Method for extrusion two-step equal channel angle of magnesium alloy

A technology of equal channel angular extrusion and equal channel extrusion, applied in the field of material processing, can solve problems such as the reduction of alloy strength, and achieve the effect of improving the strength and toughness at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

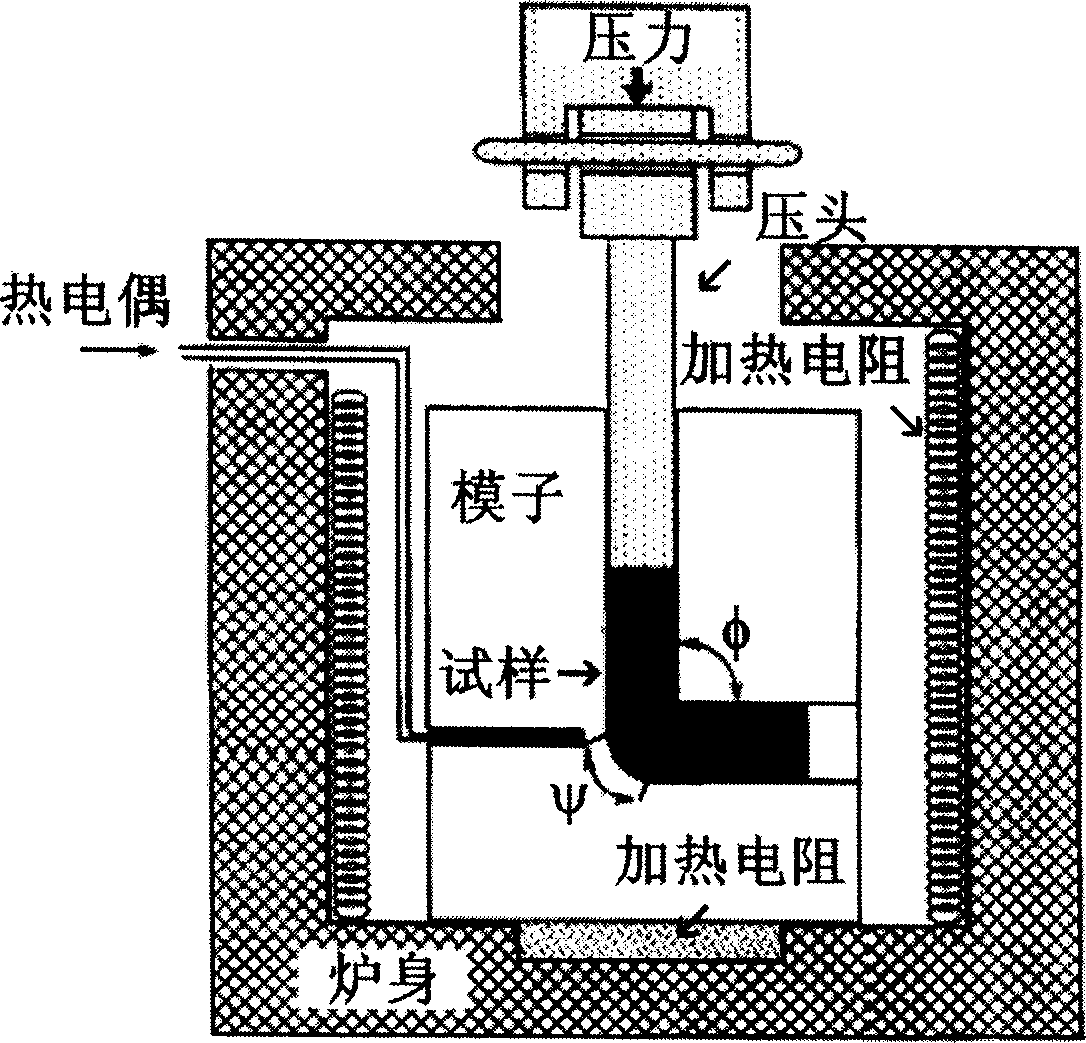

[0020] 1. According to figure 1 Design and manufacture the mold, select the channel angle φ of the mold to be 90°, the arc of the angle ψ to be 0°, and the strain amount of each pass deformation to be 1.15.

