Adhesive sticker cladding mold and facing tile cast-in-situ method using same

A technology of adhesive cladding and facing bricks, which is applied in the processing of building materials, construction, building structure, etc. Rich colors, regular molding surface, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

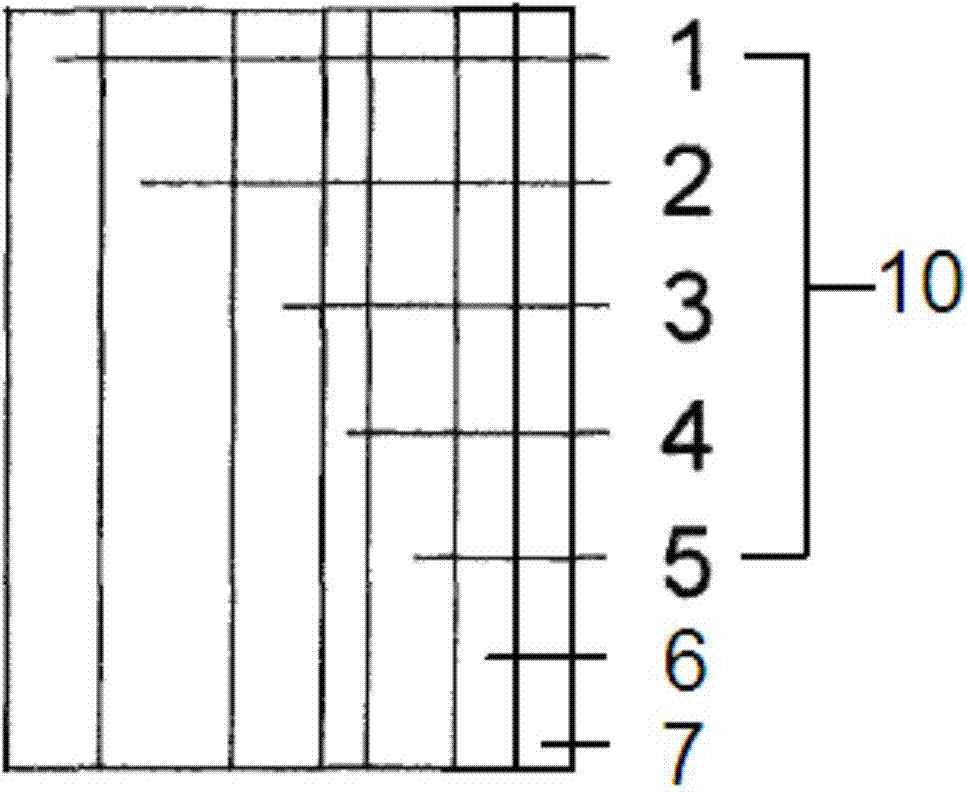

[0072] figure 1 It is a schematic diagram of the front side of the wall facing brick mold that can be demolded twice, figure 2 It is a schematic side view of a wall facing brick mold that can be demolded twice.

[0073] like figure 1 As shown, a wall facing brick mold body 8 for making facing bricks on the surface of a building has a sheet-shaped hollow structure, and the mold body 8 has a hollow brick-shaped hole 9, including a detachable inner layer mold structure 10 and outer mold structure7. The total thickness of the sheet hollow mold is figure 2 The total thickness of each layer is about 0.6mm.

[0074] like figure 2 As shown, wherein, a self-adhesive bonding area 6 is set between the inner mold structure 10 and the outer mold structure 7, and the inner mold structure 10 includes a release layer 1, a self-adhesive bonding Layer 2, bottom layer coated paper 3, paper body 4, surface layer coated paper 5. The thickness of the bottom layer coated paper 3 is about 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com