Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Small deformation force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

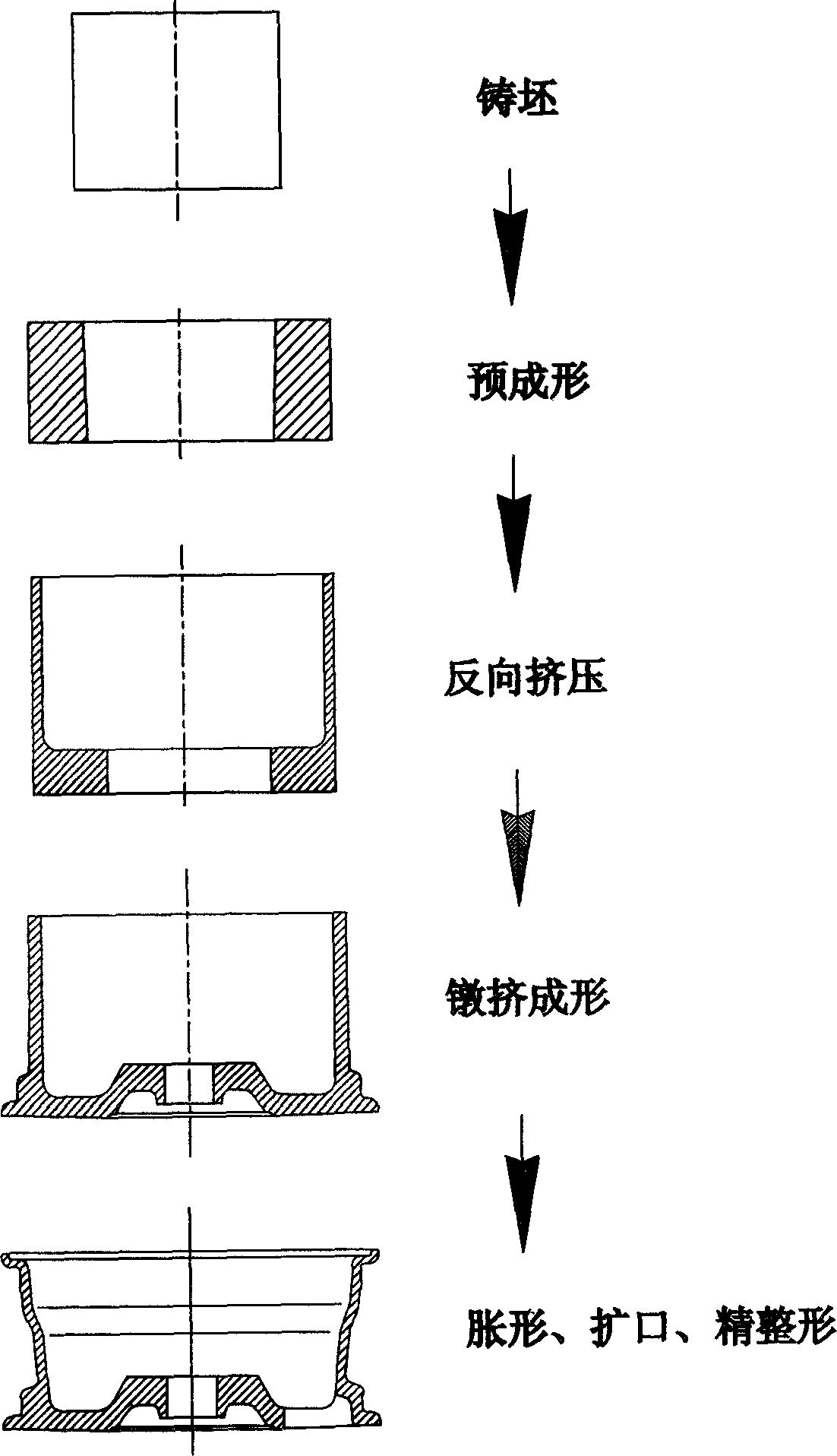

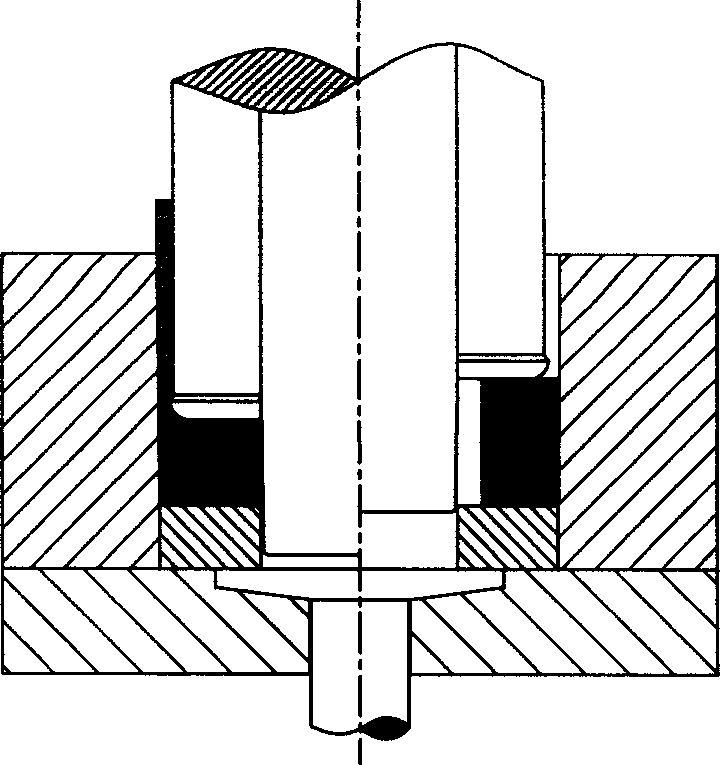

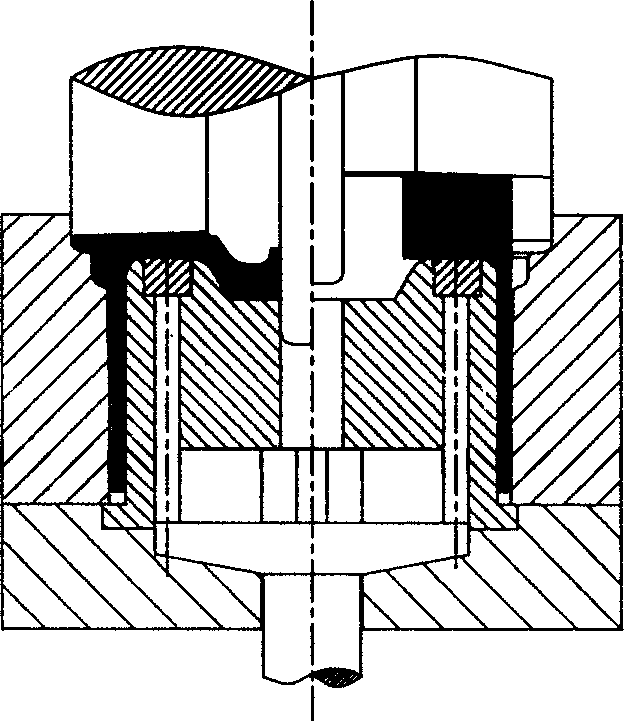

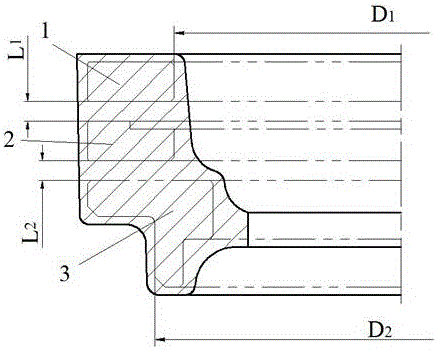

A labor-saving automobile hub forming method and device

InactiveCN1864915AWith substantive technologyReduction toolExtrusion diesExtrusion control devicesEngineeringMechanical engineering

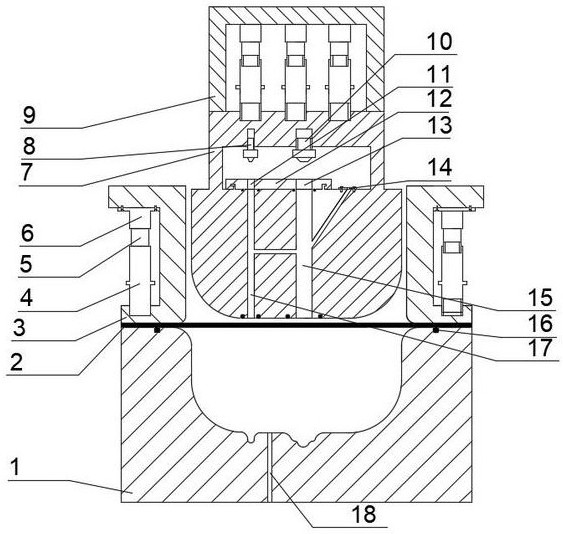

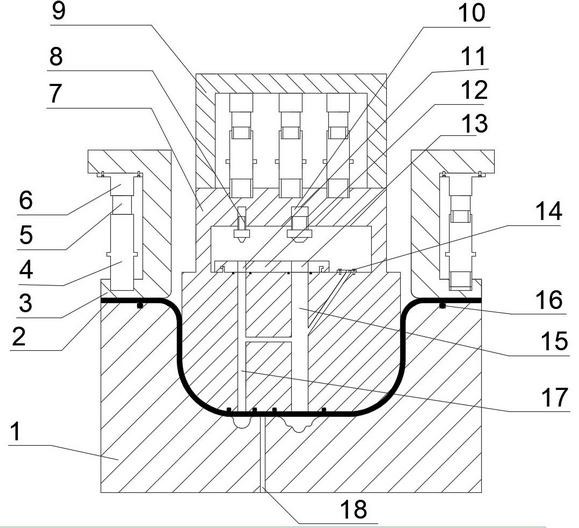

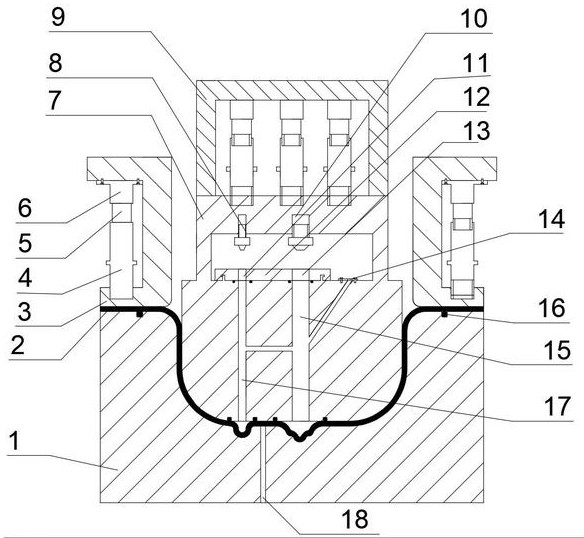

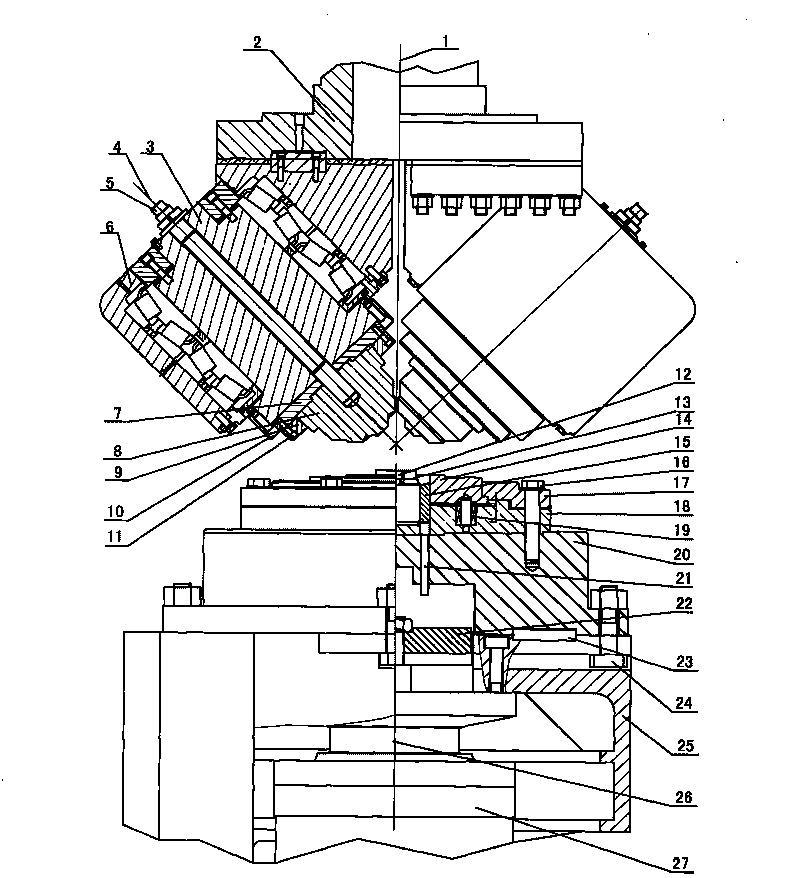

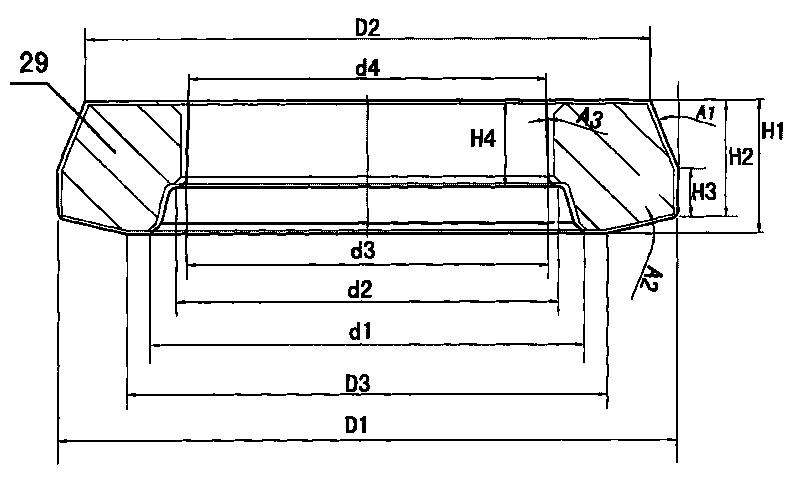

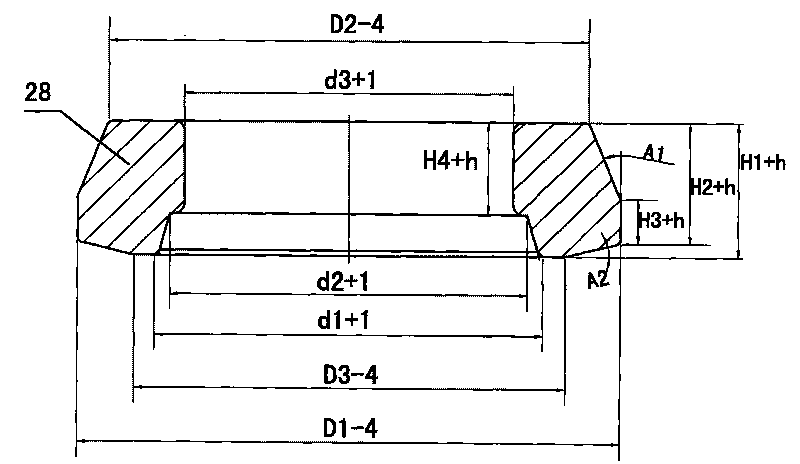

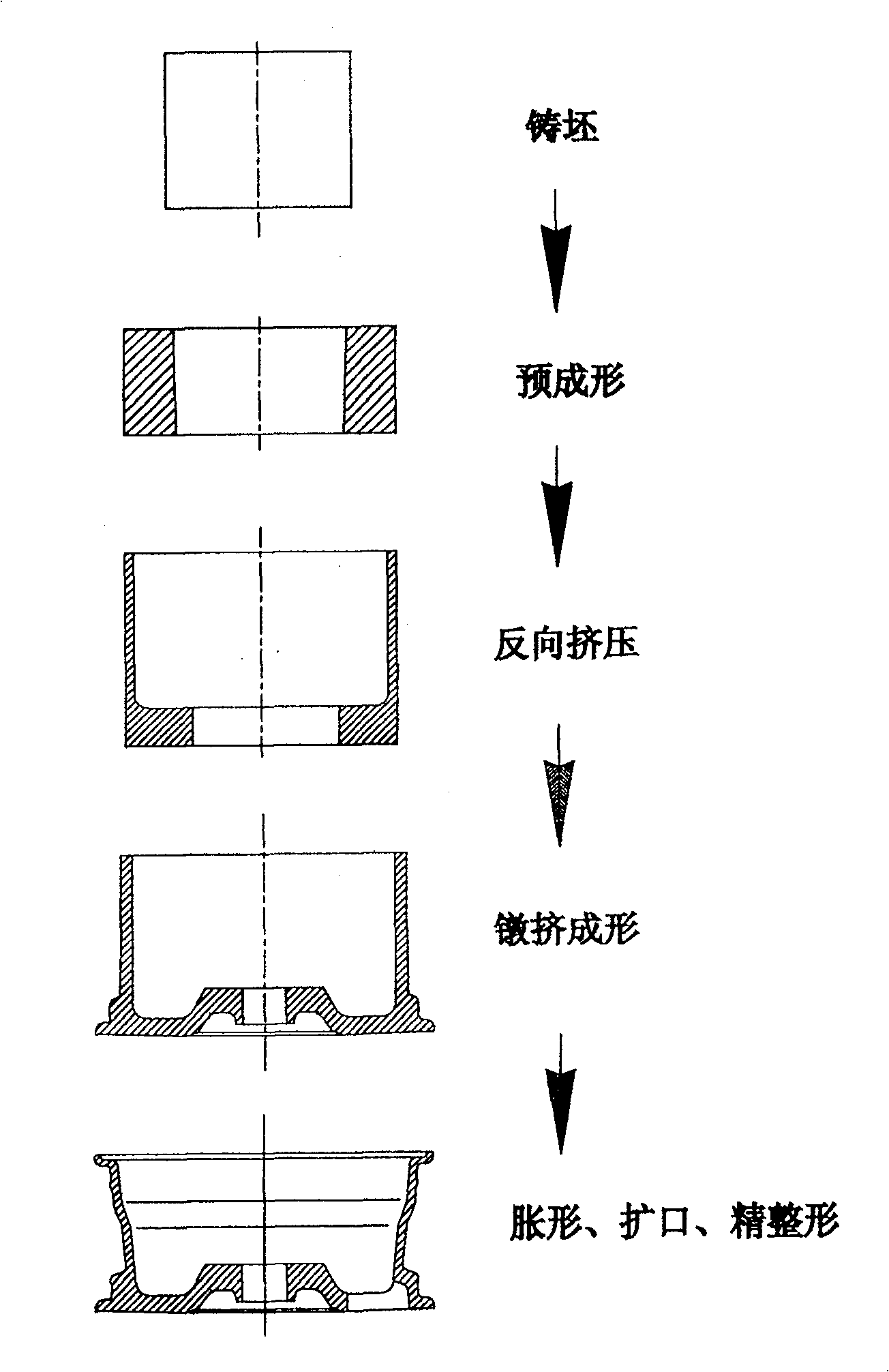

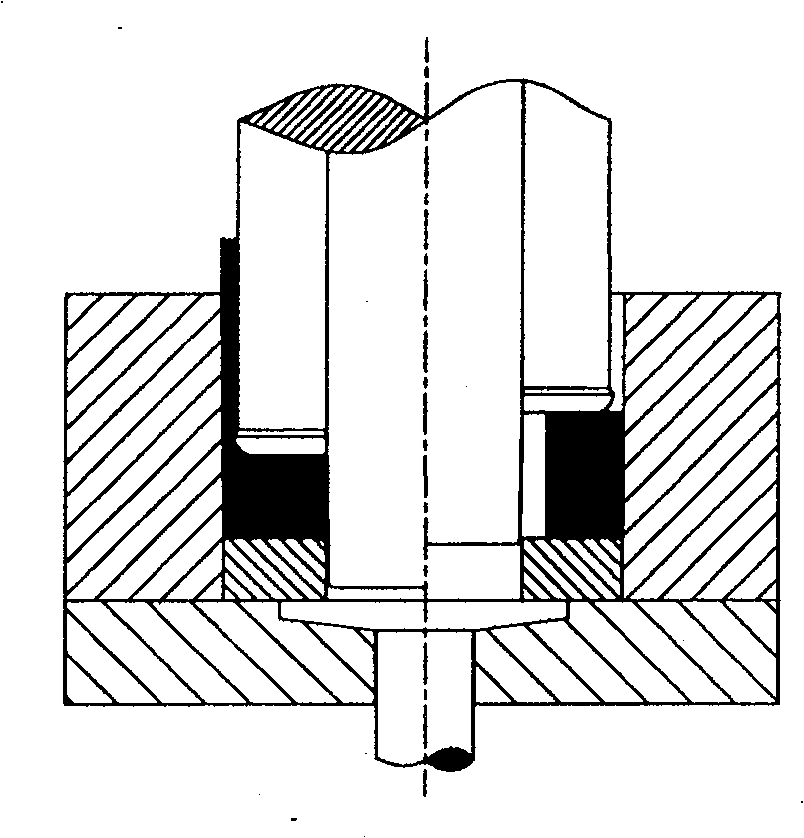

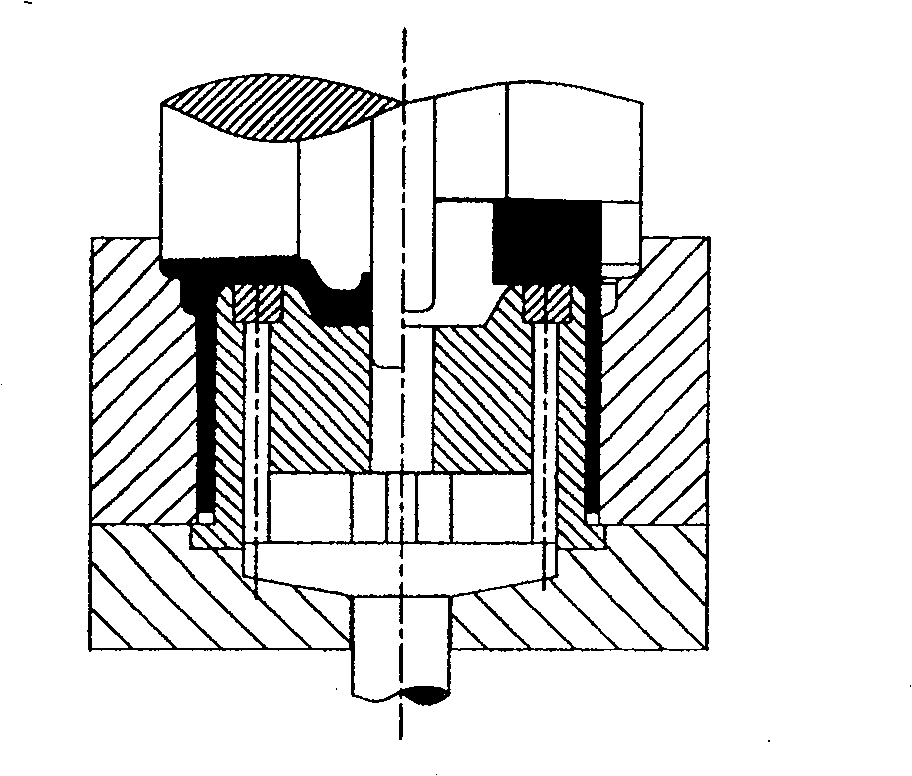

The invention relates to a method for shaping the vehicle hub and relative device. Wherein, it comprises following steps that casting blank; uniform processing; pre-shaping blank; compressing; compressing the front rim; expanding opening and folding the edge at the back rim. The invention is characterized in that: the casting blank via pre-shaping is made into hollow blank; the concave and convex moulds in the compressing step and the compressing front rim step are integrated, while the convex mound contains core axle; the compressing step compresses the hollow blank in the mould via core axle to obtain the cylinder element whose bottom has holes; the step that compressing front rim uses metal diversion to stuff and shape; the step that expanding opening and folding the edge of back rim uses integrated convex mould and separated concave mould to expand opening, fold edge an shape the back rim. The invention can simplify the process, reduce device number, reduce the shaping force, reduce the energy consumption, and reduce the producing cost. The invention is mainly used to produce aluminum and magnesium alloy hub.

