Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

270results about How to "Small tonnage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

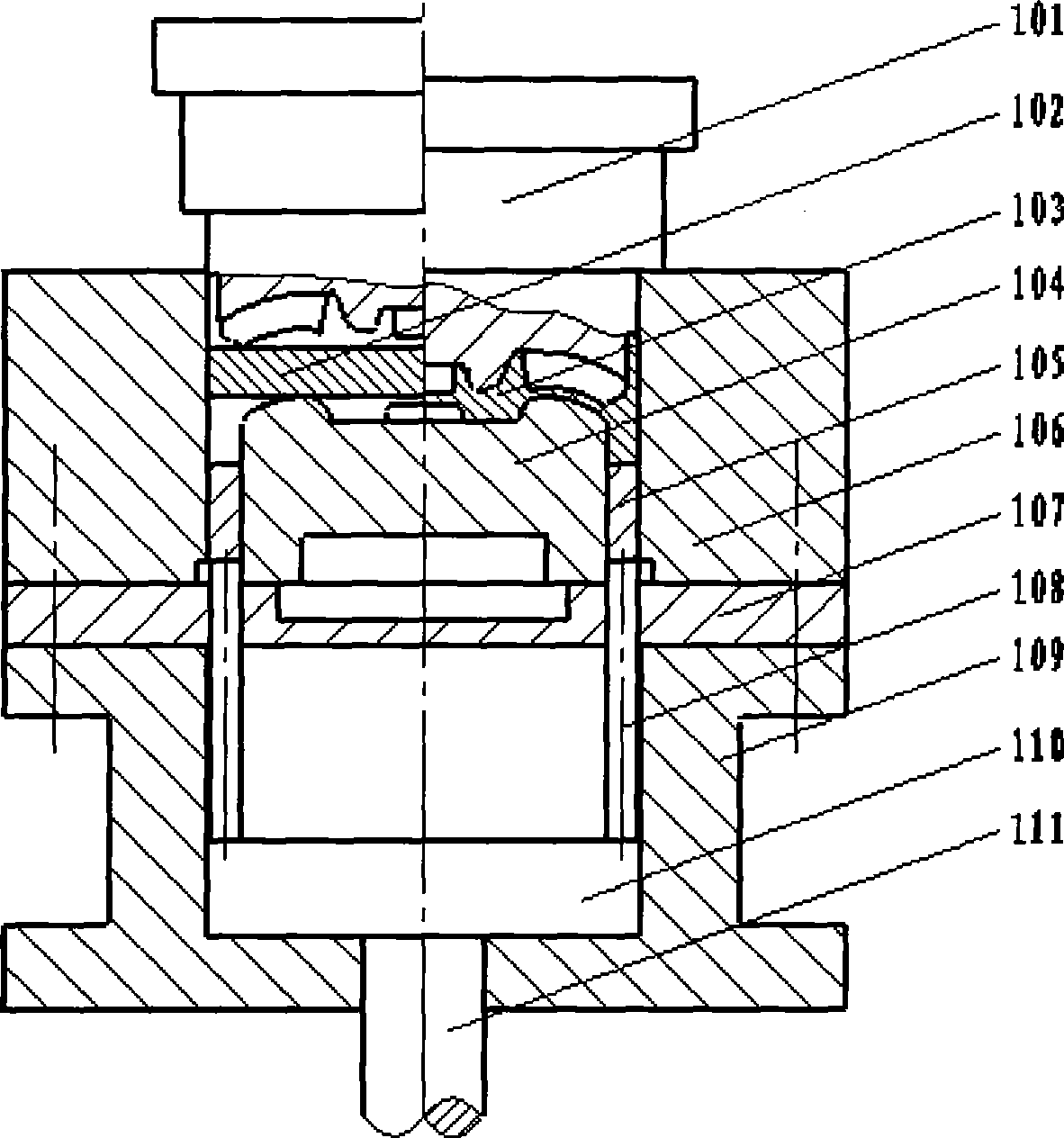

Combined plastic forming method of automobile hub and matching forming mold of automobile hub

InactiveCN102179664AReduce manufacturing costReduce investmentShaping toolsExtrusion diesAlloyEngineering

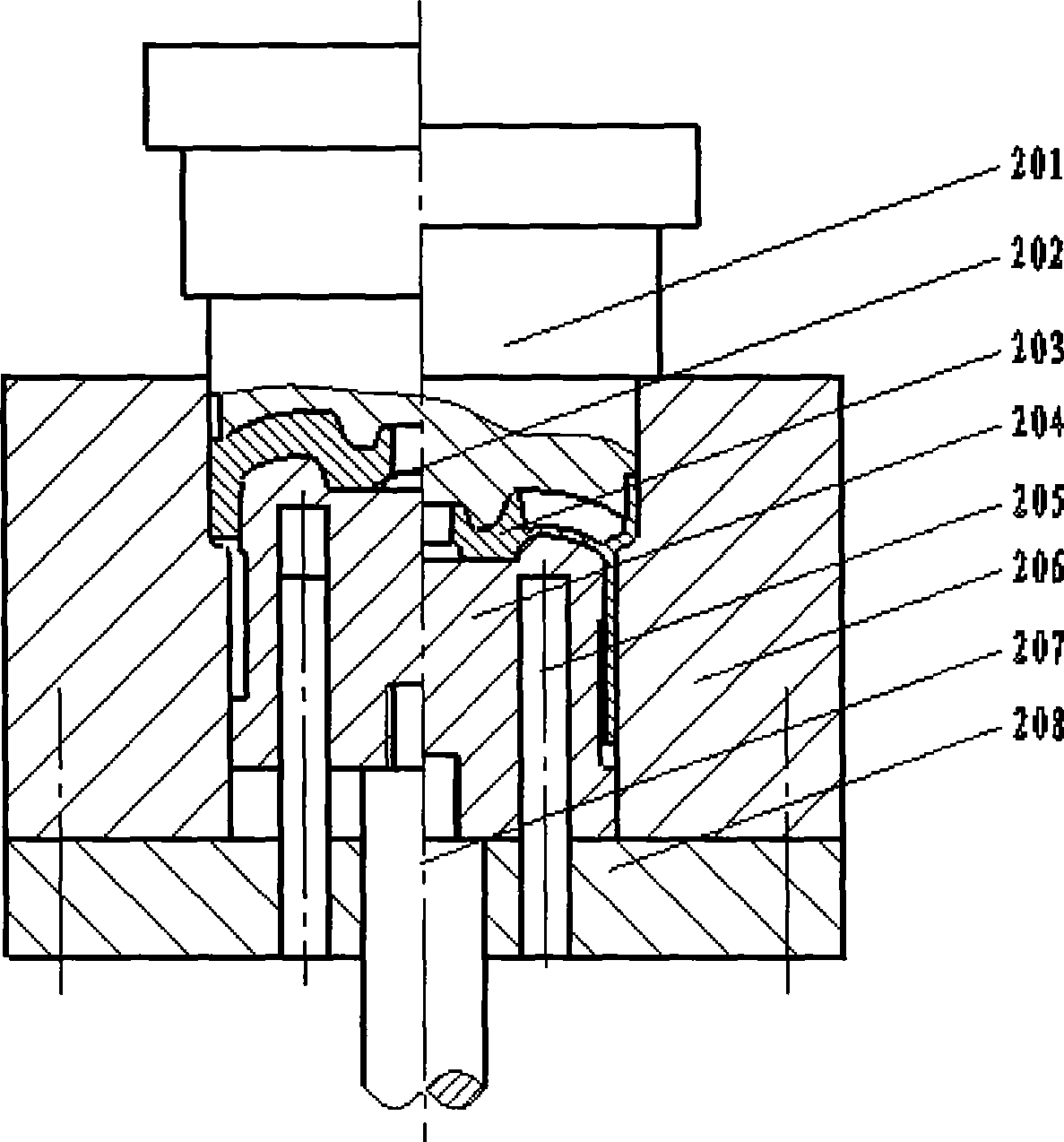

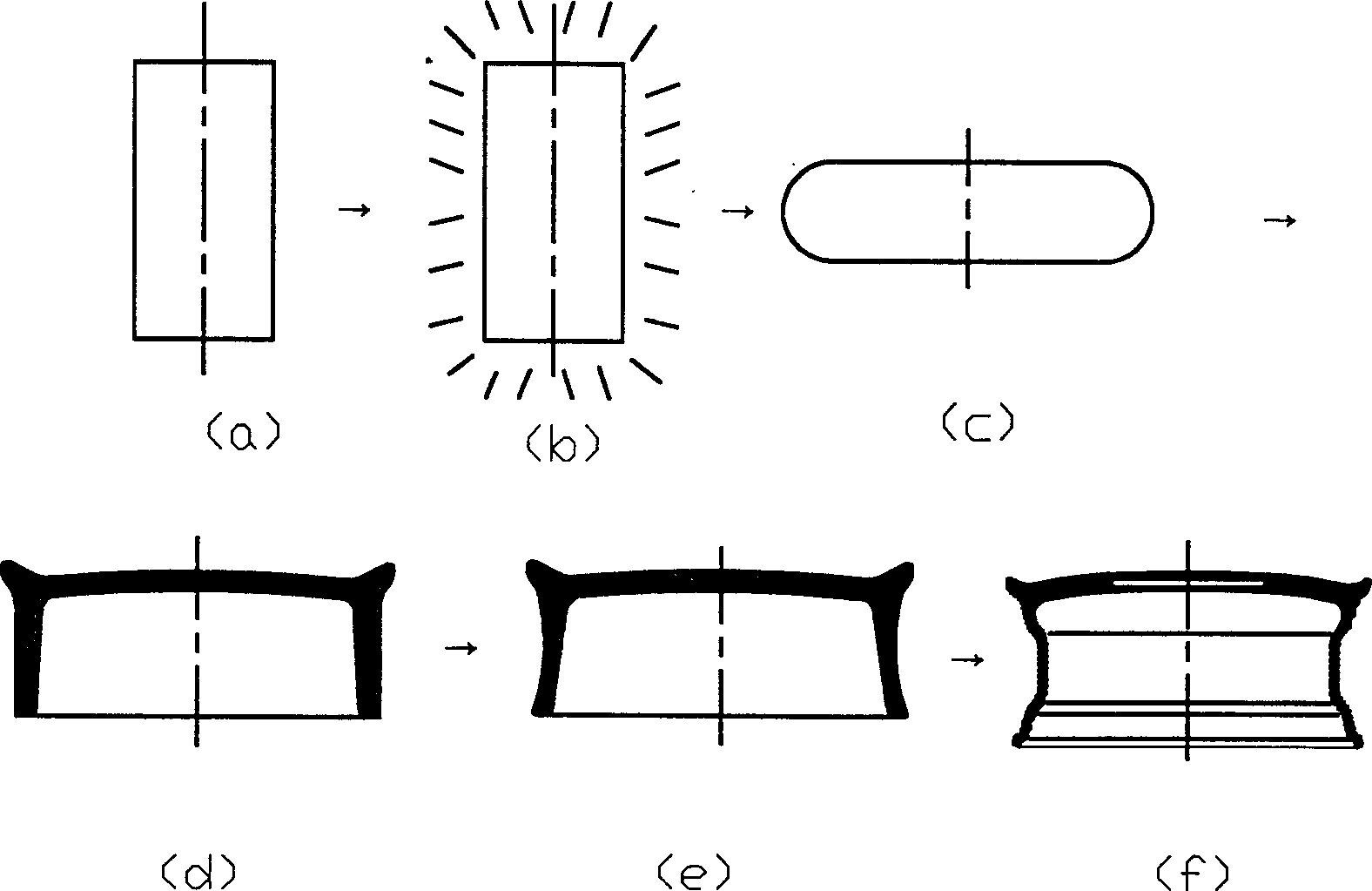

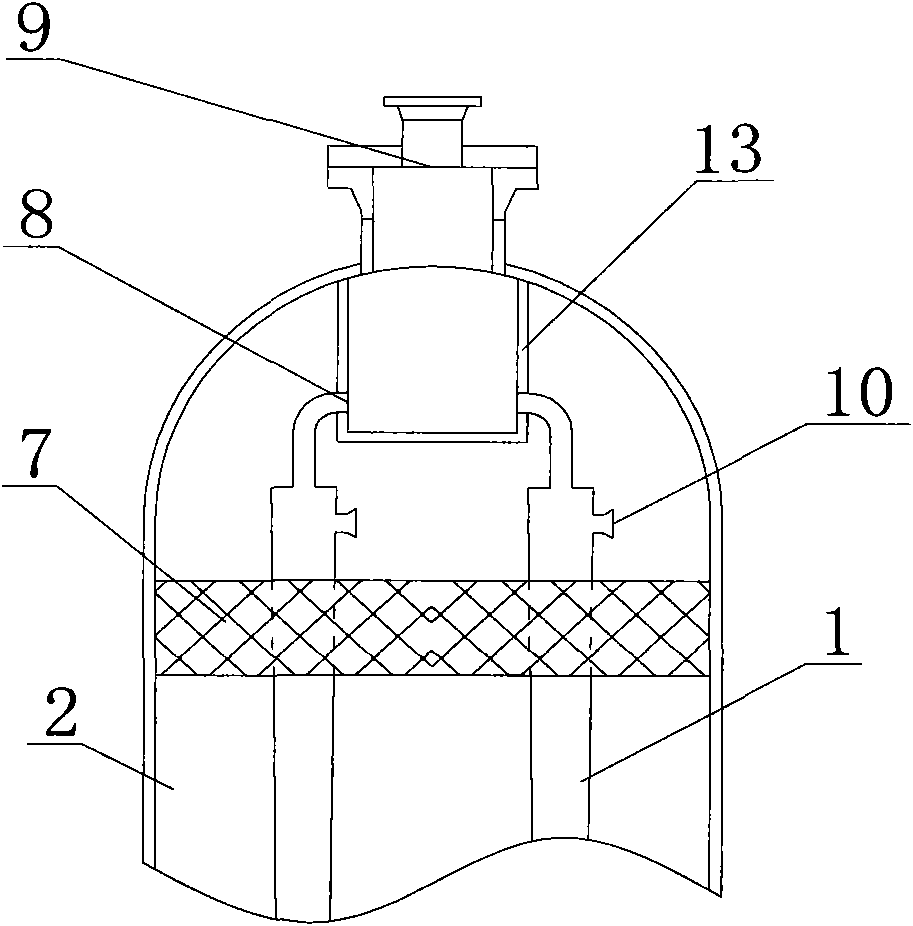

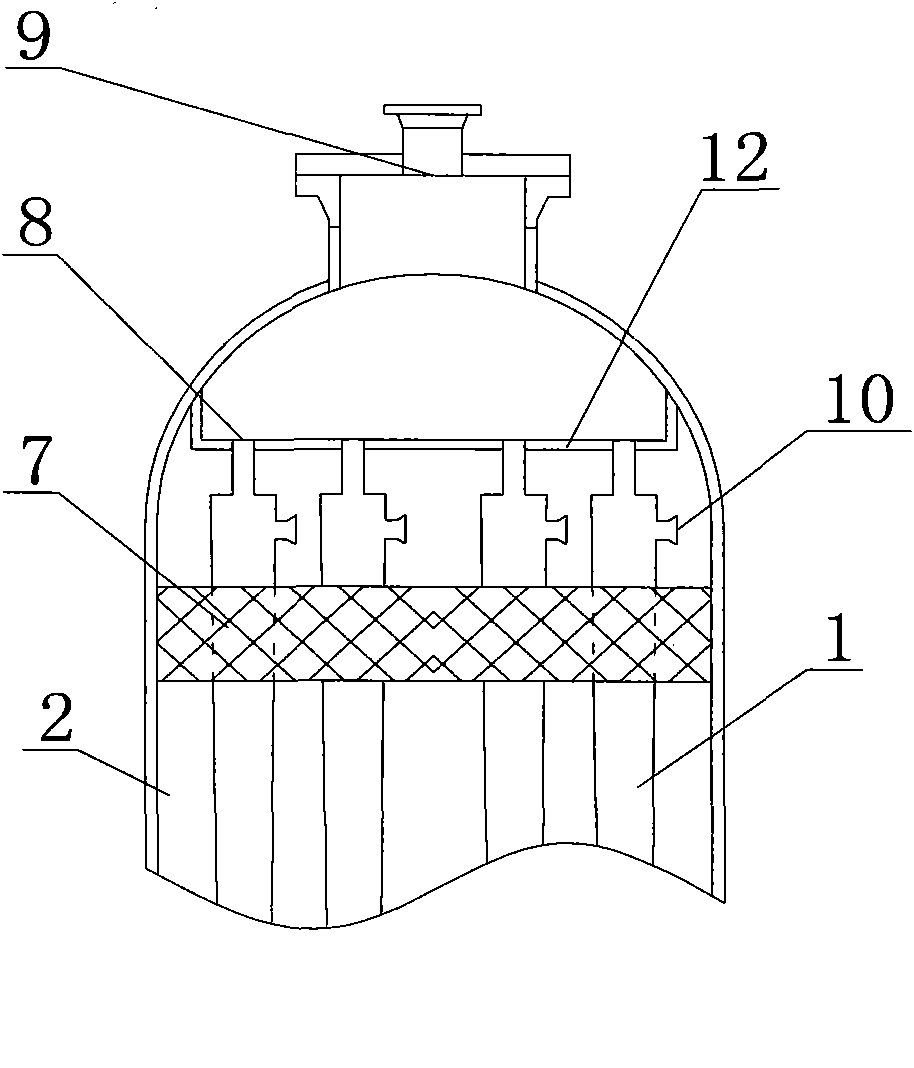

The invention discloses a combined plastic forming method of an automobile hub and a matching forming mold of the automobile hub. The method comprises the following steps of: 1, forming the automobile hub by using light-alloy blanks through a set of forming mold at two steps under the condition of constant temperature, wherein the forming mold is provided with a split lower mold, two upper extrusion male molds and two upper bulging male molds, and the upper extrusion male molds and the upper bulging male molds are sequentially matched with the split lower mold; 2, matching the blanks in the mold by using the upper extrusion male molds and the upper bulging male molds during forming; 3, pre-forming a spoke part of the hub and the lower part of a rim by adopting an extrusion process; 4, forming the upper part of the rim into a hollow pipe blank; and 5, matching the upper bulging male molds with the lower mold and forming a pre-formed part formed in the step 1 into the hub through the extrusion process. Equipment disclosed by the invention has a simple structure, the deformation resistance of each-step process is lower, the mold size and the equipment tonnage are effectively reduced,the production efficiency is improved, and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

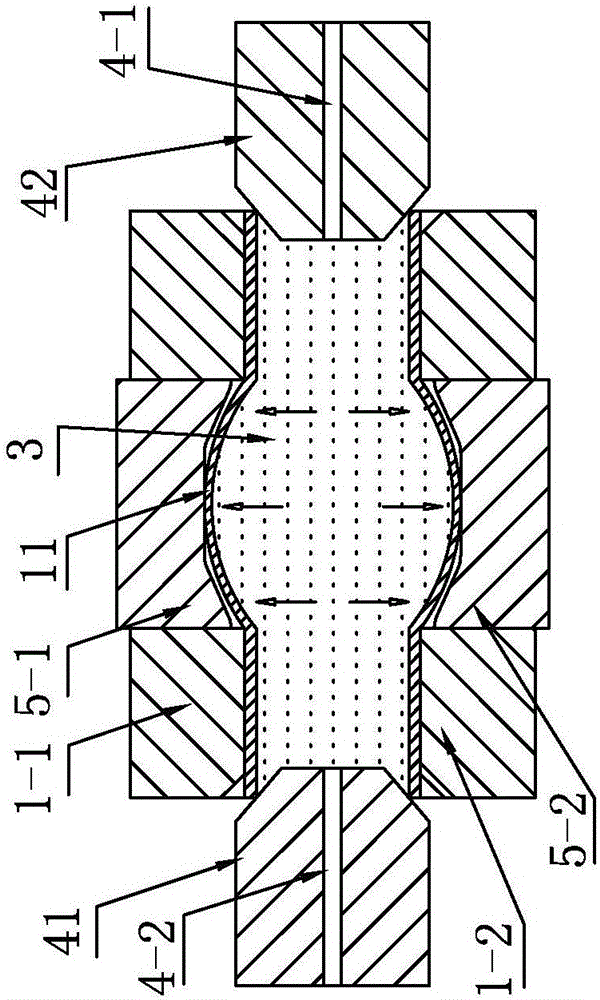

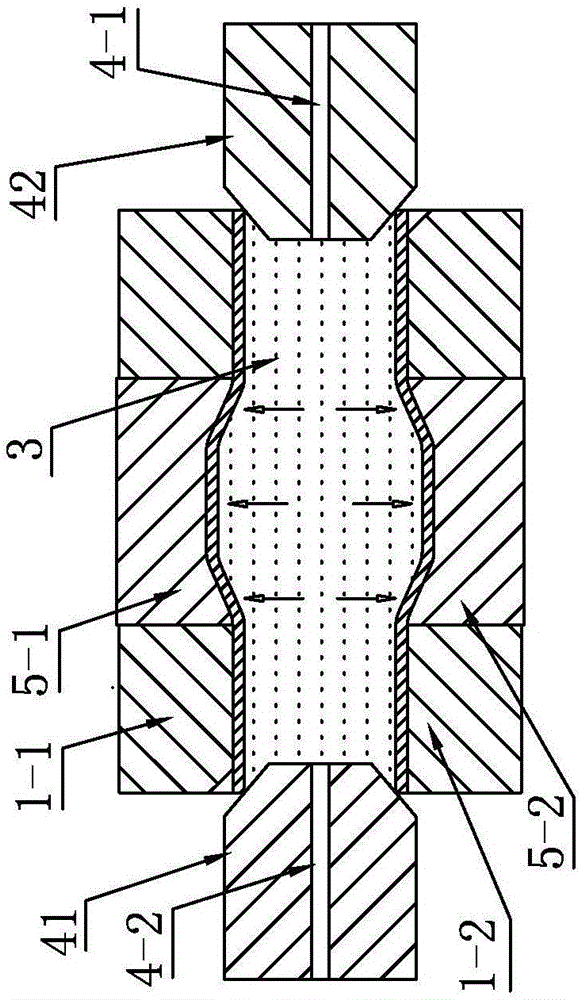

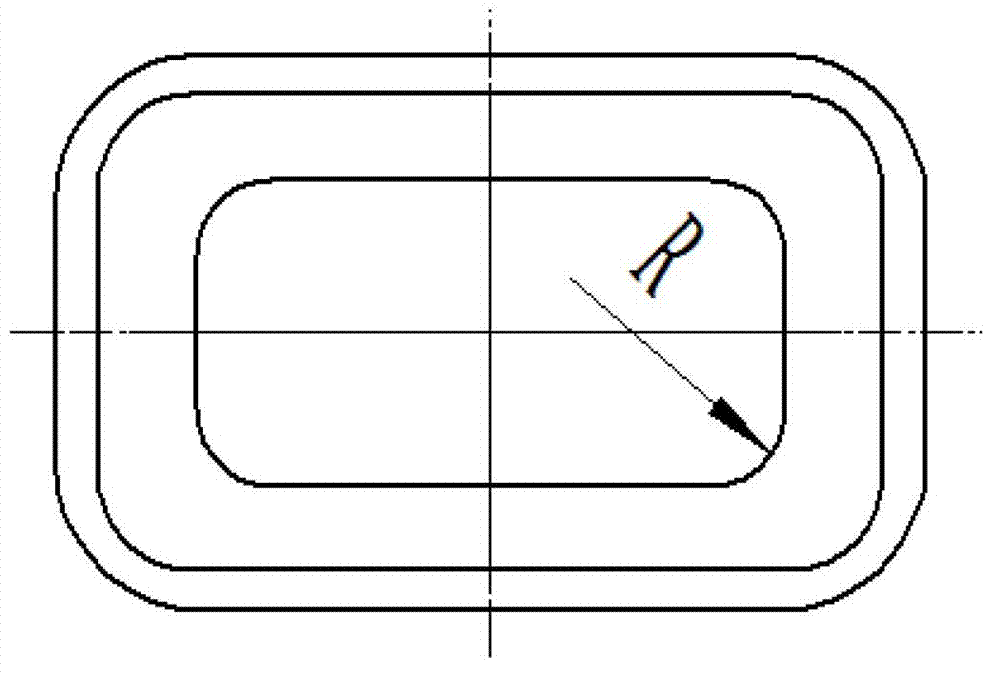

Swelling pressure composite forming method for large-section-difference special-shaped section pipe fitting

