Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about How to "No flash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

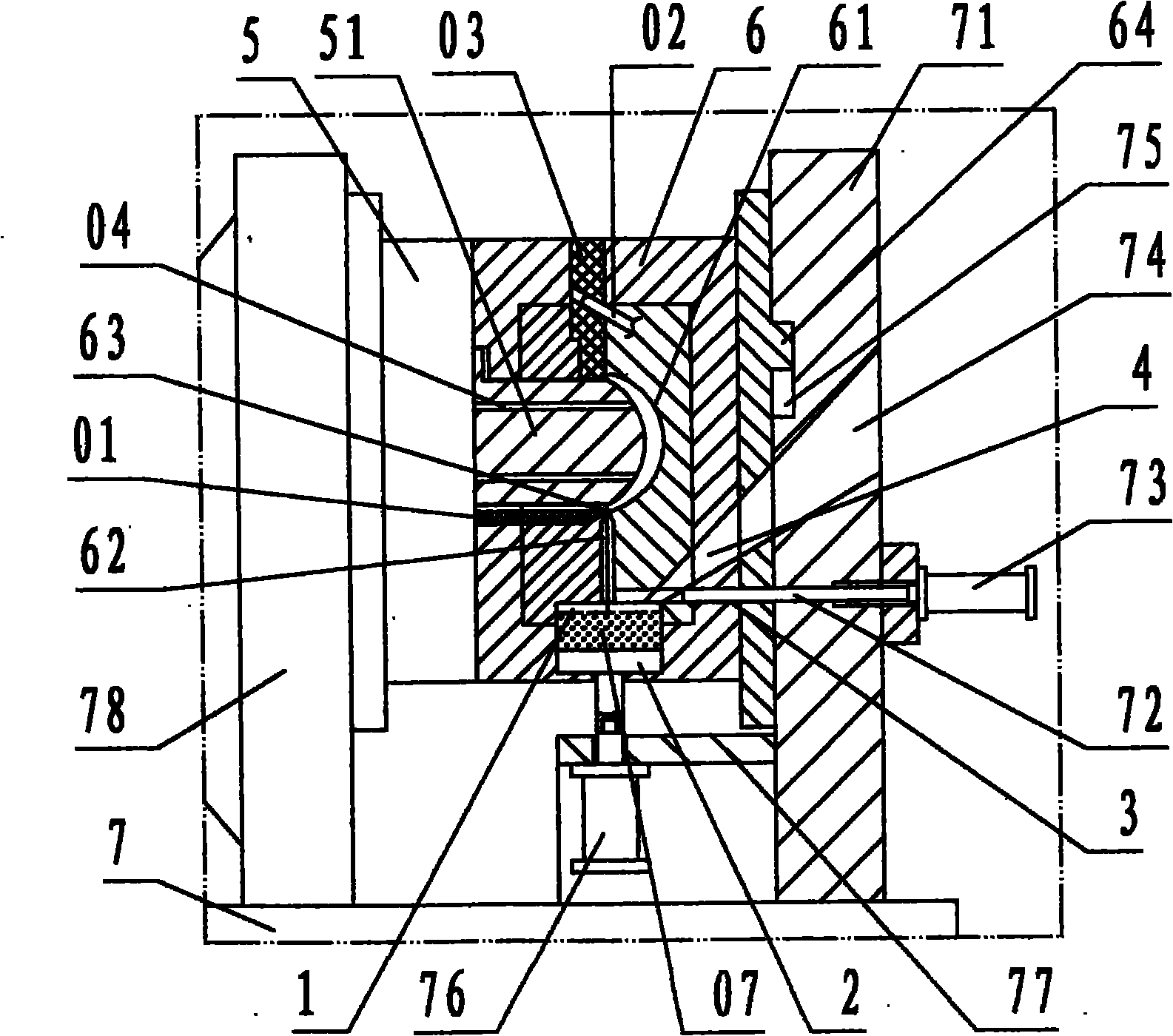

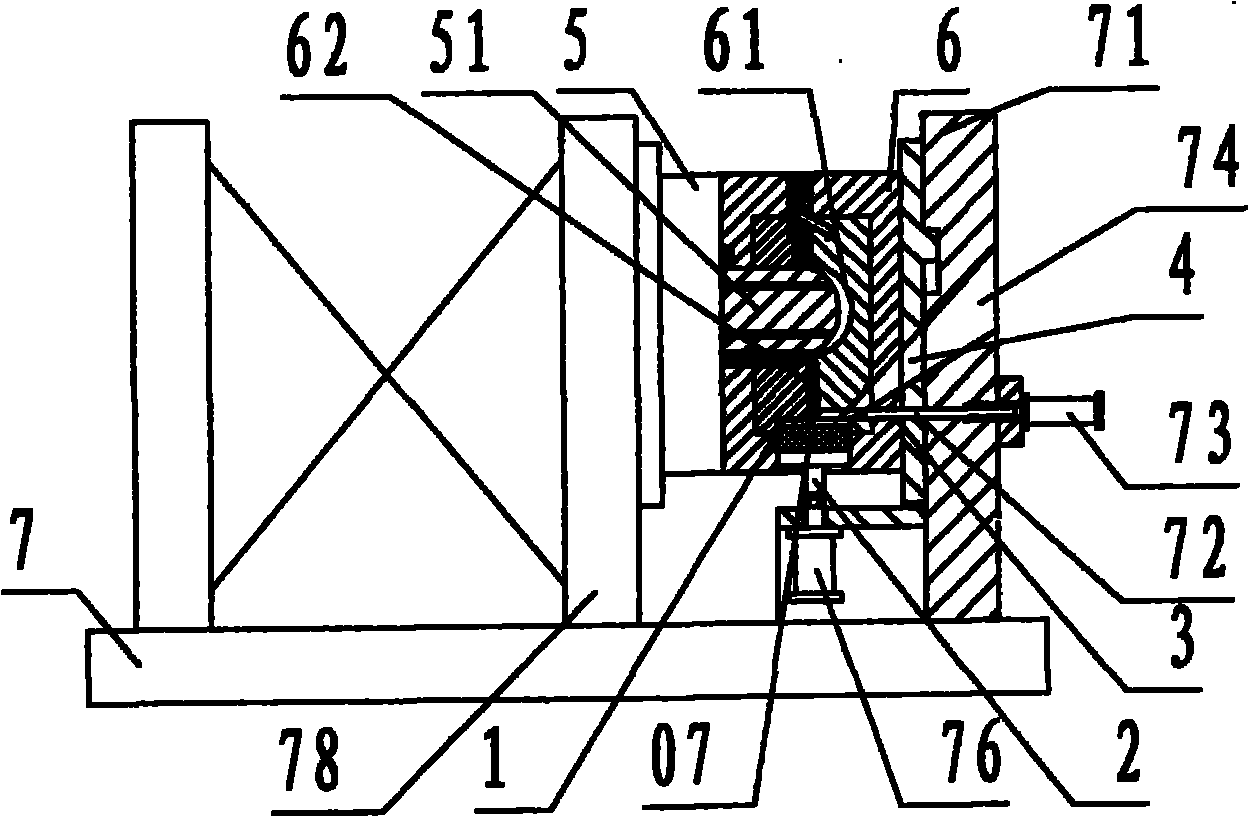

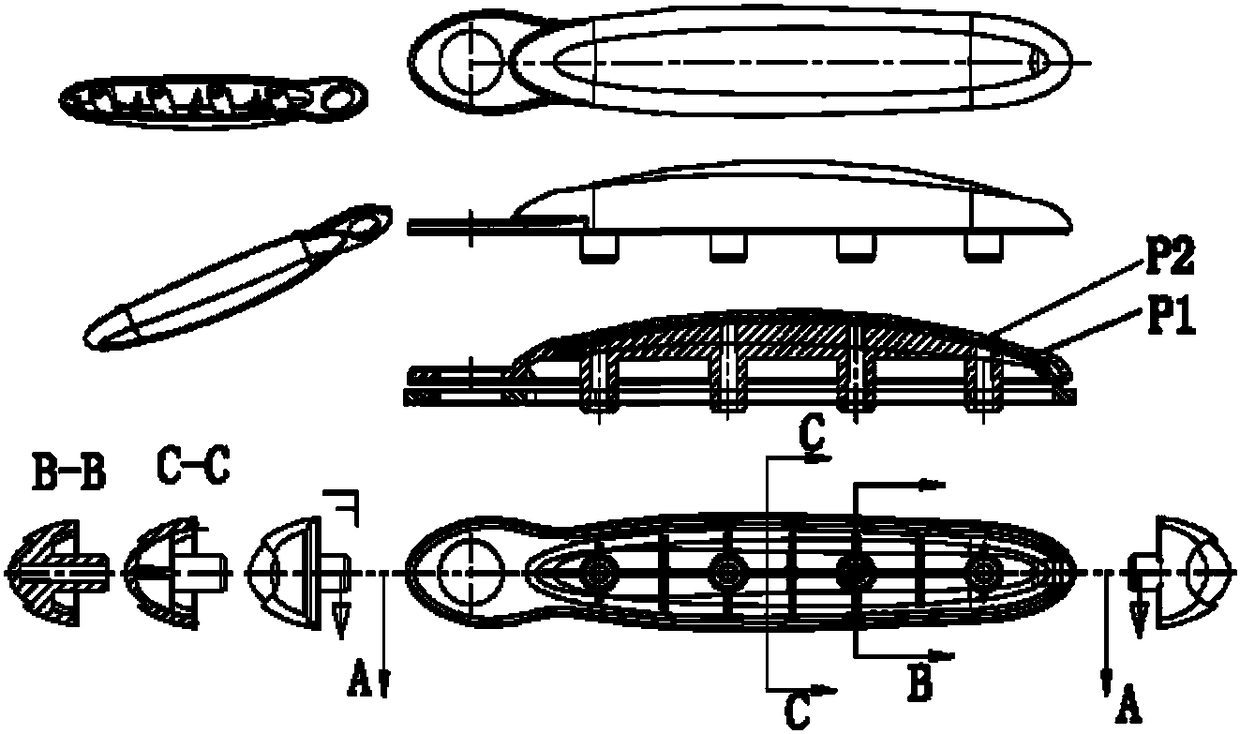

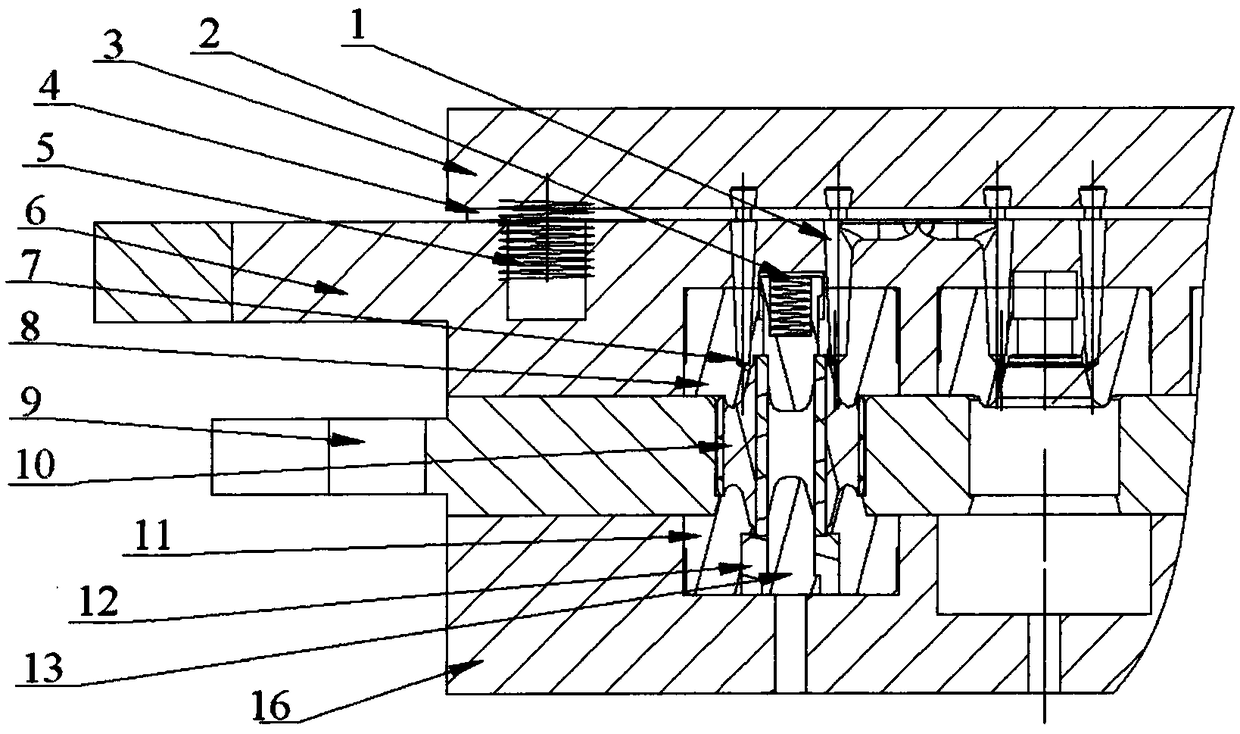

Alloy liquid extrusion casting forming device and process method thereof

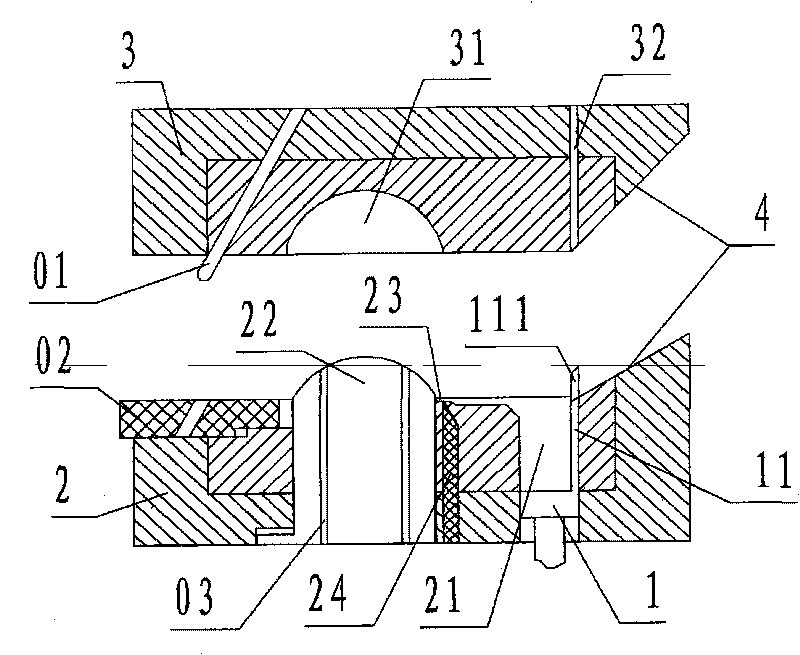

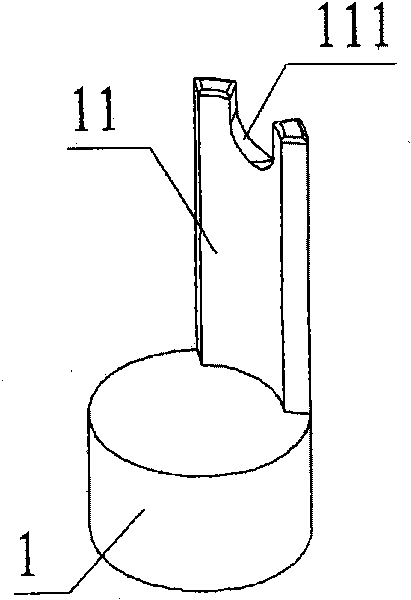

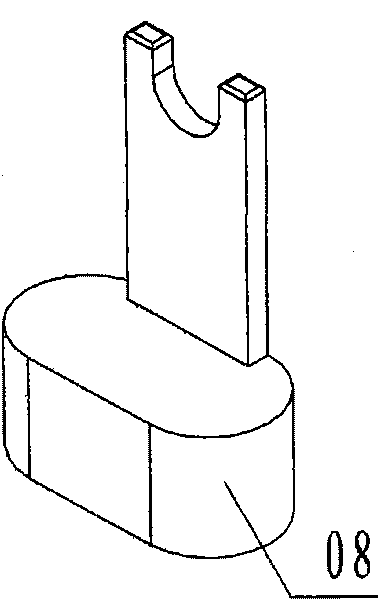

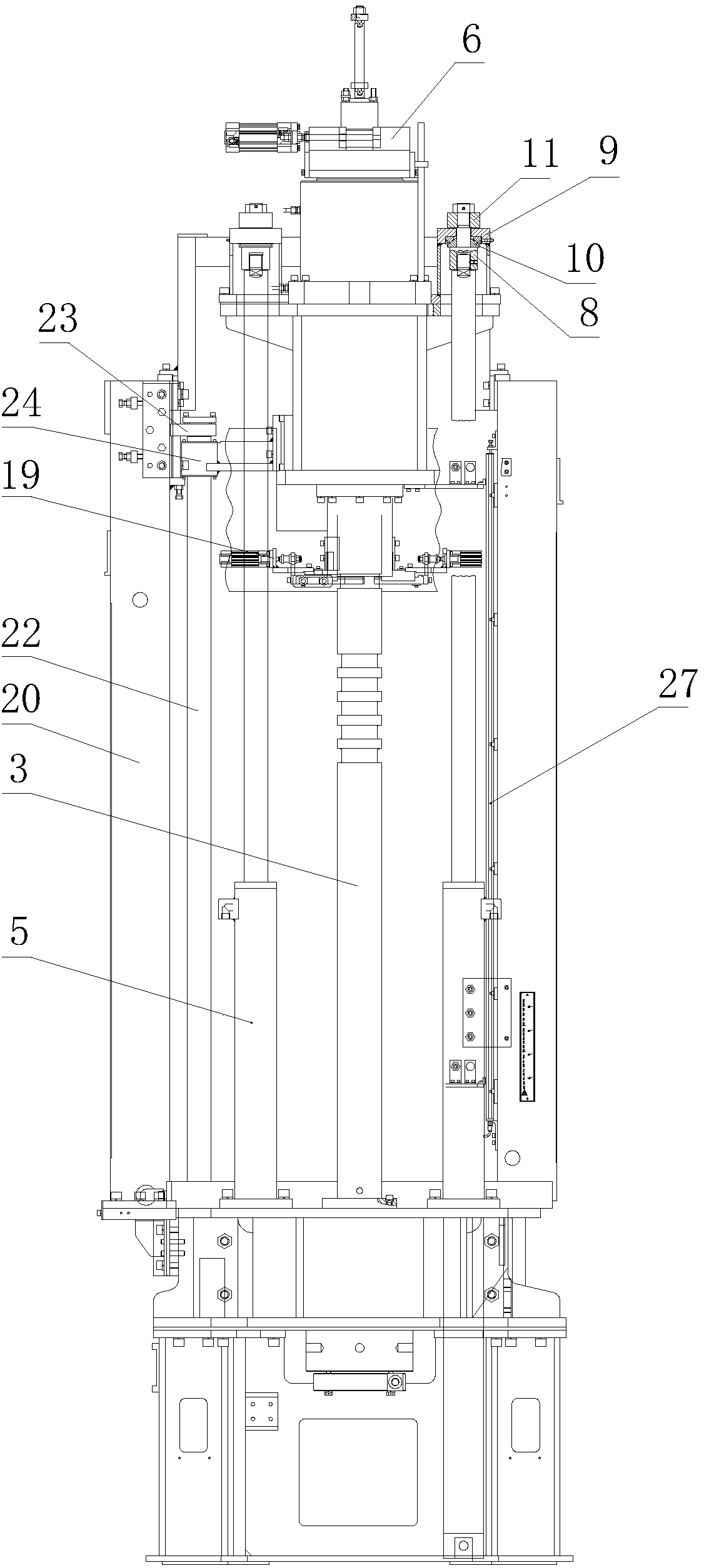

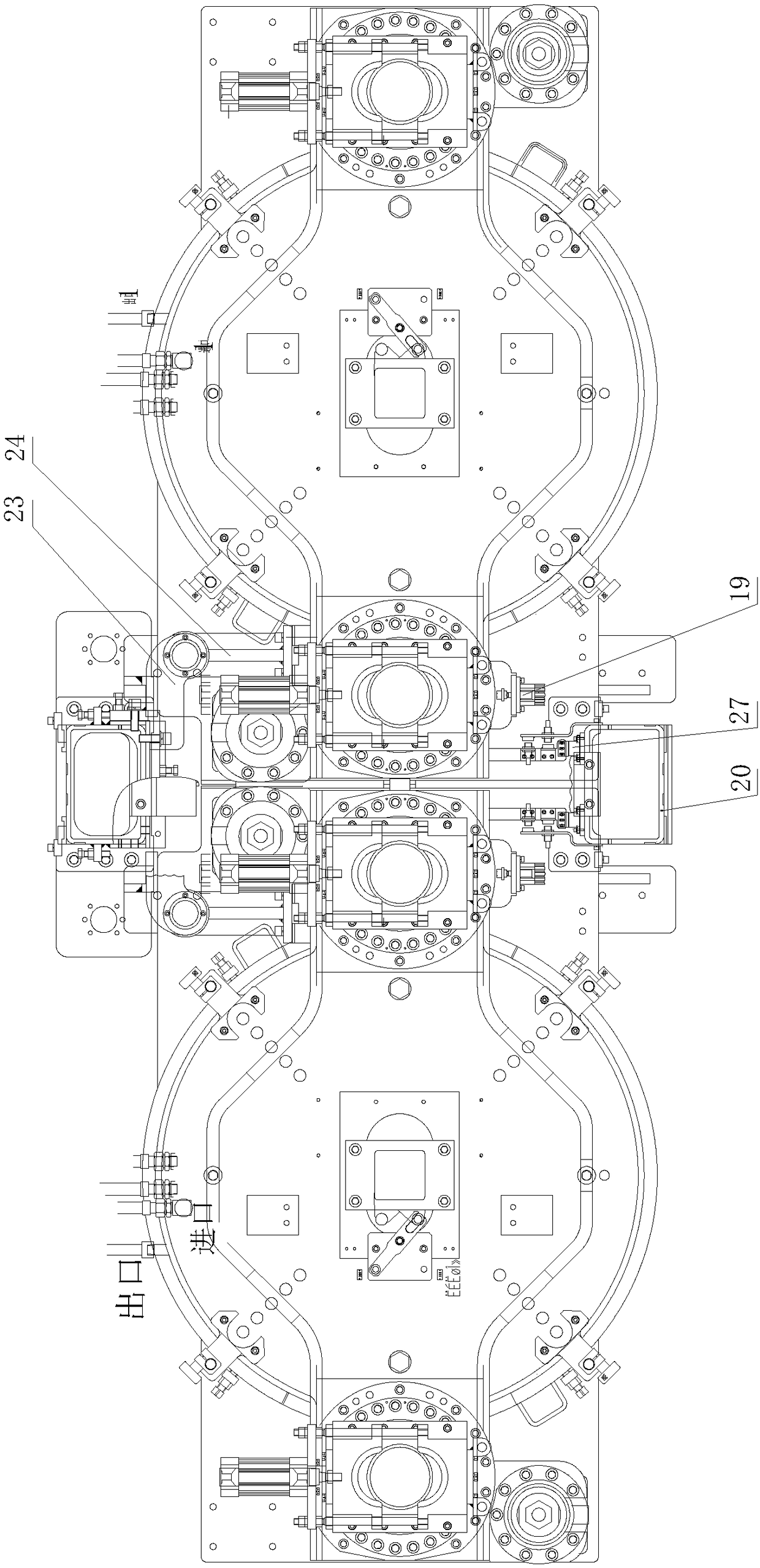

The invention discloses an alloy liquid extrusion casting forming device which comprises a hammerhead (1), a static die (2), a movable die (3) and a pouring slot (4). The device adopts the technical scheme that a declined and downward funnel-shaped pouring slot occupied by both the movable die and the static die arranged respectively by half is arranged on the parting plane on one side of a vertical die casting mould; a cylinder chamber type feed liquid chamber and the piston type hammerhead with a sealing knife is arranged on the static die; the hammerhead is controlled to be pushed up, and simultaneously the sealing knife seals the pouring slot. Firstly, feed liquid is filled into the a die cavity at high speed with low pressure, then the semisolid feed filled into the die cavity is extruded at low speed with high pressure, and the semisolid feed is gradually condensed to be formed under high-pressure low-speed extrusion. The alloy liquid extrusion casting forming device and the process method thereof integrate full casting functions of low-pressure filling and high-pressure extrusion into a whole, ensure