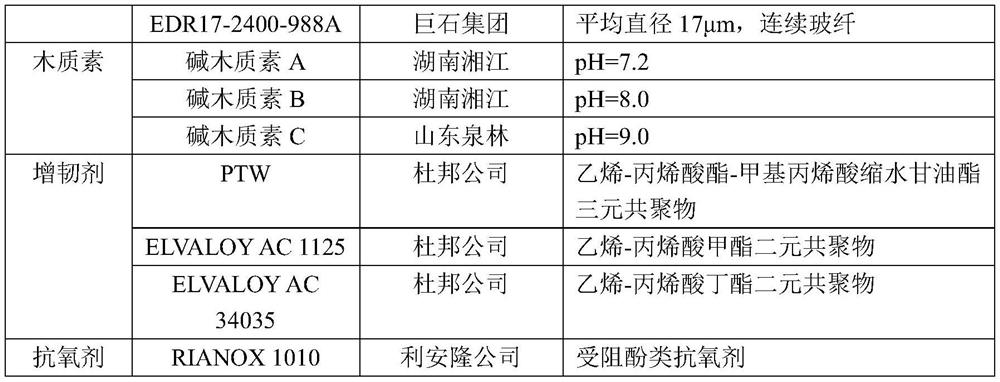

Anti-ultraviolet PBT compound as well as preparation method and application thereof

The invention discloses an anti-ultraviolet PBT compound as well as a preparation method and application thereof. The PBT compound comprises the following components: PBT, glass fibers, lignin, a flexibilizer and an antioxidant, wherein the average diameter of the glass fibers is less than or equal to 13 [mu]m, and the pH value of the lignin is 7.0-8.0. According to the preparation method, the safe, efficient and environment-friendly lignin is used as an ultraviolet absorbent of the PBT and replaces a common chemical anti-ultraviolet agent on the market, and the prepared lignin-containing PBTcompound has good anti-ultraviolet performance. Meanwhile, the low-diameter glass fibers, the flexibilizer and the like are matched with the PBT and the lignin, so that the problem that the mechanicalproperty of the PBT is reduced due to the addition of the lignin is reduced. Therefore, the PBT compound with both mechanical properties and ultraviolet resistance is prepared, the initial tensile strength of the PBT compound is greater than or equal to 100 MPa, and after ultraviolet aging, the tensile strength retention rate of a material is greater than or equal to 90%.

Owner:KINGFA SCI & TECH CO LTD

Skin-core polypropylene composite plastic high imitation rattan and preparation method thereof

InactiveCN109535460AWith matte effectWith tensile strengthCoatingsPolypropylene compositesFolding endurance

The invention discloses a skin-core polypropylene composite plastic high imitation rattan and a preparation method thereof. The high imitation rattan is prepared by the steps of: a. mixing a polypropylene matrix, a toughening agent, a compatilizer, a physical foaming agent, an antioxidant and a pigment, then conducting melt extrusion and foaming to obtain a foamed polypropylene rattan-imitating substrate; b. adding a soluble pore-forming agent, straw glue and inorganic whisker into an organic solvent to prepare a viscous outer wall solution; and c. impregnating the rattan-imitating substrate in the outer wall solution, then conducting washing and drying curing, thus obtaining the skin-core polypropylene composite plastic high imitation rattan. The method has the beneficial effects that: the high imitation rattan prepared by the method provided by the invention has a rough and matt surface, has appearance, texture and density similar to those of natural rattan, also has soft texture like natural rattan, completely achieves the performance of natural rattan, at the same time has high tensile strength and folding endurance, good mechanical properties and good durability, thus having wide application range.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

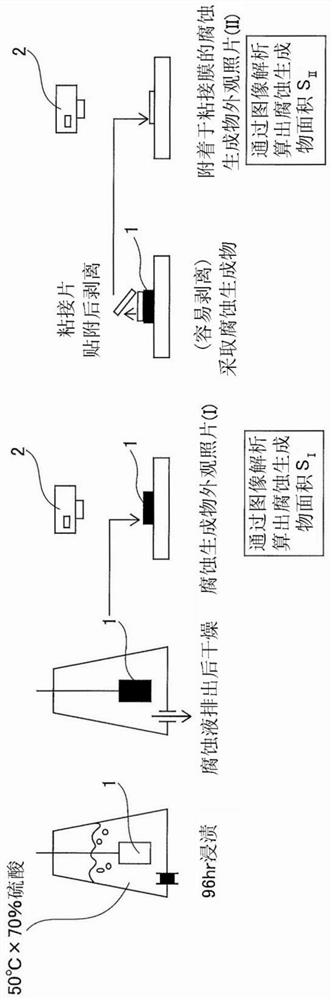

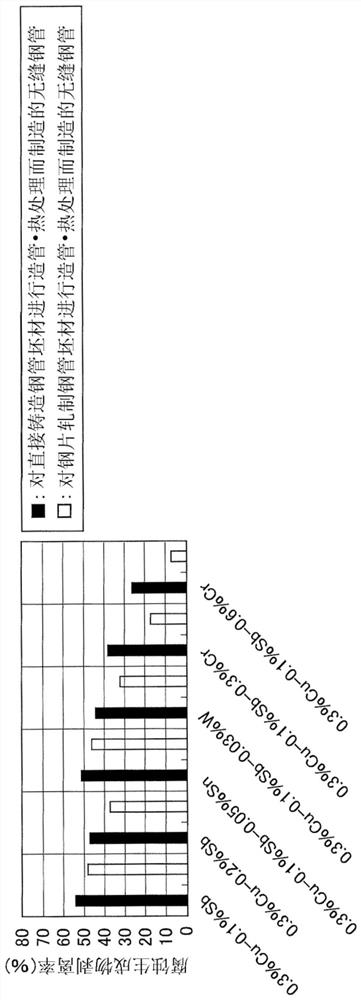

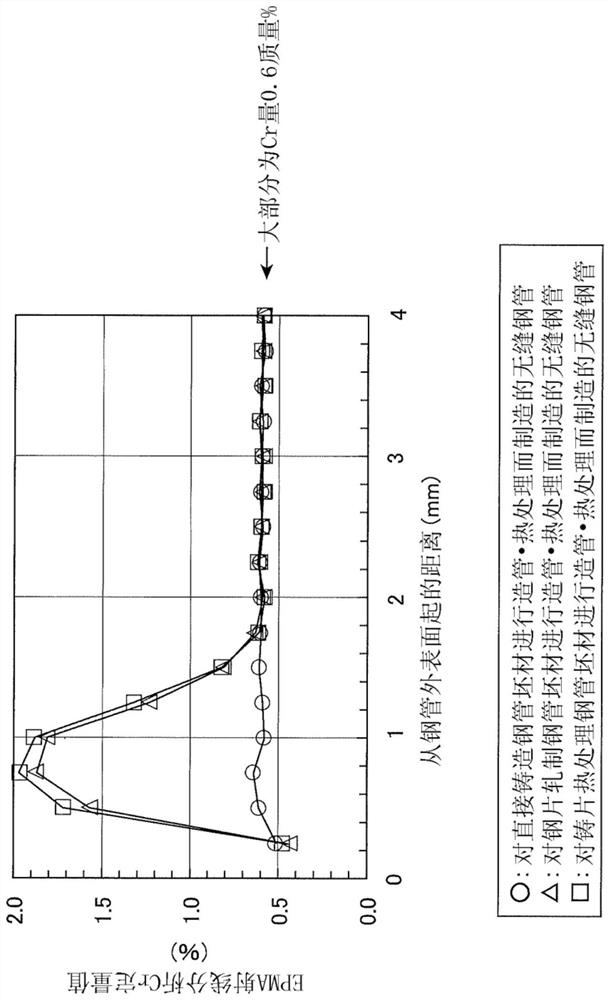

Seamless steel pipe having exceptional resistance to sulfuric acid dew-point corrosion, and method for manufacturing seamless steel pipe

PendingCN114096692AEasy to prepareHighly corrosiveFurnace typesHeat treatment furnacesPipeUltimate tensile strength

The purpose of the present invention is to provide a seamless steel pipe and a method for manufacturing the same. The present invention is the seamless steel pipe having exceptional resistance to sulfuric acid dew-point corrosion. The seamless steel pipe has a component composition containing, in terms of percentage by mass, 0.02-0.12% of C, 0.010-1.00% of Si, 0.10-2.00% of Mn, no more than 0.050% of P, no more than 0.004% of S, 0.010-0.100% of Al, 0.03-0.80% of Cu, 0.02-0.50% of Ni, 0.55-1.00% of Cr, and 0.005-0.20% of Sb, the remainder comprising Fe and unavoidable impurities. Cu*, Cr*, and Sb* satisfy formula (1): 1.7*Cu* +11*Cr* +3.8 *Sb* >= 13.5, wherein Cu*, Cr*, and Sb* are, respectively, the average Cu concentration (in terms of percentage by mass), the average Cr concentration (in terms of percentage by mass), and the average Sb concentration (in terms of percentage by mass) in a region 0.5-2.0 mm toward the center in the wall thickness direction from the outer surface of the steel pipe. The yield strength of the steel pipe is 230 MPa or greater, and the tensile strength of the steel pipe is 380 MPa or greater.