The invention provides a swelling pressure composite forming method for a large-section-difference special-shaped section pipe fitting and relates to a forming method for a large-section-difference special-shaped section pipe-shaped part. The swelling pressure composite forming method comprises the main steps that 1, the perimeters and the equivalent diameters of a plurality of cross sections on the to-be-formed large-section-difference special-shaped section pipe fitting are determined, and the structure of a swelling pressure composite forming mold and the inner cavity size and initial position of a side extrusion mold are determined; 2, an equal-diameter circular-section pipe blank with a certain length is cut and put into the swelling pressure composite forming mold; 3, the equal-diameter circular-section pipe blank is filled with a pressure medium with a certain pressure through a pressure medium inlet, and a variable-diameter circular-section pipe blank is obtained through swelling; 4, the side extrusion mold is driven to extrude the variable-diameter circular-section pipe blank, and the large-section-difference special-shaped section pipe fitting is obtained; and 5, the pressure is released, and after the swelling pressure composite forming mold is opened, the formed pipe fitting is taken out. The swelling pressure composite forming method is used for forming large-section-difference special-shaped section pipe fittings.

Owner:HARBIN INST OF TECH

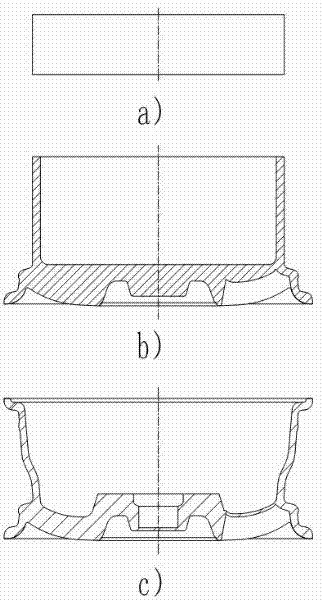

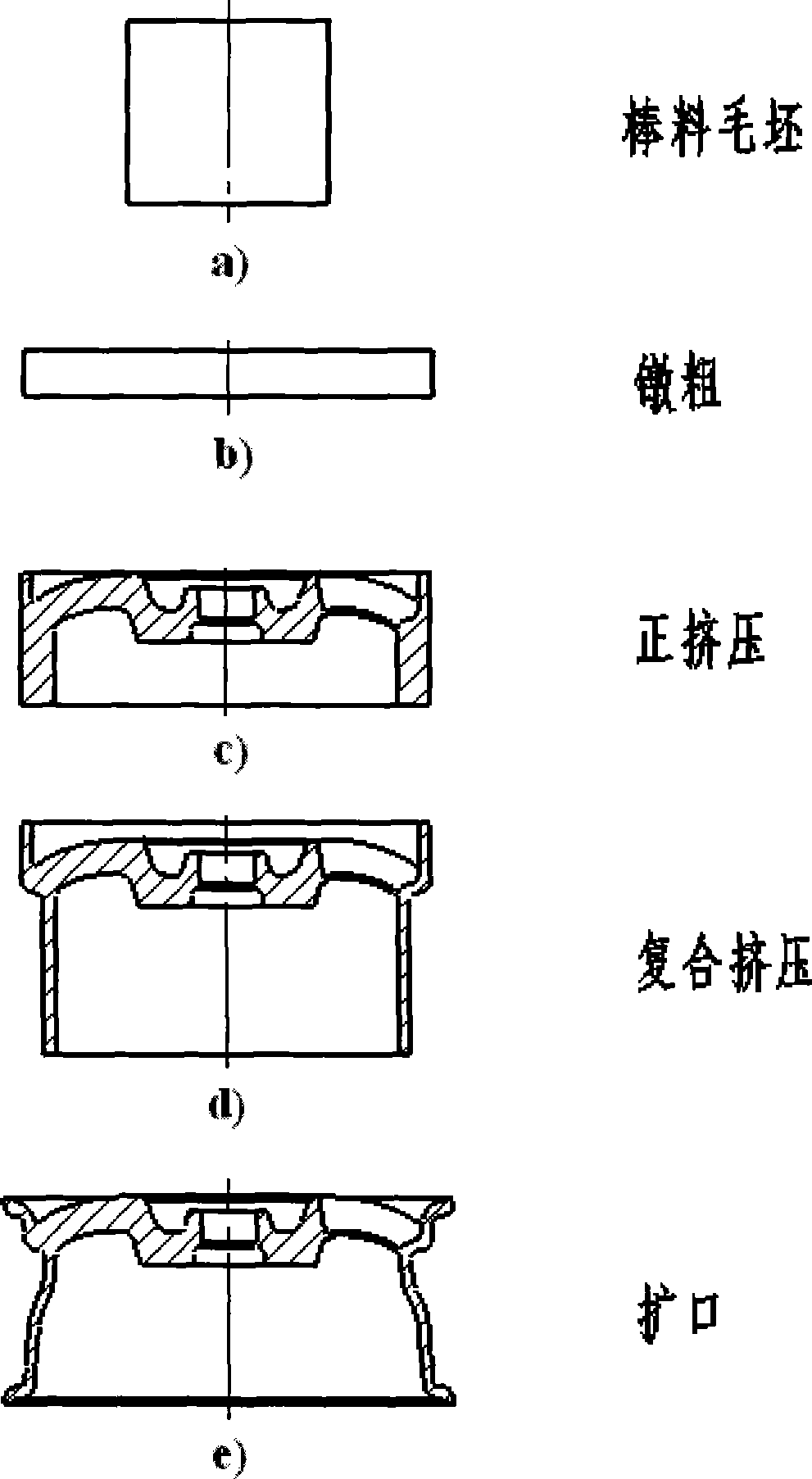

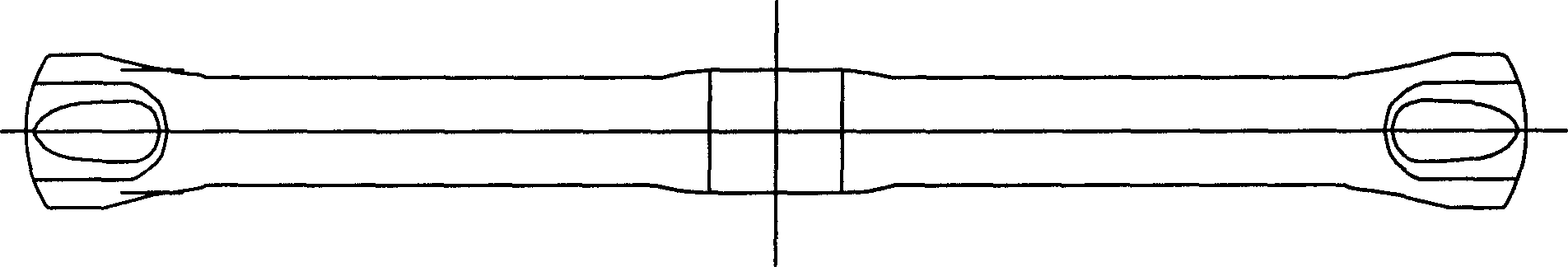

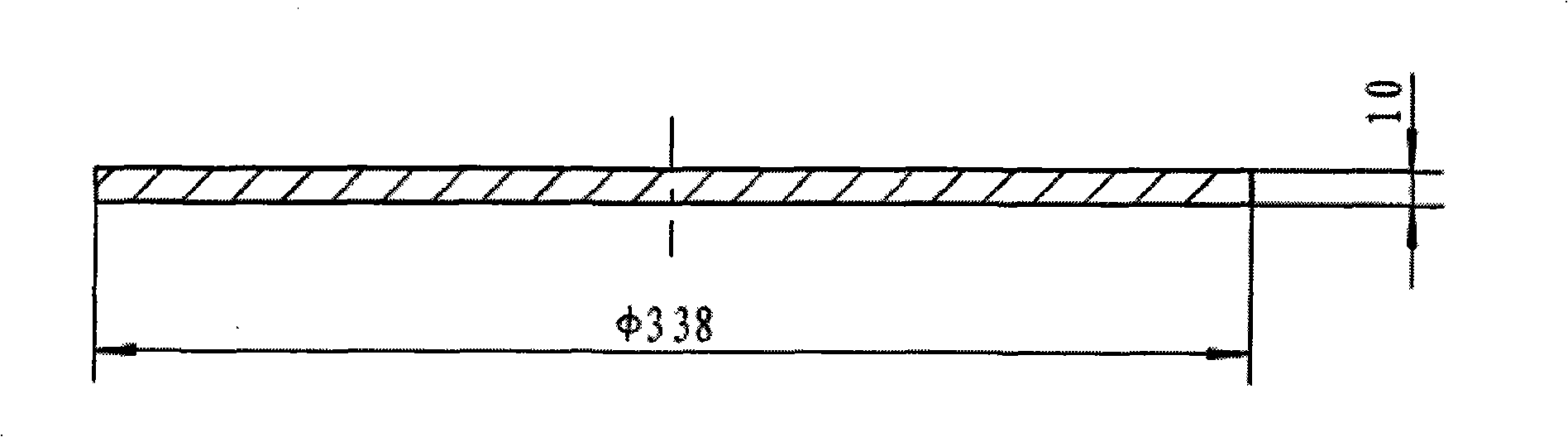

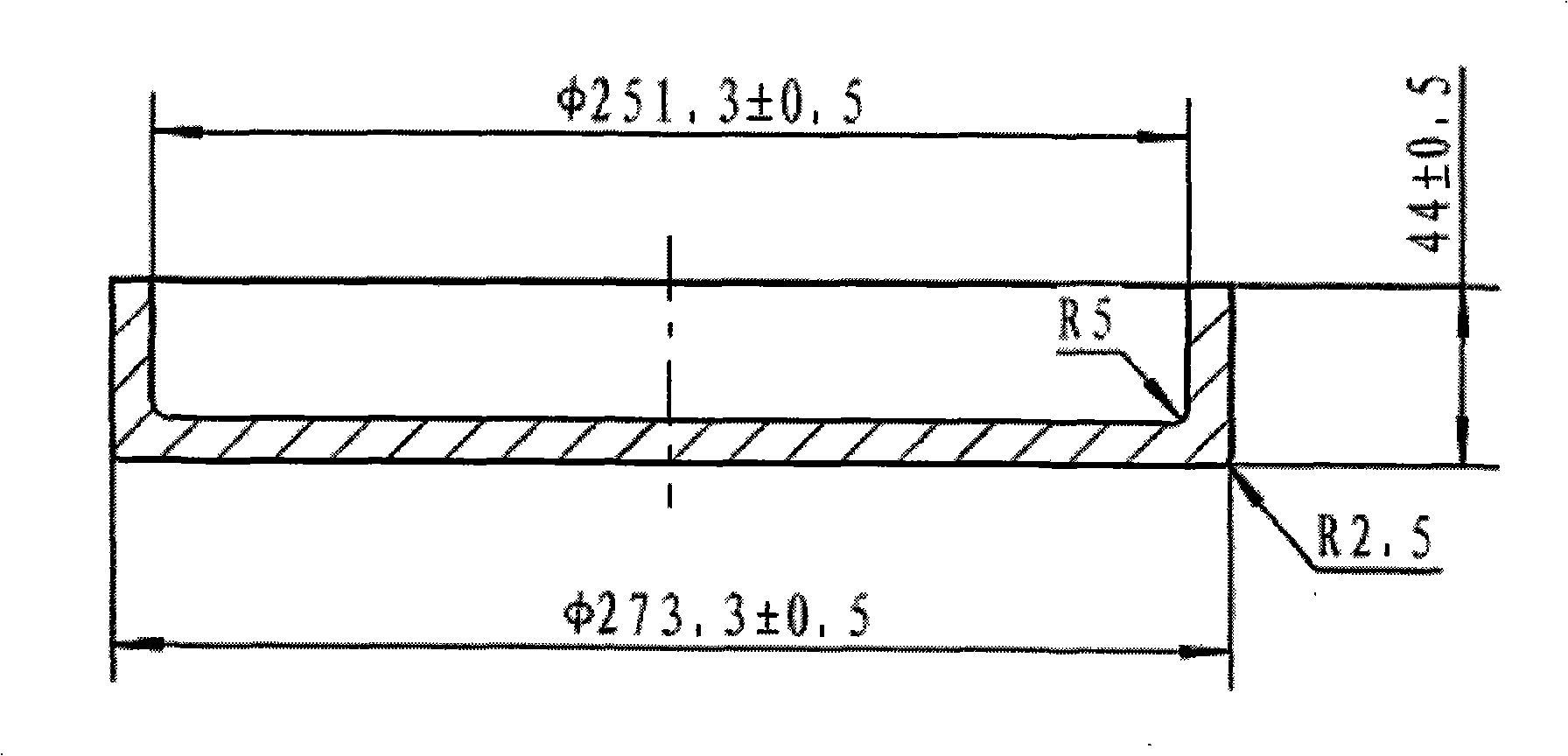

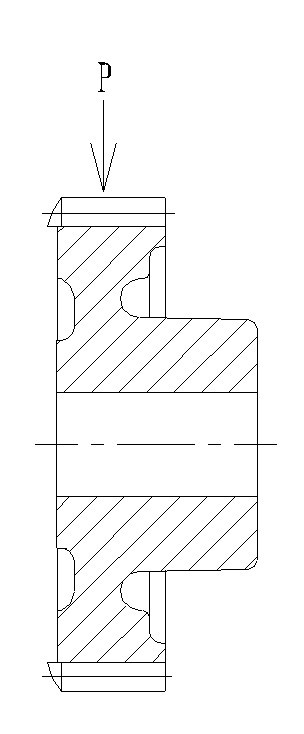

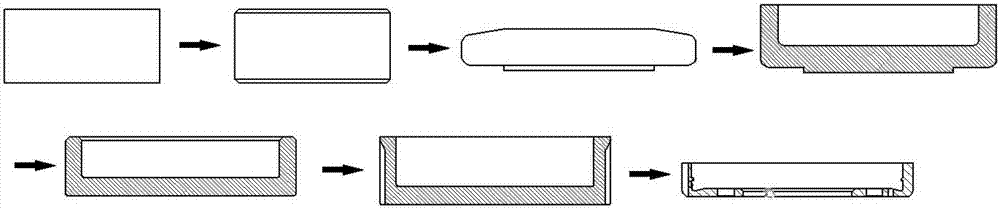

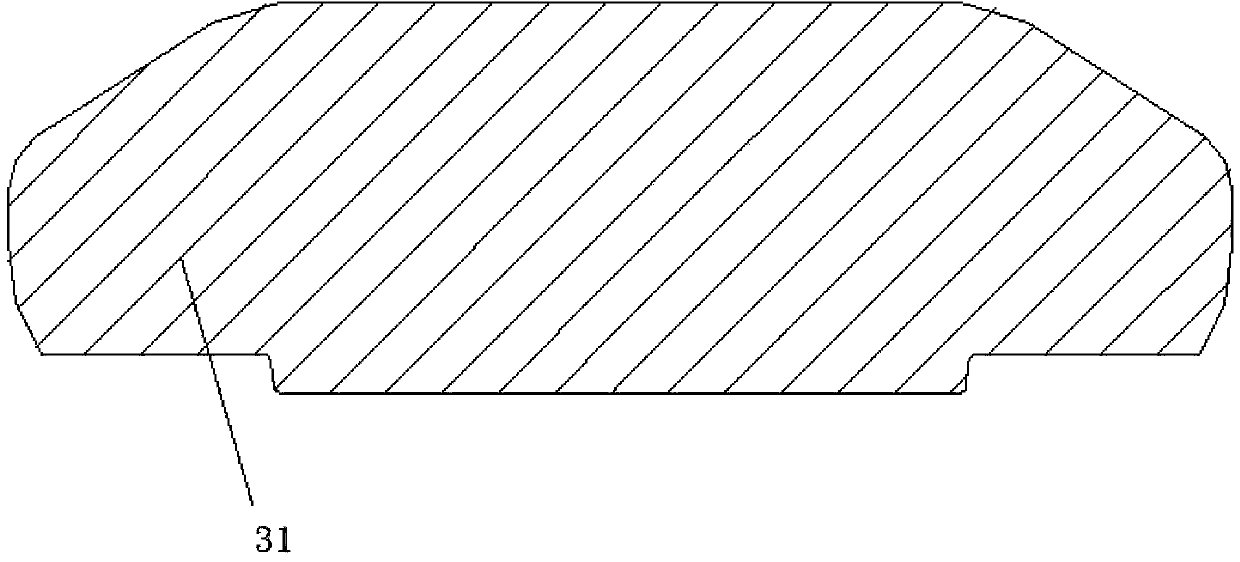

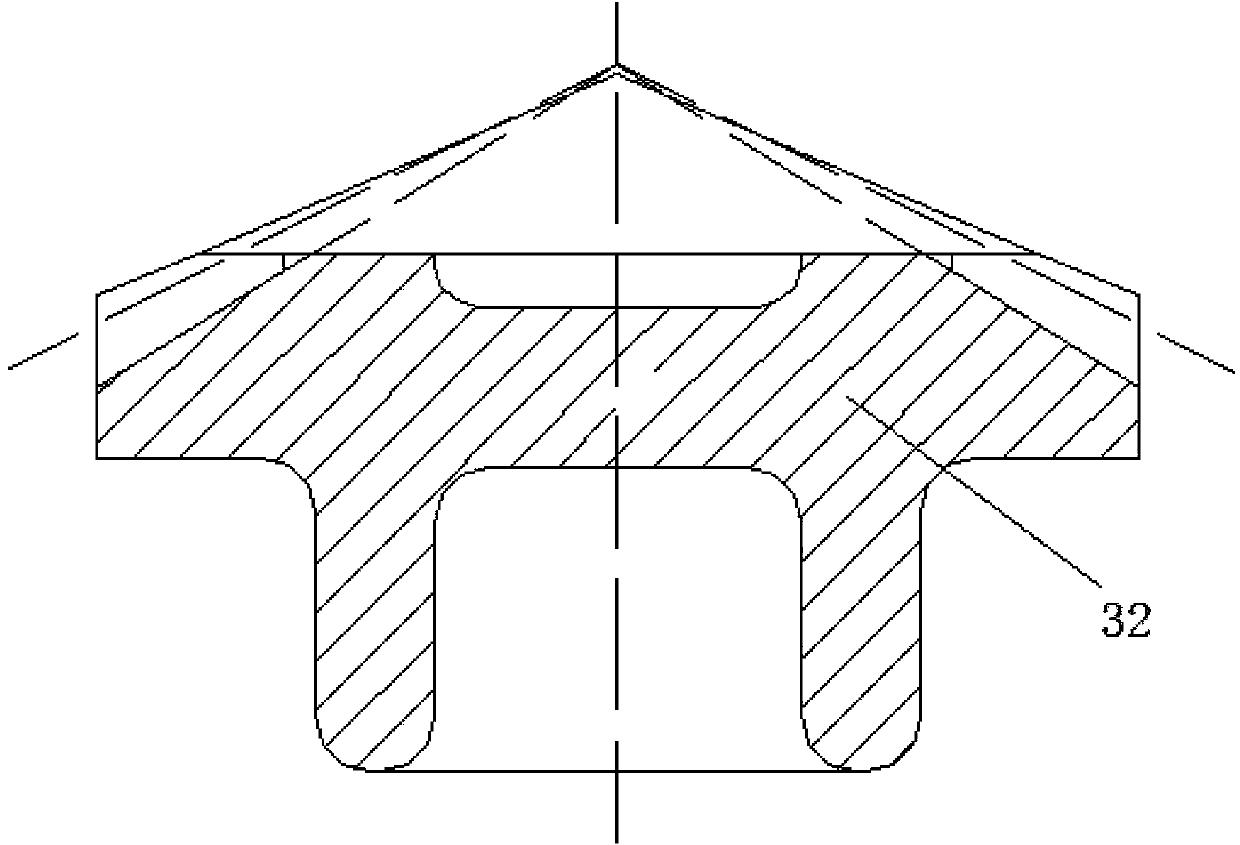

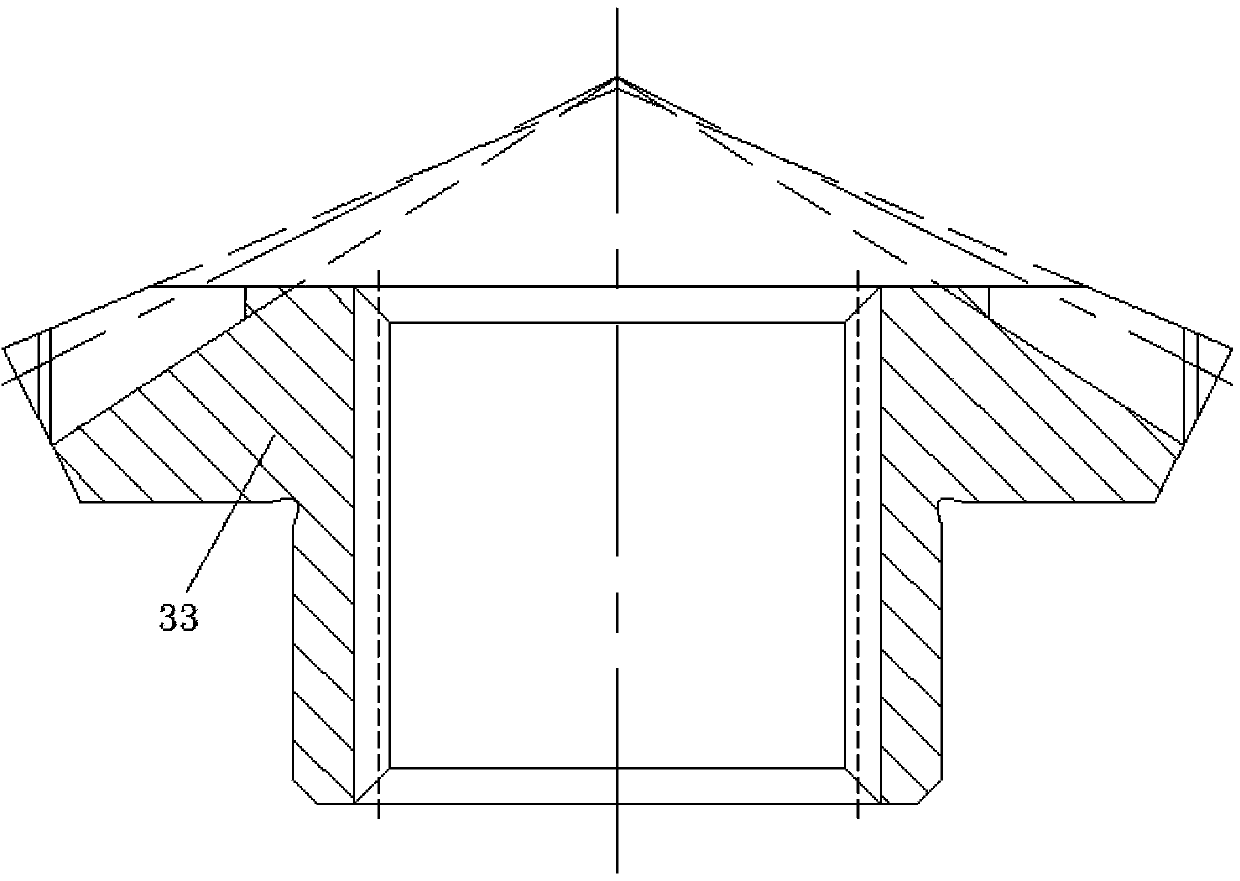

Press forming method of automobile hub and matched forming mold thereof

The invention relates to an extrusion forming method for a wheel hub of an automobile, and an extrusion piece for the wheel hub is formed by adopting work division procedures isothermally. The method comprises the following steps: a biscuit which has the same outside dimension as the outside dimension of the wheel hub to be formed is taken, and is subjected to processing and forming through forward