Extra-weather-resistant matt fluorocarbon-polyester composite powder coating and preparation method thereof

A technology of ultra-weather-resistant matt and powder coatings, applied in powder coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high material costs and slow progress, and achieve long service life, soft light, and delicate appearance and touch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

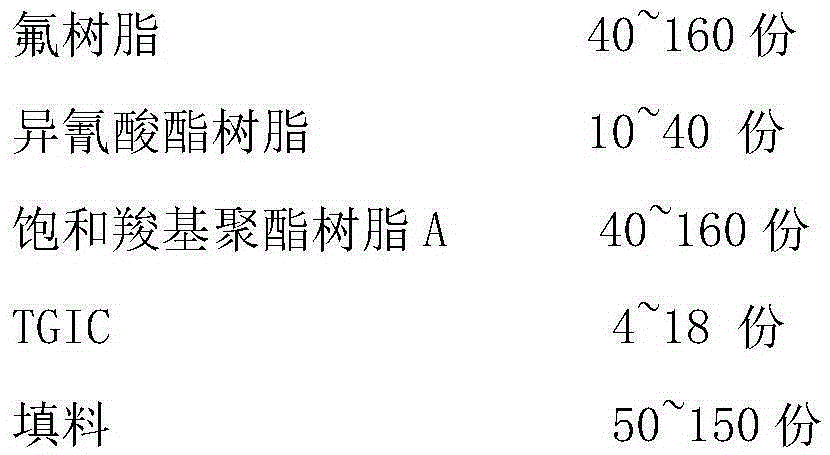

[0038] A fluorocarbon-polyester composite ultra-weather-resistant matt powder coating, including component A and component B, the specific formula is as follows:

[0039]

[0040]

[0041] The preparation method of this embodiment is as follows:

[0042] (a) Weigh each component according to the ratio of components A and B, respectively, place them in the mixing tank, fully mix and crush for 5 minutes;

[0043] (b) The crushed components A and B are melted and extruded into the twin or single-screw extruder respectively; the heating temperature of the extruder is controlled at 110°C;

[0044] (c) The extruded components A and B are tabletted, cooled, and simply crushed into flakes;

[0045] (d) Mix the flaky materials of components A and B evenly at a ratio of 1:1, and then pulverize them into a powder with a particle size (equivalent particle size D50) of 40-50 microns by a mill, and then sieve Packaged to obtain powder coating sample powder 1.

Embodiment 2

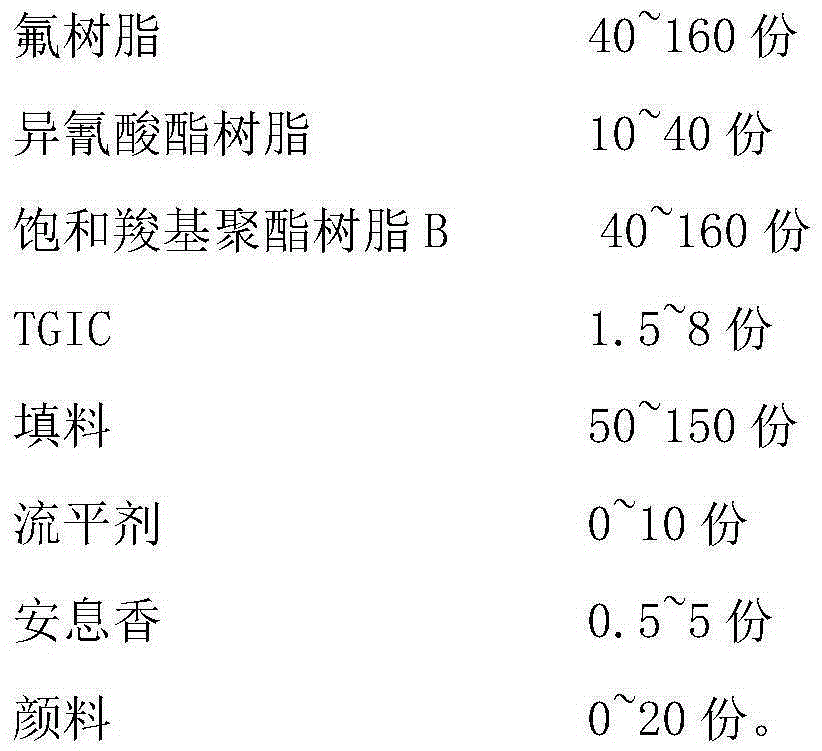

[0047] A fluorocarbon-polyester composite super-weather-resistant matte powder coating, including component A and component B compounded at a weight ratio of 1:1, the specific formula is as follows:

[0048]

[0049]

[0050] The preparation method of this example is the same as that of Example 1, and powder coating sample powder 2 is obtained.

Embodiment 3

[0052] A fluorocarbon-polyester composite super-weather-resistant matte powder coating, including component A and component B compounded at a weight ratio of 1:1, the specific formula is as follows:

[0053]

[0054] The preparation method of this example is the same as that of Example 1, and powder coating sample powder 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com