Owner:JFE STEEL CORP

Cellphone fish-finding device

InactiveCN105394006ALow costReduce volumeClimate change adaptationClosed circuit television systemsUniversal jointAquatic product

The invention relates to a cellphone fish-finding device comprising an acquisition device and a smart phone. The acquisition device is connected with the smart phone via a USB data line; the acquisition device is formed by a camera, two plug-in holes and two inward-recessed nuts; one plug-in hole is provided with a device controlling vertical or horizontal directions of the camera and positioning balance weight adding device or illuminating equipment is connected to the other plug-in hole; and the two inward-recessed nuts are individually provided with a universal joint handle, a specific rack or a connection rod. The beneficial effects are that the cellphone fish-finding device requires low cost, has small size and light weight, can be conveniently carried and has wide use ranges and high definition; and the cellphone fish-finding device is incomparable in light of price, use performance and use ranges of the equipment of the same kind. The cellphone fish-finding device can be applied to fields of underwater visual fishing, underwater search and rescue, archaeological work, exploration, aquatic product culturing, mechanical maintenance, sewers, wells, piles, bridge piers (including underwater part), communication wells, methane tanks, rescues, anti-terrorism and antiriot work and wars.

Owner:余加祥

A kind of anti-ultraviolet PBT compound and its preparation method and application

The invention discloses an anti-ultraviolet PBT compound, its preparation method and application. The PBT compound includes the following components: PBT, glass fiber, lignin, toughening agent, and antioxidant; wherein the average diameter of the glass fiber is less than or equal to 13 μm, and the pH of the lignin is 7.0-8.0. The invention uses safe, efficient and environment-friendly lignin as the ultraviolet absorber of PBT, which replaces the chemical anti-ultraviolet agent commonly used in the market, and the prepared PBT compound containing lignin has good anti-ultraviolet performance. At the same time, the low-diameter glass fiber, toughening agent, etc. cooperate with PBT and lignin to reduce the problem of the decline in the mechanical properties of PBT caused by the addition of lignin. Thus, a PBT composite with both mechanical properties and anti-ultraviolet properties is prepared, the initial tensile strength of the PBT composite is ≥ 100 MPa, and the tensile strength retention rate of the material is ≥ 90% after ultraviolet aging.

Owner:KINGFA SCI & TECH CO LTD

Wear-proof rubber pipe

PendingCN107131365AReasonable structural designImprove stability and reliabilityFlanged jointsCorrosion preventionCorrosionCeramic materials

The invention discloses a wear-proof rubber pipe. The wear-proof rubber pipe comprises a rubber pipe body and a flange arranged at the end of the rubber pipe body. The rubber pipe body sequentially comprises work layer rubber, a middle cord layer, lining and steel wire and pipe outer layer wear-proof rubber from the inner layer to the outer layer. The wear-proof rubber pipe is reasonable in structural design. The rubber pipe body is made of multiple layers of different materials and sequentially comprises the work layer rubber, middle cords, the lining and steel wire and the pipe outer layer wear-proof rubber from inside to outside, so that the stability and reliability of the rubber pipe are improved, and the rubber pipe can resist positive and negative pressure, has tensile strength, can resist large negative pressure and is scarcely influenced by the external environment. Besides, a flange is fully coated with rubber, the problems of corrosion, wear and the like can be effectively solved, and therefore the service life of a pipeline connection portion is greatly prolonged.

Owner:WUHU NAIDE RUBBER HOSE VALVE IND CO LTD

Flame-retardant thermoplastic polyolefin (TPO) waterproof material and construction method thereof

InactiveCN103640291AImprove adhesionImprove air tightnessLiquid surface applicatorsSynthetic resin layered productsPolyolefinEmulsion

The invention relates to the technical field of flame-retardant waterproof materials, and in particular to a flame-retardant thermoplastic polyolefin (TPO) waterproof material and a construction method thereof. The flame-retardant TPO waterproof material is excellent in adhesion, strong in durability, good in flame retardance, safe and environment-friendly. An emulsion is an aqueous system, is excellent in performance, and is environment-friendly; the roll coating construction of the emulsion on a TPO waterproof coiled material is convenient and safe. Compared with the conventional flame-retardant TPO waterproof material on the market, the flame-retardant TPO waterproof material has the advantages of low cost, good flame-retardant performance, environment friendliness, good durability, convenience in construction, safety, environment protection and the like, and has a quite great application value. In the actual application, the flame-retardant TPO waterproof material has the integrated characteristics of ageing resistance, high tension strength, large elongation, convenience in construction, no pollution and the like, and is quite applicable to serving as a waterproof layer for a light energy-saving roof; the product can be constructed on a wet roof, and a protection layer is not needed by an exposed part.