extrusion, combined extrusion and a flaring procedure in sequence, wherein the forward extrusion forms a wheel arm and enables the rest metal to be gathered evenly in the peripheral positions of the wheel arm preliminarily; the combined extrusion pre-forms a barrel-shaped wheel rim and the upper and the lower wheel flanges of the wheel rim; and the flaring process enables the wheel rim to be formed. The invention further relates to three sets of moulds, which include a forward extrusion and forming mould, a combined extrusion and forming mould and a wheel rim flaring mould. The technical proposal of the invention can reduce the forming force, save the investment of the equipment and the mould, lower the production cost, and improve the quality of forming products.

Owner:HENAN UNIV OF SCI & TECH

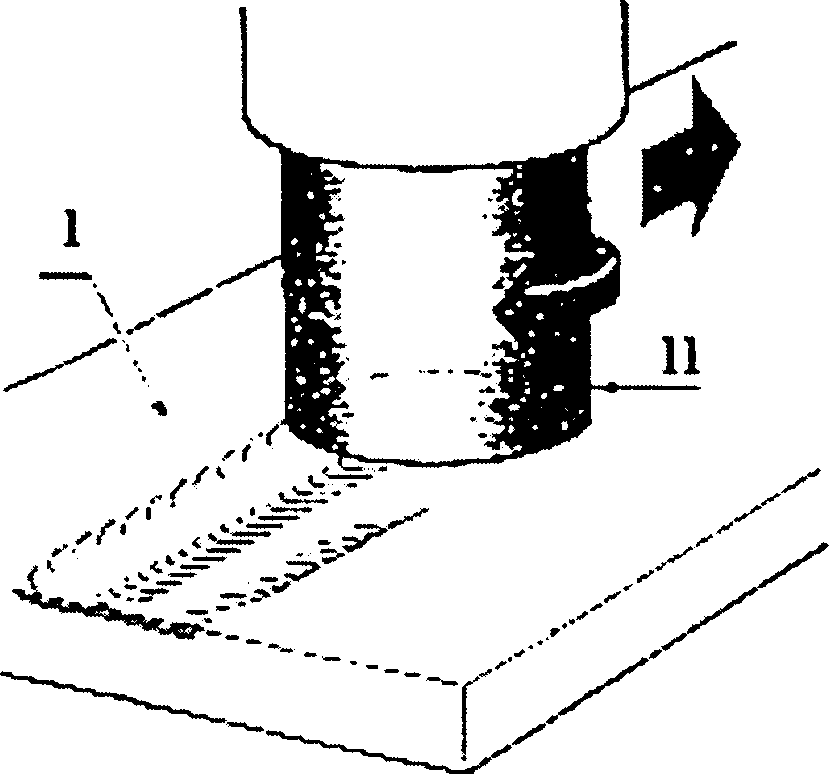

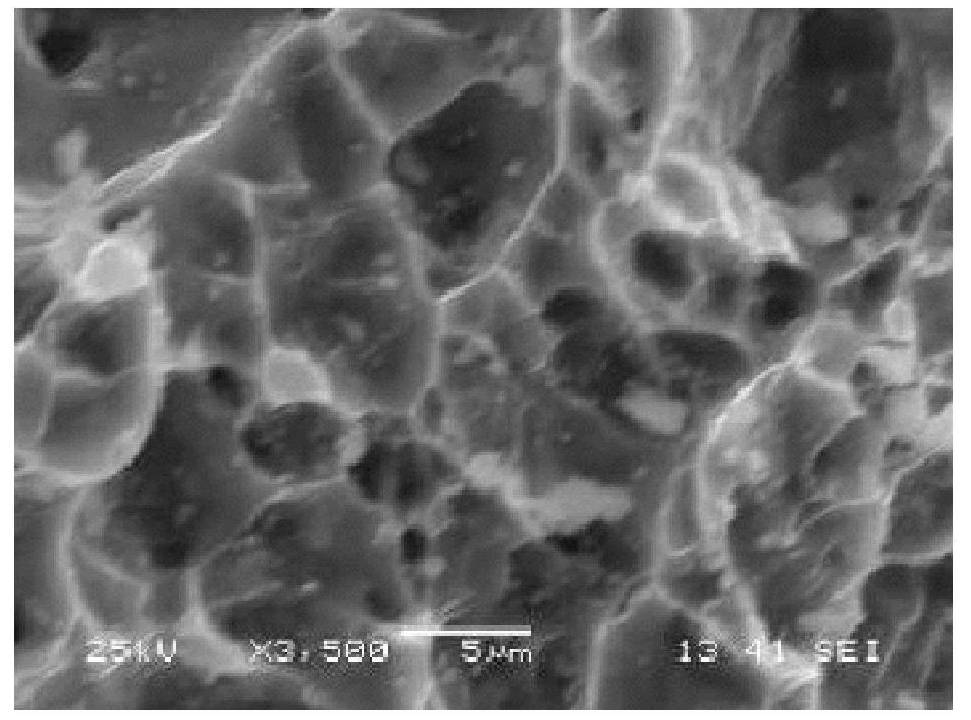

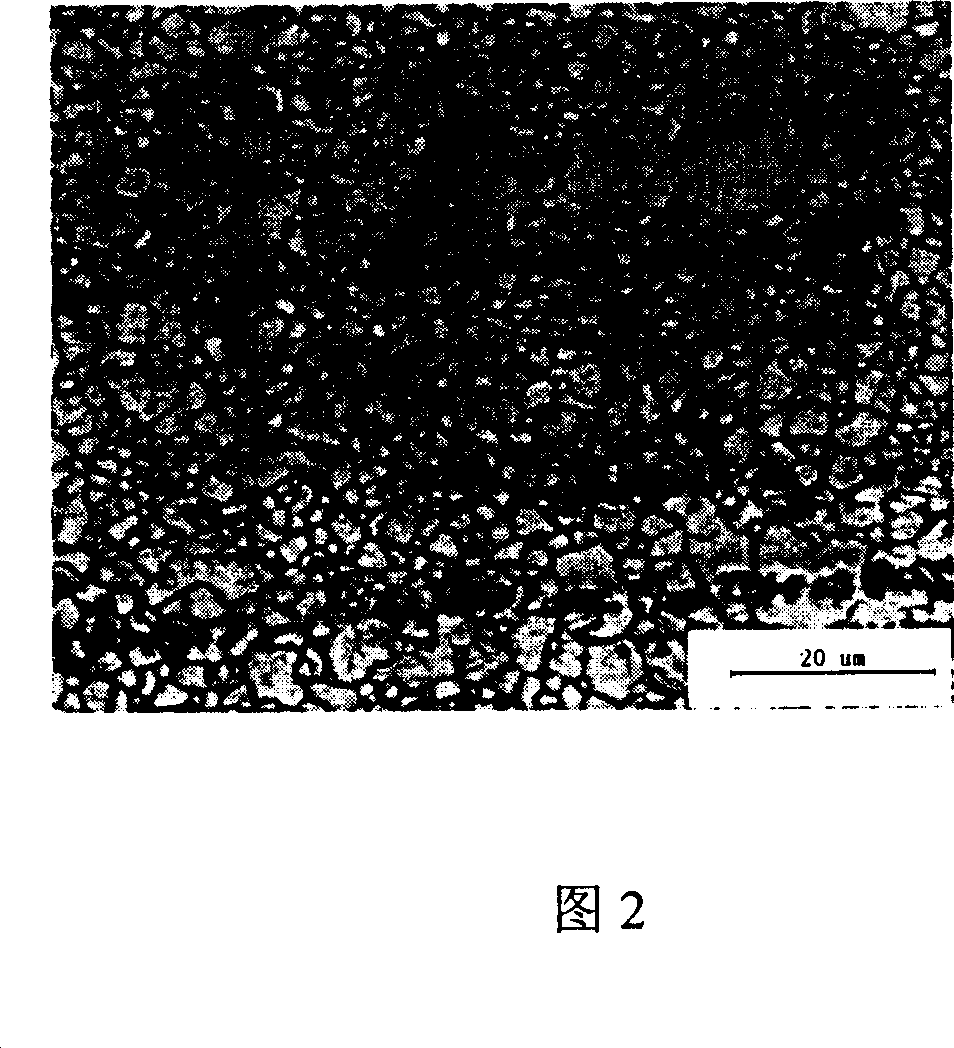

Method for preparing super fine crystal material

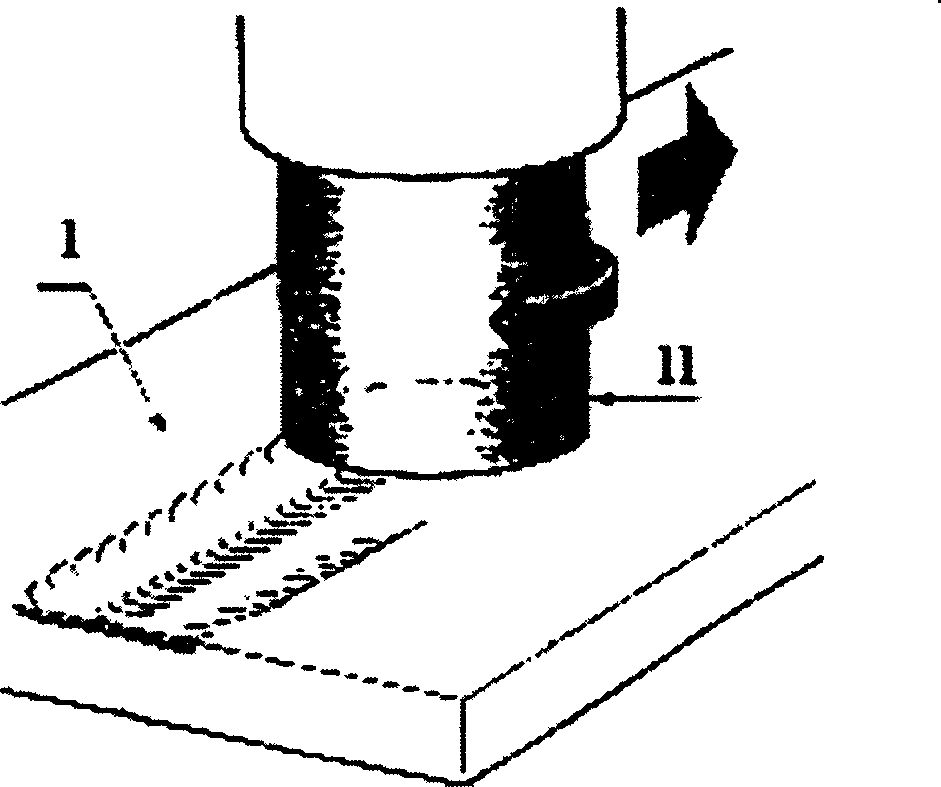

A process for preparing large-area or rod-shaped ultrafine-grain crystal material by the transfer method in strong deformation region features that A pression-torsion head pressing on a planar metal material is rotating at a certain speed while transversely moving to treating the surface of the material line by line, breaking the metallic crystal grains and generating large-area ultrafine-grain crystal material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

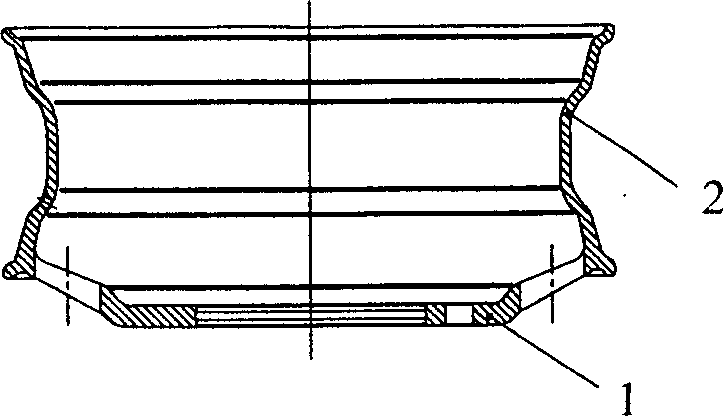

Forging and rotary extrusion forming process for aluminium alloy wheel

InactiveCN1827289AQuality improvementLight in massMetal-working apparatusMaterial consumptionRotational molding

The invention relates to a forging aluminum alloy wheel forging-rotational molding method, which combines the forging and rotational compressing techniques. In forging, molding part of spoke of wheel, and pre-molding the rim; then in rotational compressing, rotationally compressing the rim to complete the molding. Wherein, the rim is molded by forging, and the rim is mainly molded by rotational compression. The invention can combine the forging and rotational compression to express their advantages. And the inventive aluminum alloy wheel has better quality, high accuracy, less finish allowance, higher strength, and reduced material consumption.