that forming of alloy casting achieves the purposes of no gas entrapment, no cast seam, no mis-run, no forging crack, no fash, compact texture, fine crystal grain, high mechanical property, capability of performing thermal treatment and sealing, high dimensional accuracy, energy saving and low cost.

Owner:中建投(绍兴)机械科技有限公司

Plastic bottle blowing process

The invention relates to a plastic bottle blowing process. The plastic bottle blowing process comprises the following steps of (1) manufacturing a bottle preform mold, putting a raw material into a charging barrel, heating the raw material in the charging barrel, injecting the raw material into an injection mold and taking out the raw material in the injection mold after the raw material is cooledand solidified to obtain plastic bottle preforms; (2) conducting blow molding, specifically, taking out heated pipe blanks in sequence, putting the first pair of pipe blanks into bottle mold clamp mouths to be clamped stably and pressing a start button; (3) bottle blowing, wherein the bottle blowing process comprises mold closing, mouth sealing, rod dropping, air blowing, air discharging, mouth opening, rod rising, mold opening and program stopping; and (4) taking out blown bottles, detecting whether the blown bottles are qualified or not, putting the second pair of heated pipe blanks into the mold, pressing the start button to conduct second circulating production. Through the plastic bottle blowing process provided by the invention, the processing bottles are uniform in wall thickness and free of flashes and postprocessing. The bottoms of plastic parts do not have joint seams. The strength is high, and the production efficiency is high.

