Optical device, optical device apparatus, camera module, and optical device manufacturing method

A technology for optical equipment and optical components, used in radiation control devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as inability to prevent, limit the number of electrode terminals, and inability to prevent smearing or flashing, and achieve simple manufacturing. method, miniaturization, and effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

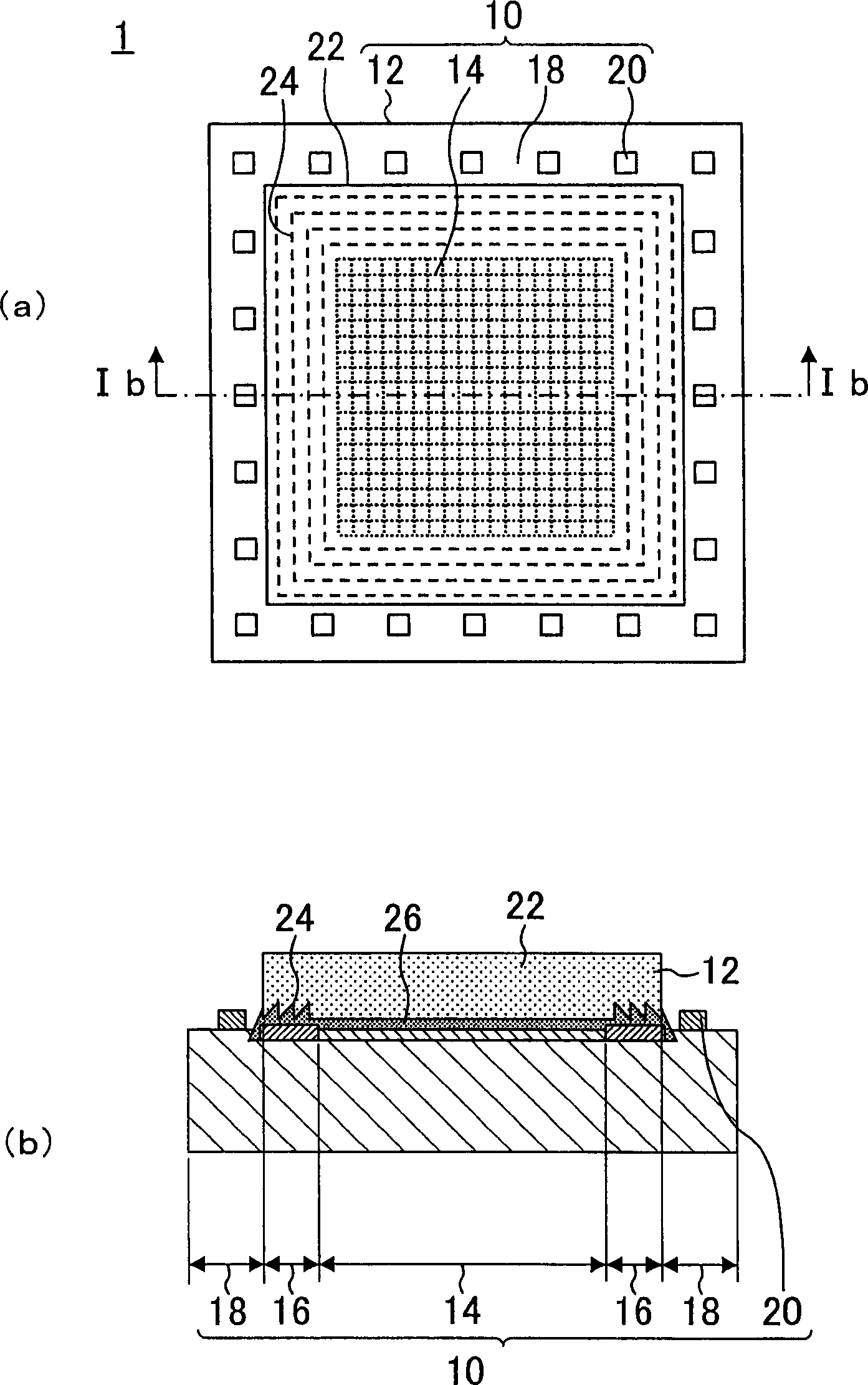

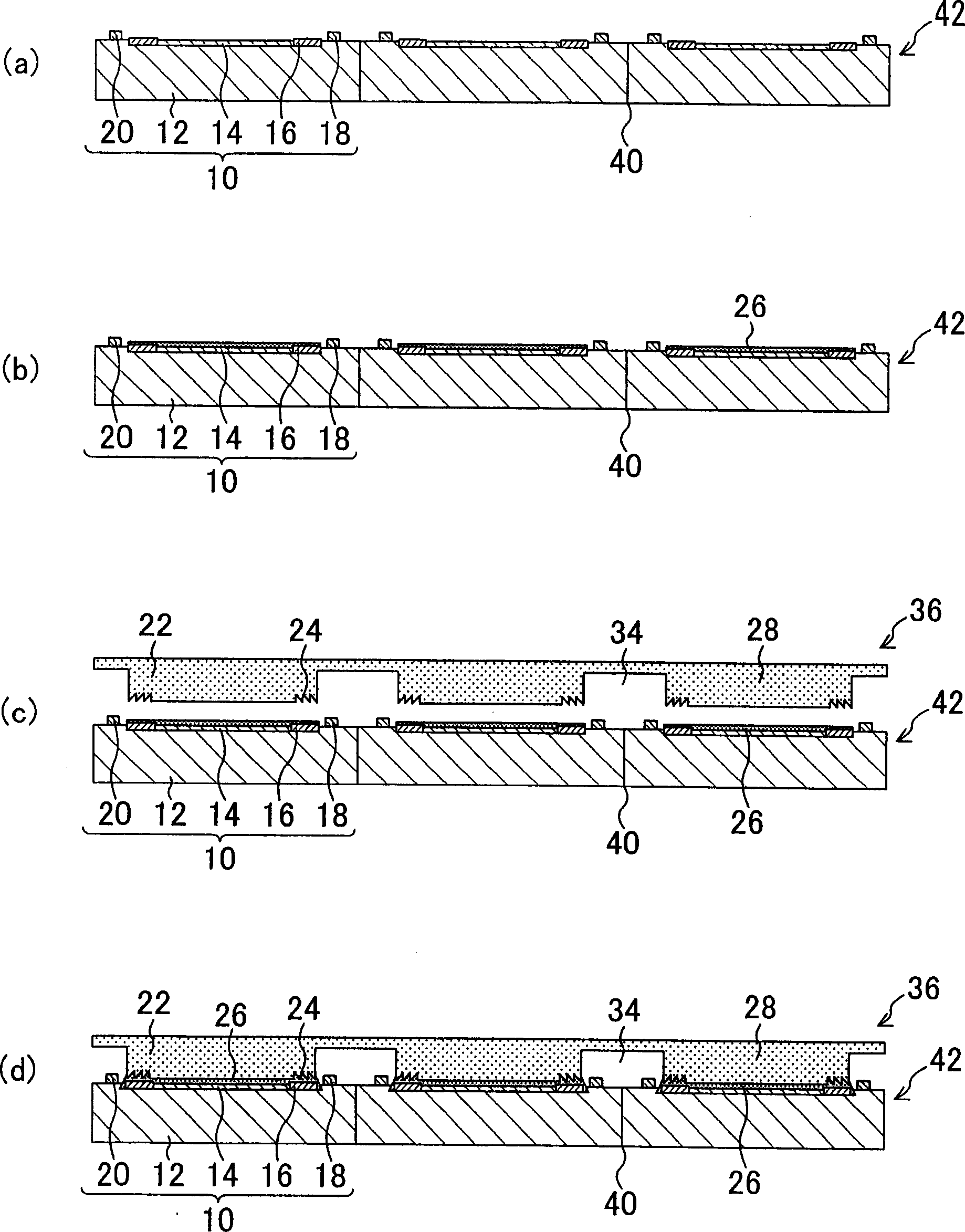

[0037] figure 1 (a) and (b) respectively show a plan view and a cross-sectional view along line Ib-Ib of the optical device according to the first embodiment of the present invention.

[0038] Such as figure 1As shown, the optical device 1 of the present embodiment includes: an optical element 10 having a semiconductor substrate 12, a photodetection region 14, a peripheral circuit region 16, and an electrode region 18 including an electrode terminal 20; a transparent member 22; The agent 26 adheres and fixes the optical element 10 and the transparent member 22 . Among them, as the optical element 10 , one or both of a light receiving element and a light emitting element are provided in the optical device 1 . The light receiving element is, for example, an image sensor such as a CMOS sensor or a CCD sensor, and the light emitting element is, for example, a laser or a light emitting diode. When the optical element 10 is a light receiving element, the light detection area 14 r...

no. 2 Embodiment approach

[0082] Figure 8 It is a sectional view showing the optical device according to the second embodiment of the present invention.