Owner:JIAXING STONE WHEEL

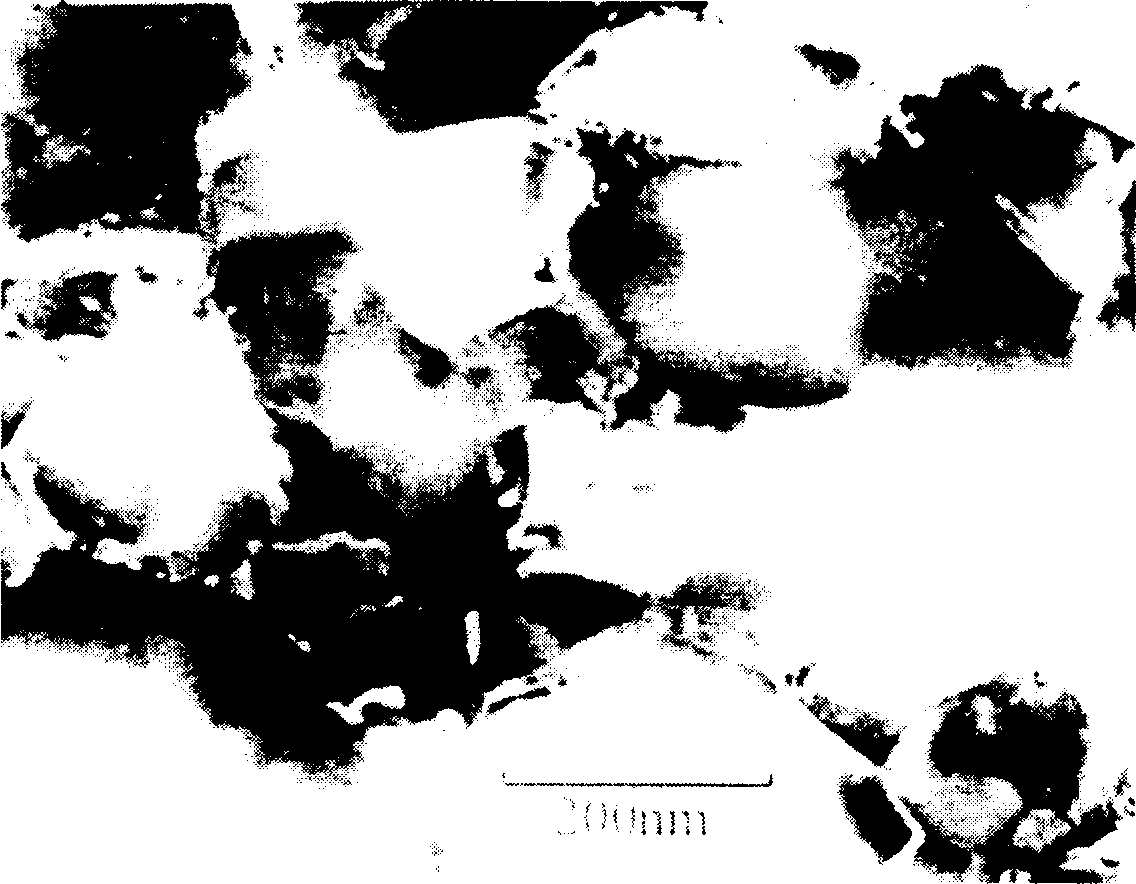

Prepn of columnar superfine crystal material

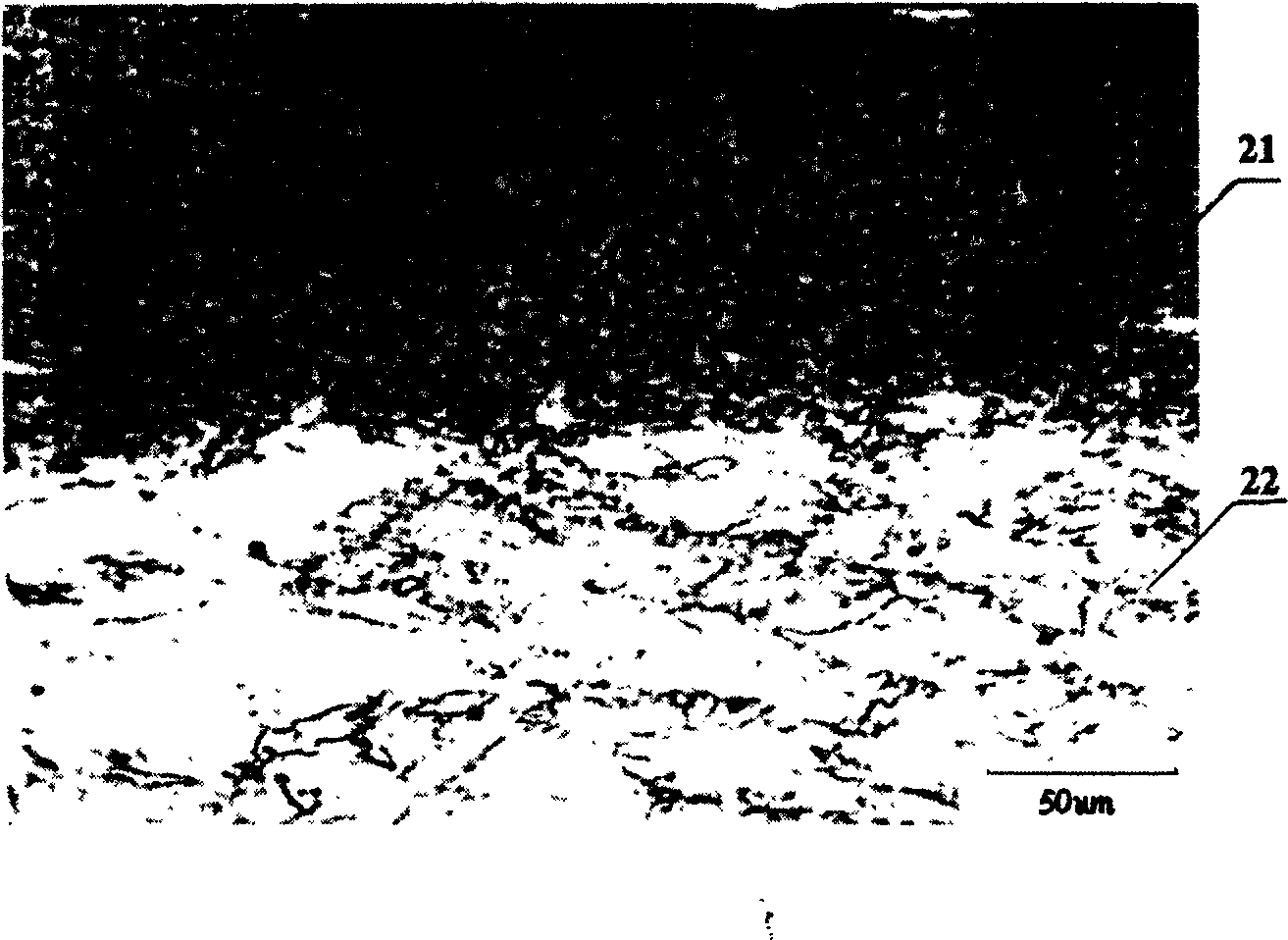

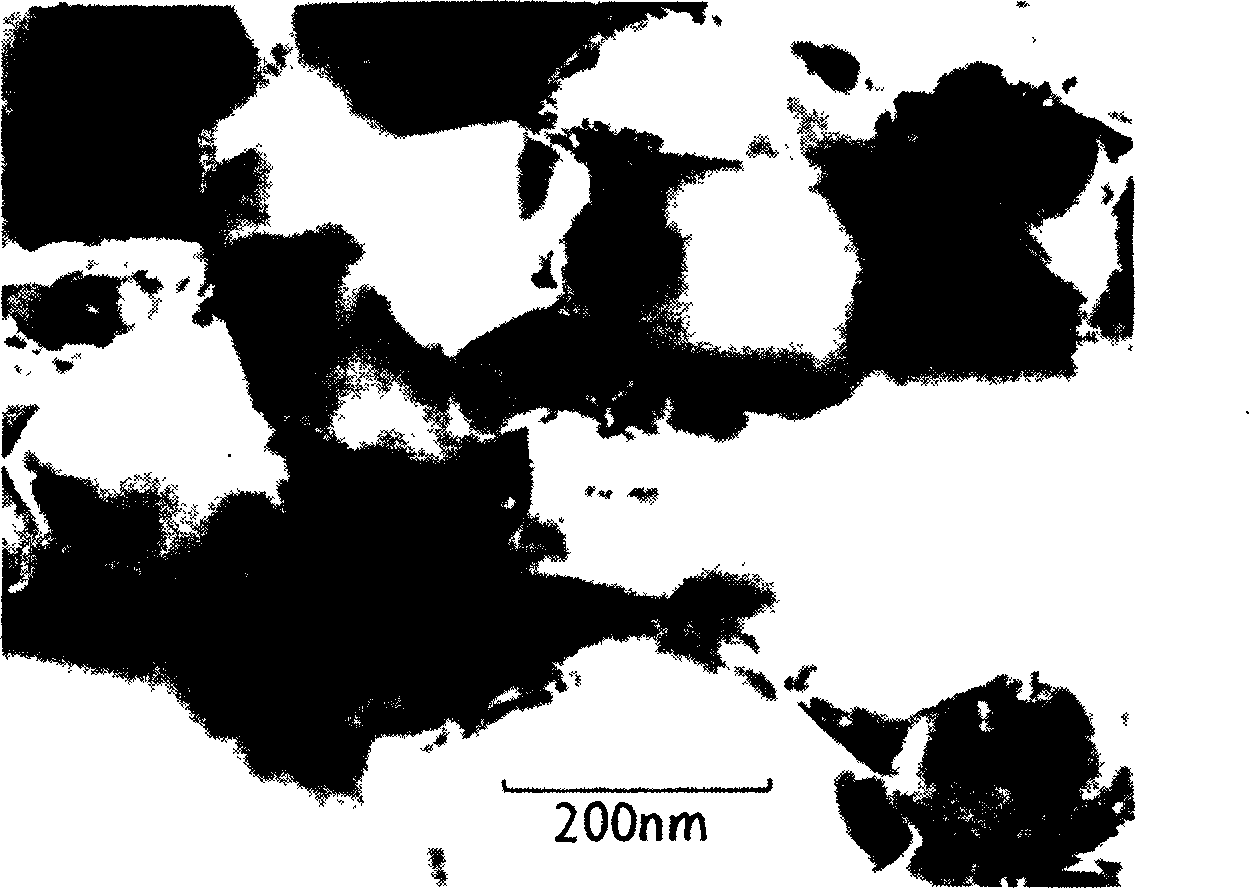

The preparation process of columnar superfine crystal material features that the rod metal material to be fined is set inside cooled sleeve, made to contact with the bottom tightly, driven to rotate at high speed and applied with certain pressure, while cooling water is introduced into the cooling sleeve, so that the rod metal material at the contact surface produces intense shearing plastic deformation and torsion deformation layer with fragmentated crystal grains. Owing the torsion deformation layer has the upper side temperature higher than lower side temperature, the torsion deformation layer is transferred from the initial friction surface to upper side high temperature area to form superfine crystal material piling layer in the lower part, and the torsion and cooling is continued until forming complete superfine crystal material. The columnar superfine crystal material is then annealed. The present invention has high deformation and low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

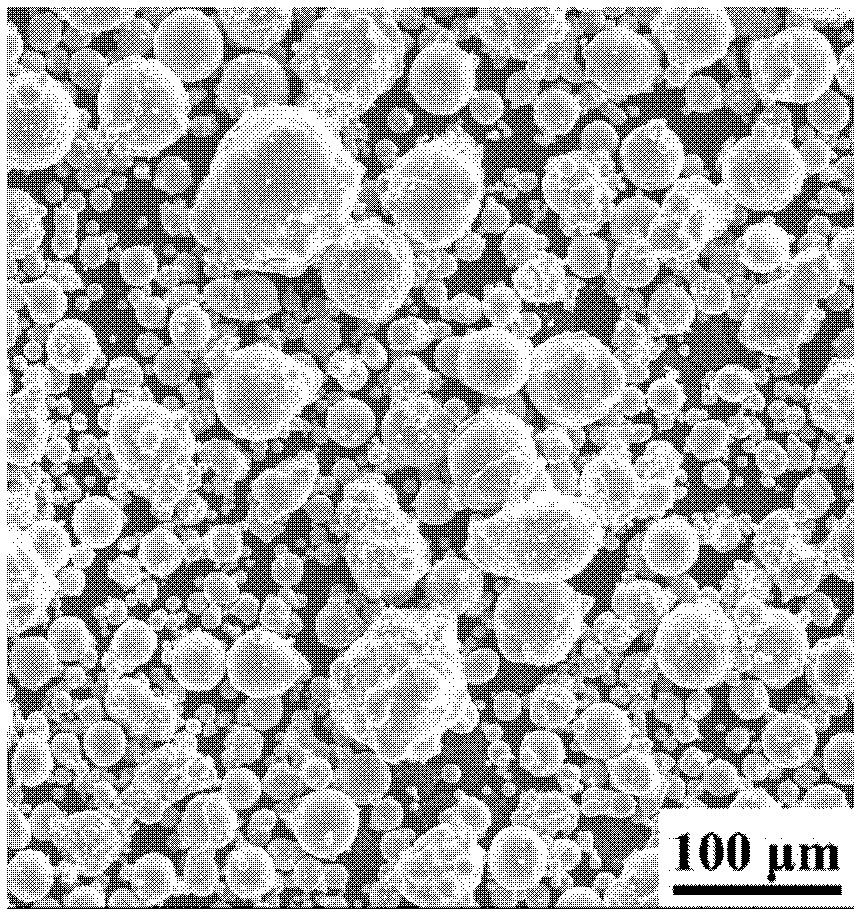

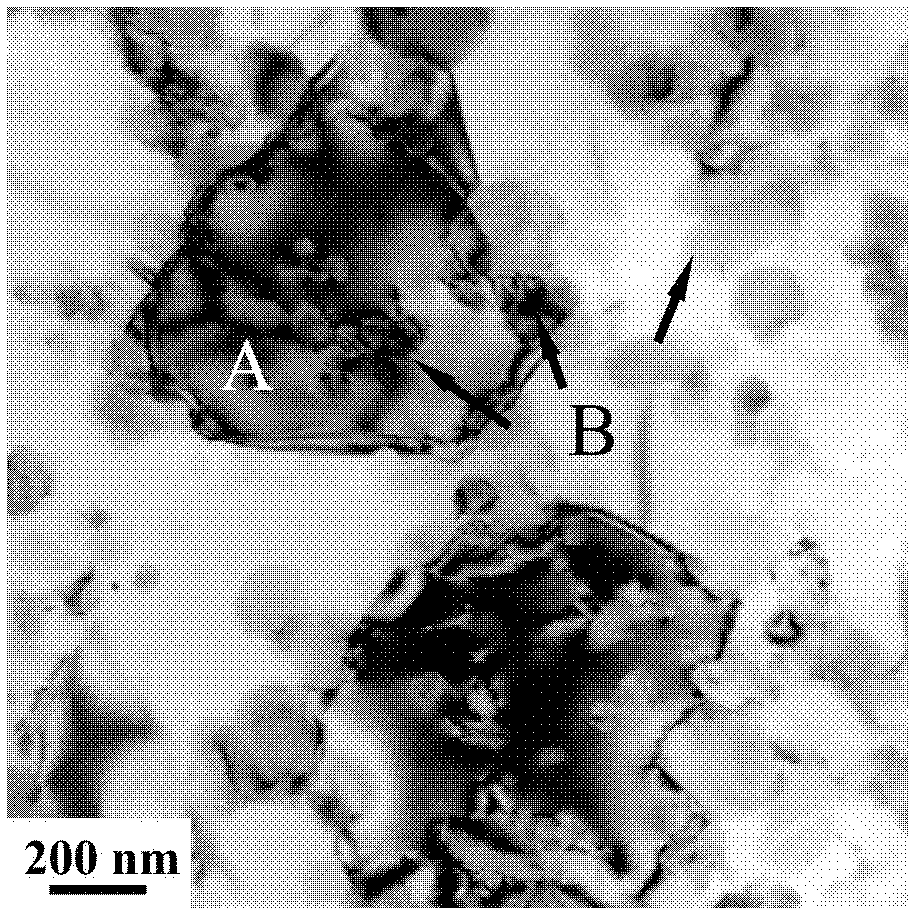

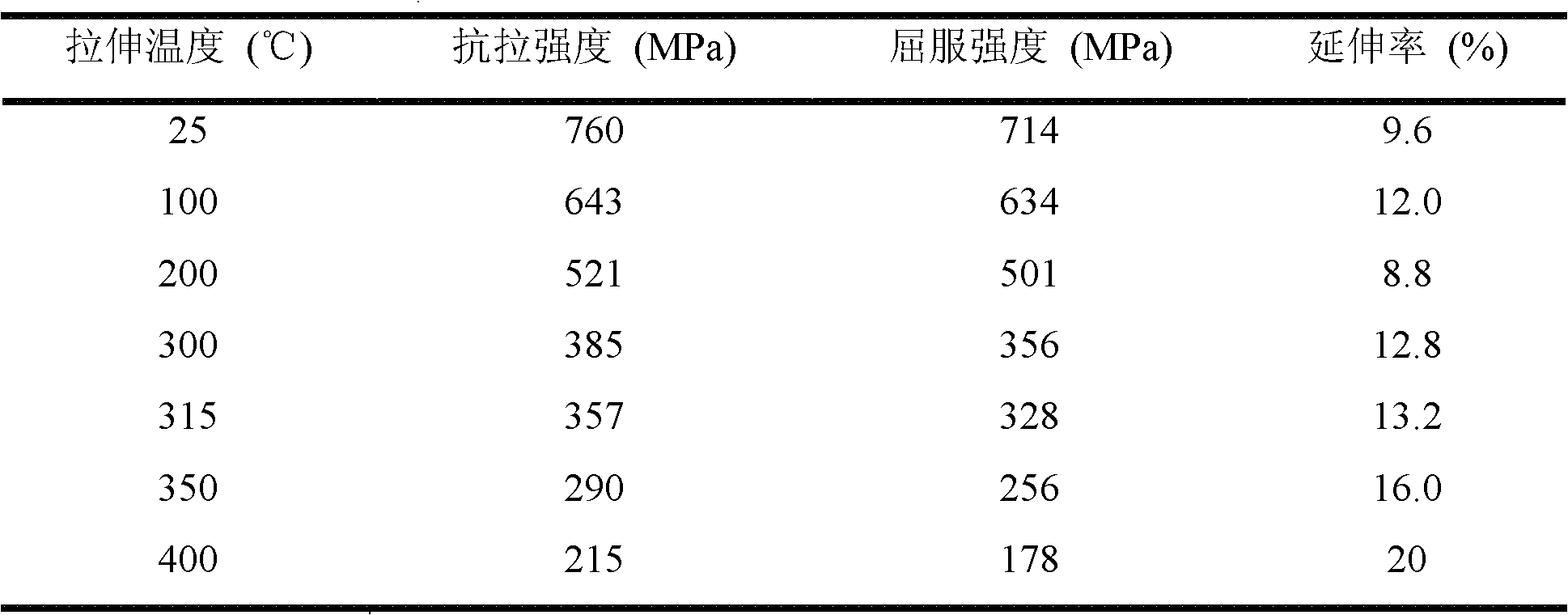

Preparation method of nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet

InactiveCN102660716AExcellent high temperature mechanical propertiesImprove corrosion resistanceNanoparticleRoom temperature

The invention relates to a preparation method of an aluminum alloy sheet, particularly a preparation method of a nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet. The invention aims to solve the problems of complex technique, high cost and multiple defects in the existing method for preparing the compacted large-size aluminum alloy sheet, and the problem of poor mechanical properties of the prepared Al-Fe-Cr-Ti-Re alloy sheet at room temperature and high temperature. The method comprises the following steps: proportioning materials, and preparing spherical alloy powder from the refined and degassed melt by a gas atomization method; and sequentially carrying out cool isostatic pressing, canning vacuum degassing, hot isostatic pressing, hot extrusion and rolling on the alloy powder to obtain the nanoparticle-reinforced Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet. The invention is mainly used for preparing the Al-Fe-Cr-Ti-Re heat-resistant aluminum alloy sheet.

Owner:HARBIN INST OF TECH

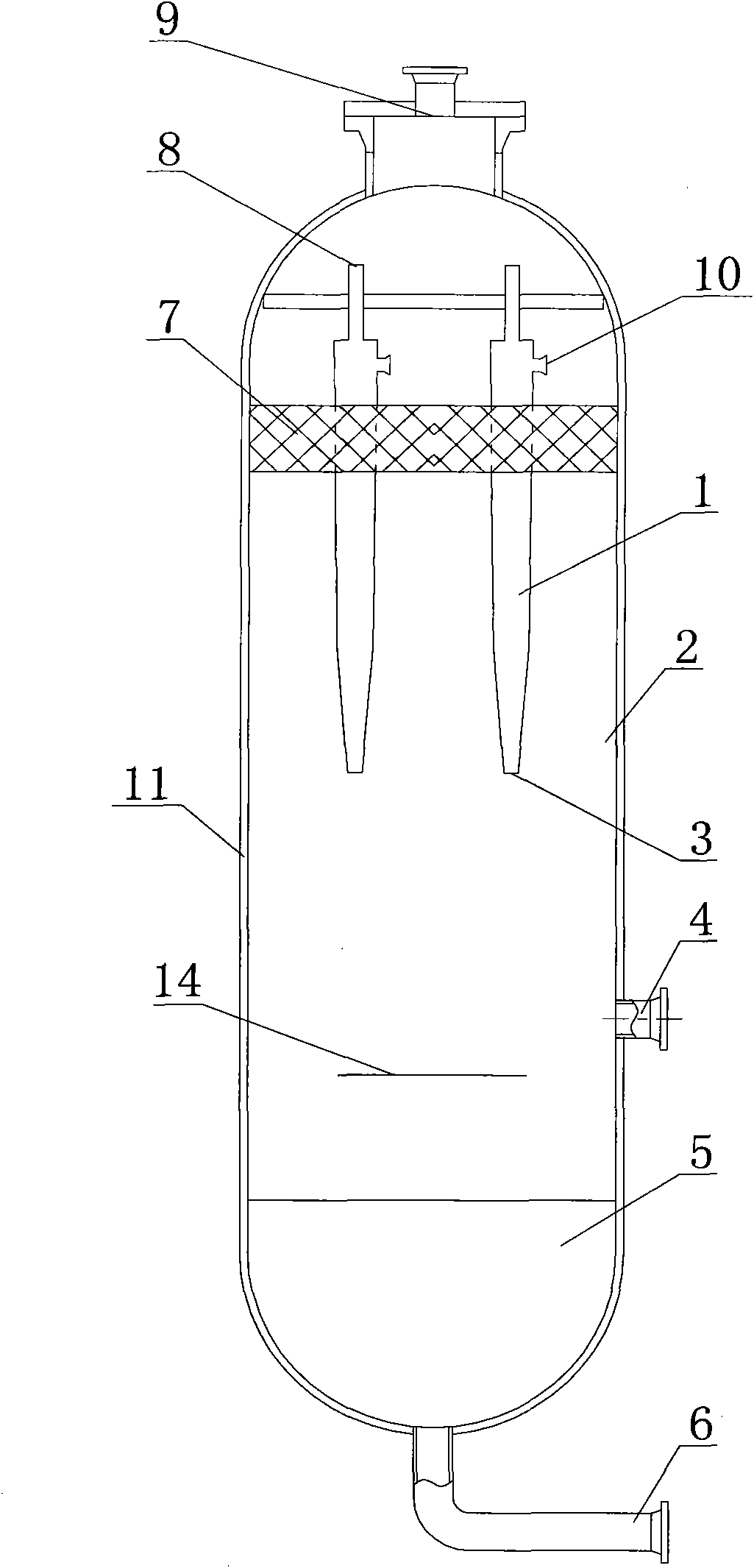

High-pressure separator and method for high-pressure separation

InactiveCN102380262AOvercoming liquid in gas mixtureOvercome the cycleCombination devicesGaseous fuelsCycloneVapor–liquid separator

The invention discloses a high-pressure separator and a method for high-pressure separation, and is characterized in that: a cyclone gas-liquid separator is disposed on the middle-upper part of a housing of the high-pressure separator; the cyclone gas-liquid separator is connected to the housing of the high-pressure separator through a column tray plate or a gas-collecting pipe; mixed gas entering the high-pressure separator is cyclone-separated by the cyclone gas-liquid separator; after oil, water and few solid particles are removed, the gas is discharged from the high-pressure separator. The invention can reduce the gas phase molecular weight of the high-pressure separator, eliminate physical factors which cause foaming of desulfurizers in a desulfurization tower, and prolong the continuous operation period of the whole device.