Owner:平湖市浩鑫塑胶股份有限公司

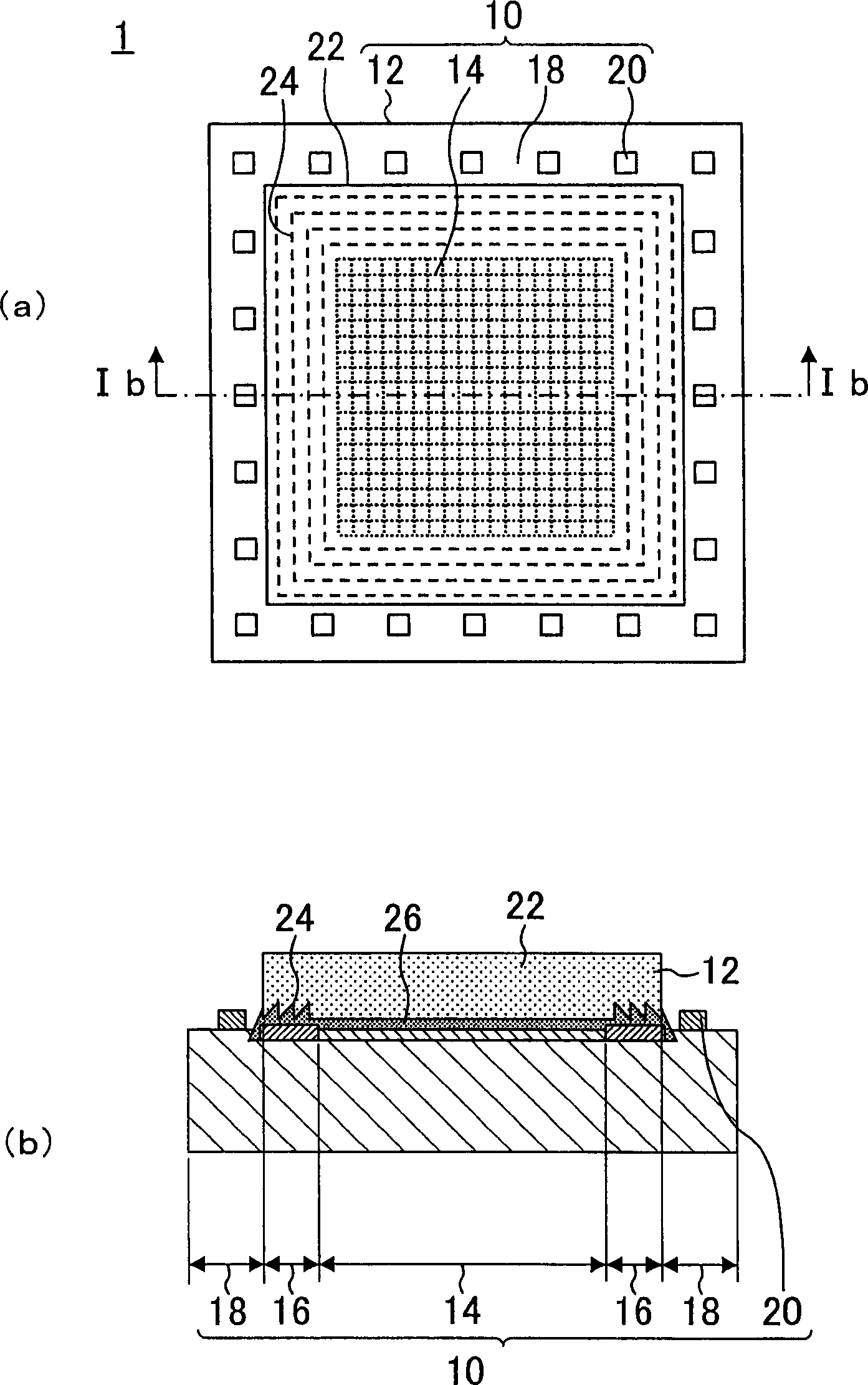

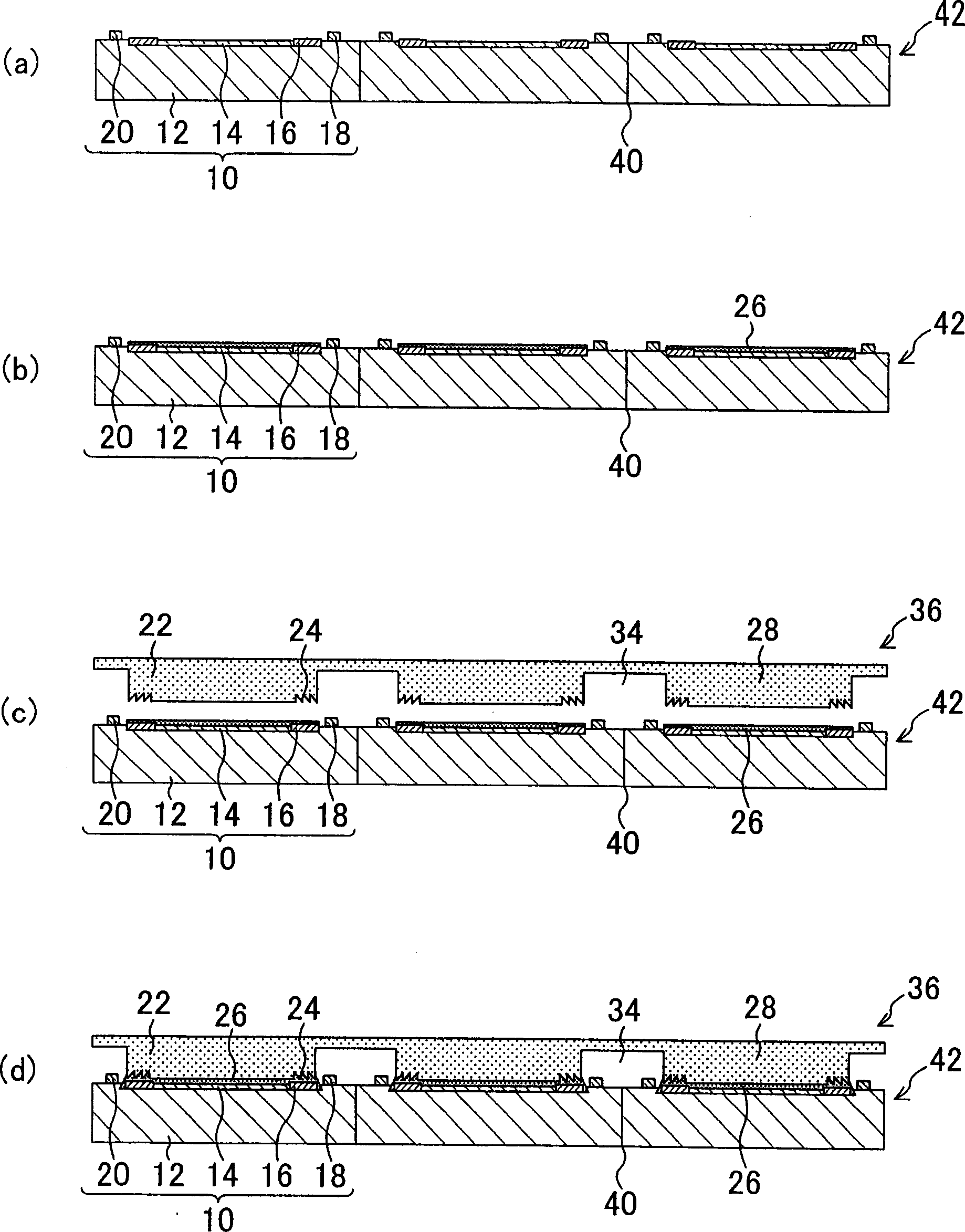

Optical device, optical device apparatus, camera module, and optical device manufacturing method

InactiveCN1901212AAchieve thinningMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesElectrical junctionCamera module

To provide a compact and thin optical device that can simplify a manufacturing process, and suppresses optical noise, and to provide a method of manufacturing the optical device. The optical device comprises a light detection region 14; a peripheral circuit region 16 formed at the outer-periphery section of the light detection region 14; an electrode region 18 formed at the outer periphery of the peripheral circuit region 16; an optical element 10 having a plurality of microlenses in the light detection region 14; a transparent member 22 arranged on the optical element 10; and a transparent resin adhesive 26 for adhering and fixing the transparent member 22 onto the circuit formation surface of the optical element 10. A roughening region 24 having a sawtooth-like cross section is formed on an adhesive surface with the optical element 10 at a portion overlapping with the outer-periphery region of the light detection region 14 flatly in a plane view in the transparent member 22.

Owner:PANASONIC CORP

Anti-dazzle film, anti-dazzle polarizer and image display apparatus

InactiveCN101726768APrevent loss of visibilityHigh anti-glare performanceDiffusing elementsSynthetic resin layered productsPolarizerVinyl acetate

The invention provides an anti-dazzle which has a resin base material film and a hard coating layer laminated on the resin base material film surface and having micro concavo-convex shapes on the surface; the hard coating layer is made of a light transparent resin with at least one kind of resin particles dispersed therein; the hard coating layer has a surface haze of 1%-10% and an inside haze of 10%-20%; the volume change rate of the resin particles is above 10% when dipped in vinyl acetate for under 23 degrees centigrade for 48 hours. And the invention further provides an anti-dazzle polarizer and an image display apparatus using the anti-dazzle film.

Owner:SUMITOMO CHEM CO LTD

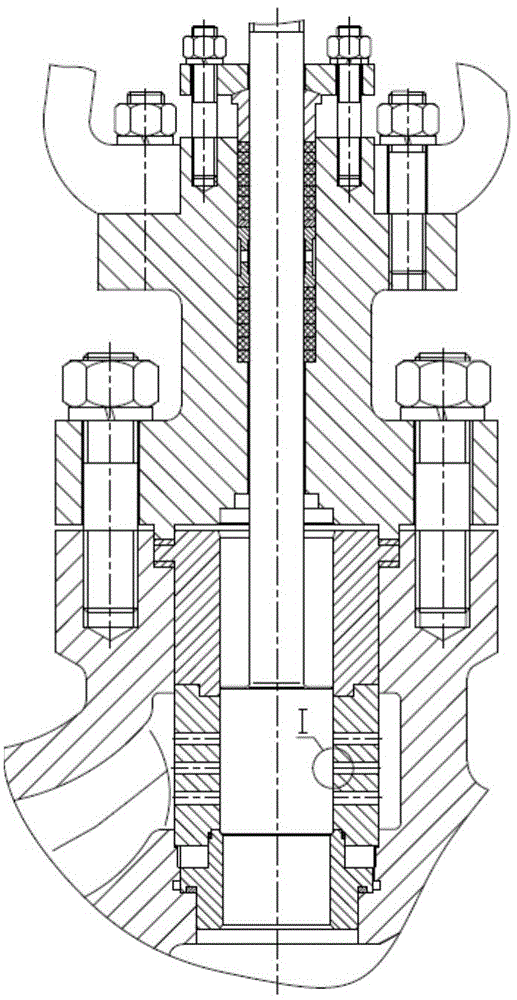

Throttling serial type multistage pressure reduction and adjustment valve

InactiveCN104455469APrecise pressure/flow controlEliminate cavitationValve members for absorbing fluid energyLift valveSolid particlePressure difference

The invention provides a throttling serial type multistage pressure reduction and adjustment valve. A valve rod and a valve element assembly are arranged inside a valve body; a valve seat assembly is provided with multistage pressure reduction units, and each stage of pressure reduction unit of the valve seat assembly is composed of a cylindrical fluid expansion unit and a throttling unit, wherein the throttling unit is shaped like a circular truncated cone, and the area of the throttling unit decreases gradually; correspondingly, the pressure reduction units are arranged on corresponding positions of the valve element assembly, wherein the stage number of the pressure reduction units in the valve element assembly is equal to that of the pressure reduction units in the valve seat assembly; each stage of the pressure reduction unit of the valve element assembly is composed of a bowl-shaped molded surface for controlling flow and a cylindrical shrinkage unit; the upper portion of the valve element assembly is provided with valve elements, and the lower portion of the valve element assembly is provided with guide rods; valve bottom drainage holes are formed in the positions, located on the outer sides of valve seat guide holes, of the bottom of the valve seat assembly; a flow diversion sleeve is arranged on the top of the valve seat assembly, and a flow diversion hole is formed in one side of the flow diversion sleeve. According to the throttling serial type multistage pressure reduction and adjustment valve, the service life of the valve can be prolonged, vibration and noise of pipelines behind the valve can be eliminated, and it is guaranteed that the adjustment accuracy of the valve is high and operation is stable under the working condition that the pressure difference is large and solid particles exist in media in the Texaco process of coal chemical industries.

Owner:BEIJING AEROSPACE PROPULSION INST +3

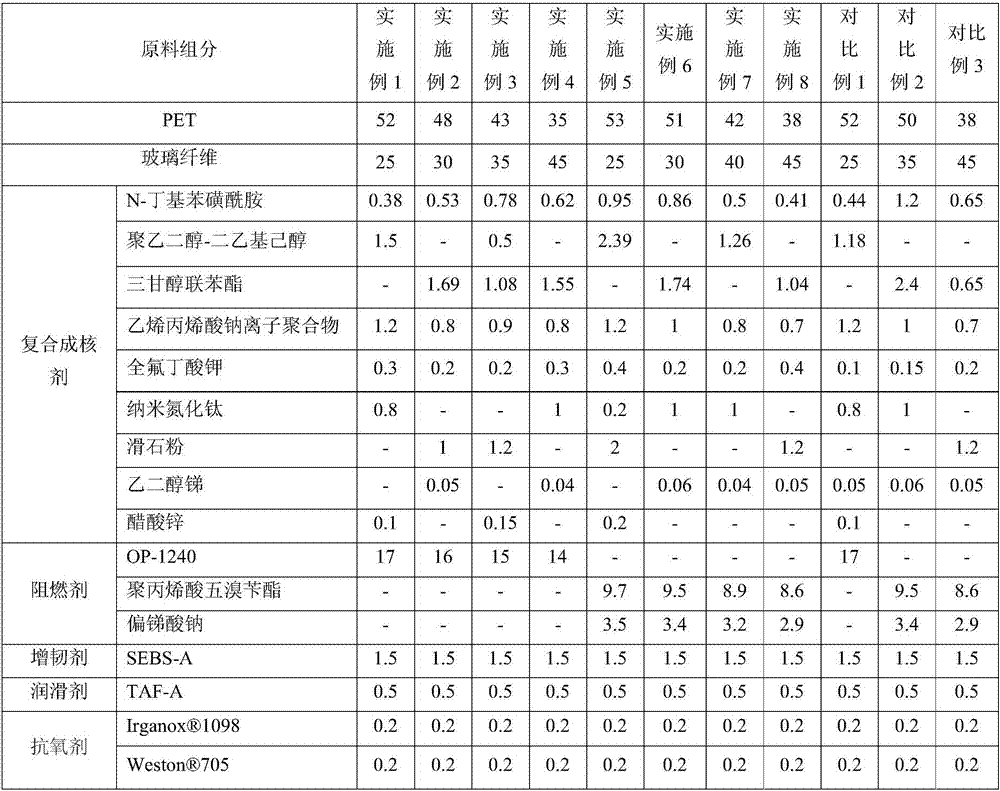

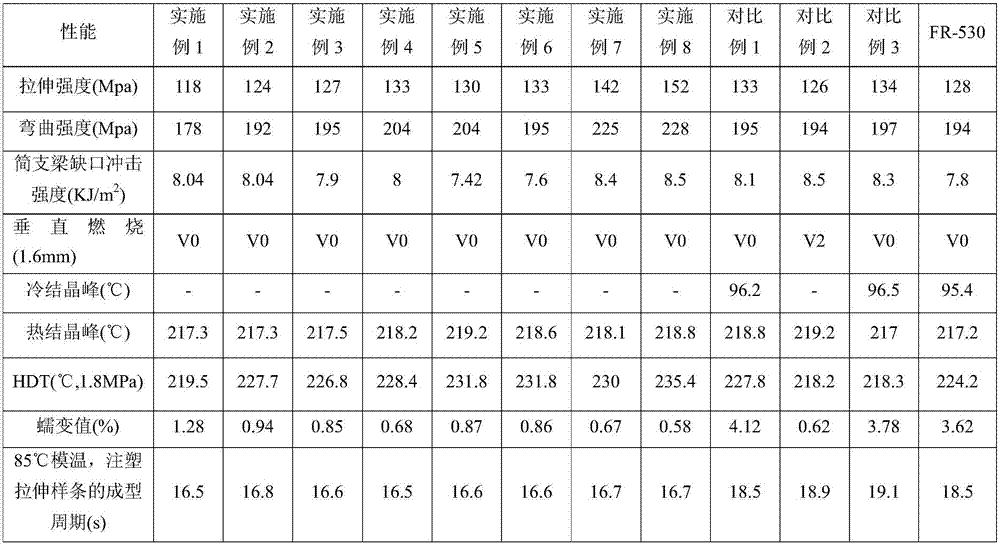

PET composite material

The invention discloses a PET composite material, which comprises the following components in parts by weight: 34 to 55 parts of PET, 25 to 45 parts of enhanced filling material, 3 to 8 parts of composite nucleating agent, and 0 to 3 parts of flexibilizer; wherein the composite nucleating agent comprises a chemical nucleating agent and a plasticizer, the weight ratio of the plasticizer to PET resin is 3.5-7:100, the plasticizer is prepared by compounding a benzsulfamide plasticizer with other plasticizers, other plasticizers can be one or more of polyethylene glycol-diethyl hexyl alcohol, neopentyl glycol diphenyl ester, tribenzyl propylidene ether diethyl hexyl alcohol, and triethylene glycol diphenyl ester, the structural formula of the benzsulfamide plasticizer is represented in the description, and in the structural formula, R represents a branched alkyl group or a straight chain alkyl group. The composite material is injection-moulded at a mould temperature of 85 DEG C, the crystallization is complete, the moulding period is short, and the PET composite material can be used to produce large moulded goods or precision thin-wall moulded goods.