Owner:ZHONGBEI UNIV

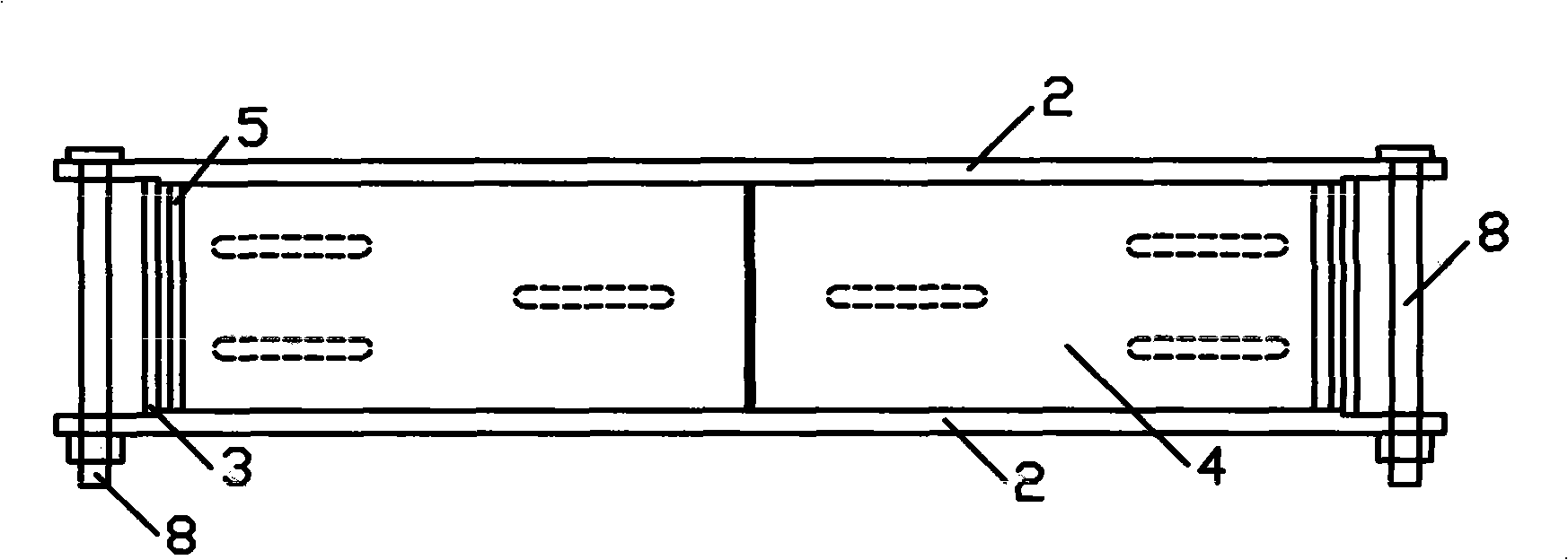

Device and method for measuring early age period linear deformation of cement based material

InactiveCN101344371AReduce frictionHigh measurement accuracyMaterial thermal coefficient of expansionMaterial testing goodsMeasurement deviceEngineering

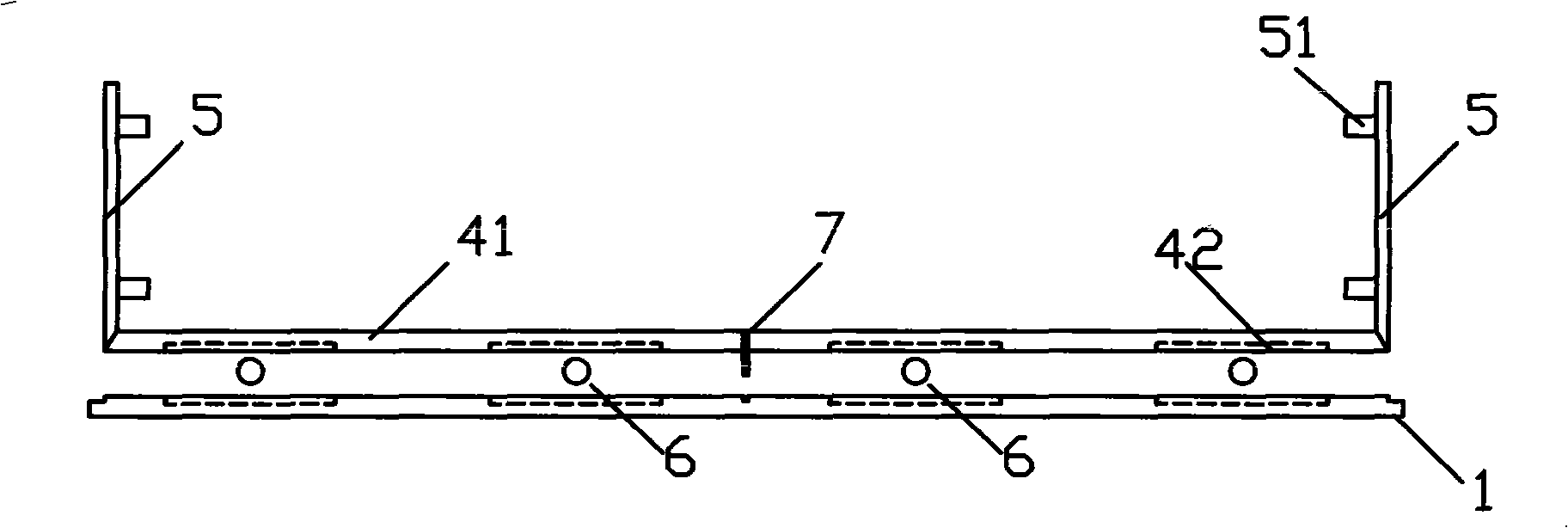

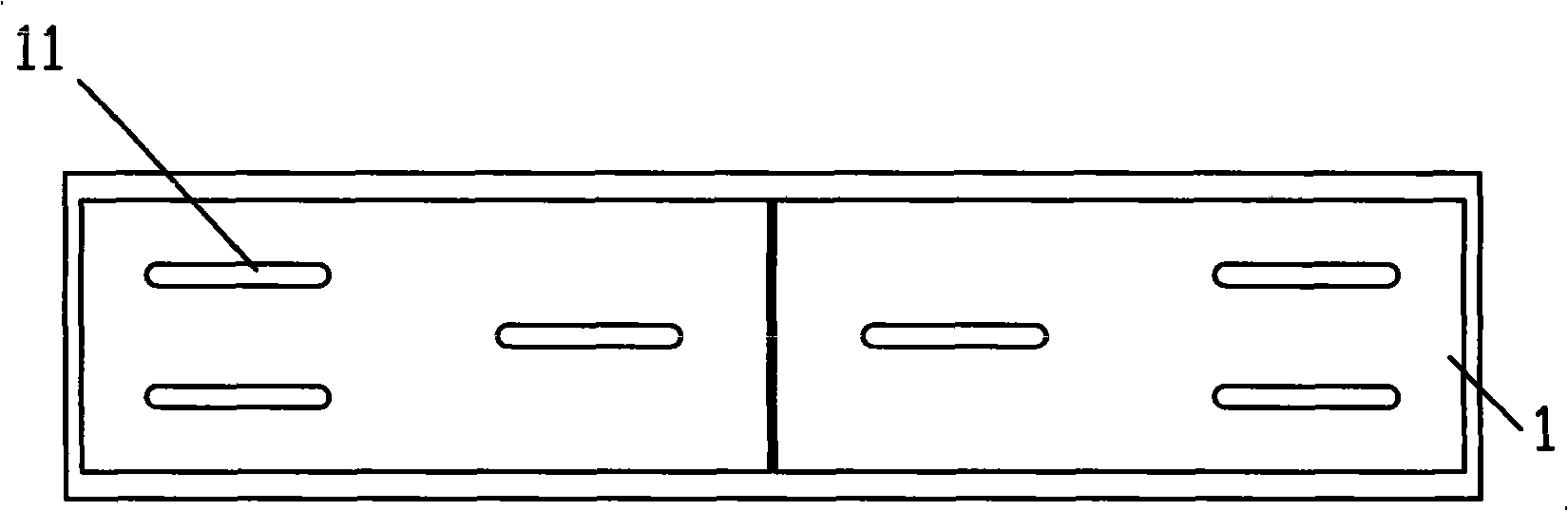

The invention discloses a measurement device and a measurement method of early-age linear deformation of cement-based materials; the measurement device comprises: a measurement containing cavity which is provided with an opening at the upper end and composed of a bottom board, a side board and an outer end board, wherein, a sliding template is further arranged on the bottom board, inner end boards are arranged at the both ends of the template, and a separation groove is arranged in the middle of the template for dividing the template into two sliding templates. Compared with the prior art, the sliding template is arranged on the bottom board of the measurement device of the invention, the template is divided into two by the separation groove, when a cement-based material sample is deformed, the displacement thereof can be measured by the sliding template which is bonded with the cement-based materials, the properties of the early-age linear deformation of the cement-based materials can be accurately reflected without the need of waiting for hardening of the cement-based materials. Sliding slots are respectively arranged on the bottom board and the template, rolling balls are arranged in the sliding slots, thereby changing sliding friction into rolling friction, greatly reducing the friction and improving the measurement precision.

Owner:HOHAI UNIV +1

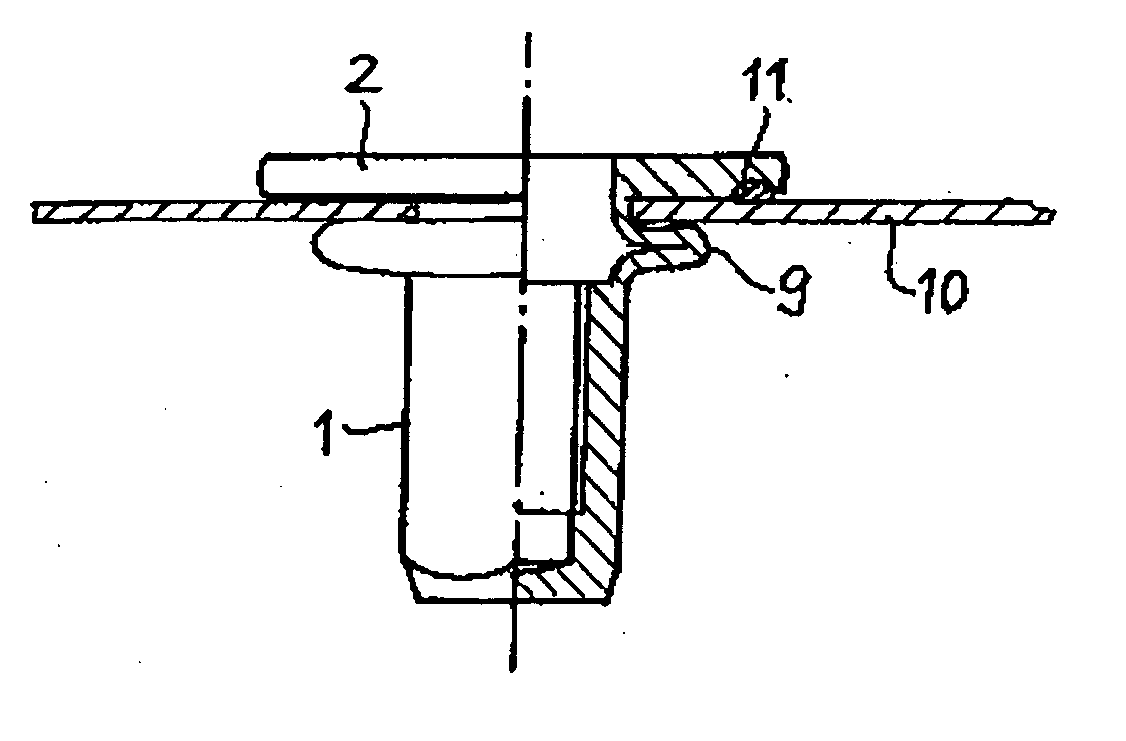

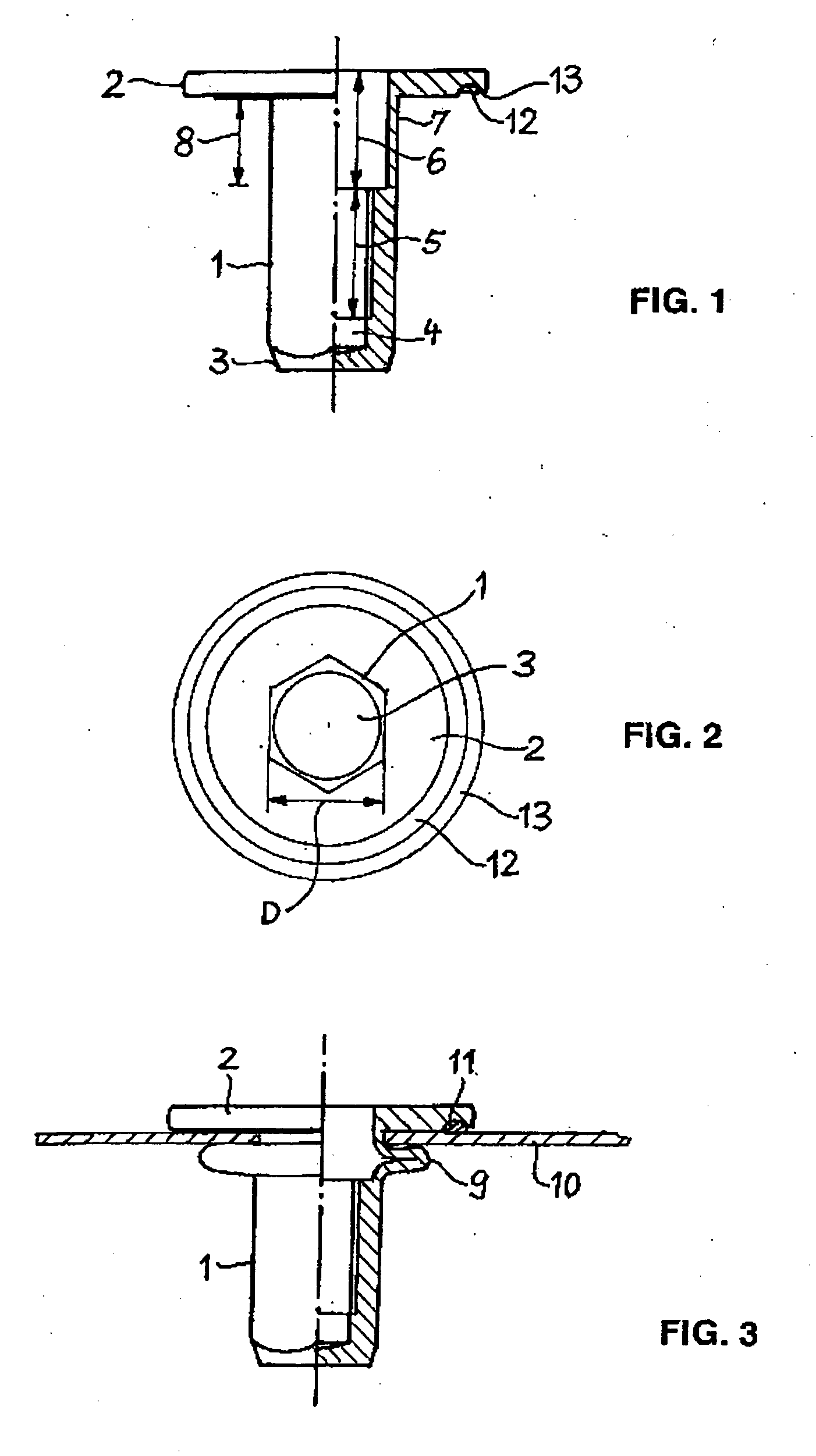

Blind rivet nut

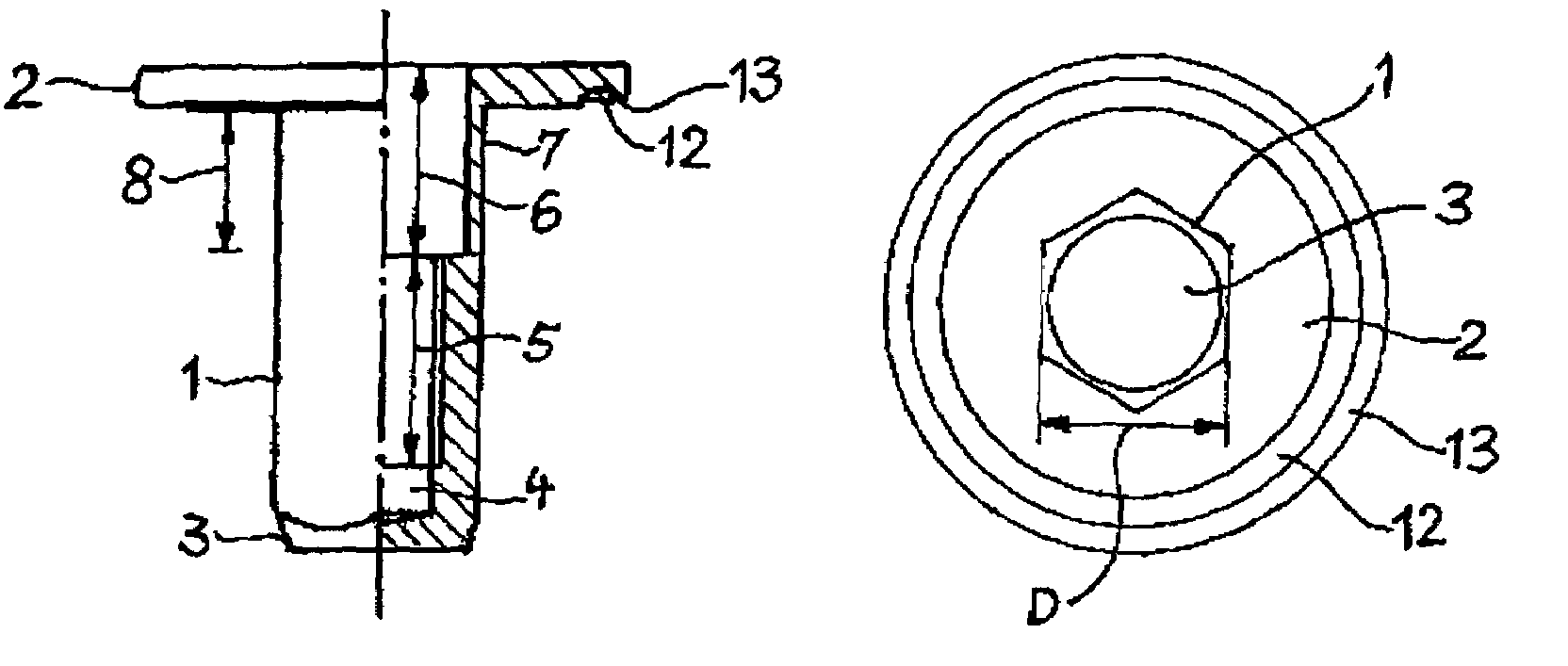

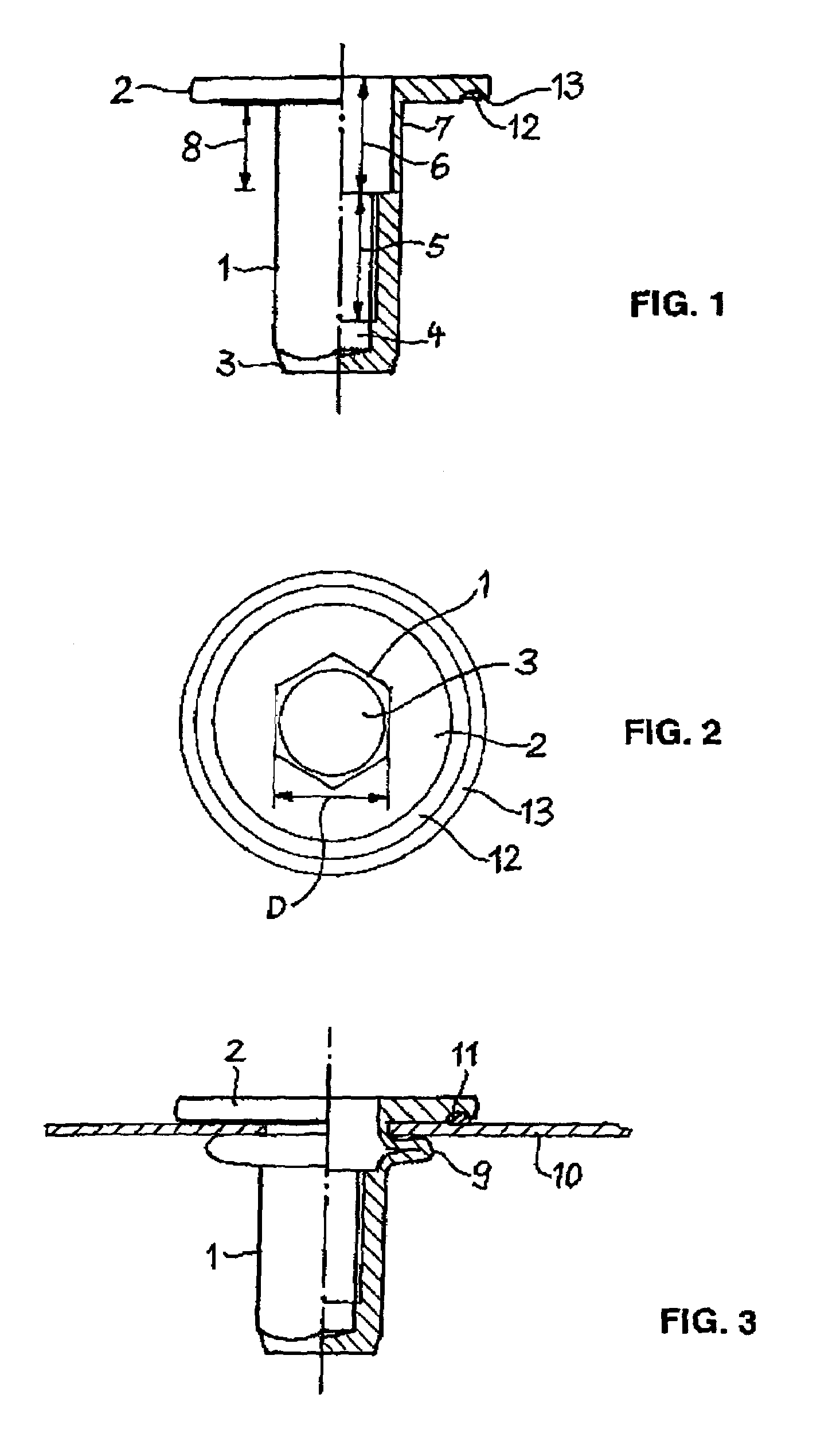

A blind rivet nut has a head configured as an annular flange and a shank comprising a head end, a foot end and a cylindrical bore closed at the foot end of the shank and extending from the head end to the foot end in lengthwise direction, and a second bore segment near the head end whose diameter is greater than the diameter of the first bore segment. The wall surrounding the second bore segment forms a plastically deformable region of the shank, and has an outer surface with the shape of a regular polygonal, in particular hexagonal, prism. To achieve a uniform and tightly sealing contact of the flange with the part accommodating the blind rivet nut, the wall thickness of the deformable region in the thinnest places is 4% to 6% of the least outside diameter of the deformable region.