Owner:CHINA PETROLEUM & CHEM CORP +2

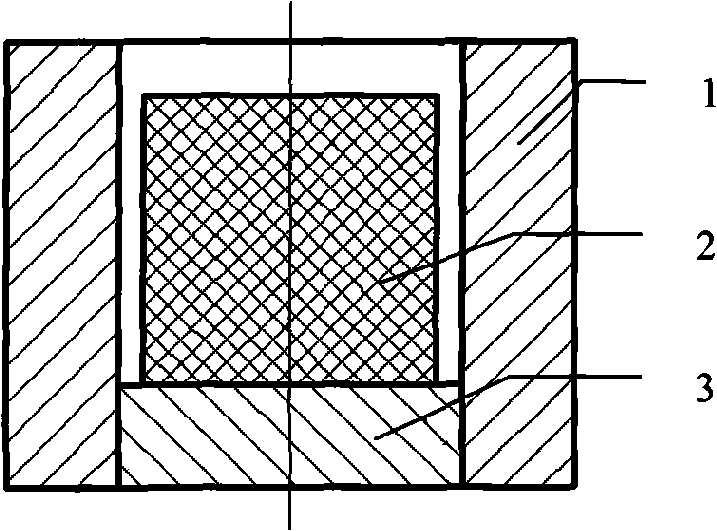

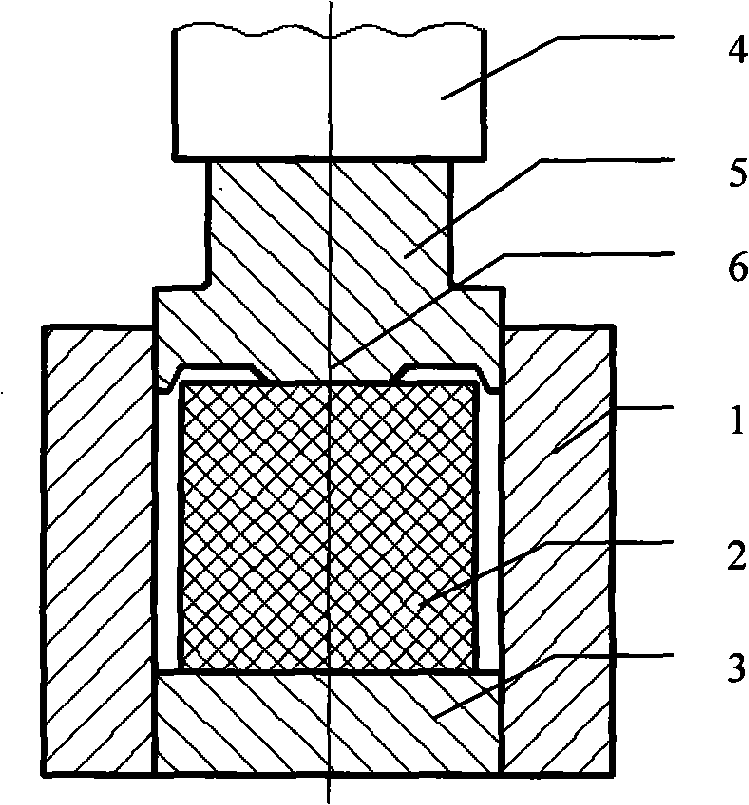

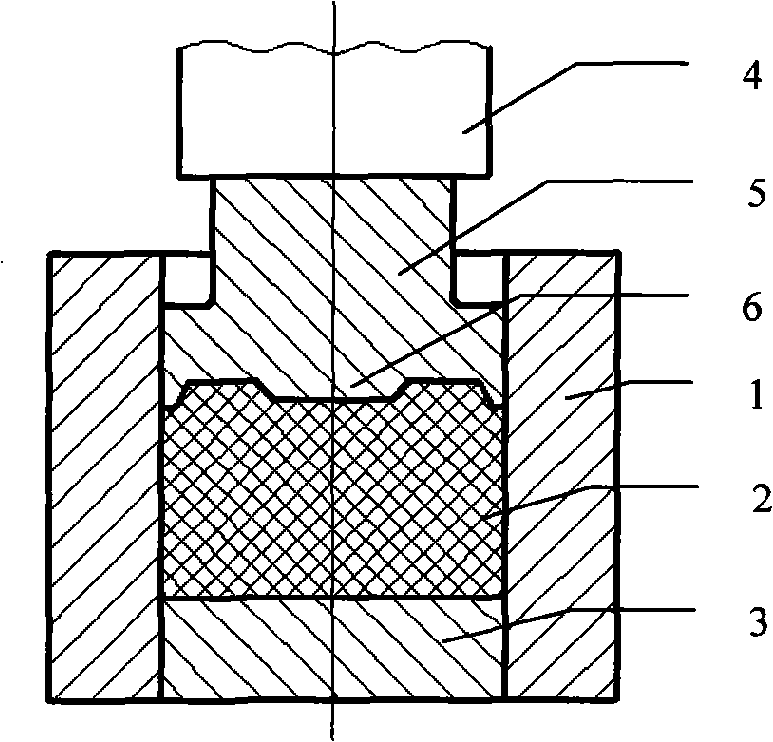

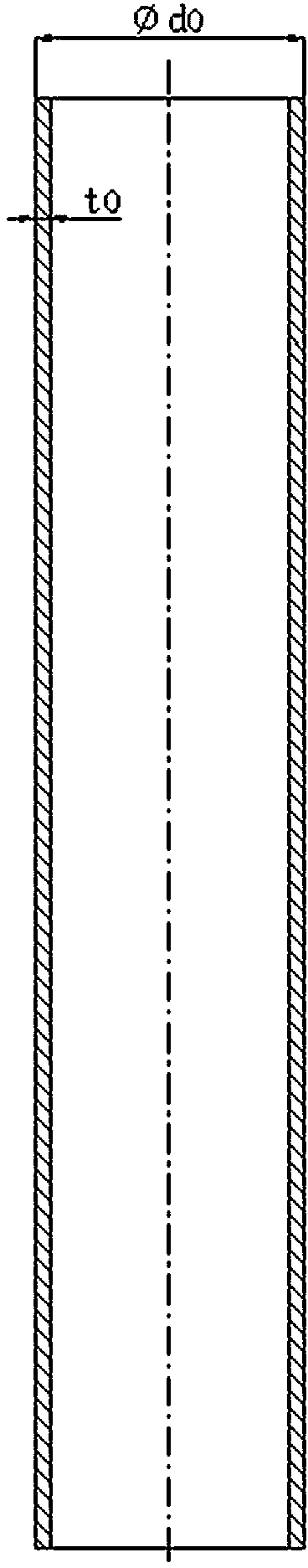

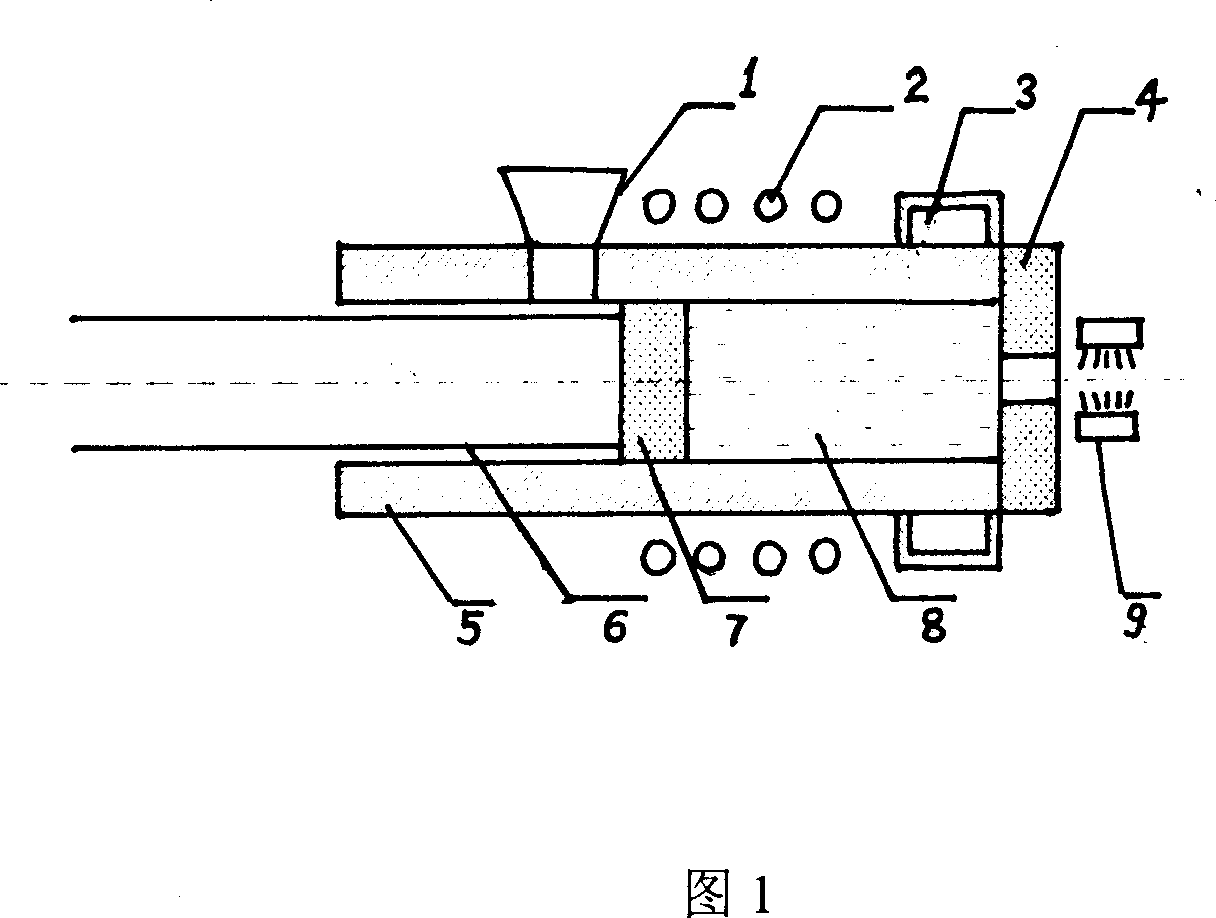

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

Powder metallurgy preparation method for rare-earth containing oxide reinforcing phase titanium alloy