Owner:JIANGSU CANLON BUILDING MATERIALS

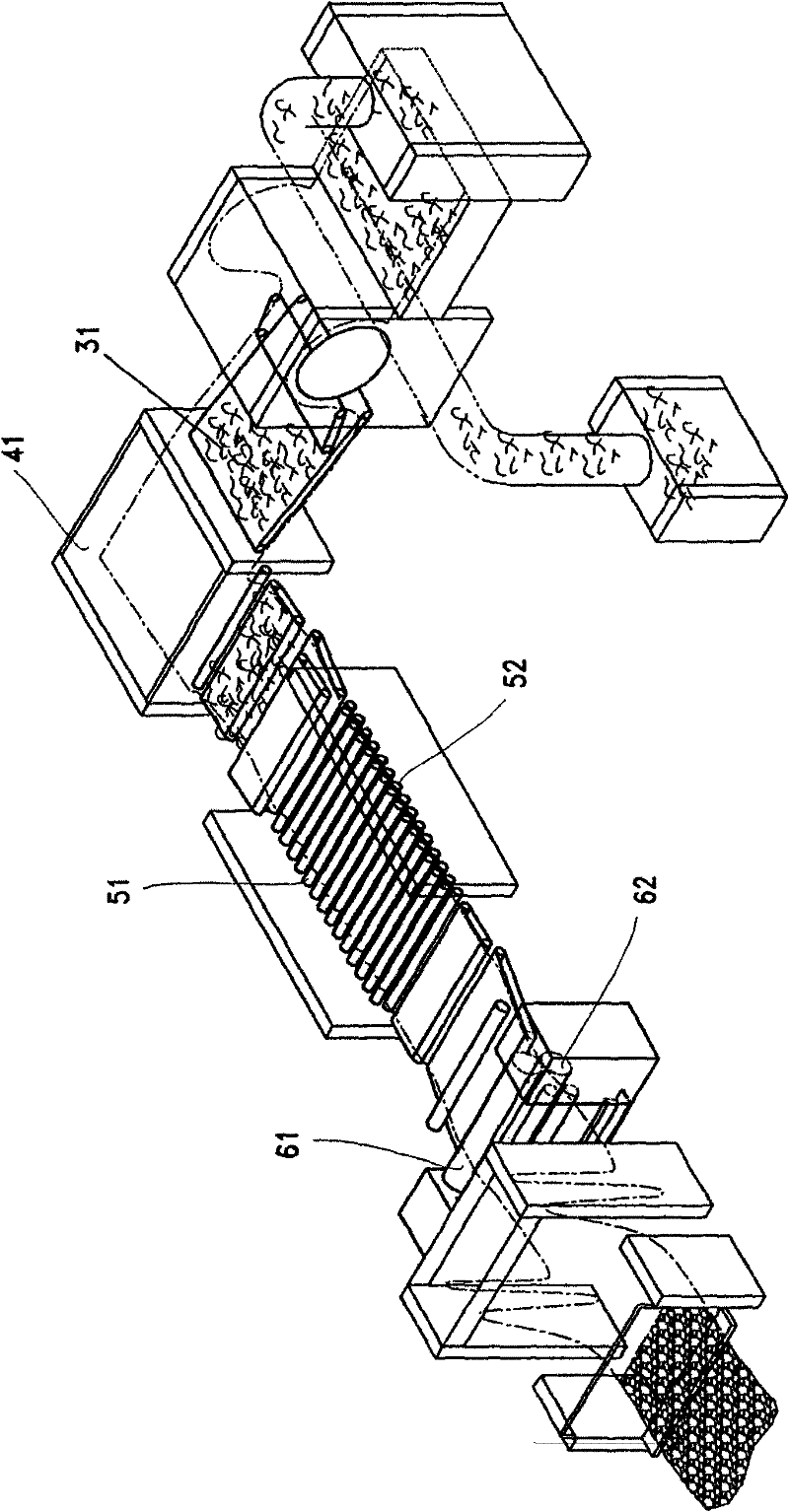

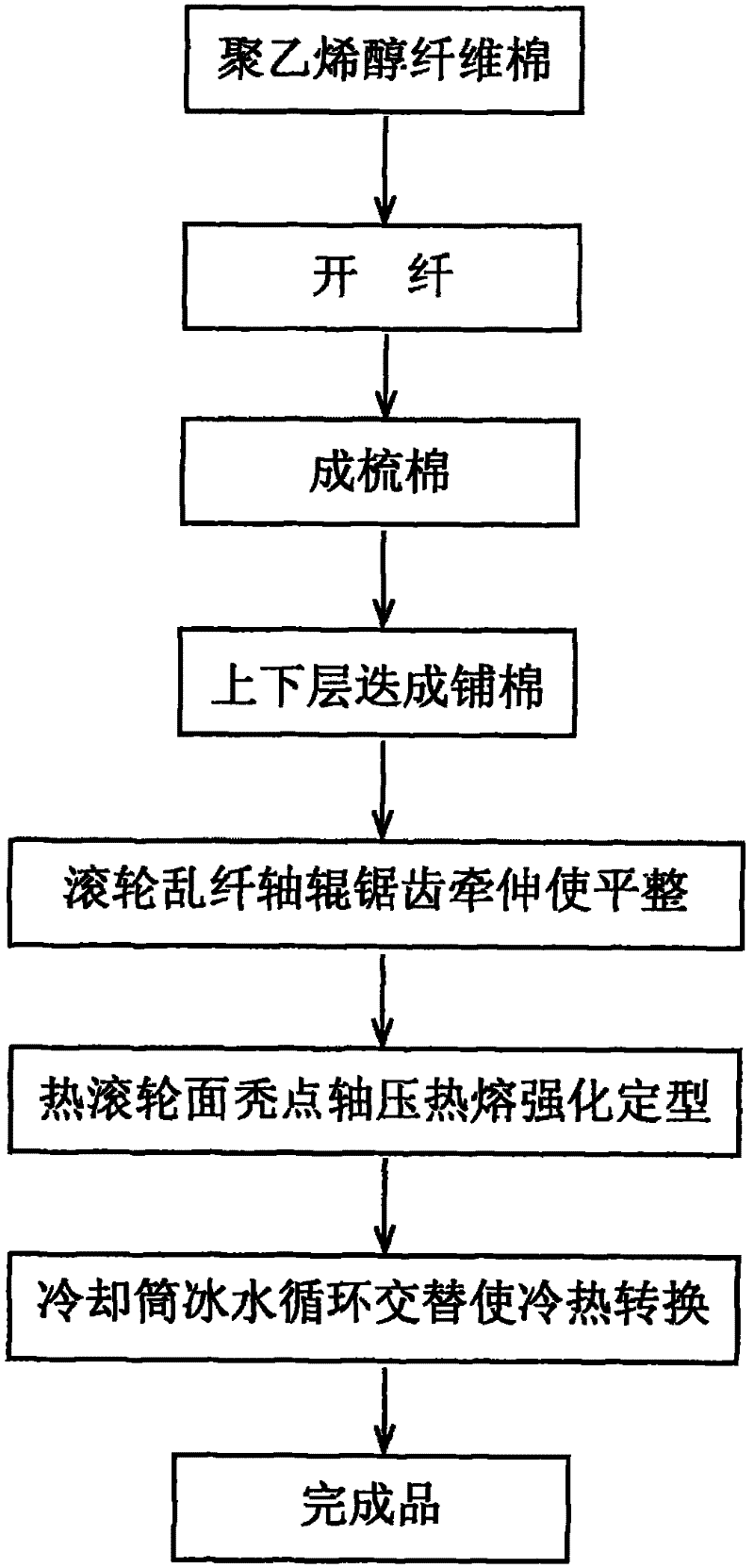

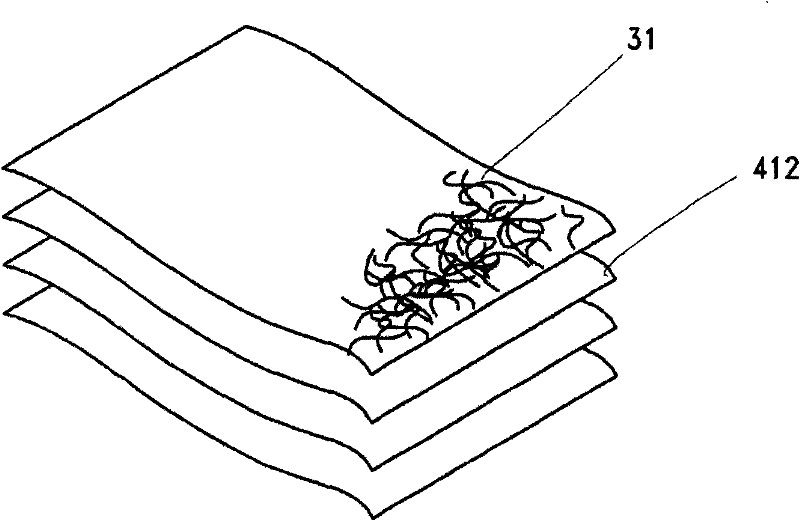

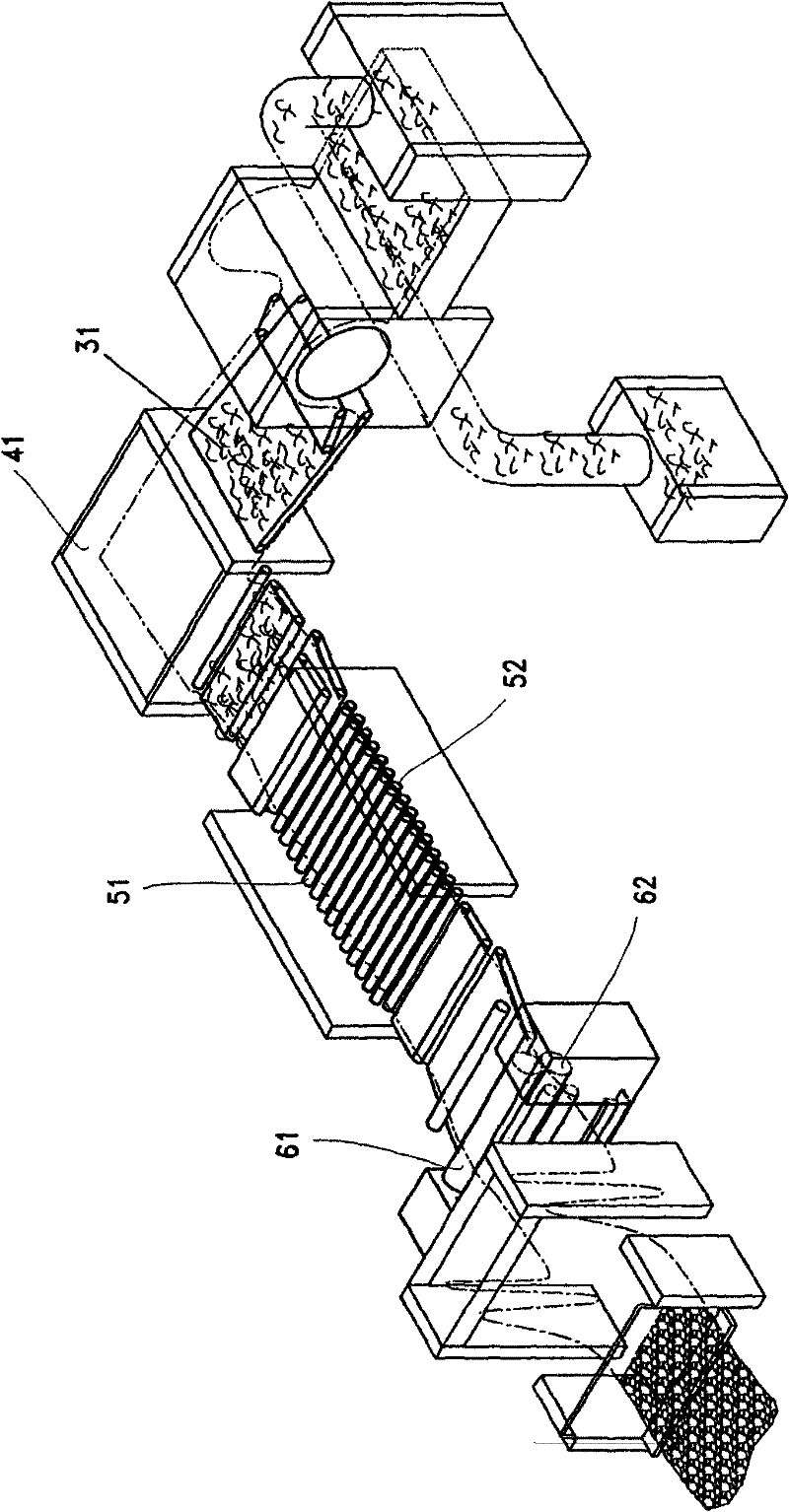

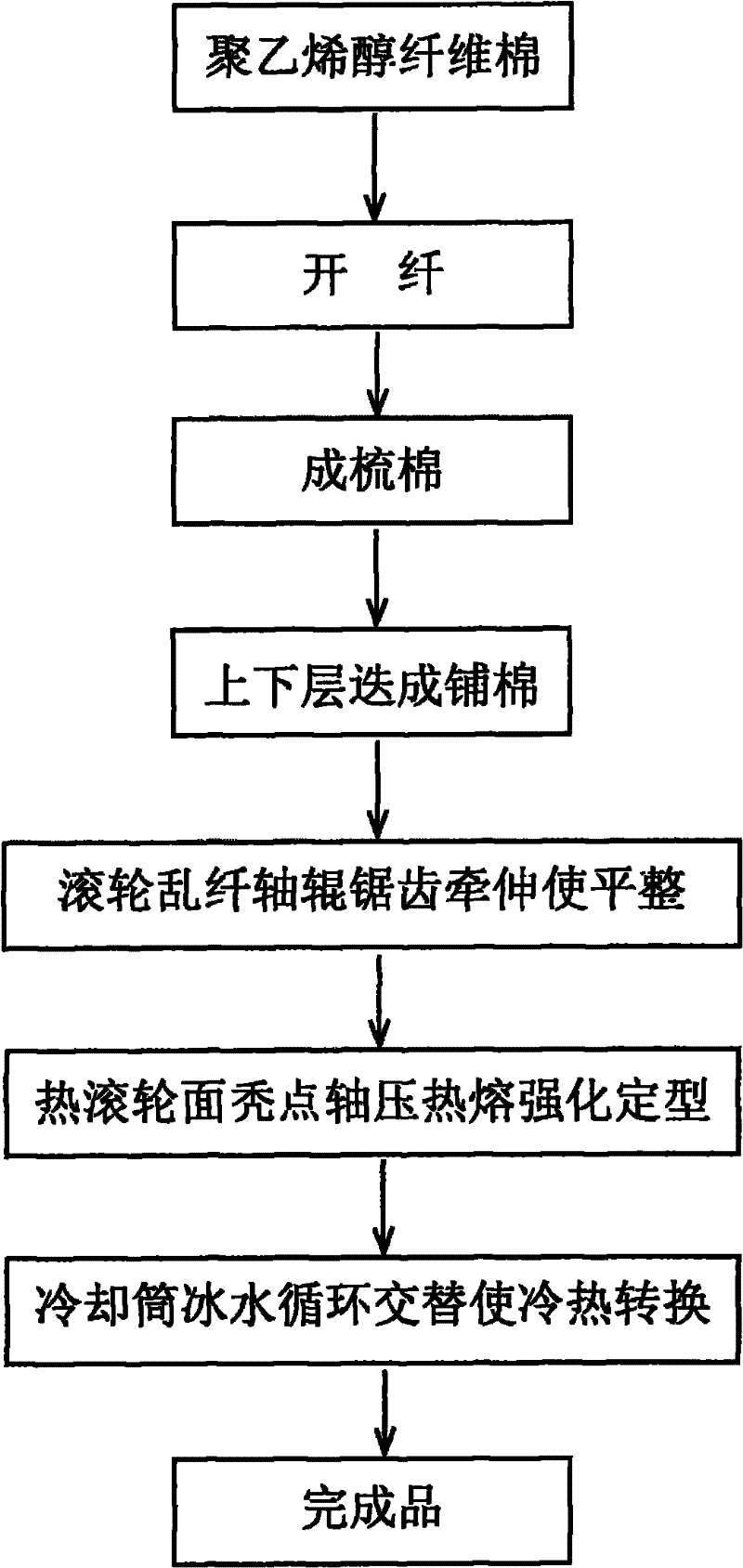

Method for weaving polyvinyl alcohol fiber lining cloth capable of dissolving in water at normal temperature

InactiveCN101748559AKeep it smoothWith tensile strengthNon-woven fabricsEmbroidering machines apparatusYarnFiber

The invention discloses a method for weaving polyvinyl alcohol fiber lining cloth capable of dissolving in water at normal temperature, comprising the following steps: (1) preparing polyvinyl alcohol fiber cotton; (2) loosely stirring the polyvinyl alcohol fiber cotton and splitting the polyvinyl alcohol fiber cotton into loose fine carded polyvinyl alcohol fiber cotton, evenly scattering and distributing the loose fine carded polyvinyl alcohol fiber cotton on a meshy conveying belt, and conveying the loose fine carded polyvinyl alcohol fiber cotton into a cotton spreading machine; (3) uniformizing and leveling the cover of cloth by the clamping and the rolling of the cotton yarn of cloth layer by two groups of axial rollers and the stretching of the cotton yarn of cloth layer by spiral sawtooth points, wherein sawteeth are distributed on the surfaces of the two groups of axial rollers which are arranged up and down; (4) hot rolling, strengthening and shaping cotton cloth by hot rolling wheels, wherein convex points are