Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

243results about How to "Reduce reflected light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

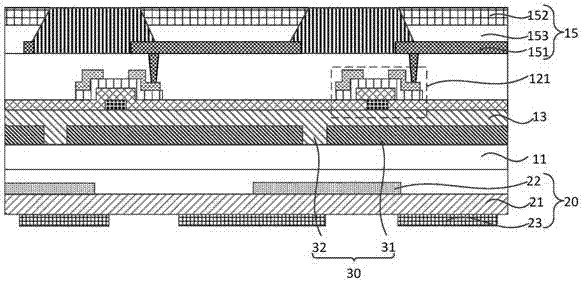

Display panel and display device

ActiveCN106940488AImprove the accuracy of fingerprint recognitionReduce reflected lightNon-linear opticsAcquiring/reconising fingerprints/palmprintsDisplay deviceComputer science

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a display module, a fingerprint recognition module, and at least one layer of black matrix, wherein the display module comprises a first substrate and multiple pixel circuits, the first substrate comprises a display region and a non-display region around the display region; multiple pixel circuits are located inside the display region of the first substrate, each pixel circuit comprises multiple thin film transistors, each thin film transistor comprises a grid electrode, a source electrode and a drain electrode; the fingerprint recognition module is formed inside the display region at one side, facing away from the thin film transistor, of the first substrate; the at least one layer of black matrix is arranged between the thin film transistor and the fingerprint recognition module, the black matrix comprises shading areas and an opening area located between the shading areas; the projections of the grid electrode, the source electrode and the drain electrode of the thin film transistor are located inside the projection of the shielding area on the first substrate. An aim of improving the fingerprint recognition precision of the display panel can be achieved by use of the embodiment of the invention.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

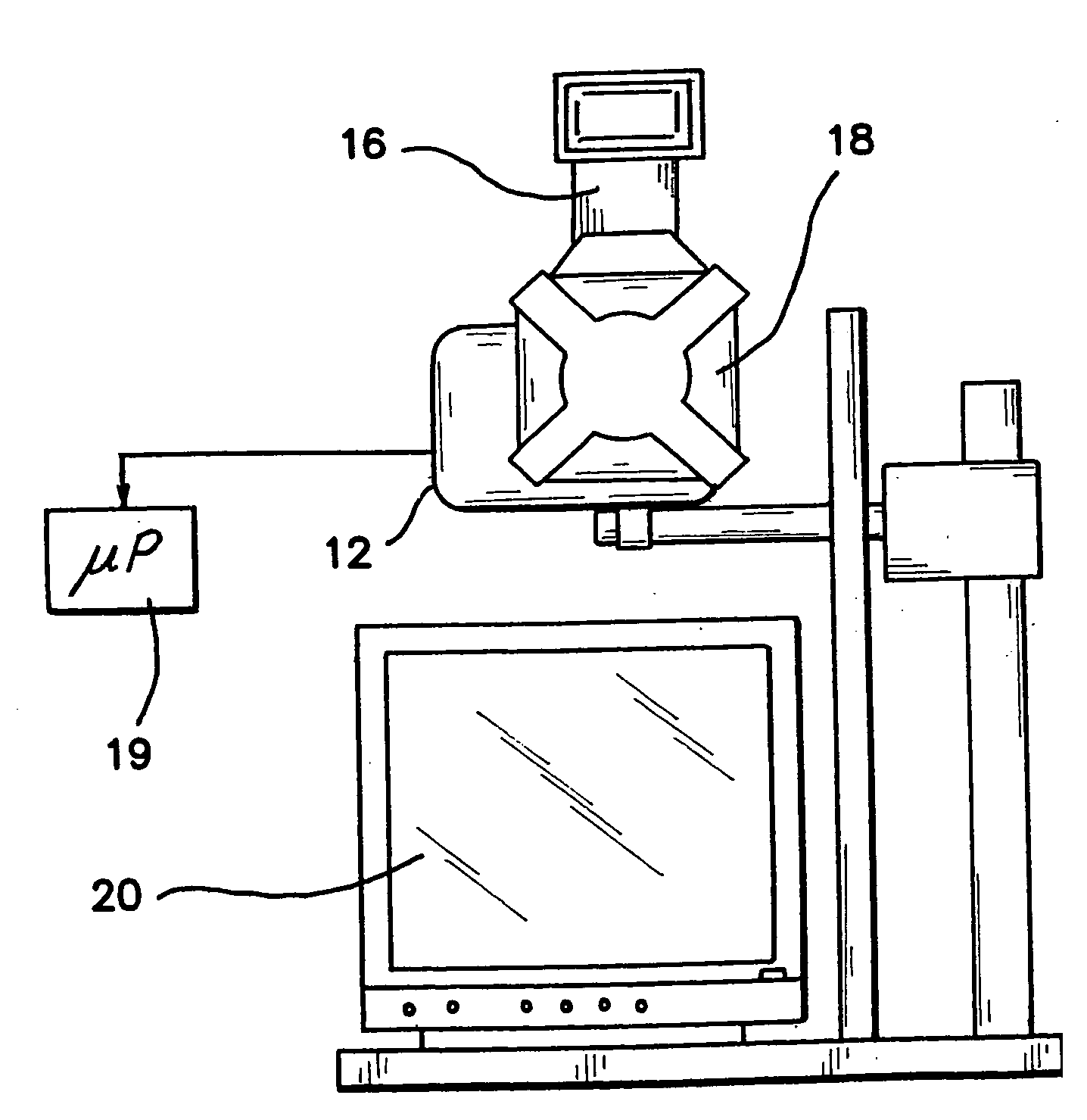

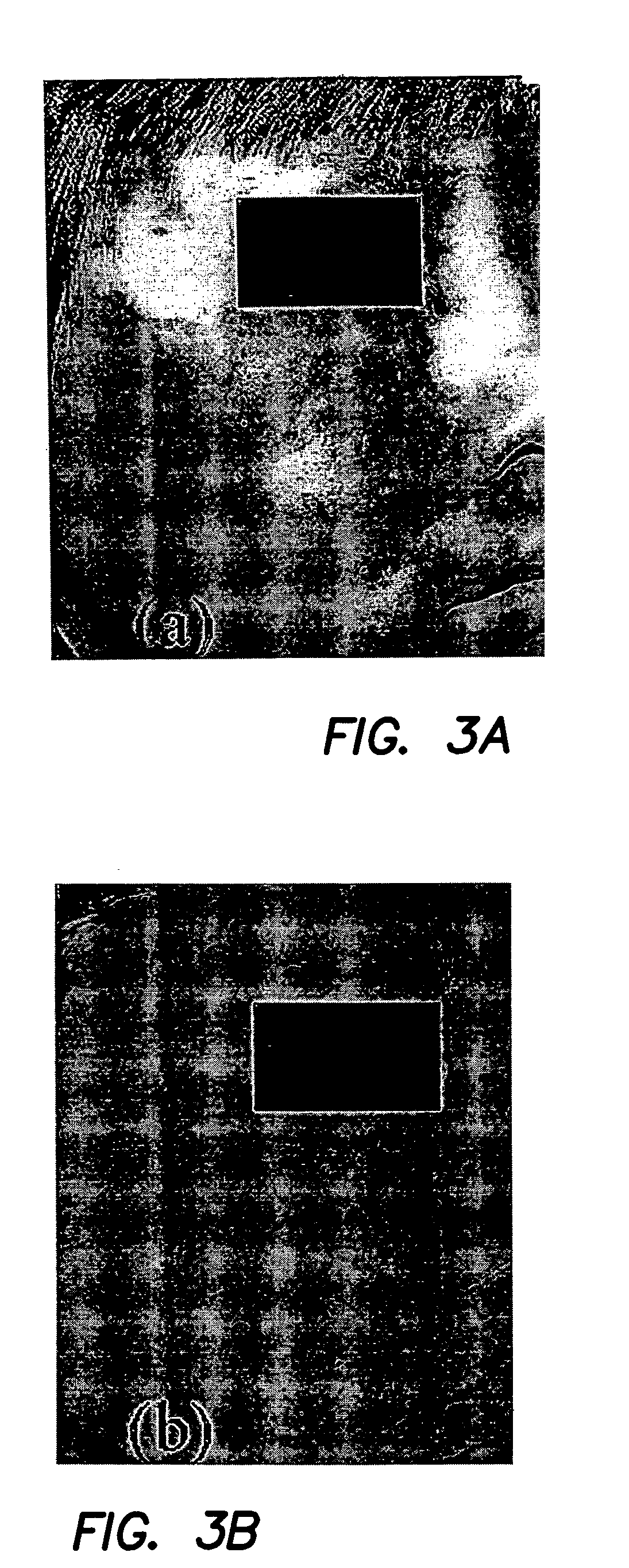

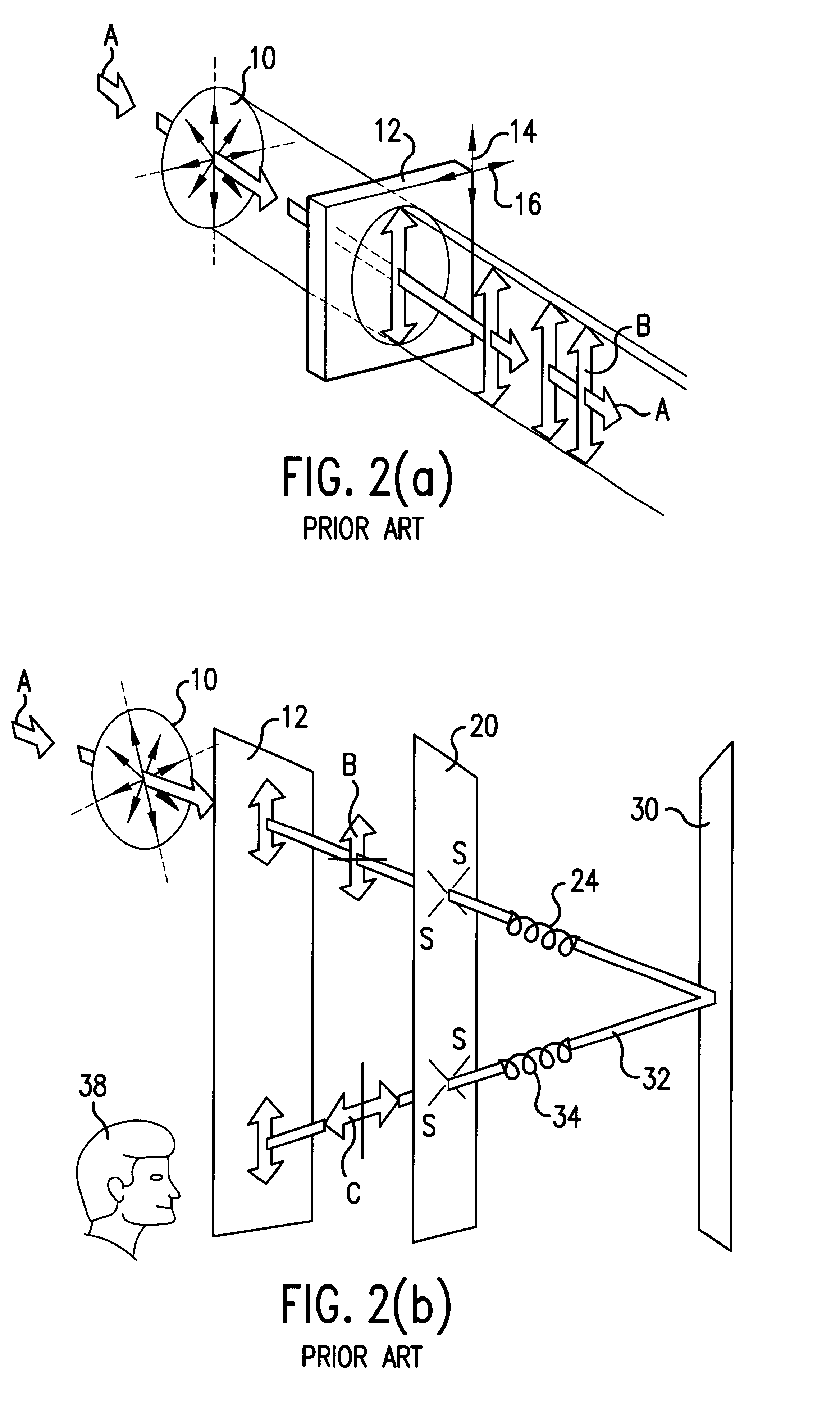

Method and apparatus for characterization of chromophore content and distribution in skin using cross-polarized diffuse reflectance imaging

ActiveUS20050030372A1Rapidly and quantitatively characterizesReduce reflected lightDiagnostics using lightCharacter and pattern recognitionDigital imagingSkin color

A digital imaging system provides color information of an entire port wine stain or other skin condition with a single image in CIE L*a*b* color space (L*, a*) derived from RGB pixel data (R, G, B). Cross-polarization optics produce marked reduction in specularly reflected light in the images. A patient positioning device allows for repeatable positioning of the patient's head or body portion. The digital nature of the system provides a near real-time mapping of melanin and erythema or other skin chromophore metrics. The cross-polarized diffuse reflectance color digital imaging system obtains subsurface skin color information and acquisition of facial images in a reproducible fashion at a fixed distance from an illumination source at optimized angles of view depending on the region of interest being imaged.

