Reforming method and mold of automobile rear axle driven gear forging piece

A technology for driven gears and automobile rear axles, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of high equipment structure requirements, large equipment tonnage, high equipment cost, etc., and achieve simple equipment structure and long service life , The effect of long mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

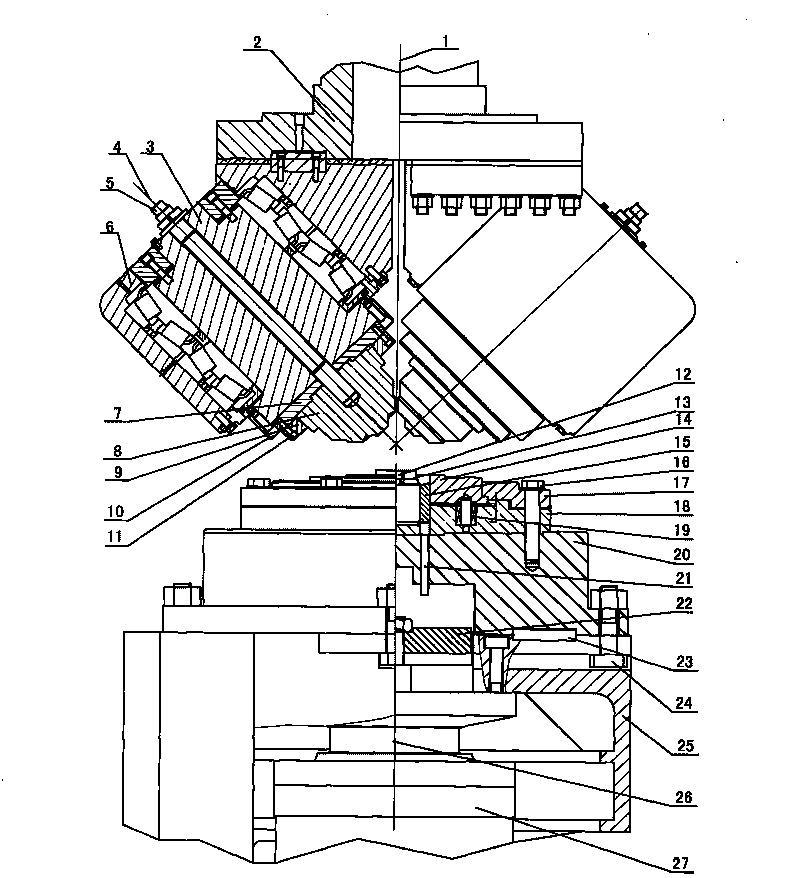

[0043] 1. The shaping method of the driven gear forging of the rear axle of the automobile

[0044] The shaping method employs a method comprising the following steps:

[0045] (1) Prepare the semi-finished product of the driven gear forging:

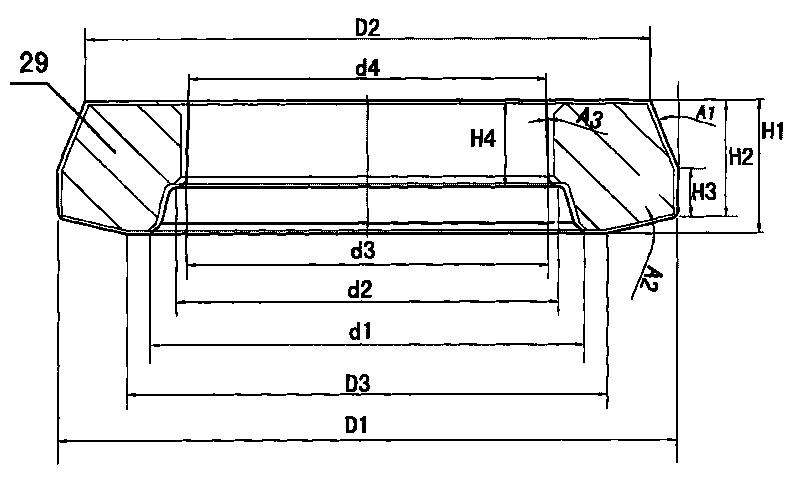

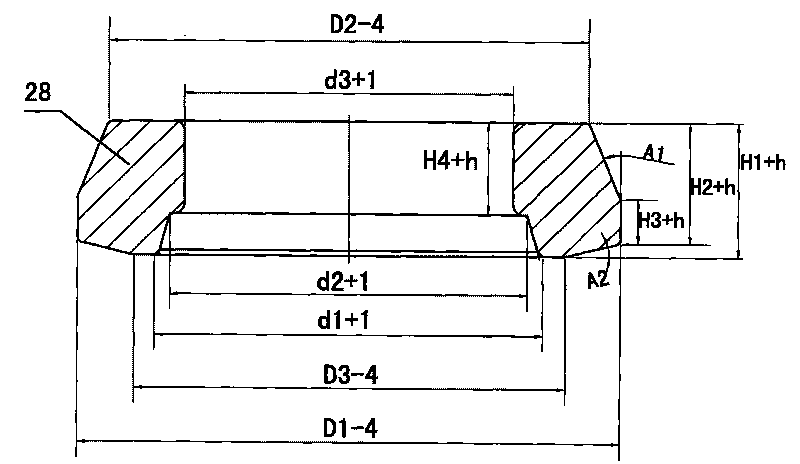

[0046] The reaming parts are manufactured through the process of upsetting → punching → punching and continuous skin → flattening → reaming. The shape of the reaming parts is the same as that of the driven gear forgings (such as image 3 Shown) are similar in shape, and the reaming parts (such as figure 2 As shown) the outer taper (A1, A2) is basically unchanged, the inner taper A3 becomes 0, the outer diameter is reduced by 4mm on the basis of the driven gear forging, and the inner diameter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com