Owner:CENT SOUTH UNIV

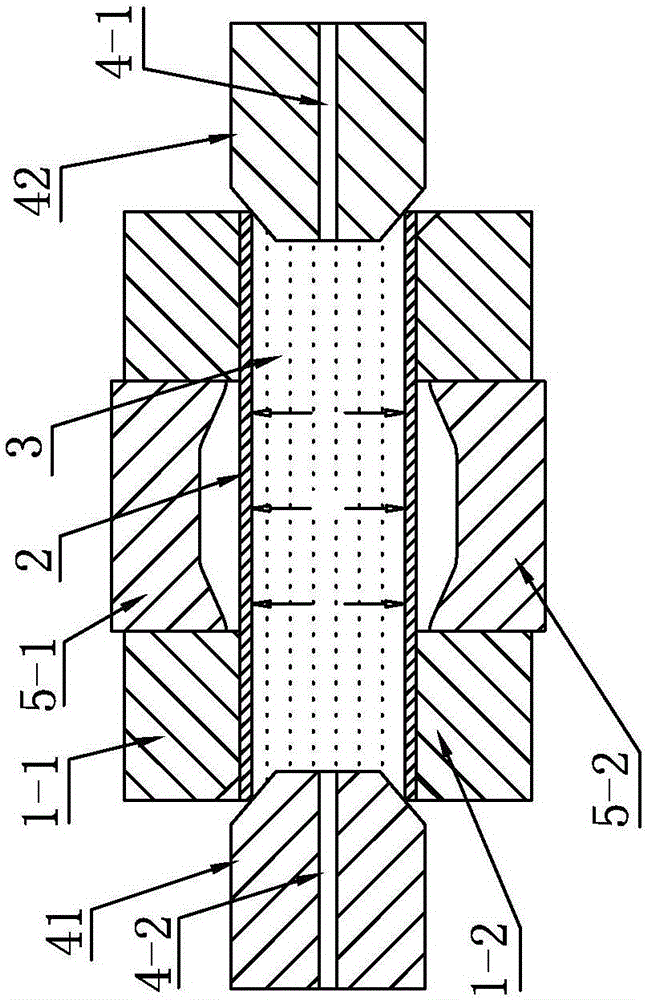

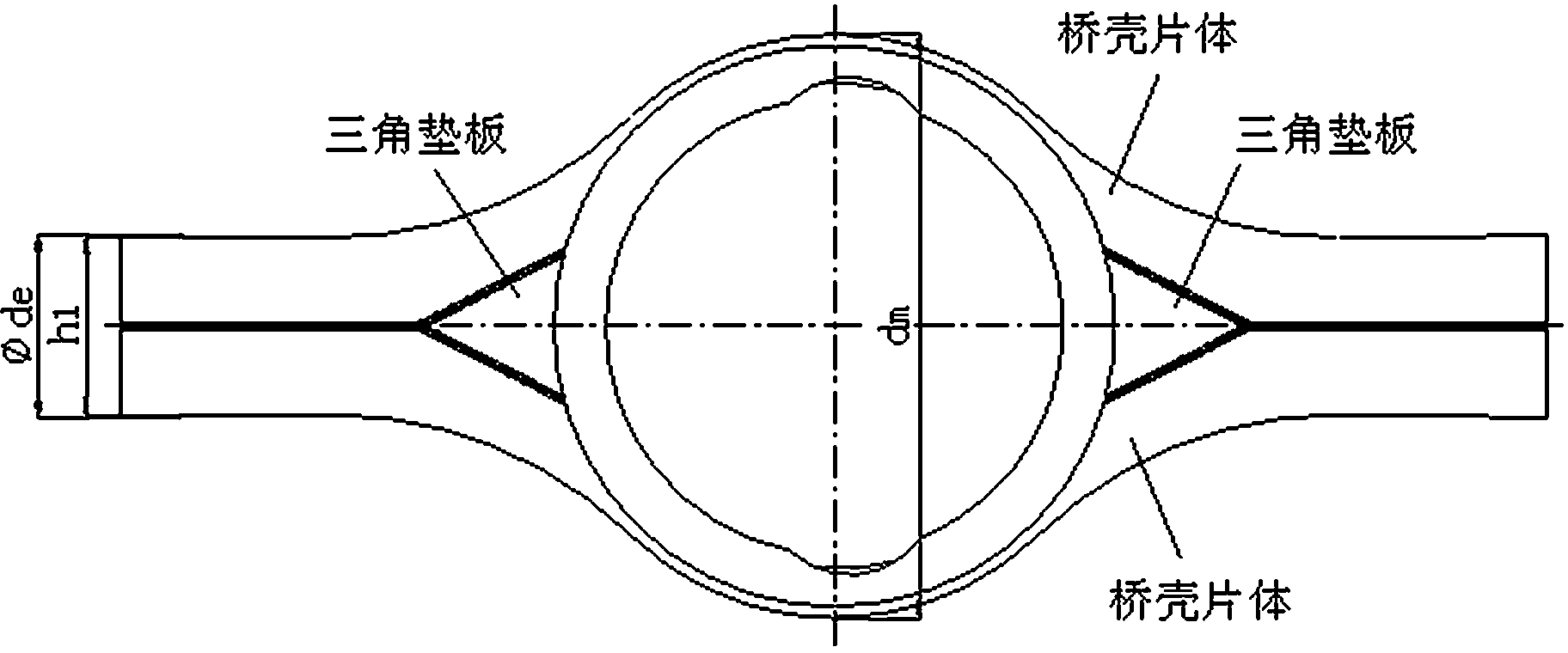

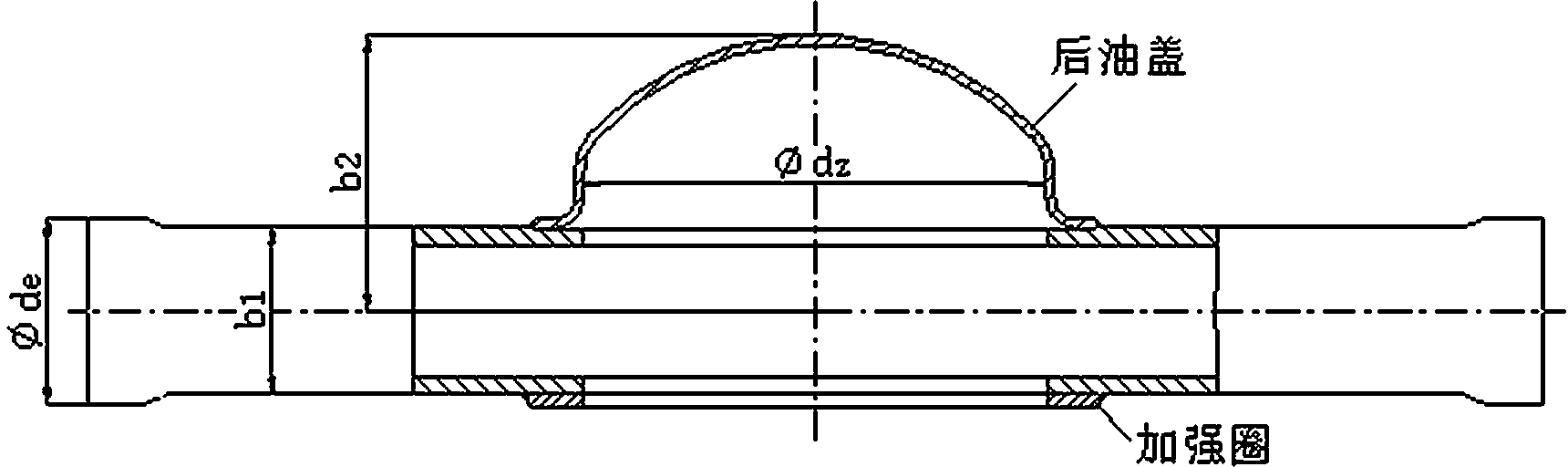

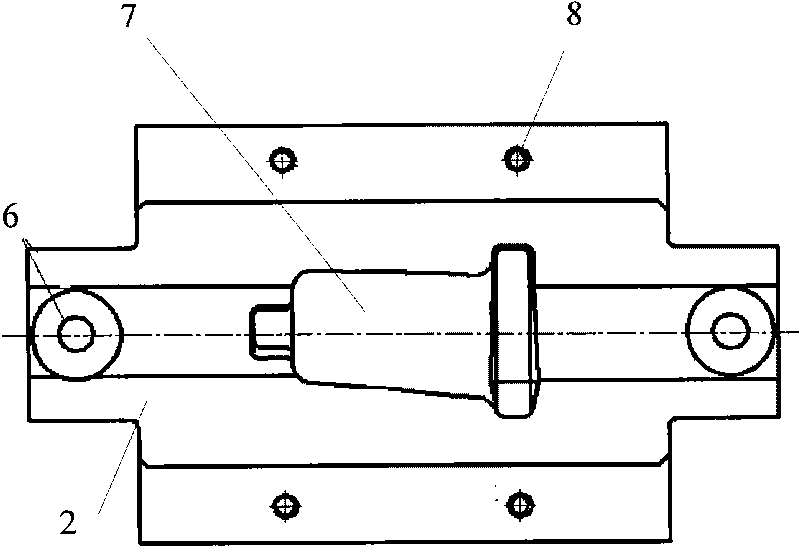

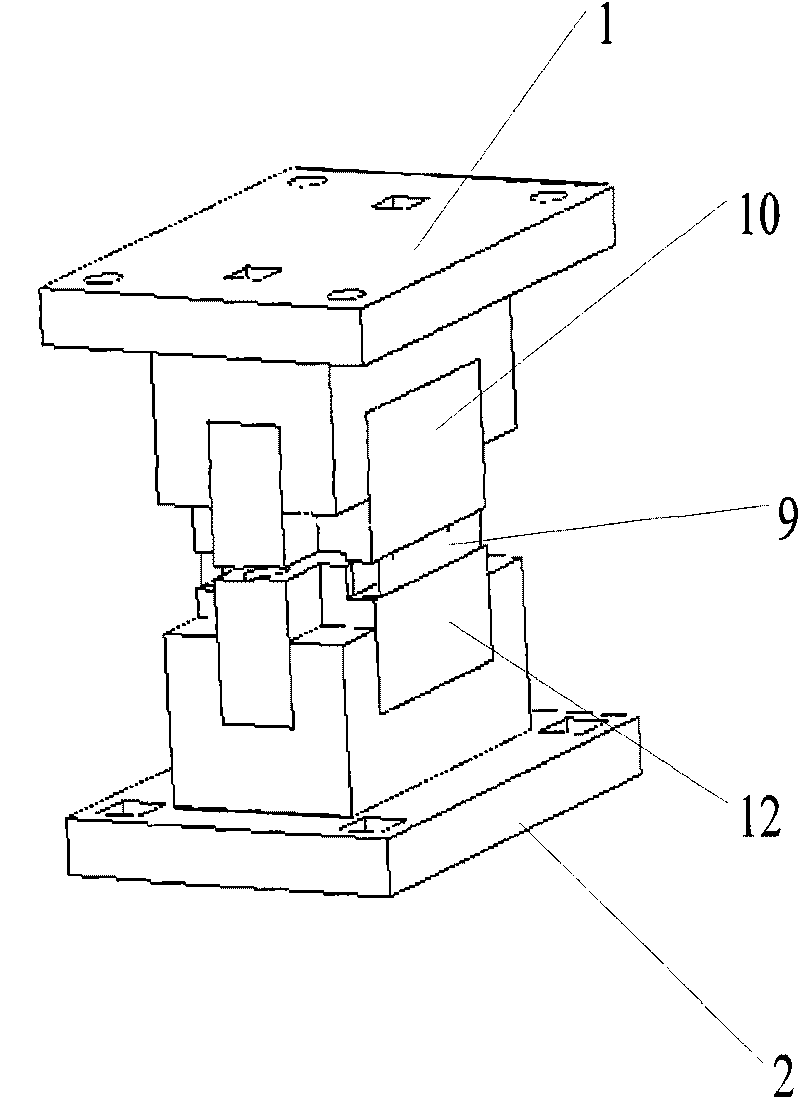

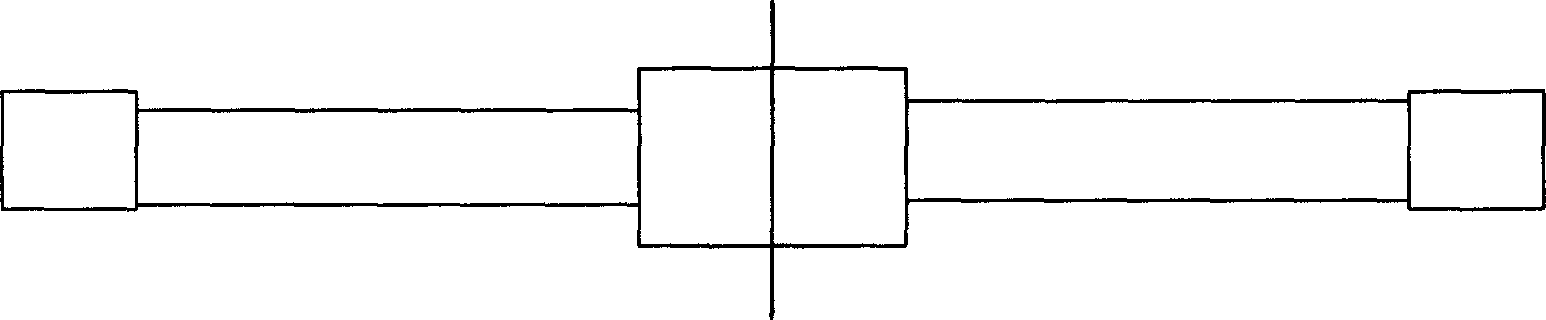

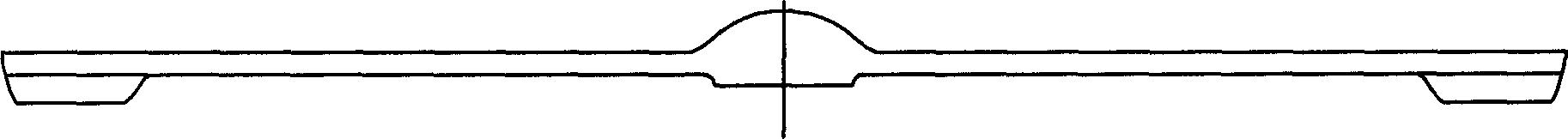

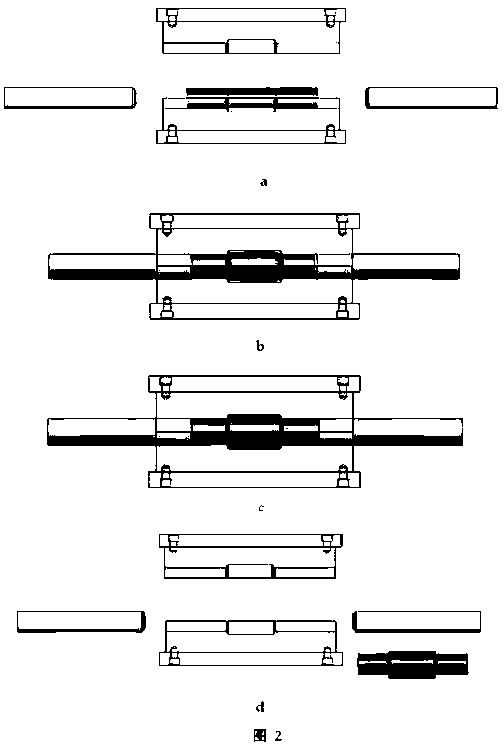

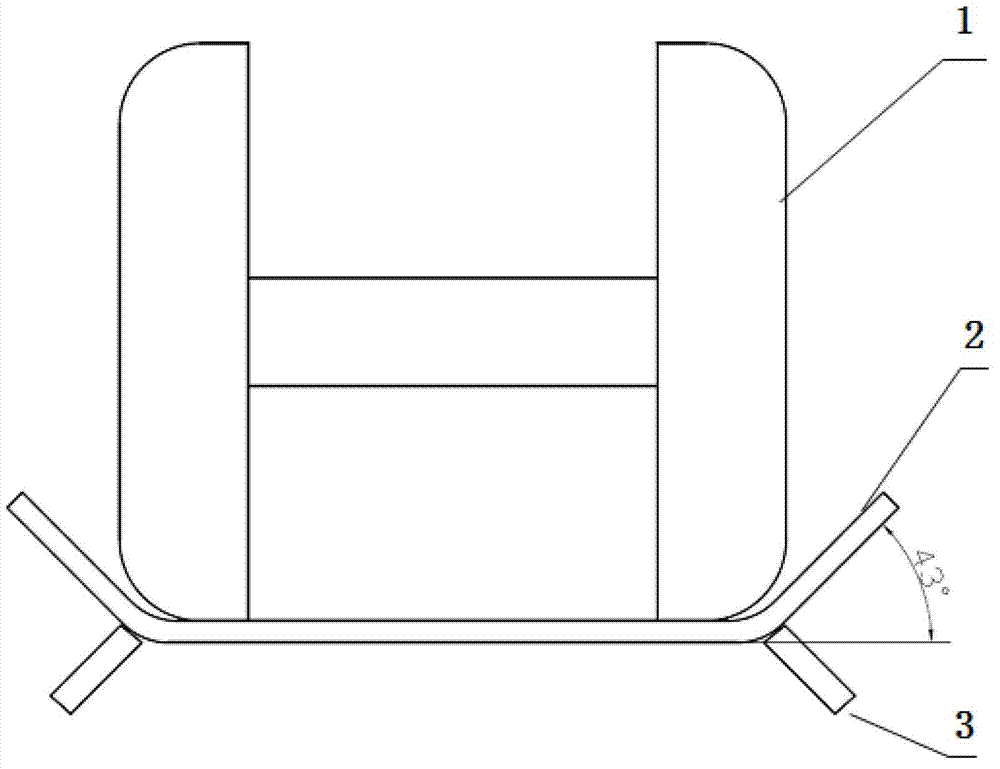

Integral forming method of weldless axle housing of heavy truck

ActiveCN103252404AReasonable distribution of wall thicknessIncreased strength and rigidityHousing FirstTruck

The invention discloses an integral forming method of a weldless axle housing of a heavy truck. According to the method, reversed central spindle necking is carried out on two sides of the axle housing first, then hydro-bugling is carried out on the middle of the axle housing to obtain a bulging tube blank with sizes of two sides of the axis different, and then necking is carried out on two ends of the axle housing to obtain a preformed tube blank; ends of the preformed tube blank are sealed by a left pressure head and a right pressure head of a die and liquid is filled in the axle housing on a four-way hydraulic machine, integral press-forming is carried out on the preformed tube blank from the upper side, the lower side, the front side and the back side through an upper module, a lower module, a front module and a back module to obtain an axle housing tube fitting, a hemispherical rear oil cap is arranged on the rear side of an axle package part, and the front side of the axle package part is a plane; a round hole is punched in the front side of the axle package, the rear oil cap is reshaped with a stamping die, and then an axle housing workpiece is obtained. The heavy truck axle housing manufactured with the method is weldless, high in strength and rigidity, high in shape accuracy, good in wall thickness distribution, and low in manufacturing cost. Compared with a traditional hydro-bugling technique, the method has the advantages that liquid pressure needed in a manufacturing process is reduced by more than 60% and the tonnage of forming equipment is reduced by more than 50%.

Owner:QINHUANGDAO TONGQIAO TECH CO LTD

Hook-face displayer back plate forming equipment and method

ActiveCN105903796AEasy to control feedingStretch smoothlyShaping toolsDomestic articlesPunchingDisplay device

The invention provides hook-face displayer back plate forming equipment. The hook-face displayer back plate forming equipment comprises an upper die and a lower die. The upper die comprises a plurality of segmented punching heads and a material pressing plate, wherein the working surfaces of the segmented punching heads are hook faces, and the material pressing plate is arranged on the outer sides of the segmented punching heads. The working surface of the lower die is a hook face matched with the working surfaces of the segmented punching heads. The edge of the lower die and the material pressing plate are matched to fix a back plate raw material. The working surfaces of all the segmented punching heads are sequentially attached to the working surface of the lower die to punch the back plate raw material, so that the back plate raw material is subjected to plastic deformation. The invention further provides a hook-face displayer back plate forming method. A workpiece is punched through the segmented punching heads in sequence, workpiece feeding is easy to control, the workpiece is uniformly stretched, an obtained hook-face back plate is thin and has certain strength, and the precise hook face can be maintained.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Isothermal forging method for titanium alloy blade

InactiveCN101733348ALower deformation temperatureImprove surface qualityForging/hammering/pressing machinesTitanium alloyMechanical property

The invention discloses an isothermal forging method for titanium alloy blade, which is implemented by the following steps: (1) coating lubricant on the surface of pre-forged titanium alloy blade blank; pre-heating with an electrothermal furnace to the deformation temperature of the blade blank; (2) fixing a lower die holder in an isothermal molding heater, and respectively fixing the upper die and the lower die on the upper die holder and lower die holder; (3) fixing the isothermal molding heater on a hydraulic press, heating to 900-930 DEG C and maintaining the temperature for at least 3h; (4) taking the blade blank out of the electrothermal furnace, putting into the upper die and the lower die in the isothermal molding heater, forging by the hydraulic press, and controlling the hydraulic press to perform return stroke operation when the dimension of the blade blank satisfies the requirement. The titanium alloy blade blank obtained by the inventive method has a preciseness satisfying technical requirement and obviously improved mechanical property.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

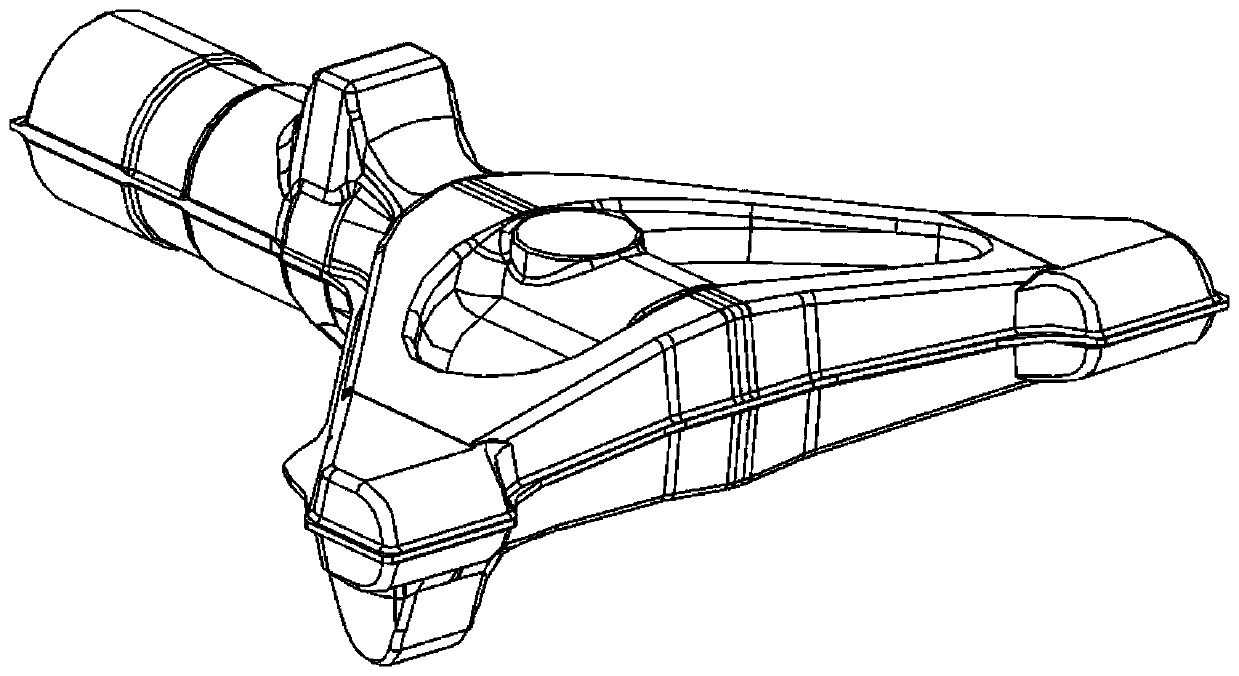

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

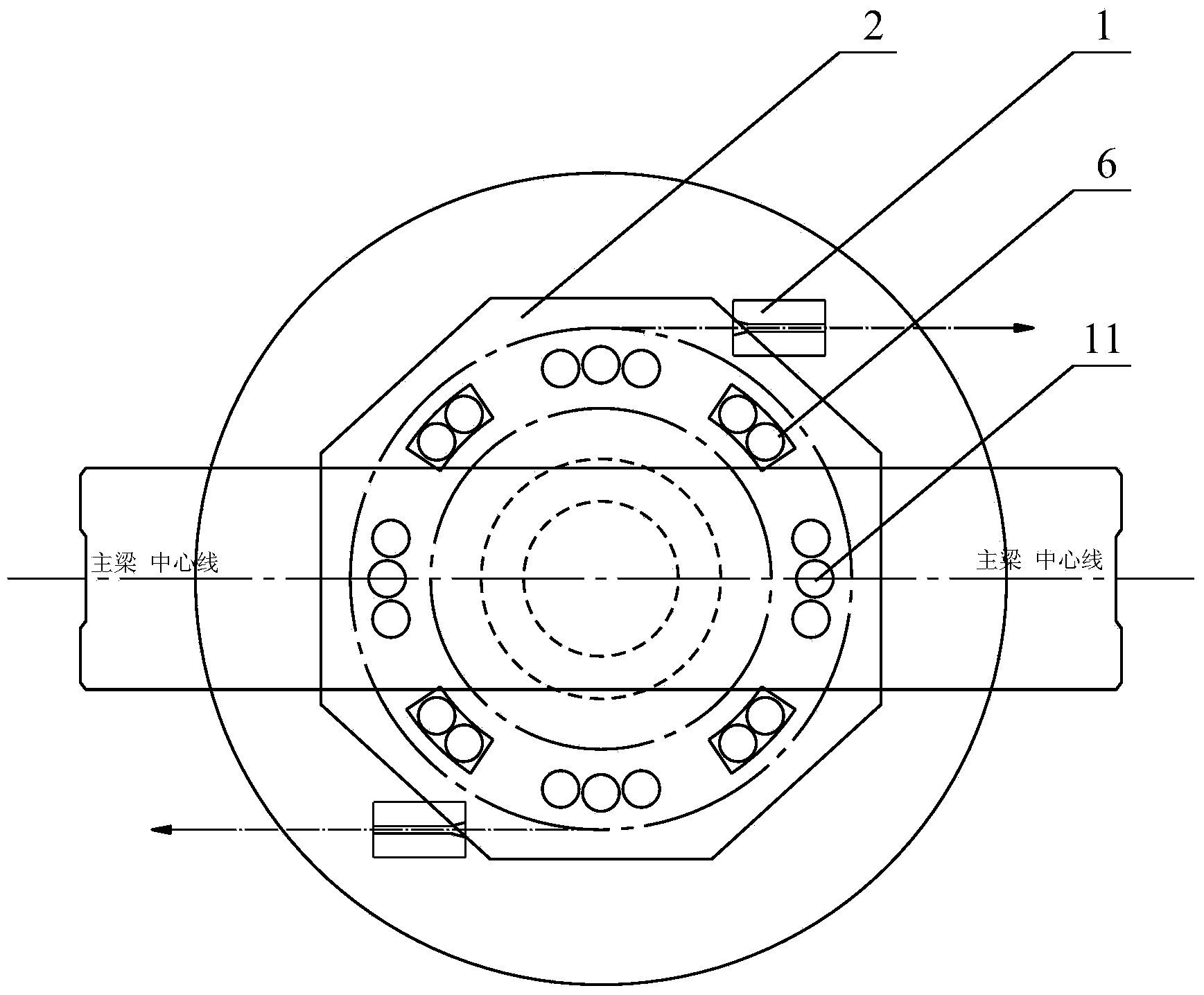

Horizontal turning system for bridge construction

The invention discloses a horizontal turning system for bridge construction, and relates to the field of bridge turning construction. The horizontal turning system comprises an upper turning disc and a lower turning disc which are arranged oppositely, wherein an upper spherical hinge is fixedly connected to the bottom of the upper turning disc; a lower spherical hinge is fixedly connected to the top of the lower turning disc; four support feet are arranged at the bottom of the upper turning disc; the four support feet are uniformly distributed on the circumference which takes the upper turning disc as the center; an included angle of 45 degrees is formed between a connecting line of two opposite support feet and the central line of a main beam; two counter-force bases and an annular slideway used in match with the support feet are arranged on the top of the lower turning disc; the counter-force bases are positioned on the outer side of the annular slideway; the counter-force bases are externally tangent to the upper turning disc; the distance between the two counter-force bases is equal to the diameter of the upper turning disc; traction devices and pull assisting devices are arranged at the tops of the counter-force bases. Three-point support is formed by the lower spherical hinge and two support feet on stress sides of a beam body, so that relatively good stability is achieved; as the hoisting weight of a jack is relatively small, the cost is effectively lowered.

Owner:中铁大桥局集团第六工程有限公司

Self-changing gearbox flywheel bracket tray deep-drawing hammer down forming process and mould

InactiveCN101402128AHigh strengthImprove deformation resistanceForging hammersForging/hammering/pressing machinesAutomatic transmissionMetallic materials

The invention discloses a method and a die for warm deep drawing and upsetting of automatic transmission flywheel pallet, and belongs to a method and a die for plastic forming of metal materials. The invention solves the problems that the prior process and die for cold stamp forming can form small pallet like parts by using only low-strength, high-plasticity carbon thin steel plate as blank materials and a process and a die for forming large pallet like parts by using No. 45 medium carbon thick steel plate with high strength and low plasticity as blank materials are not available, and is used for forging automatic transmission flywheel pallet for cars. The forming process of the invention comprises a heating step and a forming step and has the advantages of short and reasonable process flow and stability. The die of the invention comprises a deep drawing lower die, an ejecting device, a deep drawing and upsetting upper die and a guiding device, and has the advantages of reasonable structure, convenient manufacture, installation and use, reliable operation, long service life and capacity of forming flywheel pallet castings with high surface finish quality. The method and die require only one time of heating and a die set and can operate once for all, thereby improving production efficiency and forging quality of the castings.

Owner:湖北天轮机械有限公司 +1

High specific gravity tungsten alloy material and preparation method thereof

The invention relates to a high specific weight tungsten alloy material and a preparation method thereof, and relates to a tungsten alloy material and a preparation method thereof. The invention solves the problems of poor plasticity, low strength, small deflection, large residual force of the prior high specific weight tungsten alloy product, and large equipment tonnage required, long demoulding time, tightly hermetical die and high cost in the method. The high specific weight tungsten alloy material is prepared by tungsten powder, nickel powder, iron powder and cobalt powder. The preparation method comprises the following steps: firstly, preparation of mixed powder A; secondly, preparation of a blank; thirdly, sintering of the blank; fourthly, preparation of mixed powder B; fifthly, preparation of a lubricating medium; and sixthly, acquisition of the high specific weight tungsten alloy material by placing the blank and the lubricating medium into the die for extrusion forming. The high specific weight tungsten alloy material has good plasticity, large strength, large deflection and small residual force. The preparation method is simple, has small equipment tonnage required, short demoulding time and low cost, and has no strict requirement on the die.

