Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Lower deformation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

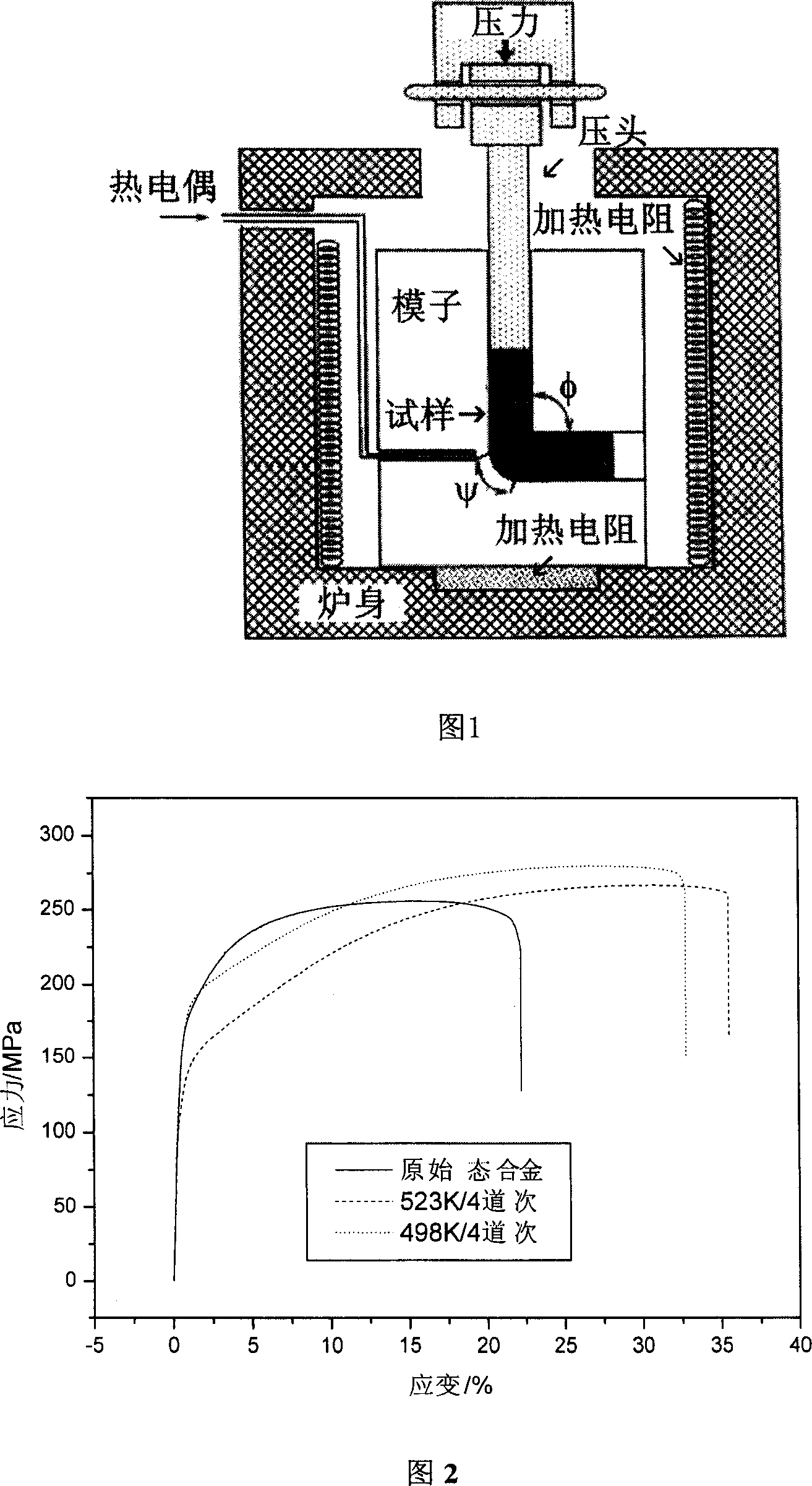

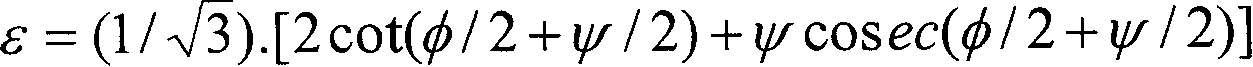

Method for extrusion two-step equal channel angle of magnesium alloy

InactiveCN1792487AGrain refinementImprove organizational structureExtrusion control devicesEqual channel angular extrusionMaterials processing

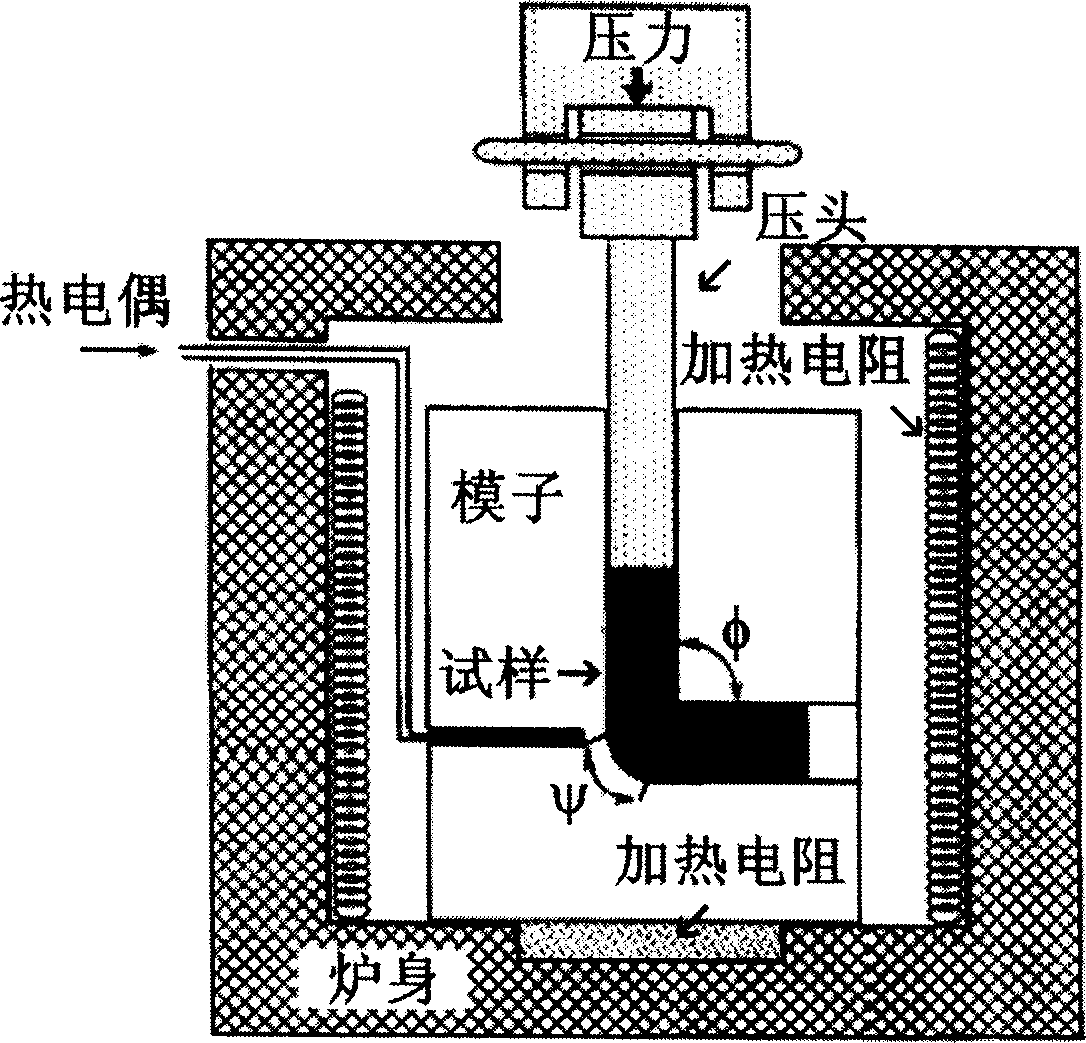

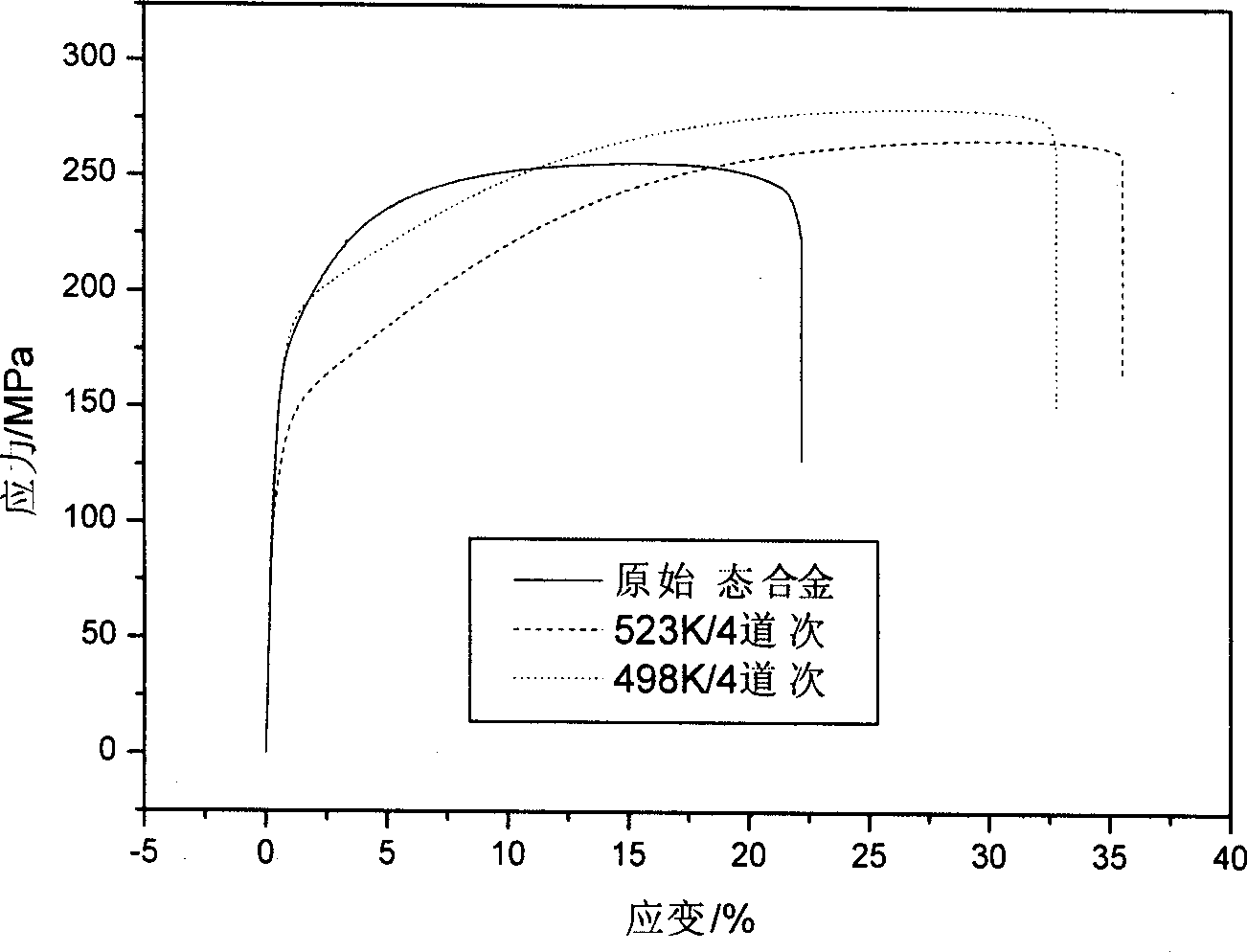

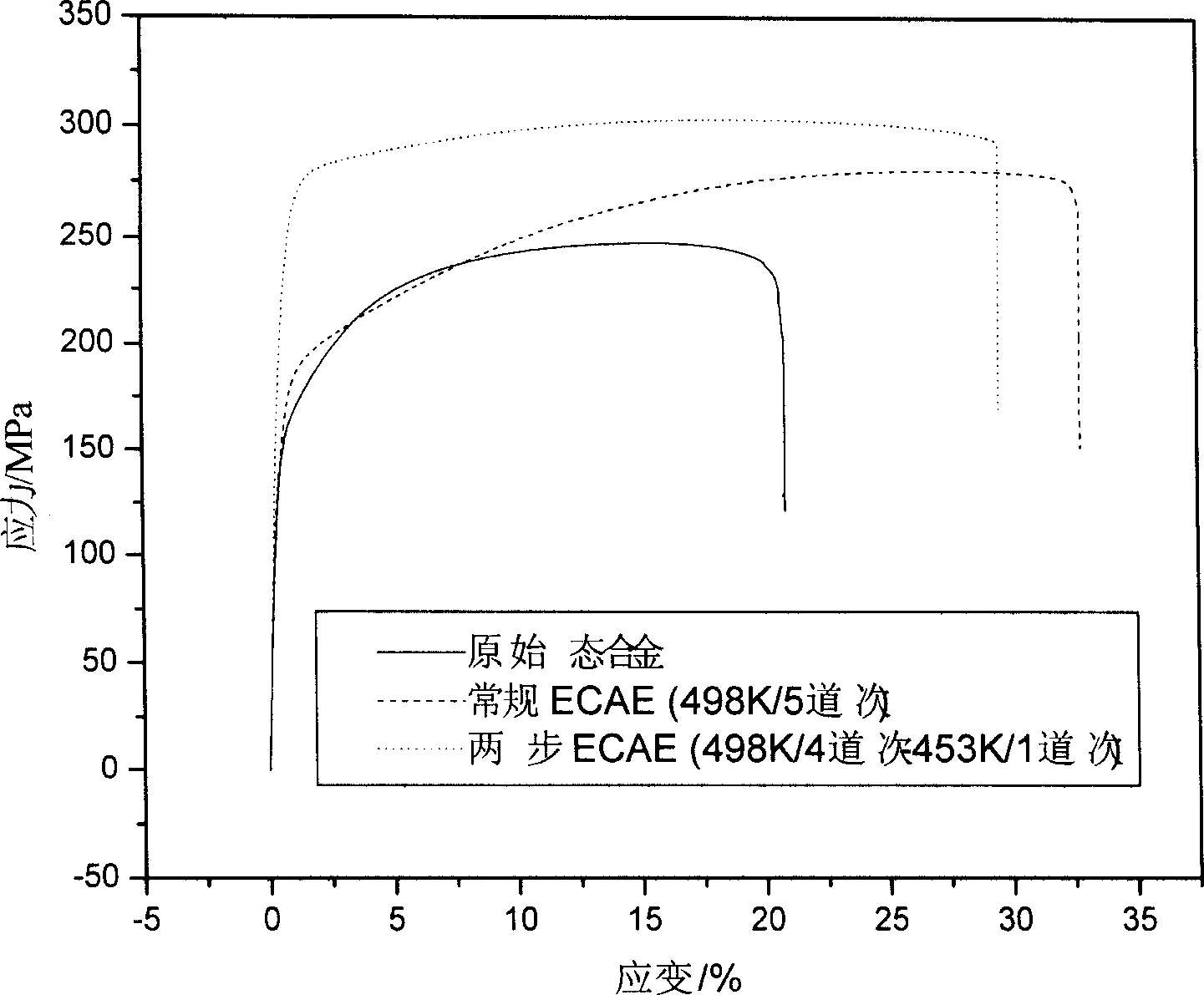

A two-step squeeze method with equal channel angle for Mg-alloy includes such steps as designing equi-channel squeezing die set, regulating deformation speed and temp to find out the lowest temp for non-crack deformation, equichannel squeezing by 2-4 passes, lowering the deformation temp, and squeezing by 4-8 passes. Its advantage is high strength and toughness.