Owner:NEWFREY

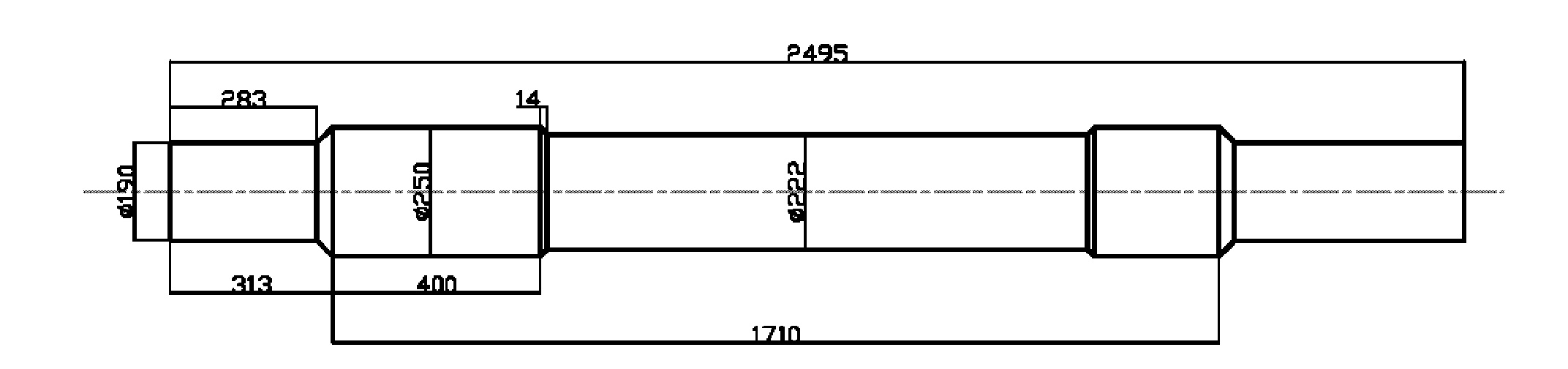

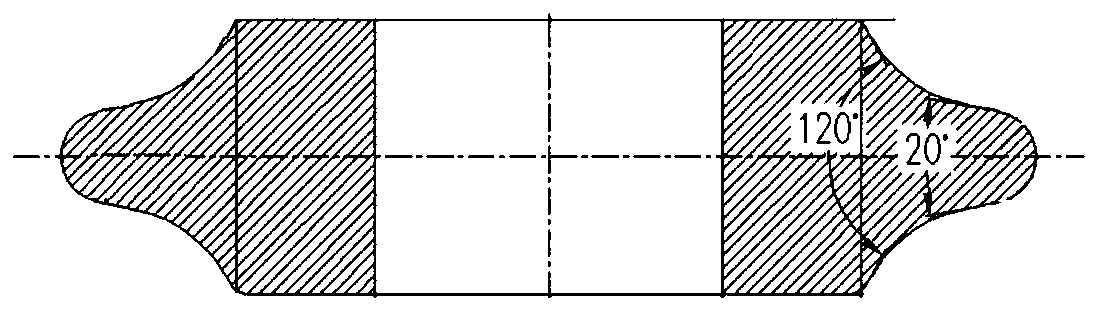

Forming method of train axle forging

InactiveCN102274921AIncrease profitIncrease productivityMetal-working apparatusEngine componentsEngineeringManipulator

The invention discloses a method for forming a train shaft forging, which comprises four passes of roll forging, wherein roll forging dies of the first pass, the second pass, the third pass and the fourth pass are sequentially mounted on the forge roll of a roll forging machine. The method specifically comprises the following steps of: conveying a blank which is previously heated to a range of 1150-1200 DEG C to a receiving platform in front of the roll forging machine, clamping one end of the blank by the manipulator of the roll forging machine using a large jaw and then orderly forming fourpasses of roll forging, wherein the blank is rotated by 90 degrees for next pass of roll forging at the completion of each roll forging; after the completion of the fourth pass of roll forging, turning around the blank by 180 degrees and then performing the four passes of roll forging orderly. With two cycles of four passes of roll forging, the clamped material head is not needed to be cut off sothat the utilization ratio of the material is increased; besides, the material is continuously and locally deformed in the roll forging process and the deformation force is low; therefore, the quality of product is excellent and the production efficiency is high.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

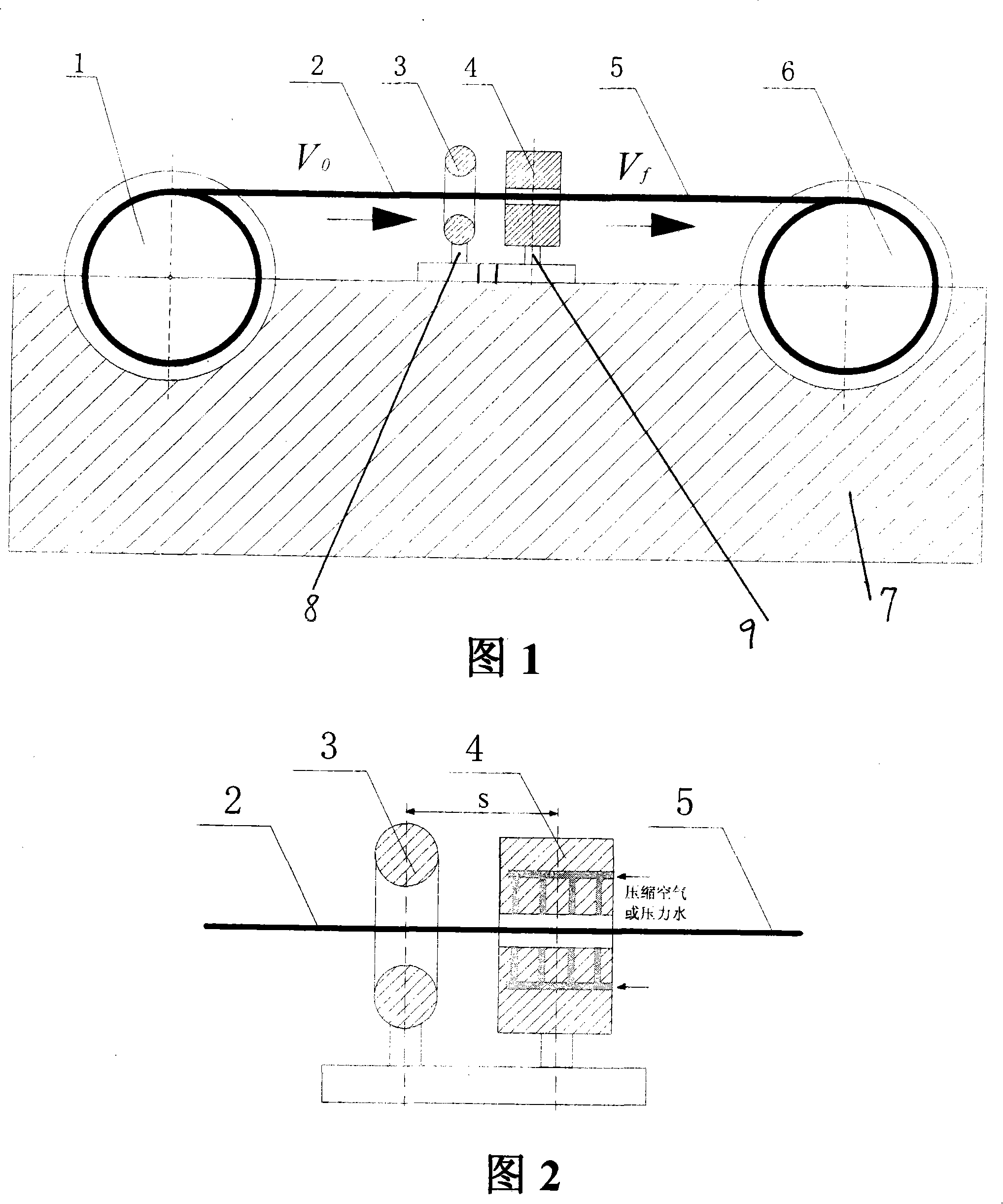

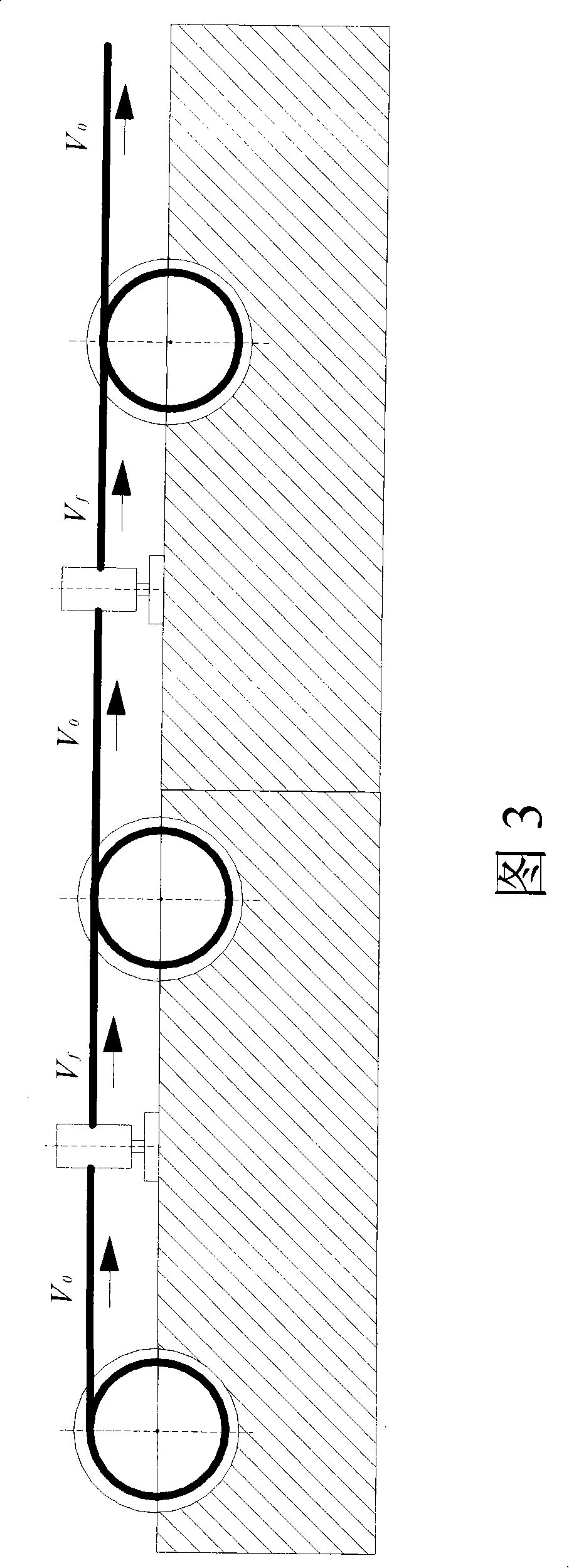

Non-mould drawing forming method and apparatus

A dieless wire drawing forming device comprises a wire pay-off drum, a wire take-up drum and a platform, wherein the wire pay-off drum is driven by a wire pay-off drum drive motor, the wire take-up drum is driven by a wire take-up drum drive motor, and the shafts of the wire pay-off drum drive motor and the wire take-up drum are respectively supported by the platform through shaft bases. The dieless wire drawing forming device is characterized in that a heater and a cooler are arranged between the wire pay-off drum and the wire take-up drum; the heater is supported on the platform through a bracket; the cooler is supported on the platform through a bracket; the distance S between the heater and the cooler is the width of a deformation region, which is determined by the performance of processed line material; the heater is a high-frequency or a middle-frequency electrical heater; and the cooler is a water cooler or an air cooler. The invention provides a dieless wire drawing processing method with high efficiency, no friction and no lubrication.

Owner:SHENYANG LIGONG UNIV

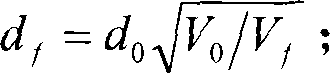

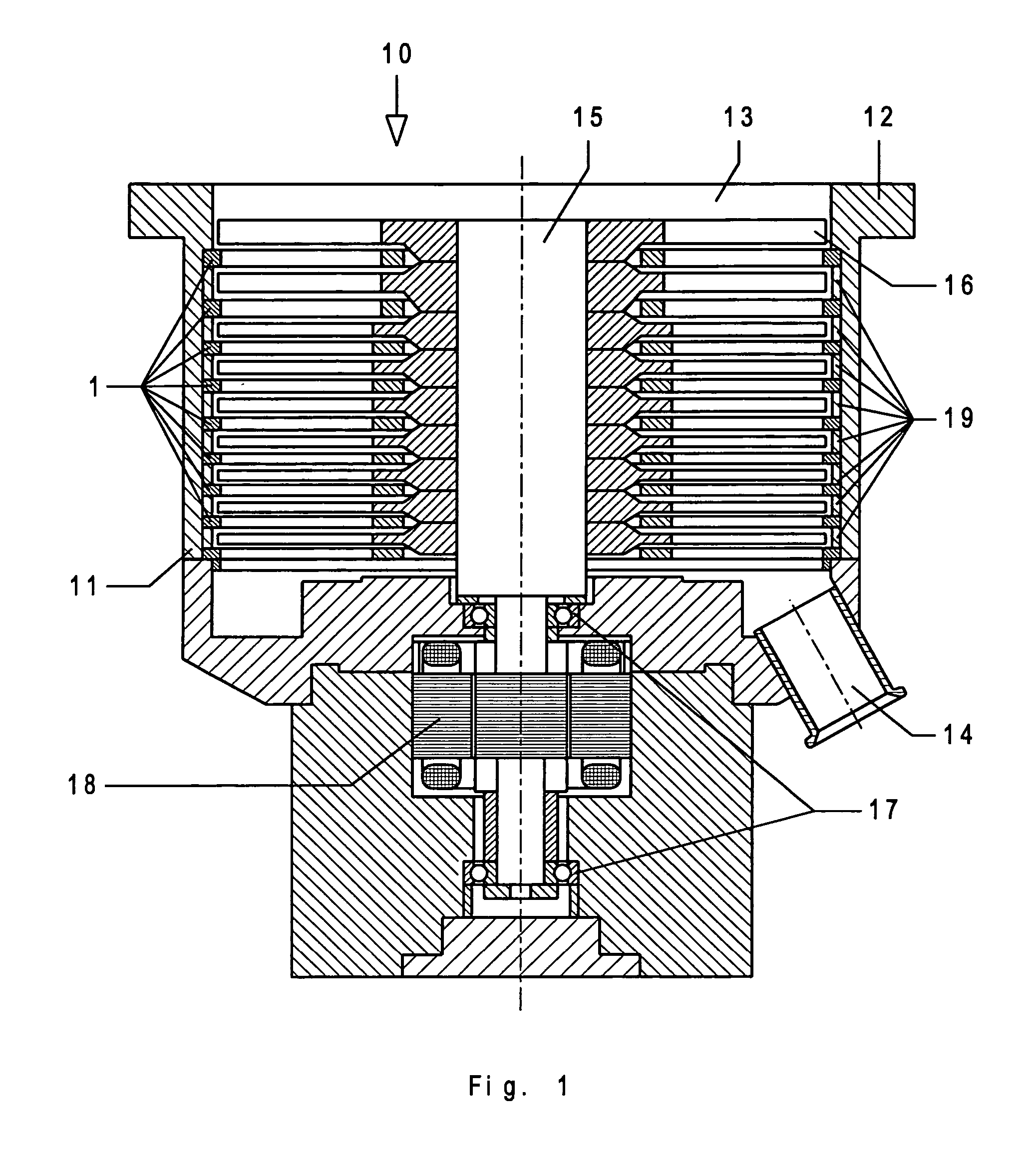

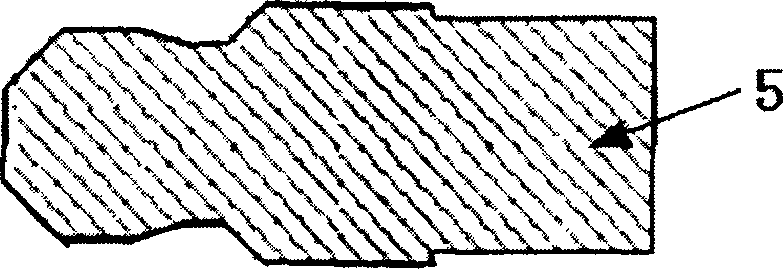

Stator disc for a turbomolecular pump

InactiveUS20060280595A1Eliminate high degree of deformationSmall regionEngine manufacturePump componentsCircular discEngineering

A stator disc for a turbomolecular pump has an inner ring (3), an outer ring (4), and a plurality of vanes (2) formed of a stator disc plane, extending between the inner and outer rings (3, 4), and having, in connection regions of the vanes with the inner and outer rings, respective radial webs (5) a circumferential width (S) of which is smaller than a vane width (T).