Owner:于洋

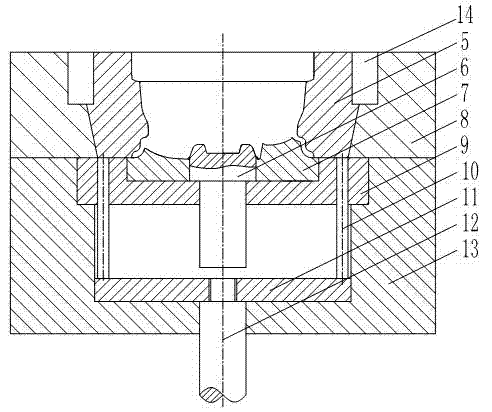

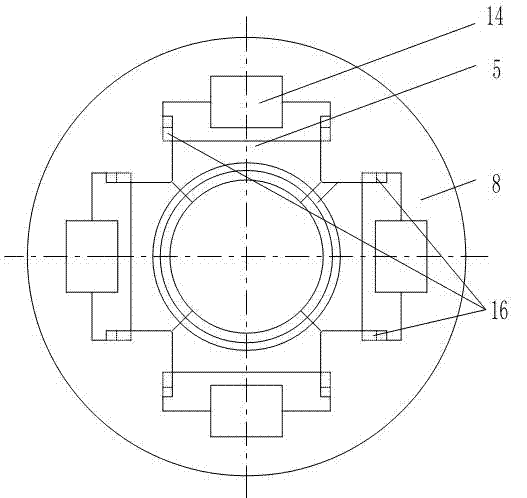

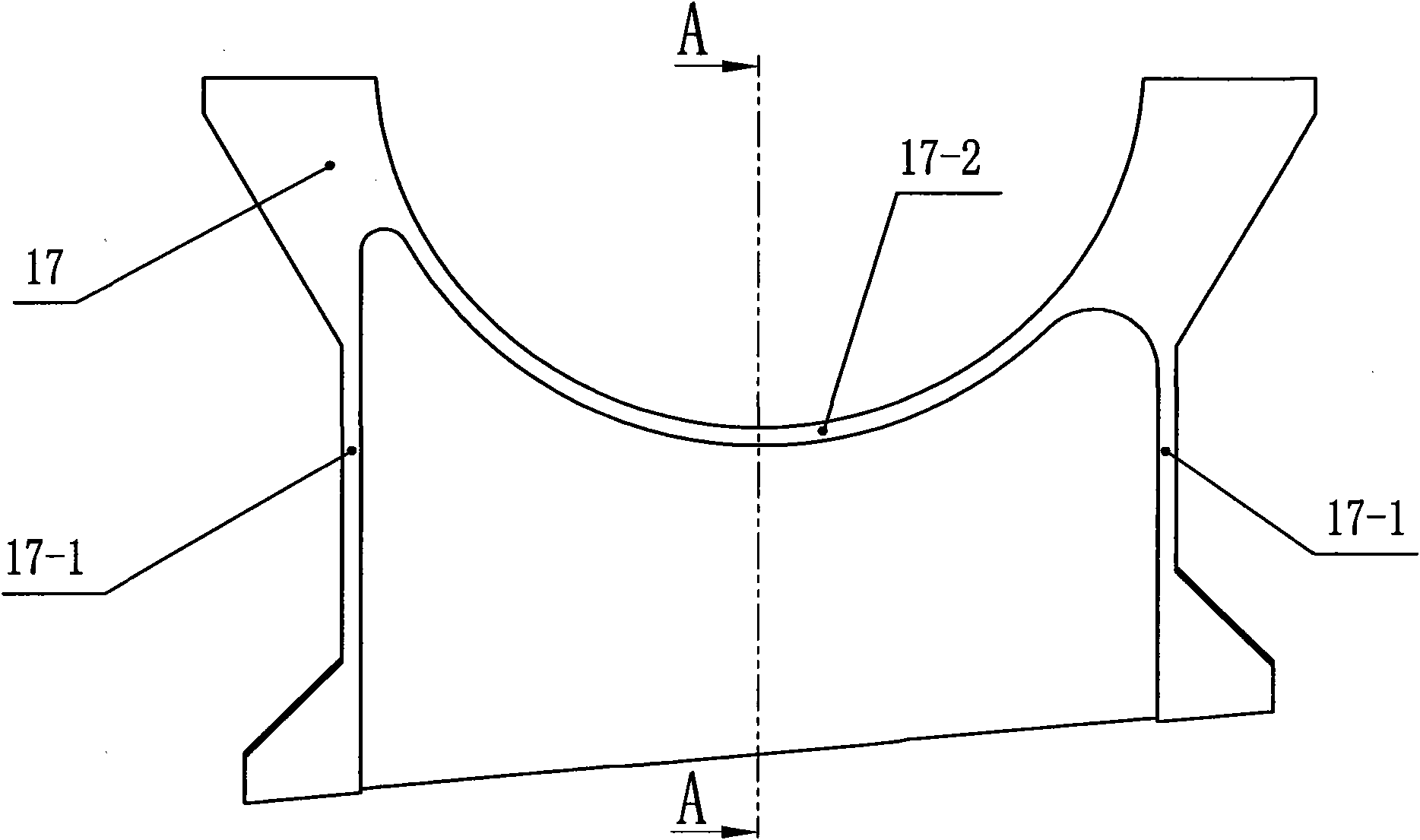

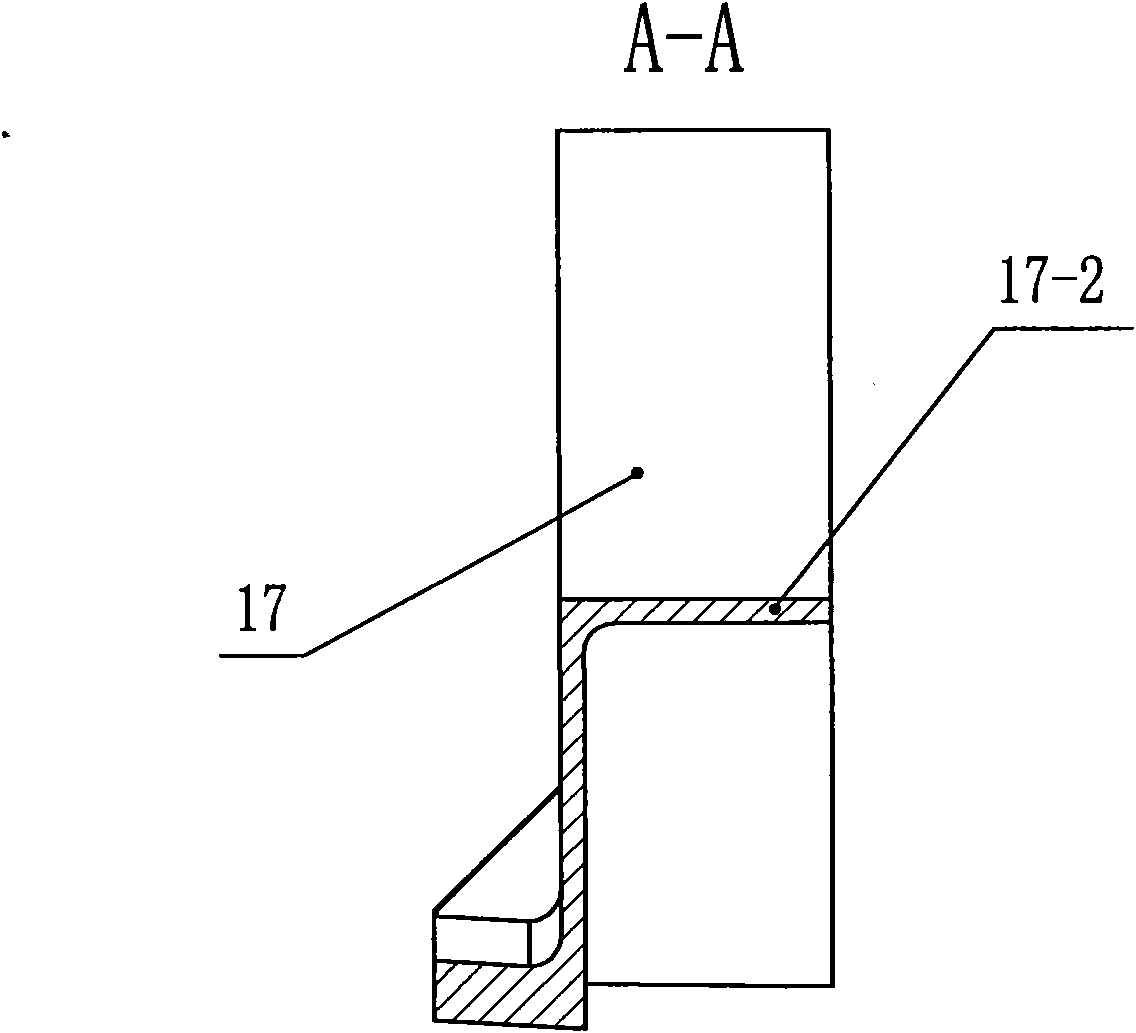

Die for controlling forming of asymmetric complex-curved rebar forge piece by using movable damping block

InactiveCN101885031AConsistent flow resistanceConsistent resistanceForging/hammering/pressing machinesEngineeringRebar

The invention relates to a die for controlling forming of an asymmetric complex-curved rebar forge piece by using a movable damping block, in particular to a forming die of an asymmetric complex-curved rebar forge piece, which solves the problem that the junction of the curved surface of an asymmetric complex-curved bar component is easily folded and not fully filled in the existing forming process. A male die (13) is provided with two pressure relief discharge openings (14), and the setting position of each pressure relief discharge opening (14) is positioned right above the corresponding side-ear connecting rib (17-1) of the asymmetric complex-curved rebar forge piece (17); the male die (13) is provided with a minor segment stepped hole (16); a movable damping block (24) is arranged in the lower end hole (16-2) of the minor segment stepped hole (16); a male die heating plate (10) is provided with a through hole (10-1) of a small punch (12) of a hydraulic press; and the through hole (10-1) of the small punch (12) of the hydraulic press corresponds to the minor segment stepped hole (16). The die is applicable to forming the asymmetric complex-curved rebar forge piece.

Owner:HARBIN INST OF TECH

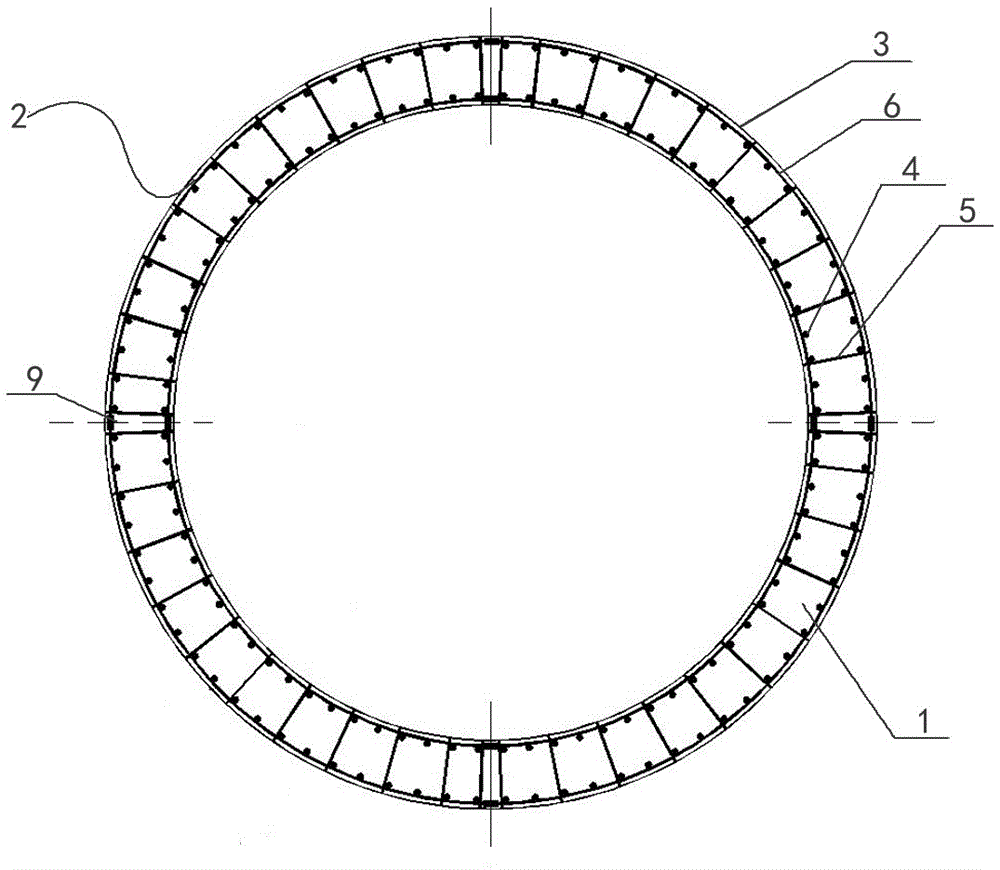

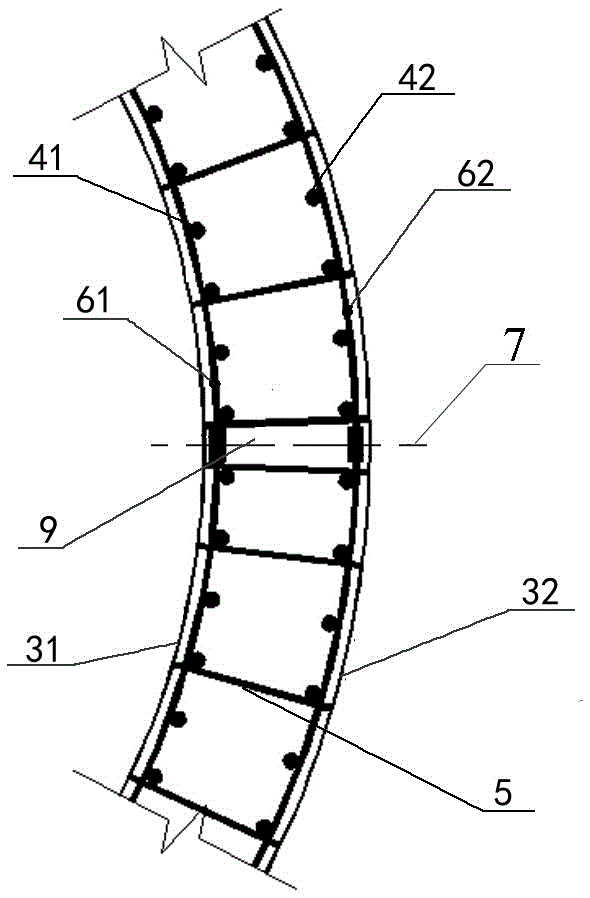

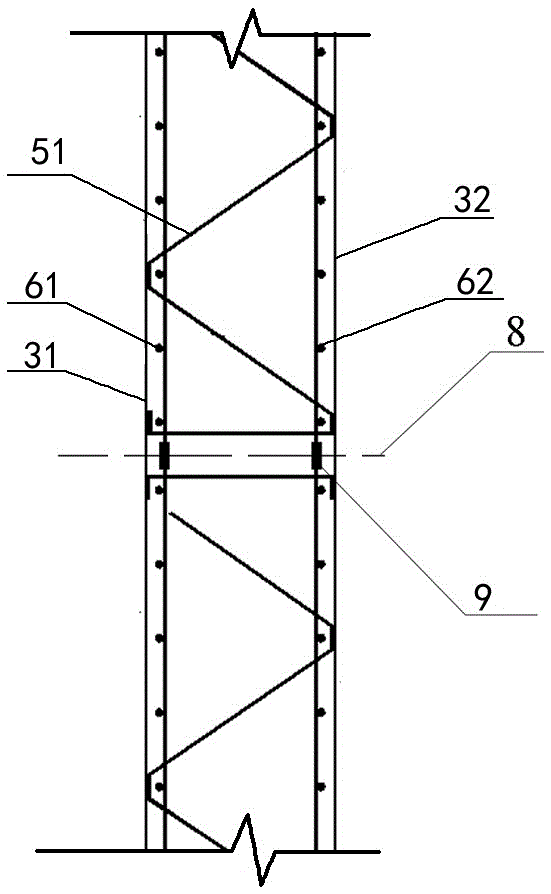

Cast-in-place concrete tower with prefabricated spatial steel bar truss formwork and construction method of cast-in-place concrete tower

ActiveCN106088780ASmall tonnageReduce lifting weightForms/shuttering/falseworksTowersHorizontal stressSUSPENDING VEHICLE

The invention discloses a cast-in-place concrete tower with a prefabricated spatial steel bar truss formwork and a construction method of the cast-in-place concrete tower. The cast-in-place concrete tower comprises the spatial steel bar truss formwork and concrete cast into the spatial steel bar truss formwork in place, and is characterized in that the spatial steel bar truss formwork is a disposable prefabricated formwork, is formed by splicing a plurality of spatial steel bar truss formwork units and is in a cylinder shape; each spatial steel bar truss formwork unit is of an arc-shaped sheet structure and comprises reinforcing bars in the middle and disposable steel formworks attached to the inner and outer sides of the reinforcing bars respectively, wherein the reinforcing bars comprise an inner layer of evenly-arranged vertical stressed steel bars, an outer layer of evenly-arranged vertical stressed steel bars, horizontal stressed steel bars used for tying the vertical stressed steel bars on the same layer, and tie stirrups arranged in a radial mode and used for tying the inner layer of vertical stressed steel bars, the outer layer of vertical stressed steel bars and the horizontal stressed steel bars at the same time. By adopting the technology, it is only needed to install the spatial steel bar truss formwork in a hoisting mode in site construction, the hoisting weight is greatly reduced, the needed crane tonnage is greatly reduced, and the construction cost is greatly reduced.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

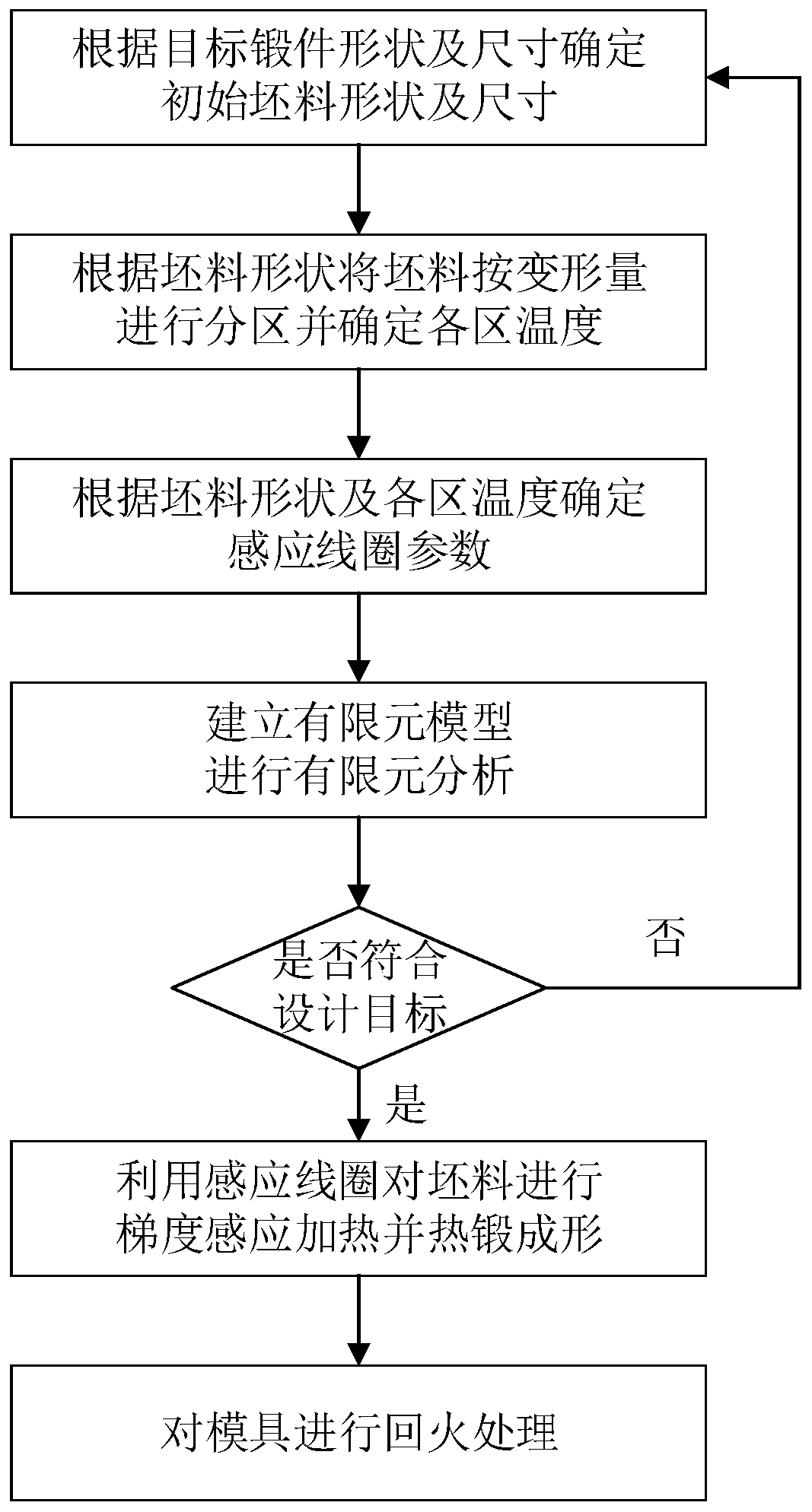

Gradient induction heating based thermal deformation workpiece blank heating method and machining method

ActiveCN109773099ARealize Controlled DesignGuaranteed dimensional accuracyHeating/cooling devicesThermoplasticThermal deformation

The invention discloses a gradient induction heating based thermal deformation workpiece blank heating method and a processing method and belongs to the field of meal thermoplastic forming. Accordingto the gradient induction heating based thermal deformation workpiece blank heating method and the processing method, a blank is designed according to the shape of a workpiece; parts, with different deformations, of the blank are subjected to rapid induction heating to different temperatures through a gradient induction heating coil, the temperature difference of different deformation parts of theblank is realized, and the continuity of the temperature of the surface of the blank is ensured. The plastic deformation resistance of areas hard to deformable is effectively reduced. The equipment tonnage can also be effectively reduced. Meanwhile, under the coupling effect of the temperature and deformation of the parts with the different deformations, the uniformity of the microstructure of awhole forged piece can be ensured, and the mechanical performance of a material is remarkably improved. Besides, the labor environment can be remarkably improved, the forged piece with the high dimensional precision, the uniform microstructure and excellent comprehensive performance is integrally formed, and automated and standardized production is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

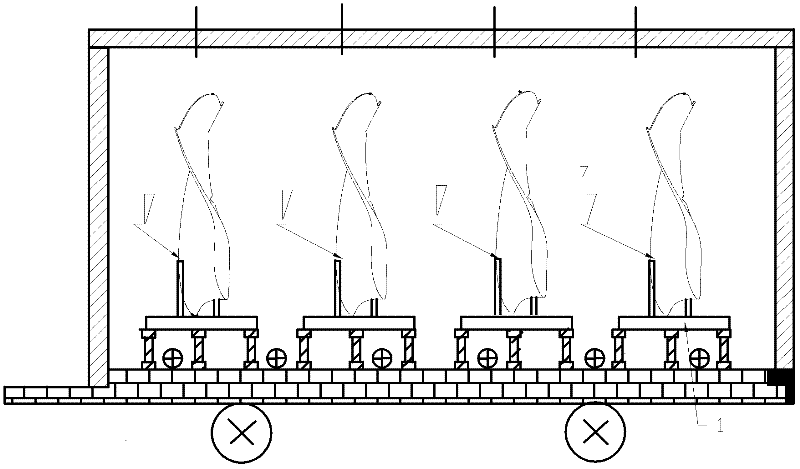

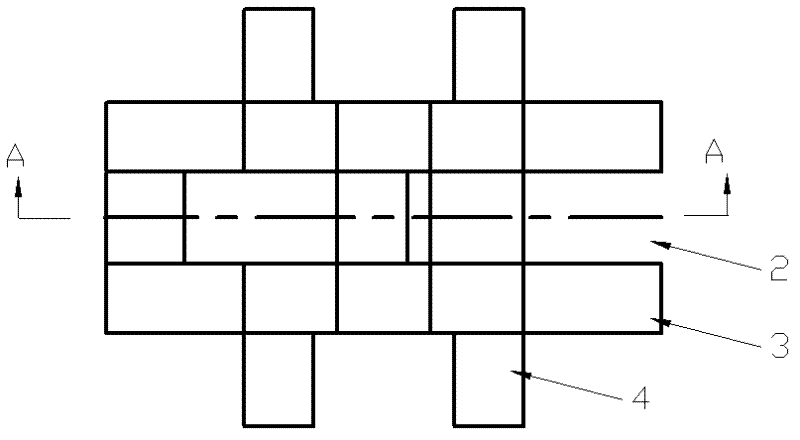

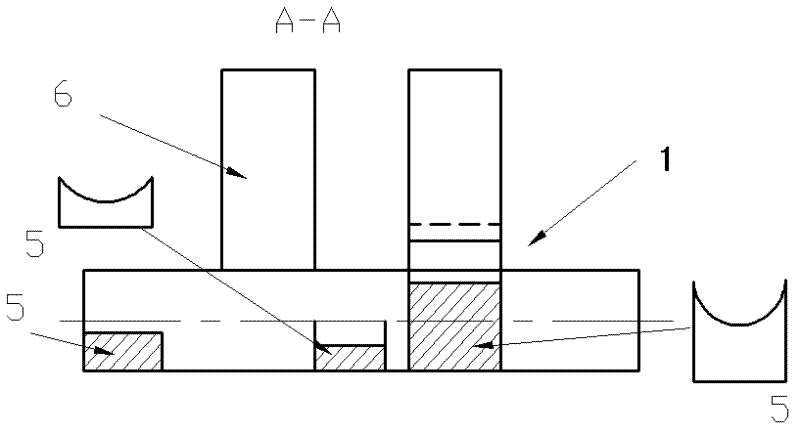

High and medium-temperature heat treatment deformation preventing device for large turbine blades

ActiveCN102560053AUnique structureWon't fallFurnace typesHeat treatment furnacesWater turbineTurbine blade

The invention relates to a deformation preventing device, in particular to a high and medium-temperature heat treatment deformation preventing device for large turbine blades. The device is characterized by being formed by assembling a casting support frame and supporting cushion blocks for supporting the casting support frame; the casting support frame is formed by assembling a U-shaped groove in the middle, groove walls on two sides of the U-shaped groove and a triangular side support which is fixed at each of two ends of the outer side of each groove wall; three cross beams with arc-shapedtops and different heights are fixed in the U-shaped groove at intervals; and two groove columns are fixed at each edge of the U-shaped groove. The device can make up the defects of the conventional blade heat treatment technology and prevent deformation of the blades in the heat treatment process according to the conventional heat treatment process mode, the characteristics of a trolley furnace and the overall dimension of the blades of different types.

