Deformation material and preparation method thereof

A deformation material, selected technology, applied in the field of toy materials, can solve the problem of high deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

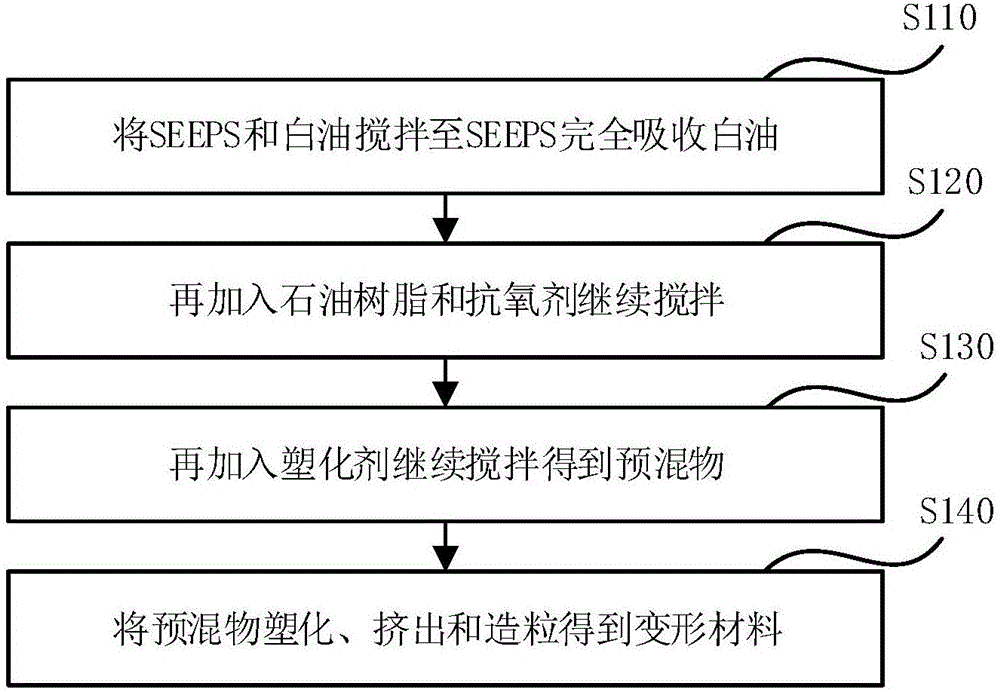

[0035] see figure 1 , the preparation method of above-mentioned deformation material, comprises the following steps:

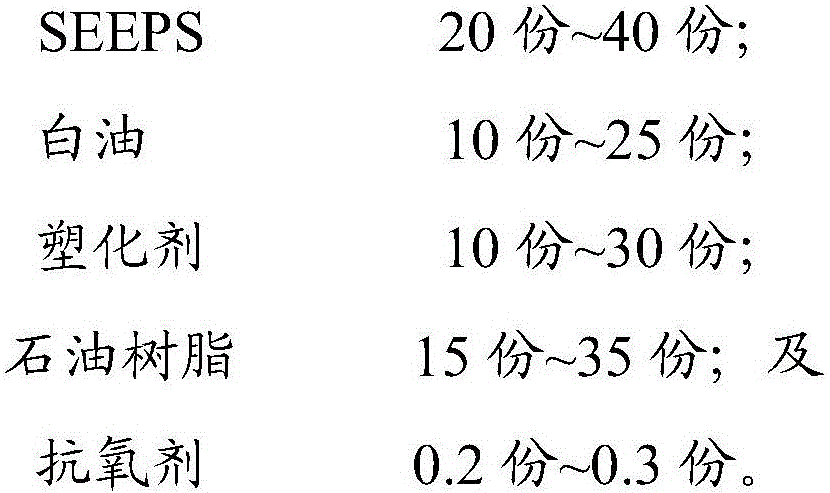

[0036] S110. Stir 20-40 parts of SEEPS and 10-25 parts of white oil until the SEEPS completely absorbs the white oil.

[0037] In one embodiment, the stirring is carried out in a high-speed mixer, the stirring speed of the high-speed mixer is 250r / min-400r / min, and the stirring time is 10min-15min.

[0038] S120. Add 15-35 parts of petroleum resin and 0.2-0.3 parts of antioxidant to the SEEPS that has completely absorbed the white oil and continue stirring.

[0039] In one embodiment, the stirring is carried out in a high-speed mixer, the stirring rate of the high-speed mixer is 250r / min-400r / min, and the stirring time is 3min-5min.

[0040] S130, adding 10-30 parts of plasticizer and continuing to stir to obtain a premix.

[0041] In one embodiment, the stirring is carried out in a high-speed mixer, the stirring rate of the high-speed mixer is 250r / min-400...

Embodiment 1

[0047] Stir 20 parts of SEEPS and 10 parts of paraffin oil in a high-speed mixer for 10 minutes until SEEPS completely absorbs the paraffin oil. The rotational speed of the mixer is 400r / min. Add 35 parts of carbon-5 hydrogenated petroleum resin and 0.2 part of (3,5-di-tert-butyl-4-hydroxyphenyl) propionate octadecanoate to the SEEPS that has completely absorbed paraffin oil and continue stirring for 3 minutes . Add 10 parts of diisononyl cyclohexane 1,2-dicarboxylate and continue to stir to obtain a premixture, and the stirring time is 3 minutes. The premix is plasticized, extruded and granulated in a twin-screw extruder to obtain a deformed material. The temperature of the twin-screw extruder is 60° C., and the rotation speed is 700 r / min.

Embodiment 2

[0049]Stir 20 parts of SEEPS and 25 parts of paraffin oil in a high-speed mixer for 12 minutes until SEEPS completely absorbs the paraffin oil. The rotational speed of the mixer is 250r / min. Add 15 parts of carbon-9 hydrogenated petroleum resin, 5 parts of PE wax and 0.3 part of tris(2,4-di-tert-butylphenyl)phosphite to the SEEPS that has completely absorbed paraffin oil and continue stirring for 5 minutes. Then add 20 parts of diisononyl phthalate and continue to stir to obtain a premix, and the stirring time is 5 minutes. The premix is plasticized, extruded and granulated in a twin-screw extruder to obtain a deformed material. The temperature of the twin-screw extruder is 80° C., and the rotation speed is 500 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com