distributed on the surfaces of the hot rolling wheels; (5) making the rolled cotton cloth pass by the surface of a cooling cylinder wheel in which circulating ice water is filled so that the cotton cloth being rapidly cooled to the normal temperature; and (6) bundling the cotton cloth into a bundle. When being used for base cloth embroidered by a machine, the polyvinyl alcohol fiber lining cloth woven by the method can dissolve in water at lower normal temperature, and the embroidered threads can not fade when the polyvinyl alcohol fiber lining cloth dissolves in water at high temperature.

Owner:KUSN SHENGYU NON WOVEN FABRICS

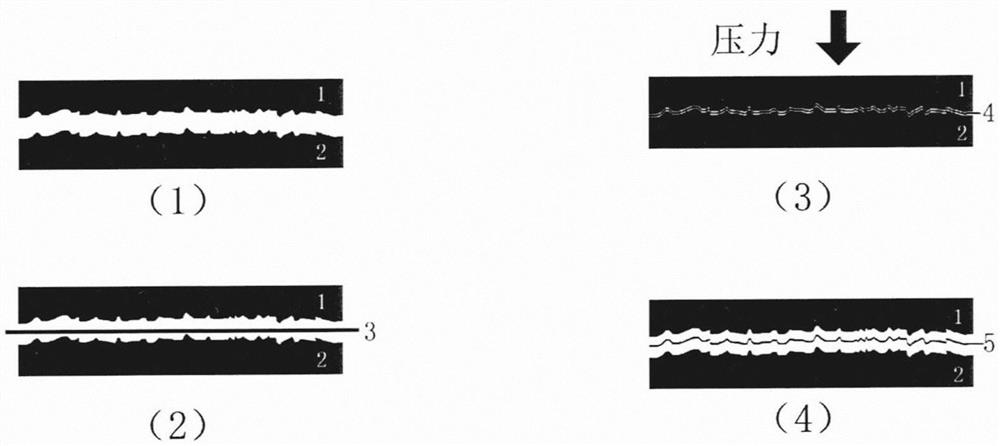

A synthetic adhesive three-layer composite non-woven self-adhesive elastic bandage and preparation method thereof are provide

InactiveCN109259931AWith tensile strengthGood self-adhesive elasticityNon-adhesive dressingsLayered productsTemperature resistanceProtein free

The invention discloses a synthetic adhesive three-layer composite non-woven self-adhesive elastic bandage which is prepared from composite cloth base material and protein-free composite adhesive through coating synthetic adhesive, and is prepared from two layers of seam-knitted impregnated non-woven elastic cloth wrapped with one lay of non-elastic hot-rolled non-woven cloth. The invention has certain tensile strength, better self-adhesive strength, better elasticity, high temperature resistance, better sweat absorption ability and better soft touch.

