Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Save metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ceramic particle reinforced steel-based mesh material

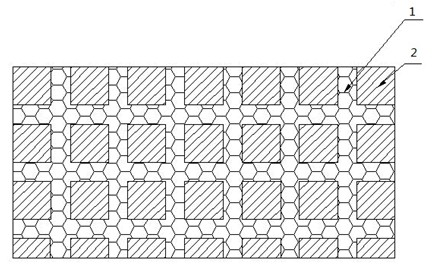

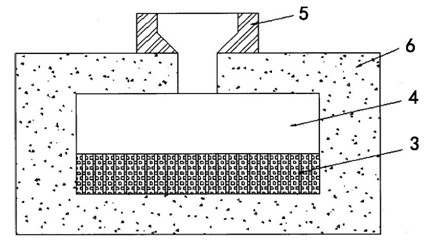

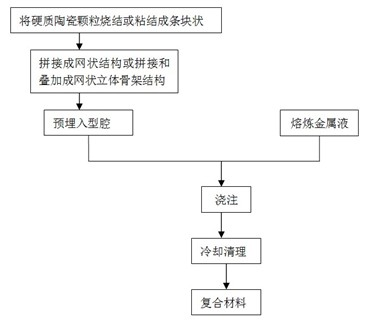

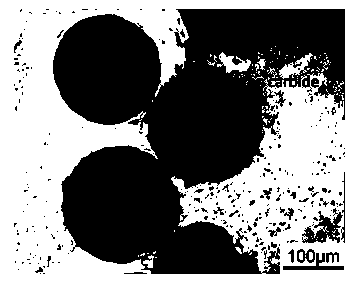

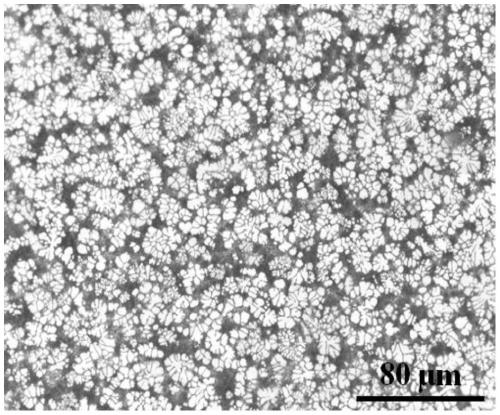

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of particle-reinforced metal matrix composite material

The invention discloses a preparation method of a particle-reinforced metal matrix composite material, and belongs to the technical field of a novel material. The method comprises the following steps: firstly, putting reinforced particles and matrix powder into a ball grinder, so as to evenly mix; then putting the mixed powder into a graphite jig, putting into spark plasma sintering (SPS) equipment; setting a proper sintering parameter, and putting the sintered sample into a vacuum tube furnace to set heating temperature, so as to change a bonding interface between the reinforced particles and the matrix in the composite material, or prompt interface reaction. The reinforced particles in the composite material prepared by the method can be well evenly distributed inside a composite layer, so that the comprehensive properties of the materials are greatly improved, the composite material is even and single in texture, the mechanical property can be changed to a certain extent, and reference is provided for high-temperature wear-resisting fields, such as steel, metallurgy, coal and the like, parts under chilled and heated conditions or other researchers for researching the composite material performances.

Owner:KUNMING UNIV OF SCI & TECH

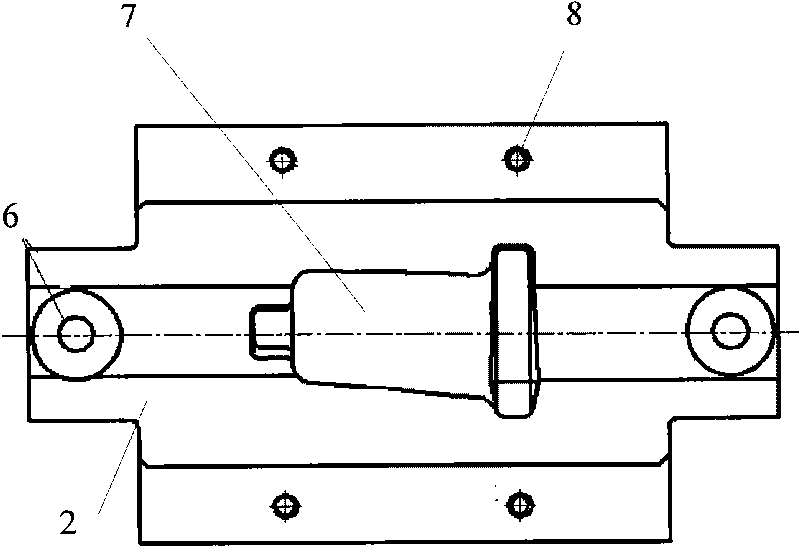

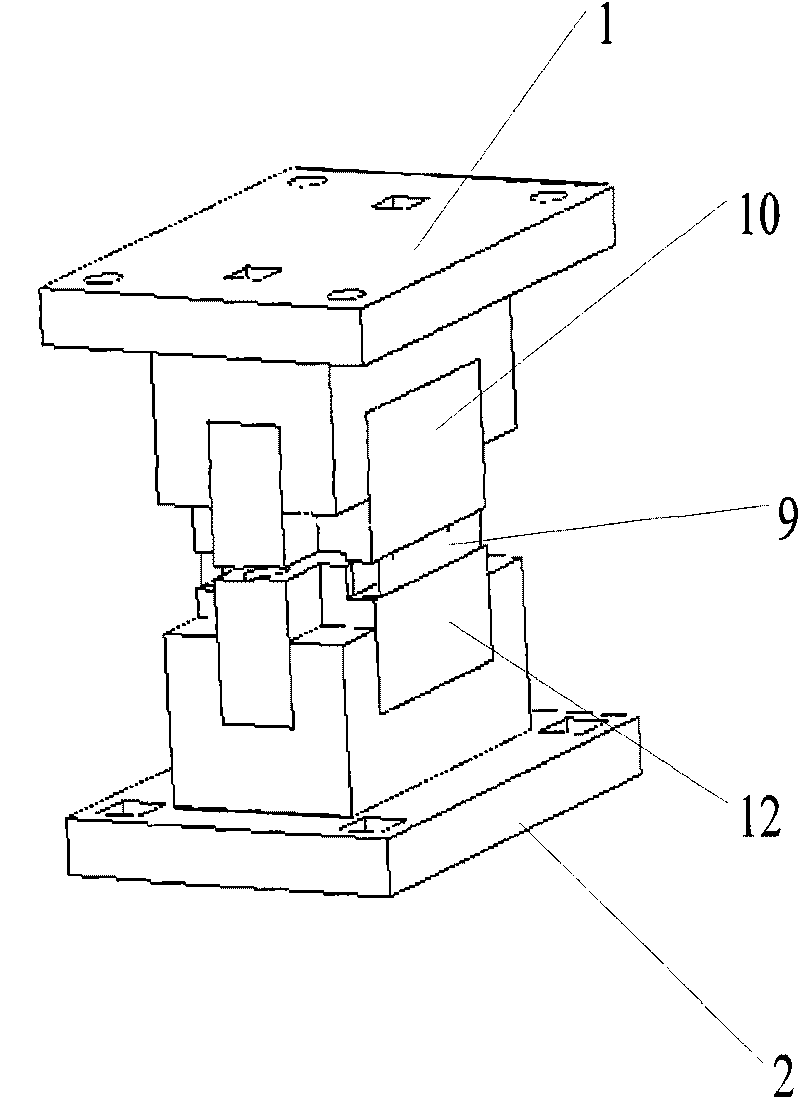

Isothermal forging method for titanium alloy blade

InactiveCN101733348ALower deformation temperatureImprove surface qualityForging/hammering/pressing machinesTitanium alloyMechanical property

The invention discloses an isothermal forging method for titanium alloy blade, which is implemented by the following steps: (1) coating lubricant on the surface of pre-forged titanium alloy blade blank; pre-heating with an electrothermal furnace to the deformation temperature of the blade blank; (2) fixing a lower die holder in an isothermal molding heater, and respectively fixing the upper die and the lower die on the upper die holder and lower die holder; (3) fixing the isothermal molding heater on a hydraulic press, heating to 900-930 DEG C and maintaining the temperature for at least 3h; (4) taking the blade blank out of the electrothermal furnace, putting into the upper die and the lower die in the isothermal molding heater, forging by the hydraulic press, and controlling the hydraulic press to perform return stroke operation when the dimension of the blade blank satisfies the requirement. The titanium alloy blade blank obtained by the inventive method has a preciseness satisfying technical requirement and obviously improved mechanical property.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