Owner:RGT UNIV OF CALIFORNIA

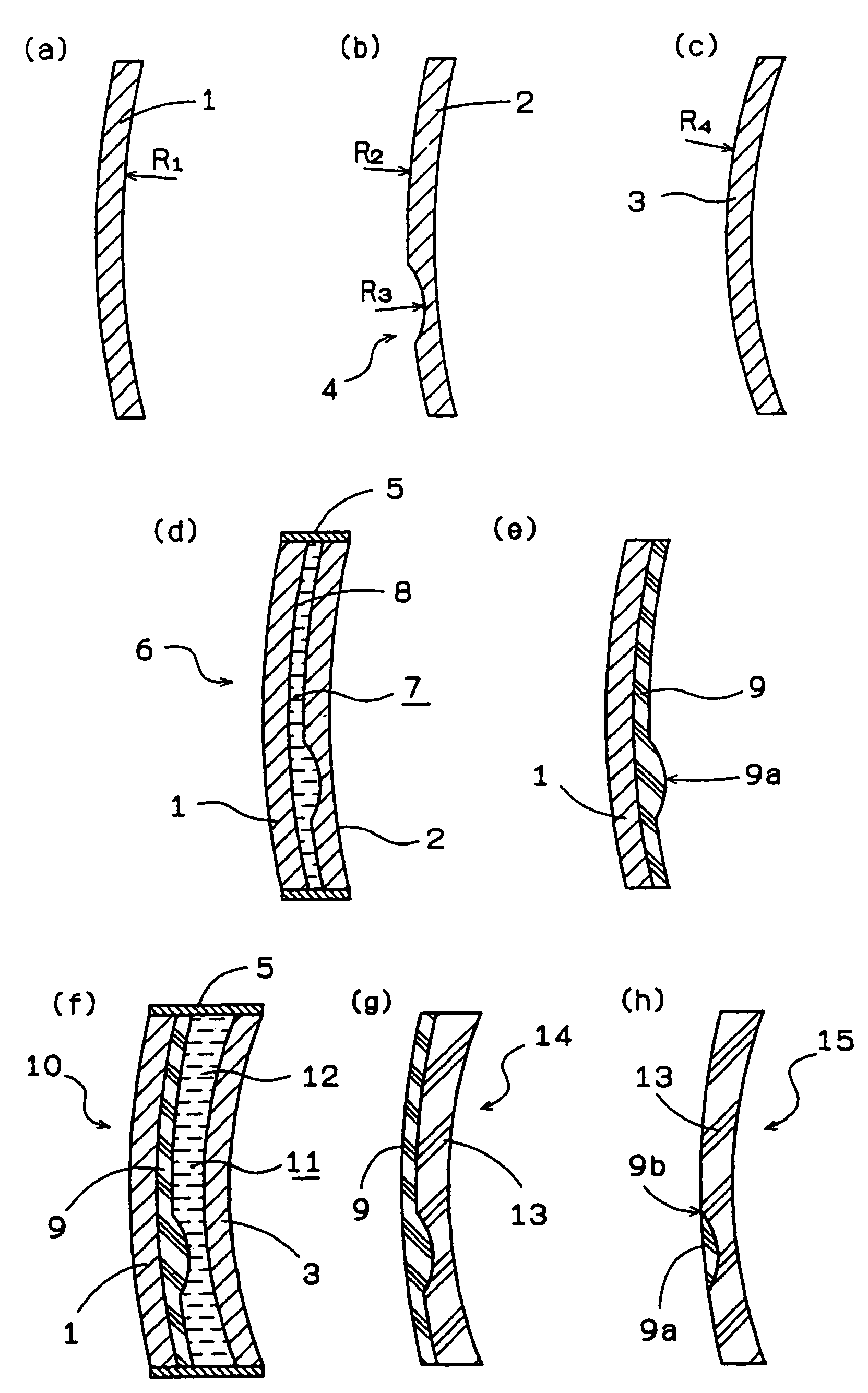

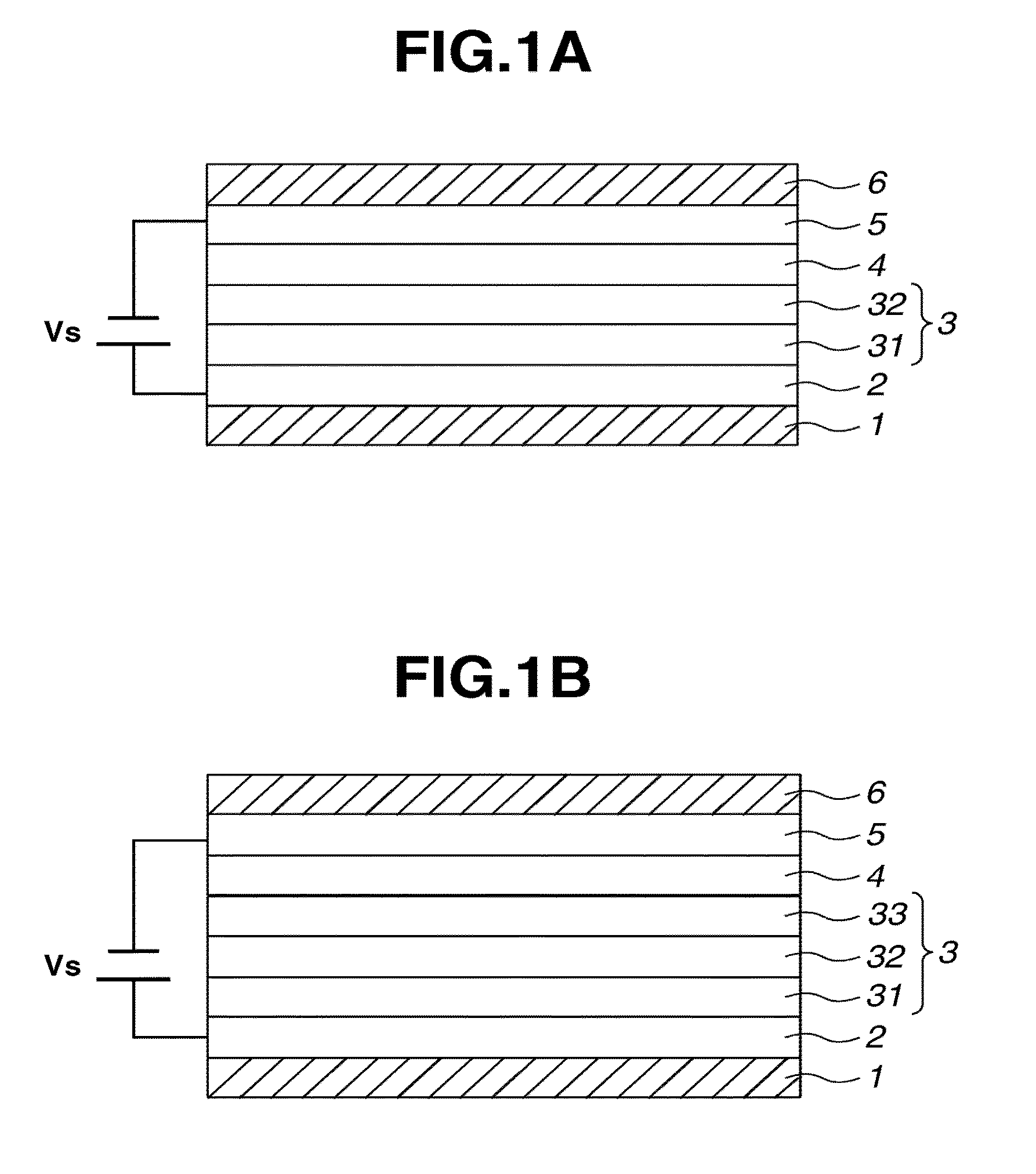

Circular polarizer comprising anti-reflection material

InactiveUS6403223B1Reduce reflected lightReduce glareSynthetic resin layered productsPolarising elementsOptoelectronicsPolarizer

An optical article comprising a first layer of a transparent resin having a self-healing property; an antireflection layer consisting essentially of a non-crystalline fluorine-containing polymer disposed underneath said first layer; and a circular polarizer disposed underneath said antireflection layer. The optical article has anti-reflective and anti-glare properties and also has self-healing properties and scuff resistance imparted by a thin, multi-layered film. The optical article thus is effective in reducing reflection and glare.

Owner:TELSPAN SERVICES

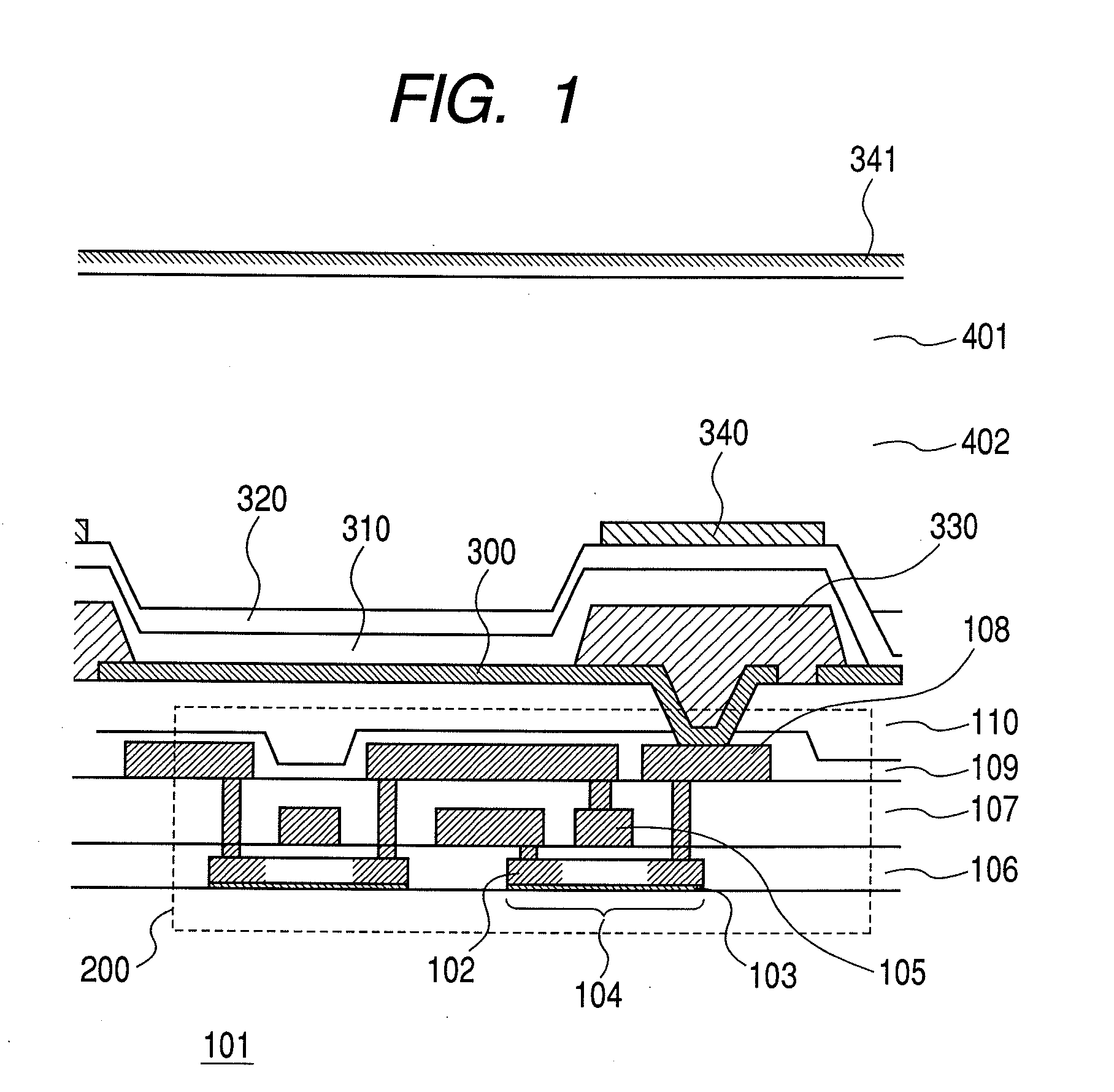

Organic light-emitting apparatus

InactiveUS20080150421A1Increase contrastReduce reflected lightDischarge tube luminescnet screensLamp detailsHigh contrastElectrical connection

An organic light-emitting apparatus is provided which is reduced in reflection of light incident on an organic light-emitting device and has a high contrast in a light environment. The organic light-emitting apparatus has a number of organic light-emitting devices and has contact holes formed for providing electrical connection to the organic light-emitting devices having a polarizing plate on a light extraction surface side. The organic light-emitting apparatus further has, on the contact holes, an insulating layer which is a light transmissive member, has an opening defining a light-emitting region of the organic light-emitting device, and covers an opening of a planarizing layer and a region between adjacent portions of a first electrodes, and a light shielding layer formed on the insulating layer so as to cover the opening in the planarizing layer.

Owner:CANON KK

Organic electroluminescence display device

InactiveUS20040189187A1Contrast of display is not enhancedLow costDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOrganic electroluminescence

An organic electroluminescence display device is provided. The OEL device includes a substrate, a first electrode layer, a second electrode layer, an organic functional layer and at least one electrochromic medium layer. The first electrode layer is disposed on the substrate, the second electrode layer is disposed over the first electrode layer, and the organic functional layer and the electrochromic medium layer are disposed between the first electrode layer and the second electrode layer. Accordingly, the electrochromic medium layer is provided as a selective light valve to improve the reflection of the external light, and thus the contrast ratio of the organic electroluminescence display device is enhanced.