Owner:NANJING 3H MEDICAL PROD CO LTD

A kind of preparation method of disposable trousers type hygienic article

ActiveCN110946711BWith tensile strengthGuaranteed stabilityAbsorbent padsBaby linensHot meltNonwoven fabric

The invention relates to the field of sanitary products, and provides a preparation method of disposable pants-type sanitary products, which solves the problems of relatively complicated preparation process and high cost of the prior art trouser-type sanitary products, and also solves the problem of adopting the preparation method of the prior art The outer clothing layer of the obtained trouser-type hygiene product has poor softness, uneven distribution of elasticity, and problems of tight feeling when used, including preparing the outer clothing layer, preparing an absorber, fixing the absorber on the outer clothing layer and welding it into a The pants-shaped structure is cut into individual products, and the preparation of the outer clothing layer includes the following steps: a, preparing elastic non-woven fabrics; b, sending the elastic non-woven fabrics prepared in step a into an activation system for activation treatment; c. Slitting the elastic non-woven fabric obtained in step b along the longitudinal direction and combining with the spunbonded nonwoven fabric through hot melt adhesive or ultrasonic wave, and each elastic nonwoven fabric after slitting is respectively located on the spunbonded nonwoven fabric. Both longitudinal sides of the cloth are spun and an outer garment layer is thereby produced.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Carbon fiber weather-resistant composite board

InactiveCN110641119AExtend the time of outdoor useWith tensile strengthSynthetic resin layered productsFiberCarbon fibers

The invention discloses a carbon fiber weather-resistant composite board which comprises a middle carbon fiber layer, wear-resistant layers and weather-resistant coating films, the middle carbon fiberlayer is arranged in the middle of the board, the wear-resistant layers are arranged on two sides of the middle carbon fiber layer, and the weather-resistant coating films are adhered to the outer sides of the wear-resistant layers. By means of the mode, the abrasion resistance and outdoor use weather resistance of the single carbon fiber reinforced board can be improved, and the application range of the carbon fiber board is widened.

Owner:TAICANG JINHAODA NEW MATERIAL CO LTD

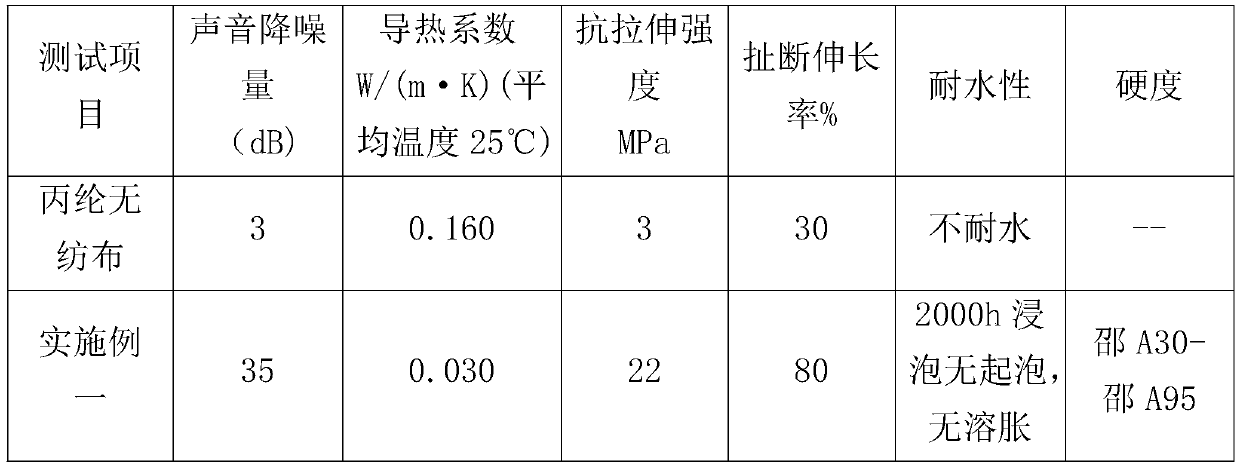

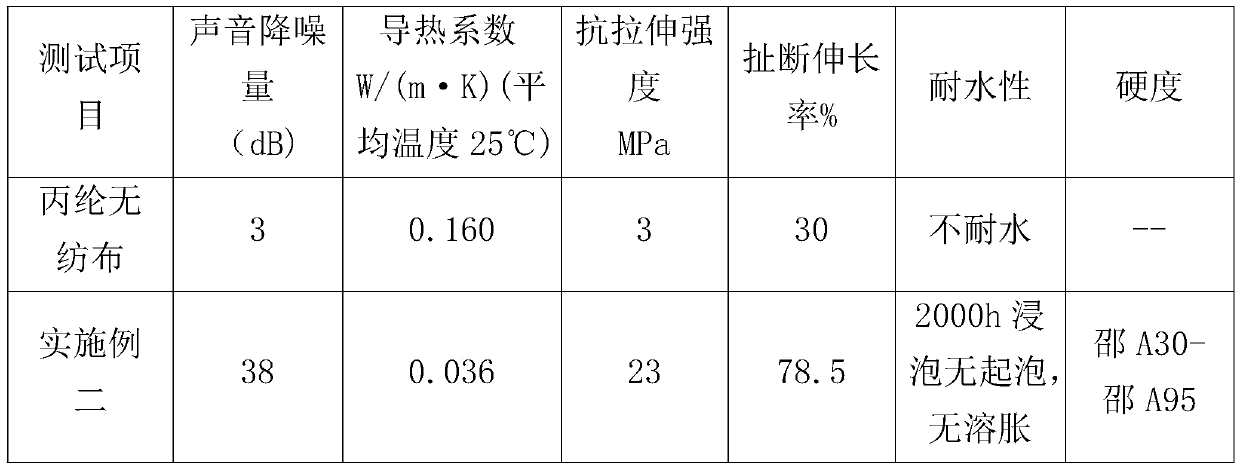

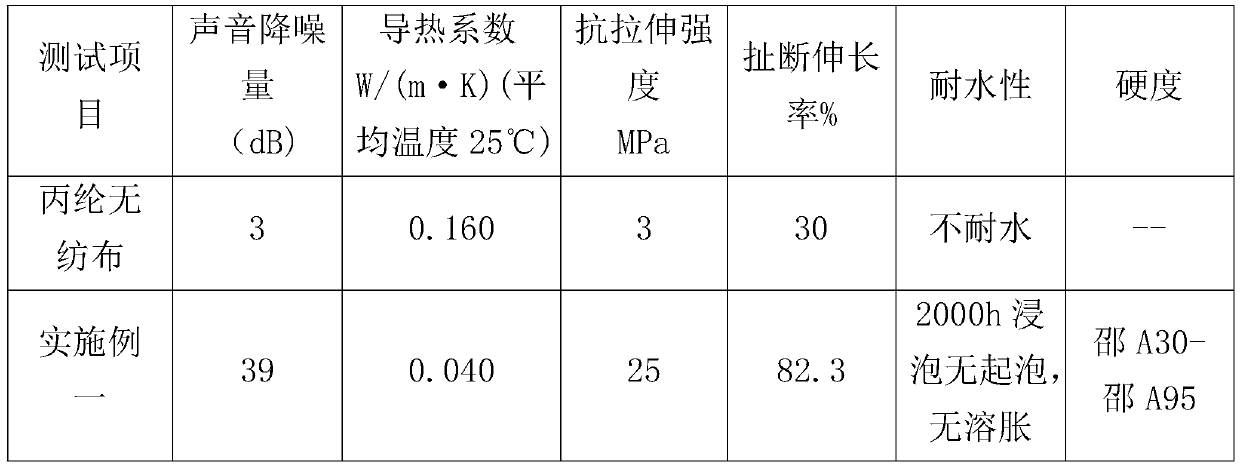

Environment-friendly heat-insulation and noise-reduction polyurea composite material and manufacturing method thereof

InactiveCN111535045AHigh solid contentEasy to makeChemical industryTextiles and paperFiberDimethyl methylphosphonate

The invention relates to the technical field of composite materials, and specifically discloses an environment-friendly heat-insulation and noise-reduction polyurea composite material. The environment-friendly heat-insulation and noise-reduction polyurea composite material comprises polyether polyol, tri(hydroxymethyl)propane, butyl acetate, isophorone diisocyanate, dimethyl methylphosphonate, a light stabilizer, polyaspartic acid resin, cellulose acetate butyrate, siloxane pigment, mica balls, silicate particles and a defoamer; a fiber texture is heated to 40 DEG C; the surface of the fiber texture is dried; the fiber texture is fixed on conveying rollers; one section of the fiber texture is placed on a fixing clamp; the fixing clamp draws the fiber texture to move forwards through a variable frequency motor under control of a PLC; relative positions of a rolling brush and a scraper to the fiber texture are controlled through sensors; a component A is mixed with a pre-mixed material to form slurry, and the slurry is pumped into a paint box by using a diaphragm pump; paint is extracted into a paint container, which is directly connected to the rolling brush, from the paint box according to a using amount; the slurry is painted on the fiber texture in a rolling manner by using the rolling brush; the slurry is slicked with the scraper and is dried; and then the environment-friendly heat-insulation and noise-reduction polyurea composite material is obtained.