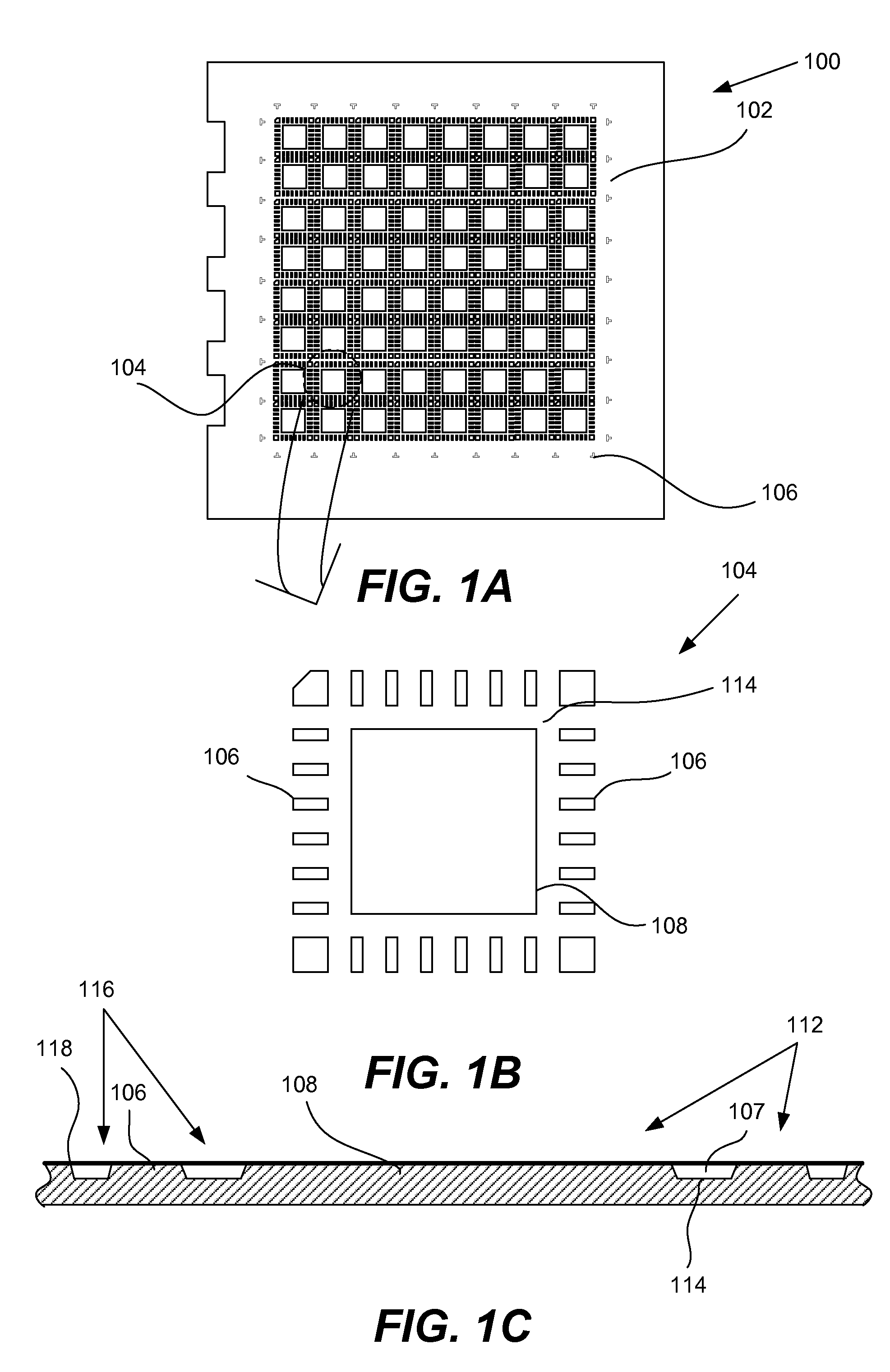

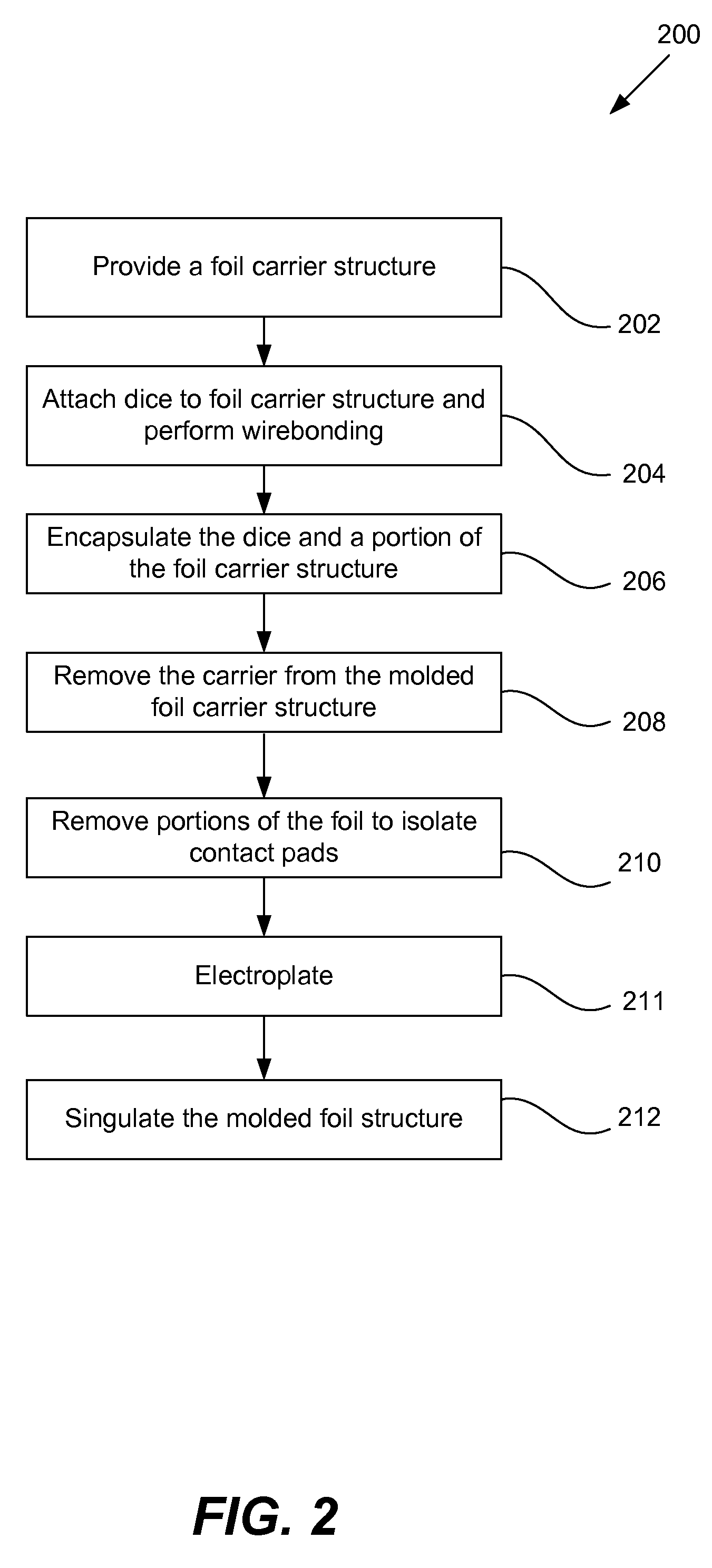

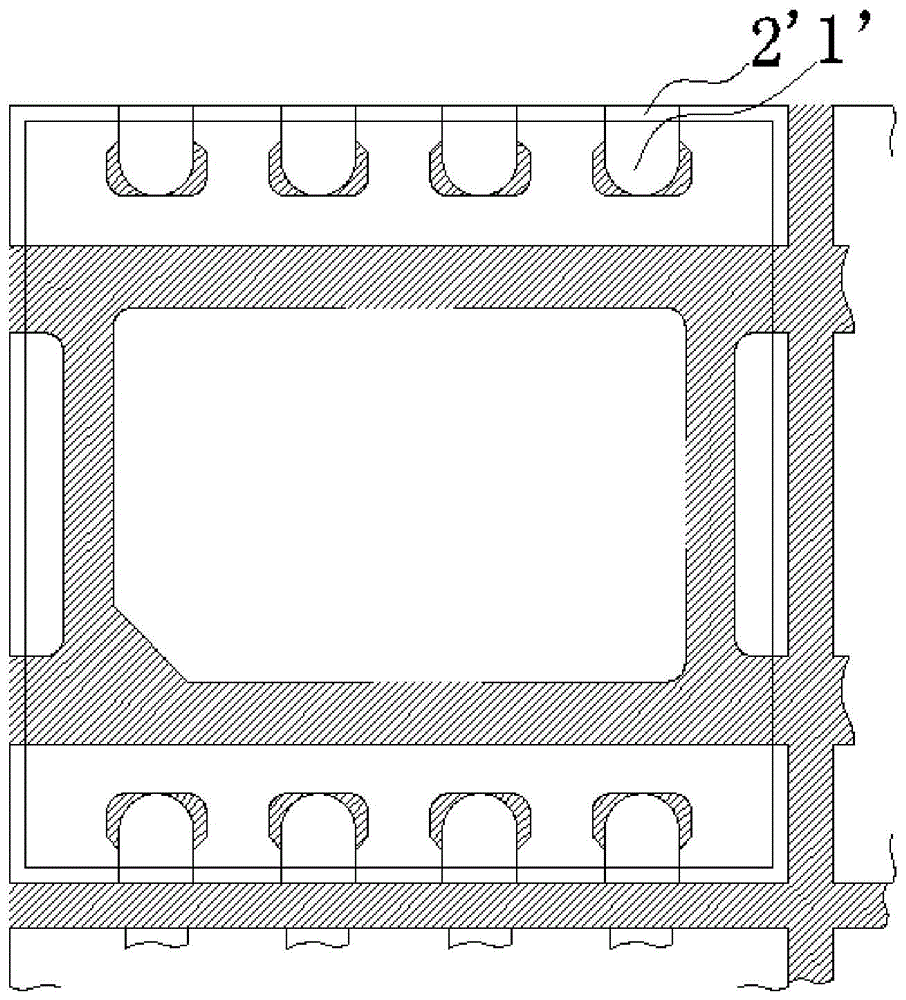

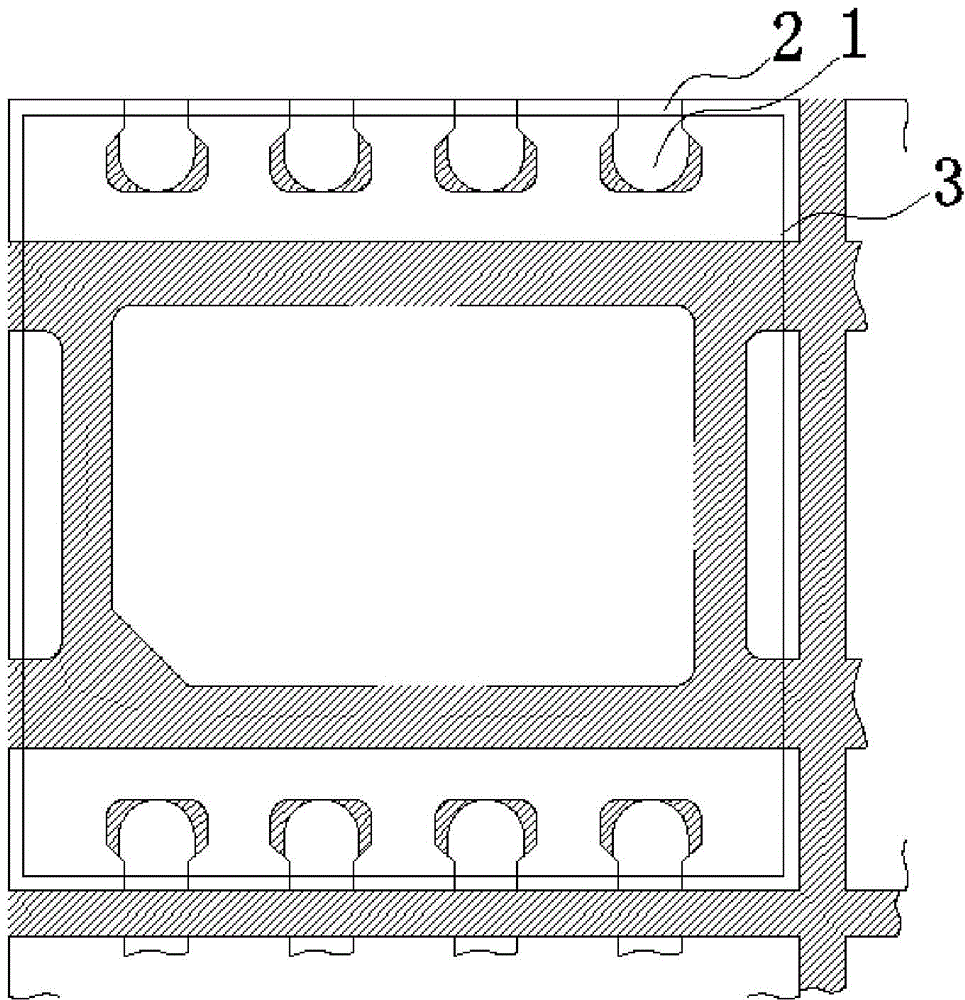

Thin foil semiconductor package

ActiveUS20100046188A1Save metalPrinted circuit assemblingSemiconductor/solid-state device detailsContact padSemiconductor package