Owner:FENGYANG L S NET FORMING CO LTD

Isothermal forging method for titanium alloy blade

InactiveCN101733348ALower deformation temperatureImprove surface qualityForging/hammering/pressing machinesTitanium alloyMechanical property

The invention discloses an isothermal forging method for titanium alloy blade, which is implemented by the following steps: (1) coating lubricant on the surface of pre-forged titanium alloy blade blank; pre-heating with an electrothermal furnace to the deformation temperature of the blade blank; (2) fixing a lower die holder in an isothermal molding heater, and respectively fixing the upper die and the lower die on the upper die holder and lower die holder; (3) fixing the isothermal molding heater on a hydraulic press, heating to 900-930 DEG C and maintaining the temperature for at least 3h; (4) taking the blade blank out of the electrothermal furnace, putting into the upper die and the lower die in the isothermal molding heater, forging by the hydraulic press, and controlling the hydraulic press to perform return stroke operation when the dimension of the blade blank satisfies the requirement. The titanium alloy blade blank obtained by the inventive method has a preciseness satisfying technical requirement and obviously improved mechanical property.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

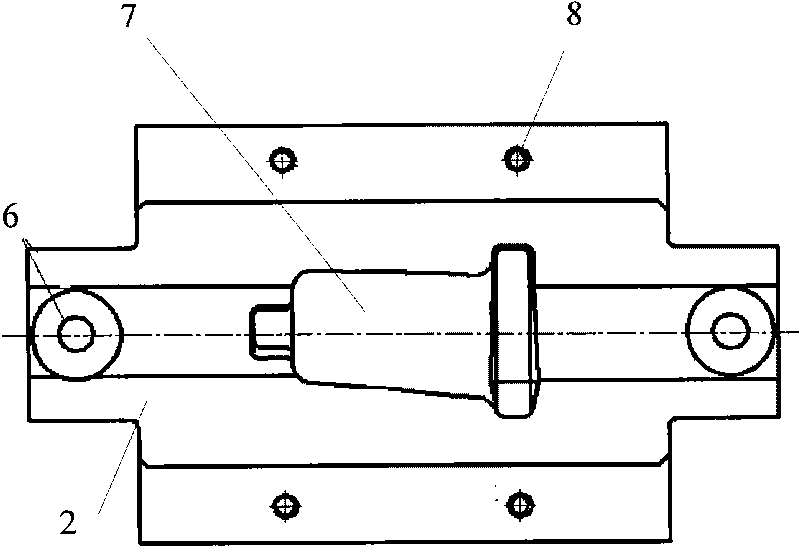

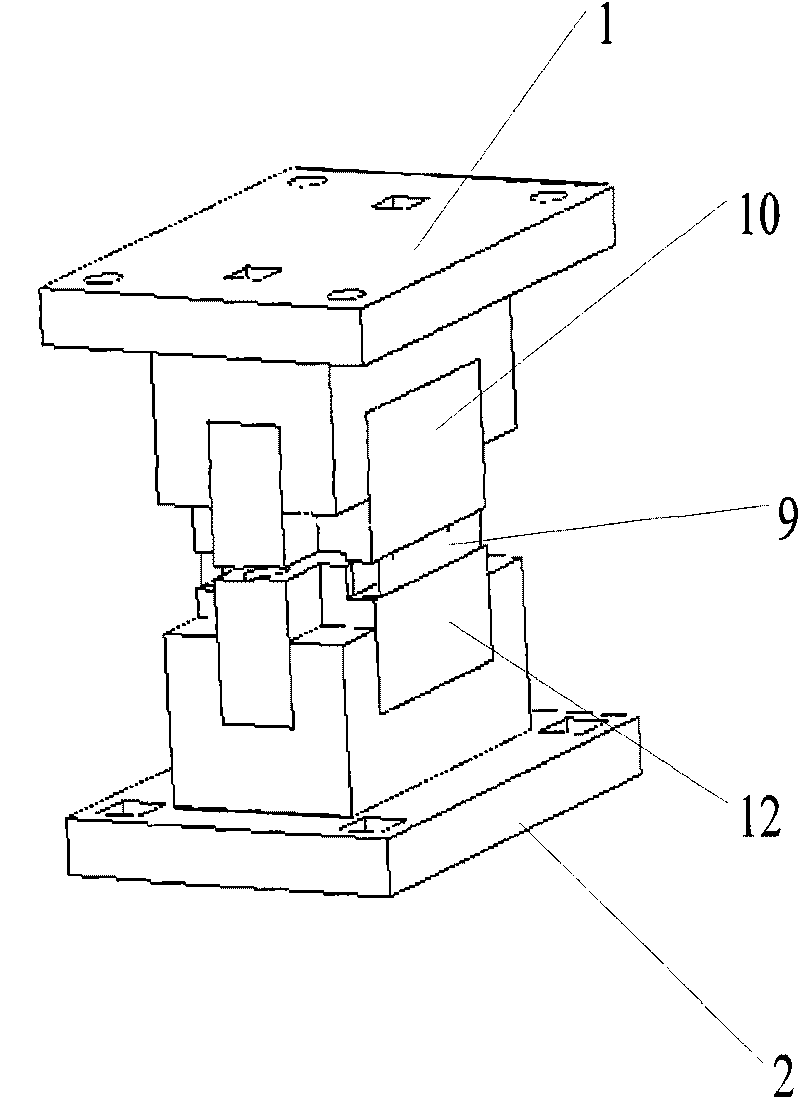

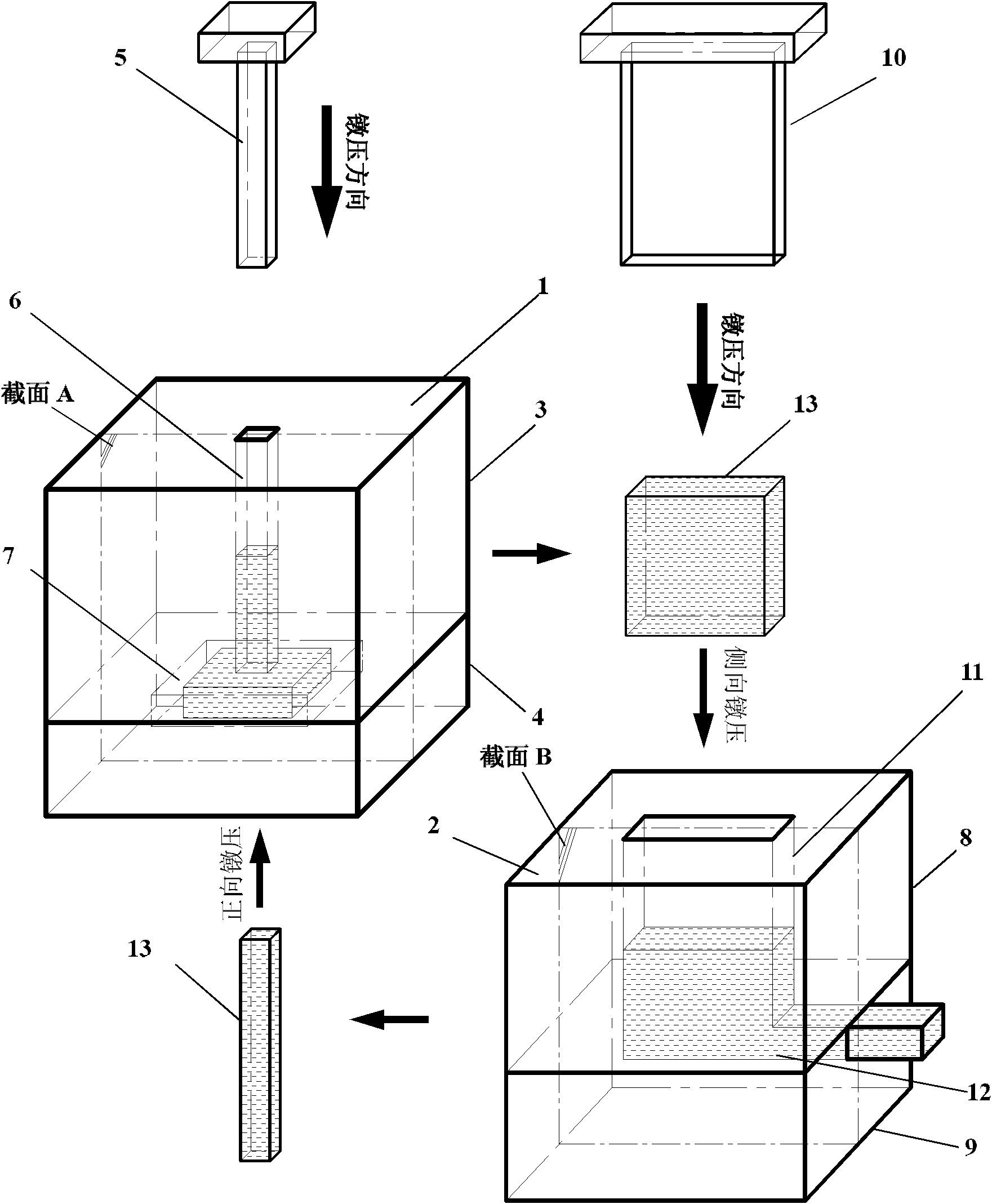

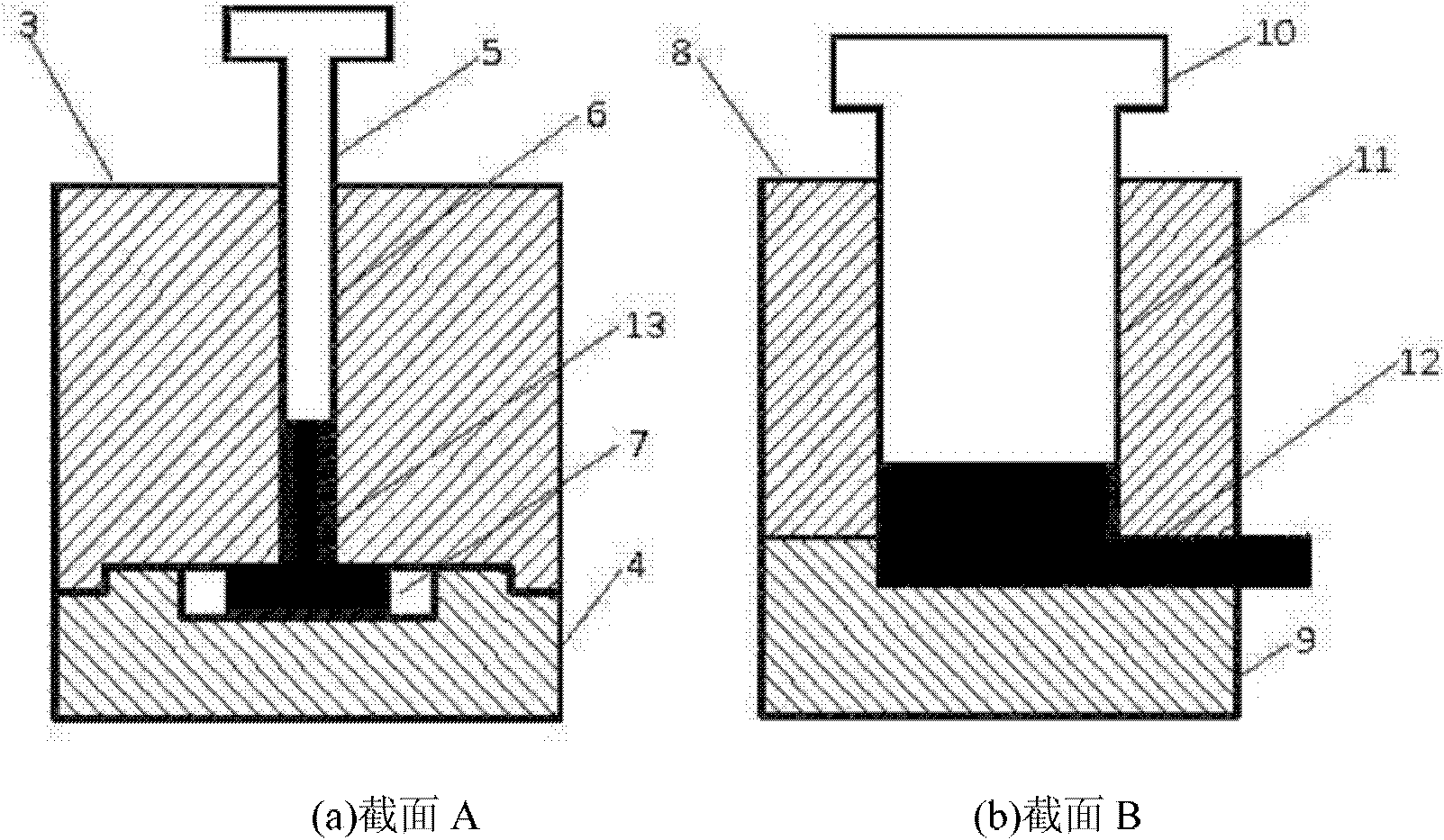

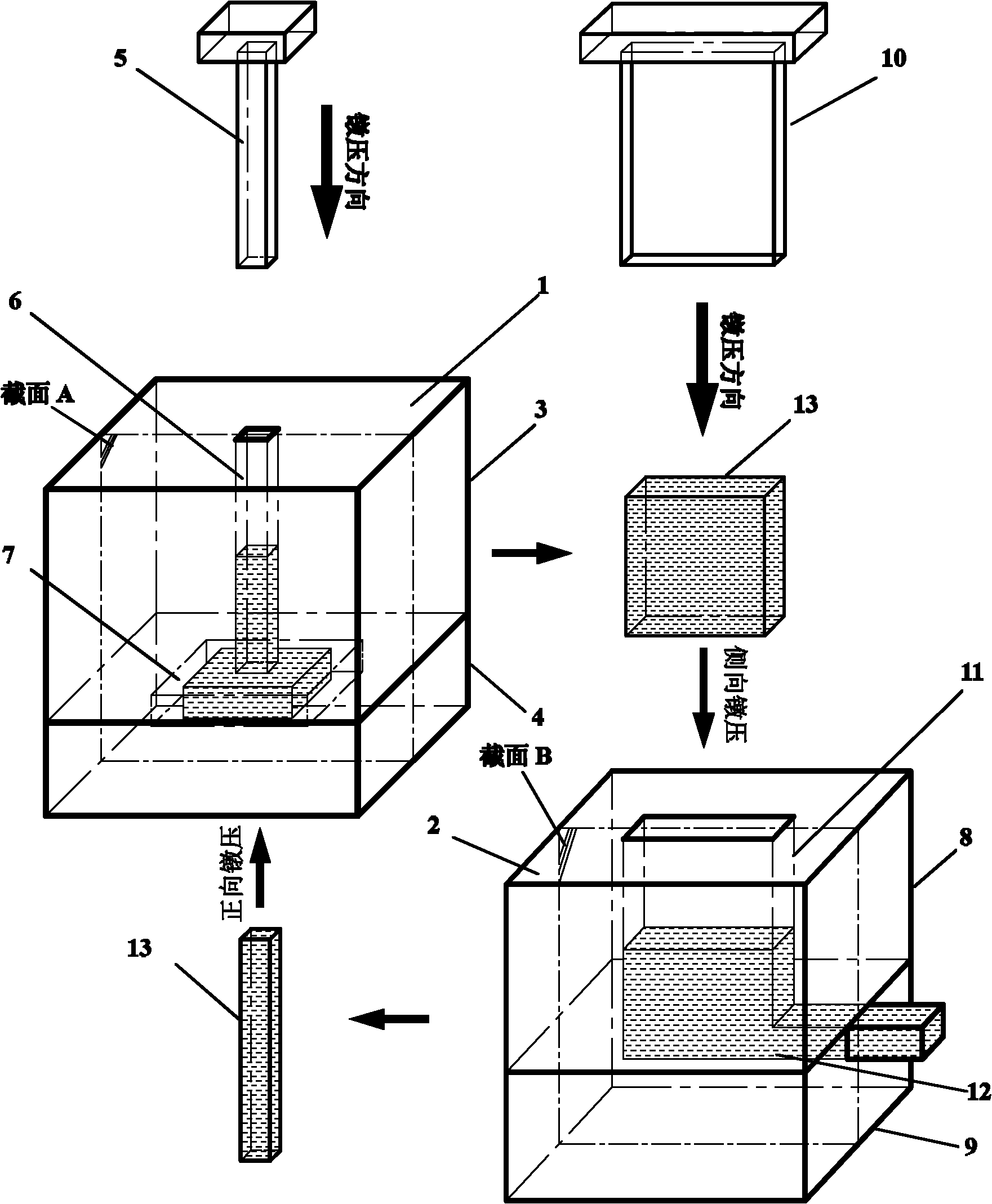

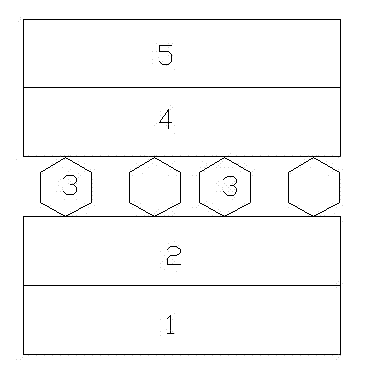

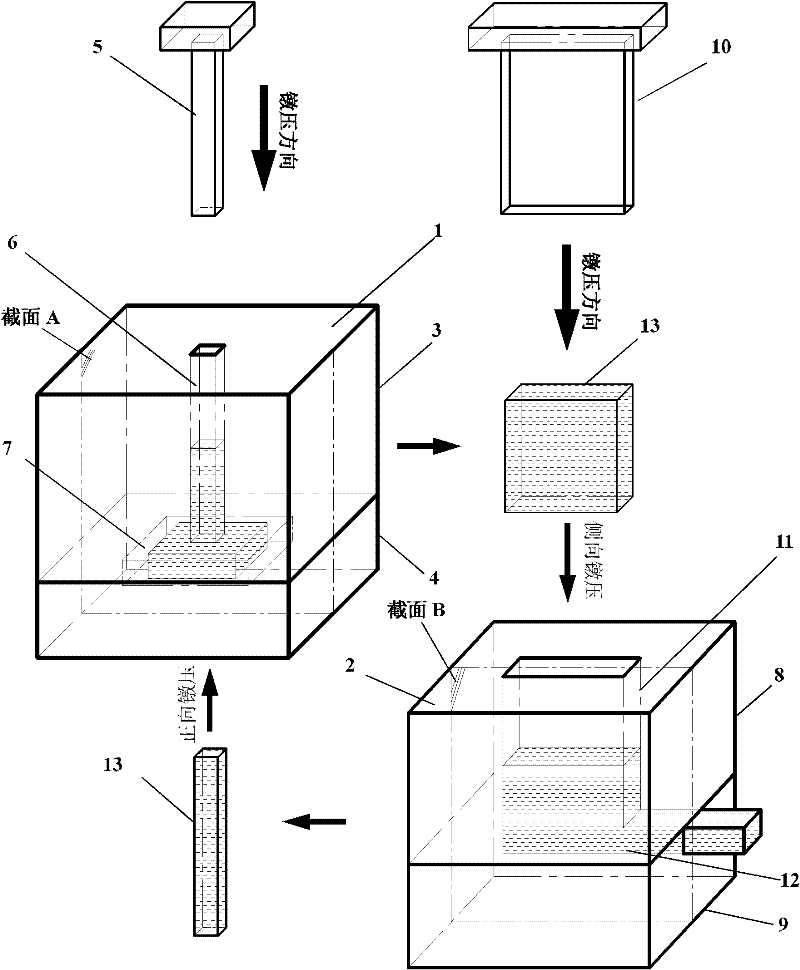

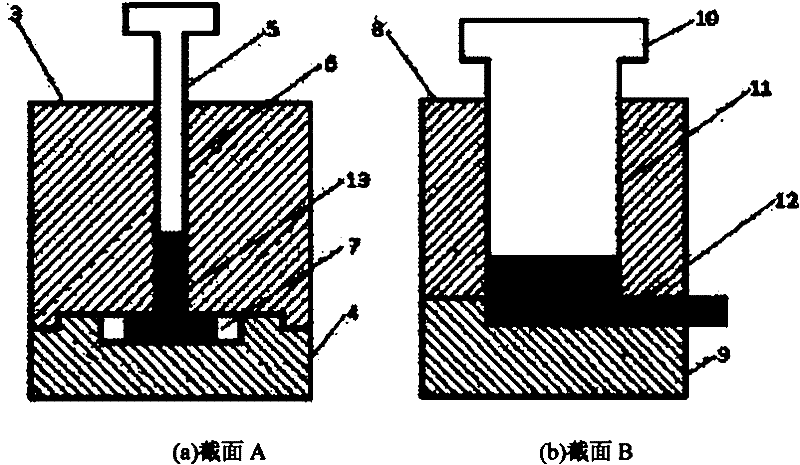

Multidirectional combined type circulating upsetting device and upsetting method

The invention relates to a multidirectional combined type circulating upsetting device and an upsetting method thereof, and belongs to the technical field of plastic forming. The upsetting device comprises a forward upsetting device and a lateral upsetting device. The method comprises the following steps of: in the forward upsetting process, prearranging bar blanks of which the cross sections