Cooling and lubricating device of hot-extrusion male die

A cooling lubrication and lubricating device technology, which is applied in the field of punch lubricating and cooling devices, can solve the problems of no lubrication, easy cracks, upsetting and other problems of punches, and achieve the effects of delaying temperature rise, reducing deformation force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

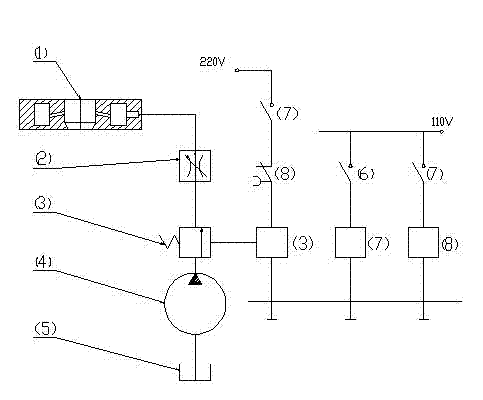

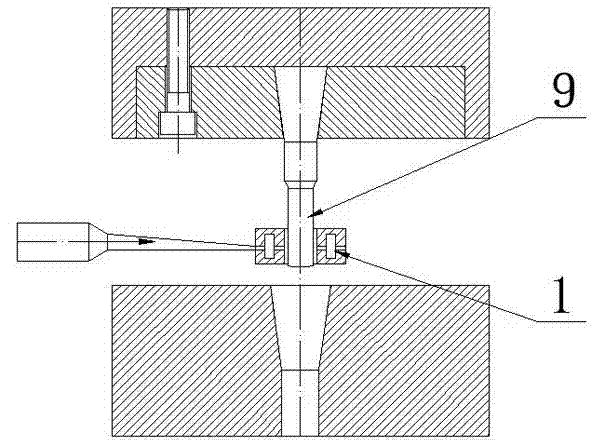

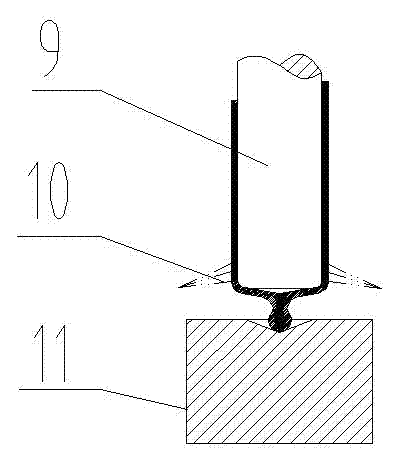

[0011] Such as figure 1 , 2 , shown in 3, lubricant nozzle of the present invention is to adopt ring nozzle 1, and the bottom of ring nozzle 1 is inverted conical, and the following is small, and the top is big, and nozzle 1 inner wall is provided with aperture, and aperture is in the form of horizontal plane. Arranged upward at a certain angle; the lubricant is extracted from the lubricant storage tank 5 through the water pump 4, flows into the annular nozzle 1 through the pipeline through the electronically controlled on-off valve 3 and the throttle valve 6, and passes through the inner ring wall of the annular nozzle 1 Evenly distributed small holes are sprayed out and sprayed on the punch 9. Due to the fast injection speed, the lubricant meets the steam diaphragm formed by the red hot punch 9 and is instantly destroyed, and the punch 9 can be cooled rapidly; The contact time between the end surface and the workpiece 11 is the longest and the temperature is the highest. Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com