Owner:青岛青材科技有限公司

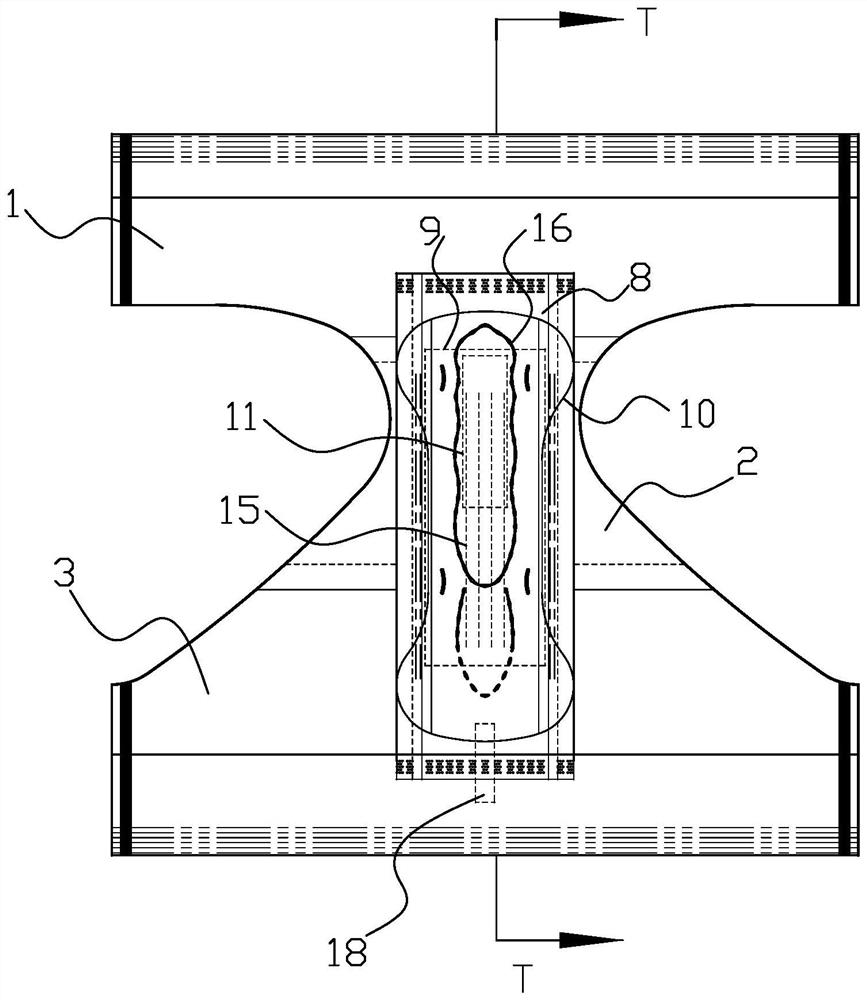

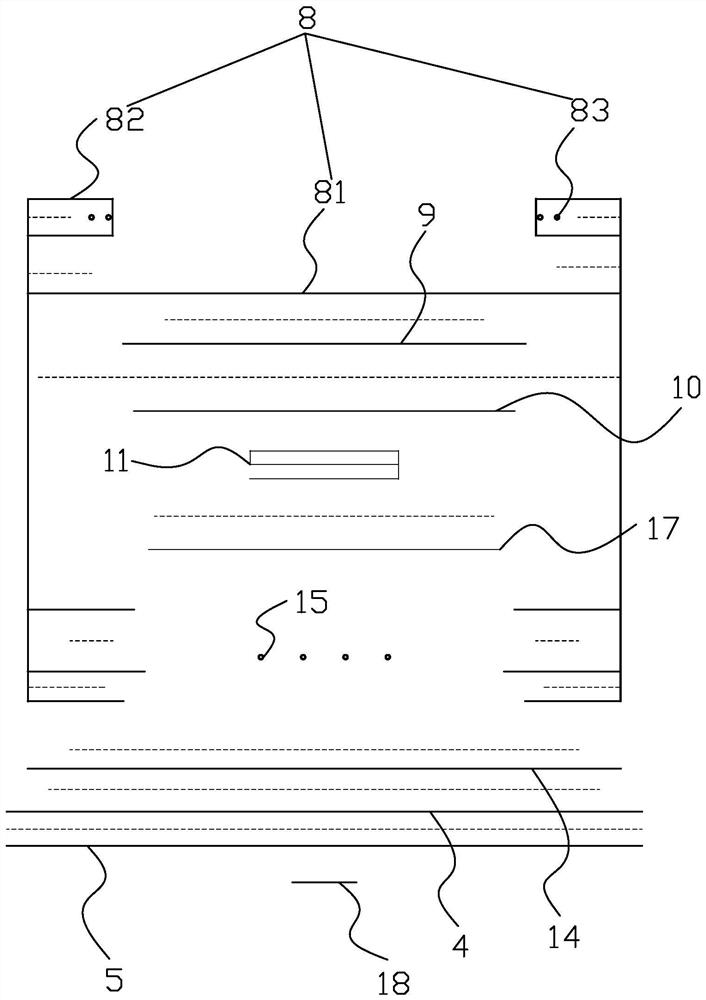

Underwater optical cable connector

ActiveCN102360104BWith tensile strengthResistant to water pressureCoupling light guidesUnderwaterDie casting

The invention relates to an optical cable connector, and provides an underwater optical cable connector, which is capable of meeting requirements on water tightness and tensile performance, and providing detachable and movable connection. The underwater optical cable connector is characterized in that mutually matched cone structures are arranged on a plug shell and a socket shell respectively sothat the plug shell and the socket shell can be in gapless sealing connection by means of insertion, a sealing connection structure is arranged between a plug and an optical cable, the space between the plug shell and a tensile taper sleeve is sealed by an 'O'-shaped sealing ring, and a sealing tail sleeve for sealing is formed in the space between the optical cable and a tail part of the whole plug by mean of integral die casting. The movable sealing connection structure is arranged between the plug and a socket of the underwater optical cable connector, the two shells are connected by cones, no gap is reserved between the inner cone and the outer cone, the space between the cones is sealed by the 'O'-shaped sealing ring, the inner cone and the outer cone are locked by a connecting nut, and the underwater optical cable connector is simple in structure, reliable in performance, extremely high in water pressure resistance and convenient in connection and detachment.

Owner:SHANGHAI FANGAO COMM TECH

Environment-friendly built-in sealant and preparation method thereof

InactiveCN110317568AFast preparationWith tensile strengthNon-macromolecular adhesive additivesPolymer scienceVinyltriethoxysilane

The invention discloses an environment-friendly built-in sealant which is prepared from hydroxyl-terminated polydimethylsiloxane, hydrophobic silicon dioxide, vinyltriethoxysilane, butyl titanate, organic bismuth and the like. The invention also relates to a preparation method of the environment-friendly built-in sealant. According to the preparation method of the environment-friendly built-in sealant, the components are put into a reaction kettle in sequence and are fully stirred under the corresponding conditions. According to the method, the cured dealcoholized silicone sealant can be quickly prepared by adding the vinyltriethoxysilane and has a certain tensile strength in a short time, so that the decoration working efficiency and the quality guarantee can be effectively improved in the indoor decoration industry; by creatively adding butyl titanate and a supplemented organic ruthenium catalyst, the butyl titanate serves as a tackifier for improving polymer adhesion, not only provided rapid cross-linking reaction can be, but also the adhesion of a polymer system is improved, and the curing efficiency and the initial tensile strength in a short time can be further improved.