are square in a forward upper die cavity of the forward upsetting device, so that the blanks are subjected to compressive plastic deformation downwards to fill in a forward lower die cavity finally; opening the forward upsetting device, taking the blanks out and putting the blanks in a lateral upper die cavity of the lateral upsetting device, with the side face facing downward, so that test samples are subjected to lateral upsetting deformation towards an lateral opening in a lateral lower die, and stopping pressing until a lateral punch presses to a parting surface of the lateral upsetting device; and repeating the steps for multiple times to perform multidirectional combined type upsetting circularly. By the upsetting device, superfine crystal blocks with uniform tissue can be prepared, so the upsetting device is used for preparing various superfine crystal materials such as pure metals, alloys, intermetallic compounds, composite materials, high polymer materials, semiconductor materials and the like.

Owner:上海治实合金科技有限公司

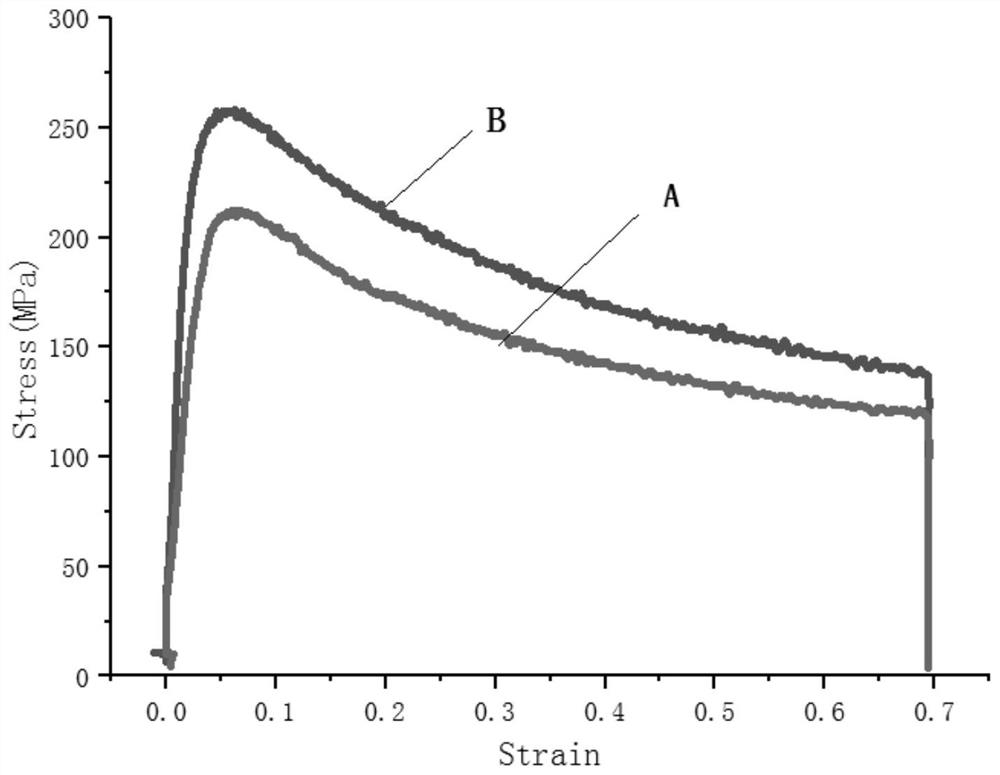

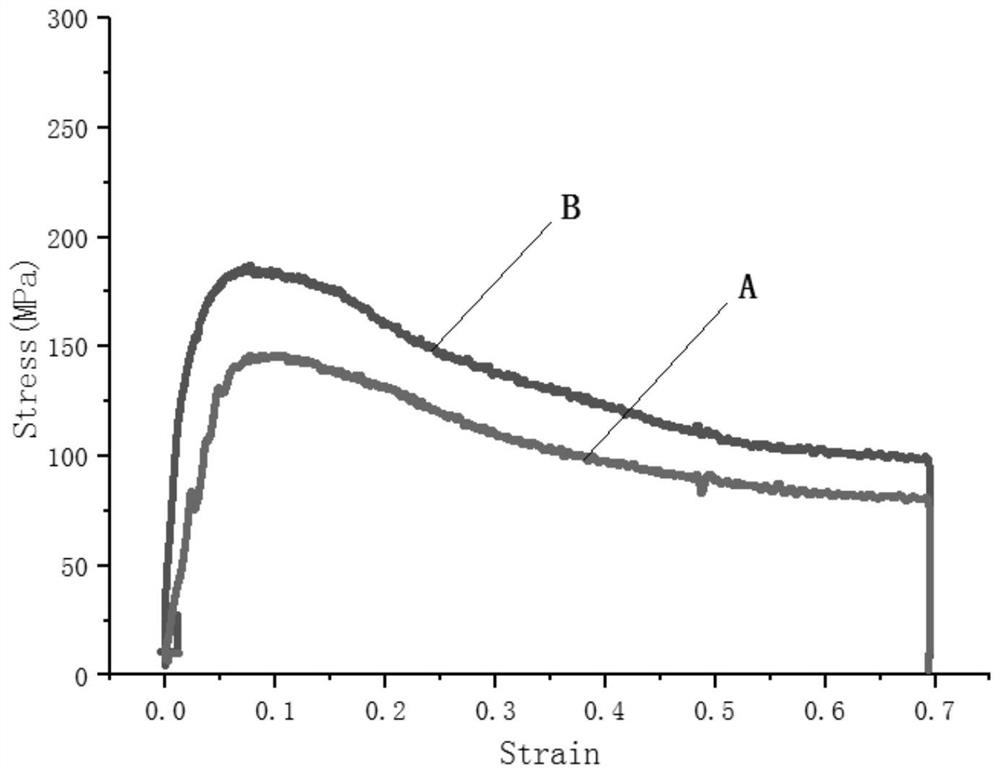

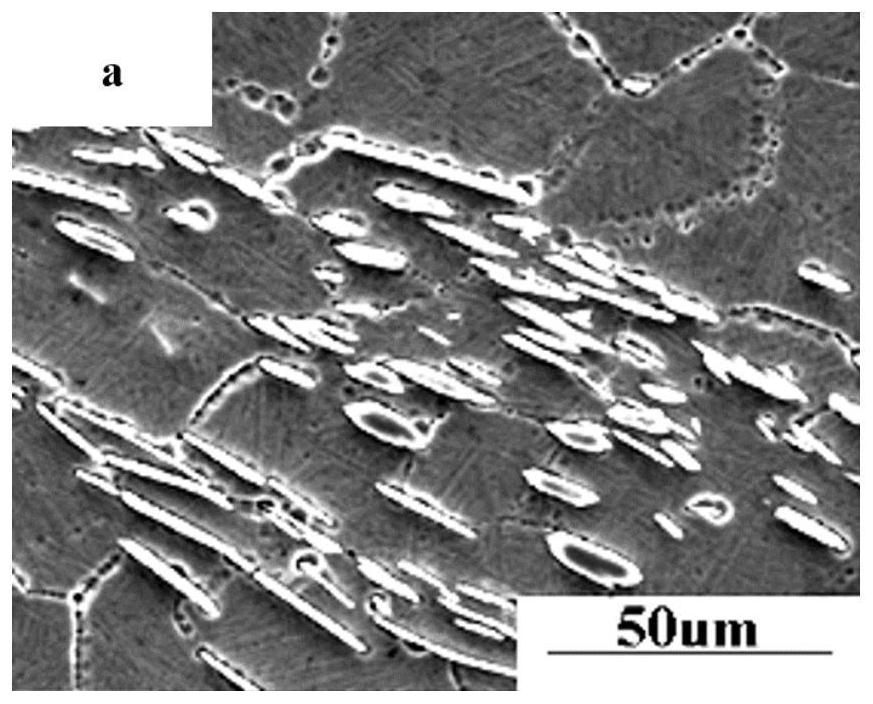

Preparation method of carbon nanotube / alloy composite with directionally aligned carbon nanotubes

The invention provides a preparation method of a carbon nanotube / alloy composite with directionally aligned carbon nanotubes. The method comprises the following steps: first, evenly mixing a carbon nanotube powder and an alloy powder according to proportion, and consolidating into block blanks; then heating the block blanks to a superplastic forming temperature of the alloy material in vacuum; and finally applying external force to form a velocity gradient field in the block blanks, so that carbon nanotubes align directionally along a filament line under the effect of fluid shear stress, and cooling and solidifying to obtain the carbon nanotube / alloy composite with directionally aligned carbon nanotubes. The invention solves the problem of directional alignment of carbon nanotubes in a carbon nanotube / alloy composite, so as to give full play to the performance of carbon nanotubes.