Owner:KOCEL EQUIP

Multi-point pressurizing type hydraulic die forging method

The invention discloses a multi-point pressurizing type hydraulic die forging method. The method comprises the steps of S1, adjusting the position and travel of each feeding pressing head to make ensure the feeding pressing head is at each corresponding hot spot position of a component and the travel of each feeding head is more than the density compact compression amount of the corresponding hot spot position; S2, pouring molten liquid under a temperature exceeding the temperature of liquid phase line of alloy into a die cavity or a pressing cavity which communicates with the die cavity; S2, fast closing the die, and applying a locking force to lock the die; S4, pressurizing the molten alloy to enable flowing and filling in the whole die cavity; S5, sequentially or synchronously applying a force to each hot spot position of the component and the pressing cavity to enable the molten alloy at the hot spot position to be fast solidified and subjected to rheological feeding until completely solidifying; S6, releasing all pressures, opening the die and removing the component. With the adoption of the method, the problem of liquid forging of large complex component can be effectively solved; the method has the advantages of being small in investment, free of shrinkage defect in the component, stable in product quality, and wide in applicable scope.

Owner:BEIJING JIAOTONG UNIV

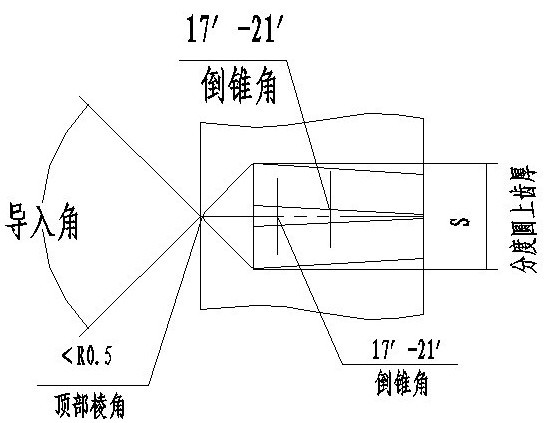

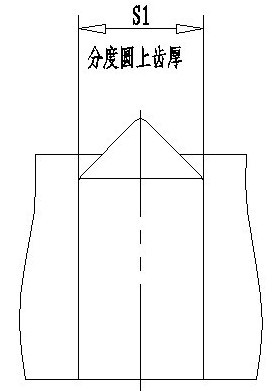

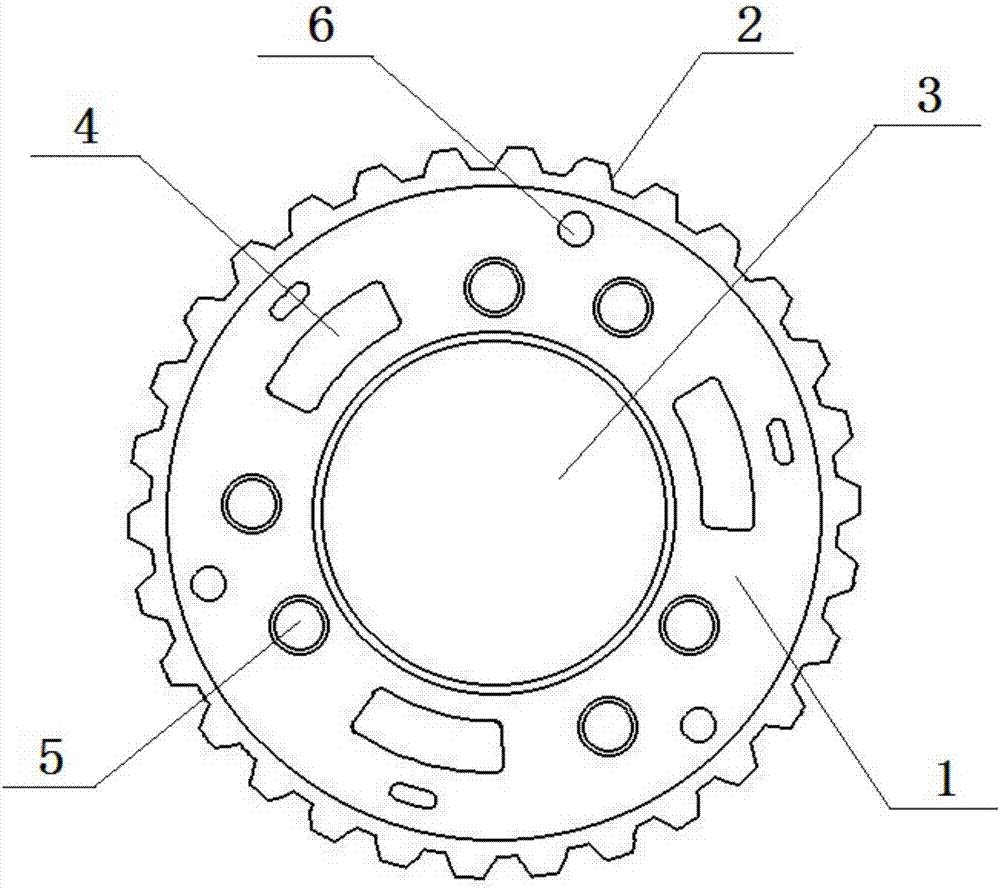

Automobile gearbox P-gear gear manufacturing method

The invention provides an automobile gearbox P-gear gear manufacturing method. An automobile gearbox P-gear gear is finally formed by conducting cold extruding after warm forging is conducted in a warm forging manufacturing mode. The automobile gearbox P-gear gear is characterized in that positive and negative combined extrusion is adopted for cold extruding, and outer teeth are extruded while extrusion forming of the petal portion in a product is finished. The product made through the method is high in accuracy, less in oxidation, good in internal metal organization and more refined in crystalline grain, and harmful structures of coarse crystals, mixed crystals and the like can be avoided; the required equipment is small in tonnage and less in forming force, tooth filling is easier, unit intensity of pressure born by a die is remarkably lowered, the service life of the die is very long, the process can be reduced, and the manufacturing time is greatly shortened (increased by 10 times compared with a gear hobbing machine). The product hardness ranges from HB 140 to HB 180, the tooth profile is fully filled and full, and it is guaranteed that large deformation cannot be generated in subsequent heat treatment of cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

Method for preparation of alloy extrudate

InactiveCN101081408AReduce consumptionSmall tonnageExtrusion control devicesTemperature controlSemi solid

The process of extruding alloy section includes the following steps: 1. pre-heating the extrusion chamber and the extrusion pad in the extruder to 300-650 deg.c; 2. pre-heating the extrusion die to 300-500 deg.c and introducing coolant to the cooling jacket in the front end of the extrusion chamber to control the temperature at 20-200 deg.c; 3. forming semi-solid and semi-liquid pulp with the metal melt and injecting quantitatively into the pouring slot of the extrusion chamber; and 4. pushing forwards the extrusion stem for the pulp to fill the extrusion chamber and solidify in the front end of the extrusion chamber, extruding out the plastically deformed pulp from the die, and cooling for the second time to obtain the required section. The process may be realized in a common extruder through slight modification, and can result in saving in machining and saving in material.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

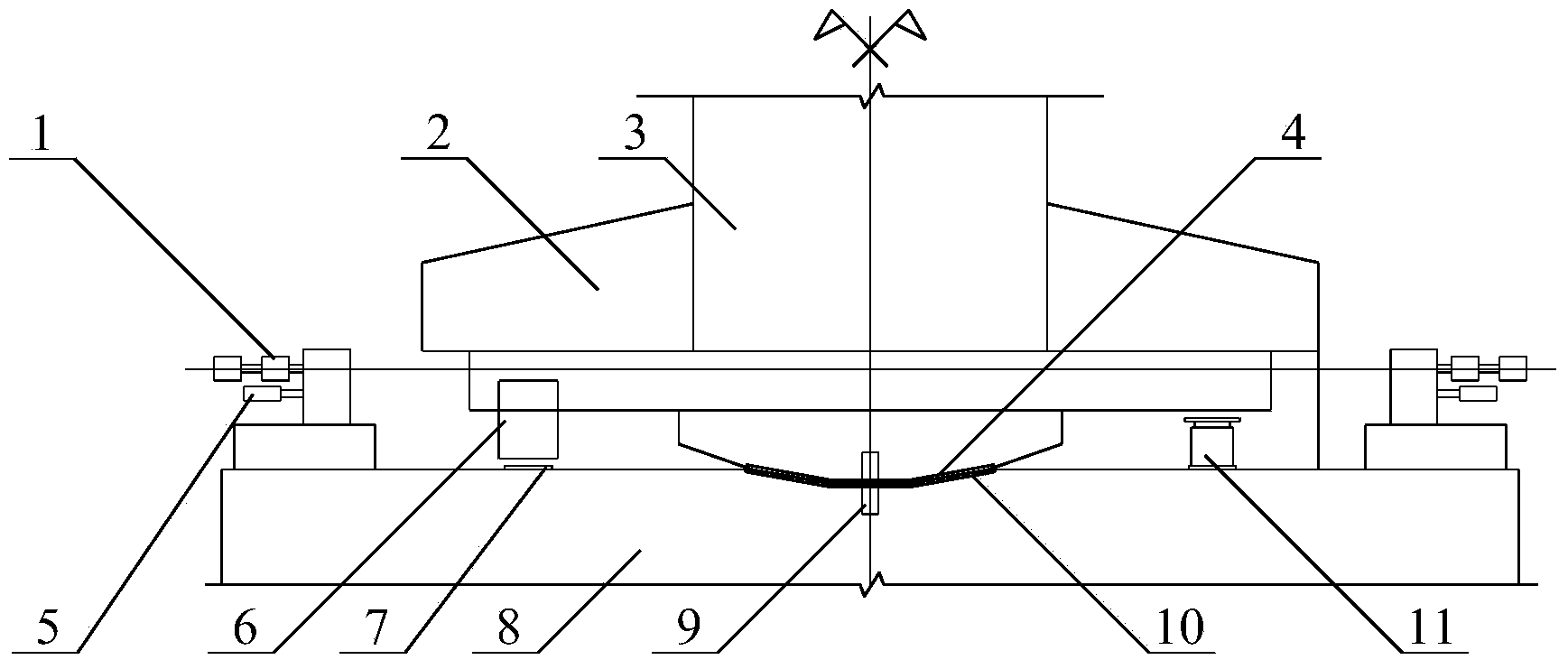

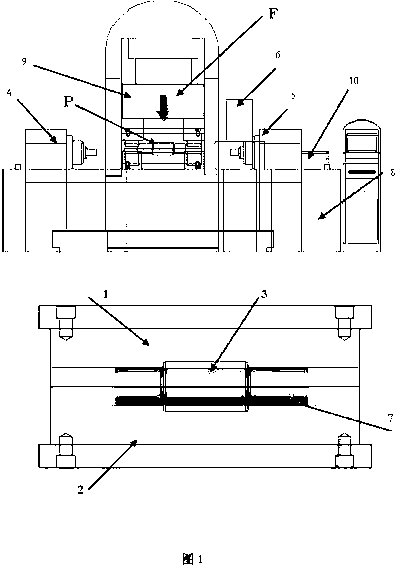

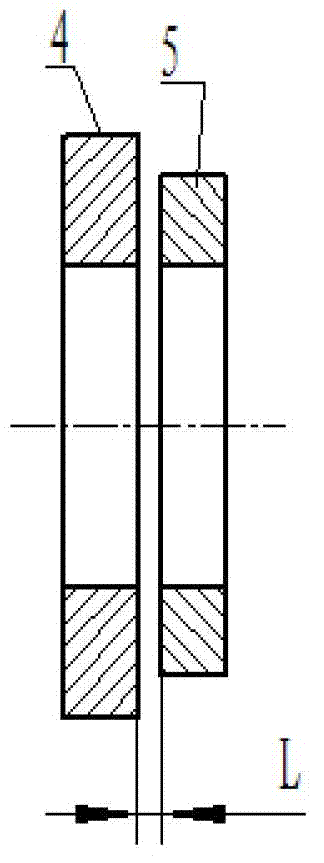

Variable-mold-clamping-force pipe internal high-pressure forming device and method

ActiveCN103212619AReduced pressure holding performance requirementsSmall tonnageEngineeringAxial force

The invention relates to a variable-mold-clamping-force pipe internal high-pressure forming method, which comprises the steps that after an upper mold and a lower mold are clamped, forming media with certain pressure is filled into a mold cavity, pushing heads on a left side and a right side simultaneously push pipe blanks into the mold cavity from the left side and the right side, the pipe blanks are pressed into the mold cavity to be formed through internal pressurization and axial force application and material compensation under the joint effect of the pressure of the forming media and the material compensation of the pushing heads, and finally the pipe blanks are in fit with the mold cavity to realize part formation. Since different mold clamping forces are adopted at different stages, the defects that the pressure required by the traditional constant-mold-clamping-force tube internal high-pressure forming method is high, the requirements on machine performance, mold performance, sealing performance and mold lubricating performance are high, the machine cost is high, the situation of mold lifting is apt to occur, the part forming pressure is high, large-deformation complex parts cannot be formed, the working efficiency is low and the like are overcome.

Owner:NINGBO POWER PRECISION HYDRAULIC MACHINERY

Precision forging method for reverse idle gear of automobile gearbox

The invention discloses a precision forging method for a reverse idle gear of an automobile gearbox. The precision forging method comprises the following steps of: shearing a raw material such as steel sticks into material sections as required; spraying lubricant on the material sections and drying; heating a blank to the temperature of between 700 and 750 DEG C, and warmly forging the blank intoa preforged blank with an opening angle and a tooth profile by a warm forging pressure machine; performing isothermal normalizing treatment on the preforged blank, sandblasting and performing surfacepolymer lubrication treatment; performing cold extrusion on the tooth profile on the preforged blank on a hydraulic machine; feeding into a tooth profile sizing die, and performing cold sizing on theopening angle; and feeding into an inverted cone die, and performing cold sizing on an inverted cone angle. By the method, the preforged blank is forged by a method of heating and warm forging under protective atmosphere, the tooth profile precision is higher than that of warm forging, and the surface roughness is high. The post process is divided into the following three steps of cold extrusion of the tooth profile, cold sizing of the opening angle and cold sizing of the inverted cone angle, so that the gradual improvement of the tooth profile precision is facilitated, and the chain effect brought by the tooth profile precision of the preforged blank is reduced. The efficiency is higher that of cutting, and materials, energy sources and time are saved.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

High-strength hot-rolling automobile longitudinal beam material and longitudinal beam manufacturing method

The invention discloses a high-strength hot-rolling automobile longitudinal beam material and a longitudinal beam manufacturing method. The longitudinal beam comprises the following chemical components in weight percent: 0.04-0.10% of C, 0.05-0.12% of Si, 1.70-2.10% of Mn, less than or equal to 0.025% of P, less than or equal to 0.10% of S, less than or equal to 0.020% of V, 0.08-0.15% of Ti, 0.04-0.09% of Nb, 0.015-0.065% of Al and the balance of Fe; the method comprises the following steps of: 1) uncoiling, flattening and stripping large beam steel plates by using a stripping cutter; 2) molding large beam steel plates in a molding roller forming mode; 3) cutting down the large beam steel plates by using a cutting module through a 45-degree beveling process; and 4) punching holes on the large beam steel plates digitally, and hot-rolling the large beam steel plates to be longitudinal beams of present lengths and cross section specifications. Automobile longitudinal beam steel plates for the longitudinal beam is high in strength, easy to mold and is applicable to molding of longitudinal beam steel plates with a 700MPa grade; desired equipment is small in tonnage; surface of the longitudinal beam is good in quality; a automobile frame longitudinal beam is changed from a double-layer automobile frame into a signal-layer automobile frame; a signal automobile is reduced by more than 300kg, so that purposes of reducing the self-weight of the automobile and reducing fuel consumption are achieved, and significant social benefits are obtained.

Owner:SINO TRUK JINAN POWER

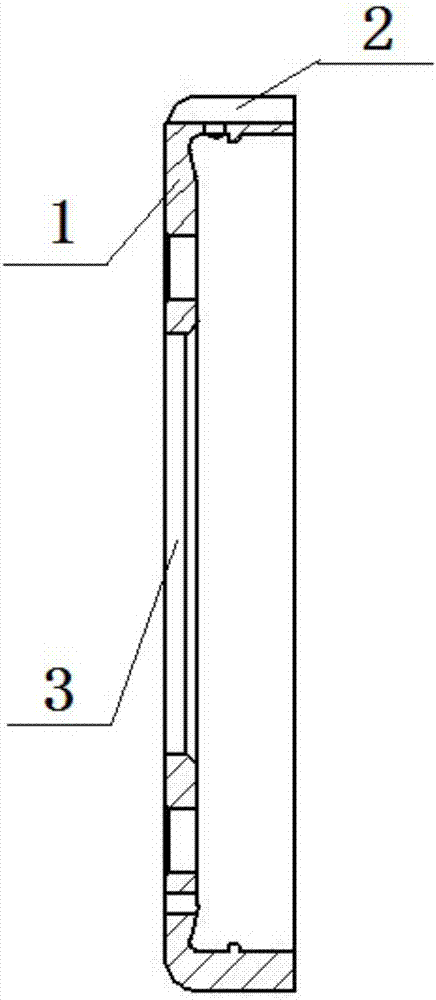

Manufacturing process for bearing plate of planetary carrier of automobile CVT automatic transmission

ActiveCN107186450AThe technical route of the manufacturing process is reasonableImprove tooth surface strengthGearing detailsAutomatic transmissionGraphite

The invention discloses a manufacturing process for a bearing plate of a planetary carrier of an automobile CVT automatic transmission. The manufacturing process comprises the following steps: (1) blanking; (2) blank making before warm forging; (3) shot blasting; (4), warm forging and extrusion forming: heating a blank to 210+ / -20 DEG C, coating graphite, then continuing to heat to 820-860 DEG C, firstly upsetting and extruding and then performing backward extrusion forming to form a round plate and forming a metal ring vertically extending to one side on the edge of the circumference of the round plate, and then punching a central hole of the round plate; (5) residual heat annealing; (6) blank making and shot blasting after the warm forging; (7) lubricating treatment; (8) outer tooth forming by cold forging extrusion: placing the lubricated blank into a female die, and performing cold extrusion to form an outer gear ring; and (9) nitriding, wherein an effective oxide layer on the surface has a depth of 0.007-0.3mm. The manufacturing process is reasonable in technical route, metal flows are not cut off, a tooth surface strength of the product is high, raw materials are saved, and the production efficiency is high.

Owner:江苏威鹰机械有限公司

Temperature cooling precision forming method of big modulus high boss bevel gear

ActiveCN103419002AGuaranteed lifeFinishing allowance is not largeForging/hammering/pressing machinesHigh volume manufacturingBevel gear

The invention discloses a temperature cooling precision forming method of a big modulus high boss bevel gear. The method includes the steps of feeding pre-upsetting blank, conducting warm forging blocking forming on a warm forging blocking forming die, afterwards, carrying out spheroidizing annealing, shot blasting, alramenting and saponification treatment, finally putting the blank into a cold-finish die so that a qualified tooth form can be squeezed out, conducting rough turning on a formed gear, carrying out heat treatment on a rough turned piece, conducting finish turning until a reserved balance is achieved, and obtaining a qualified product. By means of the temperature cooling precision forming method of the big modulus high boss bevel gear, the utilization rate of materials is improved, die cost is saved, the mechanical property of products is good, the surface dimensional precision of the products is high, and the method is suitable for mass production.

Owner:HUOSHAN HUINENG AUTO PARTS MFG

Method for manufacturing high-power annular inductor

ActiveCN102930971AGuaranteed demandSimple processTransformers/inductances magnetic coresCoils manufactureInductorEngineering

The invention relates to a method for manufacturing a high-power annular inductor, comprising the following steps: manufacturing an annular magnetic core, manufacturing an inductance coil and assembling to obtain a finished product. The high-power annular inductor manufactured by adopting the method comprises the annular magnetic core and the inductance coil. The annular magnetic core comprises more than three semi-arc shaped magnetic blocks along the circumference, wherein each semi-arc shaped magnetic block is equally divided into upper and lower halves; the surface of each semi-arc shaped magnetic block is coated with an insulating layer with a thickness of 0.2-0.5mm; the joints of the combined upper and lower semi-arc shaped magnetic blocks are arrayed in a mutual staggered way; the inductance coil is a spiral ring coil winded from a hard wire; the spiral ring coil is combined together with the semi-arc shaped magnetic blocks; and the annular magnetic core is sleeved coaxially and impregnated and cured into the whole product. The method overcomes the problems that the powdery magnetic core of the traditional annular inductor is restricted in size and can not be made from the large-area hard wire, the annular inductor is enabled to develop towards high power, and the requirement on the inductance inductor in the modern power electronics field is met.

Owner:NINGXIA YINLI ELECTRICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com