Owner:PFEIFFER VACUUM GMBH

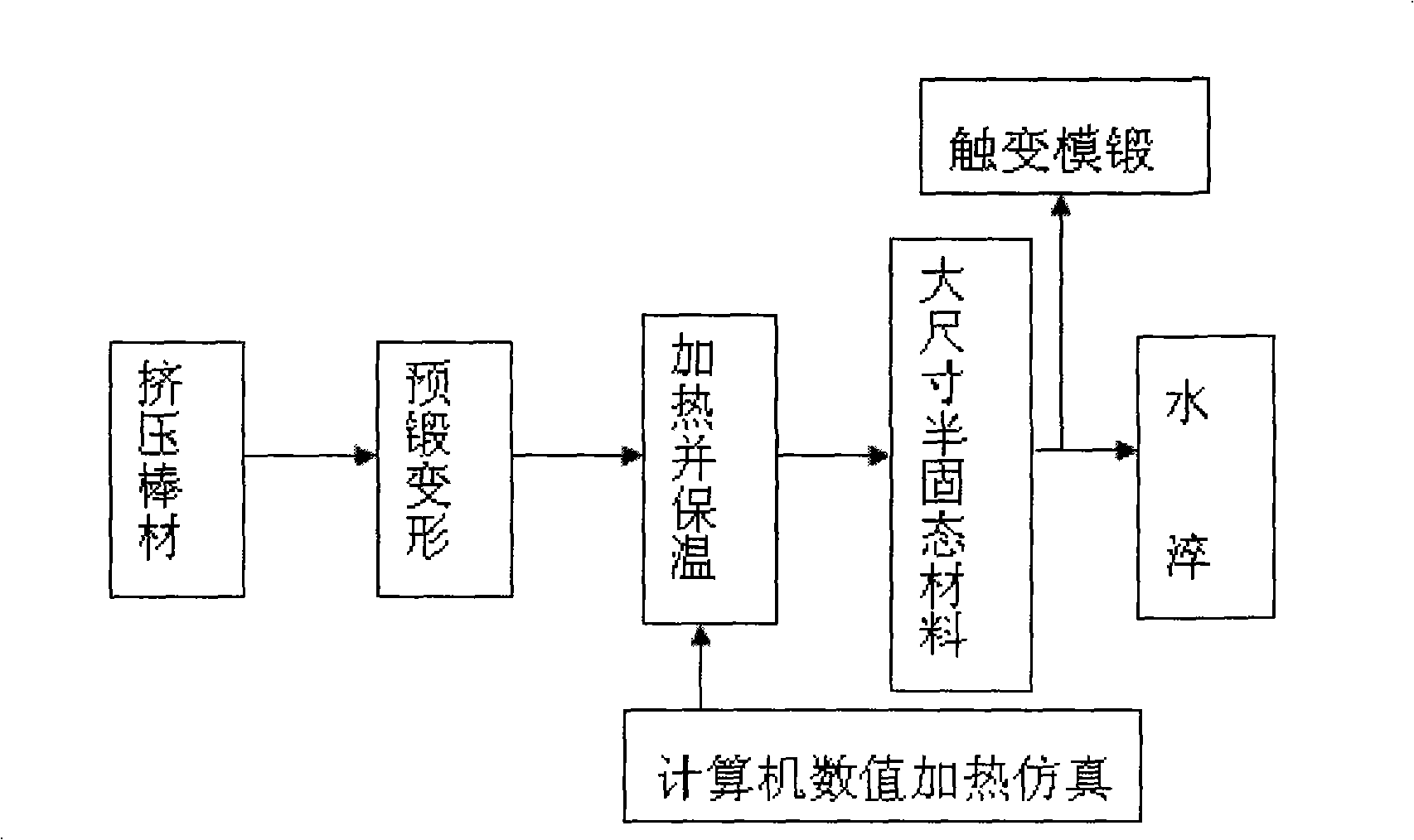

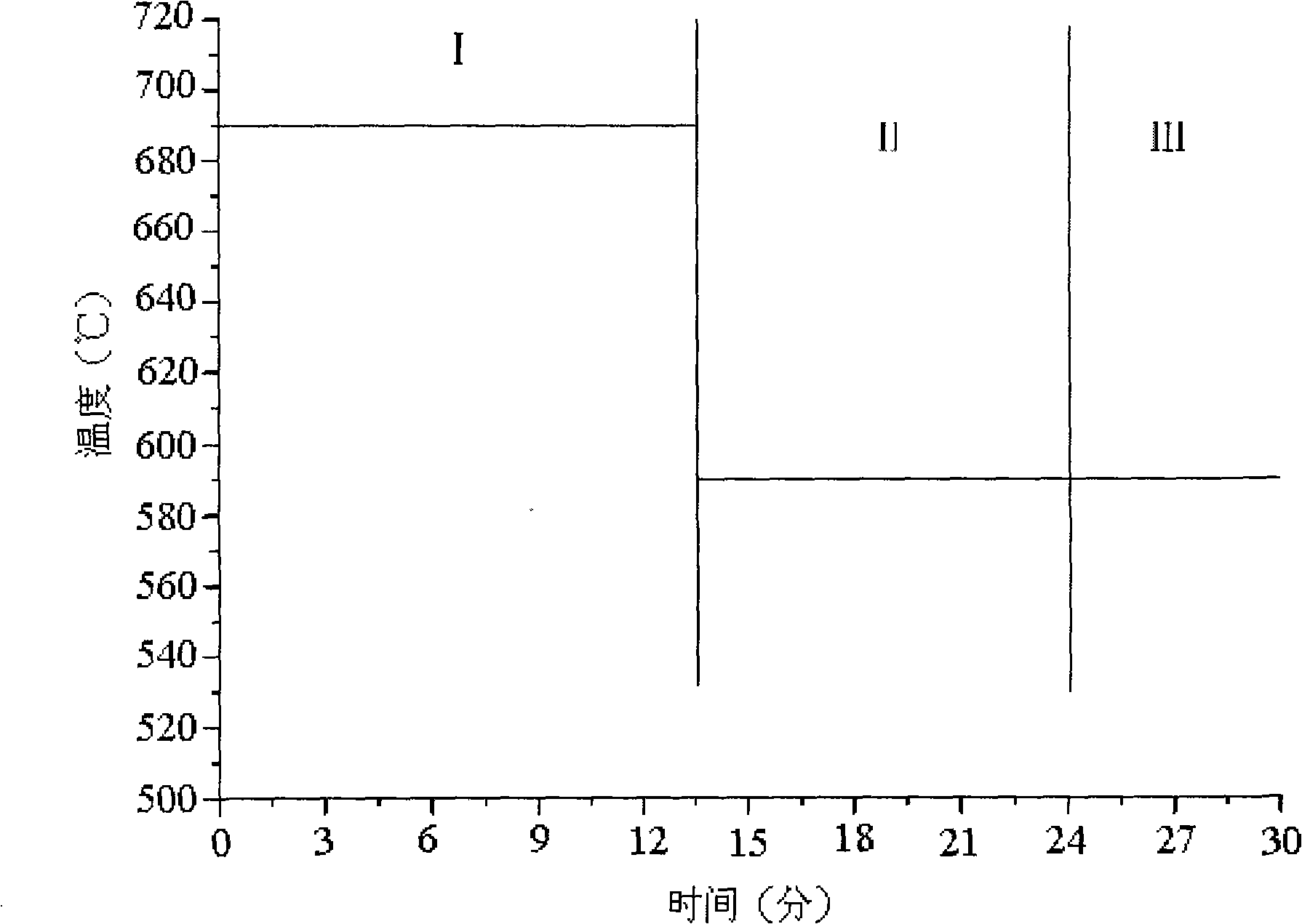

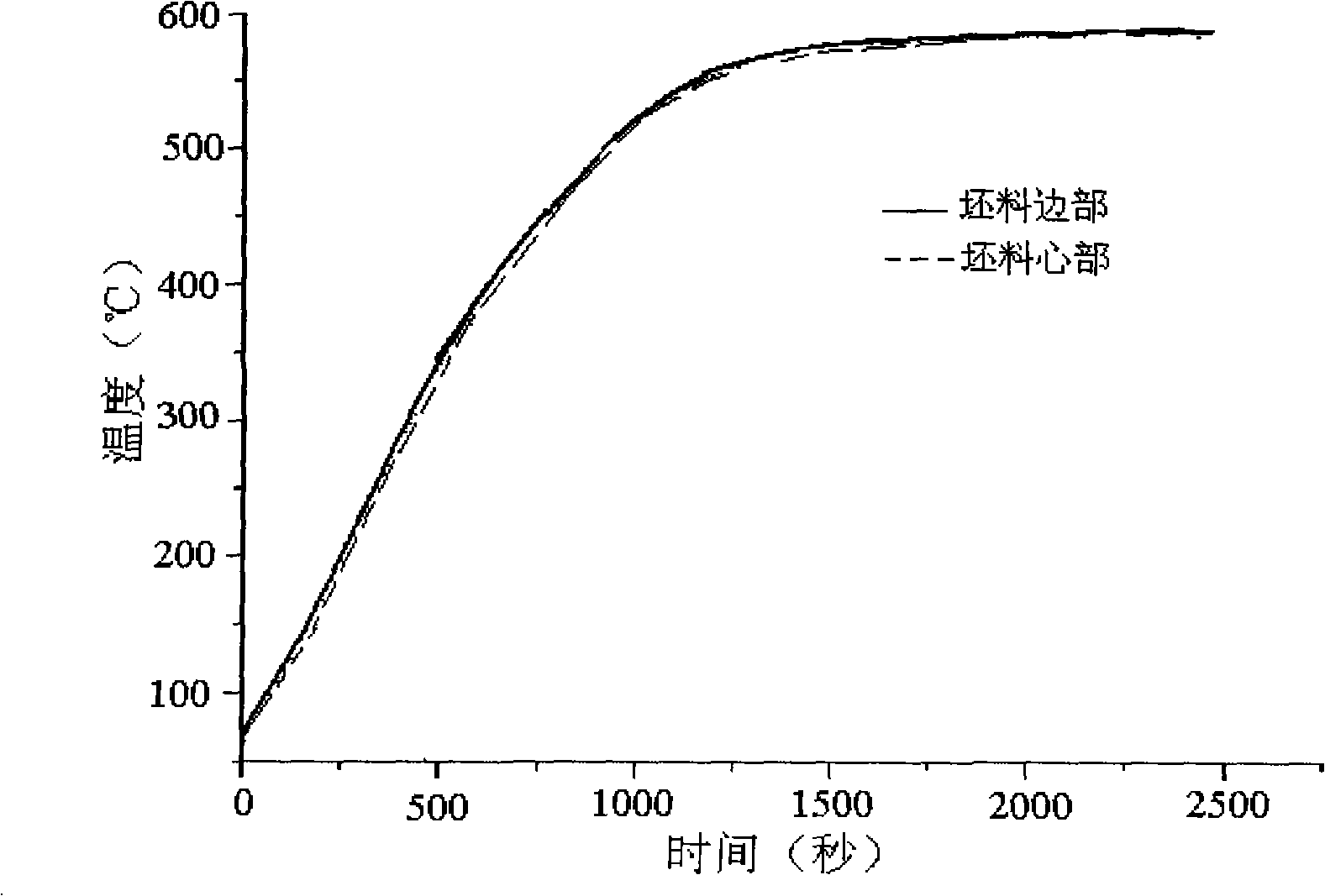

Preparation method of aluminium alloy semi-solid state blank for large size forging

The invention discloses a method for preparing semisolid aluminum alloy blank forged in big size and comprises the steps of processing a forged aluminum alloy extrusion rod to be sold on the market into a blank 150-225mm long; placing the blank in an environment with a temperature of 400DEG C-420DEG C, keeping the temperature for 1h-3h, and cooling the blank with a furnace at a speed less than 30DEG C / h; and forging the blank by adopting the dynamic loading narrow anvil small deformation technology. The preheating temperature of the anvil is 100DEG C-250DEG C, the contact area of the blank with the anvil is less than 30%, the forging principle of light-heavy-light is followed, and the total deformation degree of the blank is 20%-40%. The heating module of forging technology simulation software is used for optimizing heating technology, and triple heating technology is adopted to realize the quick uniformity and heating of the blank. Therefore, the forged fine semisolid aluminum alloy blank of big size is good in spheroidization, and uniform in grain size. The method solves the problems that the blank is too big to deform uniformly under cold deformation, and that the quick heating of the big blank and the uniformity of the blank temperature are not easy to control.

Owner:CSIC NO 12 RES INST

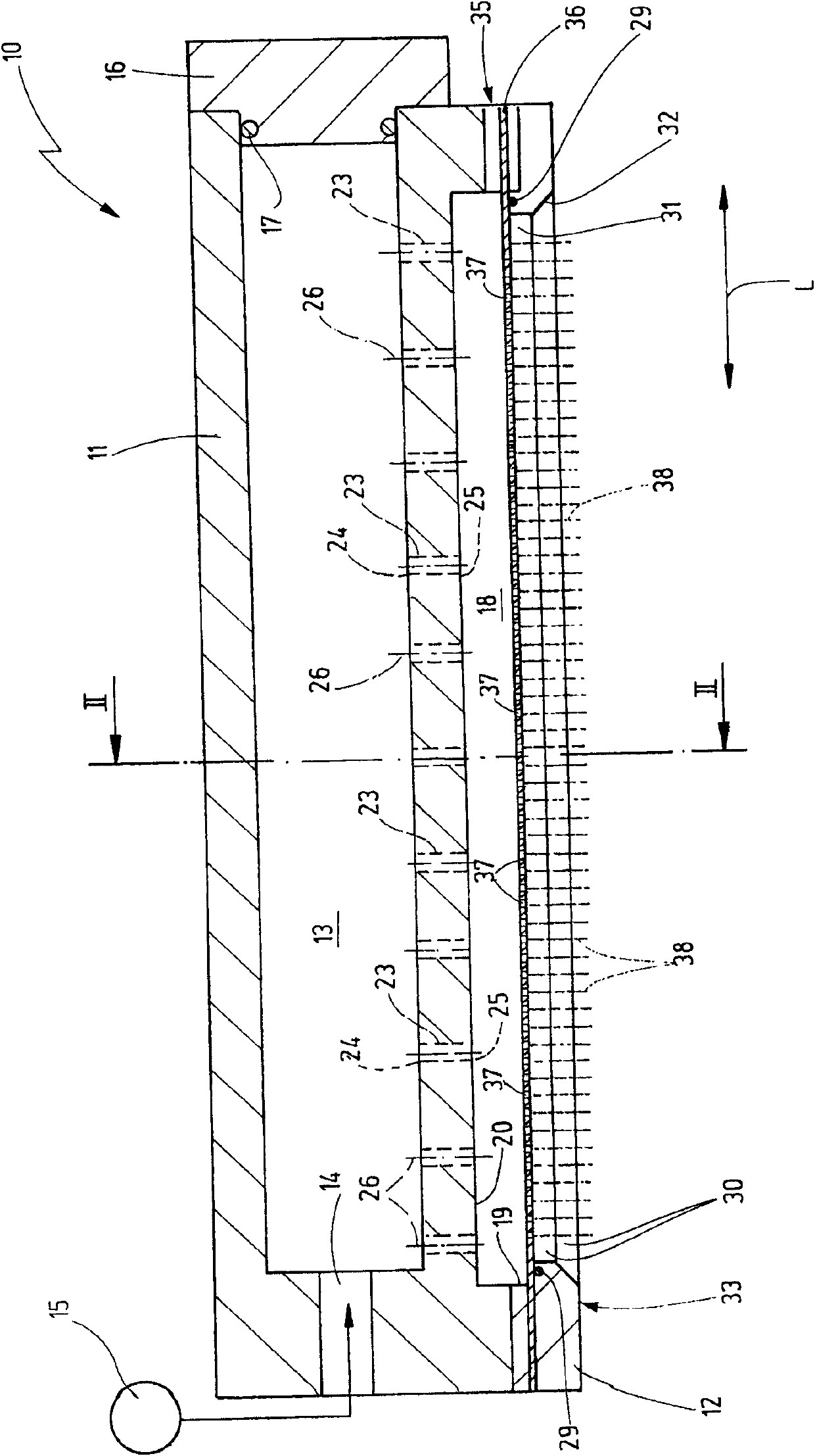

Injector for textile processing machine

InactiveCN102021752AReduced wall thicknessAvoid quality problemsSpray nozzlesNeedling machinesSpray nozzleTextile processing

The invention relates to an injector for a textile processing machine, particularly to an injector for a textile processing machine for making napping textile materials. An inflow chamber is arranged in an injector main body for acquiring a pressing medium from the inflow chamber, wherein the inflow chamber is connected to the fluid in a pressure distribution chamber through a plurality of connecting pipes; a cylindrical opening arranged in the injector main body represents a connecting channel; the channels are arranged in one or two rows so as to shift away from a longitudinal central plane of the inflow chamber; the pressure distribution chamber adjoined with the connecting pipe comprises a first wall section for forming a first declination surface; the declination surface is at least diagonally or transversely extended relative to a longitudinal axis of the connecting pipes in a plurality of sections; the medium flowed from the connecting pipe declines through the first declination surface; a water injected flow is formed through a nozzle opening; and the water injected flow is injected by an outflow opening through the injector.

Owner:GROZ BECKERT KG

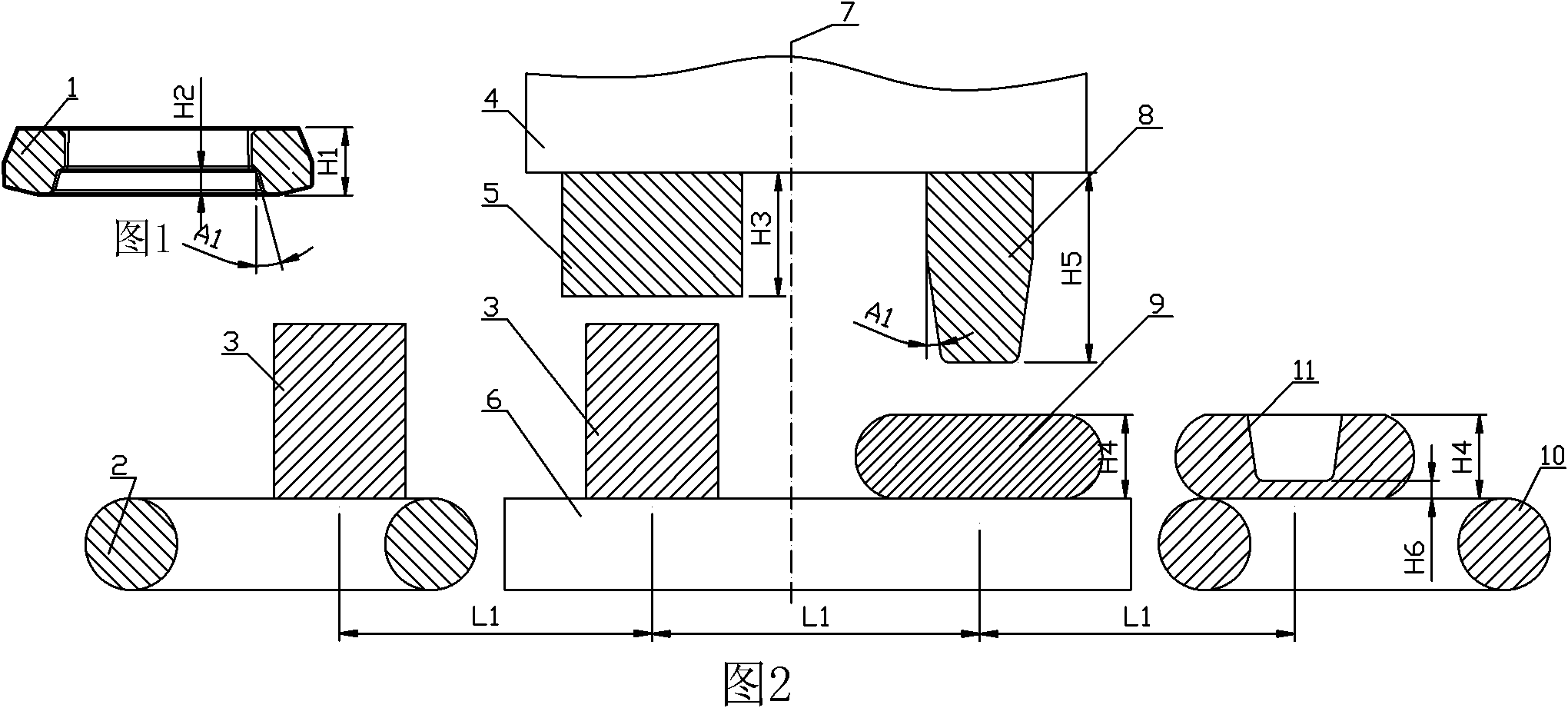

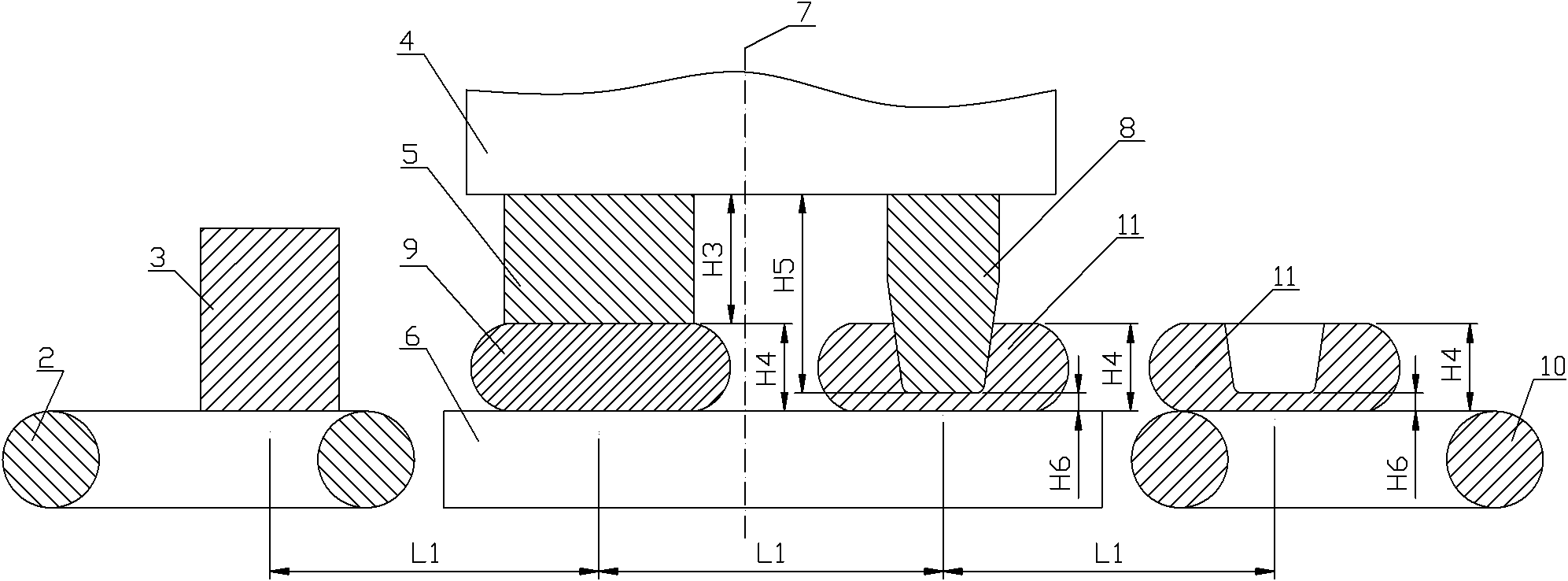

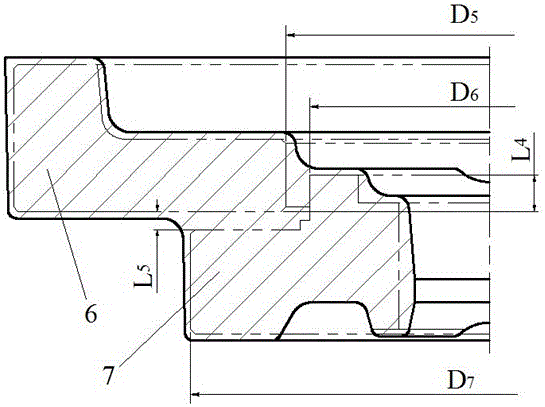

Automotive rear axle driven bevel gear blank forging production line

InactiveCN102126136ALess investmentEasy to operateOther manufacturing equipments/toolsPress ramProduction rateProduction line

The invention relates to an automotive rear axle driven bevel gear blank forging production line. The production line comprises the following equipment: preformed blank forming equipment, reaming production equipment and shaping production equipment, wherein the preformed blank forming equipment comprises two crank presses and two matched automatic feeding and discharging mechanisms so as to meet the production requirements of an upsetting step, a hole punching step, a wad punching step and a pre-shaping step, wherein the upsetting step and the hole punching step are carried out by one crank press and one matched automatic feeding and discharging mechanism; the reaming production equipment is a vertical reamer machine; and the shaping production equipment comprises a two-roller rolling machine with a shaping mould, and a matched automatic feeding and discharging mechanism, and the two-roller rolling machine shapes a reamed workpiece on the shaping mould to obtain an automotive rear axle driven bevel gear blank. The production line can effectively improve productivity, eliminates defects of forgings, and effectively saves raw materials by over 10 percent.

Owner:WUHAN UNIV OF TECH

Blind rivet nut

In a blind rivet nut having a head configured as an annular flange and a shank comprising a head end, a foot end and a cylindrical bore closed at the foot end of the shank and extending from the head end to the foot end in lengthwise direction, and a second bore segment near the head end whose diameter is greater than the diameter of the first bore segment. The wall surrounding the second bore segment forms a plastically deformable region of the shank, and has an outer surface with the shape of a regular polygonal, in particular hexagonal, prism. To achieve a uniform and tightly sealing contact of the flange with the part accommodating the blind rivet nut, the wall thickness of the deformable region in the thinnest places is 4% to 6% of the least outside diameter of the deformable region.