Owner:HENAN POLYTECHNIC UNIV

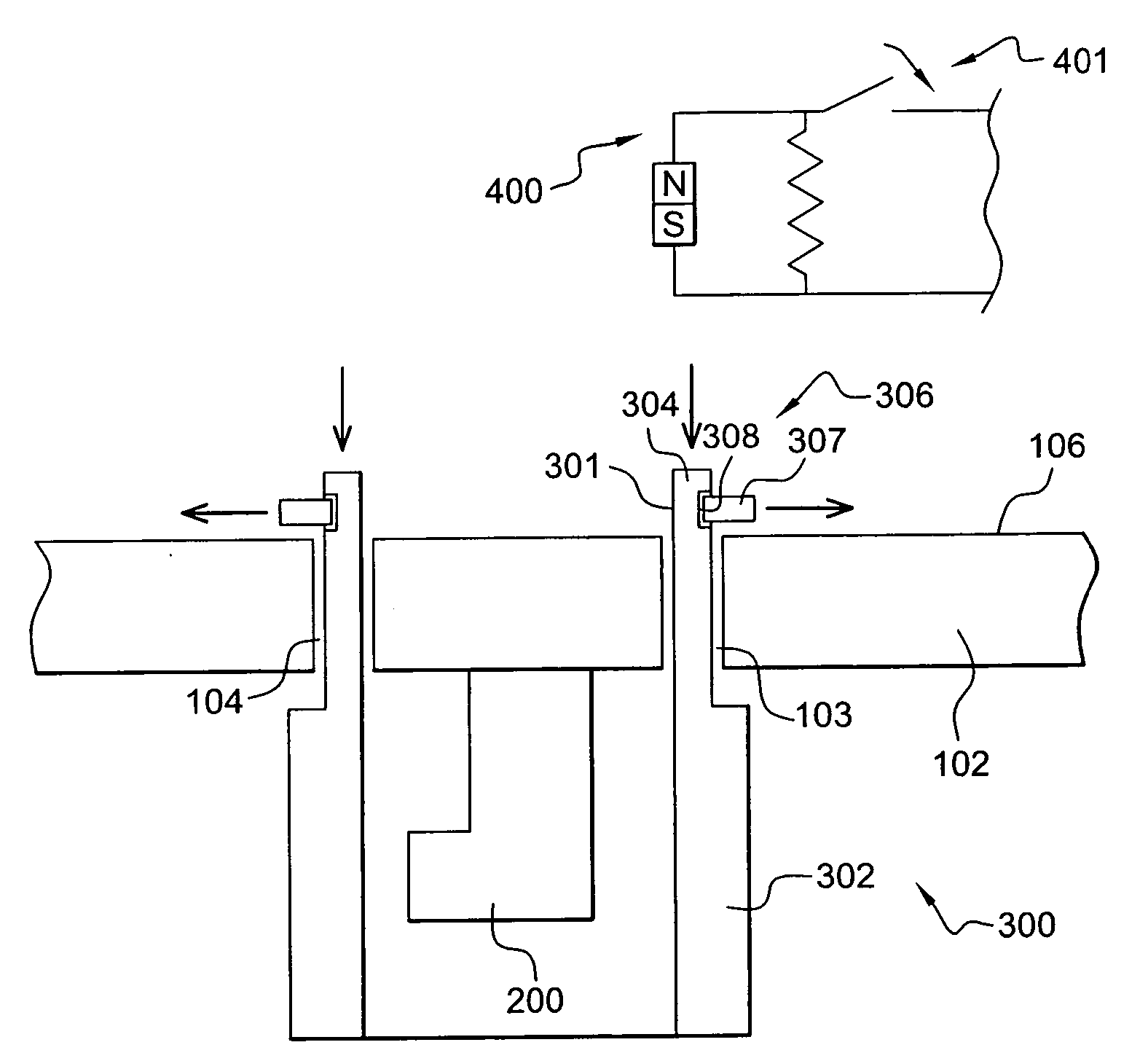

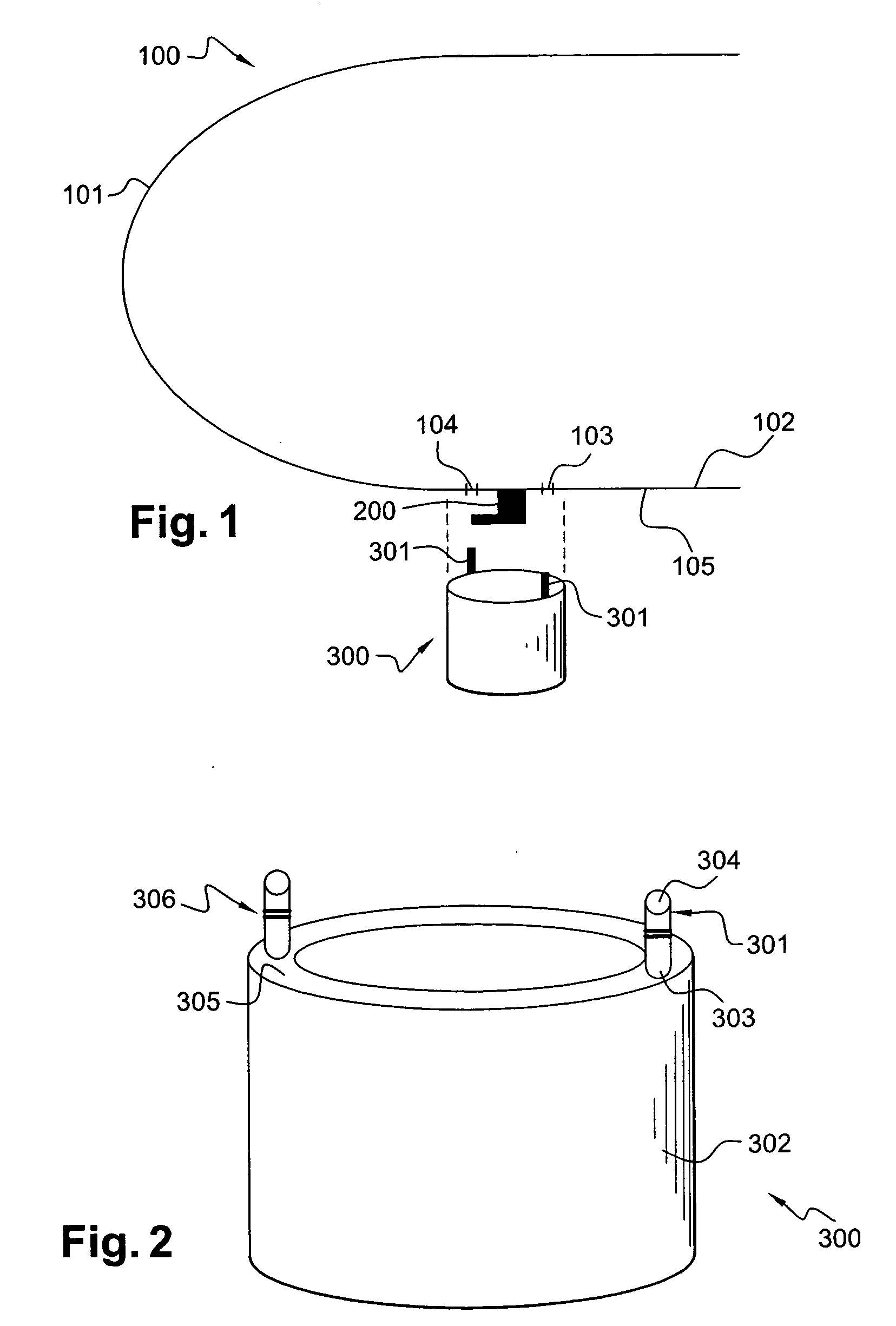

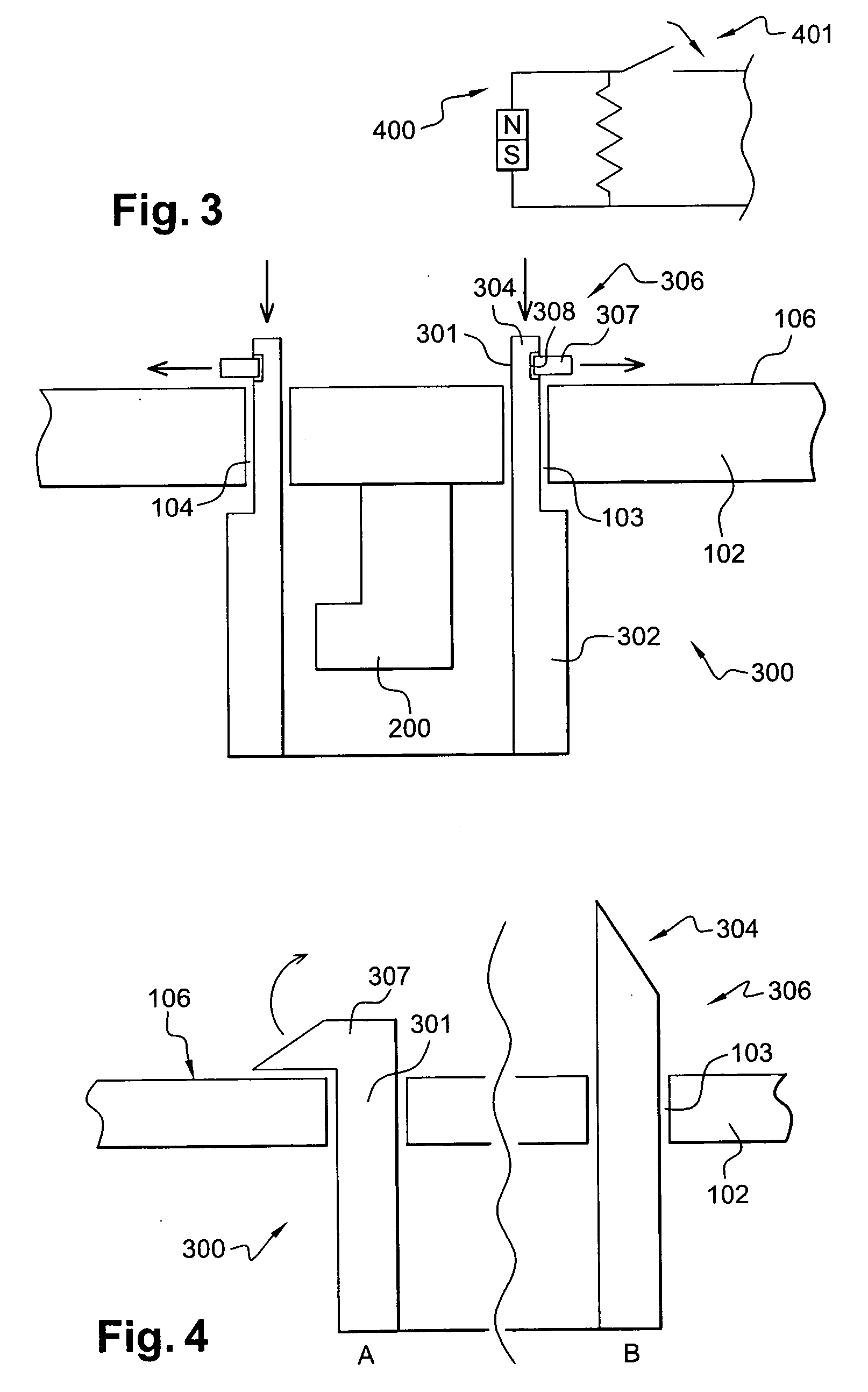

Device for the protection of a probe joined to an external wall of an aircraft

InactiveUS7175344B2Raise the deformation temperatureLower deformation temperatureThermometer detailsThermometers using electric/magnetic elementsBiomedical engineeringAirplane

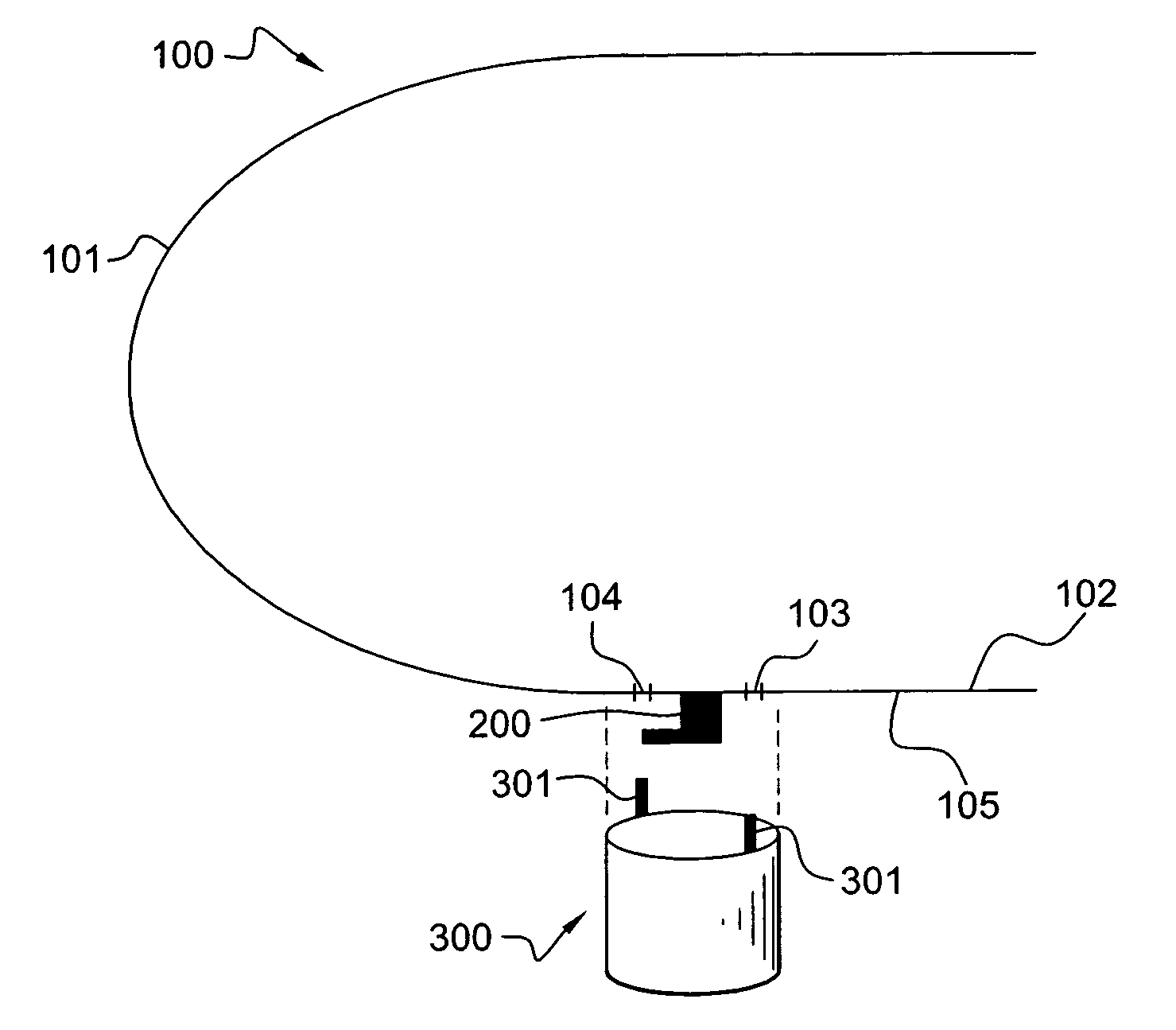

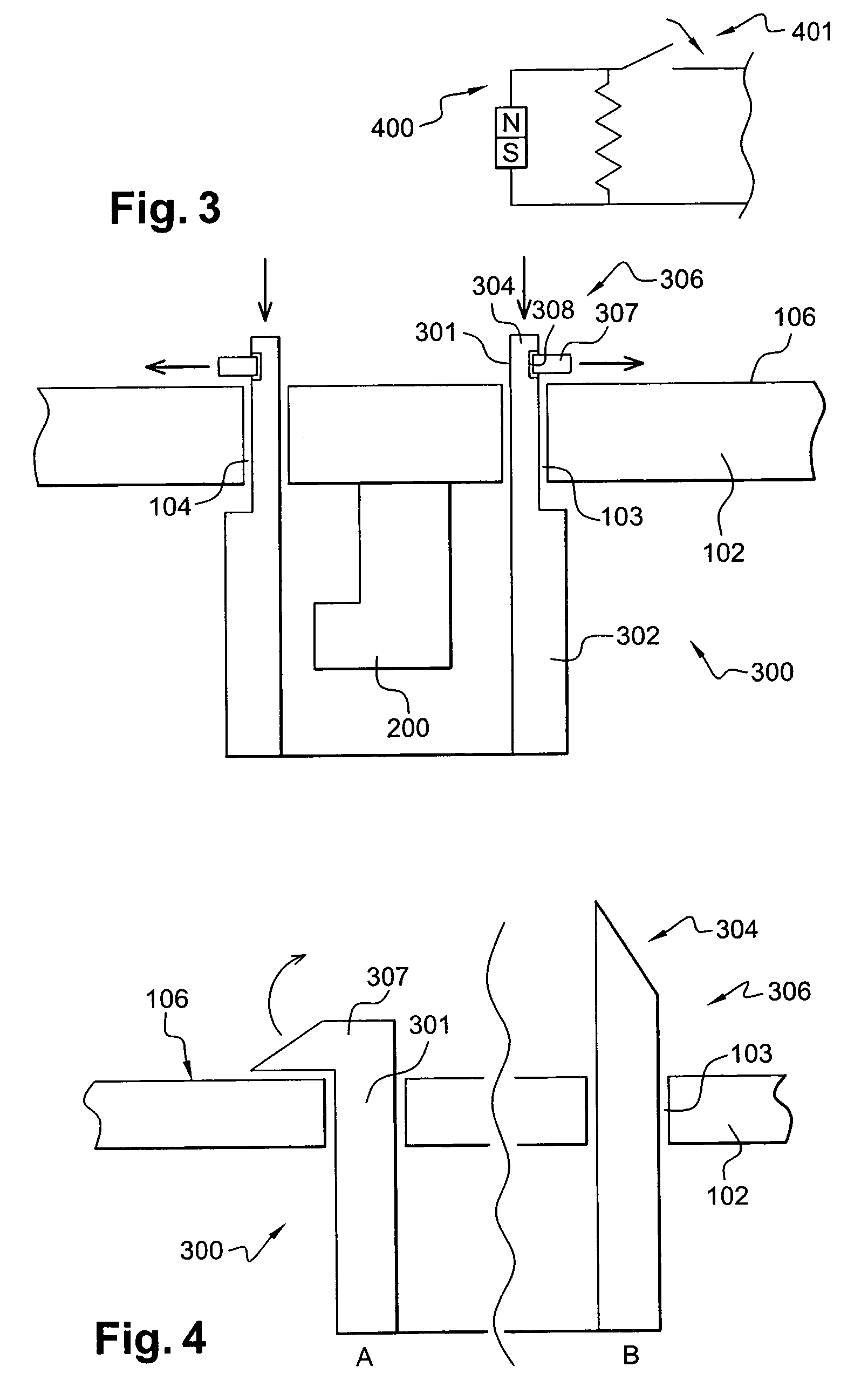

The invention relates to a device for the protection of a probe joined to a wall of an aircraft. Detachable means for fastening to the wall of the protection device are sensitive to a modification of a temperature of the probe. For example, the fastening means are made of a shape memory material. A rise in temperature enables a deformation of the fastener means and a separation of the device from the wall. It is also possible to make the fastener means out of magnetostrictive or polarizable material in order to separate the protection device when the fastener means are subjected to a magnetic field. Thus, the fastener means may comprise a polarizable pin that withdraws from a housing made on a through-hole unit when it is subjected to the magnetic field generated by an electromagnet.