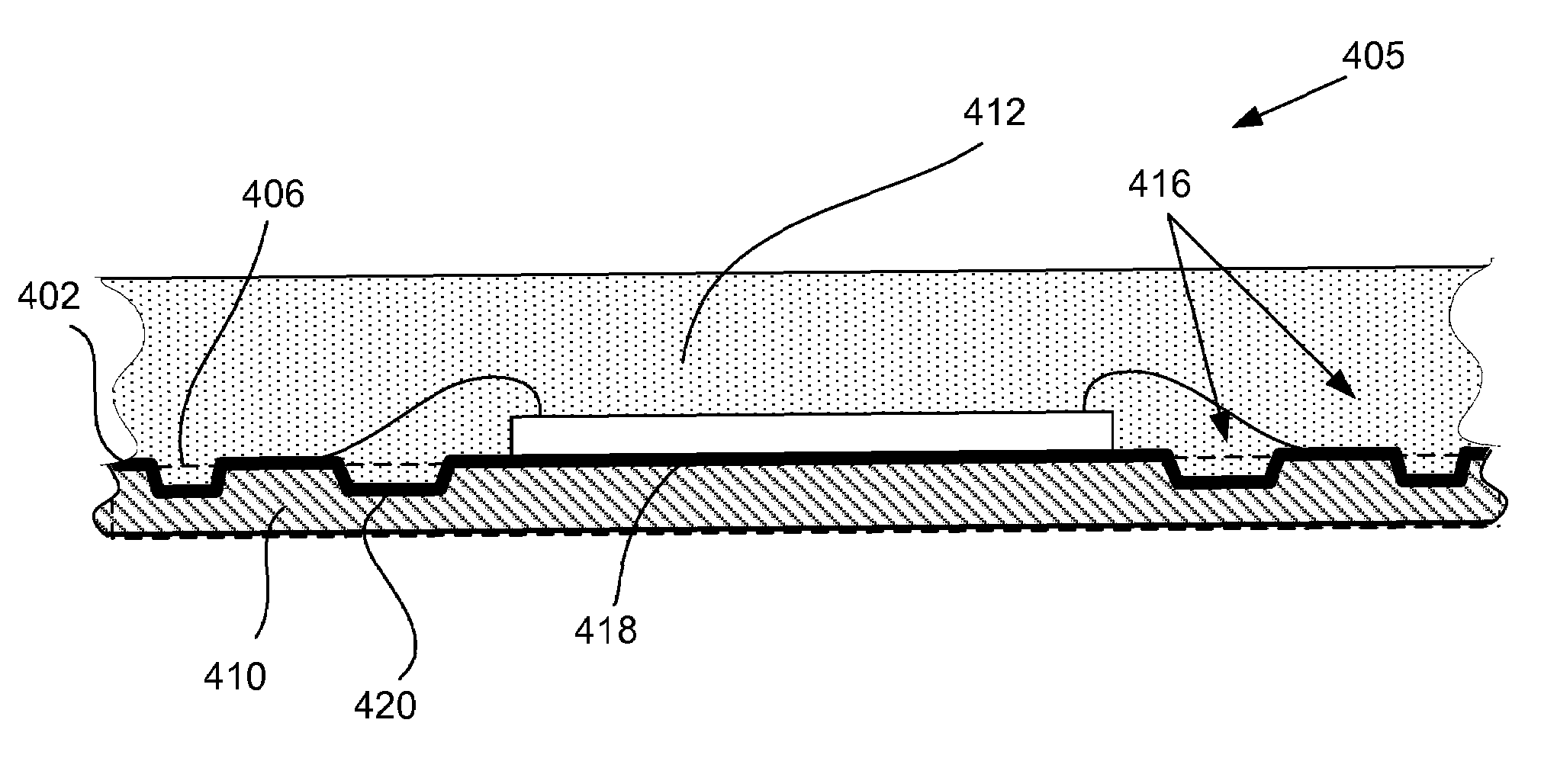

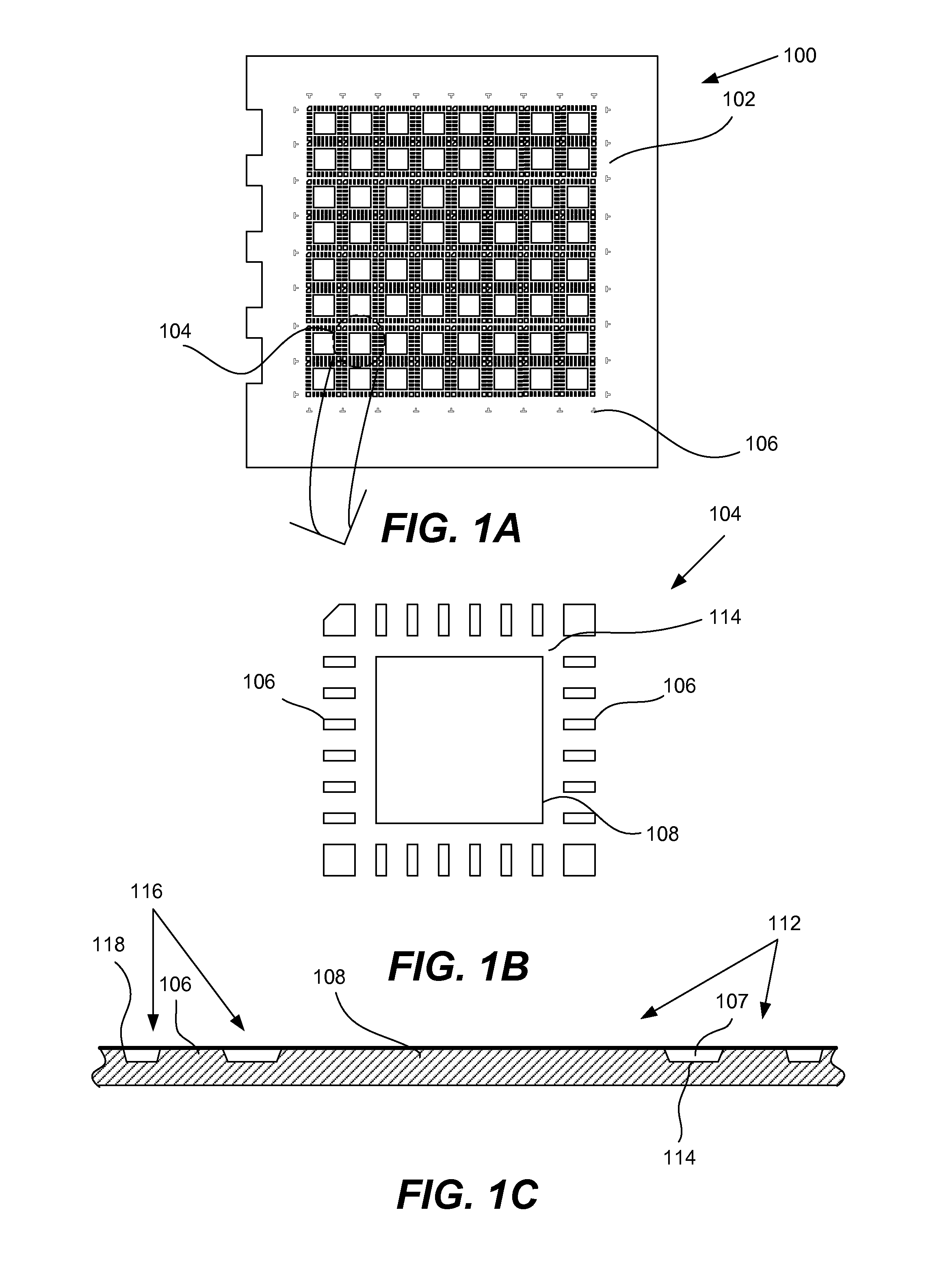

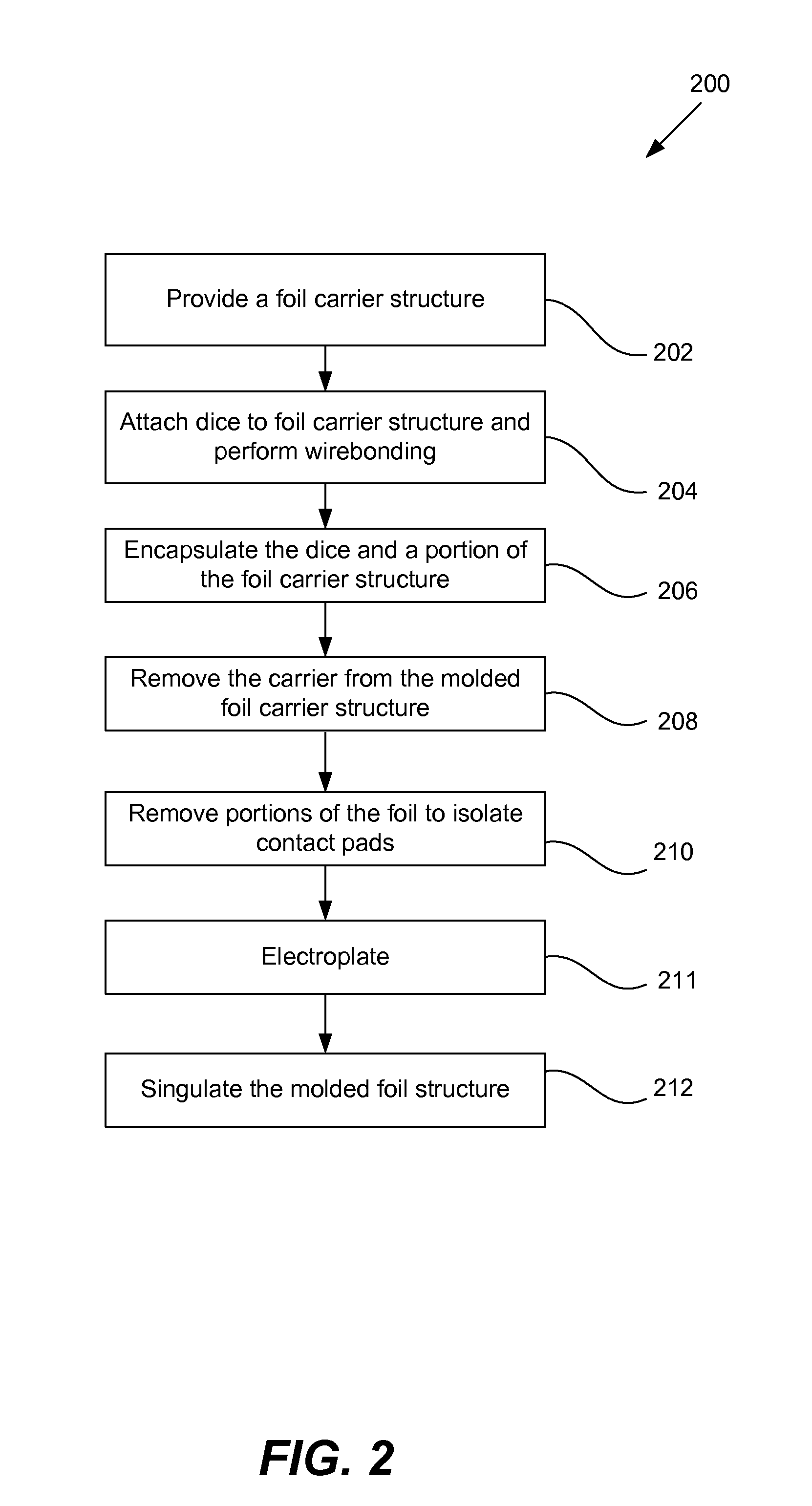

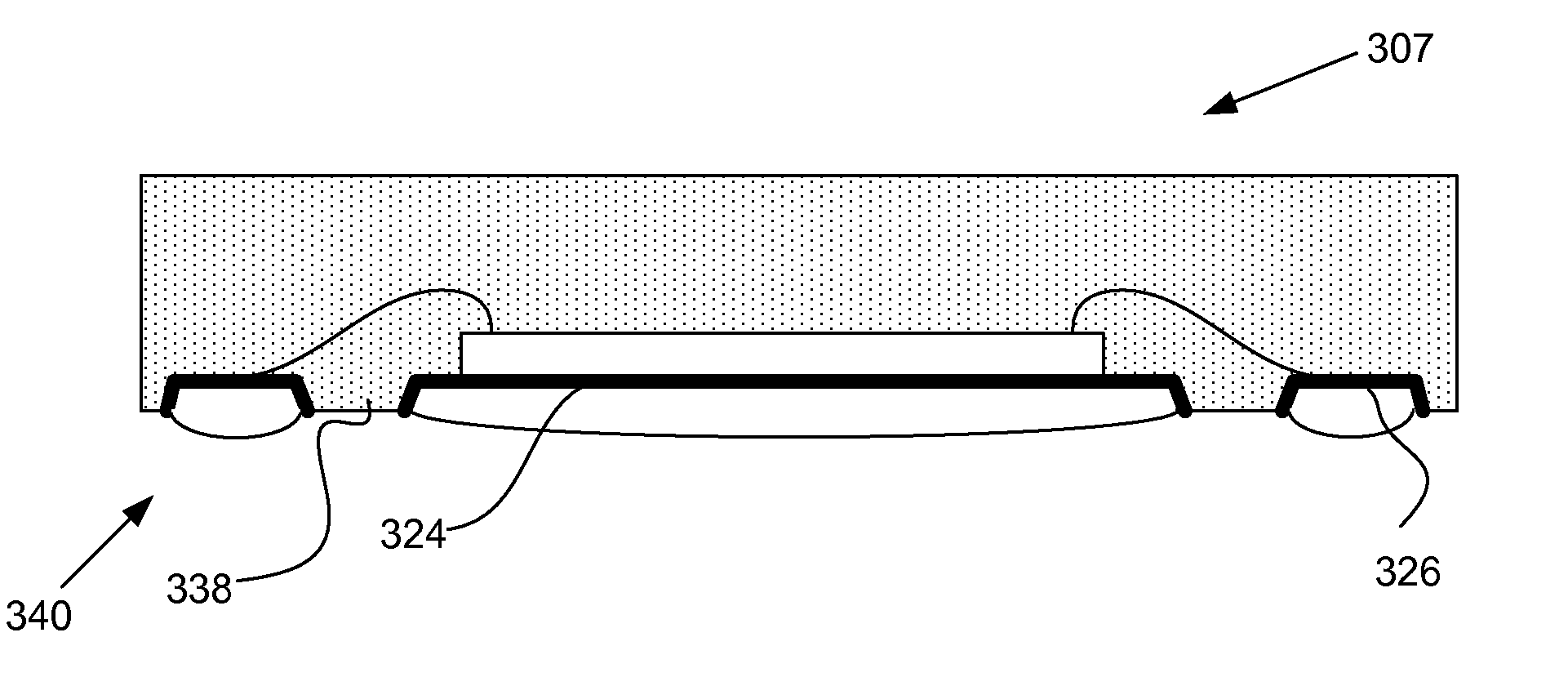

The present invention relates to methods and arrangements for using a thin foil to form electrical interconnects in an integrated circuit package. One such arrangement involves a foil carrier structure, which includes a foil adhered to a carrier having cavities. Some methods of the present invention involve attaching dice to the foil and encapsulating the foil carrier structure in a molding material. In one embodiment, the molding material presses against the foil, which causes portions of the foil to distend into the cavities of the carrier. As a result, recessed and raised areas are formed in the foil. Afterwards, the carrier is removed and portions of the raised areas in the foil are removed through one of a variety of techniques, such as grinding. This process helps define and electrical isolate contact pads in the foil. The resulting molded foil structure may then be singulated into multiple semiconductor packages.

Owner:NAT SEMICON CORP

Thin foil semiconductor package

ActiveUS7836586B2Save metalPrinted circuit assemblingSemiconductor/solid-state device detailsContact padSemiconductor package

The present invention relates to methods and arrangements for using a thin foil to form electrical interconnects in an integrated circuit package. One such arrangement involves a foil carrier structure, which includes a foil adhered to a carrier having cavities. Some methods of the present invention involve attaching dice to the foil and encapsulating the foil carrier structure in a molding material. In one embodiment, the molding material presses against the foil, which causes portions of the foil to distend into the cavities of the carrier. As a result, recessed and raised areas are formed in the foil. Afterwards, the carrier is removed and portions of the raised areas in the foil are removed through one of a variety of techniques, such as grinding. This process helps define and electrical isolate contact pads in the foil. The resulting molded foil structure may then be singulated into multiple semiconductor packages.

Owner:NAT SEMICON CORP

Preparation method of titanium-steel composite plate

ActiveCN107626764AReduce spreadImprove the bonding strength of the interfaceTitaniumMaterials processing

The invention discloses a preparation method of a titanium-steel composite plate, and belongs to the field of material processing. The preparation method of the titanium-steel composite plate comprises the steps that the surfaces of adopted titanium blanks and the surface of an adopted steel blank are treated, and then the surfaces of the titanium blanks are coated with paint and dried at the roomtemperature; the two titanium blanks with the surfaces being treated and coated with paint are aligned and stacked together, the steel blank is placed between the two titanium blanks, and then the blanks are assembled together symmetrically; the periphery of a composite blank is welded and sealed, and vacuumizing treatment is conducted; and the composite blank is placed in a heating furnace so asto be subject to heat treatment, then multi-pass rolling is conducted, the composite blank is air cooled after being rolled, and edge cutting, tension-straightening and flattening are conducted. According to the preparation method of the titanium-steel composite plate, the surfaces of the titanium blanks are coated with protective coatings, so that the titanium blanks are protected, the situationthat the composite performance is affected due to the fact that titanium with active chemical properties is oxidized and forms compounds with other elements is avoided, and the coatings are preparedfrom isolation paint which can prevent oxidization of titanium and prevent diffusion of harmful elements (such as C and N) at high temperatures.

Owner:KUNMING UNIV OF SCI & TECH

Hot roll T shaped steel production technique for ship

InactiveCN101386022AHigh precisionReduce manufacturing costTemperature control deviceWork treatment devicesHeating furnaceMetal

The invention discloses a process for producing a marine hot-rolled T-shaped steel. The raw material of the process is special steel for marine steel, and billet blanking is calculated according to the specification of a finished product, multiple lengths and the internal width of a heating furnace. The billet is heated at the temperature of 1140-1200 DEG C, firstly roughly rolled and secondarily rolled by a conventional mill train, and then finely rolled by a universal mill train to obtain a finished product rolled piece, the rolled piece is further cooled, straightened and cold sawn to length to obtain a finished product. The invention has the advantages of one-time forming by hot rolling, high precision of the finished product, and reduces metal consumption and production cost.

Owner:HEBEI JITAI SPECIAL SHAPED STEEL GROUP

High-elongation-rate heat-resistant aluminum alloy suitable for gravity casting and preparation method thereof

The invention provides a high-elongation-rate heat-resistant aluminum alloy suitable for gravity casting and a preparation method thereof. The alloy comprises the following elements of, by weight, 9.0-12.0% of Si, 0.05-0.4% of Cu, 0.02-0.05% of Mg, 0.05-0.1% of Sc, 0.6-0.8% of M and and the balance Al and inevitable Fe impurities, wherein the M comprises at least two elements of Ti, Zr and V. After gravity casting of the high-elongation-rate heat-resistant aluminum alloy suitable for gravity casting, room-temperature yield strength of the as-cast alloy can reach 143-152MPa, the elongation ratecan reach 8.0%-12.0%, high-temperature tensile strength at 200 DEG C can reach 158-170MPa, the high-temperature elongation rate can reach 10.0%-20.0%, the room-temperature yield strength and heat resistance are excellent, the alloy can be applied to automobile parts without solid solution heat treatment, so that the requirements of light-weight development of automobiles can be met.