Owner:本松新材料技术(芜湖)有限公司

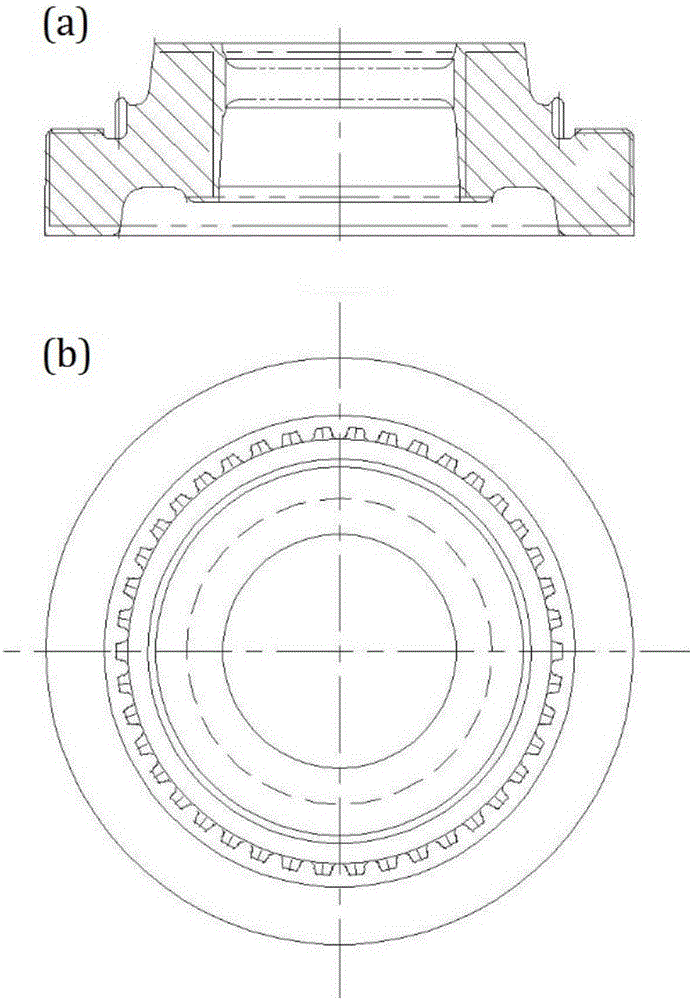

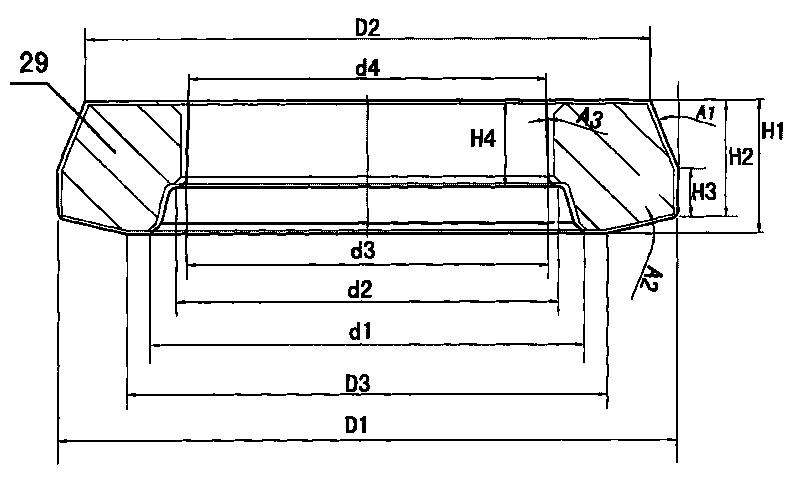

Achievement method of integral combined-tooth gear based on closed warm forging

Provided is an achievement method of an integral combined-tooth gear based on closed warm forging. After a lubricant is sprayed to the surface of a preheated rod material and the rod material is heated to reach forging temperature, the integral combined-tooth gear is obtained through closed warm forging treatment including reshaping, blank making, pre-forging, finish forging and punching. The integral combined-tooth gear meeting the dimensional precision and performance requirements can be produced under the conditions of lower temperature and higher material utilization rate.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Alloy liquid extrusion casting and forming device and technical method thereof

Owner:中建投(绍兴)机械科技有限公司

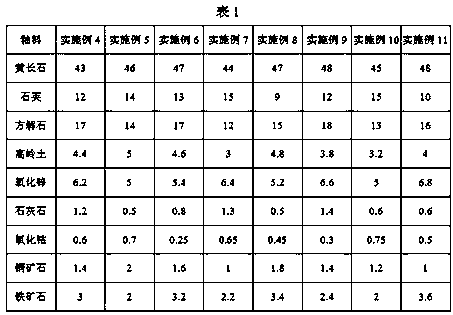

Jun porcelain purple glaze

The invention provides jun porcelain purple glaze. The glaze is prepared from the following raw materials in parts by weight: 43-49 parts of melilite, 9-15 parts of quartz, 12-18 parts of calcite, 3-5parts of kaolin, 5-7 parts of zinc oxide, 0.5-1.5 parts of limestone, 0.25-0.75 part of cobaltous oxide, 1-2 parts of copper ores and 2-4 parts of iron ores. Compared with the prior art, the jun porcelain purple glaze has the advantages that by scientific and reasonable raw material ratio and control on a firing process, the fired jun porcelain purple glaze does not have floating light, and is high in jade texture and opacifying property, and the yield is high and can reach 95% or above.

Owner:禹州市锦丰源瓷业有限公司

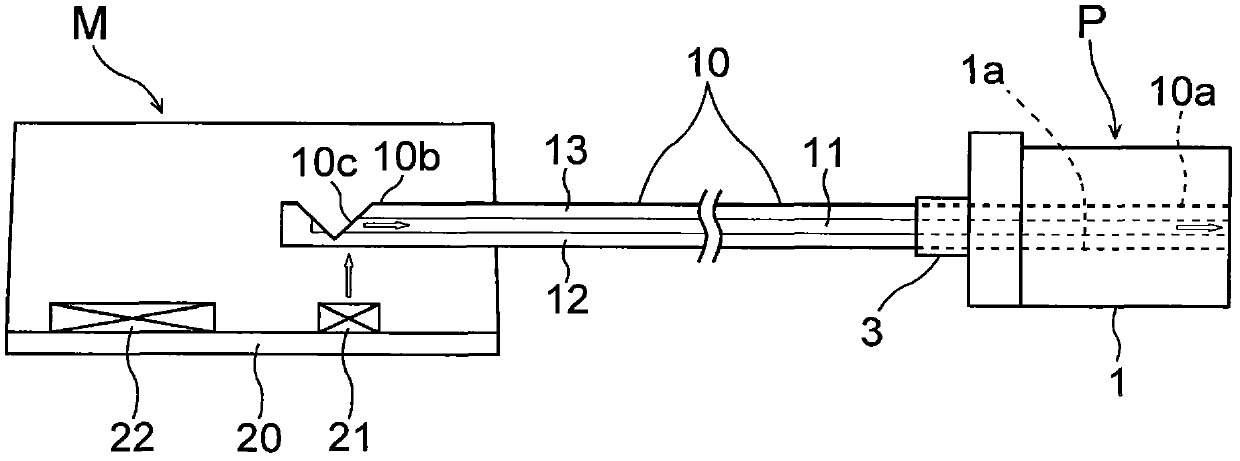

Manufacturing method for an optical connector

InactiveCN102636844ASimple and fast welding and fixingInfluence of Dimensional AccuracyCoupling light guidesOptical waveguide light guideEngineeringLength wave

Provided is a cost-effective manufacturing method for an optical connector, which enables an optical waveguide to be fixed to a ferrule easily in a short period of time. A manufacturing method for an optical connector includes: fitting an end portion of a transparent optical waveguide into an optical waveguide fitting groove of an optical connection ferrule made of a resin; and fusing and fixing the end portion of the transparent optical waveguide to the optical connection ferrule by applying a laser beam having a predetermined wavelength downward from above the optical waveguide fitting groove toward the transparent optical waveguide, so that the laser beam reaches a bottom surface of the optical waveguide fitting groove.

Owner:NITTO DENKO CORP

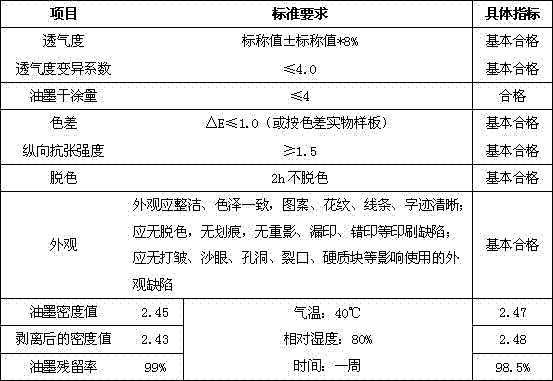

Application of aqueous ink-jet ink in tipping paper digital printing technology

InactiveCN107325640AReduce manufacturing costNo flashDuplicating/marking methodsInksPaper productionPulp and paper industry

The invention provides an application of an aqueous ink-jet ink in a tipping paper digital printing technology, and belongs to the technical field of printing. The novel application of the tipping paper digital printing technology is carried out under the requirements of related quality standards. Through a series of technological improvements on the formula of aqueous ink-jet ink dedicated for tipping paper digital printing, preparation, and printing process, finally two technology namely digital printing and tipping paper production are successfully combined. After detection, the printing layer thickness, glossiness, leveling property, surface tension, adhesive force, and safety of the tipping paper all meet the related quality standards. The tipping performance in the subsequent processing step can also meet the using requirements. The production is quick and flexible. At the same time, the printing quality is stable. The tipple paper will not have quality defects in subsequent processing step. The using requirements of digital printing and tipping paper processing can be satisfied at the same time. The application range of digital printing is enlarged. At the same time, the tipping paper production efficiency and product quality are both improved.

Owner:玉溪市星源油墨厂

Polyamide resin composition and molded article

ActiveCN101432364AFast crystallizationImproved thin-wall formabilityFlat articlesPolyamideCrystallinity

Disclosed is a polyamide resin composition for portable electronic devices, which is excellent in mechanical strength, thin shape formability, crystallinity and warping property. Specifically disclosed is a polyamide resin composition containing 30-80% by weight of a polyamide MP (A) and 20-70% by weight of a polyamide resin (B) having a melting point not less than 245 DEG C (with the total amount of them being 100% by weight). The polyamide resin composition further contains, as a filler (C), a fibrous filler (C1) as an optional component and a plate-like filler (C2) as an essential component, and the content ratio (C1):(C2) is from 0:10 to 9:1. The total amount of the filler (C) is 30-250 parts by weight relative to 100 parts by weight of the total of the polyamide MP (A) and the polyamide resin (B). The polyamide MP (A) is a polyamide resin obtained by a polycondensation reaction between a mixed diamine, which contains 90-50% by mole of meta-xylylenediamine and 10-50% by mole of para-xylylenediamine, and an alpha, omega-linear aliphatic dibasic acid and / or an aromatic dibasic acid.

Owner:MITSUBISHI ENG PLASTICS CORP

Clamping force setting method and device of injection molding machine

According to a first preset clamping force (Fs1) closed metal mold, a molten resin is injected into the metal mold and the maximum value (Fmax1) in the real clamping force detected during the molten resin injection process is used as a first maximum detected clamping force to be taken out. A second maximum detected clamping force (Fmax 2) is taken out by performing the above same action according to a second preset clamping force (Fs2). A point (Fs1, Fmax1) and a point (Fs2,Fmax2) are labeled on a coordinate, wherein the preset clamping force is used as horizontal axis and the maximum detected clamping force is used as longitudinal axis; and the two points are connected by straight line. The value of the preset clamping force on the cross point of the straight line and the straight line for representing the maximum detected clamping force and the preset clamping force is used as the proper clamping force to be used.