Owner:AIRBUS OPERATIONS (SAS)

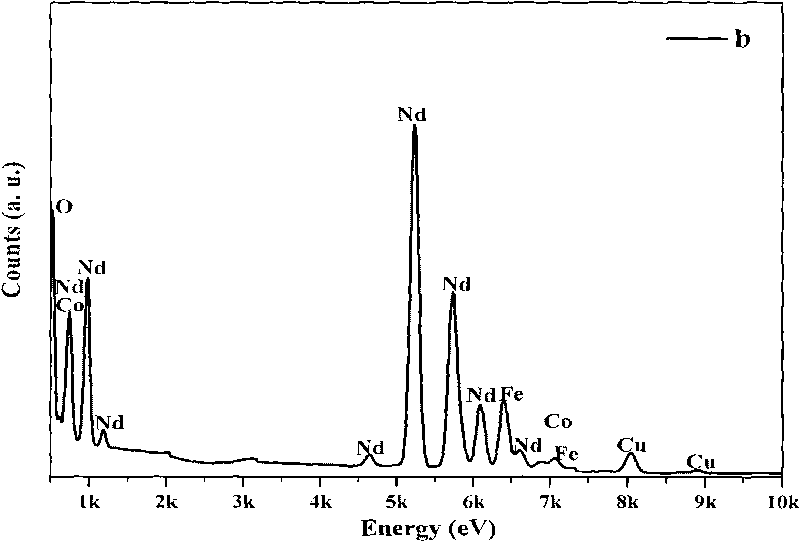

Method for simultaneously improving magnetic property and mechanical property of hot-pressing magnet ring

InactiveCN101692370ALow melting pointLow rheologyPermanent magnetsInorganic material magnetismAlloyMechanical property

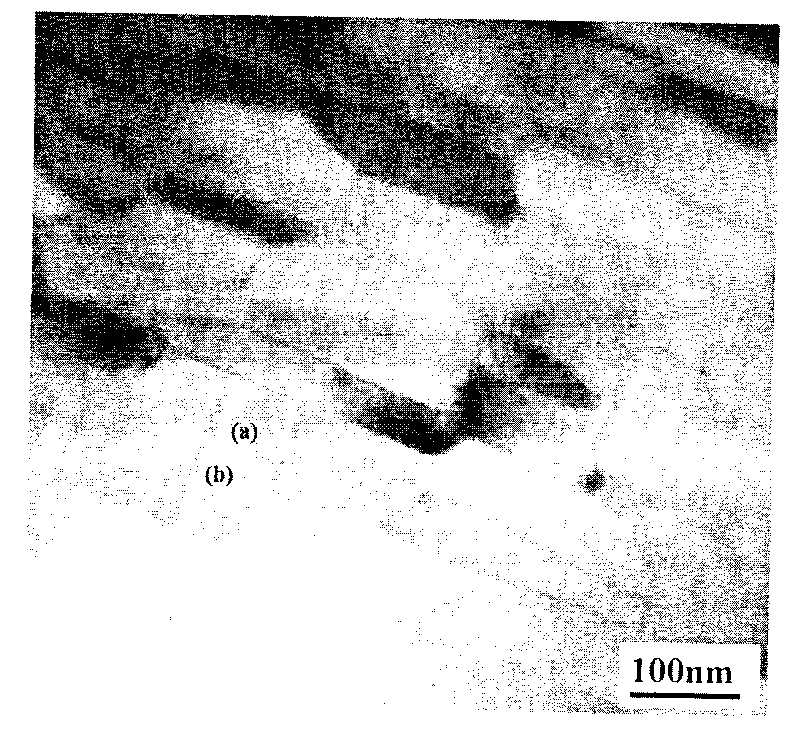

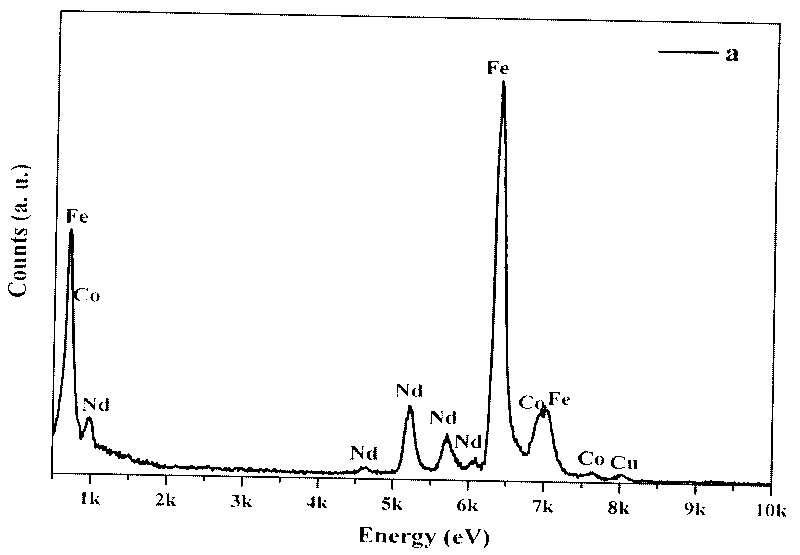

The invention discloses a method for simultaneously improving the magnetic property and mechanical property of a hot-pressing magnet ring, comprising the following steps: quickly quench a band by taking NdFeB strip-casting flake as a master alloy; then, breaking and magnetically separating the band into even quickly quenched powder; and performing hot-press shaping and hot extrusion shaping. The invention is characterized in that nanometer metal Cu powder is evenly added in quickly quenched powder before hot extrusion shaping. Compared with the prior art, the invention has the advantages that nanometer metal Cu powder with low melting point and favourable ductility is added to ensure that nanometer metal powder with the characteristic can be evenly distributed in an NdFeB crystal particle crystal boundary in a diffusing mode in the hot pressing process; the magnetic body texture is improved, and Vickers hardness of the crystal boundary phase compound is far larger than the Vickers hardness of the NdFeB magnetic body crystal boundary Nd-rich phase, thus reaching the purpose of improving the NdFeB mechanical property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

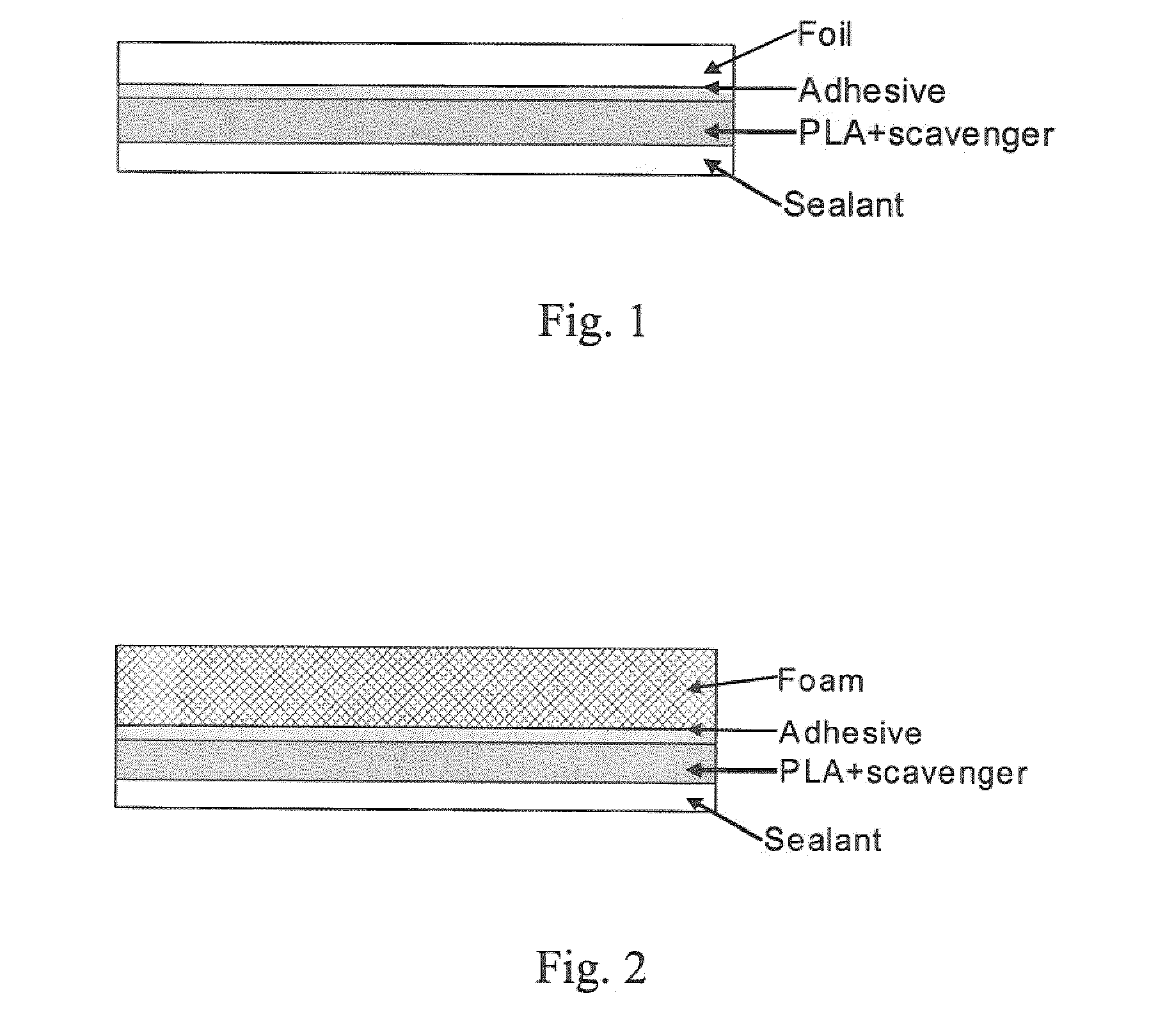

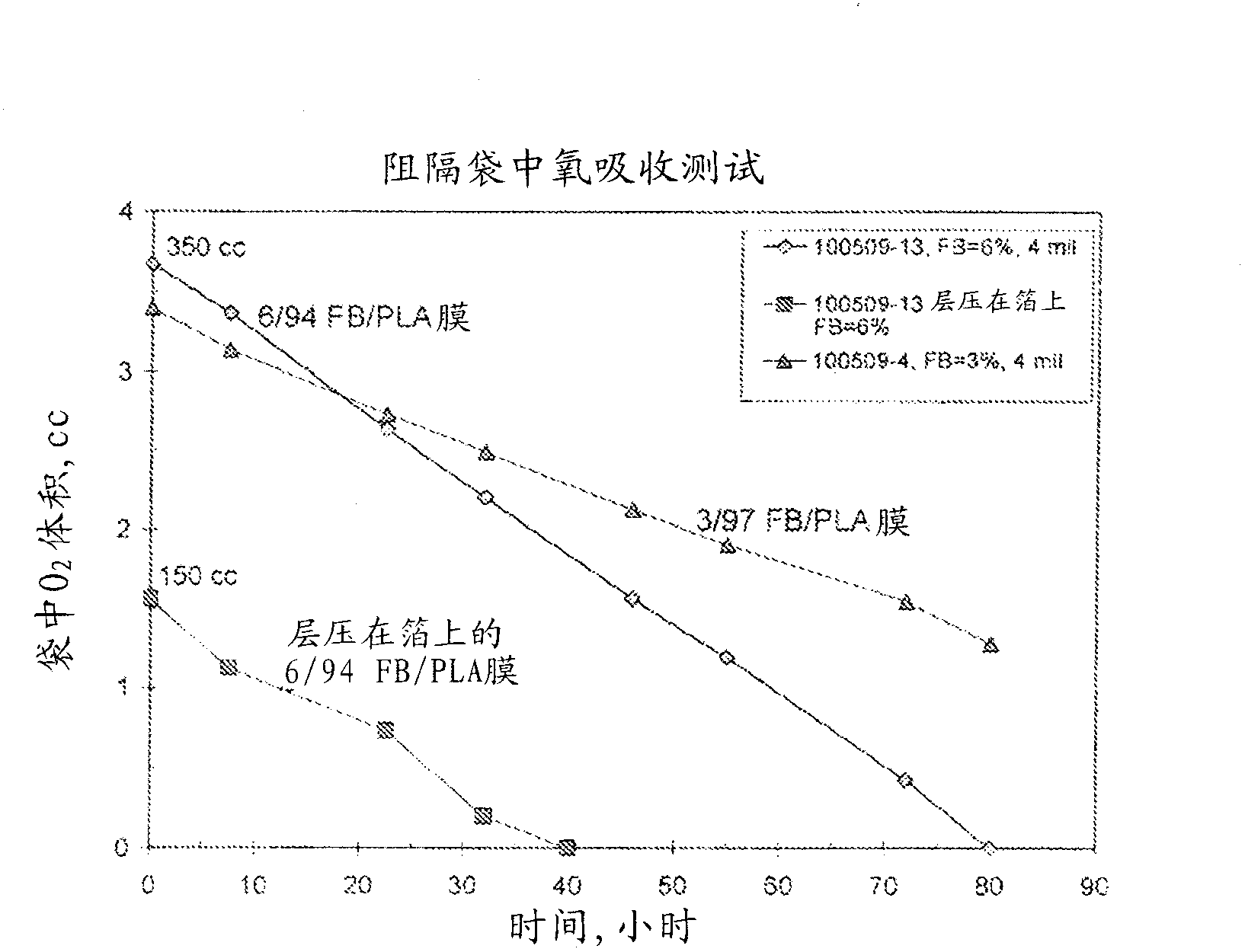

Biodegradable polymer articles containing oxygen scavenger

InactiveUS20110281125A1Lower deformation temperatureHydrogenOther chemical processesPolymer scienceBiodegradable polymer

The invention provides a biodegradable oxygen absorbing plastic comprising a biodegradable substrate a sufficient concentration of reduced iron particles to adsorb oxygen in significant quantities and reduce the deformation temperature of the substrate substantially below the deformation temperature without iron particles present.