Owner:SHANGHAI JIAO TONG UNIV

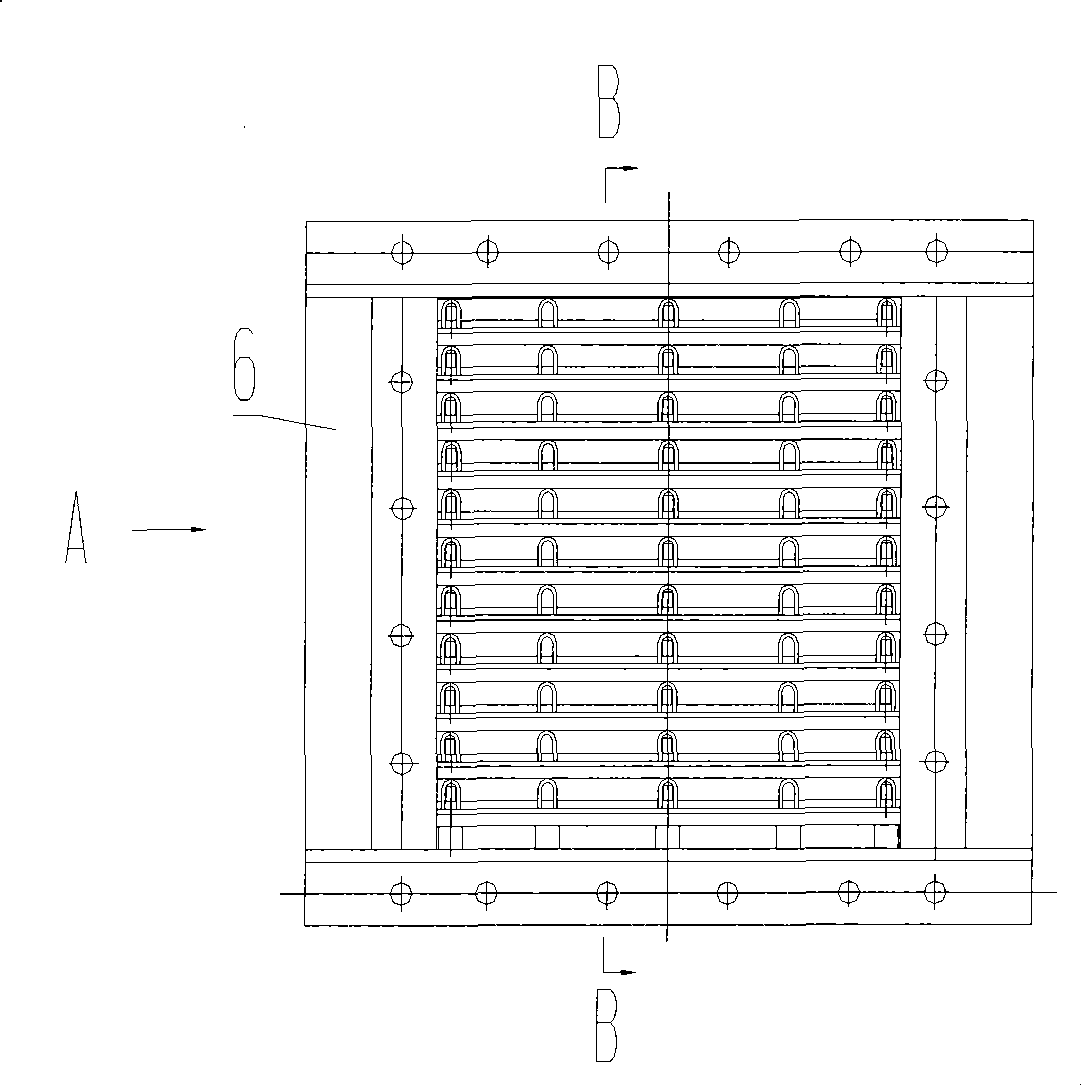

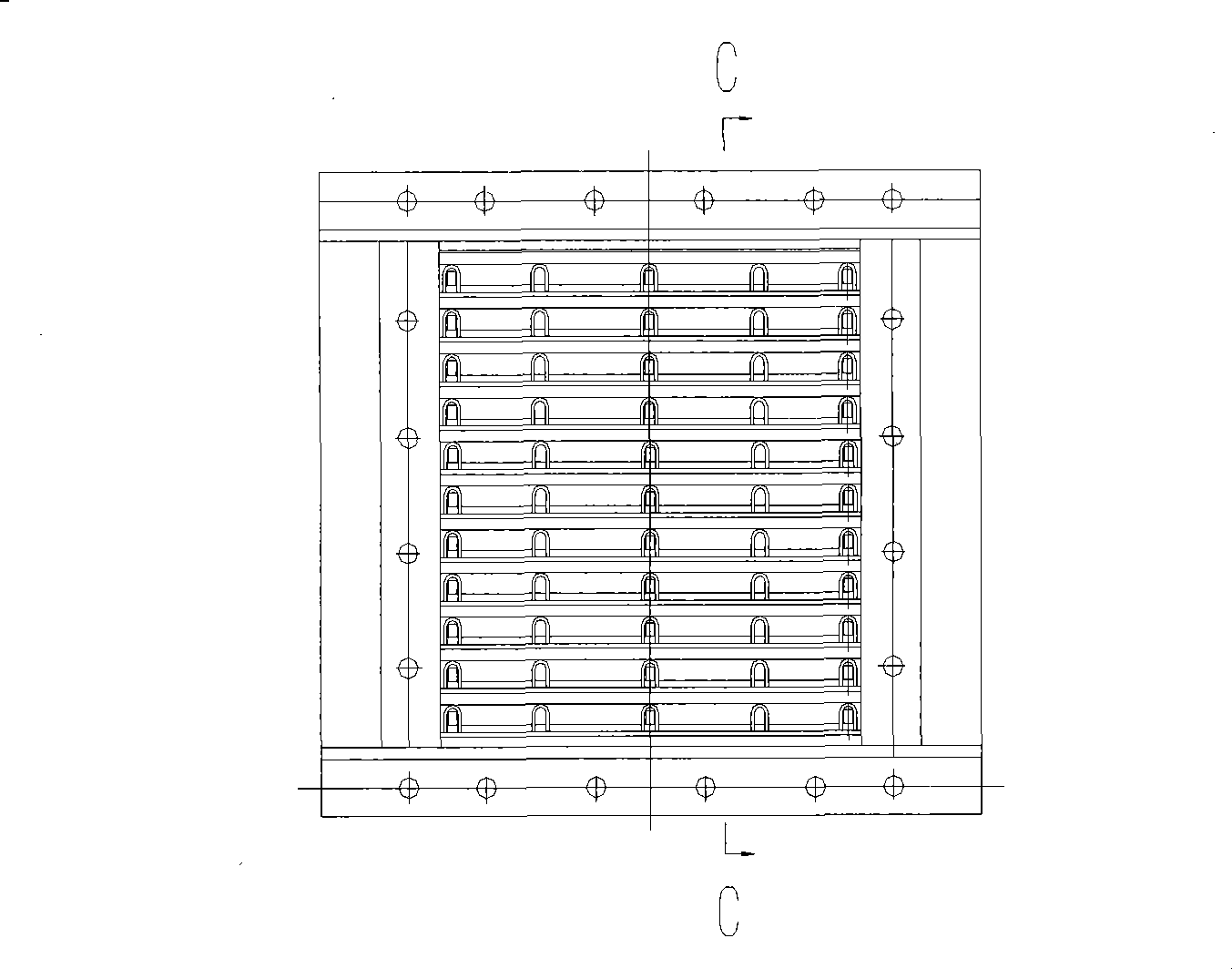

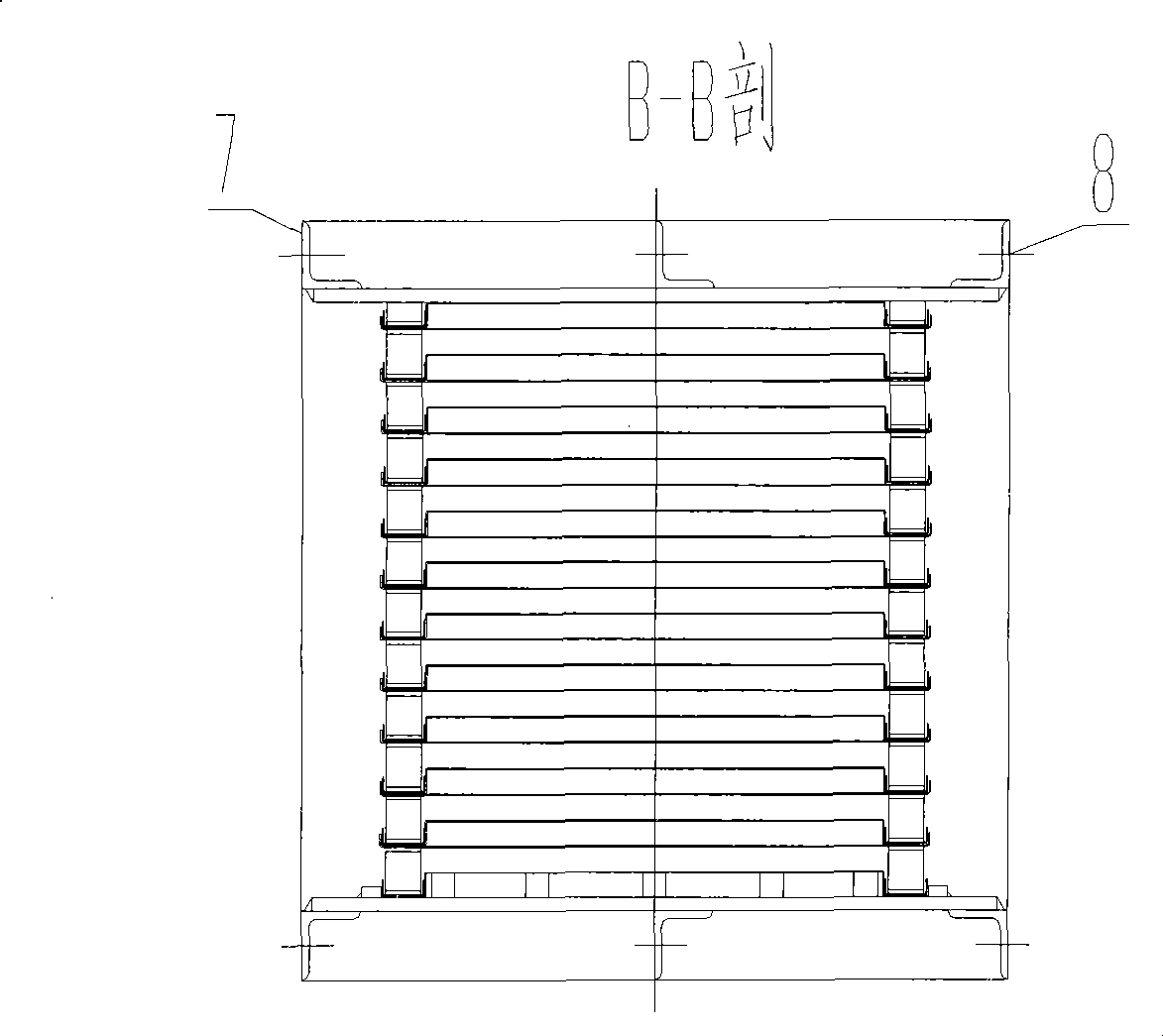

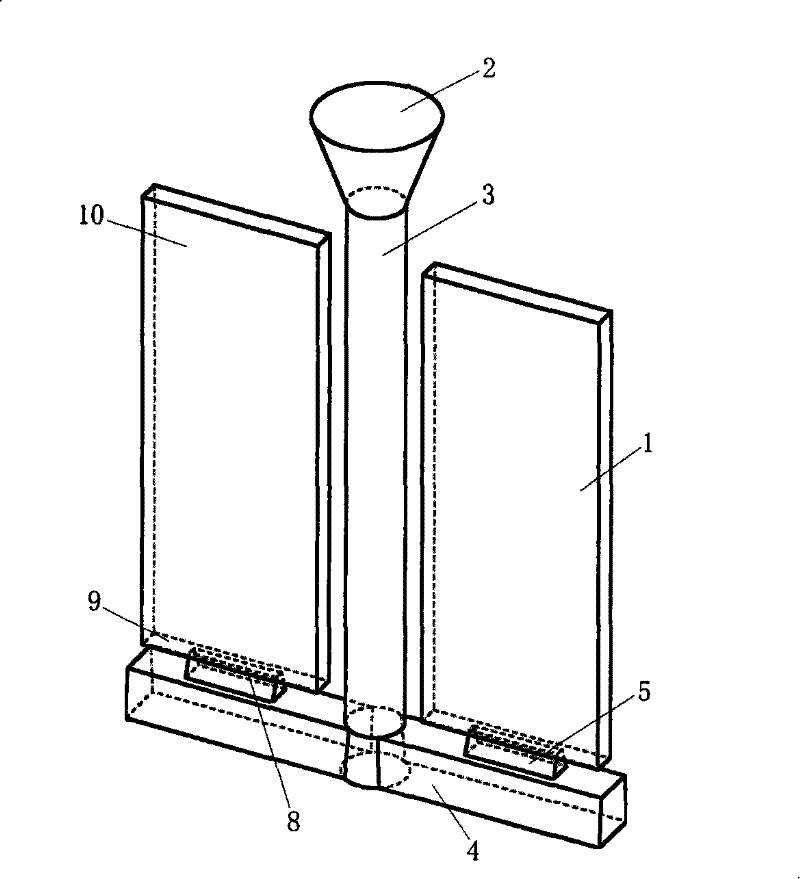

Non-welded plate type heat exchanger

ActiveCN101464105AEasy to manufactureLow costStationary plate conduit assembliesEngineeringHeat exchanger

The invention relates to the technology of heat exchangers, particularly a weldless plate-type heat exchanger. A plurality of fluid passages are formed by a plurality of heat exchange plates 1 which are vertically placed in a rectangularly (90 DEG) staggered manner, wherein, the openings of adjacent fluid passages among the fluid passages are mutually staggered at an angle of 90 DEG to form hot fluid passages and cold fluid passages; upward right-angled fold edges are formed on the two symmetric sides of each heat exchange plate 1, and right-angled double-fold edges are formed on the other two corresponding sides so as to form L-shaped fold edges; each two vertically adjacent heat exchange plates are placed in a rectangularly (90 DEG) staggered manner, that is, the downward L-shaped fold edge of an upper heat exchange plate is correspondingly placed between the upward right-angled fold edges of a lower heat exchanges plate, and the upward rectangular (90 DEG) fold edge of the lower heat exchange plate serves the function of limiting to the L-shaped fold edge of the upper heat exchange plate; a sealing gasket 5 is arranged between the lower heat exchange plate and the upper exchange plate; a flexible sealing layering 3 is arranged between each two adjacent heat exchange plates; and a support strip 2 is arranged between the passage formed by the upper heat exchange plate and thelower heat exchange plate.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