Owner:FANUC LTD

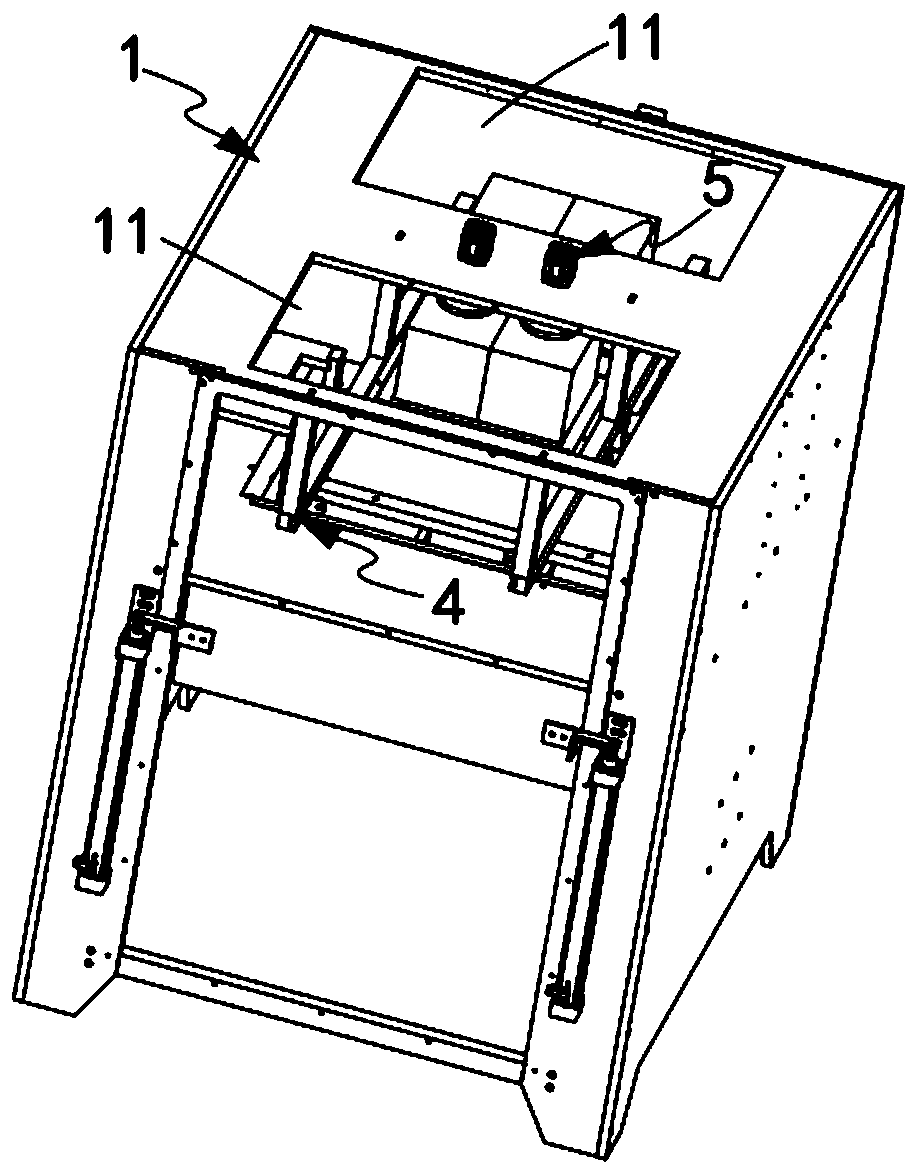

Full-automatic cast welding machine for storage battery

The invention provides a full-automatic cast welding machine for a storage battery. The full-automatic cast welding machine solves the technical problem that a conventional cast welding machine cannotcast-weld the storage battery continuously according to a technical scheme that symmetrical feed inlets are formed in the top of a shell and are matched with a slidably arranged tray, the other unoccupied material holding tank on the tray is loaded through one feed inlet when the tray carries one storage battery to move below a positioning mechanism to be cast-welded, the previously loaded storage battery is just transferred below the positioning mechanism to be cast-welded when the previous storage battery which is cast-welded is transferred to the corresponding feed inlet to be output, andthe output unoccupied material holding tank is just re-supplemented in the process of cast-welding the storage battery for waiting for cast-welding, so that the processing efficiency of the storage battery is improved and the structure of the cast welding machine is simplified.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

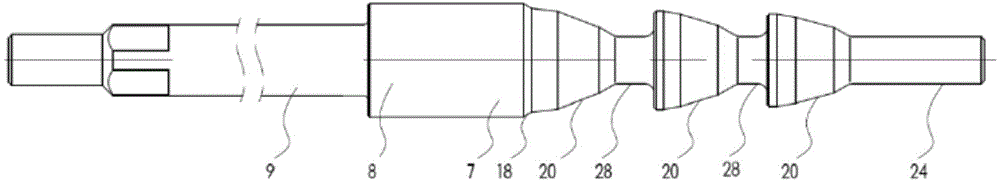

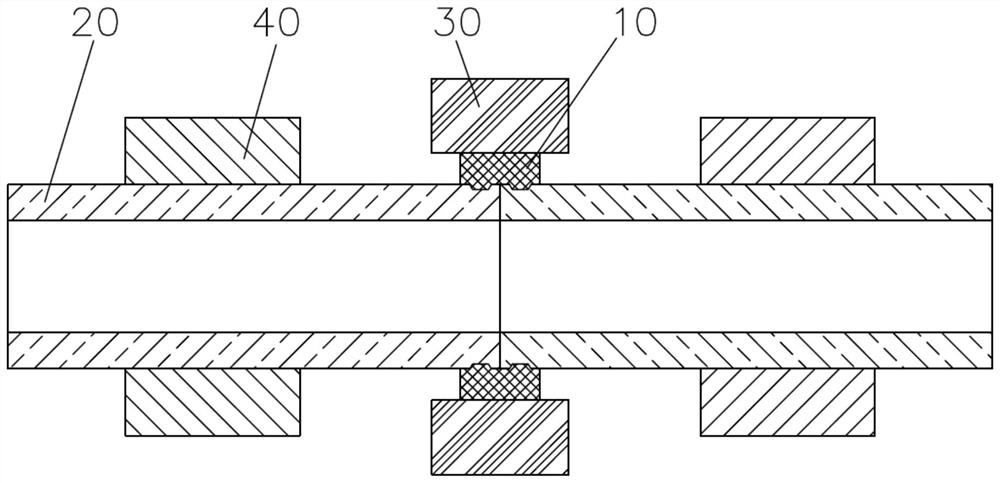

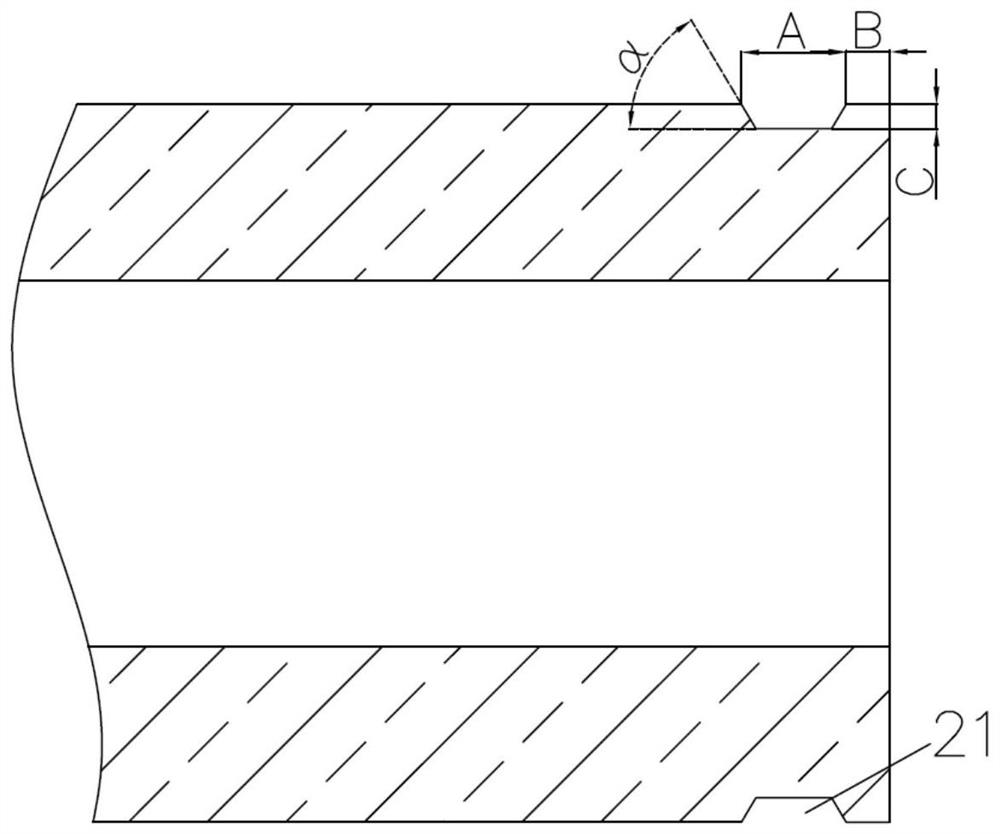

High-strength and high-reliability-sealing radial friction welding method for steel pipe fitting

ActiveCN113770507AAchieve Radial Friction WeldingImprove coaxialityNon-electric welding apparatusFriction weldingPipe fitting

The invention provides a high-strength and high-reliability-sealing radial friction welding method for a steel pipe fitting. According to the method, a clamping mode that a rotary pressurizing tool (30) clamps a steel ring welding blank (10) and fixed clamping tools (40) clamp two steel pipe welding blanks (20) respectively is adopted, and the radial friction welding mode that the steel pipe welding blanks (20) at the two ends do not rotate, the steel ring welding blank (10) rotates and pressurizes, and annular grooves (21) are formed in the welding positions of the steel pipe welding blanks (20) at the two ends is adopted; radial friction welding of a large-length steel pipe is achieved, high coaxiality of the welded steel pipe is guaranteed, meanwhile, radial run-out caused by self-rotation of the large-length steel pipe is effectively avoided, welding flashes or weld beading and the like in the pipe are avoided, the welding quality is guaranteed, the annular grooves (21) form a double-spigot locking structure, and the welding strength and the high-reliability-sealing performance of a weldment are ensured.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

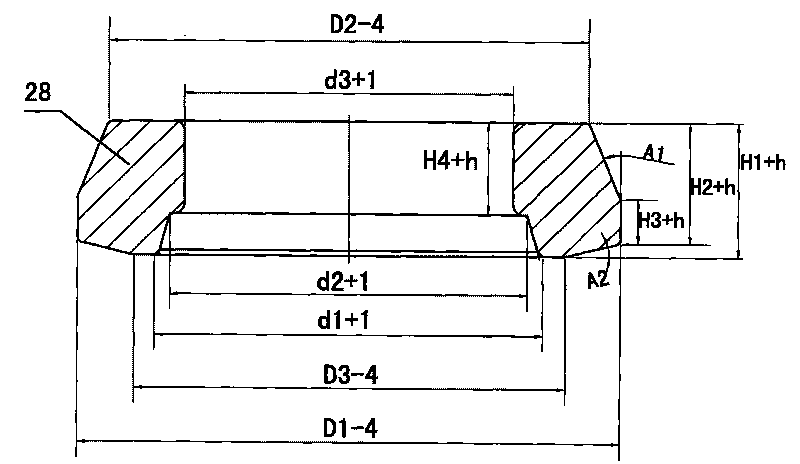

Reforming method and mold of automobile rear axle driven gear forging piece

The invention relates to a reforming method and a mold of an automobile rear axle driven gear forging piece; the method comprises the following steps: prepare a semi-finished product-a chambering piece of the driven gear forging piece, place the manufactured chambering piece into a reforming mold cavity and reform the driven gear forging piece; the mold comprises a male mold, a female mold and a stripper plate, wherein the female mold is composed of a floating mold and a closed cavity formed by a pair of rollers; the invention can effectively reform the chambering piece of the driven gear, eliminate the disadvantages of concave pit, oval shape and distortion of the surface of the chambering piece, adopt equipment with low load and simple structure can effectively reform the driven gear forging piece of the automobile rear axle and saves more than 10 percent of raw material; for instance, the driven gear forging piece with 430mm of outer diameter is reformed, the needed load is 6300kN and the blanking weight is 36 kilograms.

Owner:WUHAN UNIV OF TECH

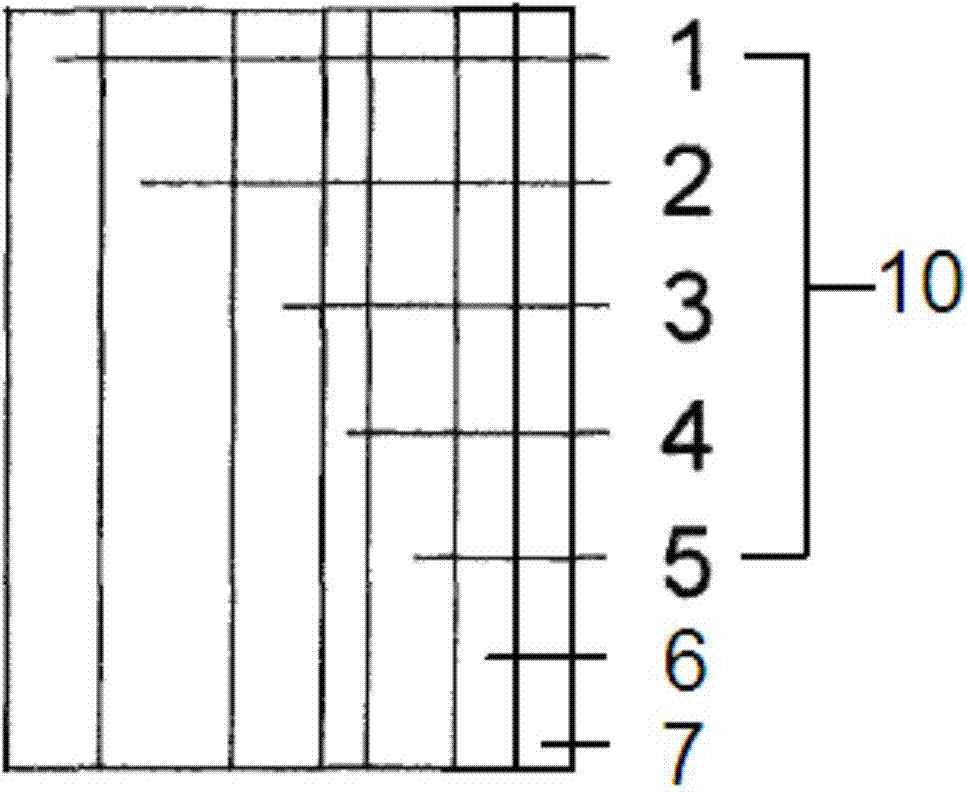

Newton ring preventing sheet, and touch panel using same

InactiveCN102362247AExcellent resistance to Newton ringsNo flashConductive layers on insulating-supportsThin material handlingDisplay deviceCRTS

Provided is a Newton ring preventing sheet, for example, used for a touch panel that is suitably used on various display screens such as recent high-definition CRT and FPD. Also provided is a touch panel using the same. A Newton ring preventing sheet (1) is configured by arranging a plurality of structural rows (2) in parallel with a pitch (3), and the height of the structural row (2) fluctuates along the extension direction of the ridge thereof. Preferably, the fluctuation of the height of the structural row (2) has periodicity, and the period of the fluctuation falls within the range of 20-4000 [mu]m.