Owner:RITDISPLAY

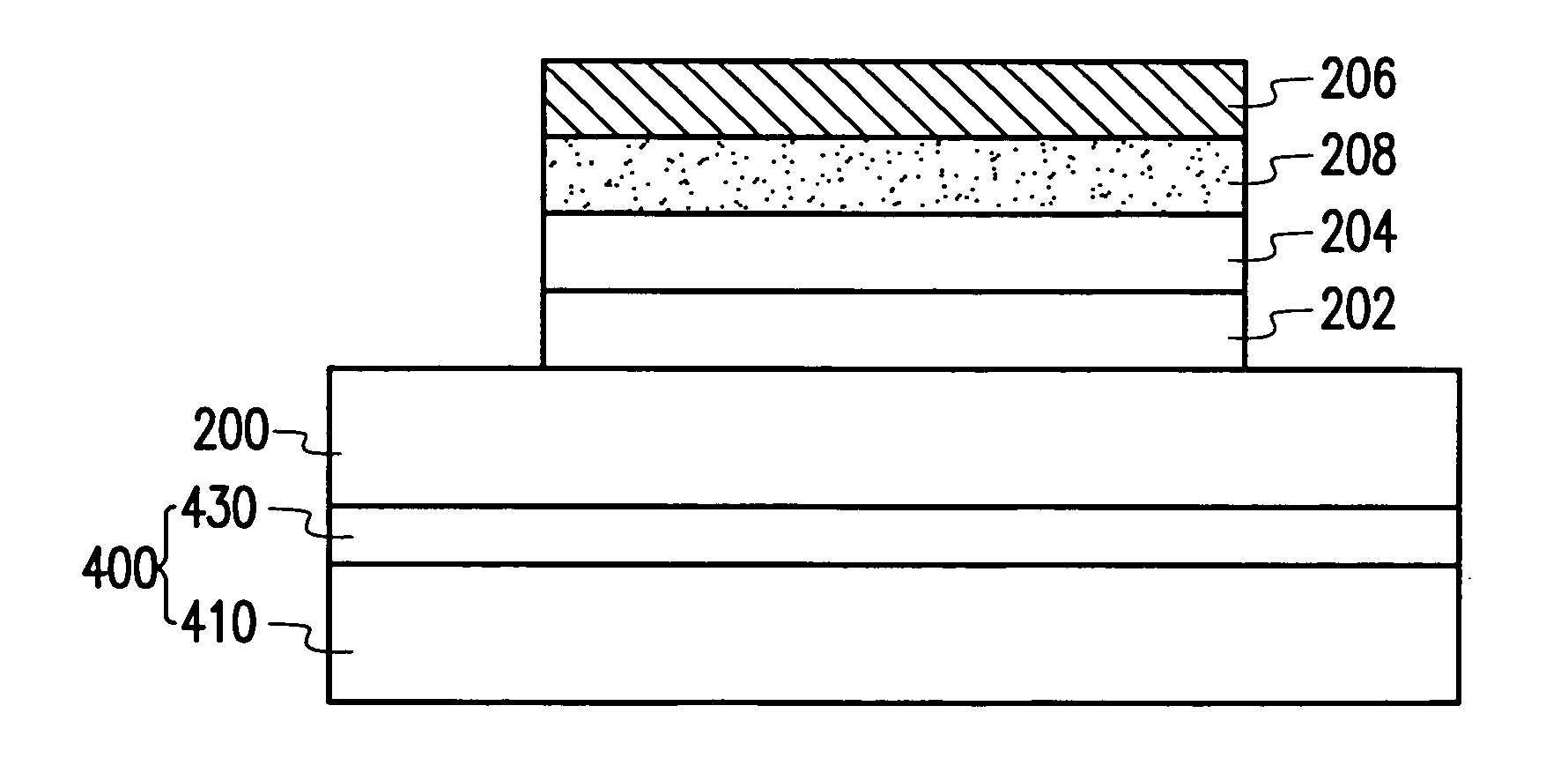

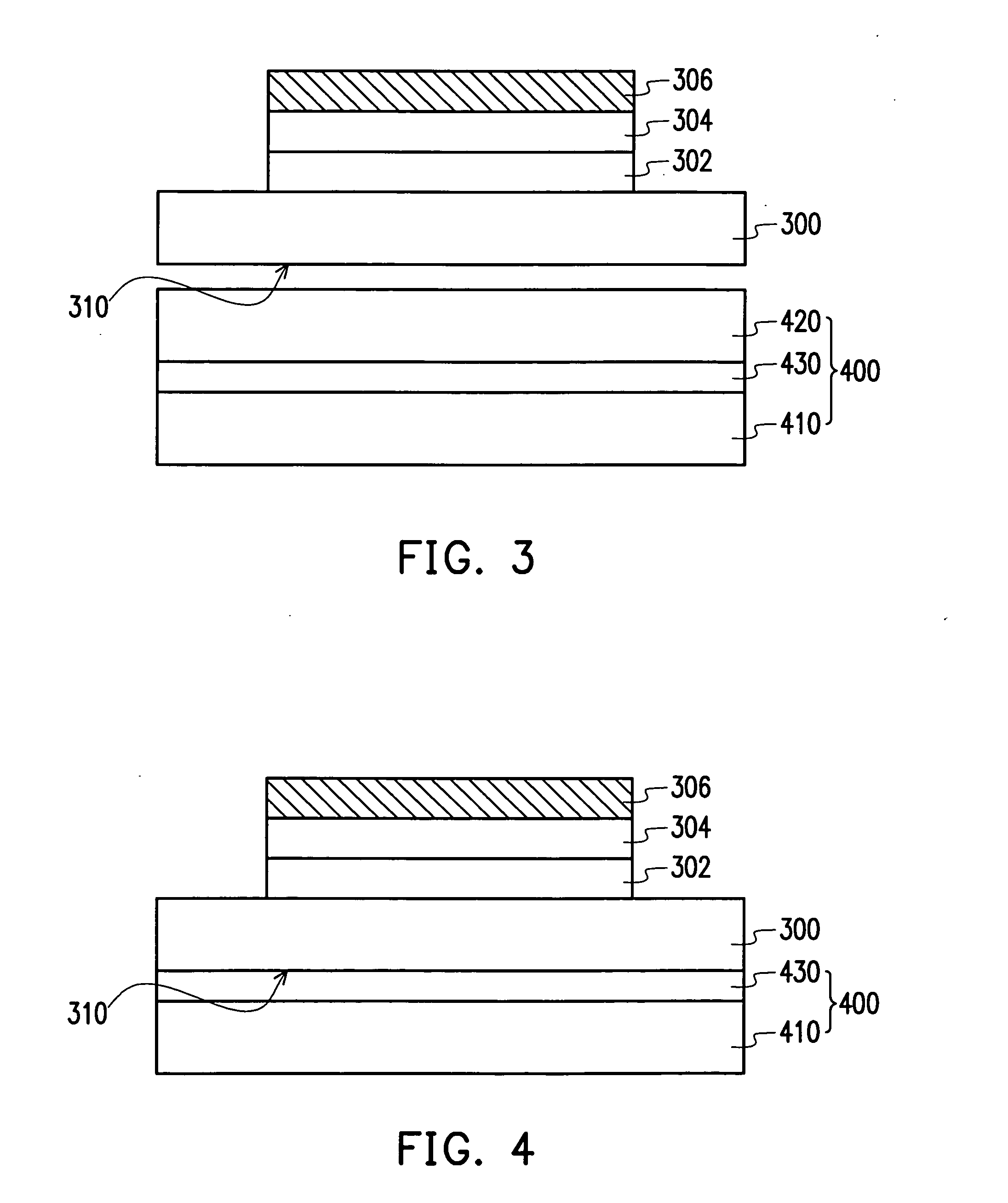

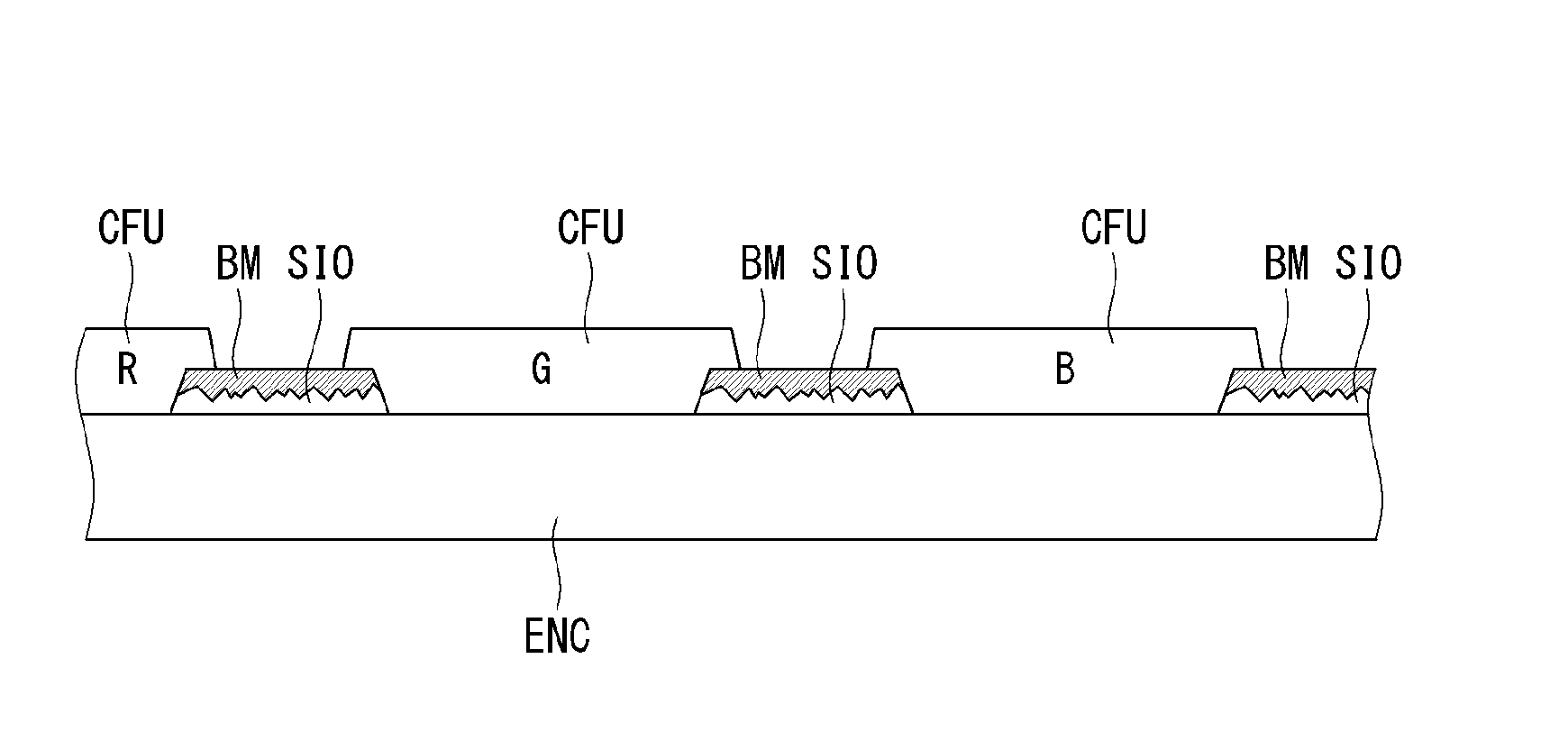

Flat panel display having low reflective black matrix and method for manufacturing the same

ActiveUS20150340412A1Avoid reflectionsReduce decreaseSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

A flat panel display having a low reflective black matrix and a method for manufacturing the same are provided. The flat panel display includes a substrate having an open area and a non-open area; a hazy layer disposed in the non-open area on the inner surface of the substrate; a black matrix stacked on the hazy layer; a driving element disposed in the non-opening area; and a display element disposed in the open area and driven by the driving element.

Owner:LG DISPLAY CO LTD

Reflective mask blank for EUV lithography and reflective mask for EUV lithography

ActiveUS20130196255A1Reduce decreaseReduce unnecessary contactOriginals for photomechanical treatmentResistLithographic artist

A reflective mask for an extreme ultra violet (EUV) lithography obtained by forming a mask pattern in an absorber layer of an reflective mask blank is useful in semiconductor production. The EUV reflective mask has two regions of a mask pattern region and a region outside the mask pattern region. The mask pattern region has the absorber layer and a non-absorber layer on the reflective layer of an substrate, wherein the region outside the mask pattern region has an EUV reflective layer, an EUV absorber layer, and a light shielding layer for suppressing reflection of EUV light and DUV-Vis light having a wavelength of from 190 to 500 nm. The EUV reflective mask reduces unnecessary exposure of resist formed on a substrate to reflected light from the region outside the mask pattern region and reduces a pattern size to produce an accurate transfer pattern.

Owner:ASAHI GLASS CO LTD

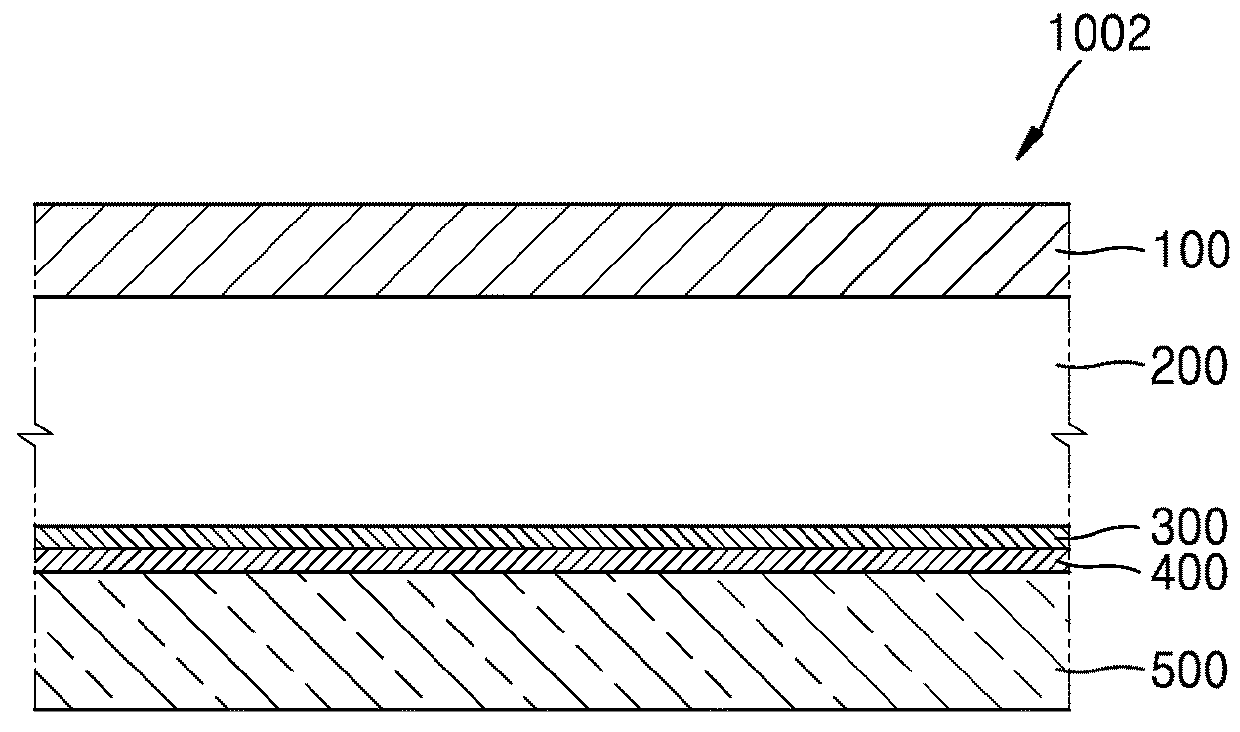

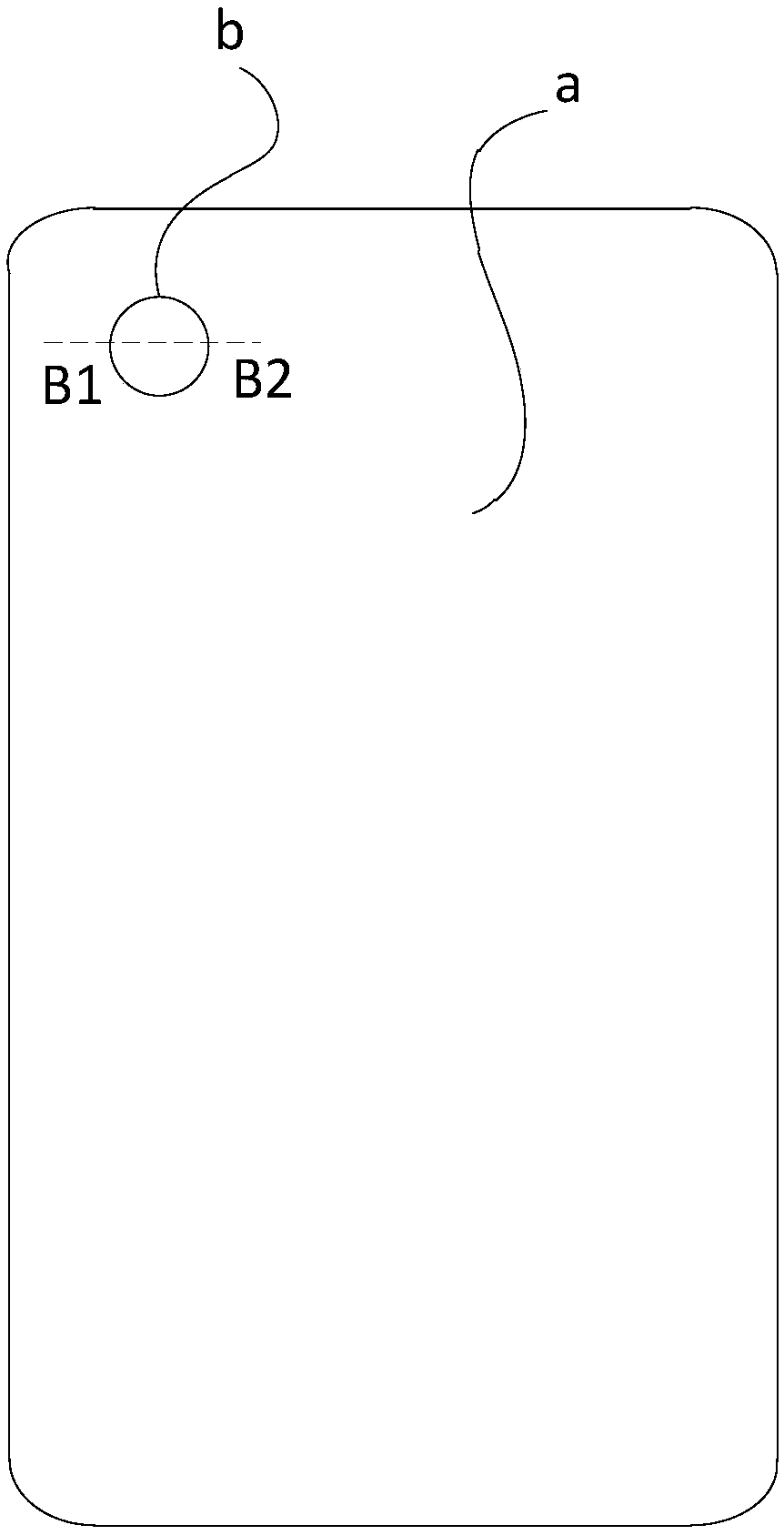

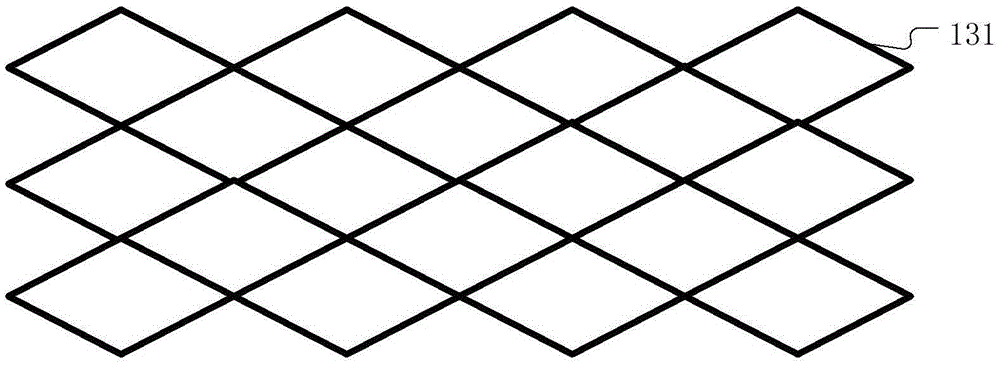

Touch sensor capable of recognizing fingerprints, display device adopting the touch sensor, and electronic device adopting the touch sensor

InactiveUS20180165494A1Reduce a Moire phenomenonReduce reflected lightConductive layers on insulating-supportsLayered productsDisplay deviceOptoelectronics

Provided is a touch sensor including a substrate; an electrode layer disposed on a top surface of the substrate, the electrode layer including a first electrode layer and a second layer that intersect each other, and a dielectric layer disposed between the first electrode layer and the second electrode layer; a transparent cover disposed on the electrode layer; and a random pattern layer including an aperiodic pattern. The random pattern layer reduces a Moire phenomenon that may occur when periodic pattern layers overlap.