Owner:江苏华硅新材料科技有限公司

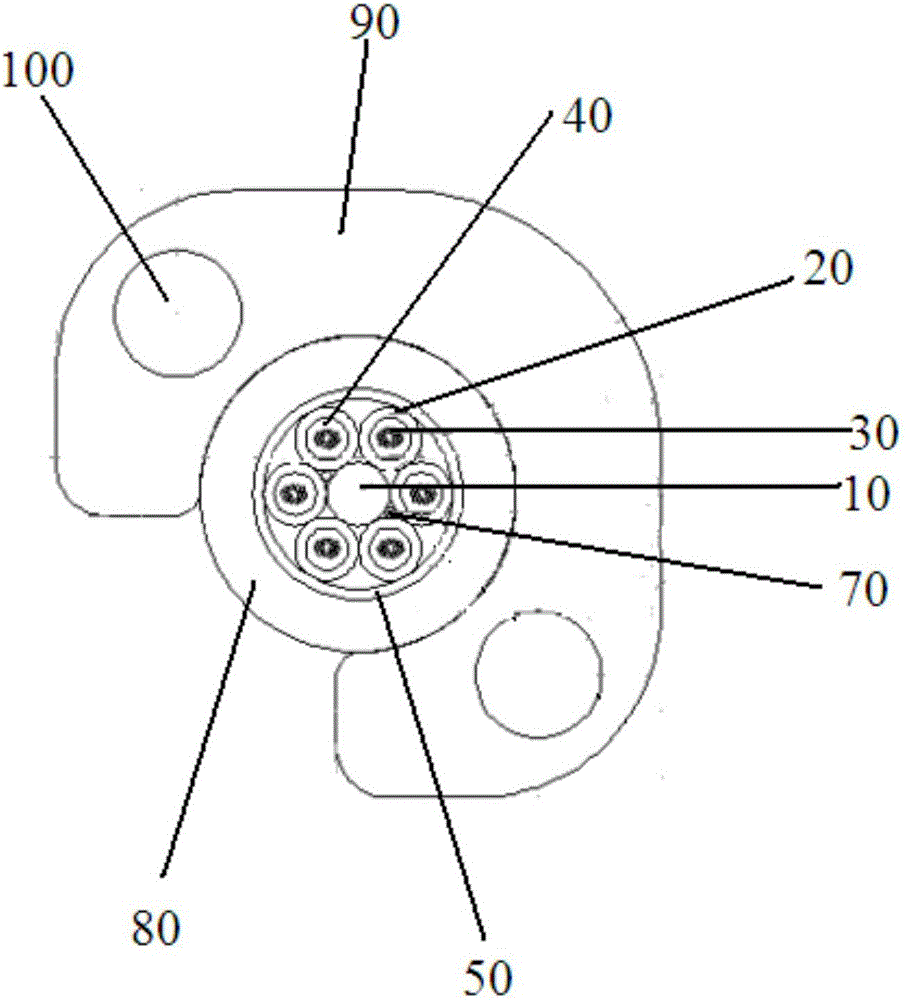

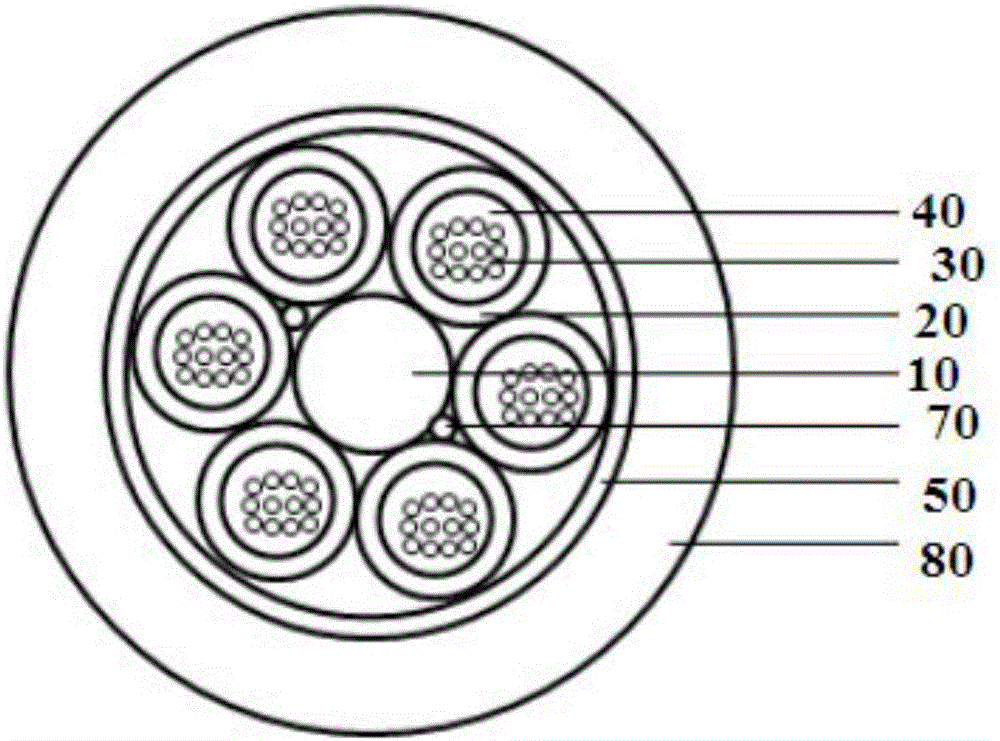

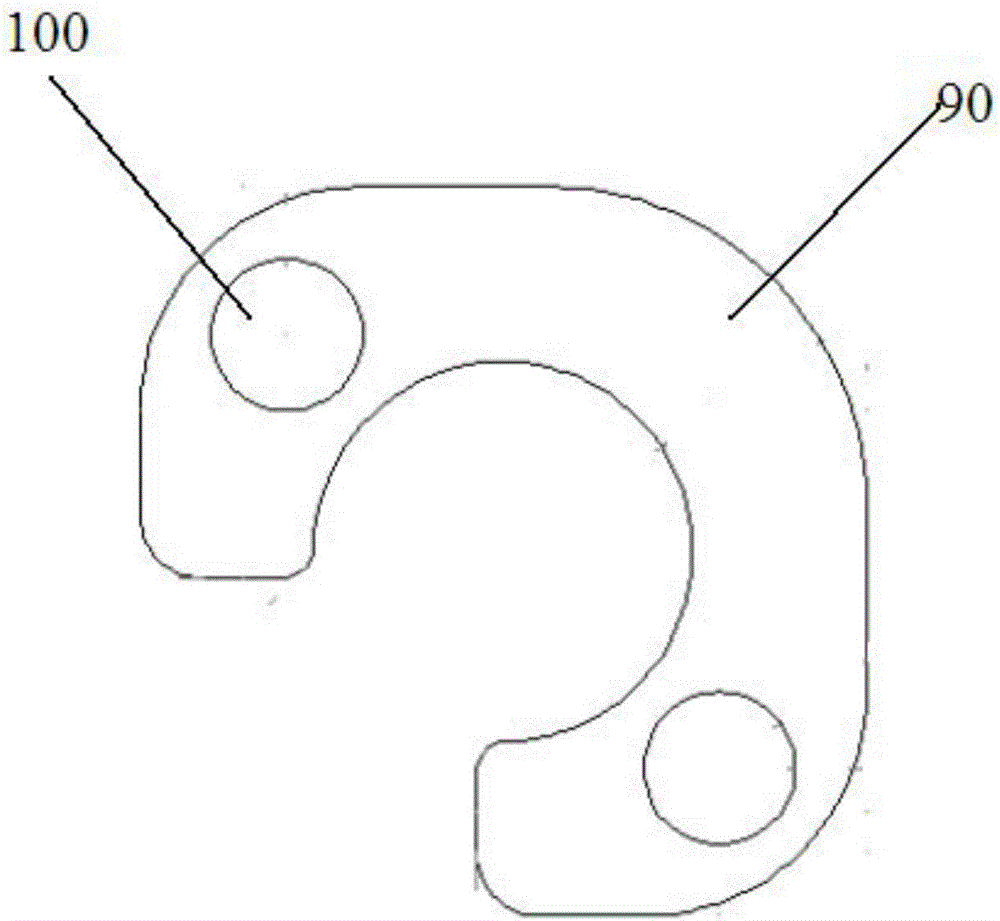

C-type-sleeve all-dielectric self-supporting optical cable used for access network and manufacturing method thereof

ActiveCN106054338ANot affected by external factorsSmooth transmissionClimate change adaptationFibre mechanical structuresAccess networkRadio access network

The invention discloses a C-type-sleeve all-dielectric self-supporting optical cable used for an access network. The optical cable comprises a light unit portion and a bearing component portion. The bearing component portion is a C-type protection sleeve which sleeves an outer portion of the light unit portion. A contact surface of the C-type protection sleeve and the light unit portion is a ''C''-shaped structure. FRP is filled in the C-type protection sleeve. The FRP is arranged at a near open end of the C-type protection sleeve and is served as a reinforcement component of the C-type protection sleeve. In the invention, the brand new C-type self-supporting protection-sleeve all-dielectric self-supporting optical cable used for an access network is exploited. By using the optical cable, manufacturing cost and construction cost of the optical cable are reduced and the novel optical cable with a low price and stable performance is created.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

Method for weaving polyvinyl alcohol fiber lining cloth capable of dissolving in water at normal temperature

InactiveCN101748559BKeep it smoothWith tensile strengthNon-woven fabricsEmbroidering machines apparatusYarnFiber

The invention discloses a method for weaving polyvinyl alcohol fiber lining cloth capable of dissolving in water at normal temperature, comprising the following steps: (1) preparing polyvinyl alcohol fiber cotton; (2) loosely stirring the polyvinyl alcohol fiber cotton and splitting the polyvinyl alcohol fiber cotton into loose fine carded polyvinyl alcohol fiber cotton, evenly scattering and distributing the loose fine carded polyvinyl alcohol fiber cotton on a meshy conveying belt, and conveying the loose fine carded polyvinyl alcohol fiber cotton into a cotton spreading machine; (3) uniformizing and leveling the cover of cloth by the clamping and the rolling of the cotton yarn of cloth layer by two groups of axial rollers and the stretching of the cotton yarn of cloth layer by spiral sawtooth points, wherein sawteeth are distributed on the surfaces of the two groups of axial rollers which are arranged up and down; (4) hot rolling, strengthening and shaping cotton cloth by hot rolling wheels, wherein convex points are distributed on the surfaces of the hot rolling wheels; (5) making the rolled cotton cloth pass by the surface of a cooling cylinder wheel in which circulating ice water is filled so that the cotton cloth being rapidly cooled to the normal temperature; and (6) bundling the cotton cloth into a bundle. When being used for base cloth embroidered by a machine, the polyvinyl alcohol fiber lining cloth woven by the method can dissolve in water at lower normal temperature, and the embroidered threads can not fade when the polyvinyl alcohol fiber lining cloth dissolves in water at high temperature.

