Method for processing gear ring blank for automobile synchronizer

A technology of synchronizer and ring gear, which is applied to vehicle parts, components with teeth, wheels, etc. It can solve the problems affecting the accuracy and service life of machine tools, the performance of finished parts, and the surface finish of tool damage, so as to reduce the expansion The hole ratio, the effect of improving the service life and reducing the amount of cutting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

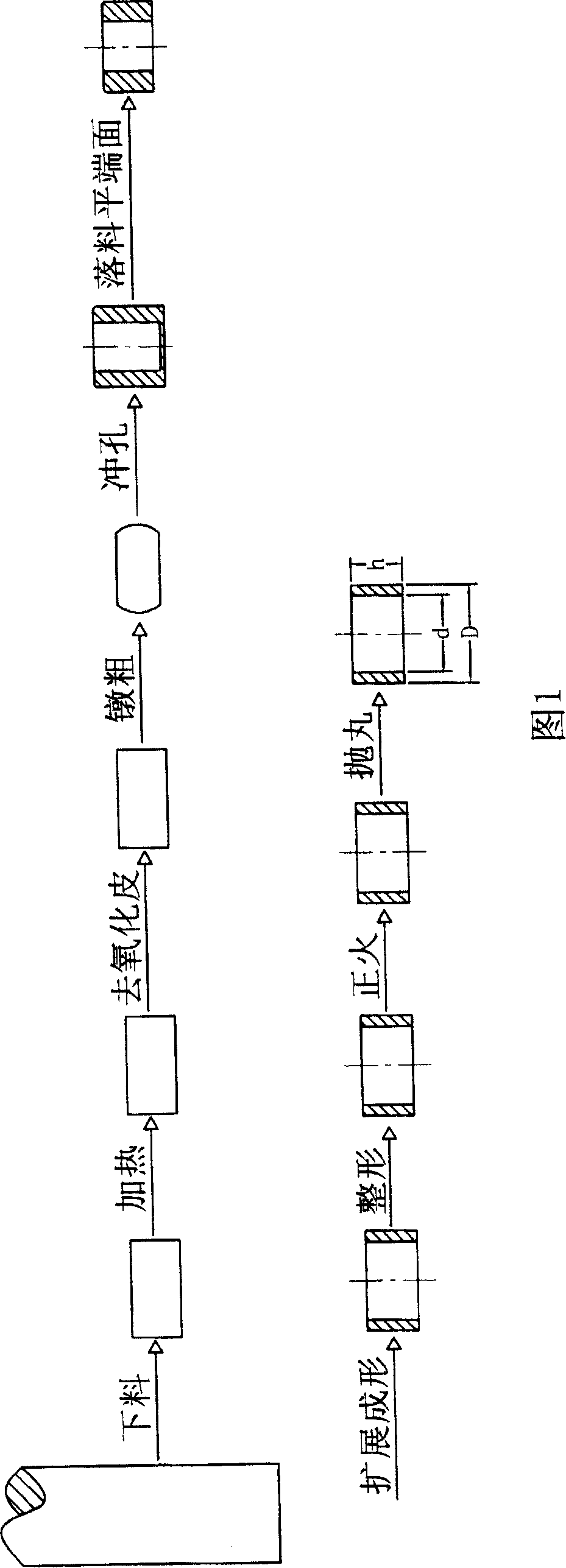

[0032] Embodiment 1, as shown in Figure 1, when using round steel 20CrMnTi as the blank processing the automobile synchronizer ring gear blank of φ100mm * φ78mm * 52mm specification, carry out as follows:

[0033] a, blanking, calculate its net weight according to the size of the finished ring gear blank, that is, net weight = density x volume = 7.85 x 3.14 x 0.052 x (50 x 50-39 x 39) = 1255 grams, in the net weight of 1255 grams On the basis of adding fire consumption 5% that is 62.75 grams, plus punching and skin consumption of 72.25 grams, the weight of the blanking material is determined to be 1390 grams, and the diameter of the round steel of 50 mm is selected, and the length of the blanking material is calculated to be 90 mm. Material length / round steel diameter=90 / 50=1.8<2.5, the round steel diameter and blanking length meet the requirements, and the round steel with a diameter of 50mm is cut into a 90mm long blank with a CQ65 type rod shearing machine.

[0034] b. Heat...

Embodiment 2

[0043] Embodiment 2, as shown in Figure 1, with round steel 20CrMnTi as blank, when processing the automobile synchronizer ring gear blank of φ85mm * φ65mm * 52mm specification, carry out as follows:

[0044] a, blanking, calculate its net weight according to the size of the finished ring gear blank, that is, net weight = density × volume = 7.85 × 3.14 × 0.052 × (42.5 × 42.5-32.5 × 32.5) = 961 grams, in the net weight of 961 grams On the basis of adding fire consumption 3% that is 29 grams, plus punching and skin consumption of 75 grams, the weight of the blanking is determined to be 1065 grams, the diameter of the round steel is 50mm, and the length of the blanking is calculated to be 54mm. Material length / round steel diameter=54 / 50=1.08<2.5, the round steel diameter and blanking length meet the requirements, and the round steel with a diameter of 50mm is cut into a 54mm long blank with a CQ65 type rod shearing machine.

[0045] b. Heating, put the billet into a low-pressure ...

Embodiment 3

[0054] Embodiment 3, as shown in Figure 1, with round steel 20CrMo as blank, when processing the automobile synchronizer ring gear blank of φ75mm * φ50mm * 52mm specification, carry out as follows:

[0055] a, blanking, calculate its net weight according to the size of the finished ring gear blank, that is, net weight = density × volume = 7.85 × 3.14 × 0.052 × (37.5 × 37.5-25 × 25) = 1001 grams, in the net weight of 1001 grams On the basis of adding fire consumption 4% that is 40 grams, plus punching and skin consumption of 70 grams, the weight of the blanking is determined to be 1111 grams, the diameter of the round steel is 50mm, and the length of the blanking is calculated to be 57mm. Material length / round steel diameter=57 / 50=1.14<2.5, the round steel diameter and blanking length meet the requirements, and the round steel with a diameter of 50mm is cut into a 57mm long blank with a CQ65 type rod shearing machine.

[0056] b. Heating, put the billet into a low-pressure gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com