Owner:KIMOTO CO LTD

Low-temperature curing conductive silver paste with high conductivity and low silver content and preparation method thereof

ActiveCN110444316AImprove conductivityStrong adhesionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePolymer science

The invention discloses low-temperature curing conductive silver paste with high conductivity and low silver content and a preparation method thereof. The conductive silver paste is composed of 5-30 wt% of homemade nano sheet-shaped silver powder, 9.6 wt% of polymer resin, 0.5-3 wt% of a conductive accelerant and 57.4-84.9 wt% of a solvent. The preparation method comprises the following steps: 1)preparing an organic carrier; 2) selecting according to the weight percentage of the formula; 3) weighing the solvent and the conductive accelerant according to the formula, and uniformly mixing; 4) adding the homemade nano sheet-shaped silver powder according to the formula, and uniformly dispersing; and 5) adding polymer resin according to the formula, and stirring until uniform conductive silver paste is formed. The conductive silver paste is excellent in conductivity after being cured into a film, the adhesive force reaches the zero level, and the silver content in the paste is greatly lower than that of commercial conductive silver paste (50-90 wt%). Therefore, the production cost is greatly reduced, and the conductive silver paste and the preparation method has a wide market application prospect.

Owner:深圳市博耀科技集团有限公司

Package structure of semiconductor device

ActiveCN101231982APackage structure is simpleSimple structureSemiconductor/solid-state device detailsSolid-state devicesEngineeringPower density

The invention relates to a semiconductor device package structure, in particular to a package structure of a miniature semiconductor device, which comprises lead frames and a wafer electrically connected with the lead frame, and integrated package housing. The wafer is sandwiched between the lead frames, and the lower surface of the lead frames below the chip is exposed to the outside of the package housing. The invention has the advantages of compact structure, low manufacture cost, good heat dissipation effect and effectively improved unit power density.

Owner:JINAN JINGHENG ELECTRONICS

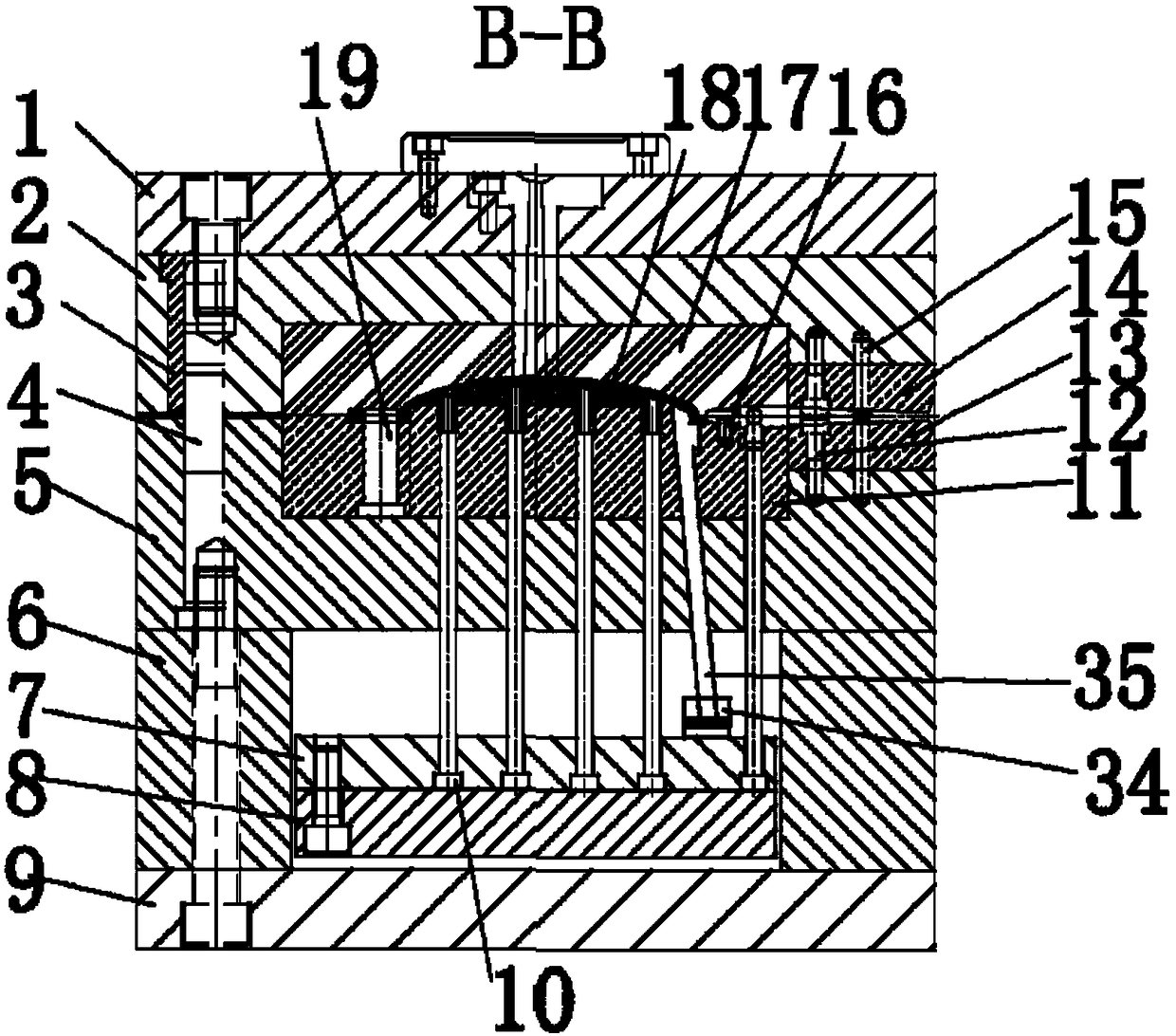

Double-color injection molding product

The invention provides a double-color injection molding product. The double-color injection molding product is manufactured by a synchronous double-color injection mold; the mold comprises a panel, afixed template, a fixed template guide sleeve, a guide column, a movable template, a mold foot, an ejector pin cover plate, an ejector pin push plate, a bottom plate, stud push rods, a mold core insert, sprue bush fastening screws, an upper sprue bush, a lower sprue bush, sprue bush locating pins and other parts. The double-color injection molding product manufactured by the synchronous double-color injection mold is good in forming quality, and black spots and color mixture are greatly improved.

Owner:乌鲁木齐九品芝麻信息科技有限公司

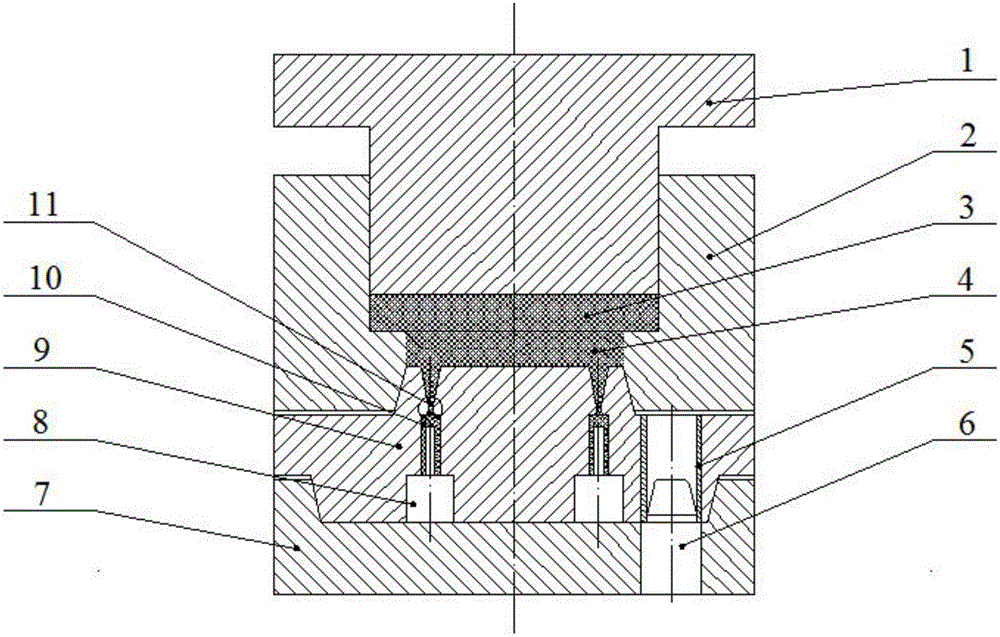

Rapid vulcanization forming process for rubber parts, and die

The invention relates to the field of rubber vulcanization, and particularly relates to a rapid vulcanization forming process for rubber parts, and a die. According to the rapid vulcanization forming process disclosed by the invention, an injection vulcanization process is adopted, a used injection die-pressing chamber is divided into an upper part and a lower part, the upper part is a pre-vulcanization cavity, the lower part is a vulcanization cavity, and a pin-point gate is arranged in the bottom of the vulcanization cavity. According to the rapid vulcanization forming process disclosed by the invention, double compounds are heated in one process through an injection die, injection vulcanization process is carried out in two times, and because the compound in the vulcanization cavity is in a positive vulcanization phase, the physical performances of the compound are far higher than those of the compound in a pre-vulcanization phase in the pre-vulcanization cavity. Therefore, the added compound can be prevented from being mixed with the compound in the vulcanization cavity, and quality of the rubber parts cannot be influenced. The cycle is continuously repeated, and a vulcanization time for the rubber parts can be reduced by half, thus the production efficiency is greatly improved.

Owner:HEFEI UNIV

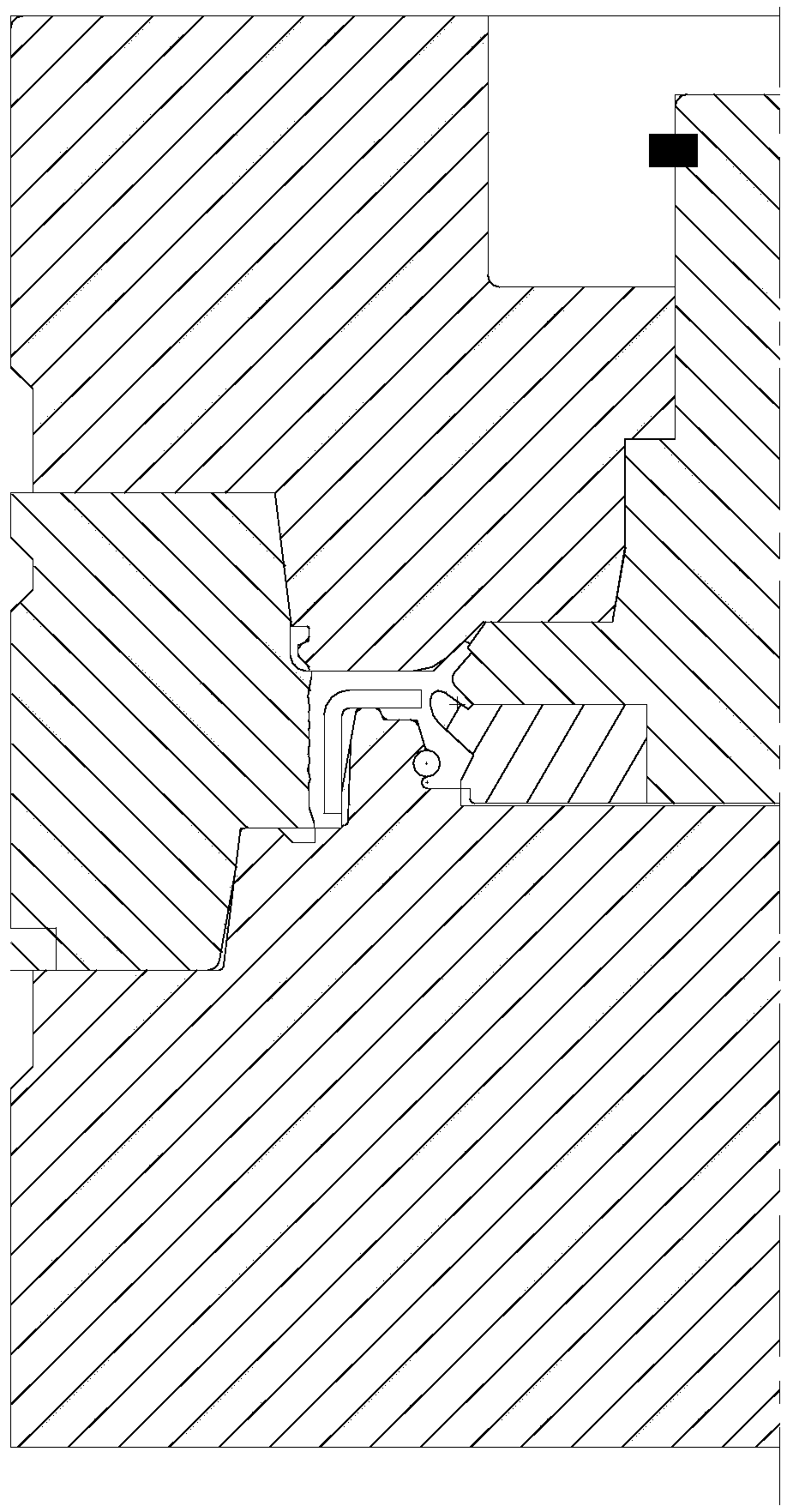

Improved oil seal type mold

ActiveCN108973030AIncrease profitAuxiliary production time is shortDomestic articlesMaterials science

The invention provides an improved oil seal type mold, which comprises an upper mold, a middle mold, a lower mold, a first mold core and a second mold core, wherein the upper mold, the middle mold andthe lower mold are in vertical arrangement; the middle mold is provided with a first die cavity; the top end of the lower mold is provided with an annular support table which extends into the first die cavity and is used for supporting an oil seal framework; the first mold core is arranged in the first die cavity; the bottom end of the first mold core is abutted against the lower mold; the secondmold core is arranged in the first die cavity; the second mold core is abutted against the first mold core; the bottom end of the upper mold is provided with an annular table extending into the firstdie cavity; in the mold matching state, a die cavity is formed among the upper mold, the middle mold, the lower mold, the first mold core and the second mold core; the die cavity is communicated witha glue injection flow passage; a glue injection opening is formed in the upper mold; a glue injection flow passage for connecting the glue injection opening and the die cavity is formed between the upper mold and the second die cavity. The non-flash design and the flash cutting process are used; shaping is used in four parts; the non-flash design is used in three positions; only the flash in theglue inlet position need to be cut.