Owner:SAMSUNG ELECTRONICS CO LTD

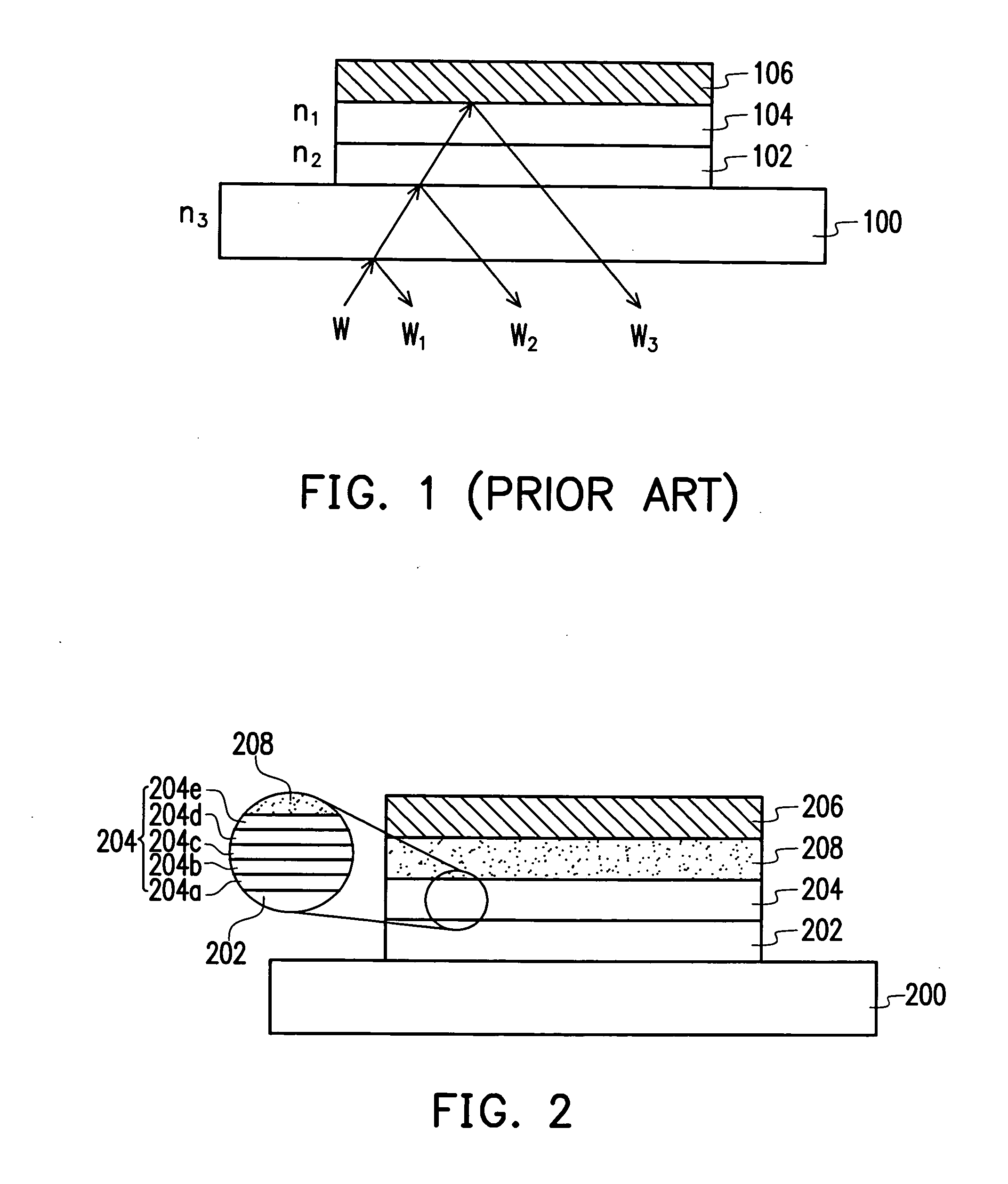

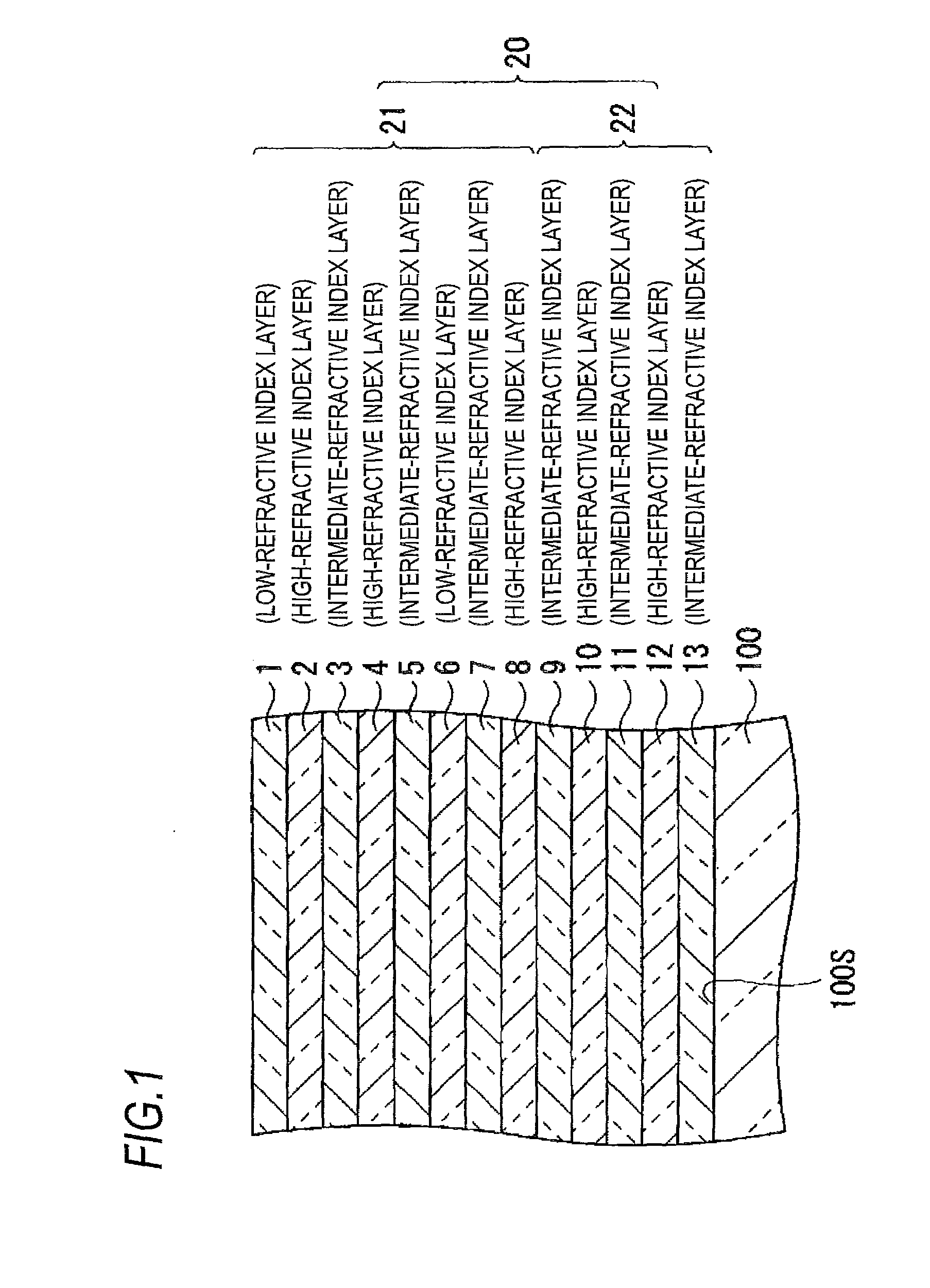

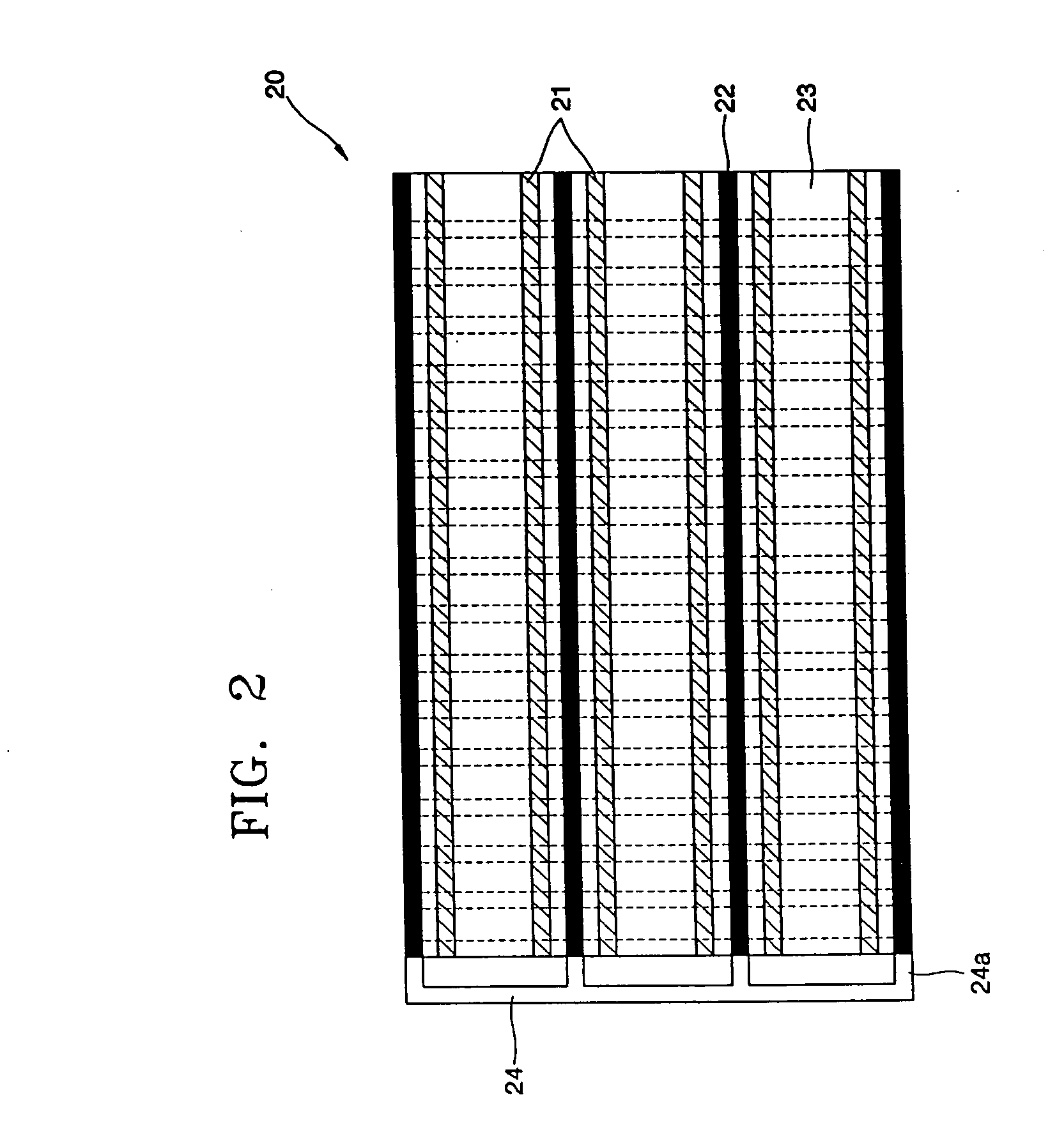

Reflection reducing film, optical member and optical system

InactiveUS20090290219A1Excellent chromaticity balanceReduce reflected lightCoatingsThin material handlingRefractive indexOptic system

A reflection reducing film is provided on a surface of an optical substrate, and is sequentially provided with a buffer layer and a reflection reducing layer. The reflection reducing layer includes first to eighth layers sequentially laminated from the side of the buffer layer. The first and sixth layers are made of a low-refractive index material having a refractive index in the range of 1.35 to 1.50 at the d-line, the third, fifth and seventh layers are made of an intermediate-refractive index material having a refractive index in the range of 1.55 to 1.85 at the d-line, and the second, fourth and eighth layers are made of a high-refractive index material having a refractive index in the range of 1.70 to 2.50 at the d-line.

Owner:FUJIFILM CORP

Plasma display panel using color filters to improve contrast

InactiveUS20050040767A1Prevents external reflection of lightIncrease contrastAddress electrodesSustain/scan electrodesImage contrastFluorescence

A plasma display panel is provided. The plasma display panel includes a front substrate, an X electrode and a Y electrode alternately formed on the front substrate, a dielectric layer formed to cover the X and Y electrodes, a rear substrate installed to face the front substrate, address electrodes formed on the rear substrate and intersecting the X and Y electrodes, barrier ribs formed between the front and rear substrates, and red, green, and blue fluorescent layers applied in discharge cells defined by the barrier ribs. The dielectric layer and the barrier ribs are colored with two complementary colors that essentially filter out nearly all light. Accordingly, it is possible to reduce outdoor daylight reflection and improve image contrast by an improved design over the use of black stripes.