Owner:MULTISORB TECH INC

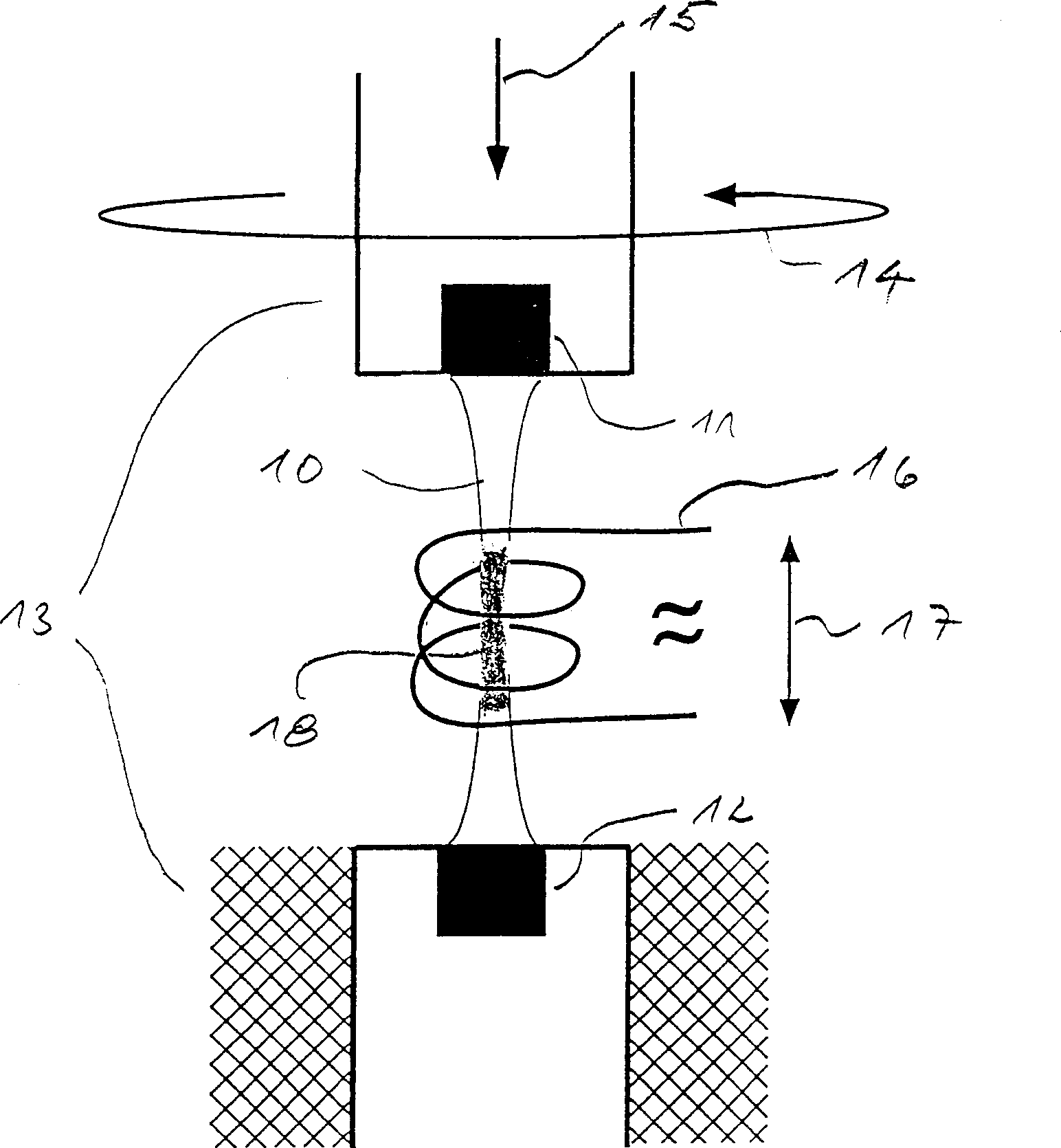

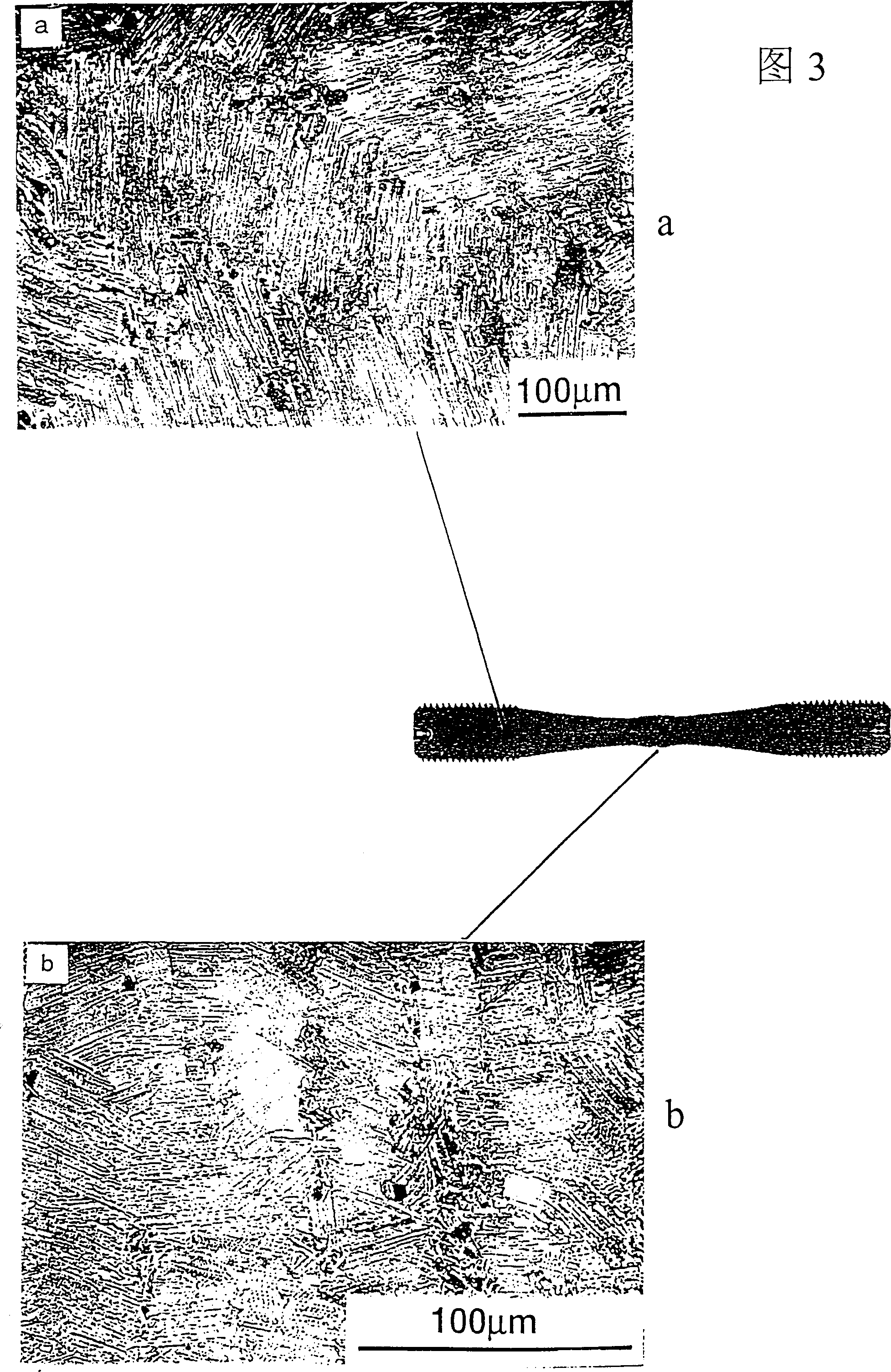

Method for strengthening metal material tissue and metal blank

InactiveCN1380437ALower deformation temperatureImprove structural performanceForging press detailsMetallic materialsMetal

Process for treating metallic materials, especially for consolidating the structure of metallic materials comprises producing a blank of the metallic materials, heating to a deformation temperature and deforming the blank. An Independent claim is also included for a blank made from titanium aluminide. Preferably deformation is exerted by producing torsion or compressing. Heating is carried out using electrical induction. Deformation is carried out at 1,000 degrees C.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

Device for the protection of a probe joined to an external wall of an aircraft

InactiveUS20050152434A1Raise the deformation temperatureLower deformation temperatureThermometer detailsSpeed/acceleration/shock instrument detailsBiomedical engineeringAirplane

The invention relates to a device for the protection of a probe joined to a wall of an aircraft. Detachable means for fastening to the wall of the protection device are sensitive to a modification of a temperature of the probe. For example, the fastening means are made of a shape memory material. A rise in temperature enables a deformation of the fastener means and a separation of the device from the wall. It is also possible to make the fastener means out of magnetostrictive or polarizable material in order to separate the protection device when the fastener means are subjected to a magnetic field. Thus, the fastener means may comprise a polarizable pin that withdraws from a housing made on a through-hole unit when it is subjected to the magnetic field generated by an electromagnet.

Owner:AIRBUS OPERATIONS (SAS)

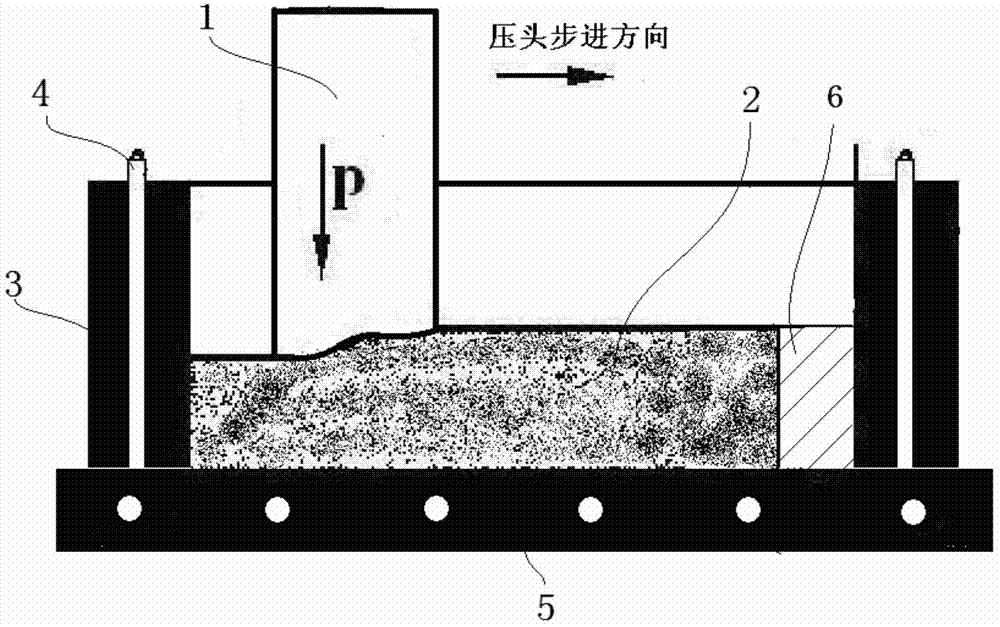

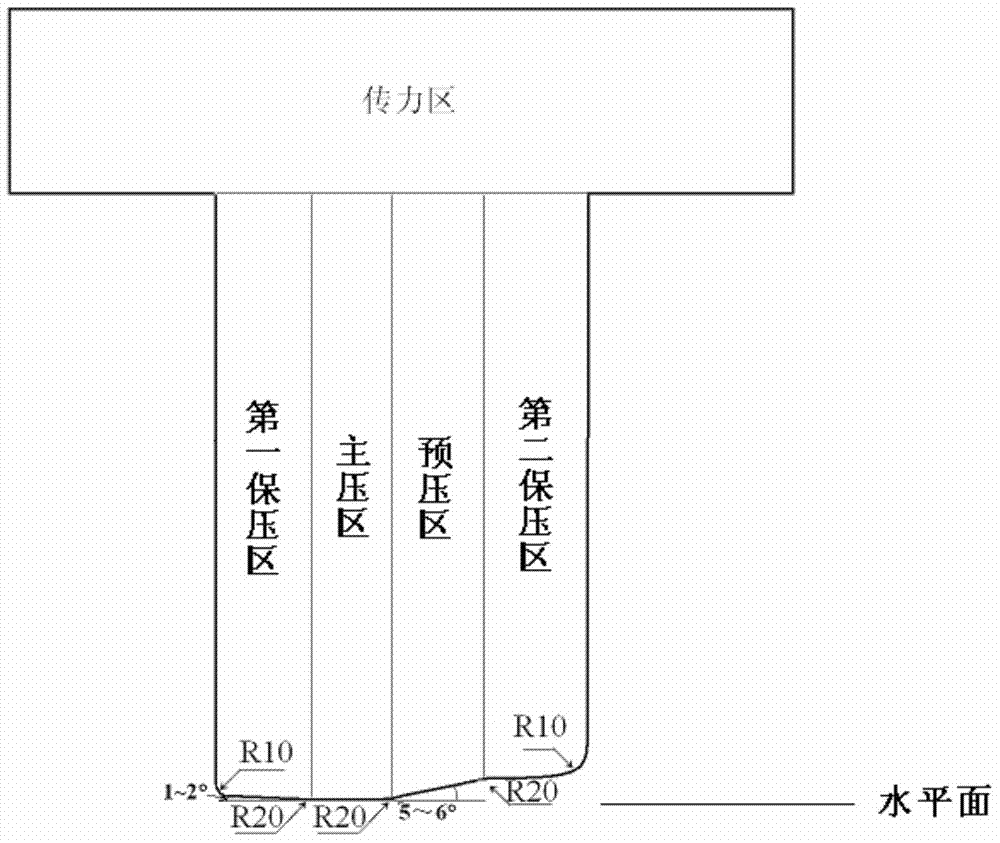

Pressing head and device for achieving densification of spray deposition porous panel and application thereof

Owner:HUAIHAI INST OF TECH

Processing and forming process of high-strength nickel-based high-temperature alloy bar

The invention relates to a processing and forming process of a high-strength nickel-based high-temperature alloy bar. The bar comprises the following components of, in percentage by mass, 16%-23% of Cr, 15%-20% of Co, 2.5%-4.0% of Al, 1.0%-2.5% of Ti, 0.5%-1.5% of Nb, 3.0%-7.0% of W+Mo, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.04%-0.07% of C, and the balance is Ni. Analloy is mainly in a dual phase structure of austenite and Ni3Al(gamma'), as well as M23C6 type carbides distributed discontinuously at a grain boundary. The alloy is prepared by adopting a vacuum smelting process, and then is forged into a bar by adopting a multi-pass small deformation mode, and finally surface turning and heat treatment are carried out on the bar. According to the process, deformation processing of the alloy with high content of W and Mo is conducted, and the final deformation of the alloy can reach 75% or higher while the strength of the alloy is considered.

Owner:HUANENG POWER INTERNATIONAL +1

Method for preparing monolayer cubic boron nitride grinding wheel by pressure welding

Disclosed is a method for preparing a monolayer cubic boron nitride grinding wheel by pressure welding. The method includes the following steps of (1) selecting a grinding wheel base material and using a mechanical processing method to prepare a grinding wheel substrate; (2) preparing an amorphous alloy binding layer with a uniform thickness in a protection environment; (3) configuring and fixing cubic boron nitride abrasive particles on the surface of the amorphous alloy binding layer at the room temperature, manufacturing a grinding wheel blank and placing a ceramic pressing piece and a pressing matter on top of the grinding wheel blank; and (4) placing the grinding wheel blank, the ceramic pressing piece and the pressing matter in a heating furnace and then rapidly cooling to the room temperature to obtain the monolayer cubic boron nitride grinding wheel. The amorphous alloy material has the advantages of high tensile strength and hardness, low heat expansion coefficient and the like, so that the strength and abrasion resistance of a grinding wheel combination material can be improved, and a residual stress formed between the abrasive particles and the combination material can be reduced. The abrasive particles are pressed into the amorphous alloy, due to the fact that many active elements which can be reacted with cubic boron nitride are contained in the material, a small amount of compound can be formed through prolonging the heat preservation time, and the holding force of the amorphous alloy on the abrasive particles can be increased. The processing quality of the prepared grinding wheel surface is high, and the grinding wheel can be used for high precision grinding processing.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Multidirectional combined type circulating upsetting device and upsetting method

The invention relates to a multidirectional combined type circulating upsetting device and an upsetting method thereof, and belongs to the technical field of plastic forming. The upsetting device comprises a forward upsetting device and a lateral upsetting device. The method comprises the following steps of: in the forward upsetting process, prearranging bar blanks of which the cross sections aresquare in a forward upper die cavity of the forward upsetting device, so that the blanks are subjected to compressive plastic deformation downwards to fill in a forward lower die cavity finally; opening the forward upsetting device, taking the blanks out and putting the blanks in a lateral upper die cavity of the lateral upsetting device, with the side face facing downward, so that test samples are subjected to lateral upsetting deformation towards an lateral opening in a lateral lower die, and stopping pressing until a lateral punch presses to a parting surface of the lateral upsetting device; and repeating the steps for multiple times to perform multidirectional combined type upsetting circularly. By the upsetting device, superfine crystal blocks with uniform tissue can be prepared, so the upsetting device is used for preparing various superfine crystal materials such as pure metals, alloys, intermetallic compounds, composite materials, high polymer materials, semiconductor materials and the like.

Owner:上海治实合金科技有限公司

Optical glass

An optical glass includes, by weight: 1% or more and 5% or less of silicon oxide (SiO2); 15% or more and 24% or less of boron oxide (B2O3); 0.1% or more and 3% or less of aluminum oxide (Al2O3); 1% or more and 14% or less of zinc oxide (ZnO); 35% or more and 45% or less of lanthanum oxide (La2O3); 5% or more and 10% or less of yttrium oxide (Y2O3); 5% or more and 13% or less of tantalum oxide (Ta2O5); and 0.5% or more and 3% or less of lithium oxide (Li2O).