Owner:安徽宁国中鼎模具制造有限公司

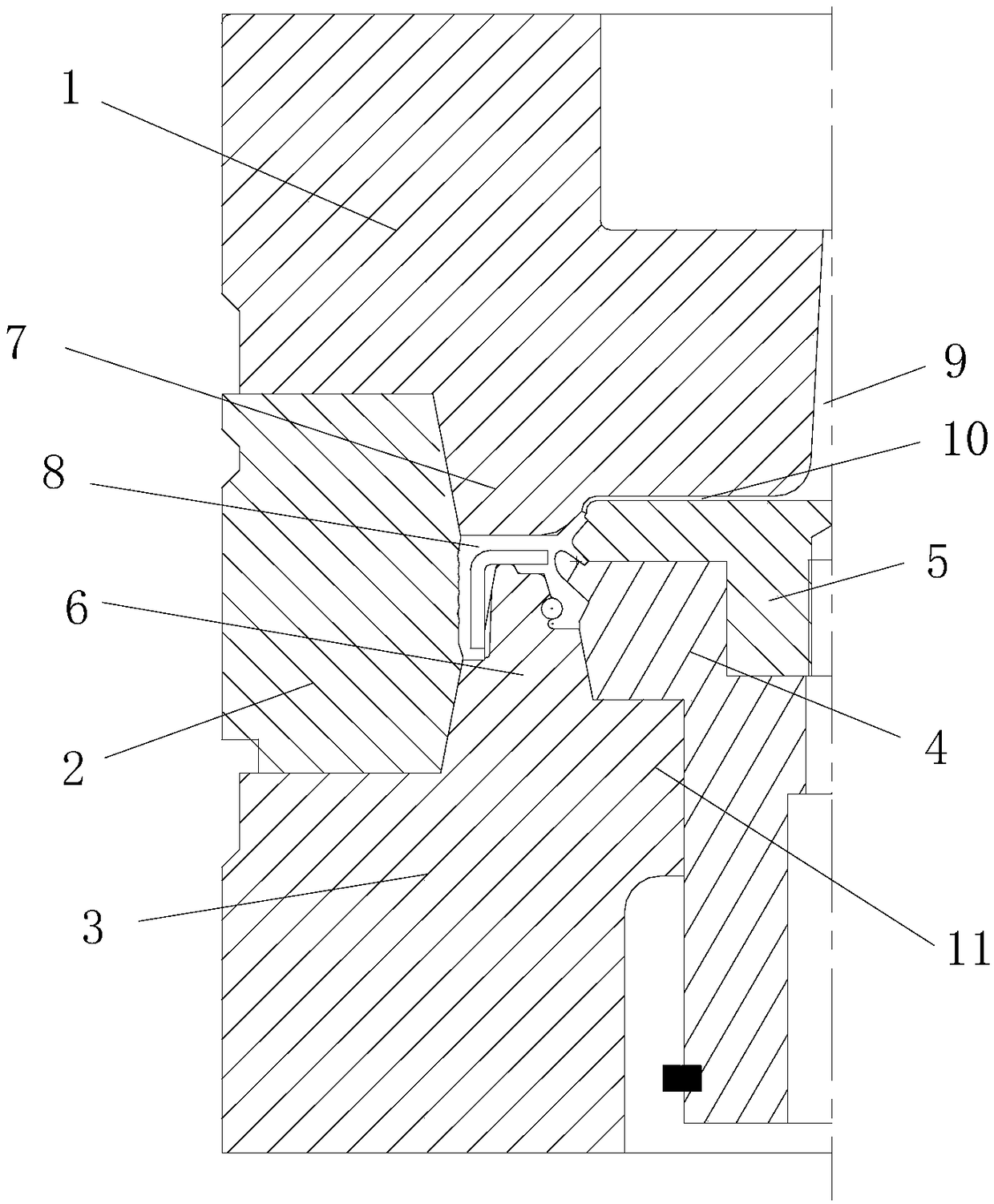

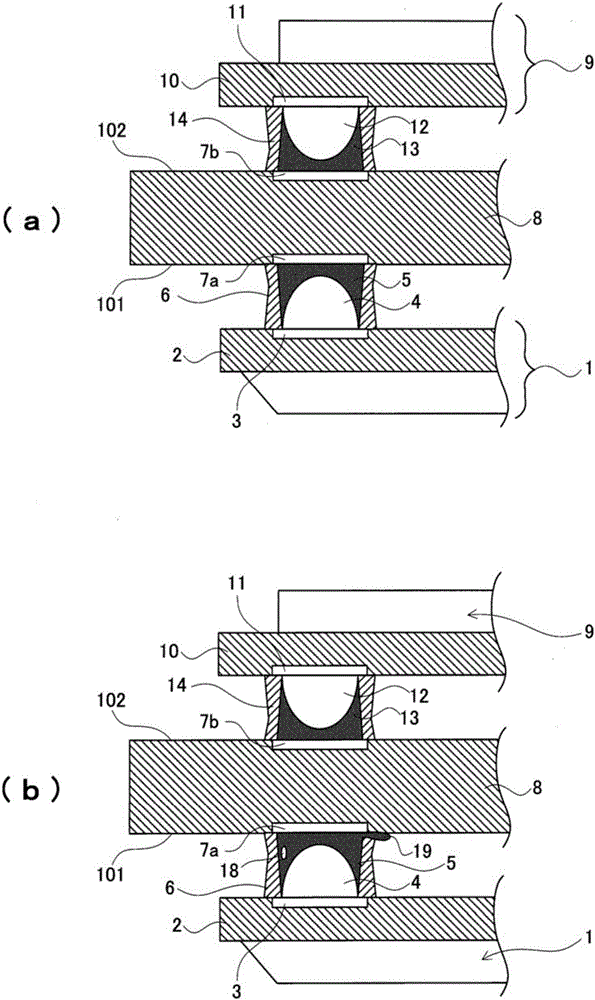

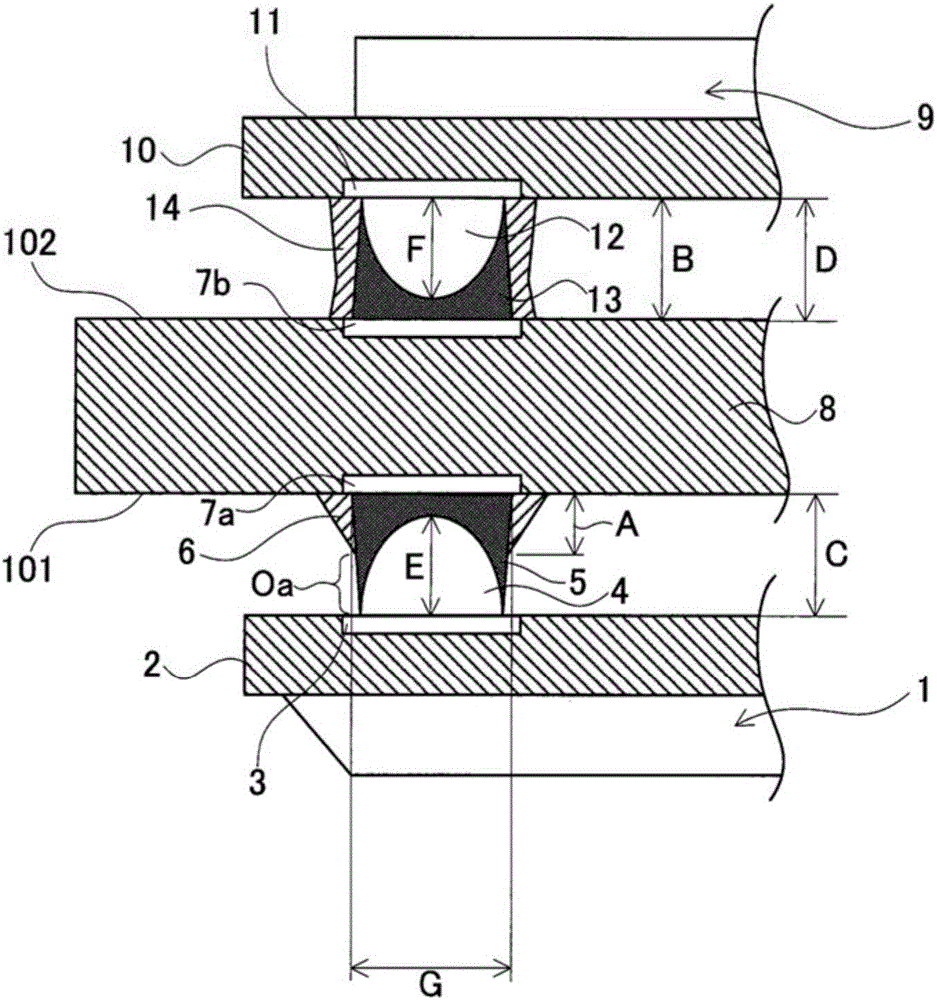

Mounting structure and method for producing mounting structure

ActiveCN106449444ANo flashPrinted circuit assemblingSemiconductor/solid-state device detailsSurface mountingBackflow

The invention provides a mounting structure capable of preventing flashing of a solder during two-surface mounting, and a method for producing the mounting structure. The mounting structure is characterized in that a mounting part (1) is mounted on a mounting surface (101) of a member to be mounted (8), and a mounting part (9) is mounted on a mounting surface (102) of the member to be mounted (8). The mounting structure includes: reinforcing resin, wherein a base end of the reinforcing resin is connected to the mounting surface (101) of the member to be mounted (8) so as to cover a part of a solder (5), and a front end of the reinforcing resin does not contact a bump (4); a part of the solder (5) forms an exposed portion (Oa) between the front end of the reinforcing resin (6) and a substrate (2) of the mounting part (1), and the exposed portion is exposed, accordingly, the re-molten solder (5) expands outward from the exposed portion (Oa) through secondary backflow when the mounting part (9) is mounted on the mounting surface (102) of the member to be mounted (8), and the solder (5) returns to an original position through cooling.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Aluminum alloy electric arc additive manufacturing quality control system and method

ActiveCN112008198AEliminate stomataEliminate crack defectsAdditive manufacturing apparatusWelding/soldering/cutting articlesControl systemQuality control

The invention belongs to the field of additive manufacturing, and discloses an aluminum alloy electric arc additive manufacturing quality control system and method. Formed aluminum alloy accumulated metal is machined in a rotational friction plastic deformation manner, the defects of pores, cracks and the like possibly existing in original accumulated metal can be effectively eliminated, and meanwhile, aluminum alloy accumulated metal grains and a precipitation phase are refined, so that the mechanical property is improved, the problem that the forming quality is difficult to effectively control during aluminum alloy electric arc additive manufacturing is solved, the method is completely different from a process optimization and wire selection method in an existing electric arc additive manufacturing aluminum alloy component quality control technology, the manufacturing efficiency is high, the cost is low, and the forming quality is stable.

Owner:HUAZHONG UNIV OF SCI & TECH

Sleeve rubber mold without trimming

The invention discloses a sleeve rubber mold without trimming. The rubber mold comprises an upper mold plate, a runner plate is arranged on the top of the upper mold plate, the bottom of the upper mold plate is connected to a lower mold plate through a middle mold plate, an upper groove is formed in the bottom of the upper mold plate, a lower groove is formed in the bottom of the lower mold plate,an upper mold insert and a lower mold insert are separately arranged in the upper groove and the lower groove, a cavity for a sleeve product is formed among the upper mold insert, the lower mold insert and the middle mold plate, an injection hole is formed in the upper mold plate, the top of the injection hole communicates to the runner plate, and the injection hole penetrates to the cavity fromthe top of the upper mold plate. The rubber mold is characterized in that an exhausting system is arranged on the upper mold plate, and the exhausting system penetrates to the cavity from the top of the upper mold plate. The rubber mold is suitable for a shock absorbing sleeve product of an automobile chassis, solves the problem of trimming the shock absorbing sleeve product in the rubber mold, and ensures that no flashes are available after the product is demolded, so that the rubber material and labor are saved, and the utilization ratio and the production efficiency of the rubber material are improved.

Owner:SHANGHAI ZHONGLI AUTO PARTS

Manufacturing method for ball valve with flange

InactiveCN107876675AIncrease profitReduce the burden onValve arrangementsMetal rollingEconomic benefitsEngineering

The invention discloses a manufacturing method for a ball valve with a flange. The manufacturing method comprises the following steps of valve body manufacturing and end cover manufacturing, a manufactured valve body and a manufactured end cover are welded, and cooling water is introduced into the valve body during welding to protect a sealing ring. According to manufacturing method, by changing the manufacturing process, the purposes of reducing waste and improving economic benefits are achieved by reducing the consumption of blanks.