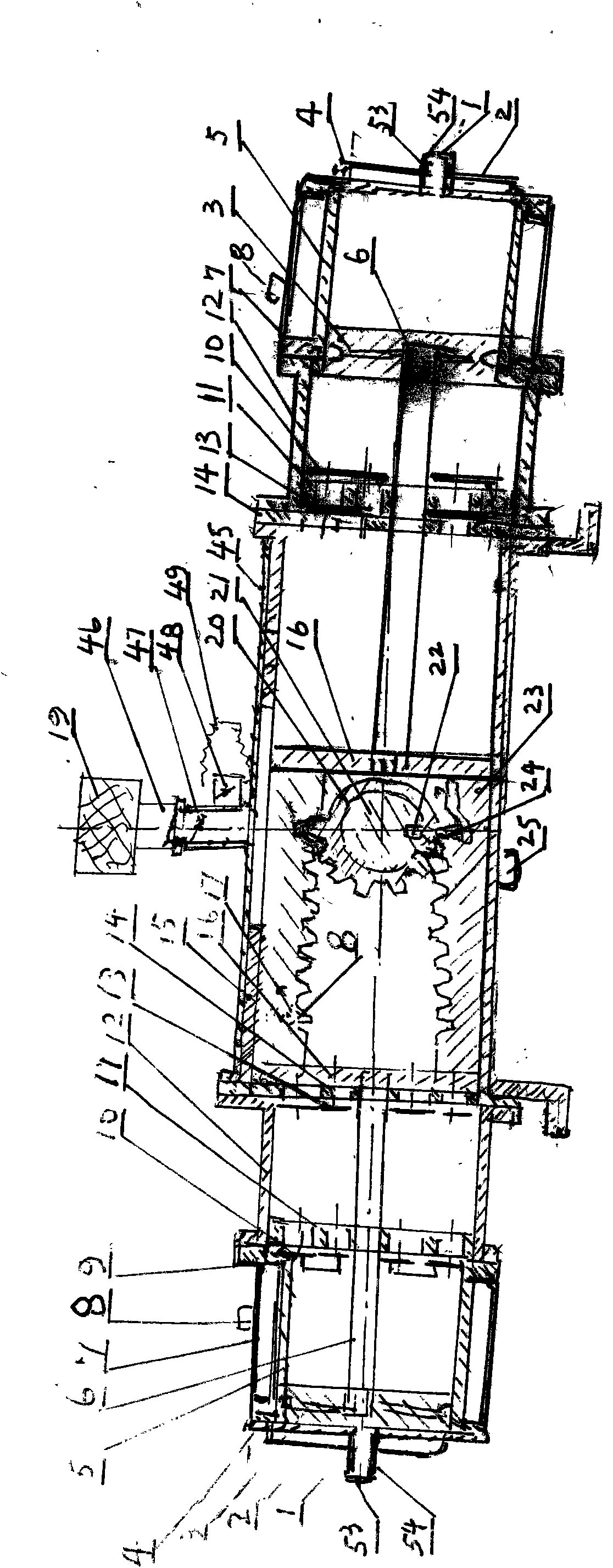

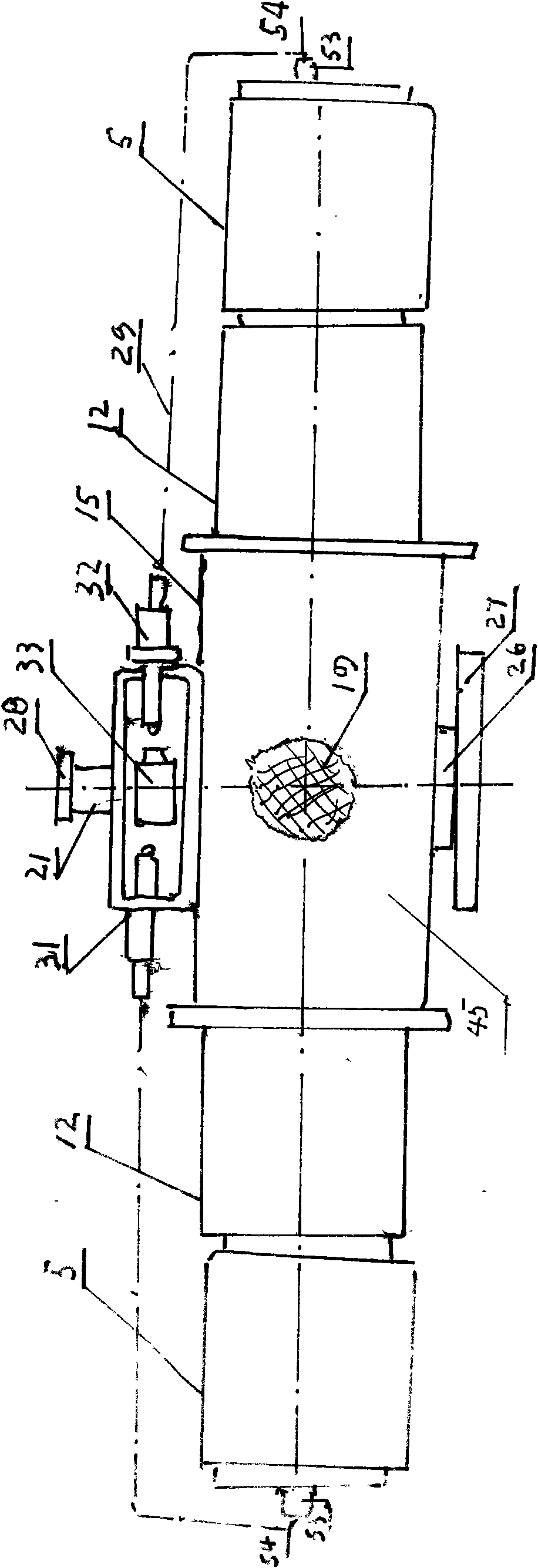

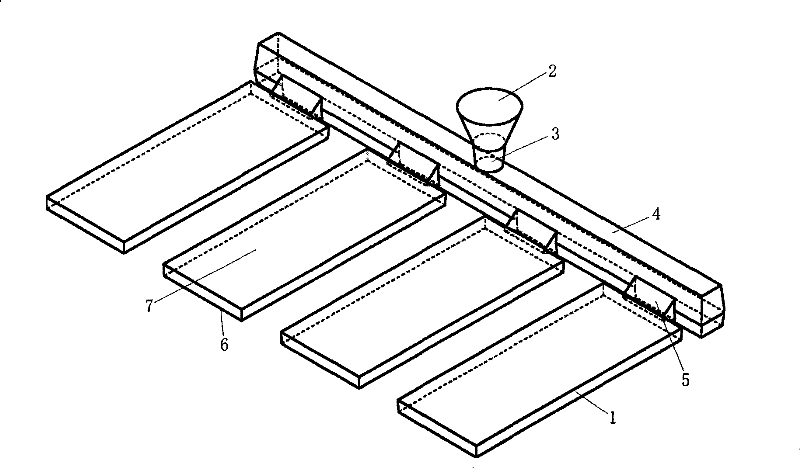

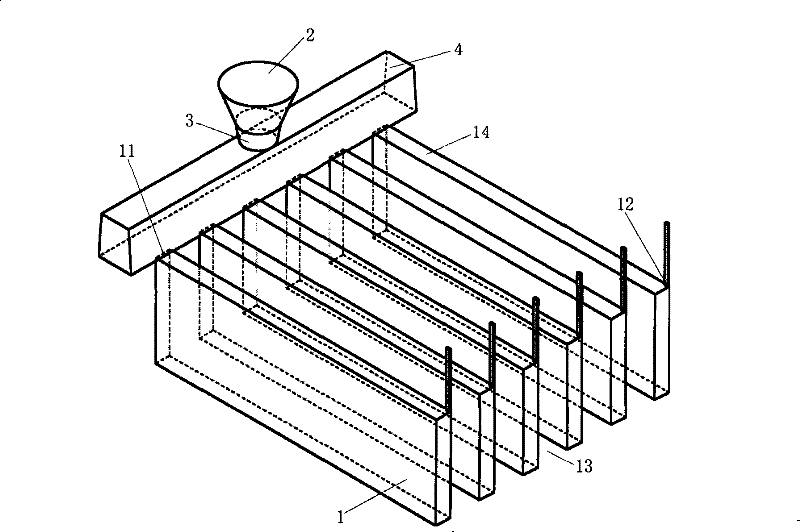

Casting method of tabular spheroidal iron piece and casting system thereof

InactiveCN101301681AReasonable structureSimple structureMolten metal conveying equipmentsCompensation effectSlag

The invention discloses a pouring method and a pouring system used for a plate-shaped ball iron casting. The method adopts a sand casting technique; the pouring system comprises a sprue cup, a sprue, a horizontal runner and a plurality of plate-shaped castings; the method adopts a type that the large plane of the plate-shaped casting is vertically arranged in parallel; the horizontal runner and the plate-shaped casting form a narrow seam edge gate so as to lead the molten steel to flow in along the wall and be stably filled from bottom to top during the pouring process. When the method and the pouring system of the invention are adopted, the molten steel is filled along the wall during the pouring process and the metal is sequentially solidified from bottom to top, thus ensuring the uniformity and consistency of the metallographic structure of the plate-shaped ball iron casting; furthermore, by the narrow seam edge gate, the pouring time is prolonged, the shrinkage compensation effect is provided during the pouring process, furthermore, the slag retaining effect is good and the defects such as slag inclusion, sand inclusion, etc. are avoided; the plate-shaped ball iron casting pouring system of the invention has reasonable and simple structure, saves the metal and has high process yield; furthermore, the pouring system is convenient to be removed; the casting adopts serial pouring, thus having small land occupying and high production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

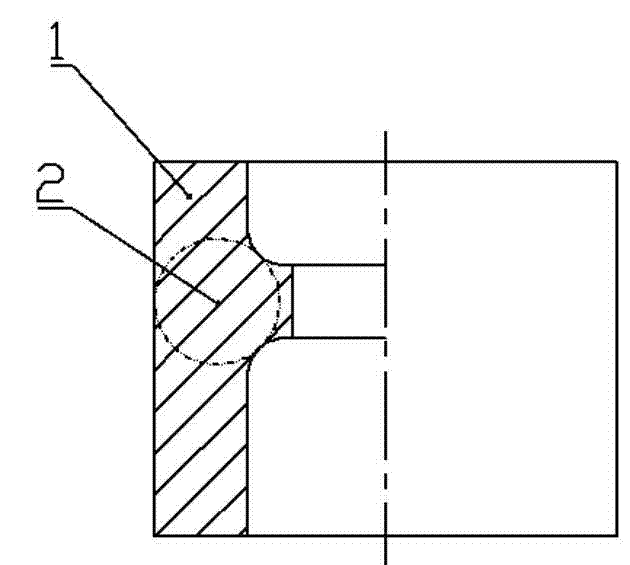

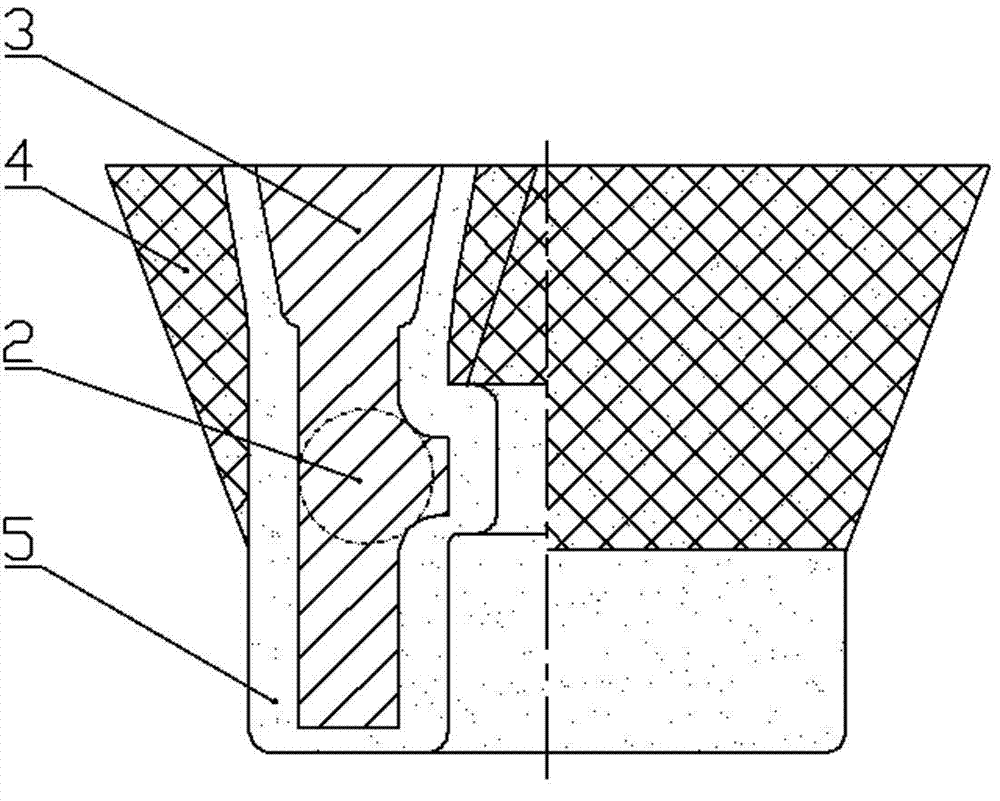

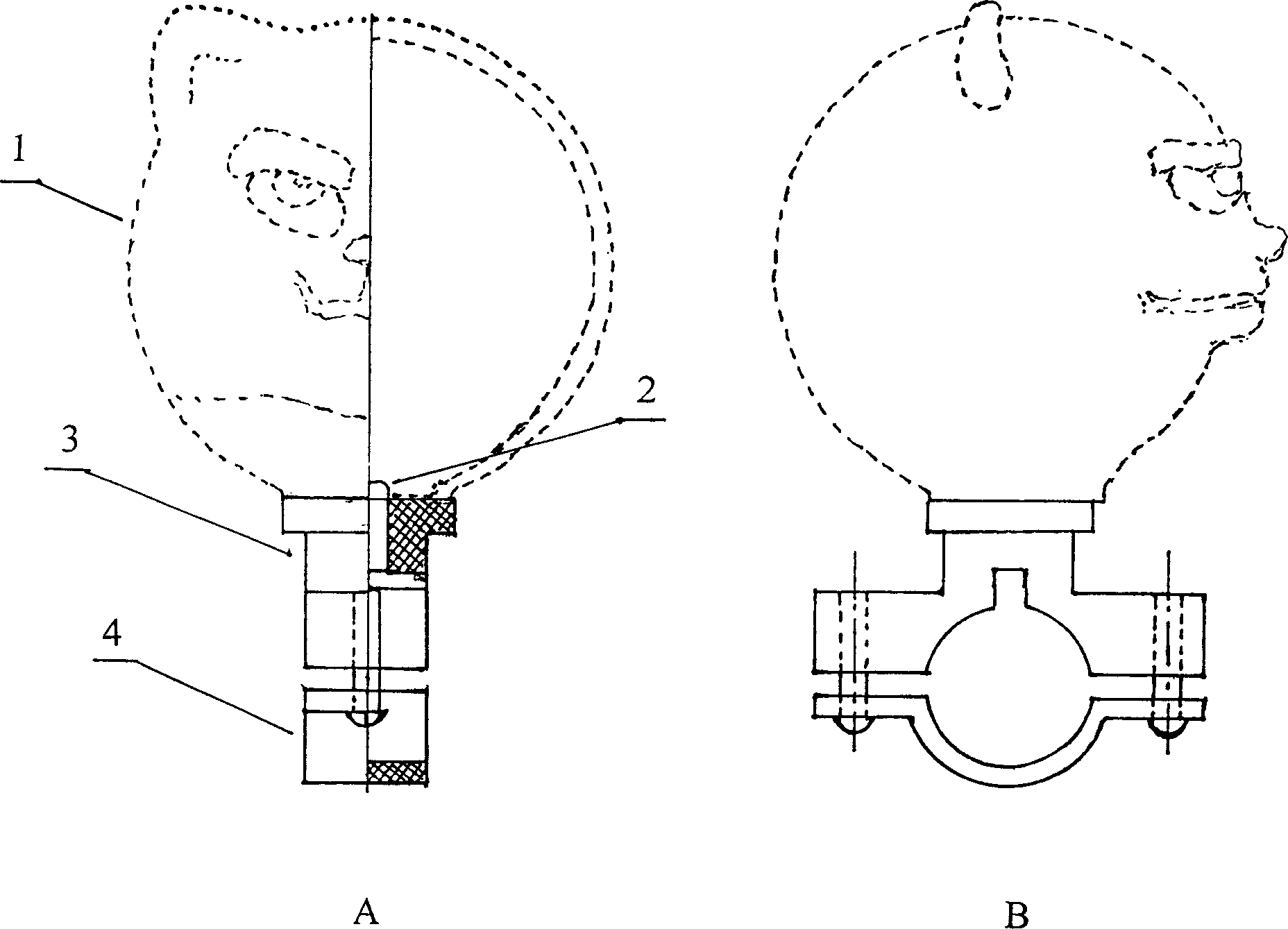

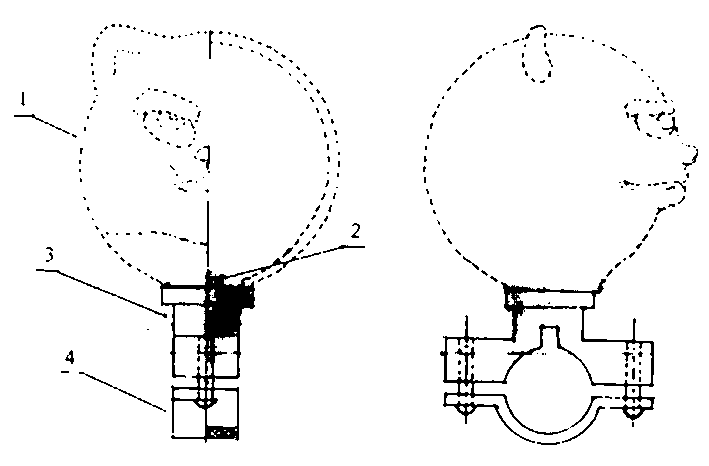

Casting method capable of preventing precise investment casting from generating hot-spot shrinkage holes

InactiveCN103394644AAvoid shrinkageSave metalFoundry mouldsFoundry coresInvestment castingHead position

The invention discloses a casting method capable of preventing a precise investment casting from generating hot-spot shrinkage holes. The casting method comprises the following steps that: a dead head position is determined according to a conventional method, and a dead head metal patch is replaced by a shell patch at a part, needing to be provided with the dead head metal patch, of the precise investment casting, wherein the material of the shell patch is mortar paste prepared from back layer slurry, back layer powder and back layer sand in a mass ratio of 1:1:5; the shell patch is bonded by the mortar paste, wherein before bonding, a layer of back layer slurry is brushed at a part needing to be bonded with the mortar paste at first, and then the wedge-shaped shell patch is formed according to a method that the thickness at a dead head is greater than that at a hot spot; after that, shell roasting and pouring are performed. Due to the action of the shell patch, the dead head and the hot spot keep a good feeding channel, thus realizing a mode of sequentially solidifying from the hot spot to the dead head, and then preventing the hot spot of the casting from generating the shrinkage holes. According to the method, patch metal for the casting is saved, the product yield of the process increases, and the visual quality of the casting is guaranteed.