Owner:FUJIFILM CORP

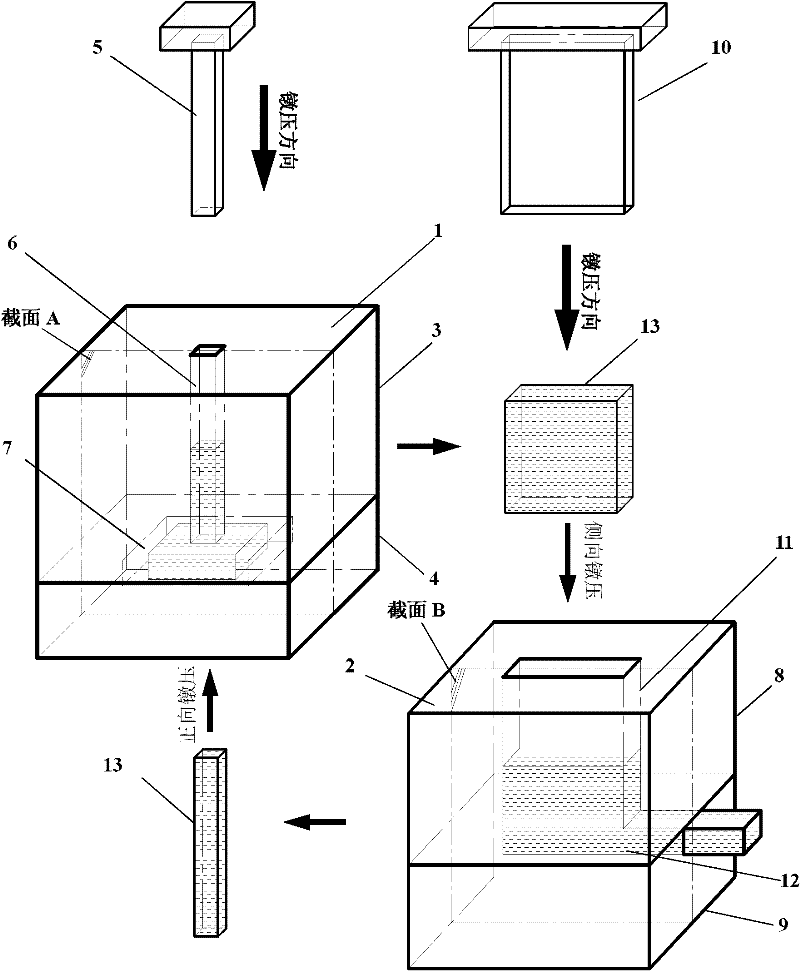

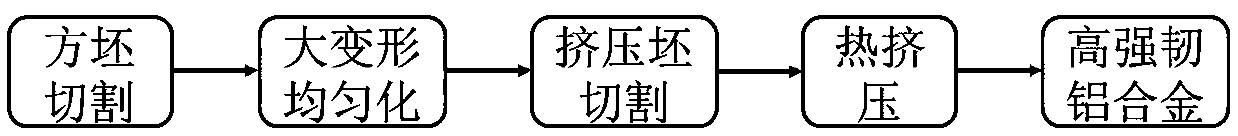

Preparation method of aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization

The invention discloses a preparation method of an aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization. The production method comprises the following steps of A, cutting 7XXX-series aluminum alloy cast ingots to obtain blanks; B, conducting continuous equal-channel angular pressing machining on the blanks at the solution temperature to realize largedeformation homogenization and obtaining supersaturated solid solution block extrusion blanks; C, cutting the block extrusion blanks into alloy bars of which the length direction is parallel to the equal-channel angular pressing direction; and D, conducting hot extrusion processing on the alloy bars to obtain the aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization. Through the preparation method, the large deformation homogenization effect is achieved through continuous equal-channel angular pressing at the solid solution temperature, the defect density of the homogenized alloy is increased, grains are refined through follow-up hot extrusion, dynamic precipitation of nano precipitated phases is promoted, the aluminum alloy structure with the refined grains and uniform and high-density nano precipitated phases is obtained, and the strength and ductility of the alloy are remarkably improved.

Owner:江苏江南创佳型材有限公司

Method for extrusion two-step equal channel angle of magnesium alloy

InactiveCN1331621CHigh strengthImprove toughnessExtrusion control devicesEqual channel angular extrusionMaterials processing

A two-step squeeze method with equal channel angle for Mg-alloy includes such steps as designing equi-channel squeezing die set, regulating deformation speed and temp to find out the lowest temp for non-crack deformation, equichannel squeezing by 2-4 passes, lowering the deformation temp, and squeezing by 4-8 passes. Its advantage is high strength and toughness.

Owner:FENGYANG L S NET FORMING CO LTD

Wear-resisting bearing steel ball and preparing method thereof

InactiveCN106834956ALower deformation temperaturePrevent from growing thickerHardnessResidual stress

The invention discloses a wear-resisting bearing steel ball. The wear-resisting bearing steel ball comprises, by weight, 0.8%-0.9% of C, 1.5%-1.65% of Cr, 0.1%-0.3% of Si, 0.4%-0.6% of Mn, 0.01%-0.03% of Ni, 0.2%-0.4% of Mo, 0.3%-0.4% of Al, 0.1%-0.2% of V, smaller than or equal to 0.01% of S, smaller than or equal to 0.01% of P and the balance Fe, wherein the expression that C-0.8Al-1.3V is smaller than 0.51% is met. The invention further discloses a preparing method of the above wear-resisting bearing steel ball. Due to the fact that all the elements are matched with a proper proportion and the proper preparing method is matched, small spherical carbide can be promoted to be evenly distributed in the steel ball, the spheroidizing annealing time is shortened, the large amount of carbide is promoted to be subjected to solid solution, wear resistance, hardness, strength and toughness of the wear-resisting bearing steel ball are greatly improved, and residual stress is eliminated.

Owner:芜湖市永帆精密模具科技有限公司

Optical glass

ActiveUS20110306487A1Stable maintenanceExcellent quantity productivityOptical elementsVitrificationRefractive index

An optical glass in includes SiO2, B2O3, Al2O3, BaO, CaO, ZnO, La2O3, Gd2O3, and Y2O3, each in a specific ratio. Further, the optical glass satisfies the following conditional expressions (1) and (2), taking the content of SiO2 as A, the content of B2O3 as B, the content in total of La2O3, Gd2O3 and Y2O3 as C, and the content in total of SiO2 and B2O3 as D.0.35<A / B<0.70 (1)0.80<C / D<1.0 (2)By the above constitution, a high refractive index and low dispersibility are secured and at the same time deformation temperature (and glass transition temperature) lowers. By containing Al2O3, the glass structure is stabilized and a failure in appearance such as cloudiness in press molding is difficult to occur.

Owner:FUJIFILM CORP

High-intensity bearing steel ball and preparing method thereof

InactiveCN106834955APrevent from growing thickerLower deformation temperatureHigh intensitySteel ball

The invention discloses a high-strength bearing steel ball. The high-strength bearing steel ball comprises, by weight, 0.85%-0.95% of C, 1.3%-1.4% of Cr, 0.1%-0.3% of Si, 0.2%-0.4% of Mn, 0.1%-0.2% of Mo, 0.05%-0.07% of Ni, 0.08%-0.1% of W, 0.2%-0.3% of V, 0.1%-0.2% of Nb, smaller than or equal to 0.01% of S, smaller than or equal to 0.01% of P and the balance Fe, wherein the expression that C-2.3W-0.9V-1.1Nb is larger than 0.14% and smaller than 0.46% is met. The invention further discloses a preparing method of the above high-strength bearing steel ball. The high-intensity bearing steel ball has good strength, hardness, wear resistance and toughness.

Owner:芜湖市永帆精密模具科技有限公司

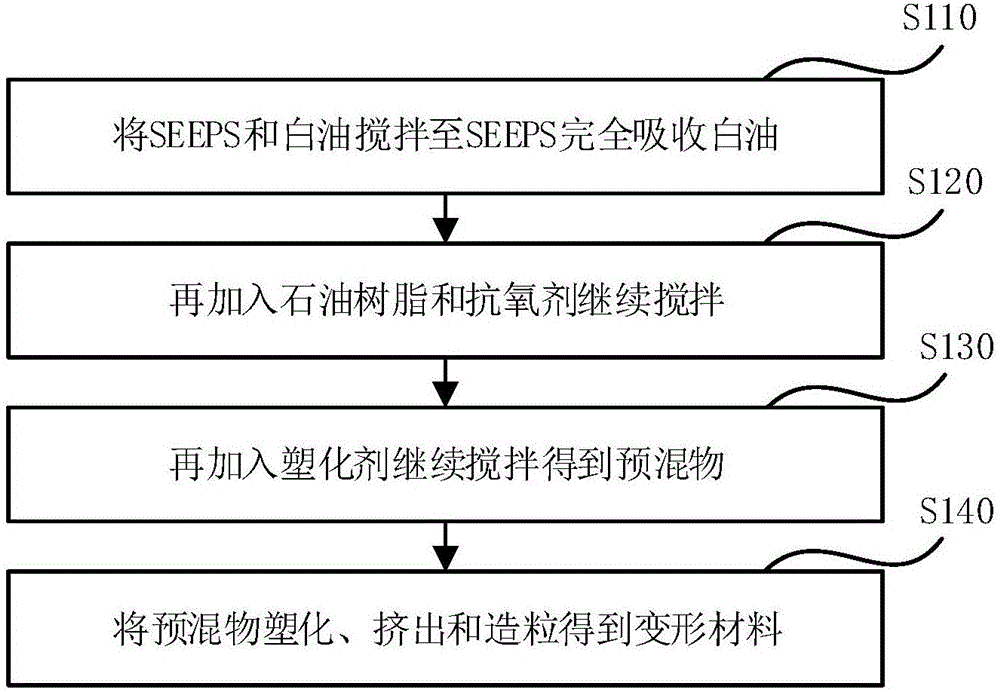

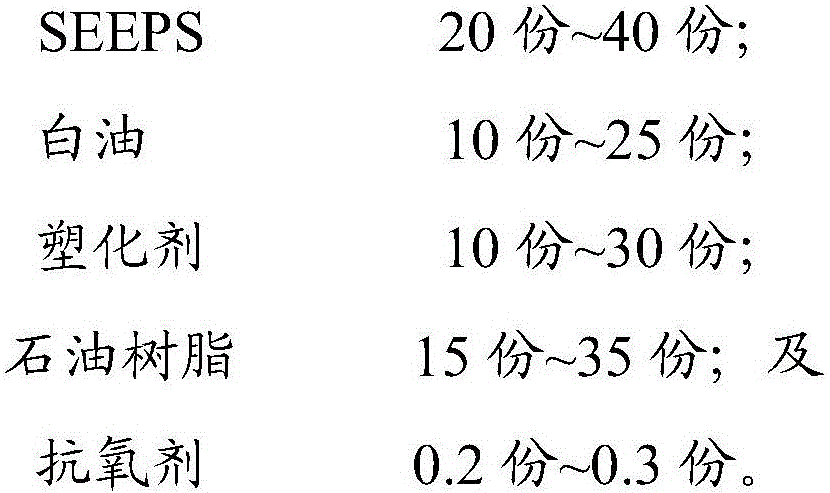

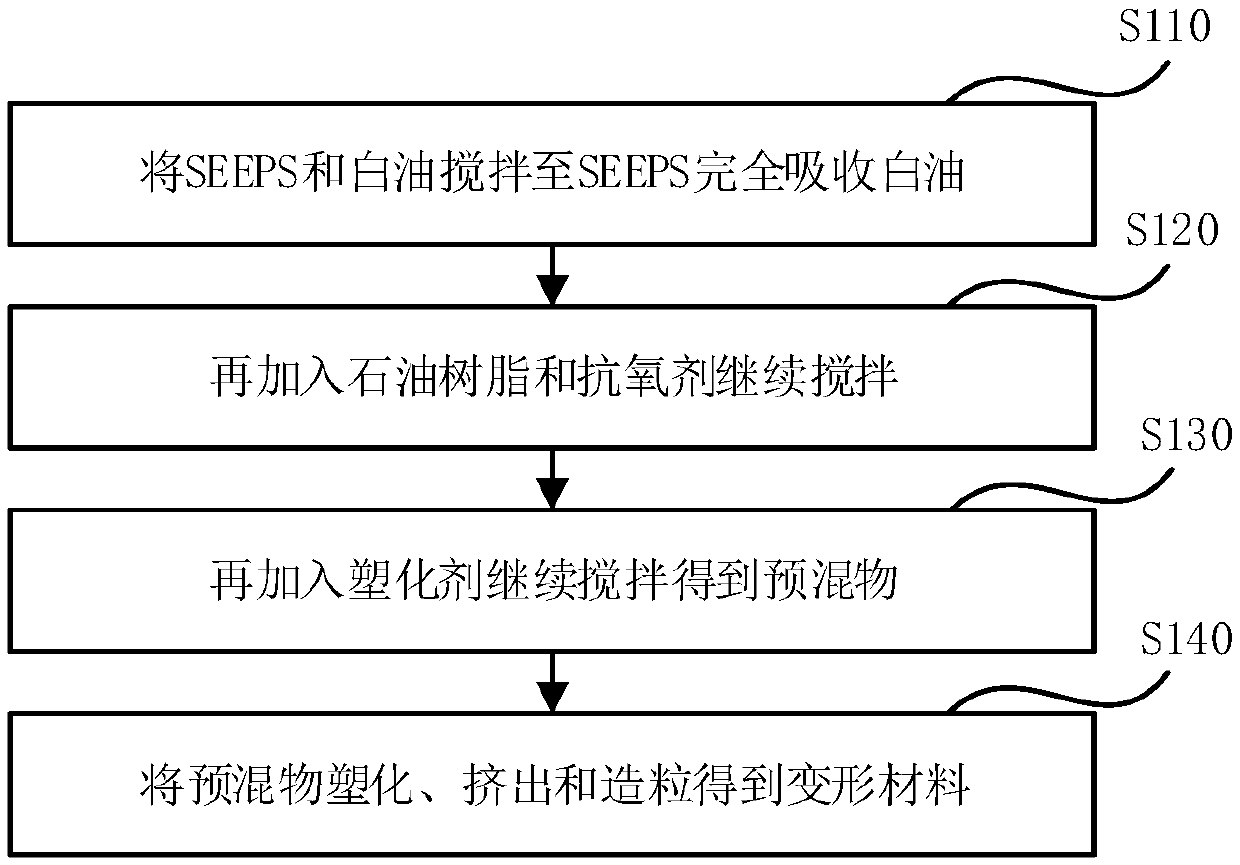

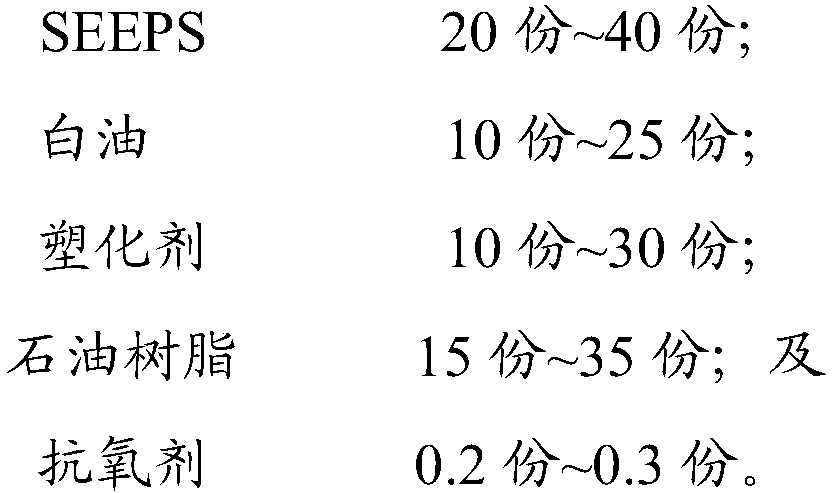

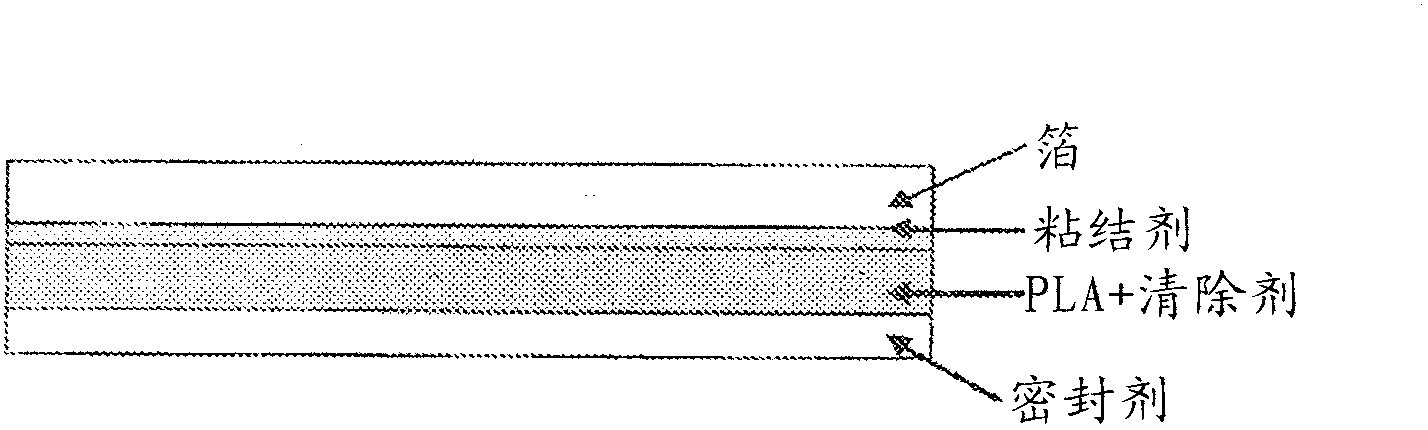

Deformation material and preparation method thereof

The invention relates to a deformation material, prepared from the following components in parts by mass: 20-40 parts of SEEPS, 10-25 parts of white oil, 10-30 parts of a plasticizer, 15-35 parts of petroleum resin and 0.2-0.3 part of an antioxidant. According to the deformation material, the SEEPS is used as a base material, the white oil, plasticizer, petroleum resin and antioxidant are used as auxiliary materials, and through reasonable proportioning, the binding property of the deformation material can be increased, and the elasticity and intensity of the material are reduced, thereby obtaining the deformation material with a lower deformation temperature. As shown by test data, the deformation temperature of the deformation material is 70-90 DEG C, the deformation temperature is lower, so the deformation material is safer in the use process for children.

