Anti-ultraviolet PBT compound as well as preparation method and application thereof

An anti-ultraviolet and compound technology, applied in the field of engineering plastics, can solve the problems of less impact on mechanical properties, decreased mechanical properties of PP and LDPE, etc., and achieve the effect of reducing mechanical properties and good anti-ultraviolet performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

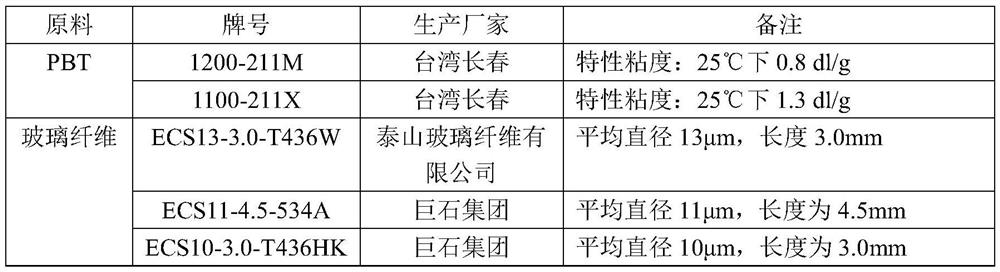

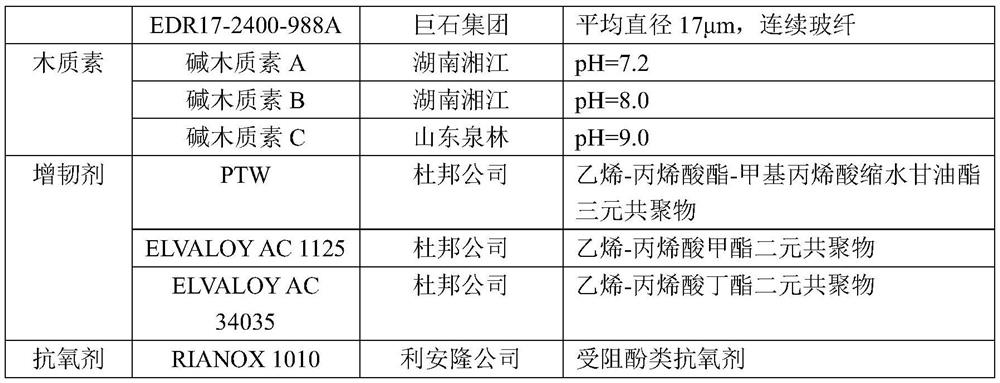

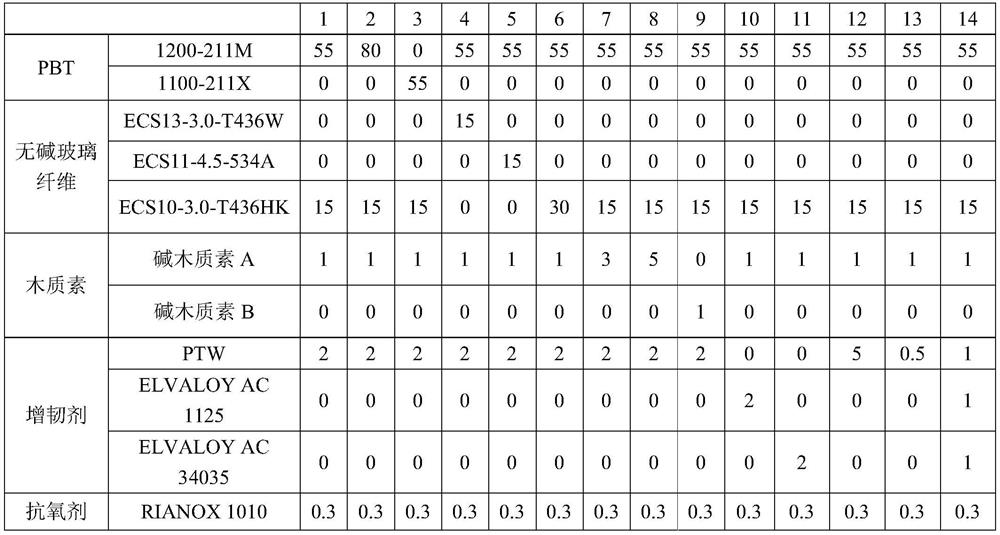

[0048] Examples 1-14 provide an anti-ultraviolet PBT compound, and the addition amount of each component of the PBT compound is shown in Table 1.

[0049] Each component add-on (weight part) in the embodiment 1~14 of table 1

[0050]

[0051] The preparation method of anti-ultraviolet PBT compound among the embodiment 1~14 is:

[0052] Mix the dried PBT with lignin, toughener and antioxidant, put it into the main feeding hopper of the twin-screw extruder, put the glass fiber into the side feeding hopper of the twin-screw extruder, and melt extrude After extraction, cooling and granulation, the anti-ultraviolet PBT compound is obtained.

[0053] The drying condition of PBT is 120°C for 4 hours, the temperature of the twin-screw extruder is 220-250°C, the feed rate is 300kg / h, and the speed of the main machine is 300rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com