Owner:NEWFREY

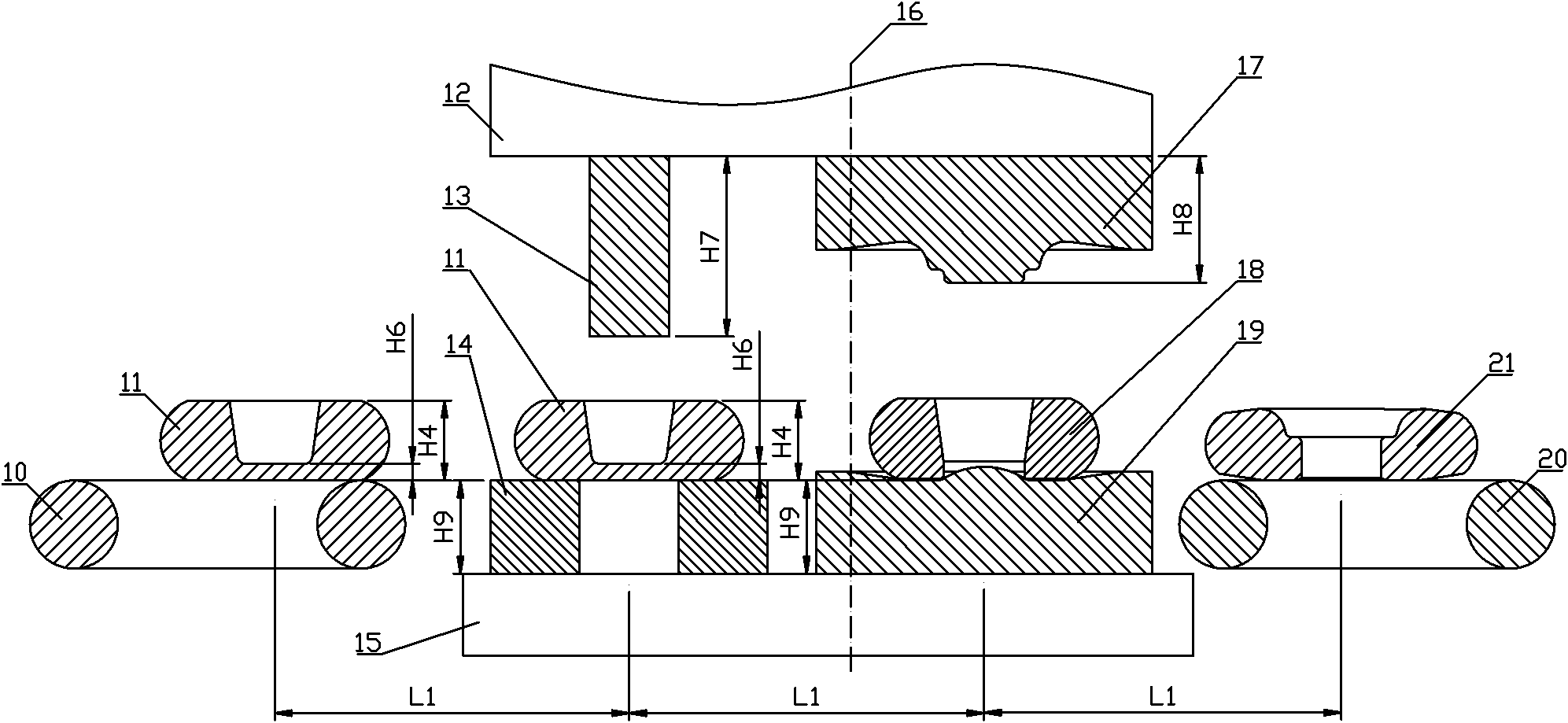

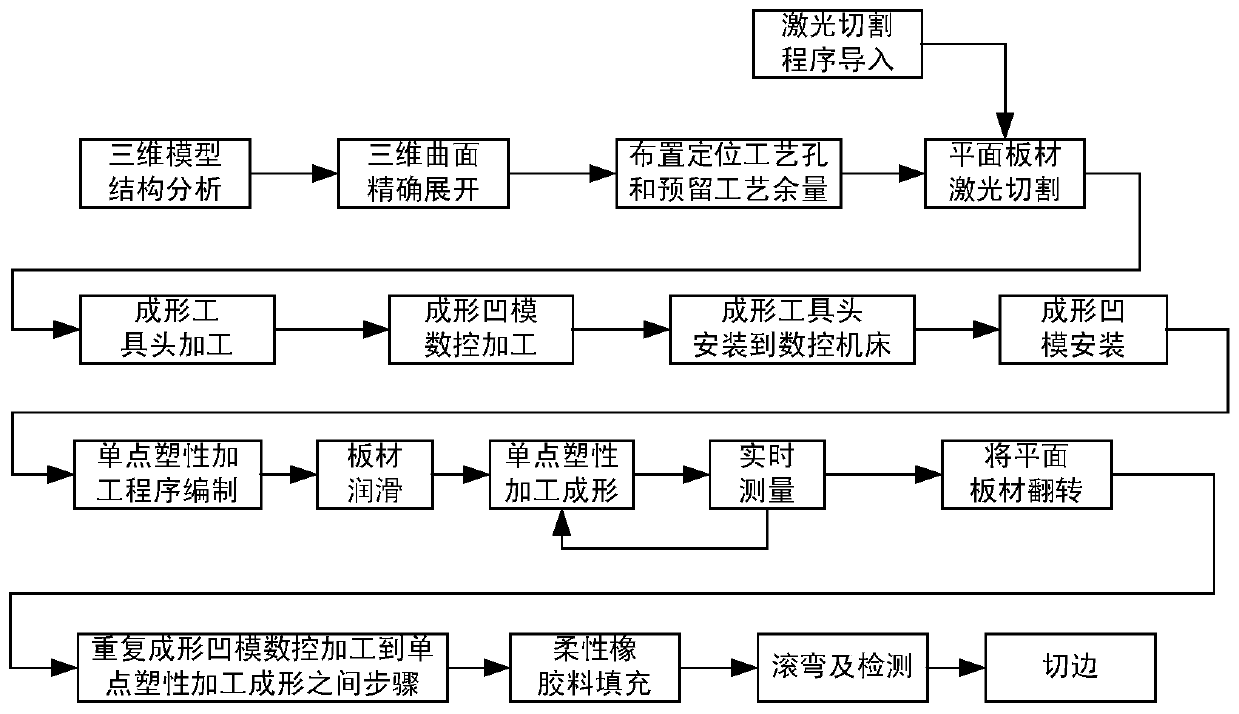

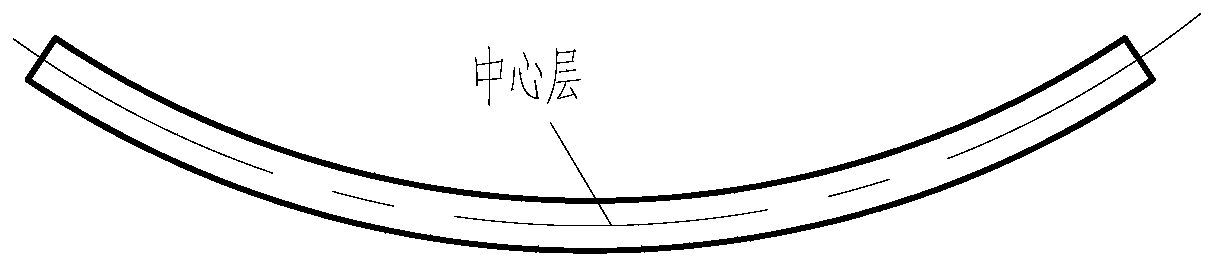

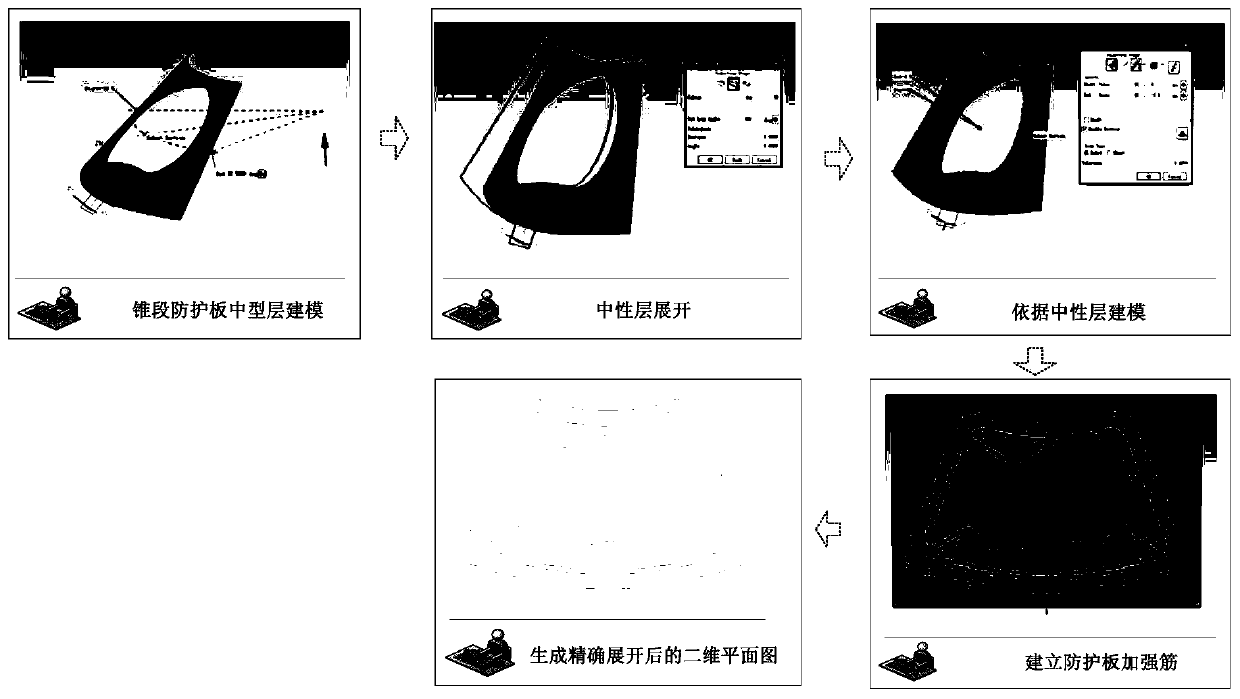

Forming method of spatial curved surface protective plate with internal and external bidirectional stiffener

ActiveCN109955043AHomogenization of stiffnessImprove the overall stiffness and anti-instability abilitySingle pointEngineering

The invention discloses a forming method of a spatial curved surface protective plate with internal and external bidirectional stiffener. Firstly the model of the spatial curved surface protective plate is accurately expanded into a two-dimensional plane model, a corresponding CAD model is obtained, and a panel is processed according to the two-dimensional plane model, and a two-dimensional planepanel after the spatial protective plate being expanded and modified is obtained, then a forming die for processing one side stiffener is designed and manufactured, the plane panel is formed by singlepoint plastic processing, and the plane panel including single surface qualified stiffener is obtained, then the plane panel with the formed single surface stiffener is turned over and placed on theforming die for processing the other side stiffener, single point plastic forming is conducted, and an aluminum alloy spatial curved surface protective plate with the internal and external bidirectional stiffener is obtained, finally, a rubber plate is filled with the inner and outer stiffeners of the curved surface protective plate for equal thickness treatment and fixedly sealing, the plane panel is rolled and bended by a three-axis rolling and bending machine, then trimming and polishing are conducted, and thus forming of the spatial curved surface protective plate with the internal and external bidirectional stiffener is completed.

Owner:BEIJING SATELLITE MFG FACTORY

Method for preparing tungsten-copper alloy wires by utilizing hot-swage technology

InactiveCN101537440ALarge processing deformationUniform deformationSingle bars/rods/wires/strips conductorsForging hammersAlcoholGasoline

The invention discloses a method for preparing tungsten-copper alloy wires by utilizing hot-swage technology, belonging to the technical field of new material manufacture. The method comprises the following steps of: weighing copper powder, tungsten powder and nickel powder according to weight percentage, then weighing alcohol additionally, and mechanically mixing the four batching materials together; additionally weighing sodium butadiene rubber-solvent gasoline solution, adding the sodium butadiene rubber-solvent gasoline solution into the mixture obtained by the former step, mixing evenly and then sieving; making graphite die-pressing and forming blank; carrying out sintering and hot-swage to obtain the wires with certain diameters and any length. The invention has the beneficial effects of simple technique, convenient operation and low manufacturing cost, also has the advantages of stable performance, high quality and high yield, solves the problems that the preparation of thin and long tungsten-copper material has complex technique and high manufacturing cost in the prior art and is widely used for processing materials such as electrodes, LED lamps and plasmas.

Owner:BEIJING SHANGHUAYANG ELECTRONICS TECH DEV

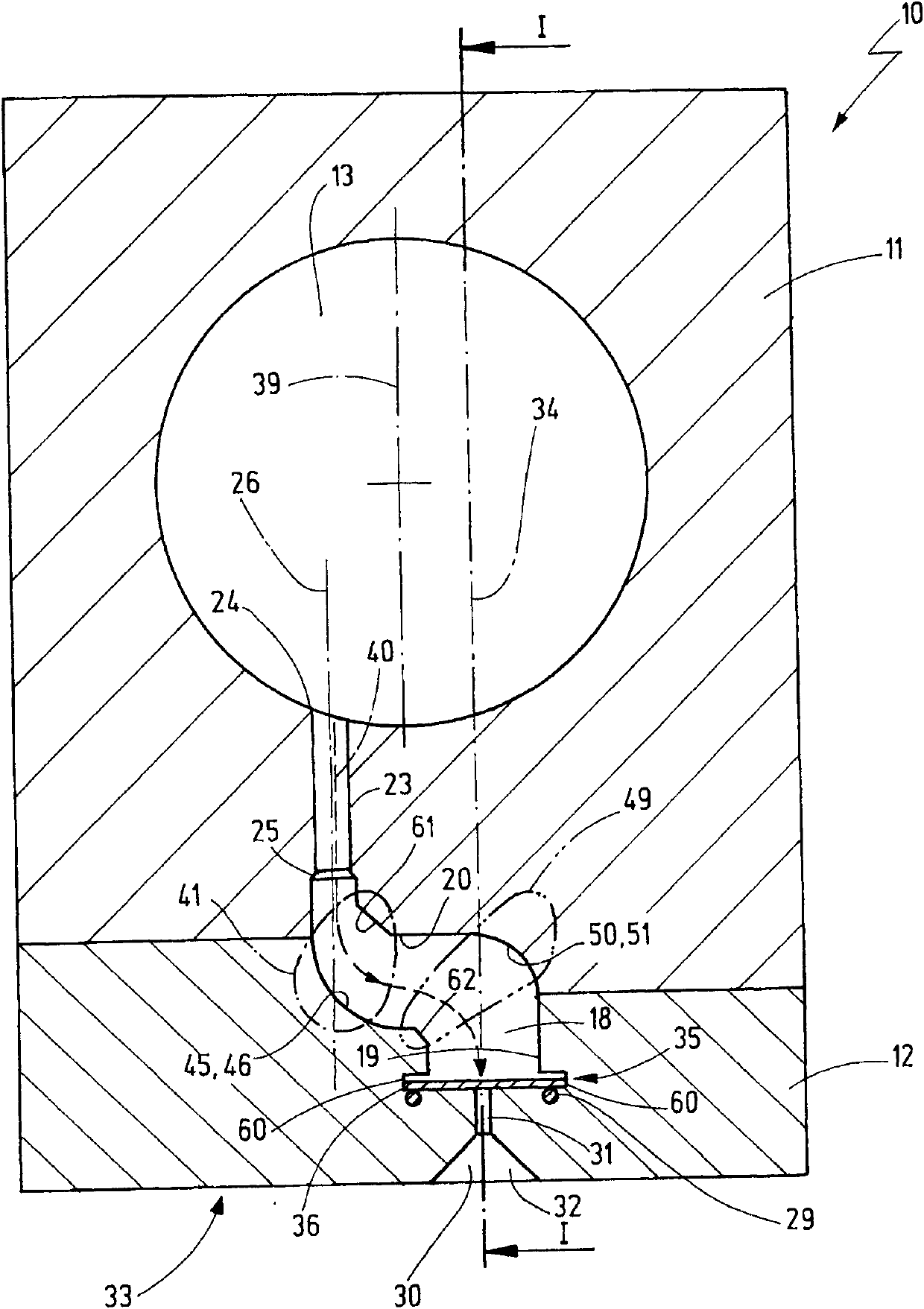

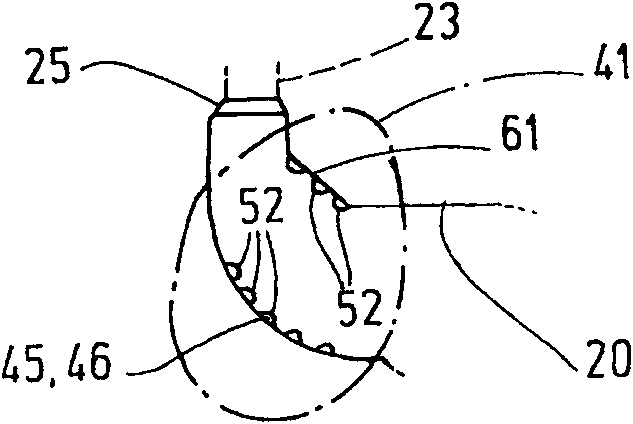

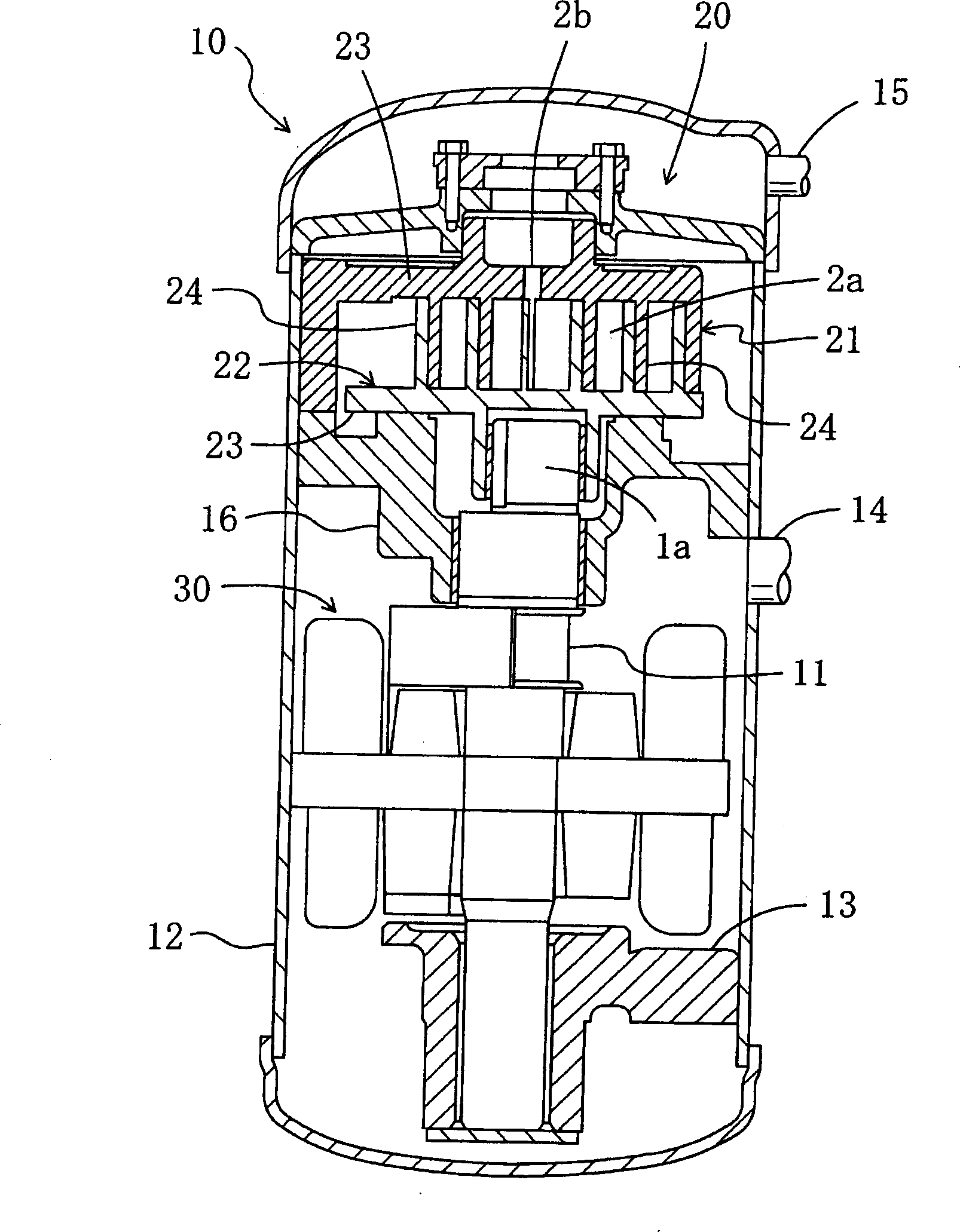

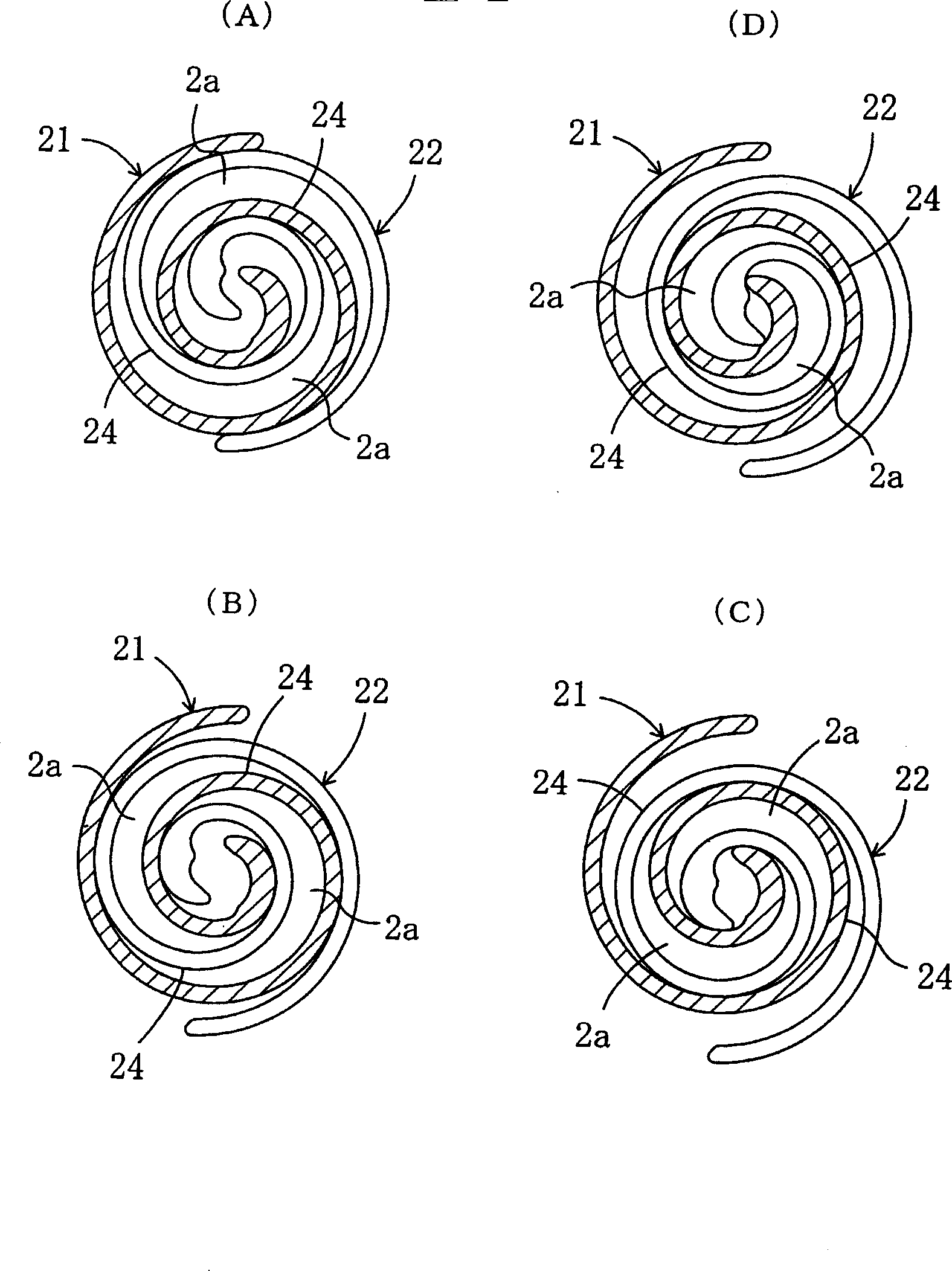

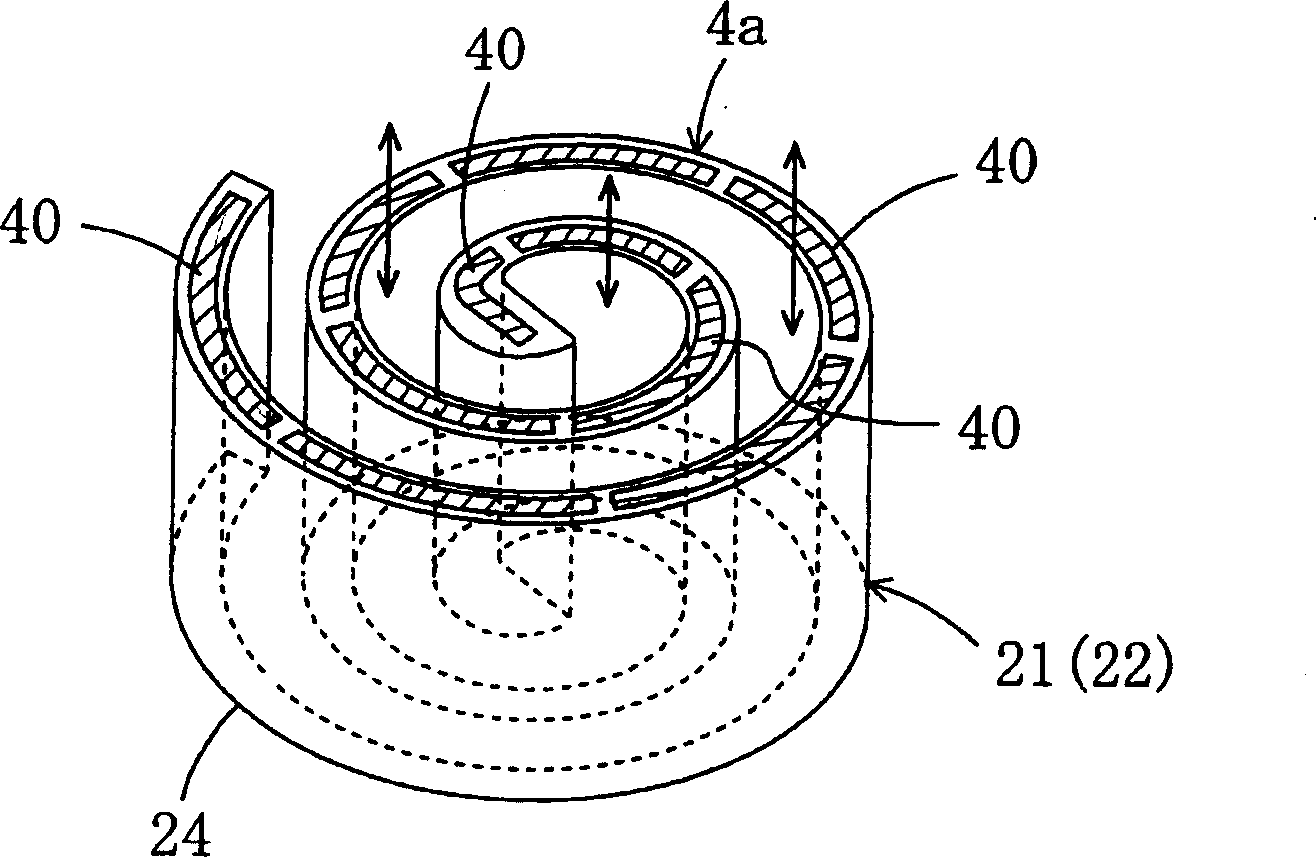

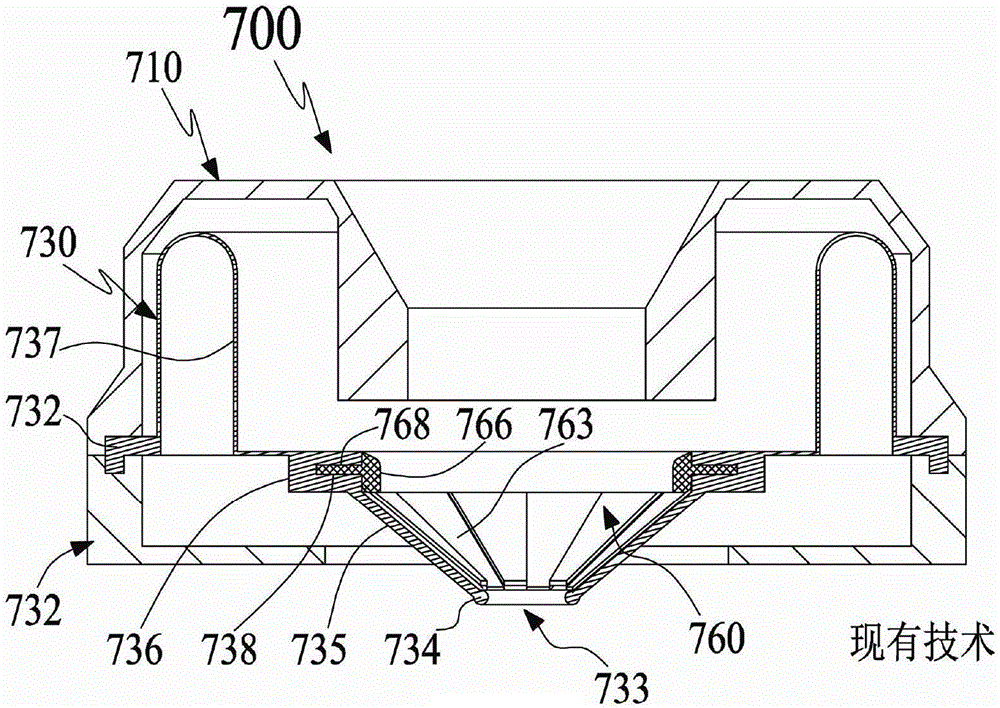

Scroll fluid machinery

InactiveCN1898472AControl capacityEasy to adjustSealing arrangement for pumpsRotary piston pumpsActuatorHigh polymer