Owner:盛嘉伦橡塑(河源)有限公司

Method for preparing secondary hardening ultrahigh-strength steel through SPS (Spark Plasma Sintering) sintering and deformation

The invention relates to a method for preparing secondary hardening ultrahigh-strength steel through SPS (Spark Plasma Sintering) sintering and deformation and belongs to the technical field of steel and iron material preparation. The method comprises the following steps that secondary hardening ultrahigh-strength steel powder is placed in an alloy mold, and discharge plasma high-pressure low-temperature preforming is carried out on SPS equipment to obtain a preformed pressed blank; then the preformed pressed blank is arranged in a graphite mold, and low-pressure high-temperature sintering is carried out on the SPS equipment to obtain a sintered blank; and finally, the sintered blank is placed in the center of the graphite mold, and high-temperature compression deformation is carried out on the SPS equipment to obtain a secondary hardening ultrahigh-strength steel blank. According to the method, the secondary hardening ultrahigh-strength steel is prepared by adopting discharge plasma sintering-discharge plasma deformation, the operation is simple, the energy consumption is low, the secondary hardening ultrahigh-strength steel with ultrahigh strength and good toughness can be directly obtained, and the subsequent complex heat treatment process is effectively avoided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Optical glass

An optical glass includes, by weight: 1% or more and 5% or less of silicon oxide (SiO2); 15% or more and 24% or less of boron oxide (B2O3); 0.1% or more and 3% or less of aluminum oxide (Al2O3); 1% or more and 14% or less of zinc oxide (ZnO); 35% or more and 45% or less of lanthanum oxide (La2O3); 5% or more and 10% or less of yttrium oxide (Y2O3); 5% or more and 13% or less of tantalum oxide (Ta2O5); and 0.5% or more and 3% or less of lithium oxide (Li2O).

Owner:FUJIFILM CORP

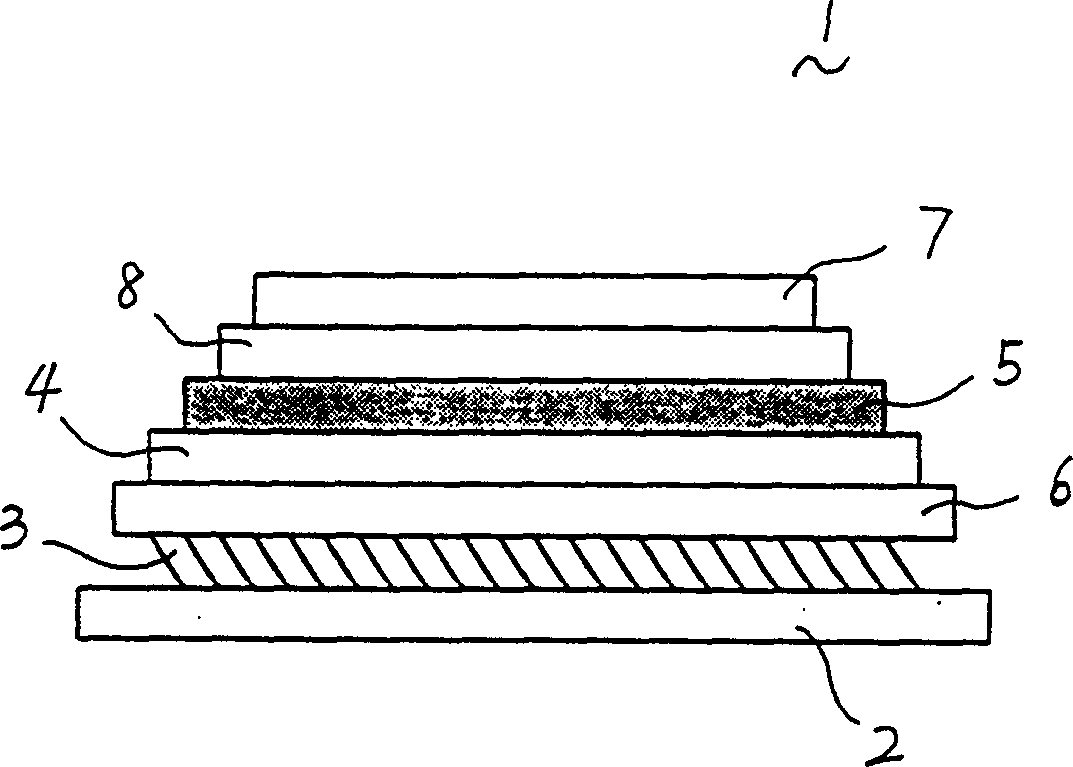

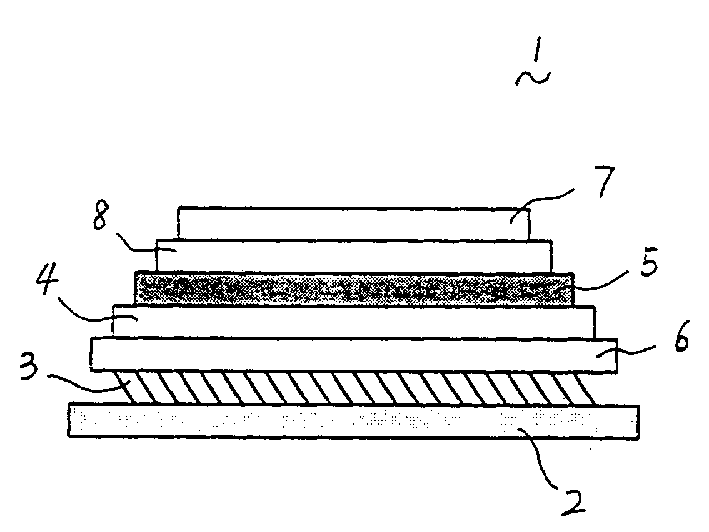

Abab-type multilayer lithium-ion battery separator with thermal shutdown function and preparation method thereof

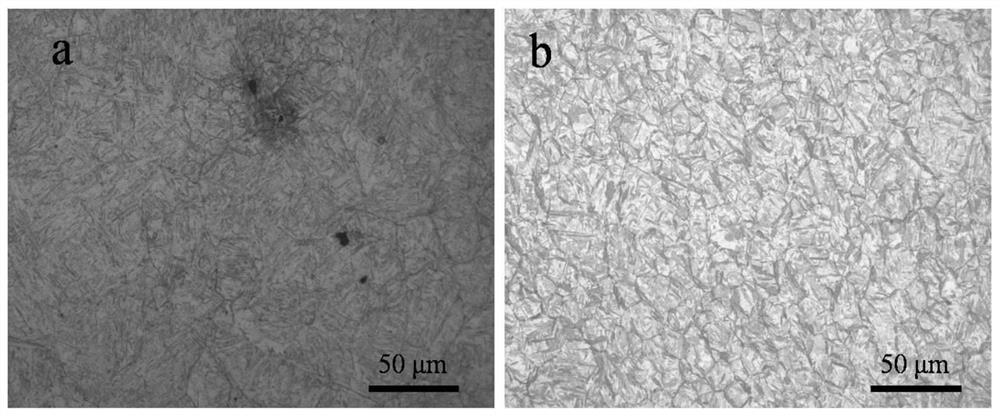

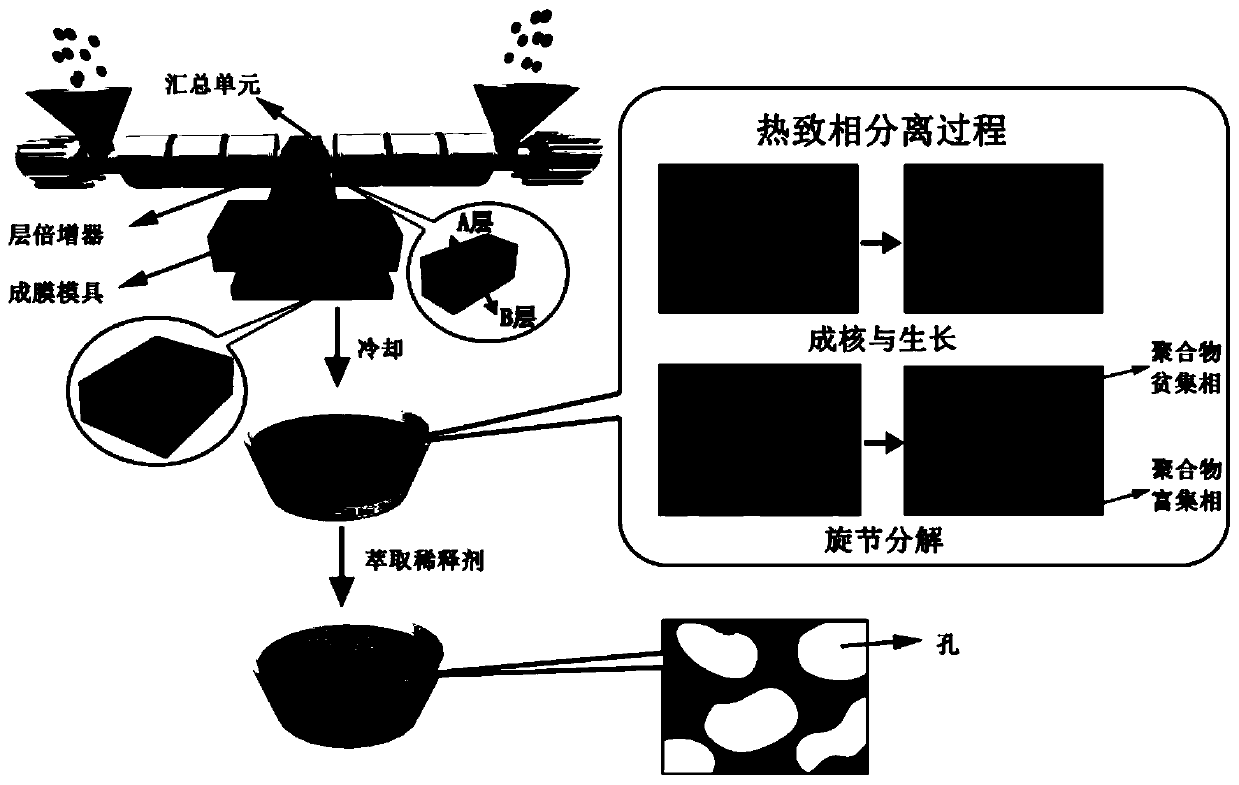

ActiveCN108470873BWide range of choicesRaw materials are cheap and easy to getCell seperators/membranes/diaphragms/spacersChemical physicsElectrical battery

The invention belongs to the technical field of polymer materials, in particular to an ABAB type multilayer lithium-ion battery diaphragm with thermal shutdown function and a preparation method thereof. The present invention selects a polymer with a higher melting point as the A layer, selects a polymer with a lower melting point as the B layer, and combines the microlayer co-extrusion technology with the thermally induced phase separation technology to prepare an ABAB alternating multilayer lithium-ion battery diaphragm. The present invention utilizes the low melting point of the polymer B layer to obtain a lower diaphragm closed cell temperature to prevent the temperature from further increasing under high temperature conditions, and utilizes the high melting point of the polymer A layer to obtain a higher film deformation temperature to avoid the positive The short circuit caused by the contact of the negative electrode makes the diaphragm have a wider safety window and more effective thermal shutdown function; the diaphragm prepared by the present invention has uniform thickness, rich submicron porous structure, uniform and controllable pore structure, and thermal stability Excellent, with an effective thermal shutdown function, and has application prospects in the fields of lithium-ion battery separators and other fields.

Owner:TONGJI UNIV

Deformable material and its preparation method

Owner:盛嘉伦橡塑(河源)有限公司

A kind of transparent modified nylon fiber with low heat change temperature and its preparation method

ActiveCN106048772BLower Vicat softening temperatureHigh transparencyMelt spinning methodsArtifical filament manufactureMicro nanoRoom temperature

The invention provides transparent modified nylon fiber with low thermal change temperature and a preparation method thereof. The preparation method comprises the following steps: placing borax in a ball mill, grinding sufficiently, and drying to obtain micro-nano borax powder; chipping PA PACM12 type nylon, drying sufficiently in an oven, mixing well with the micro-nano borax powder, melting in a heating device to form molten liquid, and cooling at high speed to room temperature to obtain modified master batch; grinding the modified master batch into powdery particles, mixing with butyl rubber, performing melt spinning to obtain primarily spun fiber, and quickly cooling the primarily spun fiber to obtain the transparent modified nylon fiber with low thermal change temperature. The fiber prepared by the method has good physical and mechanical properties, has low processing temperature, good transparency and good processibility and is useful in garment fabric or decorations.

Owner:QUANZHOU LIUYUAN DYEING PRINTING WEAVING

Biodegradable polymer articles containing oxygen scavenger

InactiveCN102947374ALower deformation temperatureOther chemical processesSynthetic resin layered productsPolymer scienceBiodegradable polymer

Owner:MULTISORB TECH INC

Processing and forming technology of a high-strength nickel-based superalloy rod

The invention relates to a processing and forming process of a high-strength nickel-based high-temperature alloy bar. The bar comprises the following components of, in percentage by mass, 16%-23% of Cr, 15%-20% of Co, 2.5%-4.0% of Al, 1.0%-2.5% of Ti, 0.5%-1.5% of Nb, 3.0%-7.0% of W+Mo, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.04%-0.07% of C, and the balance is Ni. Analloy is mainly in a dual phase structure of austenite and Ni3Al(gamma'), as well as M23C6 type carbides distributed discontinuously at a grain boundary. The alloy is prepared by adopting a vacuum smelting process, and then is forged into a bar by adopting a multi-pass small deformation mode, and finally surface turning and heat treatment are carried out on the bar. According to the process, deformation processing of the alloy with high content of W and Mo is conducted, and the final deformation of the alloy can reach 75% or higher while the strength of the alloy is considered.

Owner:HUANENG POWER INT INC +1

Glass for press molding

The present invention provides a novel glass material that allows the production of a glass product having both excellent chemical durability and high precision by a press molding method. Specifically, the present invention provides a glass for press molding, comprising 38% to 45% by weight of SiO2, 18% to 27% by weight of B2O3, 16% to 25% by weight of Al2O3, 2% to 12% by weight of ZnO, no more than 3% by weight of MgO, no more than 3% by weight of CaO, no more than 3% by weight of BaO, 13% to 18% by weight of Li2O, no more than 3% by weight of K2O, and no more than 2% by weight of Na2O; wherein the glass has a deformation temperature of 520° C. or lower; and the glass has a water resistance of grade 2 or higher as measured according to the Japanese Optical Glass Industrial Standard method for measuring the chemical durability of an optical glass.

Owner:ISUZU GLASS +1

Method for improving thermal deformation performance of titanium-based composite material

ActiveCN112899517AImprove thermal deformation abilityReduce stress peaksTitanium matrix compositesCrucible

The invention discloses a method for improving the thermal deformation performance of a titanium-based composite material, and belongs to the technical field of metal-based composite materials and preparation. The method solves the technical problems that an existing titanium-based composite material is high in thermal deformation resistance, multiple in deformation defect and the like. The method comprises the following steps that (1) raw materials for preparing the titanium-based composite material are pretreated, TiB2 powder is added, and the mixture is put into a water-cooled copper crucible; and (2) argon and hydrogen are introduced after vacuumizing is conducted, smelting is conducted, and the titanium-based composite material with the improved thermal deformability is obtained. According to the method, the thermal deformation resistance of the titanium-based composite material can be remarkably reduced, the peak stress is reduced, the deformation temperature under the same peak stress is reduced, the defects such as interface holes and deformation cracking hardly exist after deformation, and the thermal deformation performance of the material is greatly improved. In addition, the method has the advantages of economy, safety, novelty, reliability and the like, and has a good application prospect.

Owner:HARBIN INST OF TECH

Transfer method of pattern and transfer paper

InactiveCN1174875CHardness: SoftAchieve transferDecorative surface effectsOrnamental structuresCelluloseEpoxy

Owner:增城市运豪五金塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com