Owner:KUSN SHENGYU NON WOVEN FABRICS

Solid wood composite coining door panel and production technology thereof

InactiveCN101116977BHigh tensile strengthSuitable for industrial scale productionWood veneer joiningSolid woodEngineering

The invention discloses a solid wood composite molded door board, belonging to a three-layer composite structure. The structure material of the first layer is natural solid wood single board or technical wood single board, the structure of the second layer is non-woven cloth and the structure of the third layer is molded door board (fiberboard). The invention also provided the manufacturing technique which is applicable to industrialized scale production and has stable quality. The invention overcomes the disadvantage of the solid wood single board which has no transverse pulling resistance strength without any material backing and is easy to break transversely; the solid wood composite molded door is a right integration of the solid wood composite door and the molded door, which not only has the advantages of the solid wood composite door that the wood surface texture true and natural, but also has the advantages of the molded door which does not craze or deform.

Owner:桦甸市城市基础设施开发建设投资有限公司

Scar/adhesion barrier film and preparation method and application thereof

ActiveCN110893250AFull contact absorptionImprove adhesionSurgeryPharmaceutical delivery mechanismBiocompatibilitySurgery

The invention relates to a scar / adhesion barrier film prepared from single type-I collagen keeping a triple-helix structure, and a preparation method and application of the scar / adhesion barrier film.The barrier film has the characteristics of low immune antigenicity, good biocompatibility, high platelet aggregation function, intramembrane coagulation, controllable degradation rate of biologicalmaterials, certain thickness and flexible application performance, and particularly, the prepared barrier film has the characteristic of scar barrier effect, and is suitable for preventing or relieving hemorrhagic adhesion complications caused by any visceral trauma and postoperative bleeding.

Owner:许和平 +2

A kind of max phase ceramic-metal layered composite material, preparation method and application

ActiveCN109318547BHigh mechanical strengthHigh tensile strengthLamination ancillary operationsProtective equipmentMetal foilCeramic metal

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

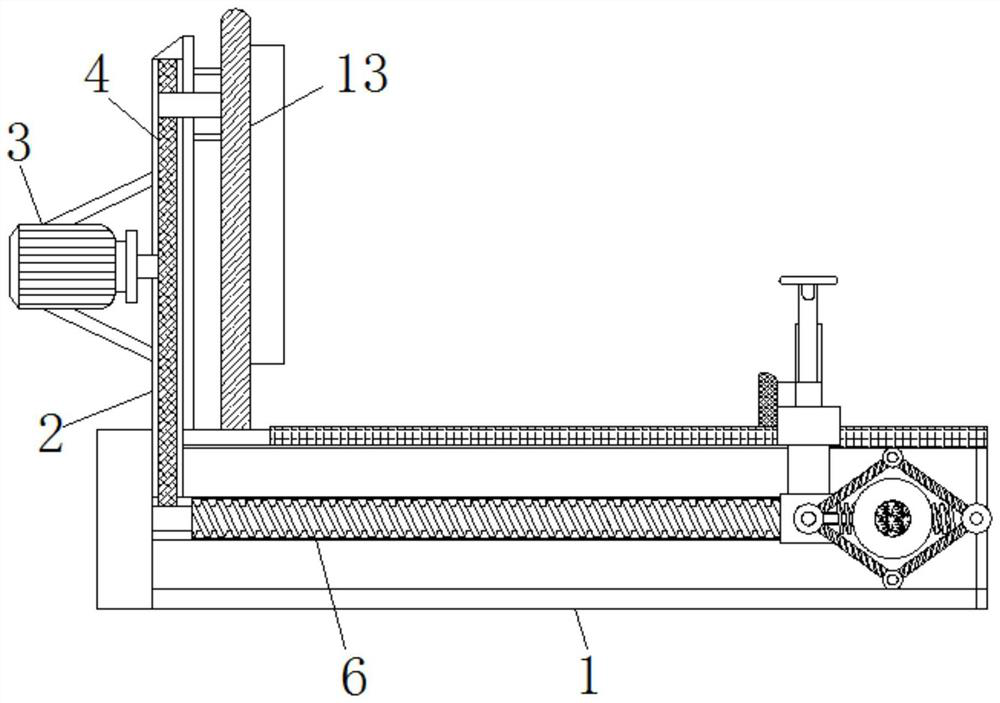

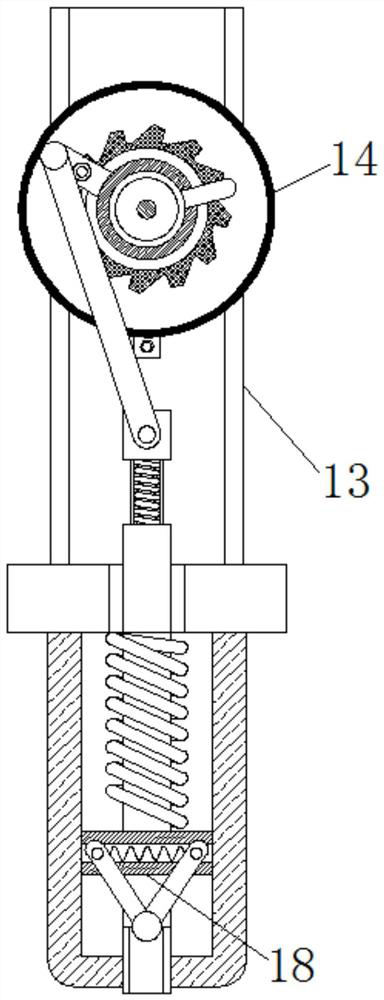

Semi-automatic office binding device

InactiveCN112172373AAchieve the effect of automatically fixing binding materialsWith tensile strengthSheet bindingWheel driveEngineering

The invention relates to the technical field of office stationery, and discloses a semi-automatic office binding device. The semi-automatic office binding device comprises a bottom plate, a fixing frame is fixedly mounted at the left end of the top of the bottom plate, a driving device is fixedly mounted at the left end of the fixing frame, a rotating shaft is rotatably connected into the fixing frame, a rotating wheel is fixedly connected to the upper end of the rotating shaft, and a screw rod is fixedly mounted at the lower end of the rotating shaft. According to the semi-automatic office binding device, the driving device drives the rotating wheel to rotate, the rotating wheel drives a rotating rod to move, the rotating rod fluctuates a connecting rod to move when passing through a cylinder, the connecting rod pulls an adjusting spring at the lower end to enable the spring to have tensile force, then an extrusion rod is released, and the extrusion rod acts on materials to be bound;and then when the connecting rod rotates on a circular guide rail by a quarter of a circle, the extrusion rod is driven to push the binding device to bind the materials downwards, and therefore the automatic bookbinding effect is achieved.

Owner:梧州星河科技有限公司

Bionic texture membrane

PendingCN112356549AWith tensile strengthReduce reboundSynthetic resin layered productsNumerical controlProcess engineering

The invention provides a bionic texture membrane which can provide a new surface treatment mode for a model manufacturing stage, a daily indoor environment, an electronic product and a daily electricappliance in the industrial design research and development process. A traditional surface treatment mode cannot meet the requirements of being non-permanent, replaceable, modifiable and convenient toconstruct, and cannot meet the surface treatment mode that the surface simulates the natural biological surface texture. According to the invention, a novel mode of a texture layer and a plurality offunctional layers is used, the surface texture of natural organisms is simulated, the performance is blended, and the thickness of the membrane is controlled, so that corresponding technical requirements and environmental requirements are met. The bionic texture membrane can be applied to manufacturing modeling design clay models, 3D printing models, numerical control machining models and surfaceeffect performance of various verification models of products in industrial product design, and non-permanent replacement of surface materials of automobile cosmetics, indoor environments, electronicproducts and daily electrical appliances. The personalized needs can be met.

Owner:王青松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com