[0083] As shown in the figure, in the optical device 4 of this embodiment, the antireflection film 74 is formed on the outer peripheral surface (side surface) of the transparent member 72, and the antireflection film 76 is formed on the inner surface of the roughened region 24, which is different from the first The optical device 1 of the embodiment is different. Other configurations are the same as those of the optical device 1 of the first embodiment.

[0084] Thus, by providing the antireflection films 74 and 76 on the outer peripheral surface of the transparent member 72 and the inner surface of the roughened region 24, respectively, it is possible to more reliably prevent reflected light from the electrode terminals 20 or lead wires from entering the photodetection region 14 .

[0085] Below, use Figure 9 A method of manufacturing the optic...

no. 3 Embodiment approach

[0105] As a third embodiment of the present invention, an optical device device using the optical devices in the first and second embodiments and modifications thereof will be described.

[0106] Figure 12 It is a sectional view showing the optical equipment device according to the third embodiment.

[0107] As shown in the figure, the optical device device 100 of this embodiment includes: a substrate 85; Frame body 89, which is arranged on the substrate 85, surrounds optical device 81; external terminal 87, which is exposed on the outer surface (here, the bottom surface) of optical device 81, for example connected to electrode terminal 20 by metal thin wire 91; and sealing A resin 93 that seals a part of the optical device 81 and the thin metal wires 91 is filled in the frame body 89 .

[0108] In the optical device 81 , since the transparent member is directly mounted on the surface of the optical element, the thickness becomes thinner compared to the case where the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com