Owner:SAMSUNG SDI CO LTD

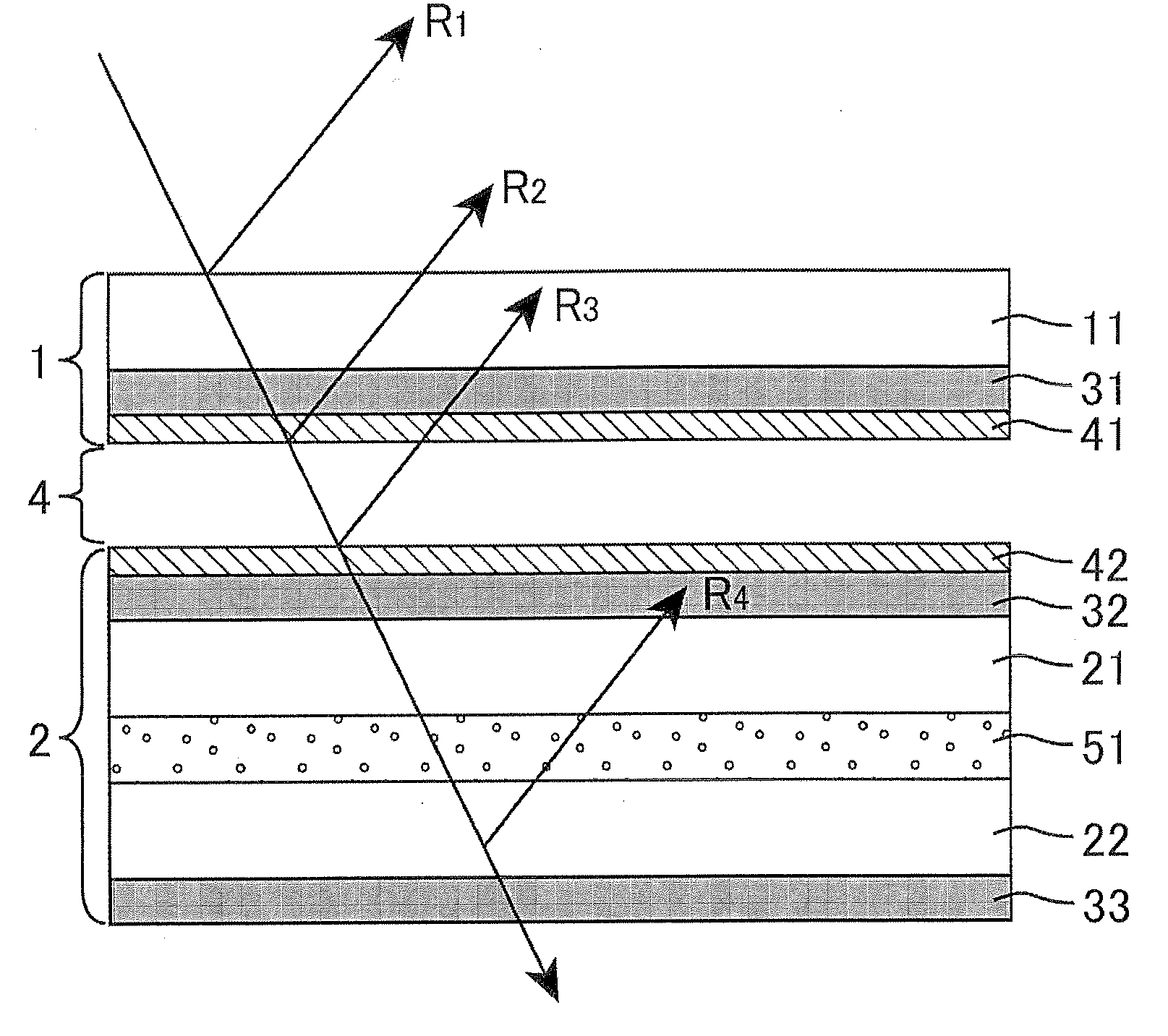

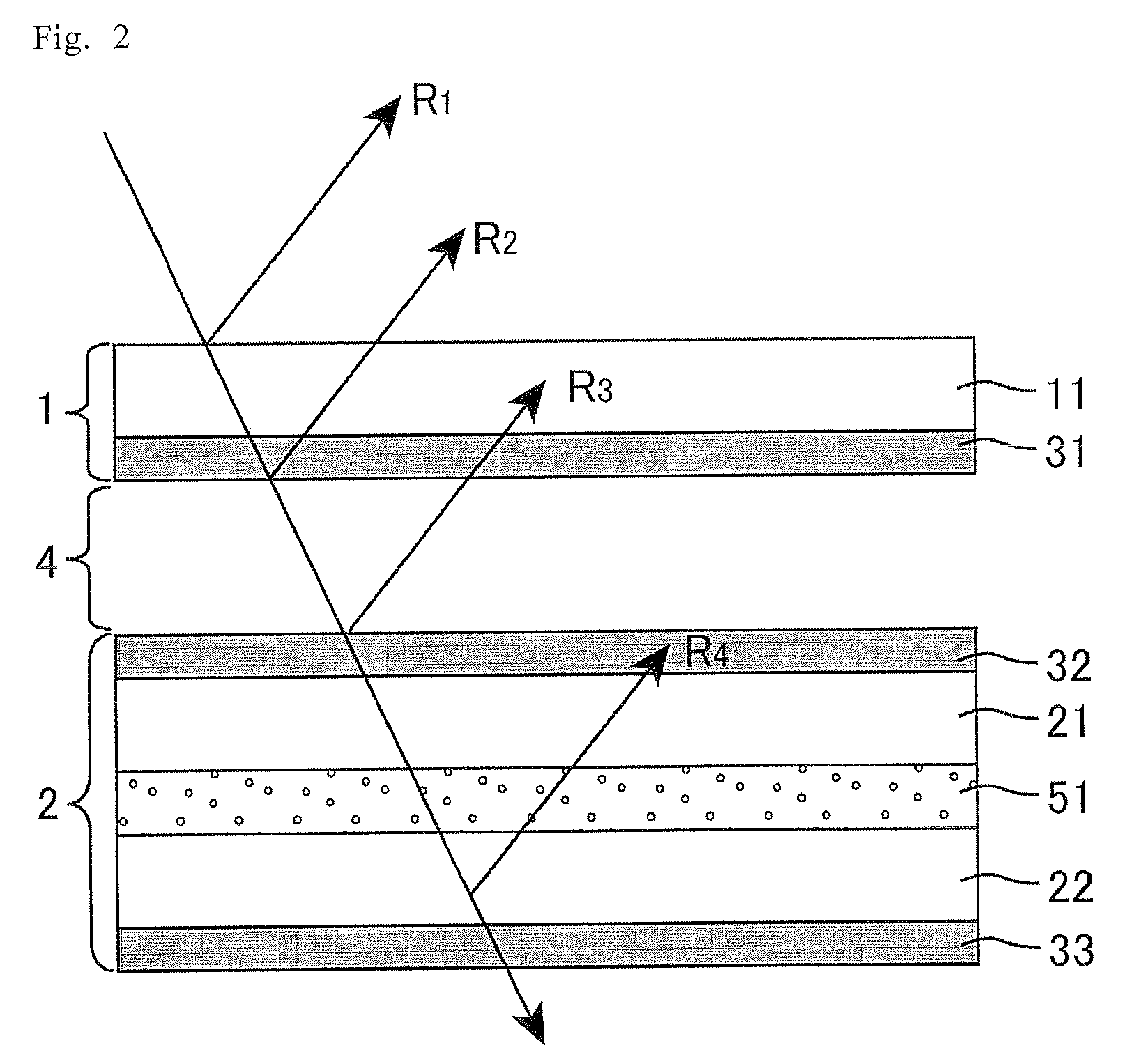

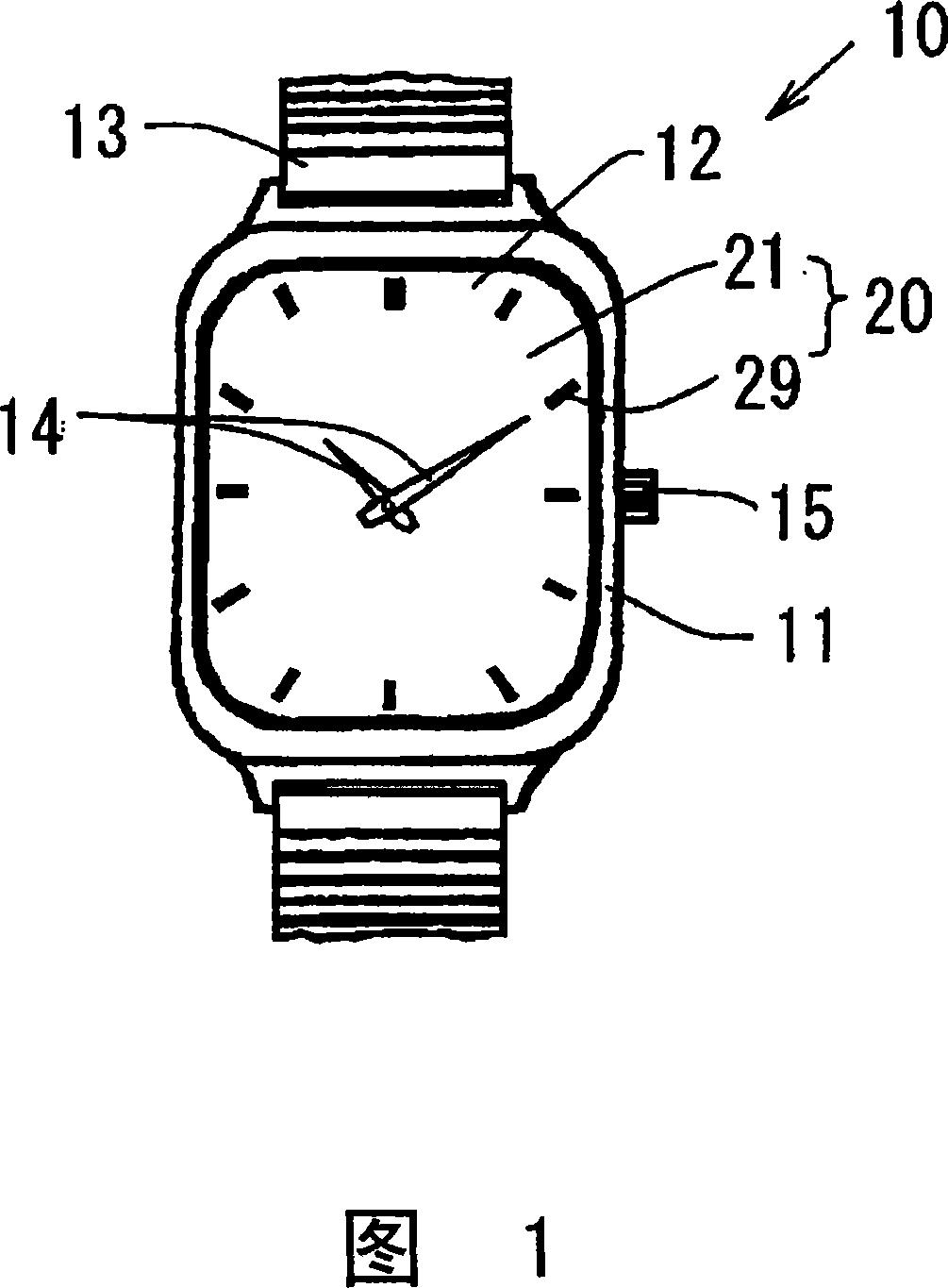

Display device

ActiveUS20110164210A1Reduce reflected lightQuality improvementDischarge tube luminescnet screensLamp detailsDisplay deviceEngineering

The present invention provides a display device which can reduce reflected light reflected on the respective surfaces of a display panel and a protective plate, even if the protective plate is disposed on the surface of the display panel, without employing a complicated structure and without degrading display quality. The display device includes: a display panel; and a protective plate disposed facing the display panel. The protective plate has a protective base material and a first polarizer, the display panel has a second polarizer of which a polarization axis is parallel to that of the first polarizer, and light passing between the first polarizer and the second polarizer is linearly polarized light.

Owner:SHARP KK

Bifocal plastic lens

A bifocal plastic lens having a bench lens and a small lens with different refractive powers. The small lens not protruding above a surface of the bench lens, a boundary between the constituent lenses being difficult to see. The small lens may be provided on a preparatory lens member including the small lens. Alternatively, the preparatory lens member has a concave portion for a small lens molding surface. A resin having a higher refractive index than a resin constituting other portions of the lens is adhered to a surface provided with the small lens or the concave portion to be the small lens molding surface in the preparatory lens member, and is cured and integrated.

Owner:ASAHI LITE OPTICAL

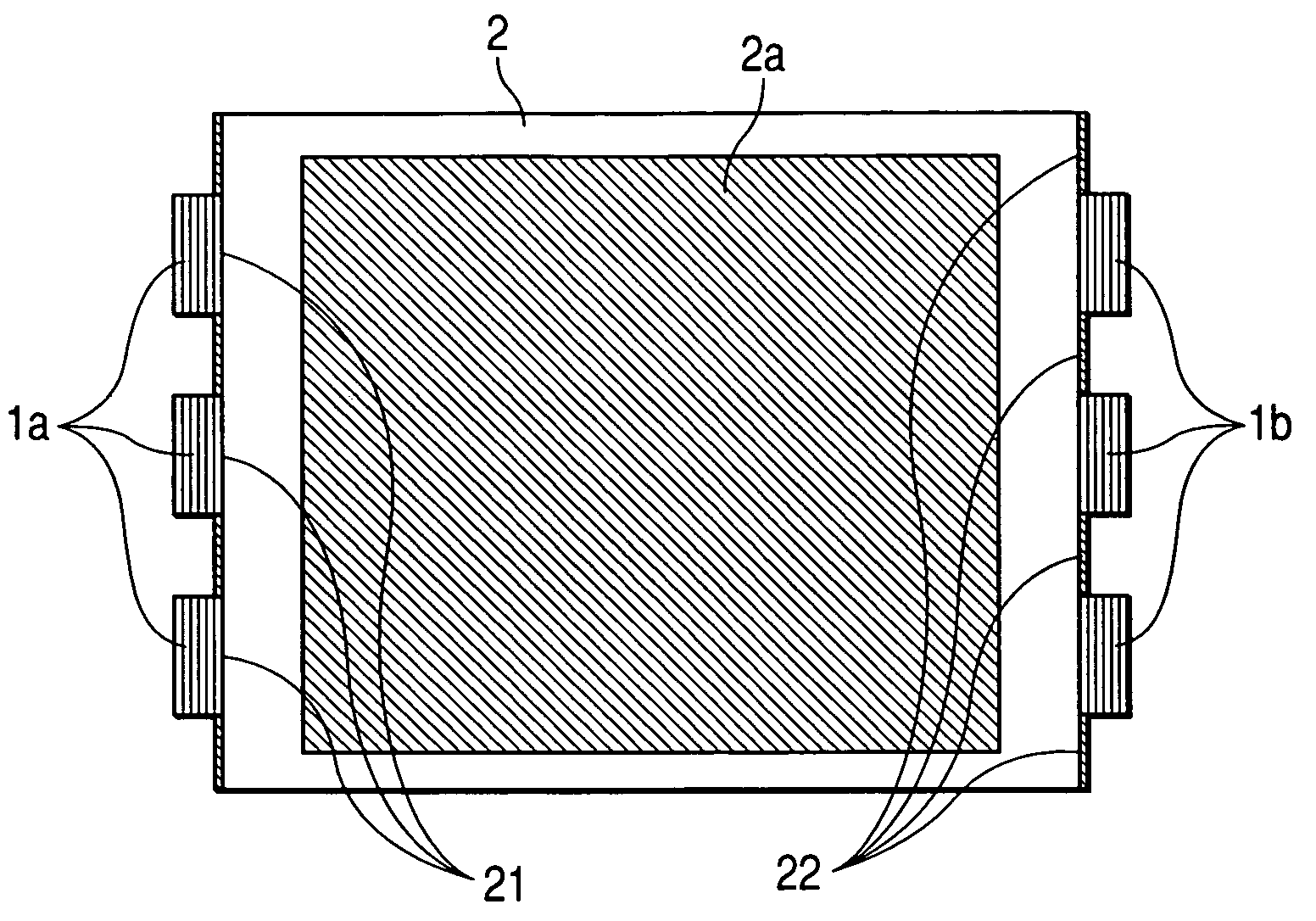

Liquid crystal display panel and display device

ActiveCN108983487AReduce light leakageReduce reflected lightNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal display panel and a display device. The liquid crystal display panel comprises an array substrate and an opposite direction substrate, both of which are oppositely arranged. The liquid crystal display panel also comprises a liquid crystal layer between the array substrate and the opposite direction substrate. The liquid crystal display panel comprises a first light-pervious area and a display area surrounding the first light-pervious area. In the first light-pervious area, the array substrate comprises a first substrate. The opposite direction substratecomprises a second substrate. The first light-pervious area has a first antireflection structure used for reducing reflection light of the first substrate and / or the second substrate. By arranging the first antireflection structure in the first light-pervious area, reflection light generated by light emitted from a backlight source of a display area on the first substrate and / or the second substrate is reduced. Therefore, a light leakage problem of the liquid crystal display panel in the first light-pervious area is avoided.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Display plate for solar cell apparatus and method of producing display plate for solar cell apparatus

ActiveCN101116038AReduce the number of manufacturing processesReduce manufacturing costVisual indicationPhotovoltaic energy generationEngineeringPrism

To provide a display plate for a solar timepiece, having a solar cell; a display plate for a solar cell apparatus, used for a desktop calculator etc. using a solar cell; and a method of producing a display plate for a solar cell apparatus. The display plate for a solar cell apparatus has a solar cell on its lower surface side. The display plate is constructed from a light transmissive substrate, a light transmissive reflection plate provided on the lower surface side of the light transmissive substrate, and a decorative member provided on the upper surface side of the display plate. Further, the light transmissive substrate has a reflection surface provided on its lower surface side or reflection surfaces on its upper and lower surface sides, and the reflection surface or surfaces are each a prism reflection surface.