Owner:HEBEI NORMAL UNIV

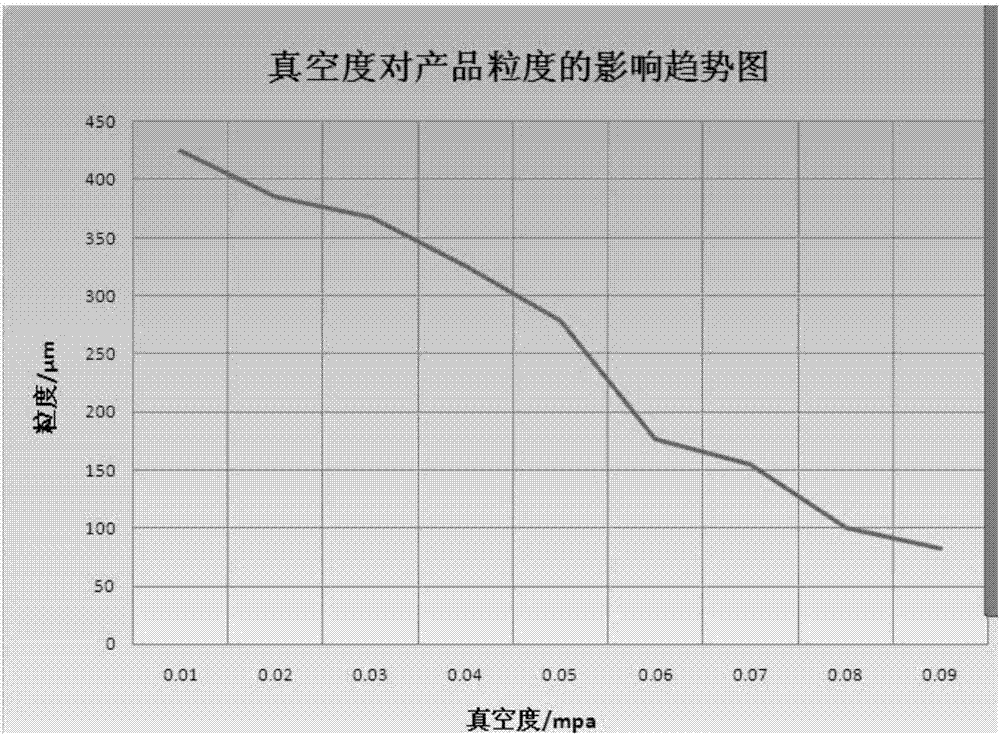

Method and device for continuous preparation of lithium hexafluorophosphate

ActiveCN107244681AEfficient productionEfficient evaporation crystallization method and advanced DBT type continuous productionCell electrodesSecondary cellsEvaporationCirculating pump

The invention relates to a device and method for continuous preparation of lithium hexafluorophosphate. The device comprises a continuous evaporation crystallizer, a condensation recoverer, a heater, an ex-situ circulation pump, a product crystal delivery pump and a separation apparatus. Specifically, the continuous evaporation crystallizer is internally equipped with a stirrer, and the lower part of the continuous evaporation crystallizer is equipped with an elutriating leg; the ex-situ circulation pump, the heater, and the continuous evaporation crystallizer are connected in order; the elutriating leg is connected to the product crystal delivery pump; the product crystal delivery pump is connected to the separation apparatus; and the condensation recoverer is connected to the upper part of the continuous evaporation crystallizer. The invention employs an effective evaporative crystallization method and the advanced DBT type continuous efficient evaporation crystallizer to make the crystalline particles of lithium hexafluorophosphate more uniform, and effectively lowers the product investment cost and energy consumption per ton, thus realizing continuous, efficient and large-scale production of lithium hexafluorophosphate.

Owner:东营石大胜华新能源有限公司

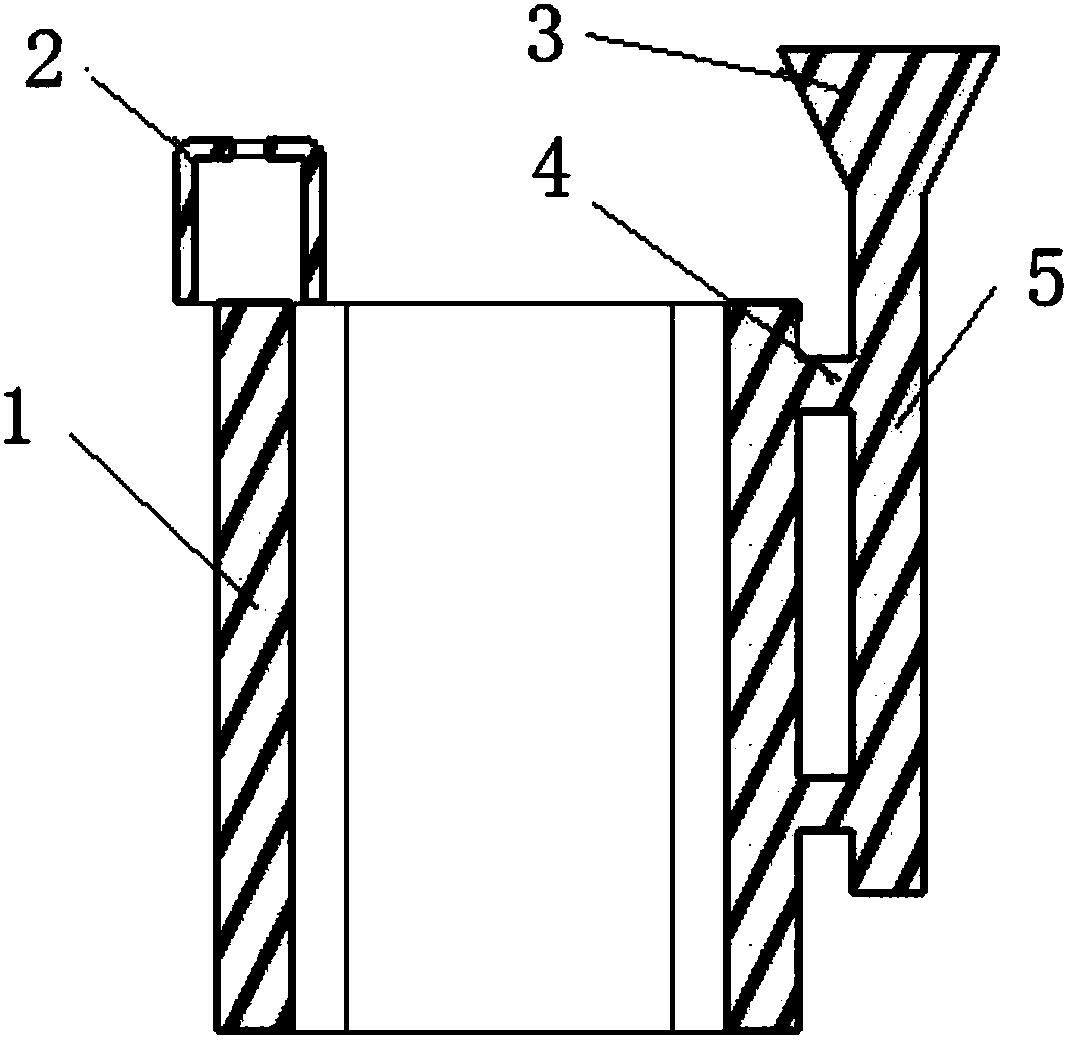

Piston reciprocating internal combustion engine cylinder piston working environment enhancement system

ActiveCN103498729BReduce frictionEliminate hazardsLiquid coolingMachines/enginesPiston ringExternal combustion engine

The invention relates to an internal combustion engine power intensifying device. A work environment intensifying system for an engine cylinder piston of a piston reciprocating internal combustion engine comprises a power mechanism and an engine cylinder of the internal combustion engine, wherein the power mechanism is a rack and gear mechanism, tappets and the engine cylinder piston are fixedly arranged at the upper end of a pressurizing frame of the rack and gear mechanism and drive all working mechanisms to act, a pressure cylinder piston is fixedly arranged at the lower end of the pressurizing frame, and the engine cylinder piston and the pressure cylinder piston perform synchronous movement and are same in stroke. Mechanical strength of the tappets is increased with bearing system heeling force as the datum, all the tappets penetrate through a diaphragm plate of an engine body and are in slide fit with the diaphragm plate in an attached mode, the length of the engine cylinder piston is the sum of the piston stroke and the length of a sector of a piston ring, and cooling fins are arranged at the positions, opposite to the outer wall face of a combustion chamber on the piston top face, in an inner cavity of the engine cylinder piston. The work environment intensifying system for the engine cylinder piston of the piston reciprocating internal combustion engine eliminates harm of the system heeling force and thermal loads of a piston set, and substantially reduces the friction, in an engine cylinder, of a conventional internal combustion engine piston.

Owner:肖光宇

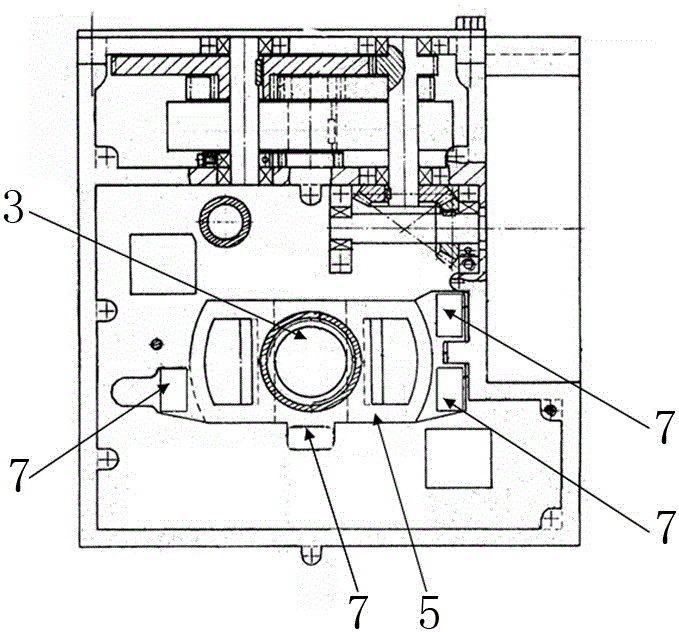

Pressure casting process for lock

The invention discloses a pressure casting process for a lock, which includes the steps: mounting a die; preheating the die; cleaning the die; spraying coatings on the die; placing the die on a die assembly device for die assembly; selecting injection pressure and filling speed; injecting liquid metal into a cavity and leading the cavity to be filled with the liquid metal; continuing injection under the action of an injection plunger until the liquid metal filled to a flow gate of the cavity is completely solidified; taking out a casting by opening the cavity after maintaining pressure; and cleaning the casting. The pressure casting process has the advantages that fine product quality is ensured, precision, strength and hardness are high, machining amount is small, large quantities of machining equipment and machining time are reduced, metal utilization rate is increased, both assembly time and the metal are saved, production efficiency is high, and mechanization and automation are easy to realize.

