Alloy liquid extrusion casting and forming device and technical method thereof

A squeeze casting and forming device technology, which is applied in the field of alloy liquid squeeze casting forming devices and its technology, can solve the problems of low dimensional accuracy, high cost, energy consumption, etc., and achieve high dimensional accuracy, high mechanical performance, and full The effect of short stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

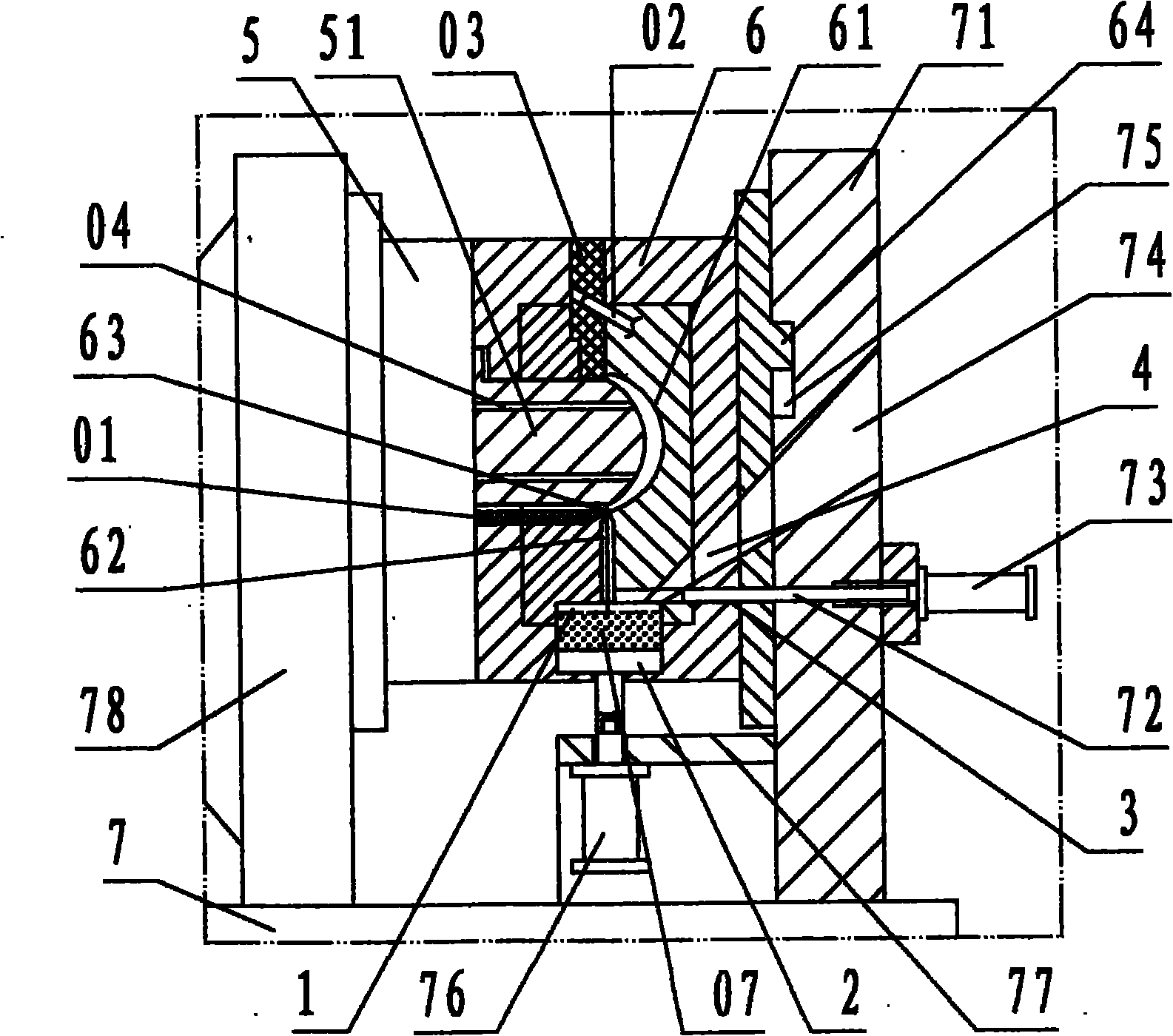

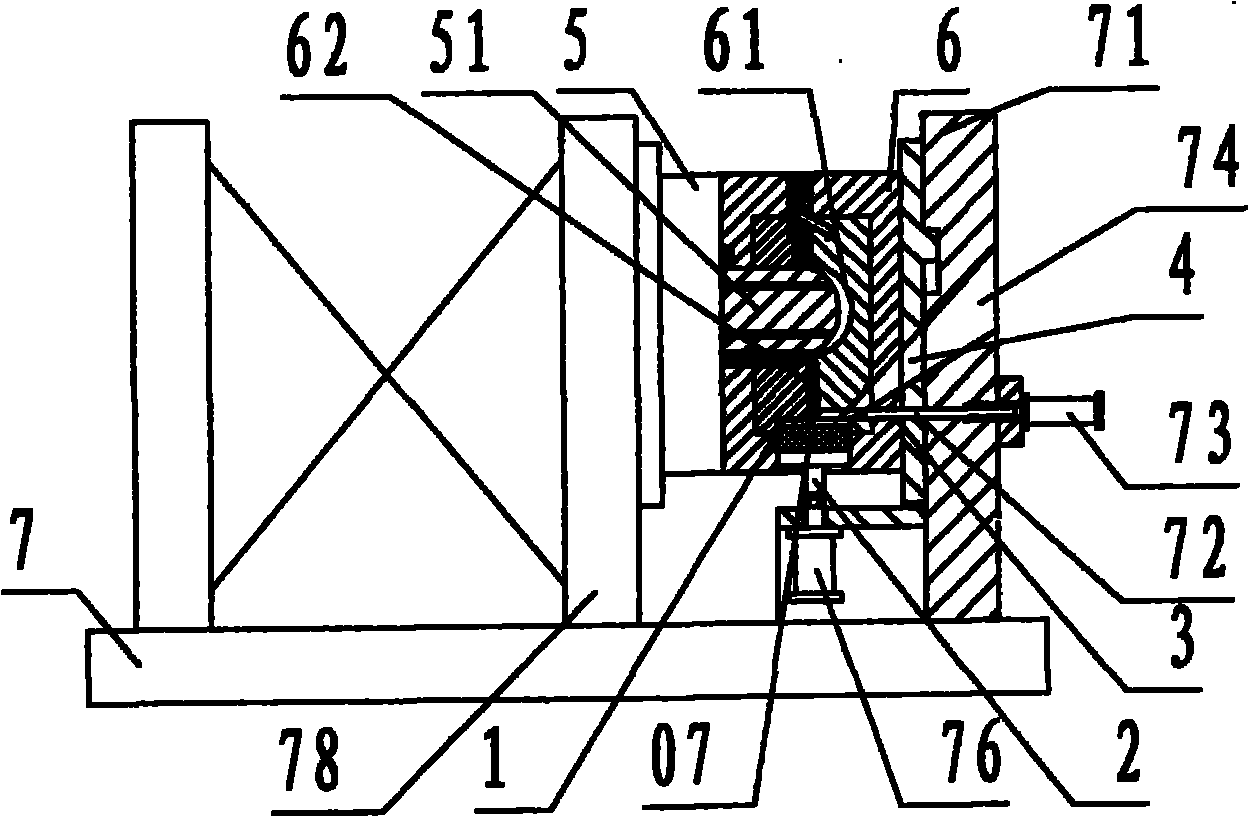

[0034] refer to Figure 1 to Figure 5, an alloy liquid extrusion casting molding device and its process method of the present invention, comprising a liquid material chamber 1, a hammer head 2, a sealing slideway 3, a pouring port 4, a static workbench 71, a sealing knife 72 and an injection device 76 , wherein: the liquid material chamber 1 is vertically arranged on the lower part of the dynamic and static mold parting surfaces of the horizontal die-casting mold, and is formed by two semi-cylindrical grooves with a top and a bottom. Cylinder cavity, in which the half valve groove is vertically arranged on the lower part of the parting surface of the static mold 6 cavity 61, and the other half valve groove is vertically arranged on the lower part of the moving mold 5 core 51 parting surface, and the positions correspond to each other The center of the top of the liquid material chamber is provided with vertically upwards, and the cylindrical conformable flow channel 62 formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com