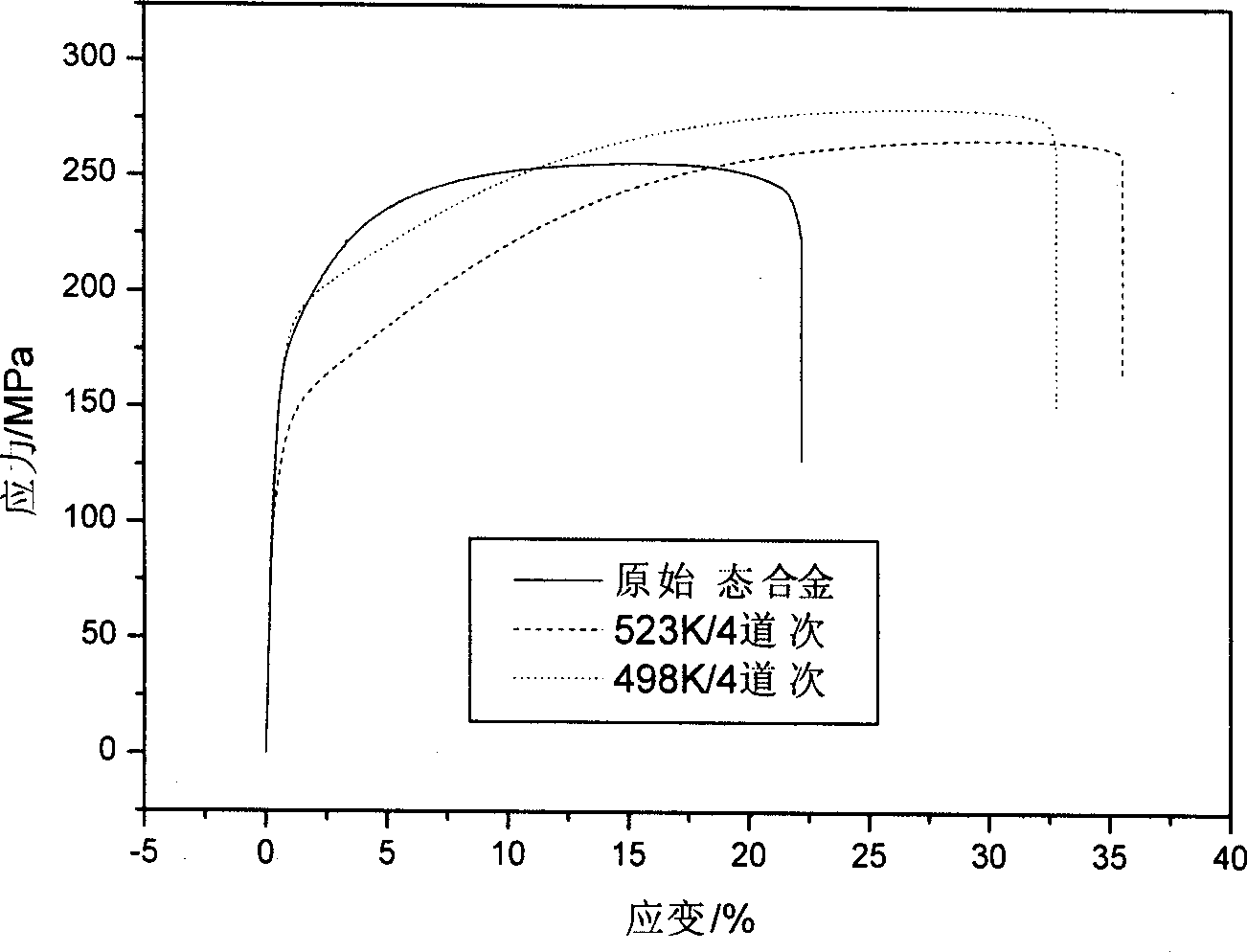

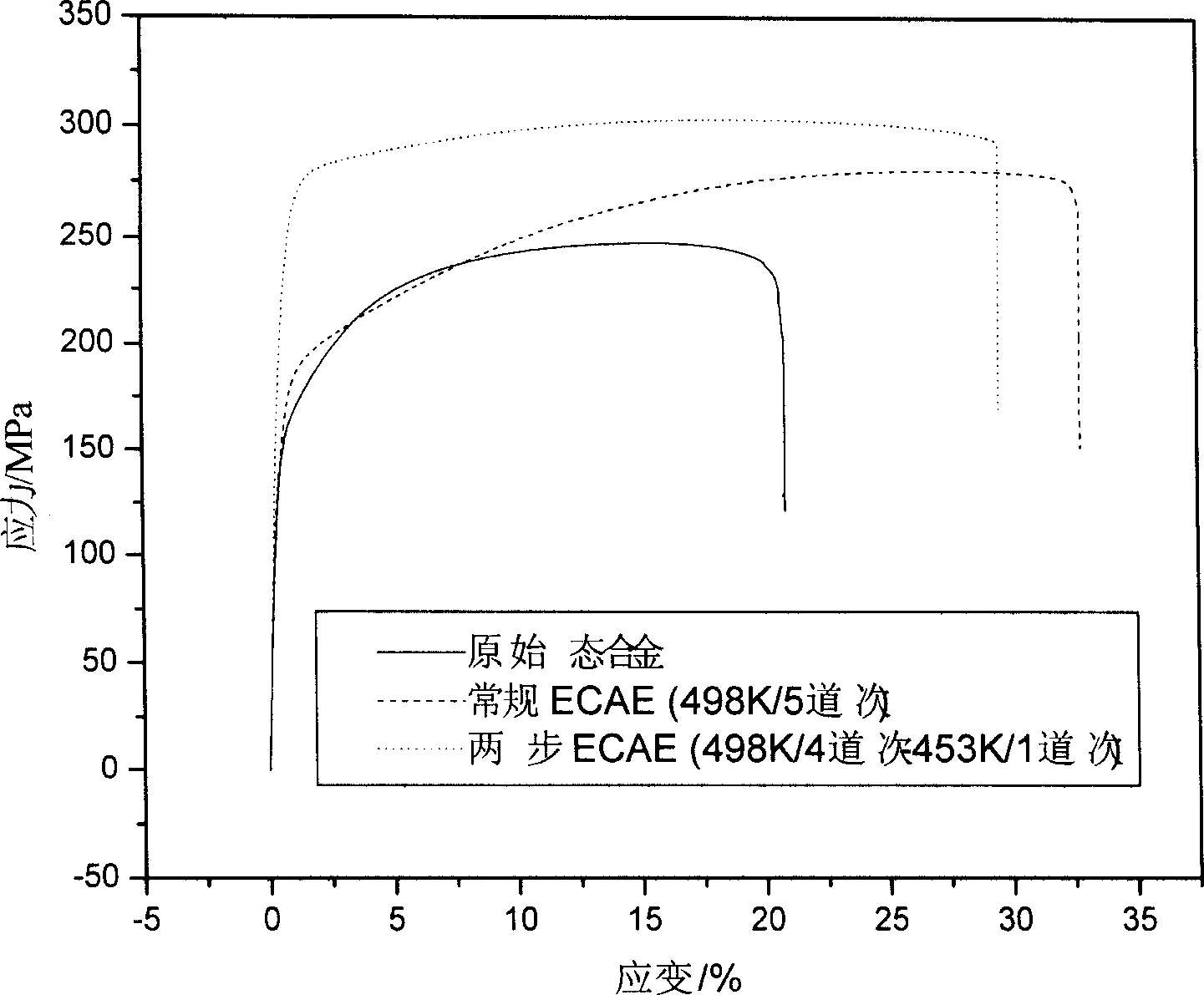

[0021] 2. The given magnesium alloy material is a conventional extruded AZ31 magnesium alloy with an average grain size of 16 μm. The mechanical properties of the alloy are: elongation 21%, yield strength 152 MPa, and tensile strength 256 MPa. The alloy was subjected to ECAE deformation, the sample size was: 10×10×90cm, the ECAE deformation was carried out, the deformation rate was set at: 0.28mm / s, and the deformation temperature range of the first deformation pass was adjusted to 200-300°C, the result It shows that the lowest deformation temperature without cracks is 225℃.

[0022] 3. The alloy is subjected to multi-pass deformation at 225°C, and the deformation route adopts B, that is, the sample is rotated 90° clockwise along the extrusion axis between each pass.

...

Embodiment 2

[0025] 1. According to figure 1 Design and manufacture the mold, select the channel angle φ of the mold to be 120°, and the angle radian ψ to be 45°.

[0026] 2. The given magnesium alloy material is a conventional extruded AZ61 magnesium alloy with an average grain size of 20 μm. The initial mechanical properties of the alloy are: elongation 19%, yield strength 202MPa, and tensile strength 302MPa. The alloy was subjected to ECAE deformation, the sample size was: 10×10×90cm, the ECAE deformation was carried out, the deformation rate was set at: 0.28mm / s, and the deformation temperature range of the first deformation pass was adjusted to 200-300°C, the result It shows that the lowest deformation temperature without cracks is 250℃.

[0027] 3. The alloy is subjected to multi-pass deformation at 250°C. The deformation route adopts D, that is, the sample is rotated 90° clockwise along the extrusion axis between the previous passes, and the sample is rotated 90° counterclockwise a...

Embodiment 3

[0030] 1. According to figure 1 Design and manufacture the mold, select the channel angle φ of the mold to be 110°, and the angle radian ψ to be 30°.

[0031] 2. The given magnesium alloy material is conventional extruded Mg97Zn2Y1 magnesium alloy, the initial mechanical properties are: elongation 2.3%, yield strength 352MPa, tensile strength 413MPa. The alloy was subjected to ECAE deformation. The sample size was: 10×10×90cm. ECAE deformation was carried out. The deformation temperature range of the first pass of deformation was adjusted to 300-400°C. The results showed that the minimum deformation temperature that can achieve no cracks is 350 ℃.

[0032] 3. The alloy is subjected to multi-pass deformation at 350°C, and the deformation route is C, that is, the sample is rotated 180° along the extrusion axis between each pass.

[0033] 4. After 4 passes of deformation, the mechanical properties of the alloy are: elongation 8%, yield strength 376MPa, tensile strength 413MPa. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com