Owner:南通顶点科技服务有限公司

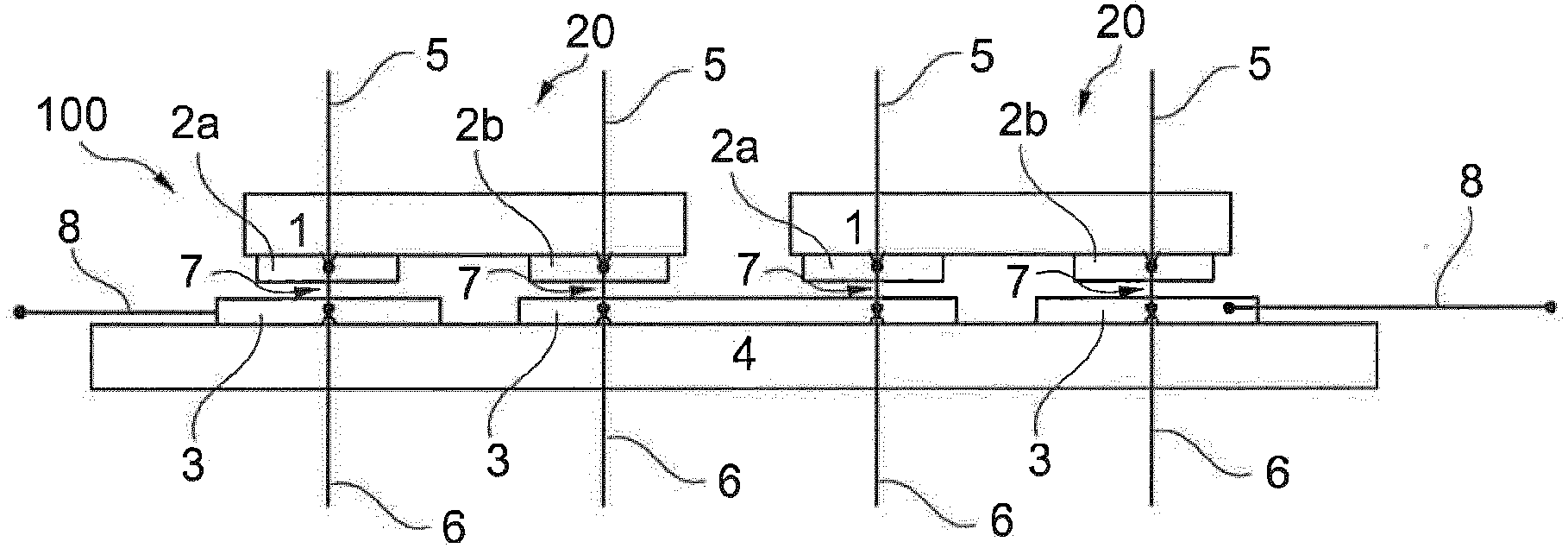

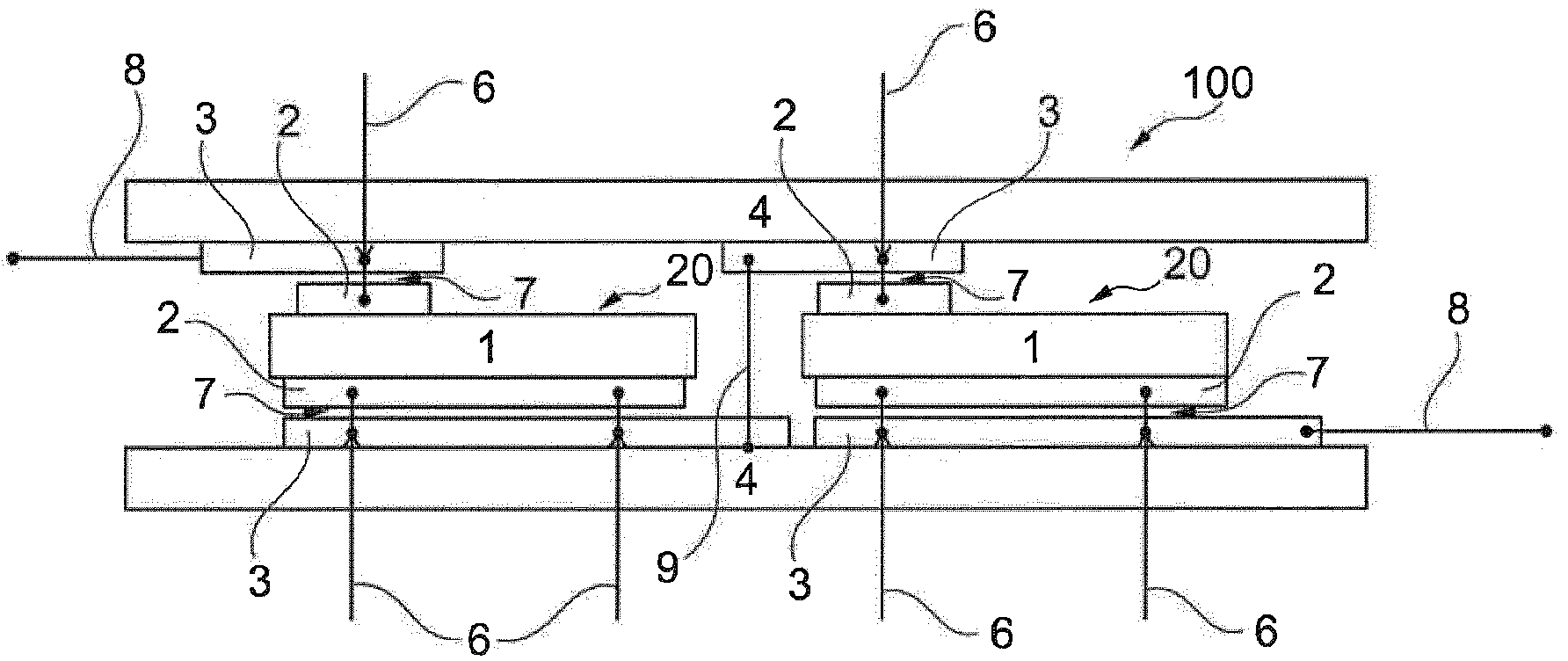

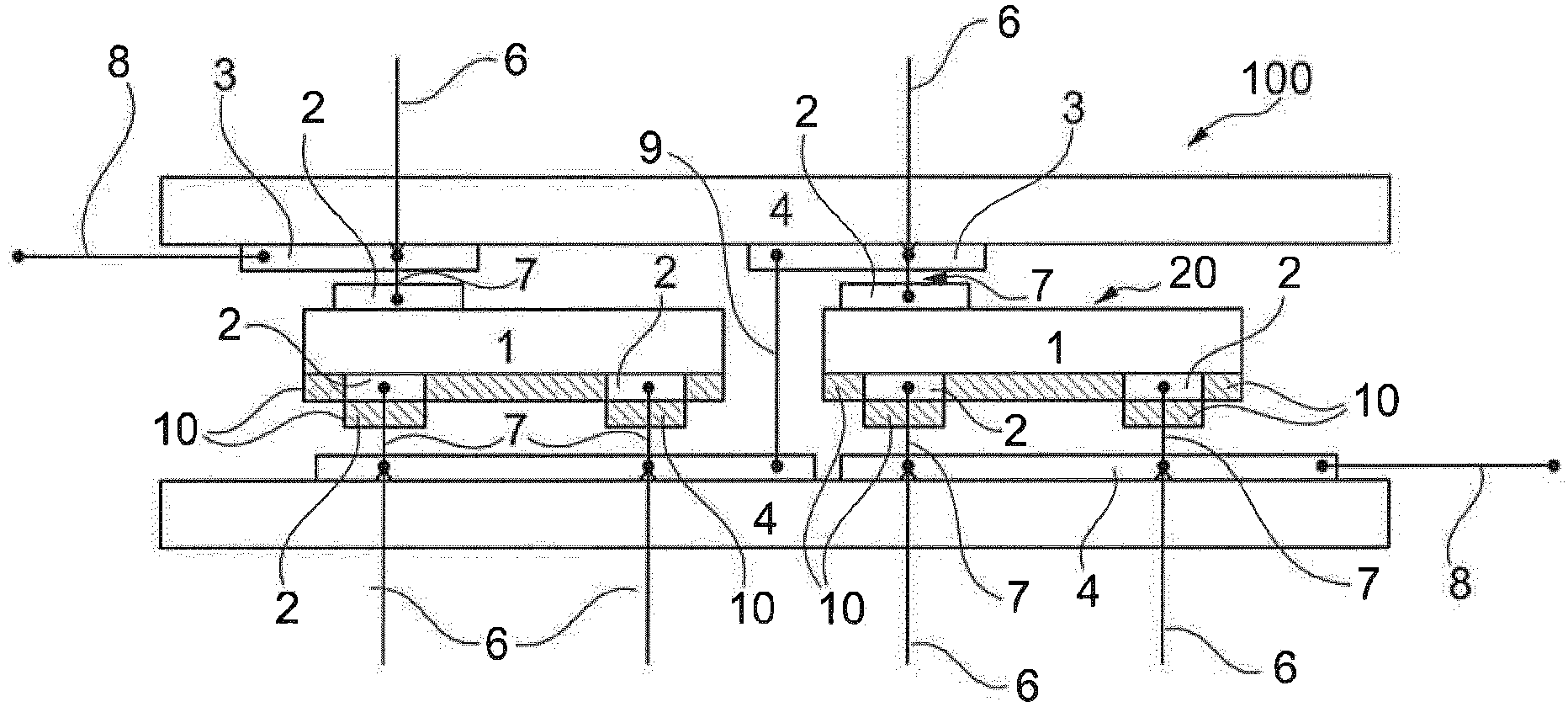

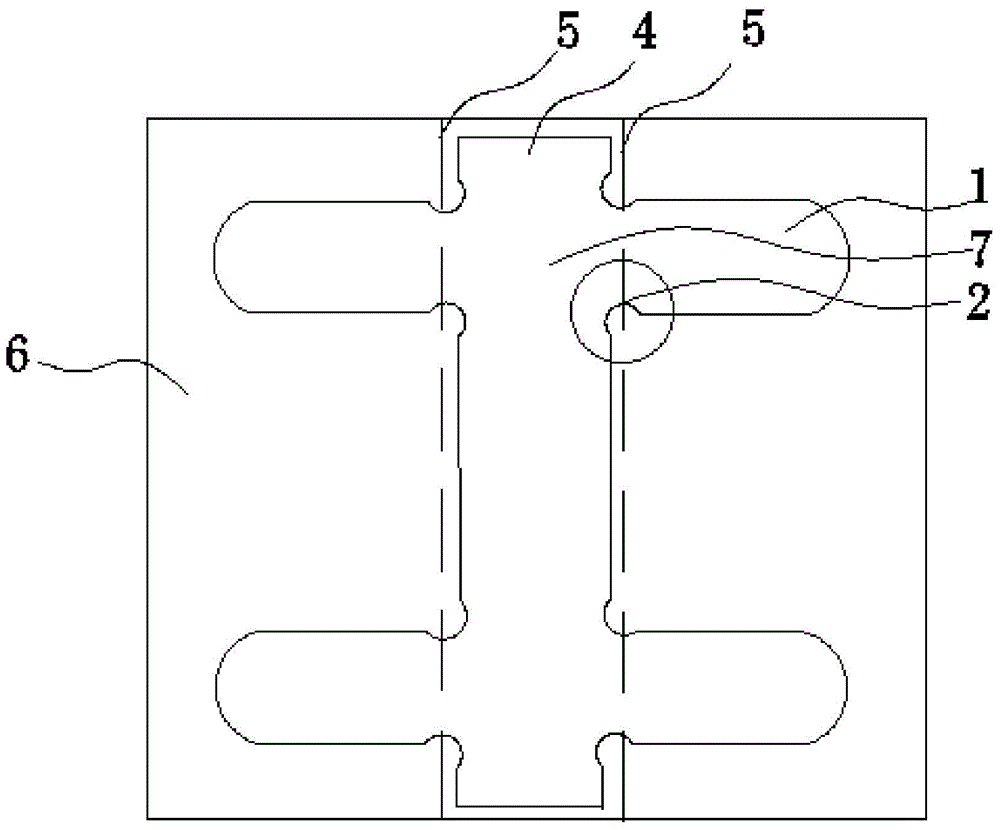

Method for electrically connecting several solar cells and photovoltaic module

InactiveCN103748691ASimple processGood lateral conductivitySolid-state devicesPhotovoltaic energy generationLaser bondingElectricity

The invention relates to a method for metallizing and connecting solar cell substrates (1) and to a photovoltaic module (100) made of several metallized solar cells (20) that are electrically connected to one another. According to the invention, a solar cell substrate (1), in which second metal layers (2a, 2b) forming electrical metal contacts are optionally provided, is attached to a carrier substrate (4), on the surface of which at least one first metal layer (3) is formed in a suitable pattern. By localized irradiation of the metal layer (2, 3) with laser radiation (5, 6) through the solar cell substrate (1) or the carrier substrate (4), energy is introduced such that the metal layer (2, 3) is heated by absorbed laser radiation (4, 5) for an irreversible bonding to the adjacent surface of the solar cell substrate (1). By the laser bonding of the metal layer (3) on the carrier substrate (4) to the solar cell substrate (1), solar cells can be connected to form a photovoltaic module, wherein conventional soldering of adjacent solar cells via metal bands is no longer required. Non-solderable, cost-effective, in particular silver-free metal layers (2a, 2b) can thus be used for contacting the solar cell substrates (1) of the solar cells (20).

Owner:INST FUR SOLARENERGIEFORSCHUNG

Heat-resistant high-pressure casting Al-Si-Ni-Cu aluminum alloy and preparation method thereof

The invention provides a heat-resistant high-pressure casting Al-Si-Ni-Cu aluminum alloy and a preparation method thereof, the aluminum alloy comprises the following elements in percentage by weight:10.5-12.0% of Si, 2.0-5.0% of Ni, 2.0-4.0% of Cu, 0.05-0.2% of Mg, 0.1-0.5% of Cr, 0.01-0.04% of Sr, 0.3-0.6% of M, 0.1-0.5% of Fe and the balance of Al, wherein M is at least two elements of Ti, Zr,and V. The tensile strength of die-casting alloy at room temperature, 350 DEG C instantaneous and 350 thermal insulation is 318-360 MPa, 140-155 MPa and 75-93 MPa, and the elongation is 1.2-2.0%, 5.3-6.3% and 5.8-7.2%; without solution heat treatment, the die-casting alloy can be applied to automotive heat-resistant parts such as pistons so as to meet the needs of automotive lightweight development.

Owner:SHANGHAI JIAO TONG UNIV

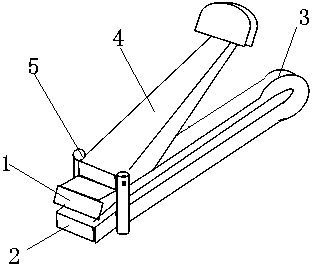

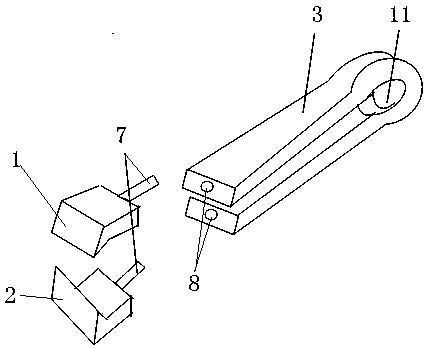

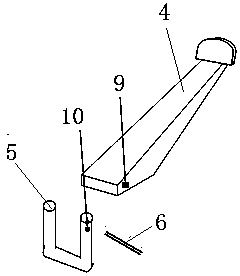

Environment-friendly nail clippers

The invention relates to a pair of environment-friendly nail clippers. The environment-friendly nail clippers are formed by an upper knife edge, a lower knife edge, a spring clip, a handle, a pull ring and a pull ring pin. The rear portion of the upper knife edge and the rear portion of the lower knife edge are each provided with a tail core, the spring clip is in the U shape, inner holes are formed in the two ends of the spring clip, and the tail core of the upper knife edge and the tail core of the lower knife edge are inserted into the two inner holes respectively. The pull ring is concave, transverse holes are formed in the two ends of the pull ring, and the pull ring is clamped to the outer side of the front end of the spring clip from bottom to top; a transverse hole is formed in the lower end of the handle, and the upper end of the handle is in the tongue shape; the lower end of the handle is movably connected with the pull ring through the pull ring pin. When the environment-friendly nail clippers are used, the handle and the pull ring are moved to the front portions of the ends of the spring clip and then are pressed downwards. When the environment-friendly nail clippers are not used, the handle and the pull ring are moved to the rear portion of the spring clip, and the handle is turned forwards. The environment-friendly nail clippers are simple in structure, practical and reliable, and metal materials are saved.

Owner:SHANGHAI INST OF TECH

Pressure casting process for bearing block

The invention discloses a pressure casting process for a bearing block, which includes the steps: mounting a die; preheating the die; cleaning the die; spraying coatings on the die; placing the die on a die assembly device for die assembly; selecting injection pressure and filling speed; injecting liquid metal into a cavity and leading the cavity to be filled with the liquid metal; continuing injection under the action of an injection plunger until the liquid metal filled to a flow gate of the cavity is completely solidified; taking out a casting by opening the cavity after maintaining pressure; and cleaning the casting. The pressure casting process has the advantages that fine product quality is ensured, precision, strength and hardness are high, machining amount is small, large quantities of machining equipment and machining time are reduced, metal utilization rate is increased, both assembly time and the metal are saved, production efficiency is high, and mechanization and automation are easy to realize.

