Jun porcelain purple glaze

A technology of purple glaze and Jun porcelain, applied in the field of glaze, can solve the problems of loss of collection value, too bright color, flashy, etc., achieve the effect of strong jade texture and opacity, high yield rate, and promote crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

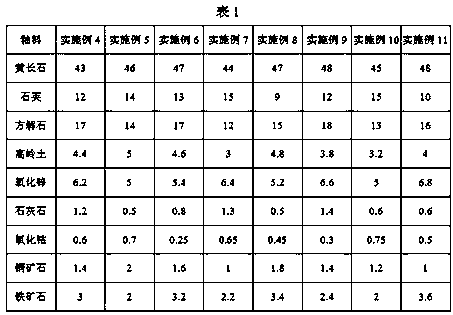

Examples

Embodiment 1

[0021] A Jun porcelain purple glaze, the glaze is prepared from the following raw materials in parts by weight: 43-49 parts of feldspar, 9-15 parts of quartz, 12-18 parts of calcite, 3-5 parts of kaolin, and 5-7 parts of zinc oxide 0.5-1.5 parts of limestone, 0.25-0.75 parts of cobalt oxide, 1-2 parts of copper ore, and 2-4 parts of iron ore.

[0022] The preparation method of above-mentioned Jun porcelain purple glaze comprises the following steps:

[0023] (1) Preparation of glaze slurry:

[0024] ①Calcinate the kaolin, limestone and zinc oxide of the same weight as the kaolin at 920-980°C for 3-5h, after calcination, turn off the heat and keep it warm for 20-30min, then cool naturally, and set aside;

[0025] ② Mix the above-mentioned feldspar, quartz, calcite, cobalt oxide, copper ore, iron ore with calcined kaolin, limestone and zinc oxide, add water ball mill, and sieve to obtain a glaze with a mass concentration of 53-55%. pulp;

[0026] (2) Glazing: immerse the gree...

Embodiment 2

[0035] A Jun porcelain purple glaze, the glaze is prepared from the following raw materials in parts by weight: 46 parts of feldspar, 12 parts of quartz, 16 parts of calcite, 4 parts of kaolin, 6 parts of zinc oxide, 1 part of limestone, and 0.5 part of cobalt oxide , 1.5 parts of copper ore, 3 parts of iron ore.

[0036] The preparation method of above-mentioned Jun porcelain purple glaze comprises the following steps:

[0037] (1) Preparation of glaze slurry:

[0038] ①Calcinate the kaolin, limestone and zinc oxide of the same weight as kaolin at 950°C for 4 hours in the above parts by weight, turn off the flame and keep it warm for 25 minutes after calcination, then cool naturally and set aside;

[0039]② Mix the above-mentioned feldspar, quartz, calcite, cobalt oxide, copper ore, iron ore with calcined kaolin, limestone and zinc oxide, add water ball mill, and sieve to obtain a glaze slurry with a mass concentration of 54%;

[0040] (2) Glazing: immerse the green body in...

Embodiment 3

[0049] A Jun porcelain purple glaze, the glaze is prepared from the following raw materials in parts by weight: 48 parts of feldspar, 13 parts of quartz, 12 parts of calcite, 4 parts of kaolin, 6 parts of zinc oxide, 1 part of limestone, and 0.65 parts of cobalt oxide , 1.2 parts of copper ore, 3 parts of iron ore.

[0050] The preparation method of above-mentioned Jun porcelain purple glaze comprises the following steps:

[0051] (1) Preparation of glaze slurry:

[0052] ①Calcinate the kaolin, limestone and zinc oxide of the same weight as the kaolin at 960°C for 5 hours. After calcination, turn off the heat and keep it warm for 30 minutes, then cool it naturally and set aside;

[0053] 2. Mix the above-mentioned feldspar, quartz, calcite, cobalt oxide, copper ore, iron ore with calcined kaolin, limestone and zinc oxide, ball mill, and sieve to obtain a glaze slurry with a mass concentration of 55%;

[0054] (2) Glazing: immerse the green body in the glaze slurry prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com