The invention discloses a scroll fluid machinery, wherein a fixed scroll (21) with a scroll-shaped lap (24) and a movable scroll (22) are installed on an end plate (23). High polymer actuators (40) adjusting a clearance between the lap (24) and the end plate (23) are fitted into recessed parts at the tip of the lap (24). The high polymer actuators (40) change its shape in the height direction of the lap (24) to adjust the clearance. The high polymer actuators (40) are commonly used as seal members between the end plate (23) and the lap (24). On the other hand, the recessed parts are formed so that a thickness between the recessed parts and the inner peripheral surface of the lap (24) is different from a thickness between the recessed parts and the outer peripheral surface of the lap (24).

Owner:DAIKIN IND LTD

Forging method of soliding fork

InactiveCN1785550AExtend your lifeExtended service lifeForging/hammering/pressing machinesPunchingEngineering

A technology for forging the slide fork includes such steps as heating the blank, transverse rolling by wedge part, clamping the rod part of blank by upper and lower female dies for precise locating, punching by upper and lower punching heads for precisely shaping the fork part, and removing the residual material from the fork part. Its advantages are high precision and long service life of upper and lower female dies.

Owner:INNER MONGOLIA FIRST MACHINERY GRP

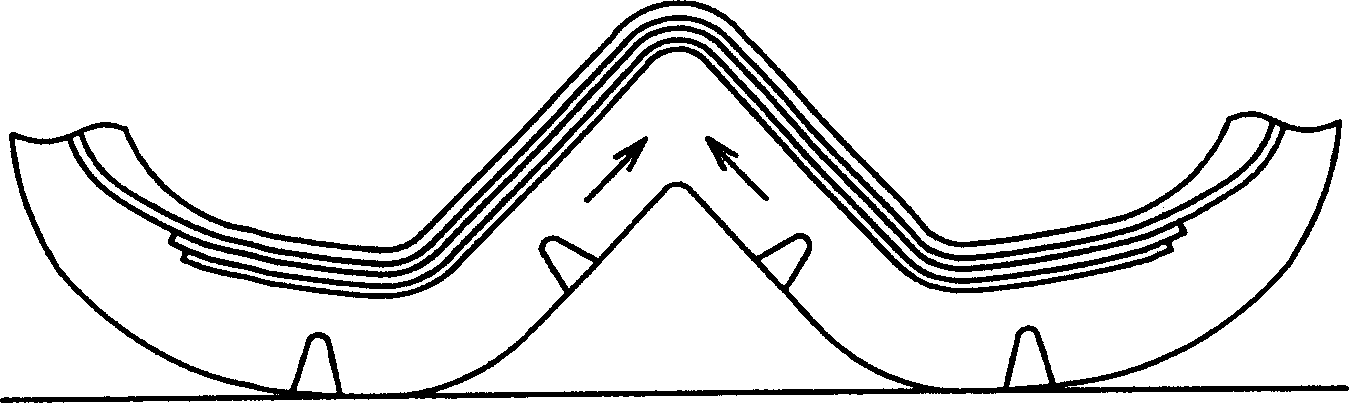

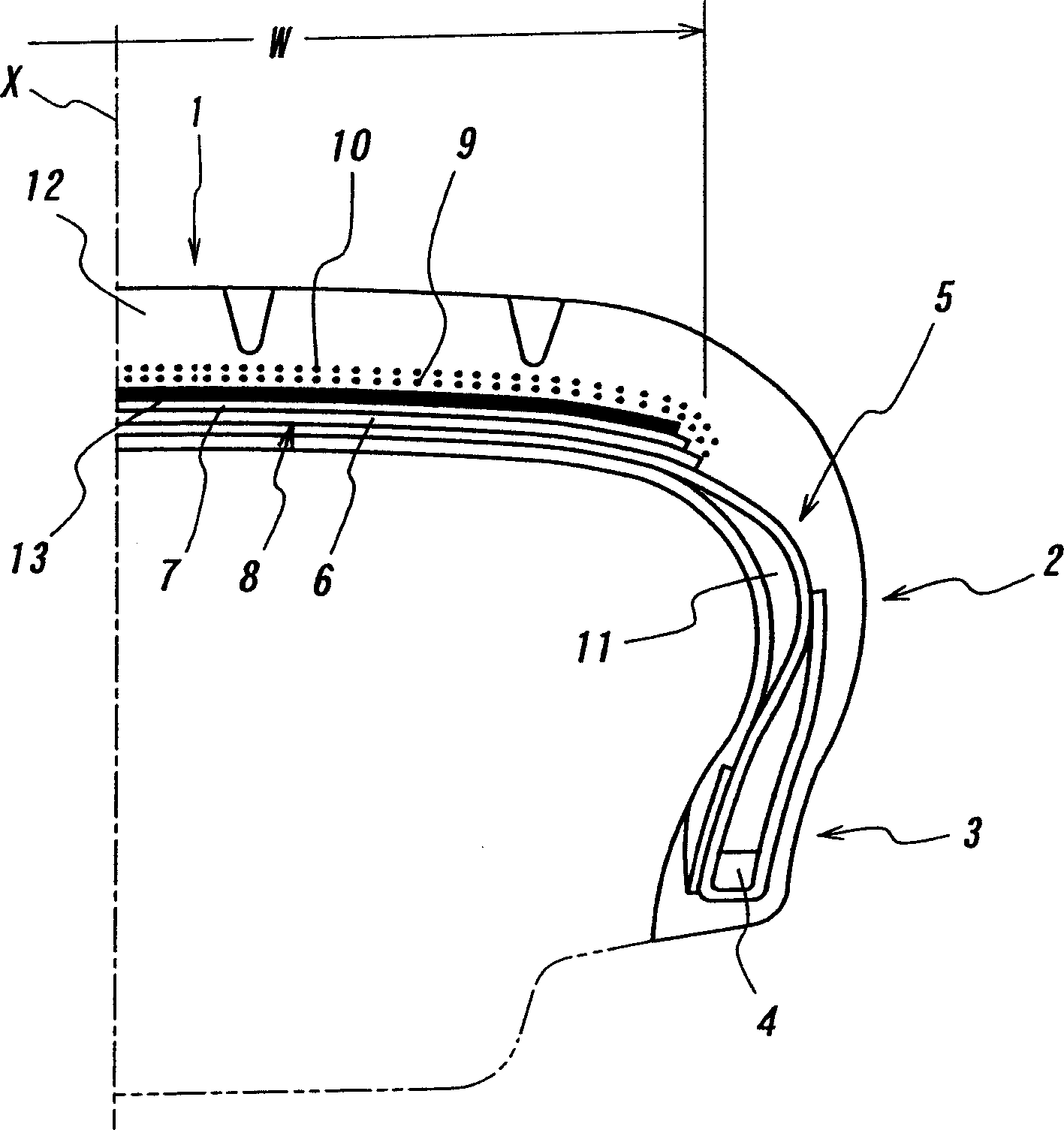

Pneumatic tire

InactiveCN1514776AHigh compression rigidityTaxiing displacement limitPneumatic tyre reinforcementsTyre tread bands/patternsGround contactEngineering

It is to provide a pneumatic tire in which a bulk modulus of elasticity of a tread rubber is small and an inverse V-shaped bending in a tread portion is suppressed to effectively prevent separation failure, breakage and the like of a belt layer, which comprises a radial carcass, a belt of two belt layers with a cross cord arrangement reinforcing a tread portion at an outer peripheral side of a crown portion of the radial carcass and a rubber reinforcing layer having a crescent-shaped form at a cross section, wherein the tread rubber forming a ground contact face of the tread is made of rubber having a bulk modulus of elasticity of not more than 4 GPa and an additional belt layer of cords having a cord angle with respect to an equatorial plane of the tire larger than that of cords in each of belt layers is arranged on an outer peripheral side of the belt and a compression rigidity of the additional belt layer in a widthwise direction of the tread is made 2 times or more larger than that of the belt layer.

Owner:BRIDGESTONE CORP

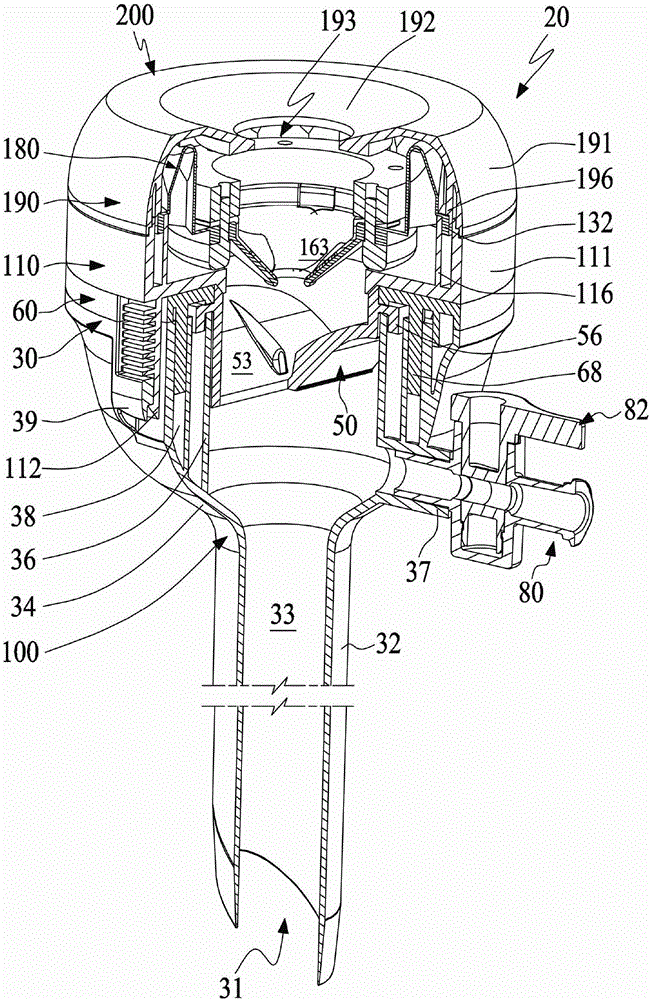

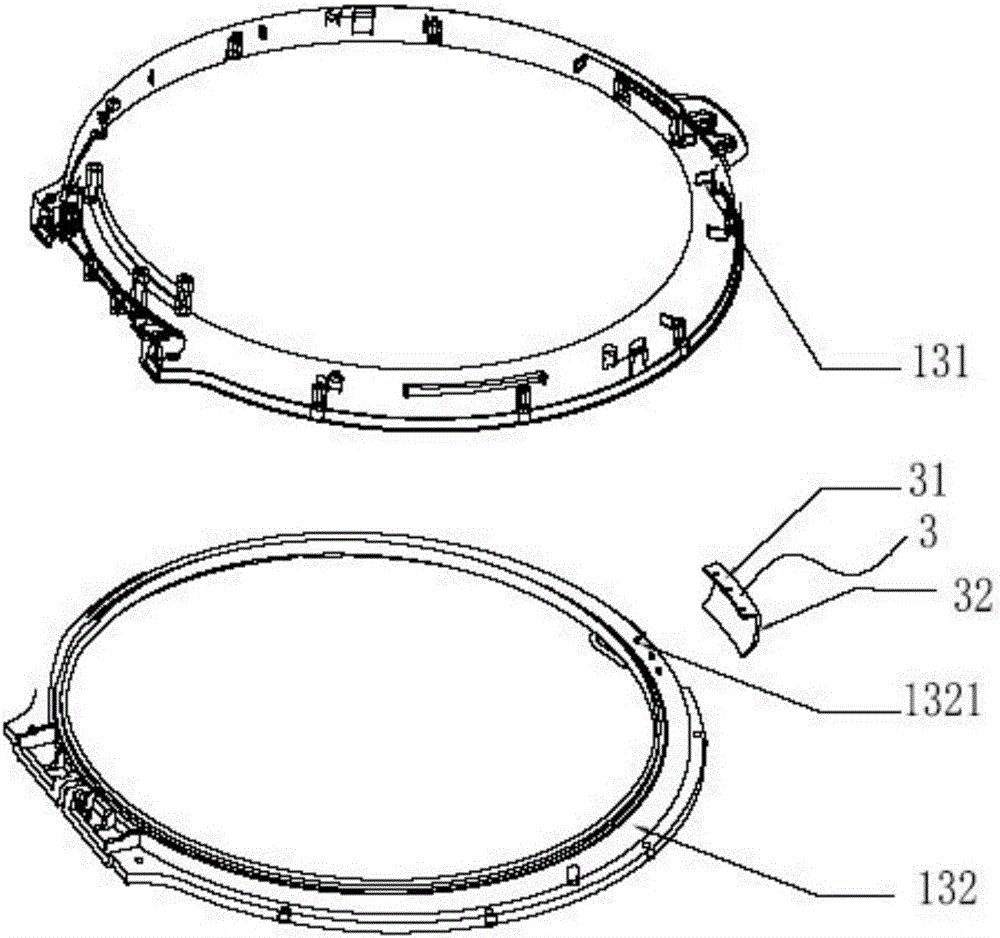

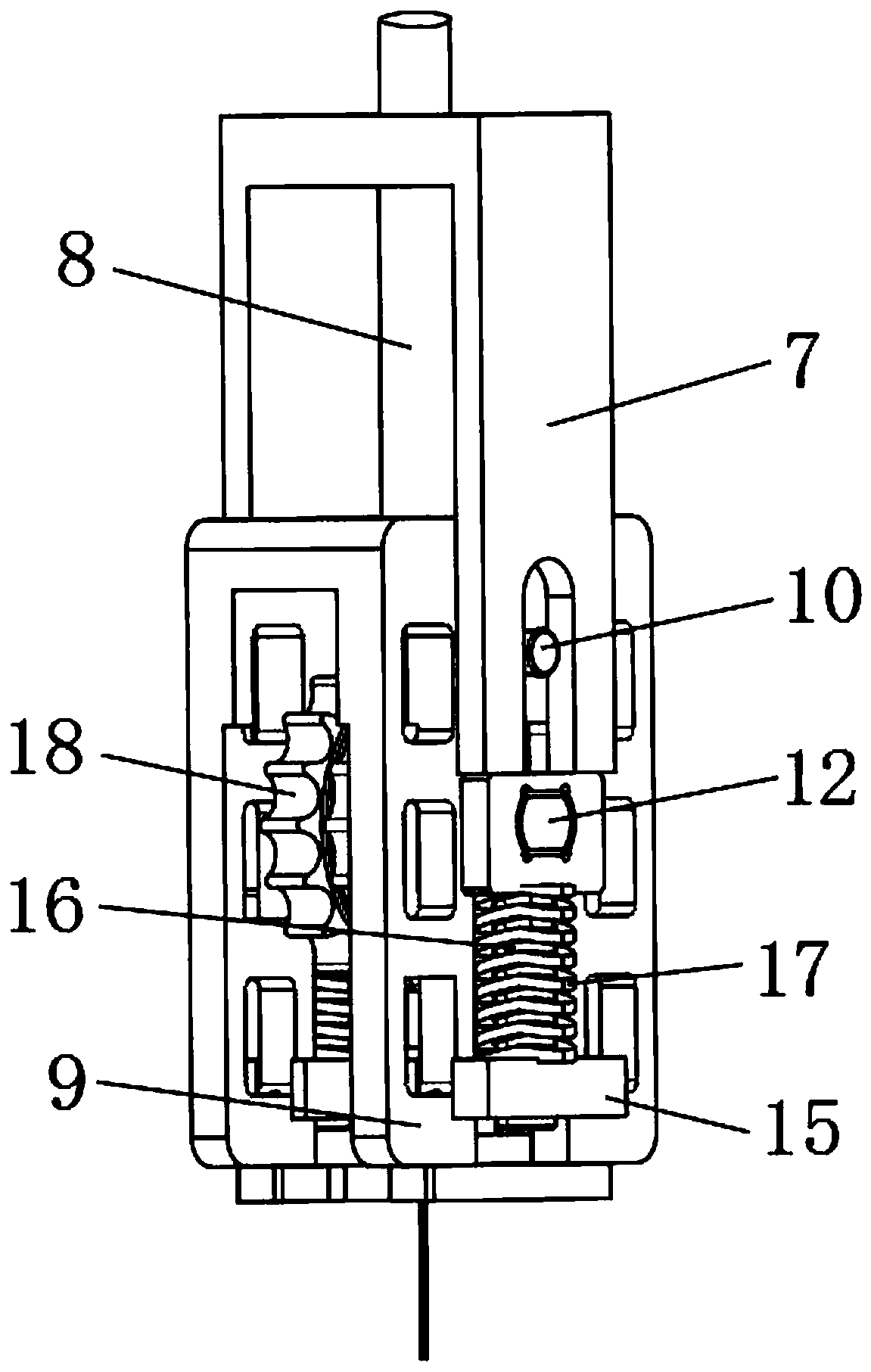

Puncture device sealing membrane containing multi-dimensional floating wrinkles

ActiveCN106137338ASmall deformation forceFree from damageCannulasSurgical needlesWrinkle skinEngineering

Owner:5R MED TECH CHENGDU CO LTD

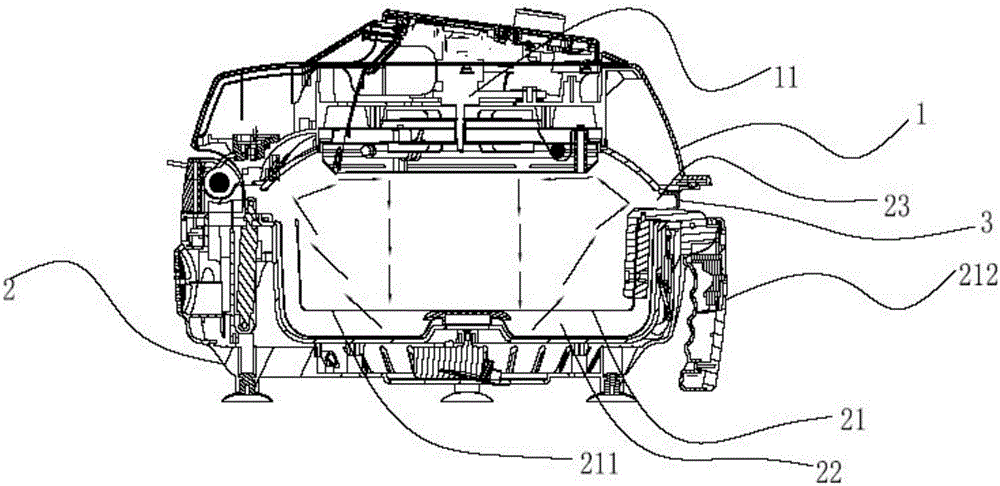

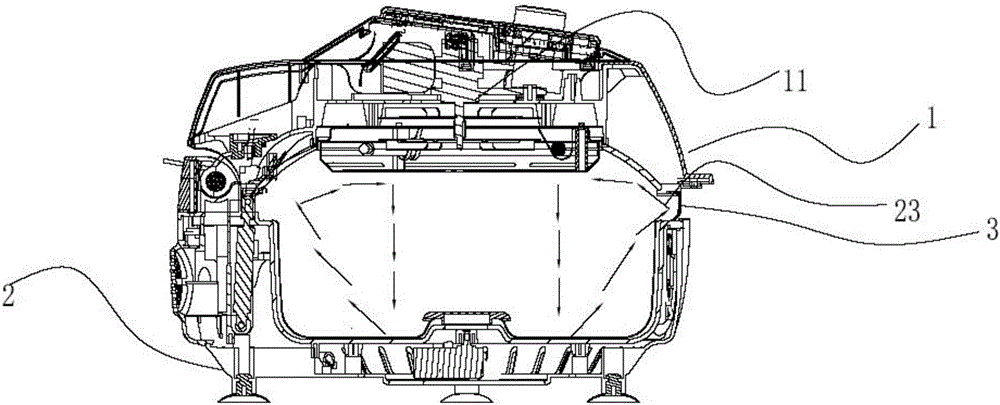

Multifunctional flip type air fryer

ActiveCN105852674AAchieve normal cookingImprove the heating effectDeep fat fryersEngineeringElectrical equipment

The invention relates to the technical field of kitchen appliances, in particular to a multifunctional flip-top air fryer. The air fryer of the present invention includes a pot body and a cover body, the cover body can be rotatably connected with respect to the pot body, the pot body includes a cavity capable of accommodating a frying basket, and the pot body and / or cover body is provided with a The gap of the handle of the frying basket, the flip-type air fryer also includes an elastic wind-shielding device, the elastic wind-shielding device includes a wind-shielding piece, the wind-shielding piece is arranged at the gap, when the frying basket is taken out, The windshield covers the notch. When cooking without a frying basket, the food is directly placed in the cavity, and the elastic windshield device closes the gap, so that the airflow in the cooking cavity will not be discharged from the gap. On the one hand, the cooking efficiency is ensured, and on the other hand, the hot air flow is prevented. burn the user. Therefore, the air fryer of the present invention can realize cooking through the frying basket or without using the frying basket.