Owner:SICHUAN KAITZ VALVE MFG

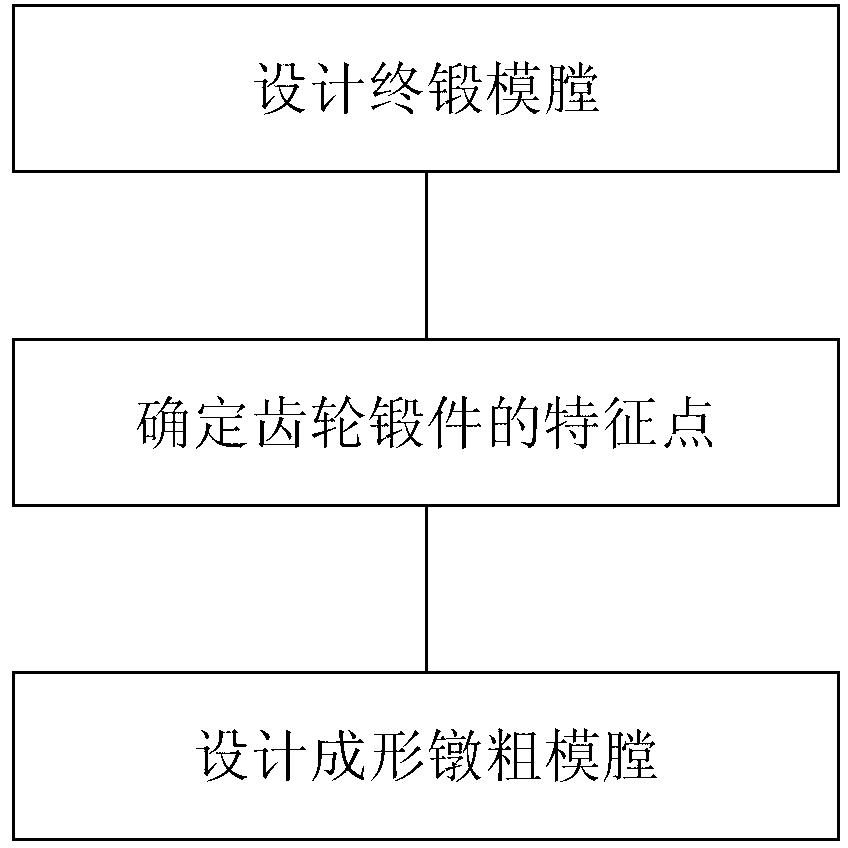

Method for designing gear forging die by three-order non-uniform rational B-splines

InactiveCN103056270AEasy to controlThe process is easy to realizeForging/hammering/pressing machinesWheelsSection planeGear wheel

A method for designing a gear forging die by three-order non-uniform rational B-splines includes: determining feature points K1, K2, K3 and K4 representing symmetrical basic shape of a gear forging shaft, and using the feature points as basis for the design of three-order non-uniform ration B-spline cures and surfaces for the gear forging die; allowing the contour profile of a formed upsetting impression to be curves when determining the shape of the formed upsetting impression, and allowing points of segments in the curves of the formed upsetting impression to correspond to the feature points K1, K2, K3 and K4 of a gear forging respectively. The complex process of preforming, upsetting and final forging for the gear forgings is simplified, performing of the complex gear forgings can be completed by two procedures, single heating and one tool set, and accordingly cost is effectively lowered and work efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

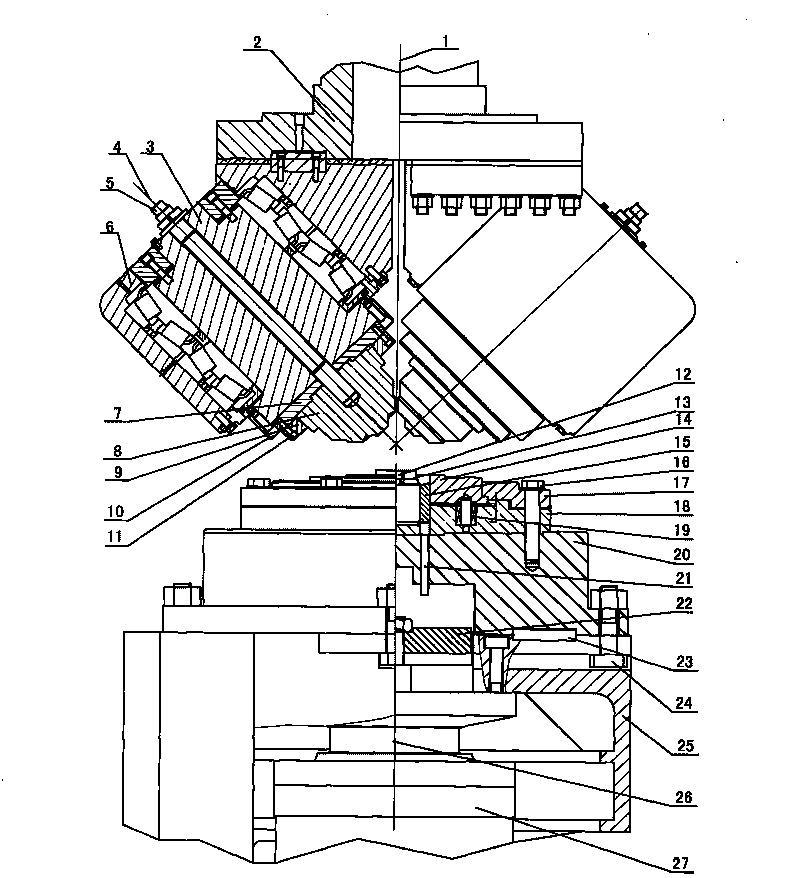

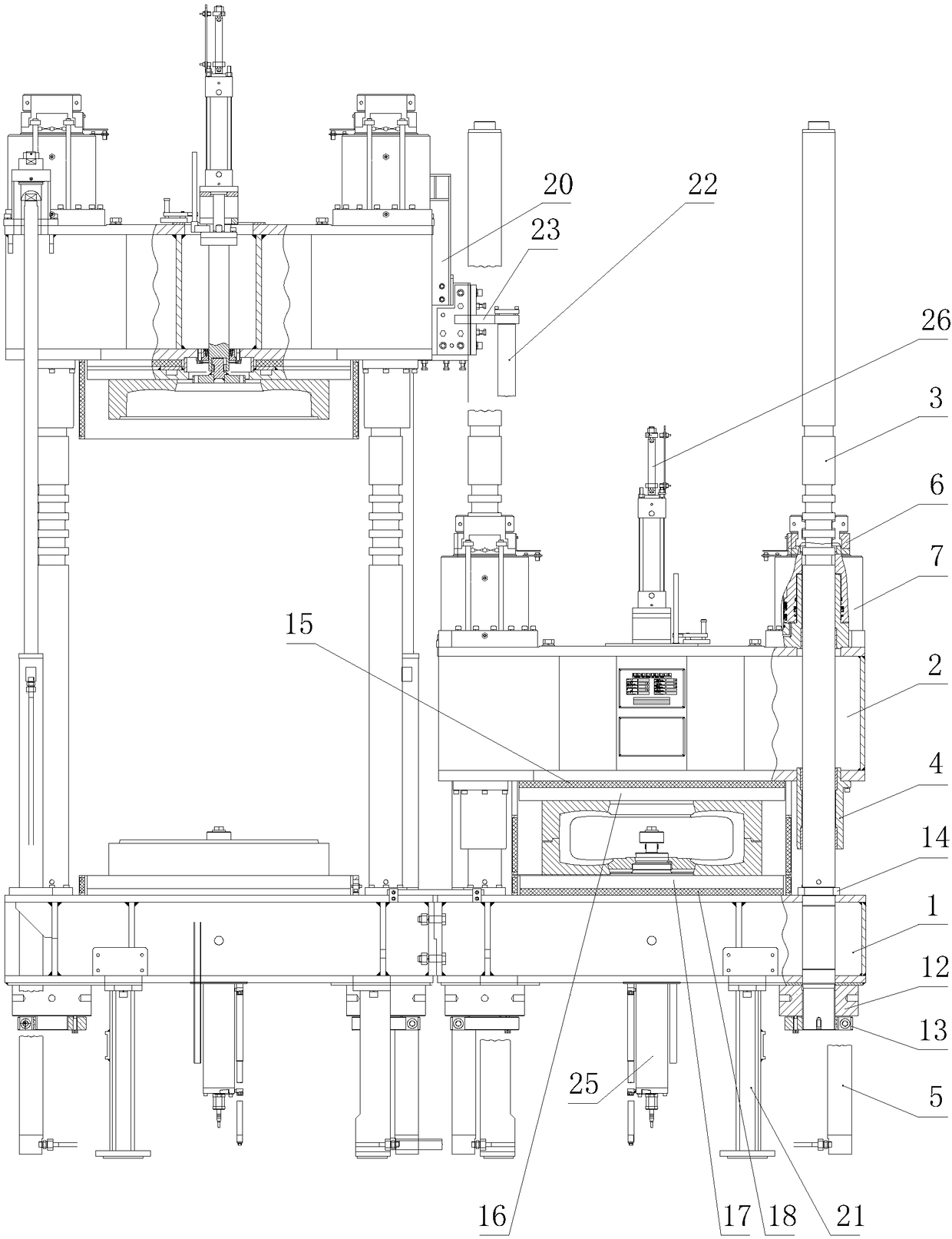

Intelligent double-guide-post hydraulic tire shaping vulcanizing machine and mold changing method thereof

The invention discloses an intelligent double-guide-post hydraulic tire shaping vulcanizing machine and a mold changing method thereof. Ascending and descending position displacement detection devicesin a cross beam mold opening and closing position, a shaping position and a mold closing locking mechanism entering and exiting position are connected with an electric control system to reach the goals of controlling the cross beam mold opening and closing, shaping, and mold closing locking mechanism entering and exiting position; the displacement of an upper cross beam is detected through a displacement detection device; the digital and intelligent no-mold-regulating mechanism and mold-regulating-free intelligent mold replacement can be realized by matching an electric control system PLC anda control computer to set the position height; meanwhile, the digital and intelligent setting and automatic detection and control of the mold closing position and secondary steam inflating shaping position and mold opening limit position can be realized; the mold regulating and mold replacement time is reduced; the production efficiency is improved.

Owner:广州通誉智能科技有限公司

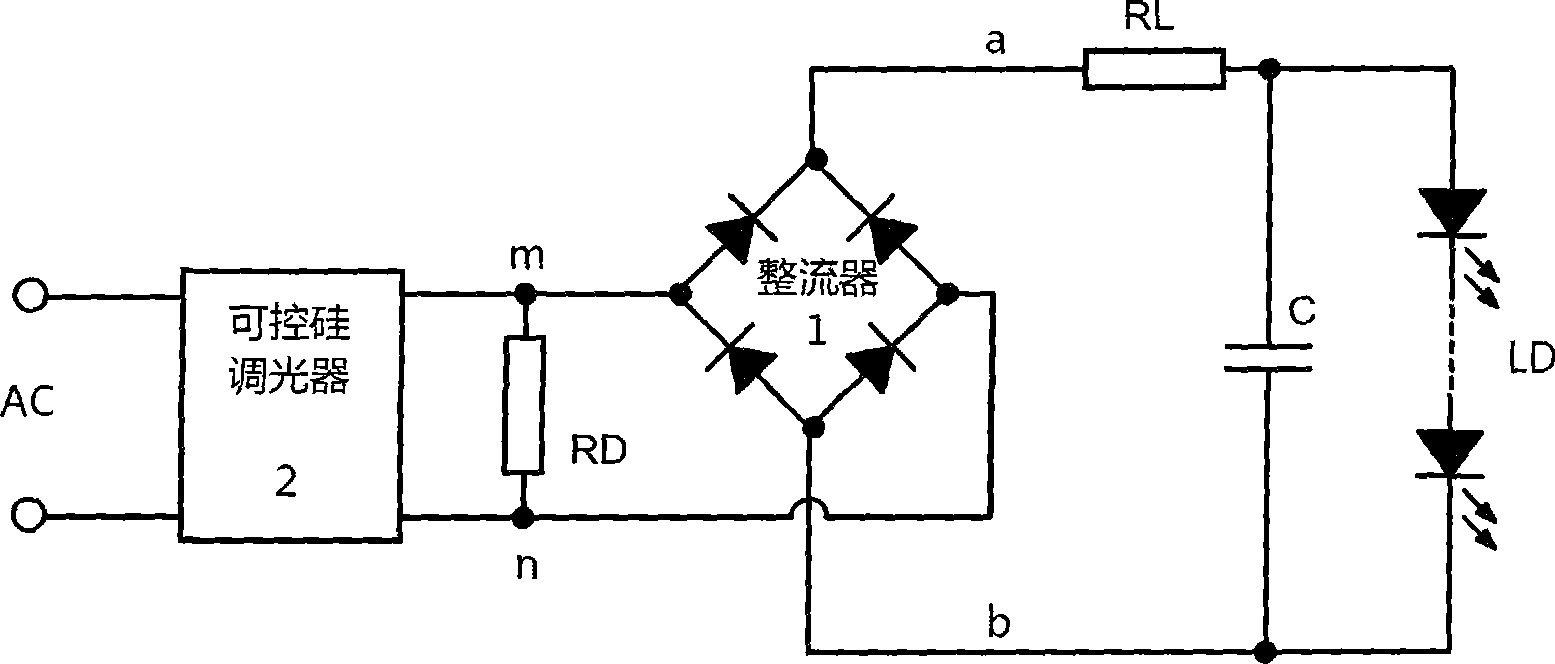

Light modulation power supply and light modulation lamp

InactiveCN101368710ANo flashPoint-like light sourceElectric circuit arrangementsEngineeringLight-emitting diode

Disclosed are a light-adjusting power supply and a light-adjusting lamp which comprise a rectifier and a controllable silicon light adjuster connected with the power supply side of the rectifier; the light-adjusting power supply and the light-adjusting lamp are characterized in that a flash elimination resistor is in bridge connection with two power wires between the rectifier and the controllable silicon light-adjuster. At least a LED used as the light source load is connected between the other end without serial connection of the rectifier of the light-adjusting lamp and the other output end of the rectifier. The light-adjusting power supply and the light-adjusting lamp eliminate the flash phenomenon generated when the light source used as the load is adjusted to be in the low brightness.

Owner:SHANGHAI WILLIAMS LIGHTING

Adhesive sticker cladding mold and facing tile cast-in-situ method using same

InactiveCN104499668ARegular molding surfaceUniform color blockCovering/liningsBuilding material handlingBrick

The invention provides an adhesive sticker cladding mold applied to cast-in-situ of facing tiles on the surface of a building. The mold is a sheet-shaped hollowed-out mold which can be released twice, comprising an inner layer and an outer layer which can be separated from each other. The invention also provides a facing tile cast-in-situ method using the adhesive sticker cladding mold. The adhesive sticker cladding mold and the facing tile cast-in-situ method using the adhesive sticker cladding mold have the advantages that the facing tile can be manufactured on the building; the facing tile is uniform in color, can be demolded twice, and is regular in forming surface, and free of flash; the decorative effect close to facing tile is achieved; the pattern and color are rich; one or a plurality of art bricks with gradient color can be particularly manufactured; in addition, the mold is lightweight, safe and firm, and convenient to construct.

Owner:SHANGHAI GIANT ENERGY SAVING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com