Owner:CITIZEN WATCH CO LTD

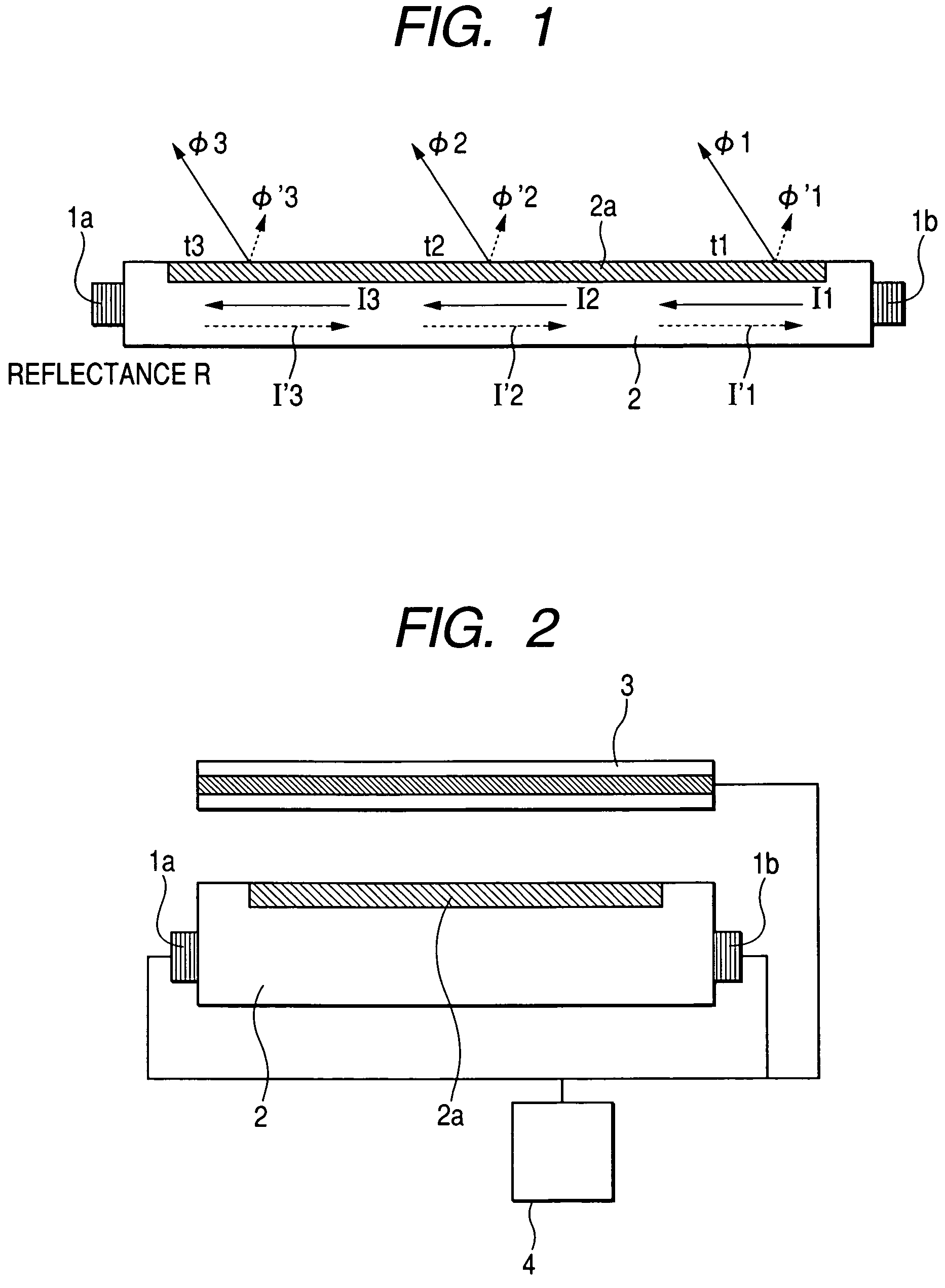

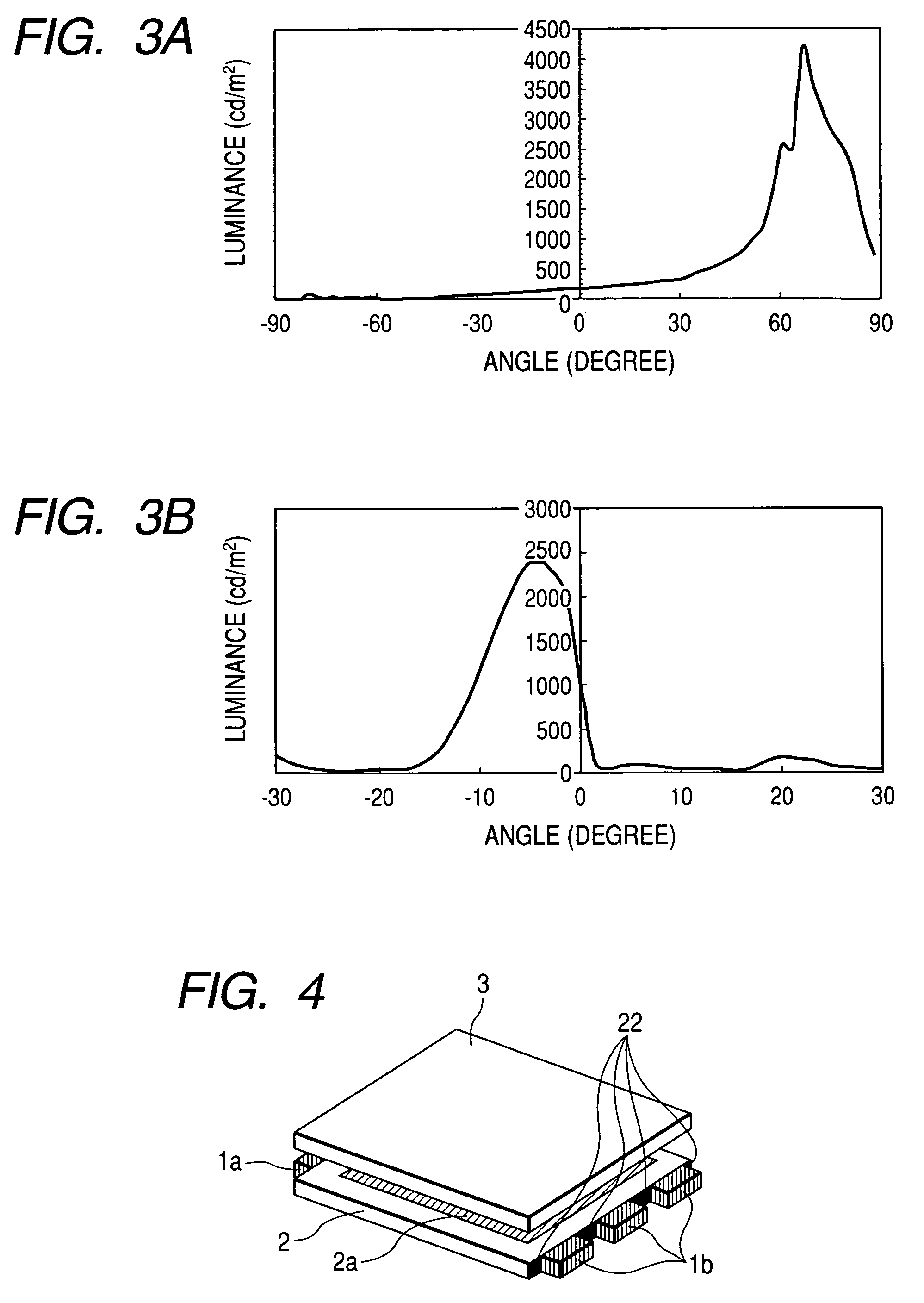

Display device with light guide plate having antireflection portions on light incident surfaces

ActiveUS7576805B2Increase contrastIncrease display contrastNon-linear opticsReflectorsLight guideDisplay device

Owner:MITSUBISHI ELECTRIC CORP +1

Spatial light modulator featured with an anti-reflective structure

InactiveUS7542197B2Reduce reflected lightShort wavelengthColor television detailsNon-linear opticsSpatial light modulatorLength wave

A spatial light modulator supported on a device substrate includes a plurality of light modulation elements to modulate a light emitted from a light source. The spatial light modulator and the device substrate further comprises a cyclic structure on a surface of the spatial light modulator and / or the device substrate for preventing a reflection of the incident light from the cyclic structure. In an exemplary embodiment the cyclic structure includes cyclic structural elements having a distance between two cyclic elements shorter than the wavelength of an incident light for preventing a reflection of the incident light from the cyclic structure.

Owner:IGNITE INC

OLED display panel and touch panel

ActiveCN105528119AReduce reflected lightReduce blackening processInput/output processes for data processingPolarizerOptoelectronics

The invention provides an OLED display panel and a touch panel. The touch panel comprises a linear polarizer, a 1 / 2 wave plate layer, a 1 / 4 wave plate layer and a touch electrode layer, wherein the 1 / 2 wave plate layer is formed on one side of the linear polarizer, the 1 / 4 wave plate layer is formed on one side, away from the linear polarizer, of the 1 / 2 wave plate layer, the touch electrode layer is formed on one side, away from the linear polarizer, of the 1 / 4 wave plate layer and comprises a plurality of touch electrodes, and the touch electrodes are meshed metal grids. The OLED display panel and the touch panel have the advantages that panel reflectivity is reduced, and panel touch precision is increased at the same time.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Electrochromic element and method of forming same

InactiveUS8614848B2Low wavelength dependenceReduce reflected lightWave amplification devicesNon-linear opticsTransmittanceRefractive index

An electrochromic element includes a pair of transparent electrodes, and an electrolyte layer and an electrochromic layer disposed between the pair of transparent electrodes. Transmittance of light is changed by a voltage applied to the pair of transparent electrodes. The electrochromic layer includes a first electrochromic layer and a second electrochromic layer stacked upon each other. Both of the first and second electrochromic layers are made of titanium oxide. The first electrochromic layer is in contact with one of the pair of transparent electrodes. The second electrochromic layer is in contact with an electrolyte-layer side of the first electrochromic layer. A refractive index n0 of the transparent electrode in contact with the first electrochromic layer, a refractive index n1 of the first electrochromic layer, and a refractive index n2 of the second electrochromic layer satisfy the relationship n0<n1<n2.

Owner:CANON KK

Multi-mode lighting system with proximity sensor

ActiveUS20170055328A1Reduce reflected lightReduce glareLighting applicationsLighting support devicesProximity sensorUser input

Described herein is a lighting system capable of responding to user input provided via proximity sensors. In some embodiments, proximity sensors are communicatively coupled to a processor capable of receiving input from the sensors. The sensors may be arranged in a row such that an object moving down the row proximate to the sensors may trigger each sensor sequentially. In some embodiments, the lighting system may alter a beam configuration or cycle between various lighting modes in response to receiving input from the proximity sensors. In some embodiments, the order in which the sensor input is received may be used to determine which lighting mode to cycle to.

Owner:THE COLEMAN CO INC

Single-face matt polyester film and preparation method thereof

InactiveCN101259771AGood matte effectHigh light transmittanceSynthetic resin layered productsPolyesterSurface layer

The invention discloses a single-side matt polyester film with a layered structure comprising at least a first film layer and a second film layer which are co-extruded, compounded with each other and arranged next to each other; the first film layer is arranged on the surface layer of the polyester film and is a matt layer, which contains 50 to 80 wt percent of the polyester, 20 to 50 wt percent of nylon polymer and 0 to 0.5 wt percent of crystal nucleating promoter; the second film layer is a highly transparent layer, the main component of which is the polyester. The invention also discloses a method for manufacturing the single-side matt polyester film. As the method does not require the aforehand special preparation of the matt master batch, the whole process is simple. The manufactured polyester film not only has favorable matt effect, but also has excellent transmittance and is in particular applicable to the use for printing, aluminum plating and compounding in the field of packaging.

Owner:WEIFANG FUWEI PLASTIC

Bifocal plastic lens

InactiveUS20090091705A1Reduce reflected lightOptical articlesOptical partsSmall lensRefractive index

A bifocal plastic lens having a bench lens and a small lens with different refractive powers. The small lens not protruding above a surface of the bench lens, a boundary between the constituent lenses being difficult to see. The small lens may be provided on a preparatory lens member including the small lens. Alternatively, the preparatory lens member has a concave portion for a small lens molding surface. A resin having a higher refractive index than a resin constituting other portions of the lens is adhered to a surface provided with the small lens or the concave portion to be the small lens molding surface in the preparatory lens member, and is cured and integrated.

Owner:ASAHI LITE OPTICAL

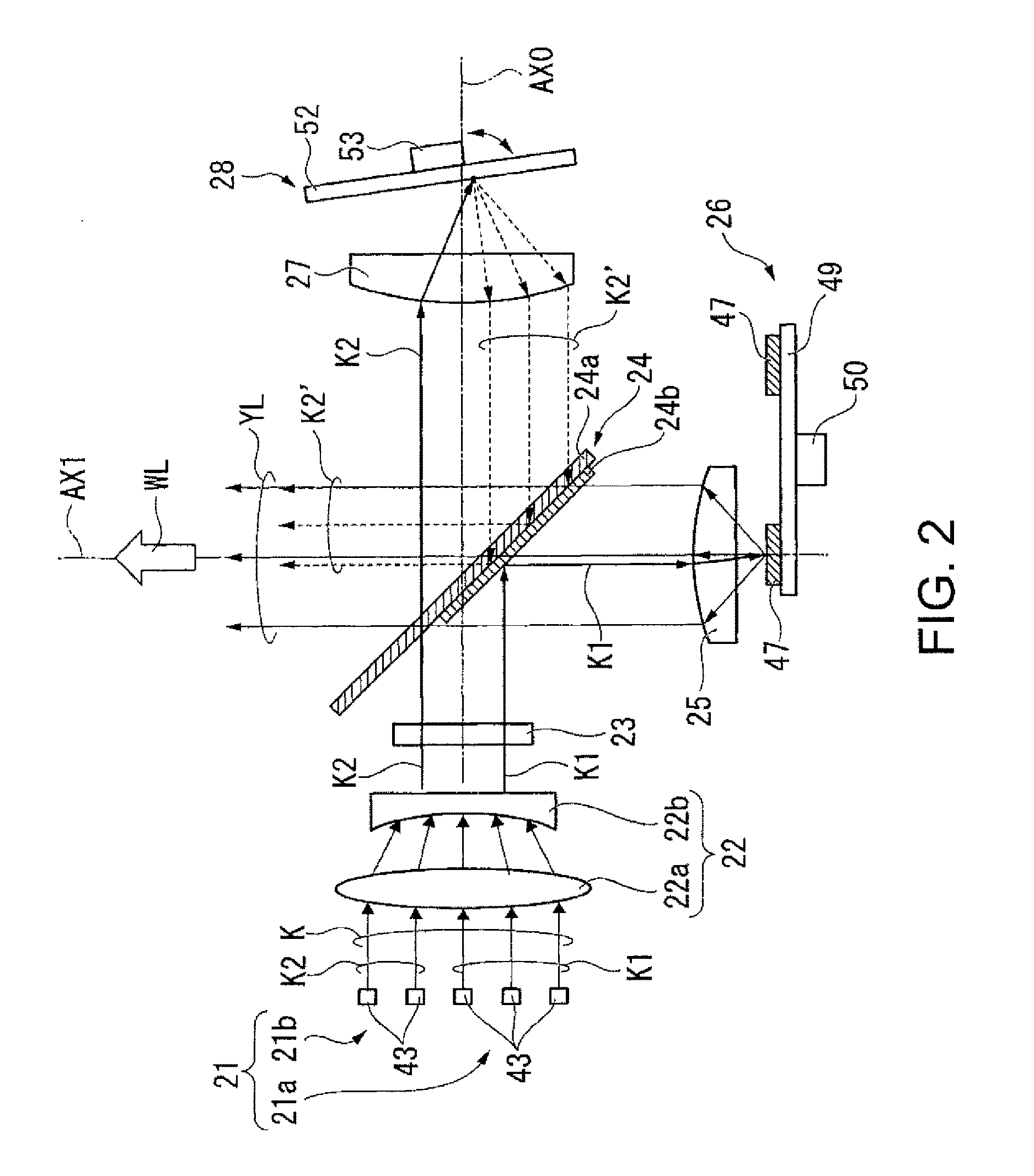

Light source device and projector

ActiveUS20160373705A1Avoid influenceReduce lossesDiffusing elementsPicture reproducers using projection devicesLight beamWavelength conversion

A light source device according to the invention includes a light source, a light separating / combining element including a dichroic layer, a wavelength conversion layer, and a diffusely reflecting element. A bundle of light beams emitted from the light source includes a first light bundle and a second light bundle. The first light bundle enters the wavelength conversion layer via the dichroic layer. The second light bundle enters the diffusely reflecting element without entering the dichroic layer, and is converted into diffusely reflected light. The dichroic layer combines the third light bundle from the wavelength conversion layer and the diffusely reflected light from the diffusely reflecting element with each other.