Owner:JOYOUNG CO LTD

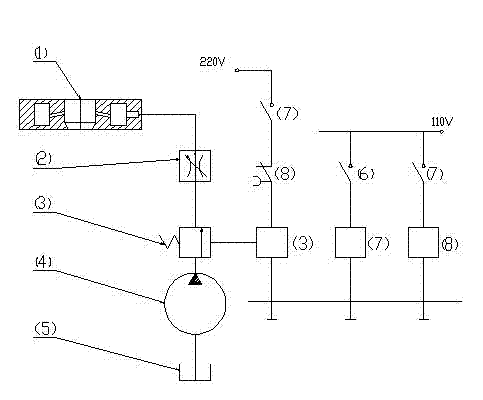

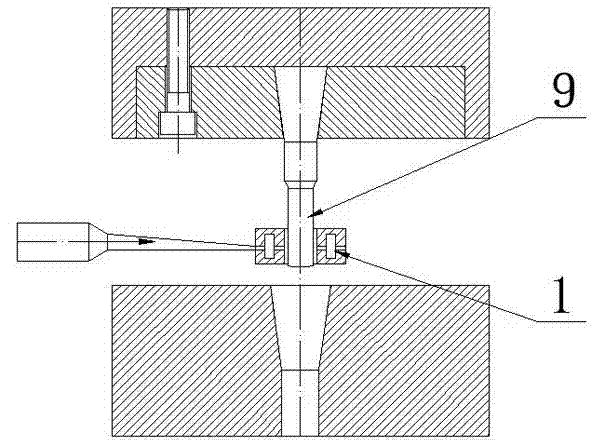

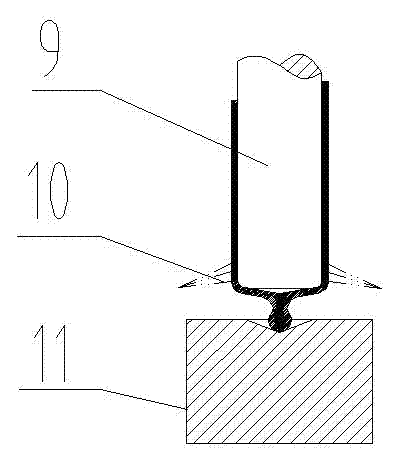

Cooling and lubricating device of hot-extrusion male die

The invention relates to a cooling and lubricating device of a hot-extrusion male die in a hot-extrusion process, in particular to a cooling and lubricating device of a male die in small and deep hole extrusion, which is mainly used for solving the problem that in the hot-extrusion process, a large amount of ejected water for cooling the male die can thoroughly cool the male die, but the temperature is too low and service life can be shortened, and in a fast continuous extrusion process, lubricants cannot be ejected on the male die fast, a punch head is seriously abraded, and service life is short. The cooling and lubricating device adopts an annular nozzle to be sequentially connected with a throttle valve, an electric control on-off valve, a water pump and a lubricant box through pipelines, and the electric control on-off valve is connected with an auxiliary switch for controlling the electric control on-off valve to be on and off. The cooling and lubricating device adopts spraying from down to top, ensures temperature of the male die not to be overlow by controlling flow of the lubricants, spraying time and positions, leads the lubricants to be left on the male die evenly and form a protection layer on the male die, accordingly delays temperature rising of the male die and prolongs service life of the male die.

Owner:襄阳中铁宏吉工程技术有限公司

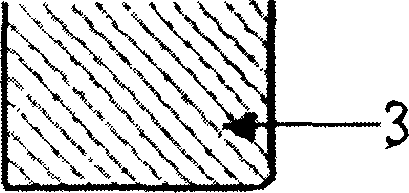

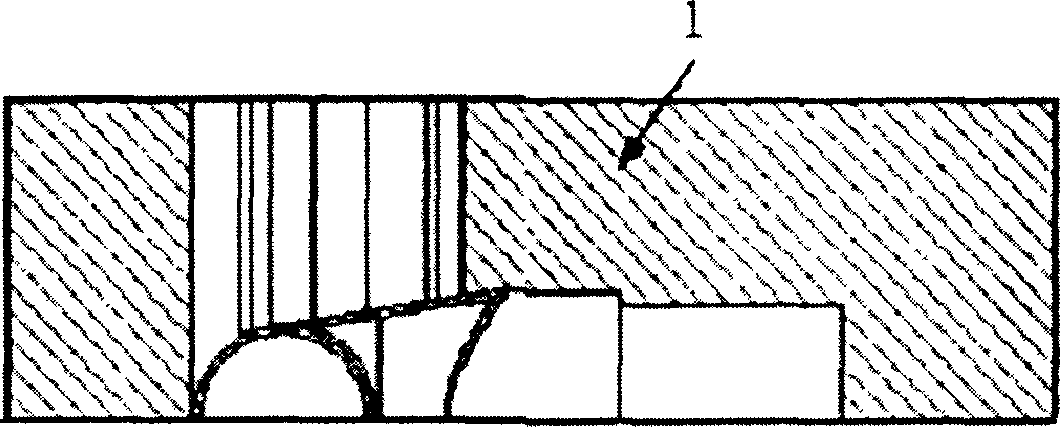

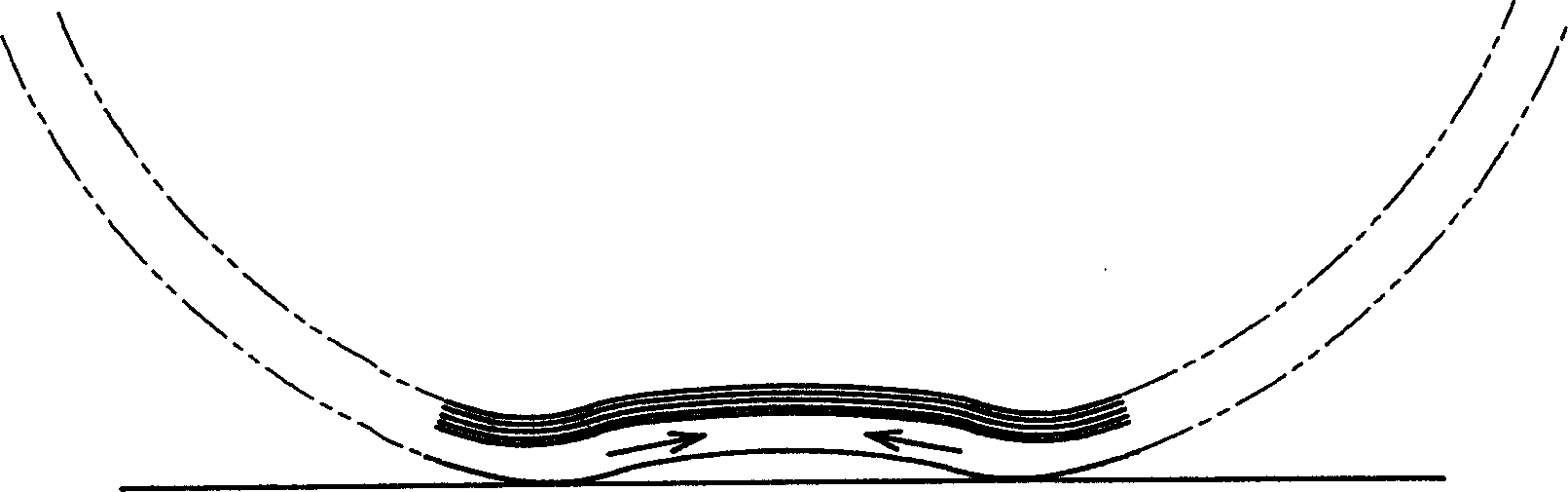

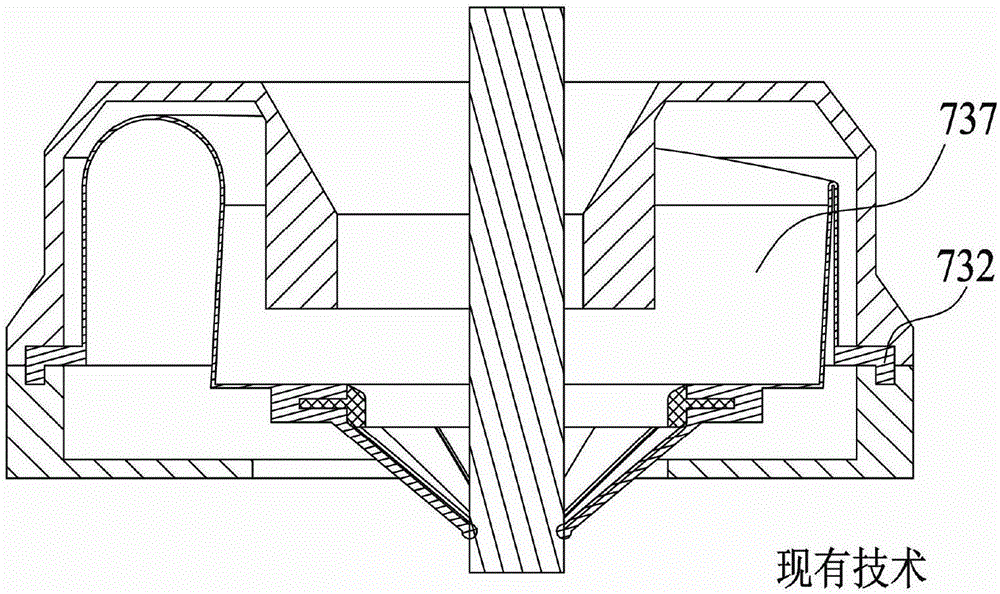

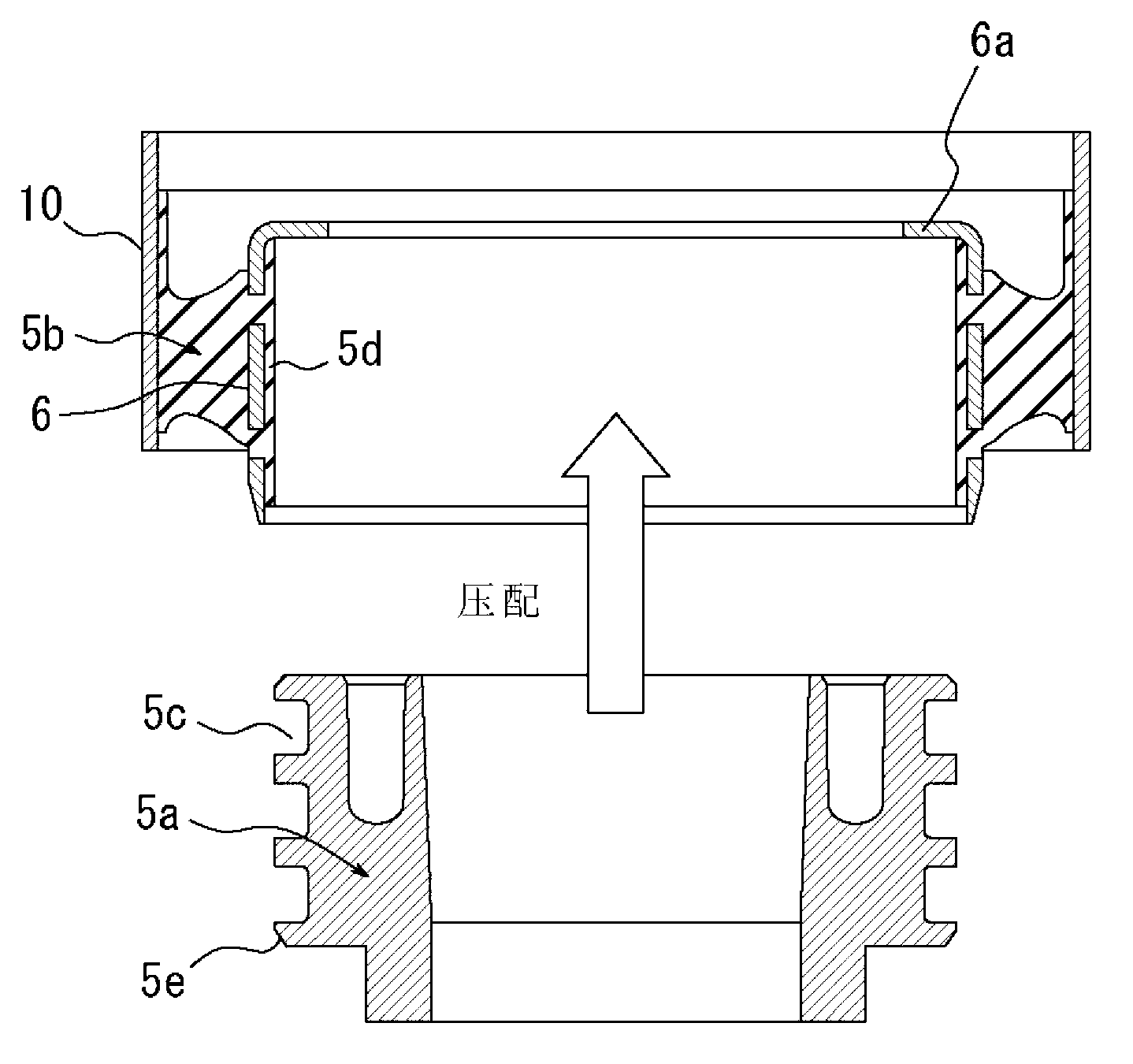

Liquid seal anti-vibration device and manufacturing method thereof

ActiveCN102884338AAvoid deformationIncrease the vibration reduction functionSpringsSprings/dampers manufactureMechanical engineeringEngineering

The disclosed liquid seal anti-vibration device is provided with: an inner tube (1) and outer tube (2); rubber bodies (3, 4) connecting said inner and outer tubes (1, 2) in a liquid-tight manner at two positions separated in the axis direction; a partition wall which, disposed between the two rubber bodies (3, 4), divides into two parts in the axis direction the space between the inner and outer tubes and which comprises an annular rigid member (5a) and an elastic member (5b); liquid chambers (8, 9) formed by sealing a noncompressible fluid in each of the spaces formed by the partition wall (5); and a restricted passage (7) allowing communication between the two liquid chambers (8, 9) formed by the partition wall (5). The aforementioned partition wall (5) is configured from the annular rigid member (5a), which protrudes from the inner tube (1) towards the outer tube side, and from the elastic member (5b), which connects said annular rigid member (5a) to the outer tube (2). The aforementioned restricted passage (7) is configured from one or multiple passage grooves (5c), which, formed on the outer peripheral surface of the annular rigid member (5a), extend at least one time around the circumference thereof, and from a bounding rigid tube member (6) which, attached to the aforementioned elastic member (5b), seals the openings of the passage grooves (5c) via a seal member (5d) in a liquid-tight manner.

Owner:BRIDGESTONE CORP

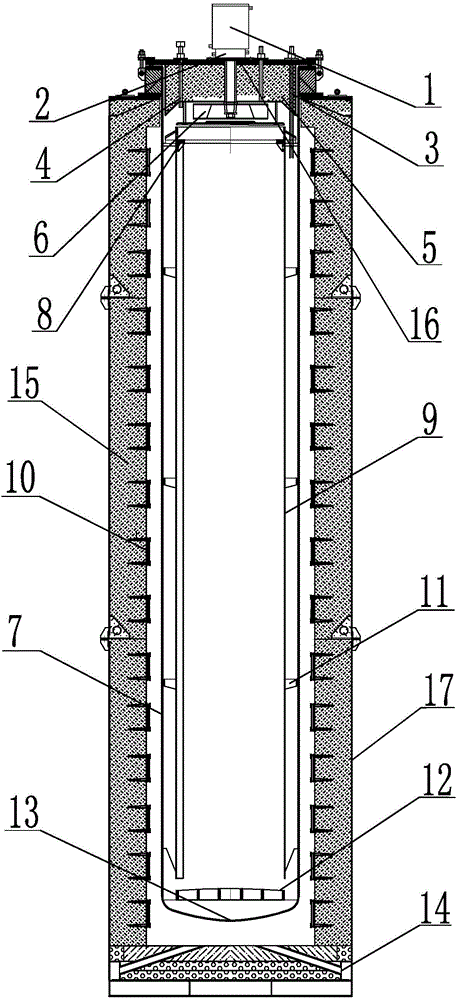

Pit-type nitriding furnace

InactiveCN104928619AHigh strengthAvoid deformationSolid state diffusion coatingEngineeringWater tanks

The invention relates to a pit-type nitriding furnace. The pit-type nitriding furnace comprises a furnace shell, a furnace cover, an inner furnace container and a wind guide barrel. The inner furnace container is arranged inside the furnace shell. The wind guide barrel with the two ends open is hung in the inner furnace container. A tripod is arranged between the wind guide barrel and the inner furnace container for supporting. The bottom of the inner furnace container is an arc surface. A furnace container bottom board is arranged at the position where the bottom of the inner furnace container and an inner furnace container body are connected and is provided with holes. A draught fan is fixed in the middle of the upper end of the furnace cover. A cooling water tank is arranged between the draught fan and the furnace cover. A heat collection box is fixed to the lower end of the furnace cover. The draught fan is connected with a blade through a shaft penetrating through the heat collection box. The draught fan is arranged on the furnace cover, the wind guide barrel is arranged inside the inner furnace container, and the draught fan and the inner furnace container are matched, so that gas is emitted and circulates from bottom to top and heat inside the furnace is distributed more uniformly. The tripod is arranged between the wind guide barrel and the inner furnace container and further improves the intensity of the inner furnace container, and the inner furnace container can be effectively prevented from deforming.

Owner:浙江长兴天盛工业炉有限公司

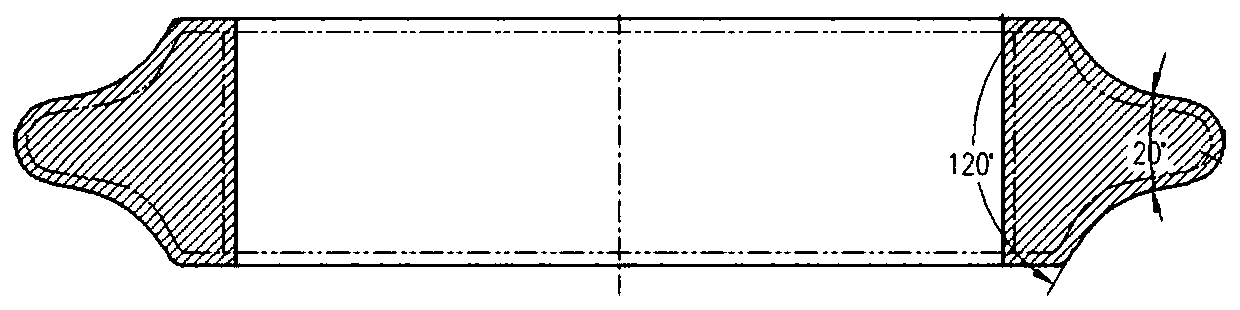

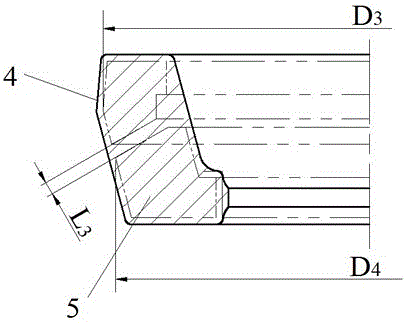

Rolling method for specially-shaped alloy steel ring part with section containing suddenly-changing curve

ActiveCN110666081AFine internal organizationIncrease profitEngine componentsMetal rollingFiberUltimate tensile strength

The invention discloses a rolling method for a specially-shaped alloy steel ring part with a section containing a suddenly-changing curve. The rolling method for the specially-shaped alloy steel ringpart with the section containing the suddenly-changing curve comprises the following steps: blanking to obtain an initial blank; preparing a ring rolling blank from the initial blank which reaches a forging temperature requirement; and placing the ring rolling blank in a ring rolling machine, and carrying out ring rolling forming to obtain a forged ring part with the specially-shaped section. Therolling method for the specially-shaped alloy steel ring part with the section containing the suddenly-changing curve is capable of realizing rolling for the specially-shaped ring part with the section containing the suddenly-changing curve; the deformation force needed by the specially-shaped ring rolling is greatly reduced, and the production cost is lowered; the rolling achieves high internal quality and close internal structure, crystalline grains are fine, fibers are arrayed in the circumferential direction, the mechanical strength and the wear resistance are obviously improved, and the fatigue life is obviously prolonged; high product accuracy, a low machining amount and a high material utilization rate are achieved; high production efficiency and a high rolling speed are achieved; the defects of incomplete filling, fishtail pits, dimension deviation and the like in the ring rolling process are solved; and the method is capable of realizing the most economic and efficient batch production as one-process rolling forming.

Owner:BEIJING NORTH VEHICLE GROUP CORP

Preparation method of carbon steel tube/stainless steel tube composite tube

InactiveCN104043677AHigh bonding strengthRealize the large amount of secondary deformationReduction rateAlloy

Owner:谢光玉

Overlapping type combined forging method

InactiveCN105689615ASave materialSmall deformation forceMetal-working apparatusMaterial consumptionEngineering

The invention relates to an overlapping type combined forging method. The overlapping type combined forging method is characterized by comprising the steps that two or more parts are overlapped and combined into a connected part, then the chipping allowance is added to the outer surface of the connected part to form a combined die forging, after combination, from the projection areas, the small forging is wrapped by the large charging, the projection area of the large forging is not increased, and the combined die forging or the connected part is separated through blanking, heating, die forging and cutting machining. By means of the reasonable combination and the selected proper separation method, forgings which cannot be subjected to combined forging in a traditional method can be forged through the combined forging method, and the combined forging application range is widened. After the overlapping type combined forging is formed, two or more forgings consume one finishing allowance jointly, and therefore material consumption is reduced. A cutting separation face can be directly used as a finish machining locating basis, and the effects of saving materials, reducing deformation force and improving the production efficiency can be achieved.

Owner:NANCHANG GEAR FORGE PLANT

Method for preparing tungsten copper alloy wire materials by using hot-swage technology

InactiveCN102225434ALarge processing deformationUniform deformationSingle bars/rods/wires/strips conductorsForging hammersGraphiteMaterials processing

The invention discloses a method for preparing tungsten copper alloy wire materials by using hot-swage technology, comprising the following steps: weighing copper powder, tungsten powder and weighing glycerol as additive by weight percentage, mechanically mixing the three ingredients; putting the mixed viscous fluid with a certain fluidity in a graphite die; pre-buring in a vacuum sintering furnace; sintering the infiltrated copper in the furnace under the protection of hydrogen or helium; finally processing by hot-swage and centerless grinding to obtain wire materials with a certain diameter and random lengths. The invention has the advantages of simple technology, convenient operation, low cost, and stable performace, high quality and high yield of the products, solves the problems of complicate technology and high cost of preparing slender tungsten copper material existed in the prior art, and can be widely used in material processing of electrode, LED lamp and plasma.

