Throttling serial type multistage pressure reduction and adjustment valve

A decompression regulating valve, string-type technology, applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of insignificant decompression effect, inability to effectively eliminate cavitation, internal parts damage, etc., to reduce the degree of erosion, Prevents flashing and cavitation and prolongs service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A throttling string type multi-stage pressure reducing regulating valve according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

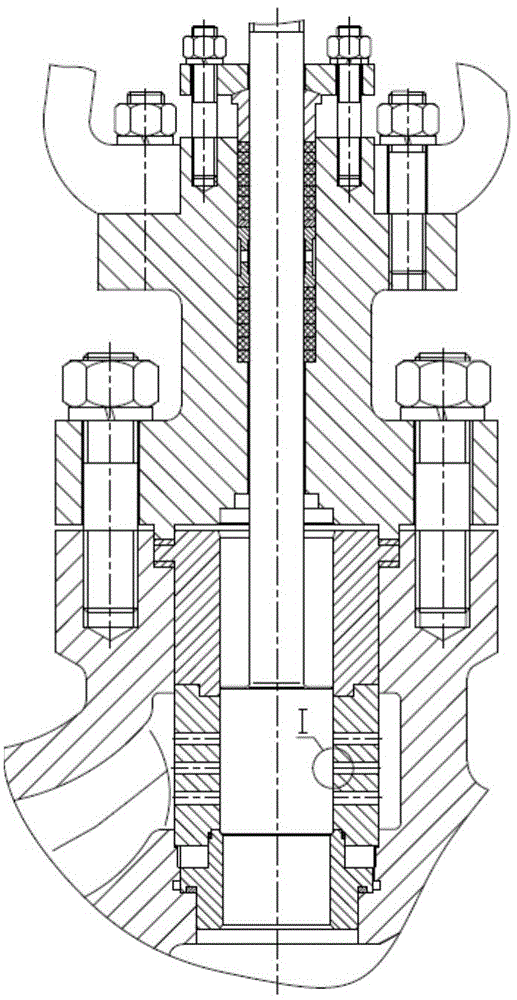

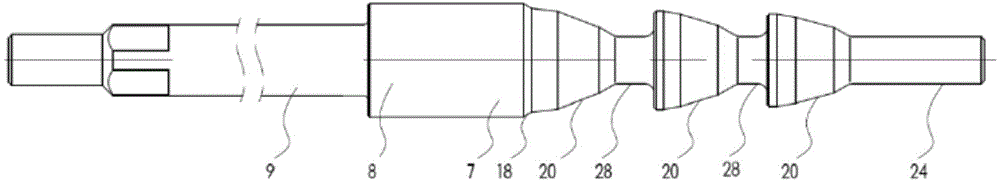

[0028] Such as figure 2 As shown, a throttling series multi-stage pressure reducing regulating valve according to the present invention includes a valve body 1, a valve seat assembly 2, a stuffing box 5, a middle flange 6, a valve core assembly 7, a packing assembly 10, Packing plate 11, middle flange bolts and nuts 12, packing plate bolts and nuts 13, valve seat set screws 14, stuffing box winding pad 15, valve seat winding pad 16, etc.

[0029] Wherein, the lower part of the valve body 1 and the valve seat assembly 2 are connected through valve seat set screws 14 . A valve seat winding pad 16 is set at the connection between the valve body 1 and the valve seat assembly 2, and the valve seat winding pad 16 is pressed by the valve seat set screw 14 so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com