Owner:SEIKO EPSON CORP

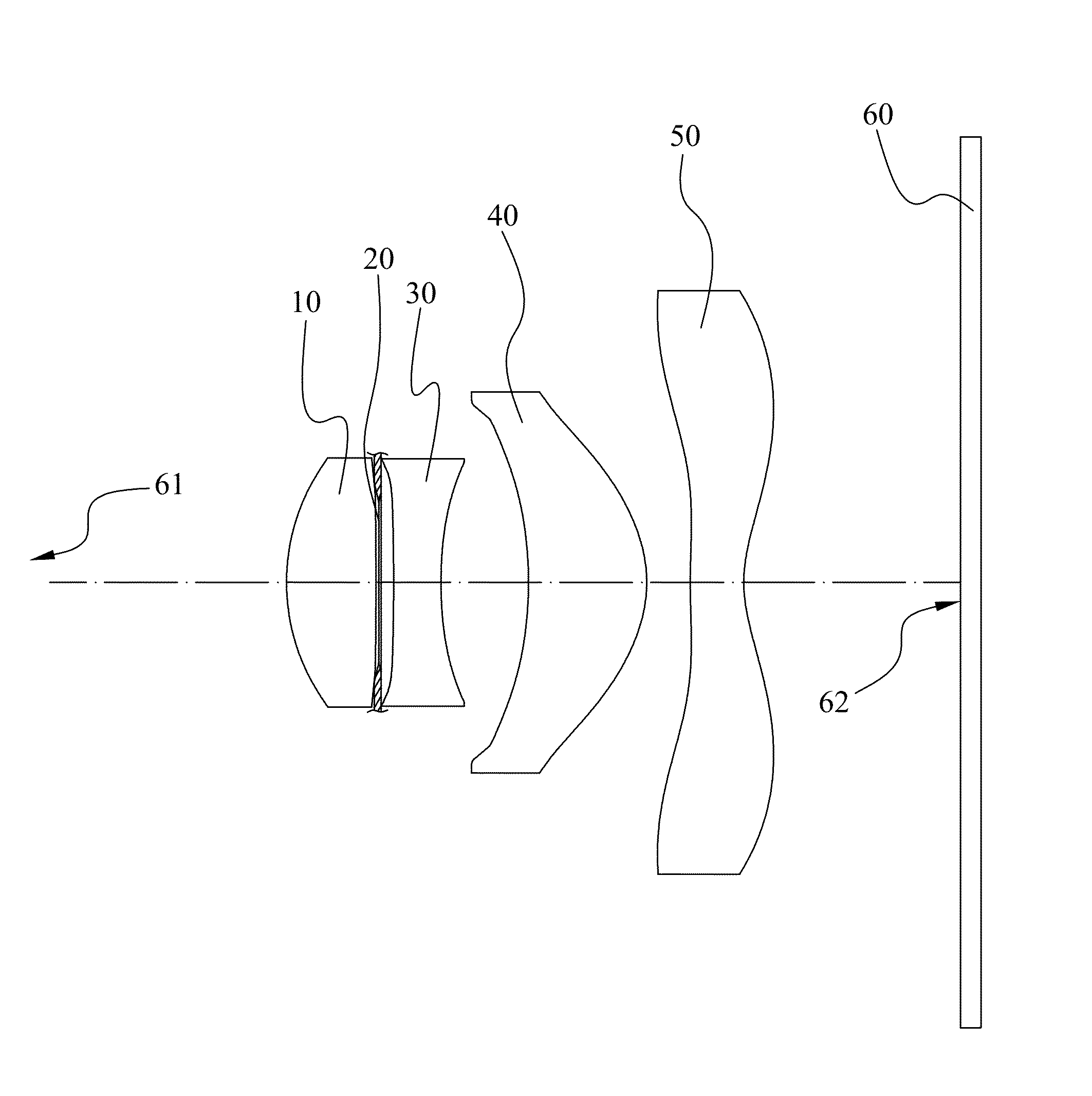

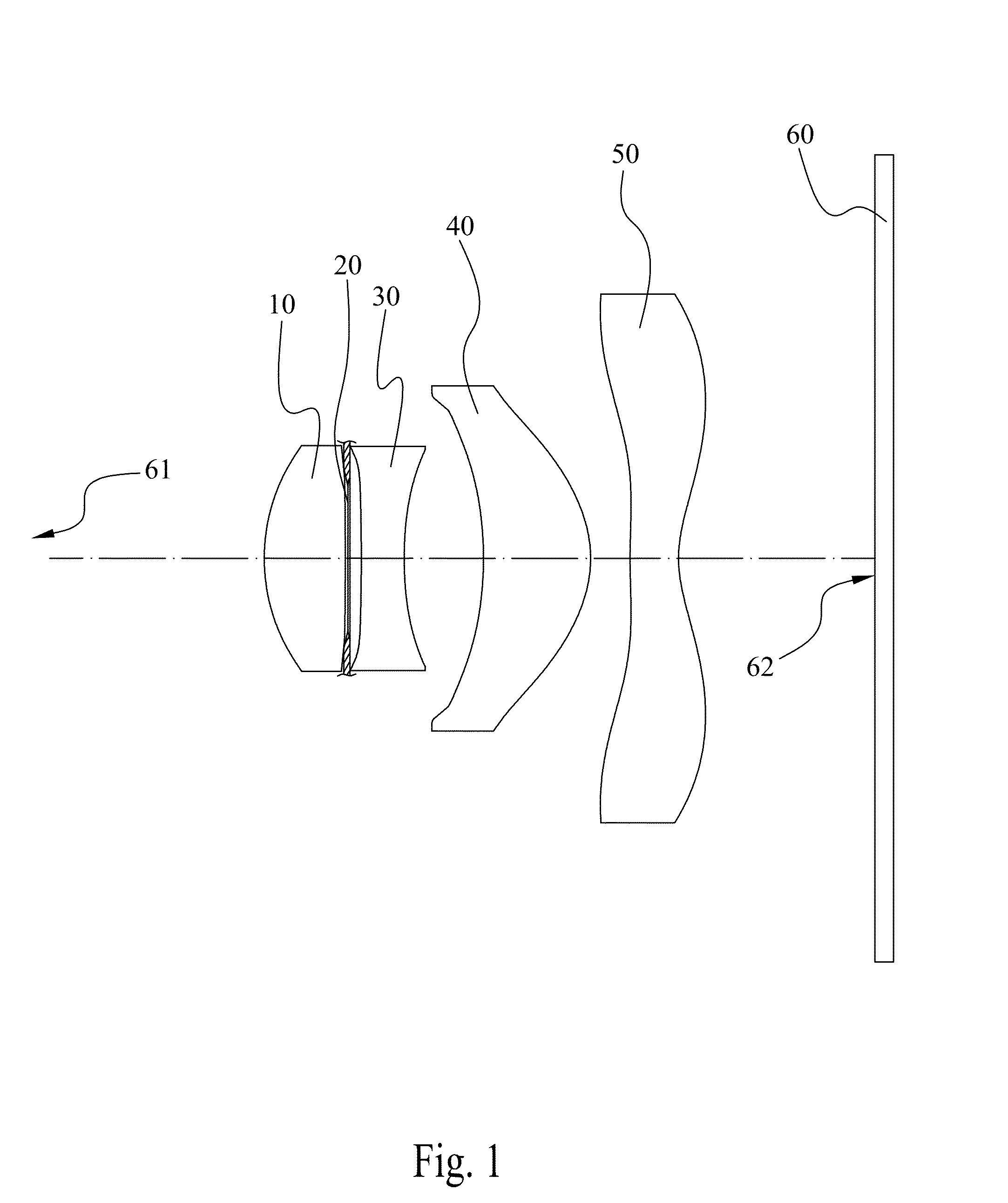

Imaging lens apparatus

An imaging lens apparatus comprises four lenses with refractive power by which lead the light from the object side to the image side: a first lens with a convex object-side surface and positive refractive power, at least one surface of the first lens is aspheric; an aperture stop set next to the first lens; a second lens which is a biconcave lens with negative refractive power, at least one surface of the second lens is aspheric; a third lens which is a positive meniscus lens with a concave object-side surface, both side of the third lens are aspheric; and a fourth lens which is a negative meniscus lens with a convex object-side surface, both side of the fourth lens are aspheric with at least one inflection point; and the imaging lens apparatus satisfy the conditions below: |1 / slope_S8|>0.9; −0.2 <SAG_S8<0.1.

Owner:GLORY SCI

Method for darkening treatment of black polyester fabrics

ActiveCN102677470APromote absorptionIncrease the black depth valueFibre typesHeating/cooling textile fabricsPolyesterPolymer science

The invention provides a method for darkening treatment of black polyester fabrics. The method comprises a first-stage darkening posttreatment procedure and a second-stage darkening posttreatment procedure, wherein the first-stage darkening posttreatment procedure comprises the following steps of: padding black polyester fabrics in treating liquid of 10 to 60g / l organic fluorine-type polymer finishing agent or acrylic ester-type polymer finishing agent, keeping the padding residue rate at 55 to 175 percent, performing infrared drying, roasting the polyester fabrics, performing baking setting treatment at the temperature of between 175 and 215 DEG C for 30 to 90 minutes; and the second-stage darkening posttreatment procedure comprises the following steps of: padding the polyester fabrics obtained by the first-stage darkening posttreatment procedure in treating liquid of 10 to 85g / l hydrophilic linear organosilicon finishing agent, keeping the padding residue rate at 45 to 150 percent, performing infrared drying, roasting the polyester fabrics, performing baking setting treatment at the temperature of between 180 and 220 DEG C for 30 to 90 minutes. By the technical scheme of the invention, the black depth value of the black polyester fabrics is increased by over 20 percent, and the test data obtained by the Datacolor instrument show the L value of the ultra-black polyester fabrics can reach 9.59.