Owner:SHANXI LIGONG MECHANICAL & ELECTRICAL TECH

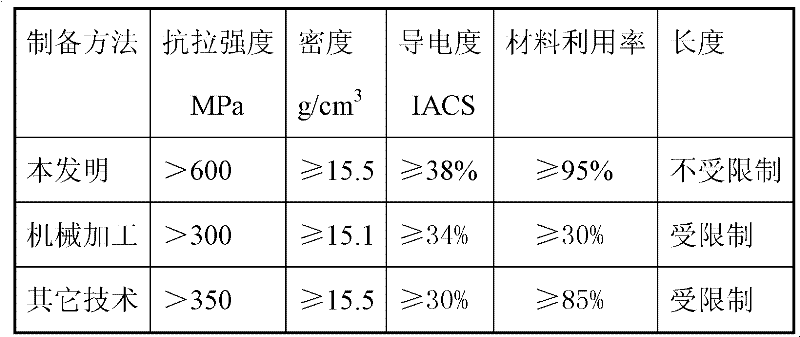

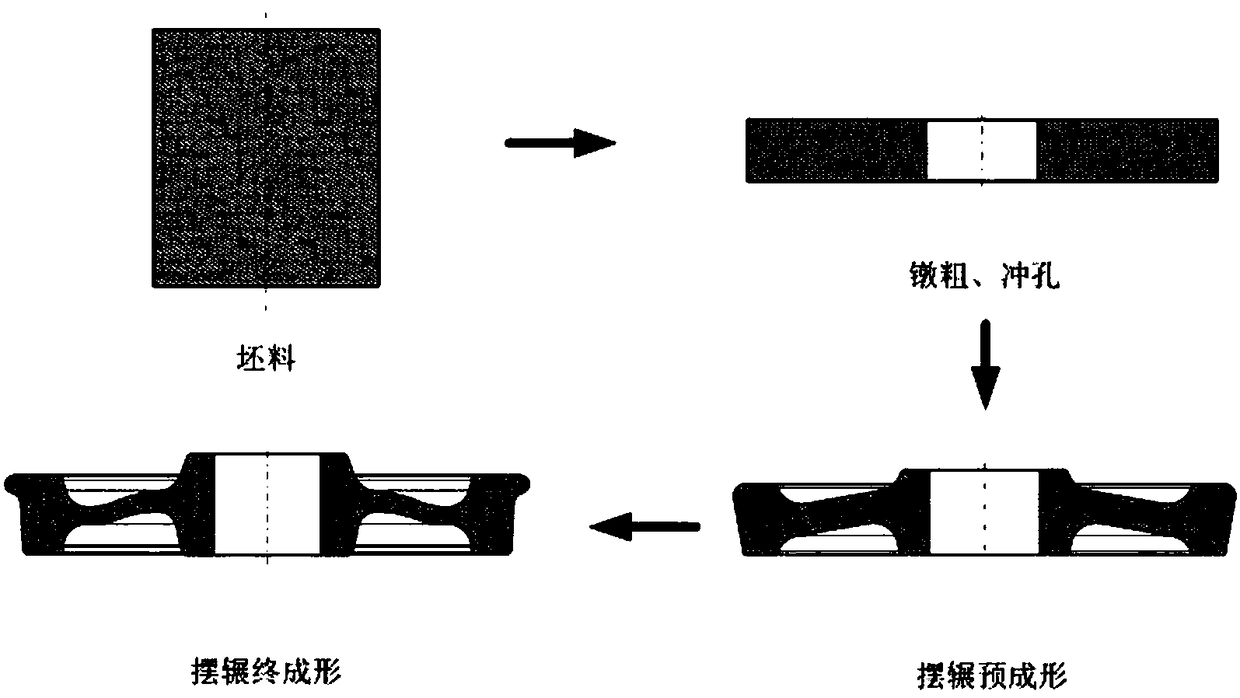

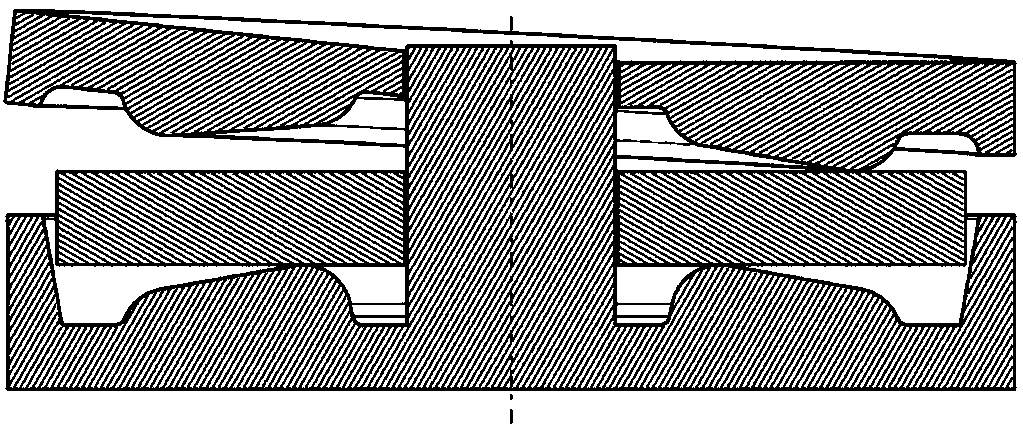

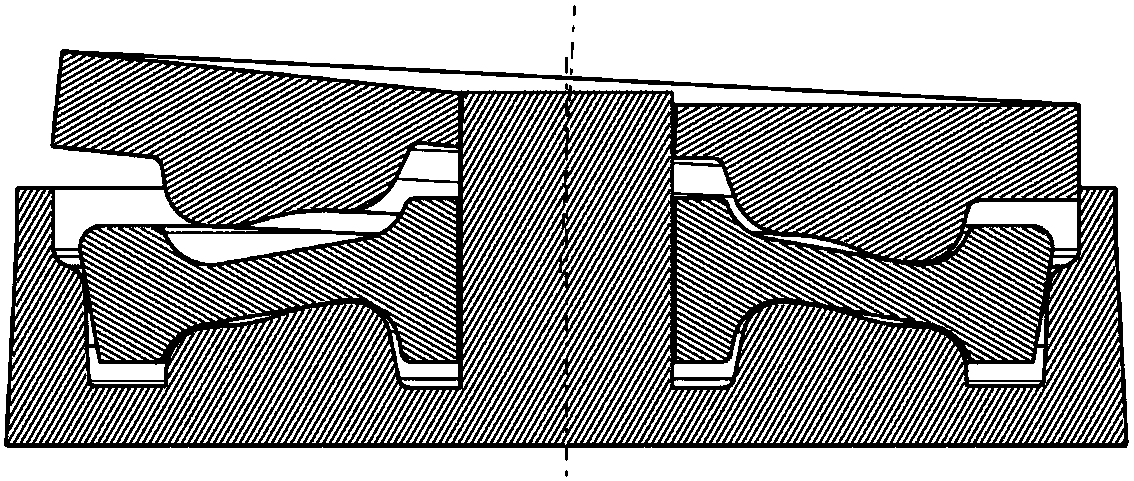

Train wheel rotary forging forming method

InactiveCN108237193ASolve the problem of easy eccentricityResolve accuracyDisc wheelsWorking environmentWheel sizing

The invention belongs to the field of wheel-shaped part hot forging forming, and particularly relates to a train wheel rotary forging forming method. The method comprises the following steps that a, acontinuous casting steel billet is cut to obtain a blank with the diameter phi being 380*432 mm and heated to 1200 DEG C; b, a precast blank is obtained through a pressure machine, particularly, theblank is subjected to upsetting and punching on the 50MN pressure machine to form the precast blank, and the hole diameter and outer diameter of the precast blank are controlled in the working procedure to be approximate to the size of a cavity which is adopted during rotary forging final forming; c, rotary forging preforming is carried out, particularly, a preformed blank is obtained from the precast blank on a first rotary forging press, metal at the positions of a well disc, a hub and a rim needs to be reasonably distributed according to preformed blank materials, and therefore the cavity of a die can be completely filled with the metal when the rotary forging is finally formed; and d, rotary forging final forming is carried out, and particularly, a train wheel rotary forged part is formed from the preformed blank on a second rotary forging press. The problems and defects existing in existing train wheel forming methods are well solved, the train wheel size precision and concentricity can be improved, the cutting amount can be reduced, large-power forming equipment is not needed, and the working environment of workers is improved.

Owner:JILIN UNIV

Thin-wall component variable-speed liquid filling-ultrasonic-laser composite forming method and system

ActiveCN114505395AImprove stress statusSimple wayShaping toolsIncreasing energy efficiencyUltrasonic vibrationAerospace

The invention relates to a variable-speed liquid filling-ultrasonic-laser composite forming method and system for a thin-wall component, which is used for forming a metal or composite material ultra-deep cavity complex feature component, forming an ultra-deep cavity feature by utilizing an ultrasonic vibration coupling passive liquid filling forming technology, and forming a complex small feature by utilizing a laser coupling high-speed liquid filling forming technology. According to the method, the forming limit, the forming quality and the complexity of the thin-wall component can be effectively improved, and the defects of cracking, wrinkling and the like in the forming process are reduced. The method has wide application prospects in the high-speed carrying fields of aerospace, automobiles and the like, especially in the aspect of integrated forming of ultra-deep-cavity thin-wall components with multiple complex characteristics, the forming performance of the plate is greatly improved, the blank in the forming field of the ultra-deep-cavity components is filled, the complexity of the formed components is widened, and the forming quality is improved.

Owner:HEBEI UNIV OF TECH

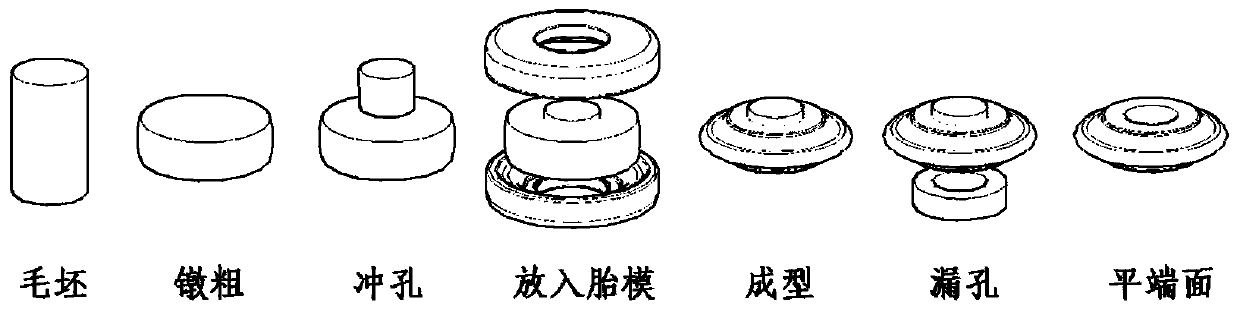

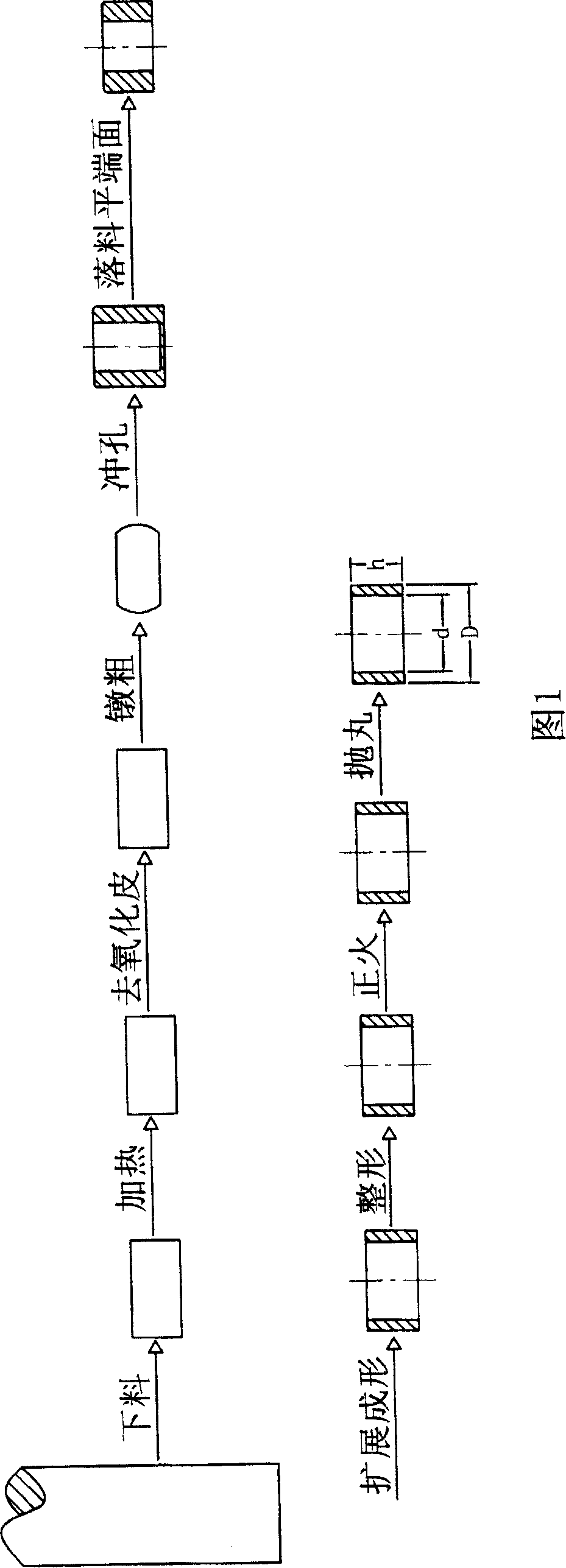

Method for processing gear ring blank for automobile synchronizer

InactiveCN100394075CExtended service lifeReduce contact areaPortable liftingFurnace typesPunchingEngineering

Owner:CHONGQING CHANGFENG PRECISE BLANK

Reforming method and mold of automobile rear axle driven gear forging piece

The invention relates to a reforming method and a mold of an automobile rear axle driven gear forging piece; the method comprises the following steps: prepare a semi-finished product-a chambering piece of the driven gear forging piece, place the manufactured chambering piece into a reforming mold cavity and reform the driven gear forging piece; the mold comprises a male mold, a female mold and a stripper plate, wherein the female mold is composed of a floating mold and a closed cavity formed by a pair of rollers; the invention can effectively reform the chambering piece of the driven gear, eliminate the disadvantages of concave pit, oval shape and distortion of the surface of the chambering piece, adopt equipment with low load and simple structure can effectively reform the driven gear forging piece of the automobile rear axle and saves more than 10 percent of raw material; for instance, the driven gear forging piece with 430mm of outer diameter is reformed, the needed load is 6300kN and the blanking weight is 36 kilograms.

Owner:WUHAN UNIV OF TECH

A labor-saving automobile hub forming method and device thereof

InactiveCN100475429CReduction toolReduce equipmentShaping toolsExtrusion diesEngineeringMechanical engineering

Owner:ZHONGBEI UNIV

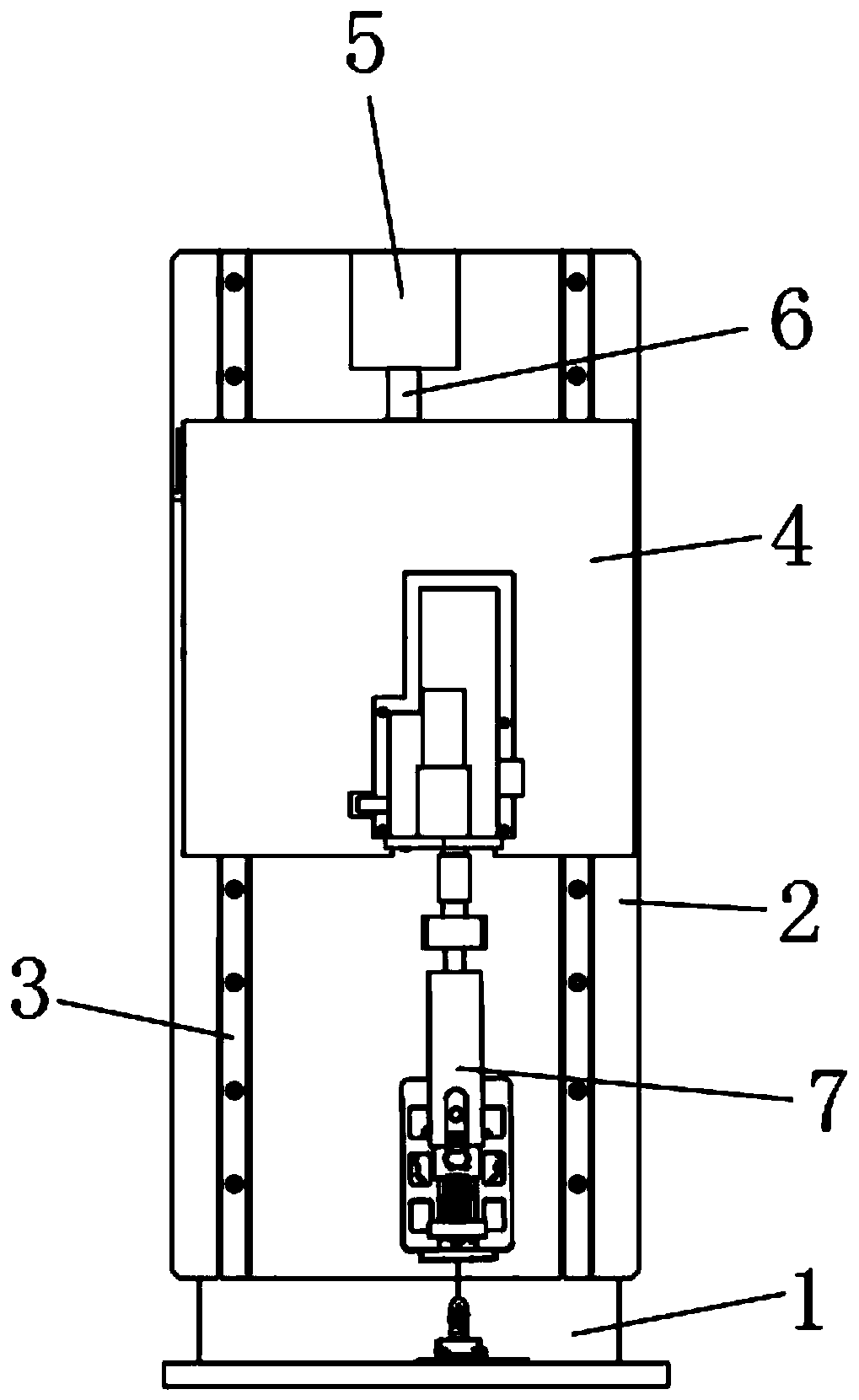

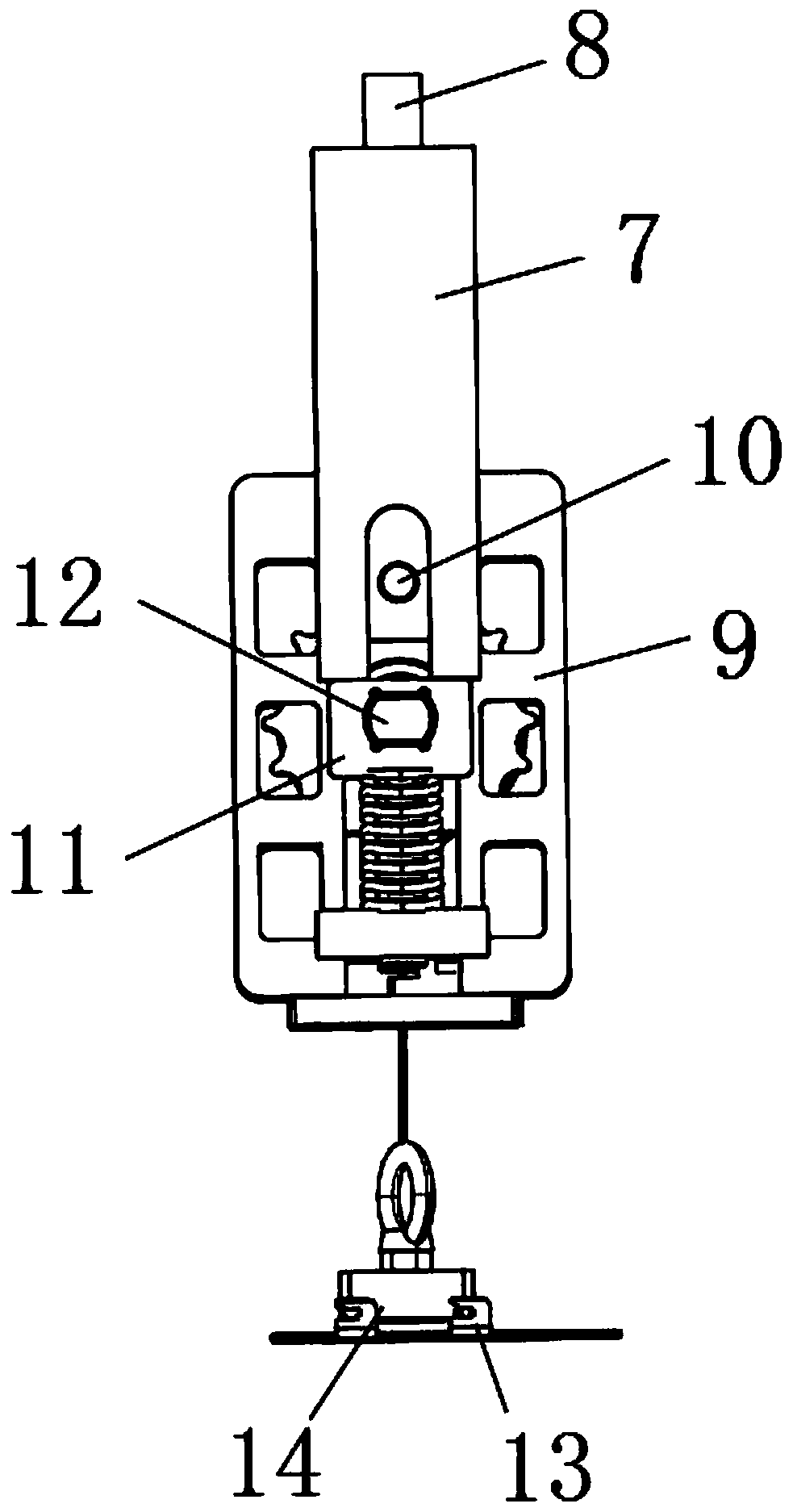

Tension test equipment and steel wire rope tension test method thereof

ActiveCN111289364AInstant stretching forceAvoid damageMaterial strength using tensile/compressive forcesPull forceTest equipment

The invention discloses tension test equipment and a steel wire rope tension test method thereof. A tension bar is arranged, a clamping block is arranged at one end of the tension bar, and the clamping block and a clamping sleeve are clamped and fixed through a clamping groove; when a tension test is carried out, a transition block applies acting force to the clamping sleeve through a fixing shaft, the clamping sleeve applies acting force to the connecting rod through the connecting block, the acting force is transmitted to a first bracket through the connecting rod so as to provide drawing force for the steel wire rope; the clamping sleeve is clamped with the clamping block, the connection mode between the clamping sleeve and the clamping block is no longer hard contact, when the clampingsleeve transmits a tensile force, the steel wire rope is deformed under the action of tension, the instantaneous tensile force of the steel wire rope can be buffered in a clamping mode between the clamping sleeve and the clamping block, when the steel wire rope is stretched, the instantaneous acting force borne by the steel wire rope is not too large, and therefore damage to material performancecaused by the too large acting force at the moment of stress of the steel wire rope is avoided, and the tension test result of the steel wire rope is more accurate.

Owner:深圳天溯计量检测股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com