Owner:绍兴柯桥中侨置业有限公司

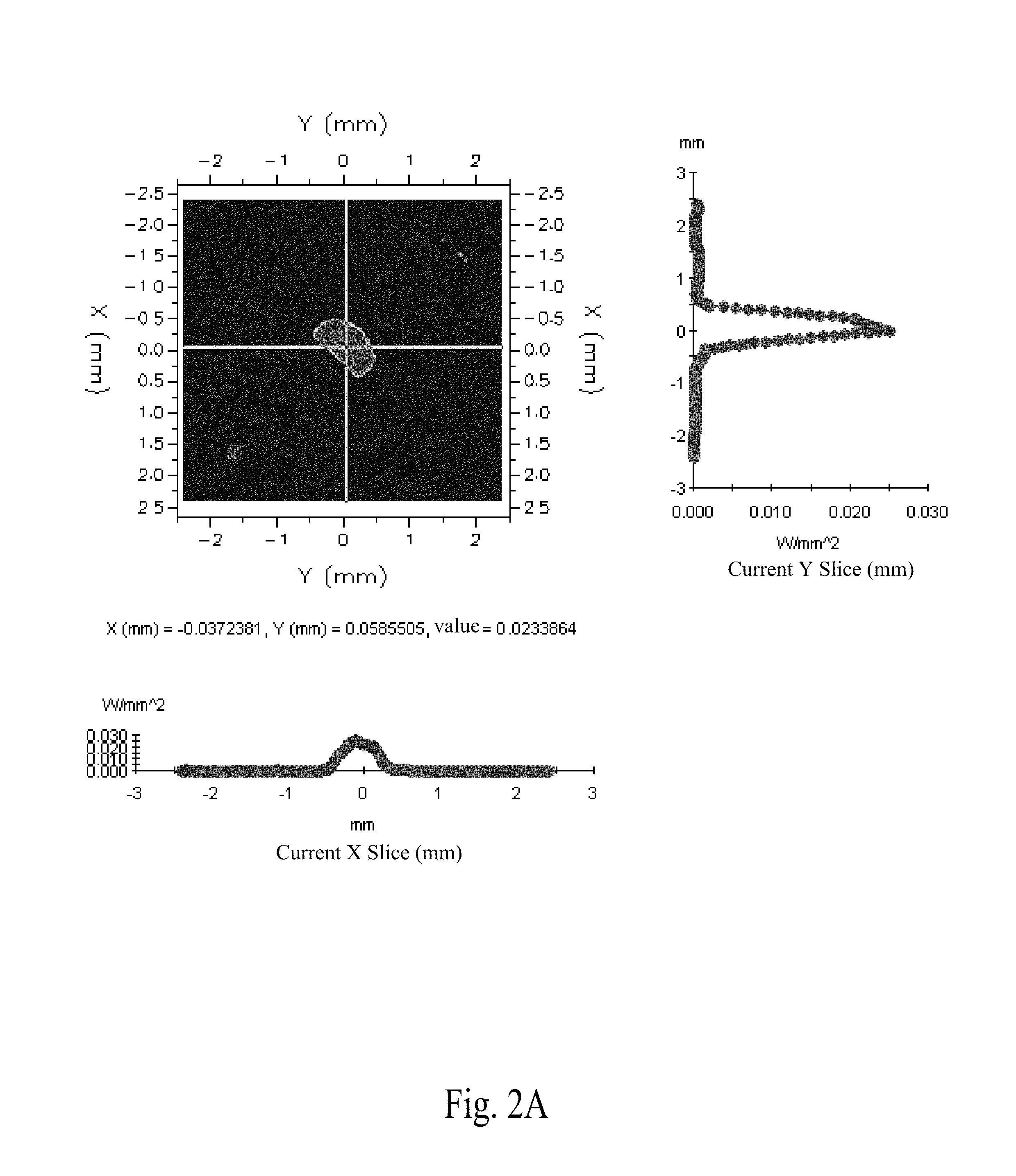

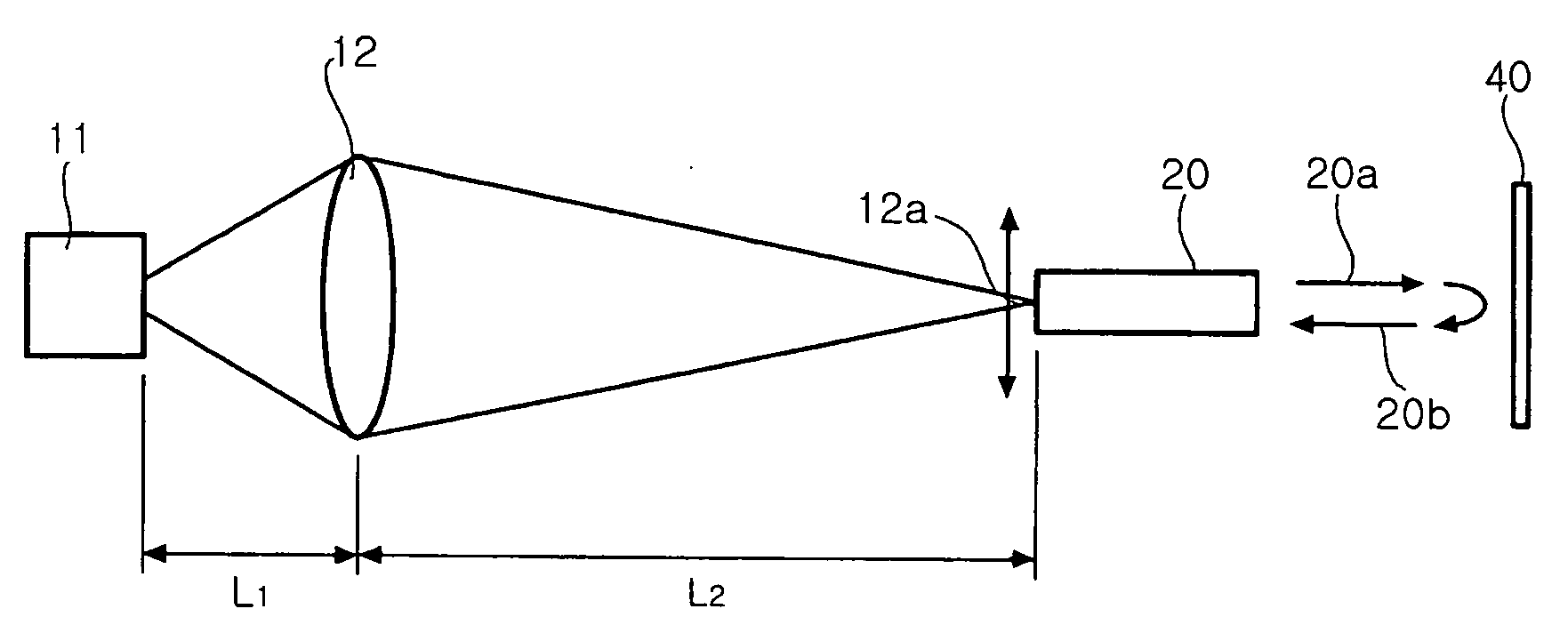

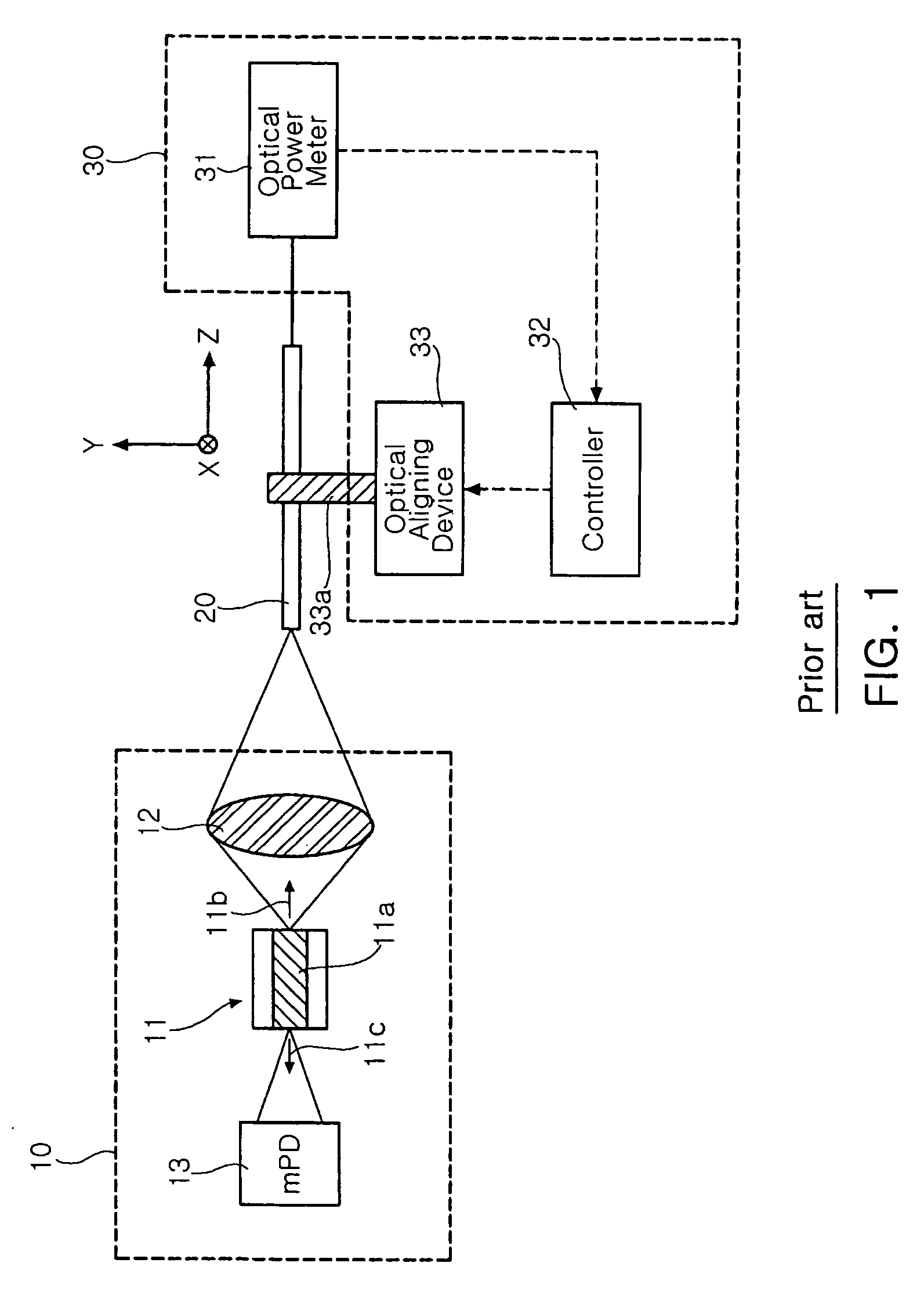

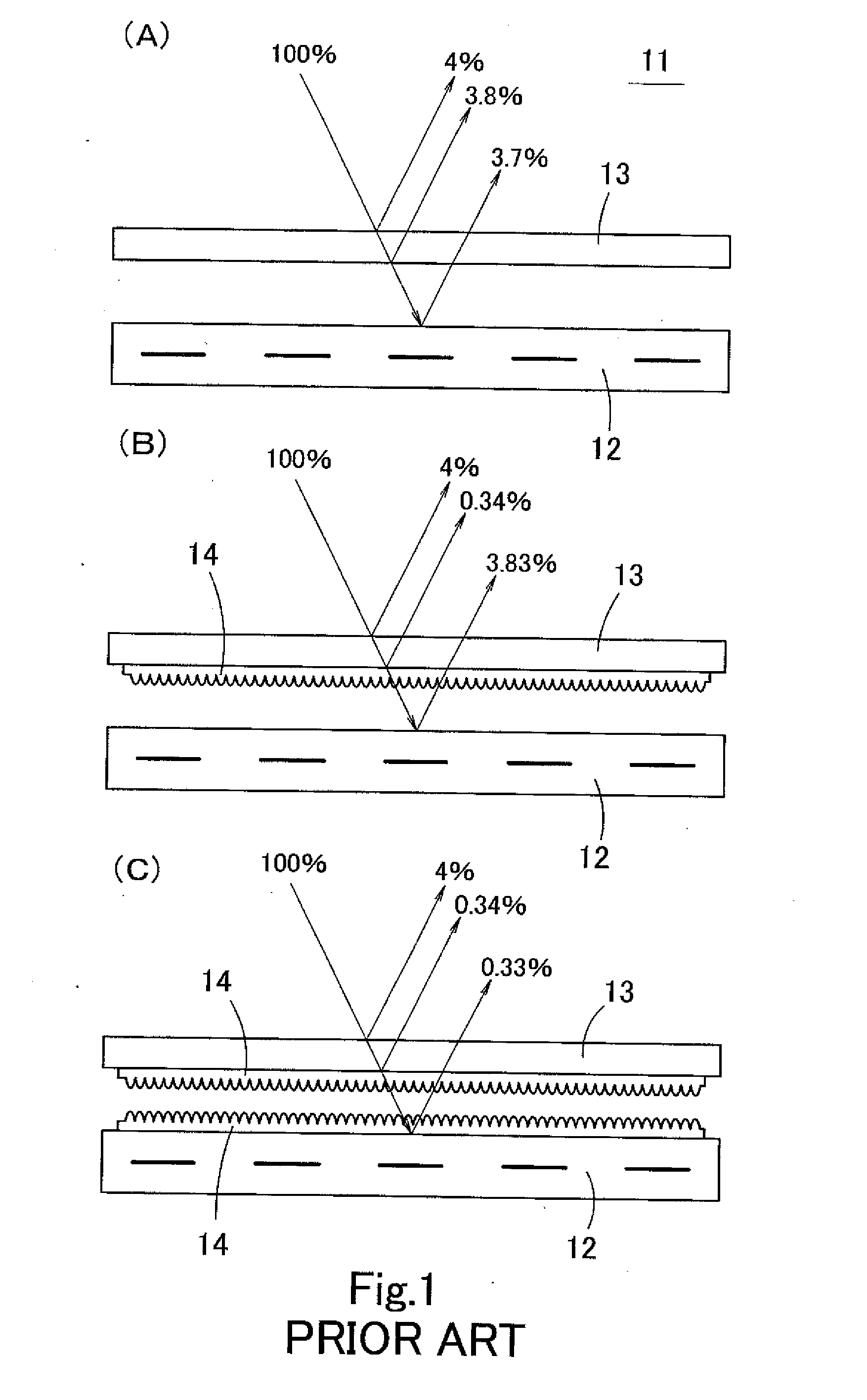

Optical alignment method and apparatus

InactiveUS20070133931A1Reduce reflected lightReduce inputInvestigating moving sheetsUsing optical meansTransceiverOptical isolator

In disclosed optical alignment method and apparatus thereof, external reflection entering laser diode by feedback from transmission line of low cost bidirectional optical transceiver module without optical isolator for subscribers is reduced so as to reduce RIN considering high optical coupling efficiency. The external reflection is minimized using property that output current increases in proportion to external reflection during optical alignment. For optimal optical alignment, external reflection and RIN are previously measured according to optical alignment position between subassembly and optical fiber. Optimal position is determined by both light output and RIN, and predetermined ratio of the mPD output current of minimum RIN position to that of maximum light output power position.

Owner:ELECTRONICS & TELECOMM RES INST

Touch-control display device, touch-control liquid crystal display device and manufacturing method thereof

InactiveCN101539676AGood visibility and contrastEliminate distractionsStatic indicating devicesNon-linear opticsPolarizerLiquid-crystal display

The invention discloses a touch-control liquid crystal display device, which comprises a liquid display unit, a touch-control panel and a second polarizer, wherein the liquid crystal display unit comprises a lower substrate, an upper substrate, a liquid crystal layer and a first polarizer; the upper substrate is arranged opposite to the lower substrate; the liquid crystal layer is arranged between the lower substrate and the upper substrate; the first polarizer is arranged on the lower substrate; the touch-control panel is arranged opposite to the liquid crystal display unit; and the second polarizer is arranged on the touch-control panel and is positioned between the liquid crystal display unit and the touch-control panel. Because of the low intensity of the reflected light generated in the touch-control liquid crystal display device, the device can provide good contrast degree and visibility.

Owner:WINTEK CORP

Antireflection film

InactiveUS20150116834A1Hard to preventReduce reflected lightNon-linear opticsOptical elementsFilm baseEngineering

On a surface of a film base material (22), an antireflection structure configured by nano-sized optical projections (23) to suppress reflection of light and protective pillars (24) to prevent the optical projections (23) from being flattened out are arranged. The protective pillar (24) has a truncated cone shape. When a diameter of the protective pillar (24) at a proximal end thereof, a height of the protective pillar (24), and an angle between a side surface of the protective pillar (24) and a central axis of the protective pillar (24) on a section passing through the central axis of the protective pillar (24) are given by D, H, and θ, respectively, these values satisfy a relationship: D>2H×tan(2θ).

Owner:SOKEN CHEM & ENG CO LTD

Low-Reflectance Self-Illumination Unit Display

InactiveUS20080042553A1Reduce the amount requiredIncrease contrastDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceTransmittance

The present invention provides a self-illumination unit display comprising a display substrate, a light-absorbing structure, a driving circuit unit, a self-illumination unit and a light modulation layer. The light-absorbing structure, the driving circuit unit and the self-illumination unit are all formed on the inner surface side of the display substrate, while the light modulation layer is preferably formed on the outer surface of the display substrate. The light-absorbing structure is formed on the inner surface of the display substrate, and is substantially located within the non-light-emitting area. The driving circuit unit is located above the light-absorbing structure. The self-illumination unit is substantially located within the light-emitting area. The light modulation layer is disposed on the outer surface of the display substrate. The light transmittance of the light modulation layer is approximately greater than 42%.

Owner:AU OPTRONICS CORP

Optical apparatus with loss compensation capability and optical amplifier for loss compensation

InactiveUS7061669B2Improve performanceHigh gainFibre transmissionActive medium shape and constructionUltrasound attenuationEngineering

An optical apparatus having a loss compensation capability includes between an input connector 1A and an output connector 1B an input side optical parts 2 including an input monitor, an amplification medium 3, a loss medium 4, and an output side optical parts 5 including an output monitor in this order, and is provided with a control circuit 6 for controlling a gain based on a monitor result of input / output light. The amount of reflection attenuation on all points, on which the light can be reflected on the optical path from the output end of the amplification medium 3 to the output connector 1B, can be smaller than the amount of reflection attenuation on the end face of the output connector 1B.

Owner:FUJITSU LTD

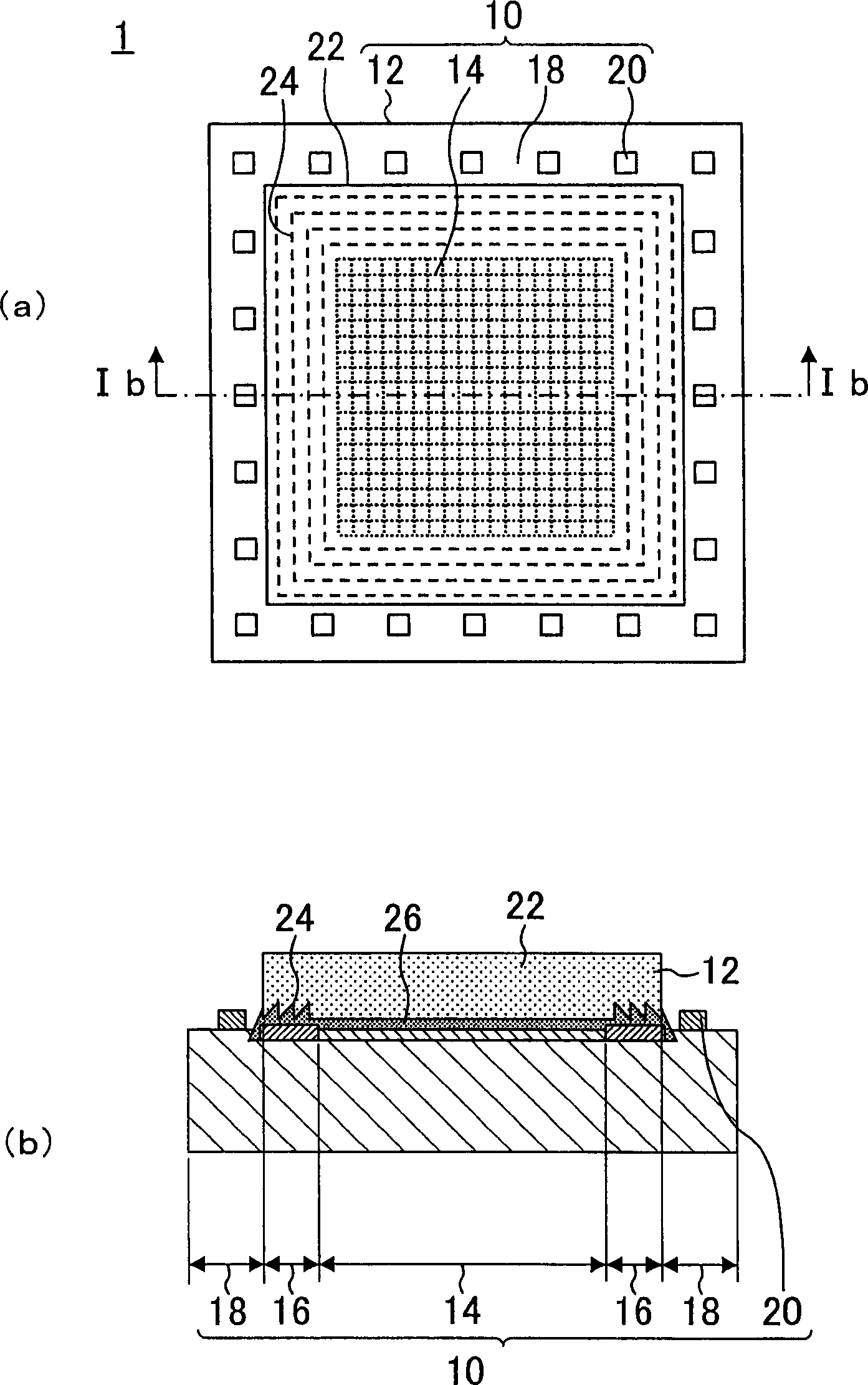

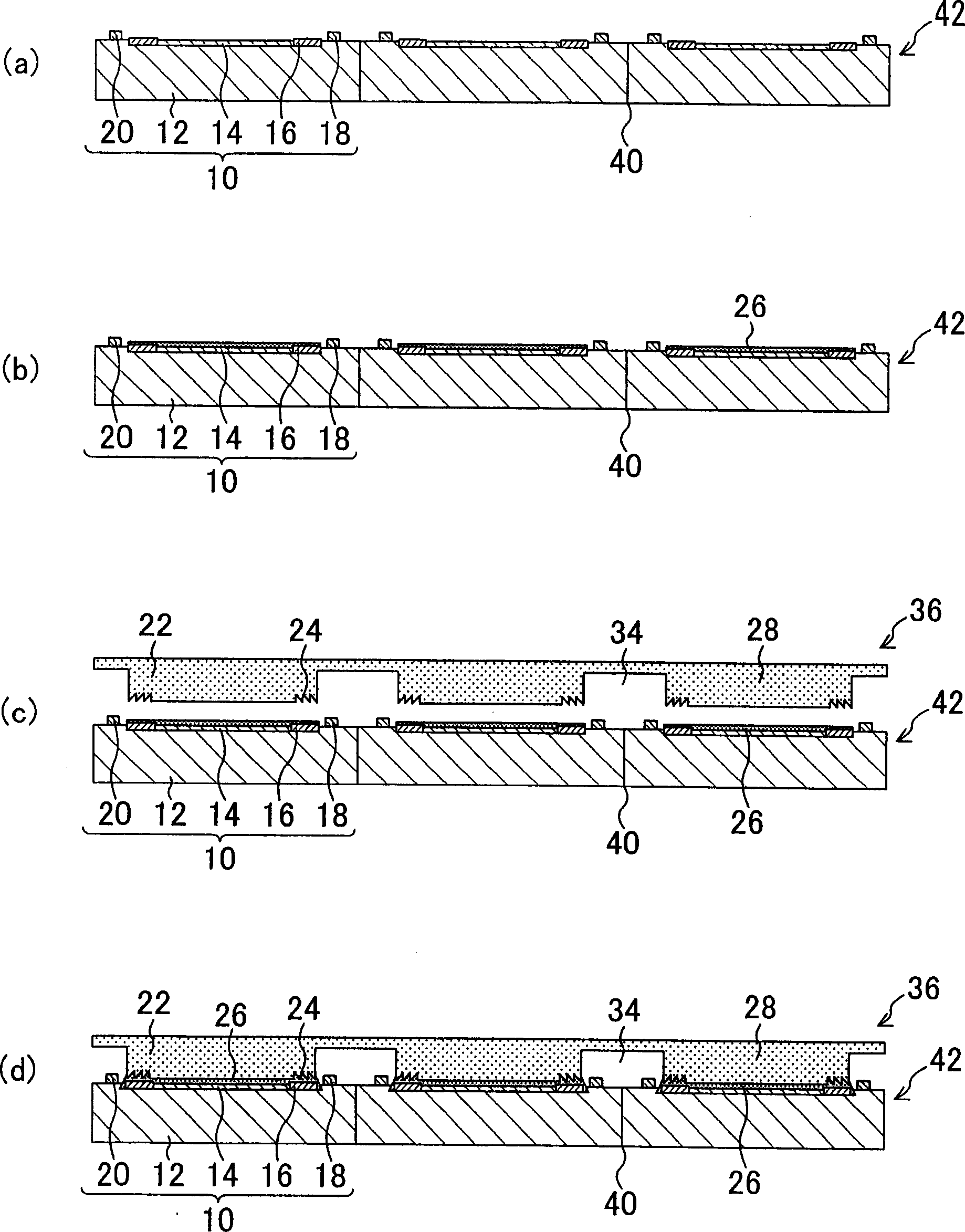

Optical device, optical device apparatus, camera module, and optical device manufacturing method

InactiveCN1901212AAchieve thinningMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesElectrical junctionCamera module

To provide a compact and thin optical device that can simplify a manufacturing process, and suppresses optical noise, and to provide a method of manufacturing the optical device. The optical device comprises a light detection region 14; a peripheral circuit region 16 formed at the outer-periphery section of the light detection region 14; an electrode region 18 formed at the outer periphery of the peripheral circuit region 16; an optical element 10 having a plurality of microlenses in the light detection region 14; a transparent member 22 arranged on the optical element 10; and a transparent resin adhesive 26 for adhering and fixing the transparent member 22 onto the circuit formation surface of the optical element 10. A roughening region 24 having a sawtooth-like cross section is formed on an adhesive surface with the optical element 10 at a portion overlapping with the outer-periphery region of the light detection region 14 flatly in a plane view in the transparent member 22.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com