Owner:南通新景华企业管理服务有限公司

Municipal solid waste incineration power generation system

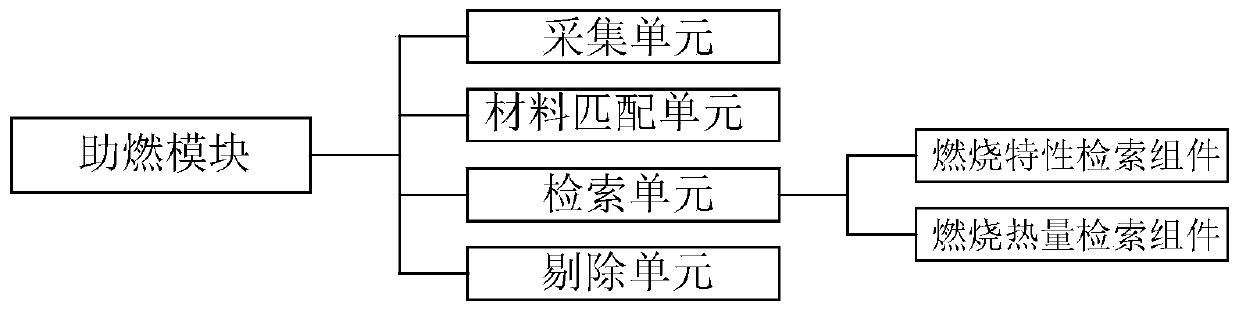

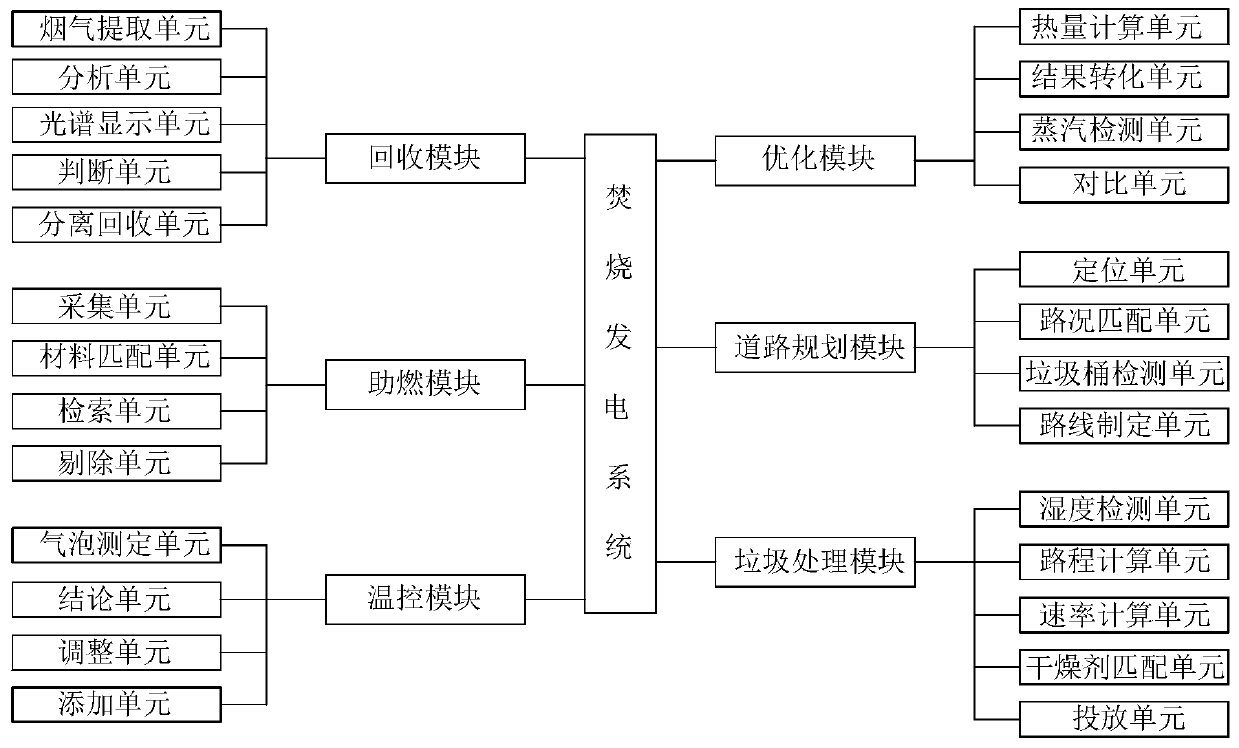

PendingCN110046723ASave metalIncrease profitSustainable waste treatmentForecastingMunicipal solid waste incinerationAnalysis data

The invention belongs to the field of municipal solid waste treatment processes, in particularly relates to a municipal solid waste incineration power generation system which comprises a recovery module, a combustion-supporting module, a temperature control module, an optimization module, a road planning module and a waste treatment module. The recovery module comprises a flue gas extraction unit,an analysis unit, a spectrum display unit, a sorting unit, a judgment unit and a separation and recovery unit; the analysis unit is used for carrying out component analysis on the flue gas transmitted by the flue gas extraction unit, sending an analysis signal to the spectrum display unit and sending analysis data to the arrangement unit; the spectrum display unit is used for carrying out spectrum display on garbage combustion according to the analysis signal sent by the analysis unit and sending the spectrum data to the arrangement unit. The system is mainly used for solving the problems that in the prior art, metal in the waste incineration process cannot be recycled, the combustion condition cannot be monitored in real time, and whether the heat transmission condition is blocked or notcannot be known.

Owner:周旭东

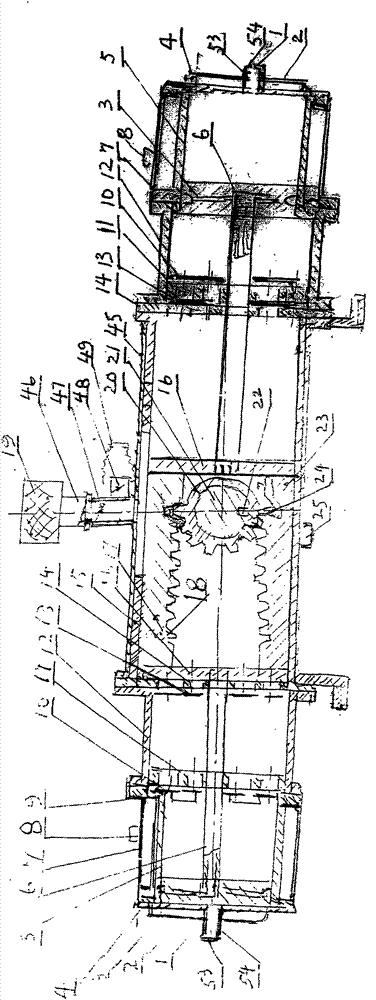

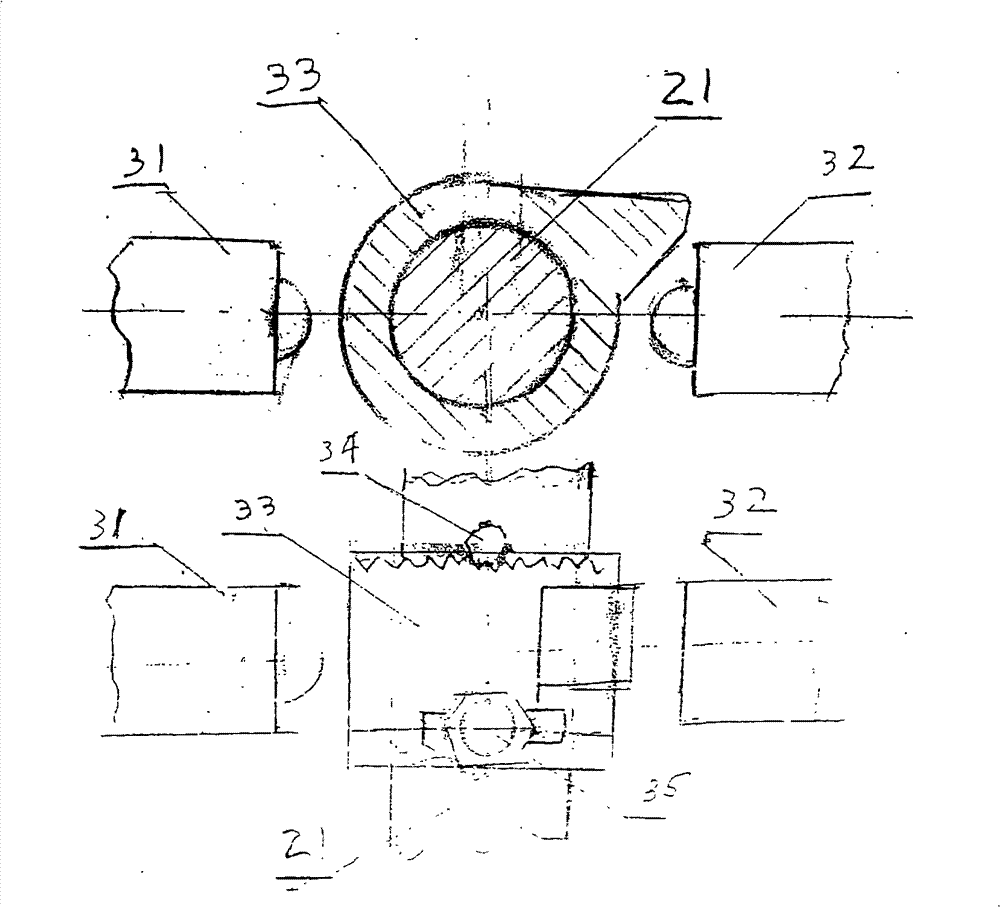

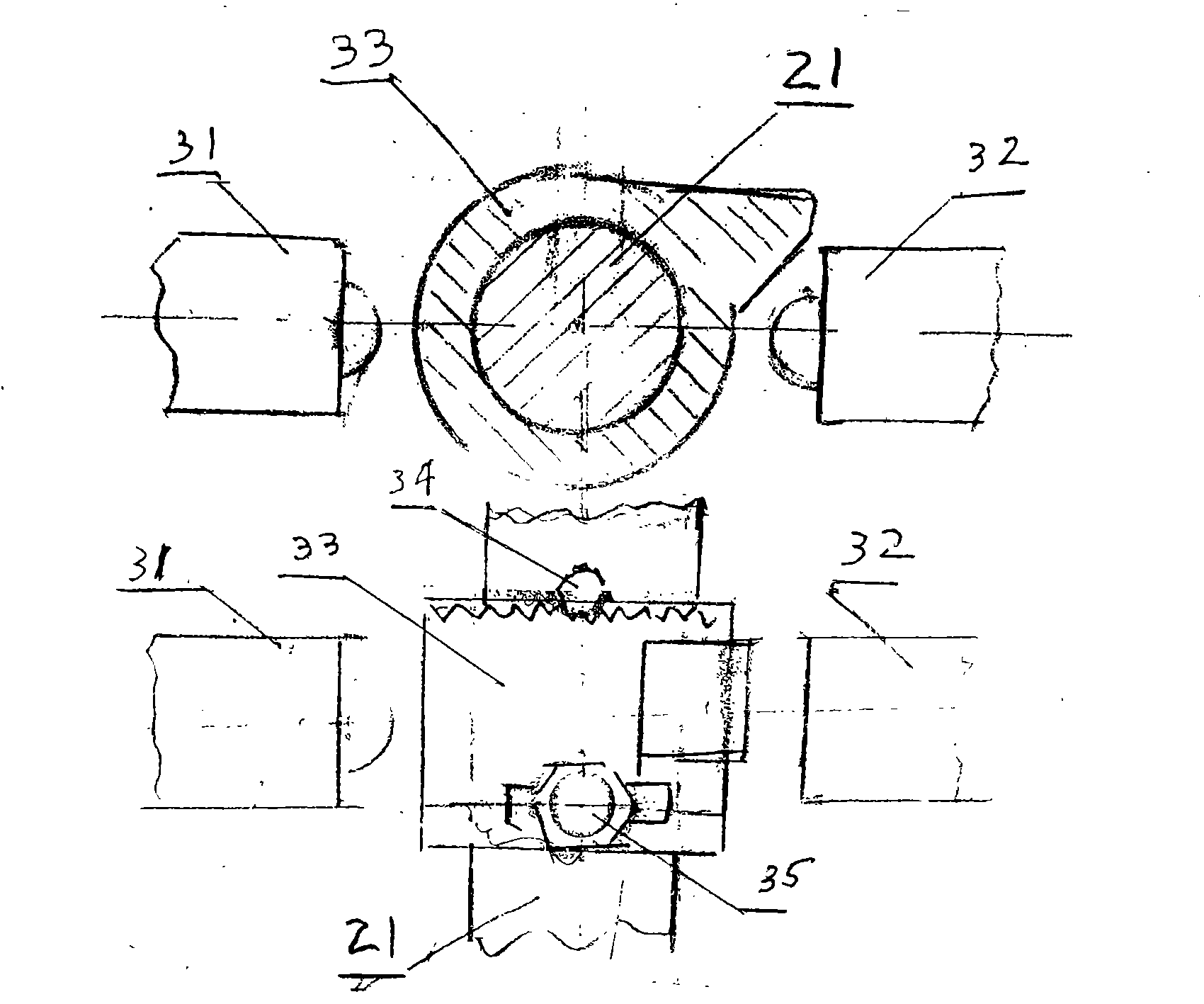

Multi-energy, low-carbon, energy-saving and environment-friendly synchronous one-stroke anti-detonation internal combustion engine

The invention relates to a multi-energy, low-carbon, energy-saving and environment-friendly synchronous one-stroke anti-detonation internal combustion engine. The engine is different from the existing internal combustion engines such as a four-stroke internal combustion engine and a two-stroke internal combustion engine, further perfects an authorized one-stroke anti-detonation free-piston engine and an authorized one-stroke anti-detonation internal combustion engine of the applicant, and is characterized in that two or more opposite air cylinder heads are arranged; an air inlet scavenging cylinder is arranged behind each of the two main air cylinders (detonation working air cylinders) at the two ends, and connected with a middle engine body; two air cylinders and two pistons are arranged on each side by taking a main shaft as a center, are the same in structure; in a center line of the air cylinders, the four pistons form a piston body which pushes a half-gear-shaped part through an upper rack and a lower rack to drive the main shaft to rotate in a clockwise direction; the two sides perform counter detonation; and since the main shaft works outwards, the purpose of synchronous operation incapable of being achieved by the former two patents in practice is achieved. In addition, a multi-energy device is designed; multiple energy can be used only by changing several parts on the same engine body; and the multi-energy device is a revolution of the existing internal combustion engines.

Owner:向探真

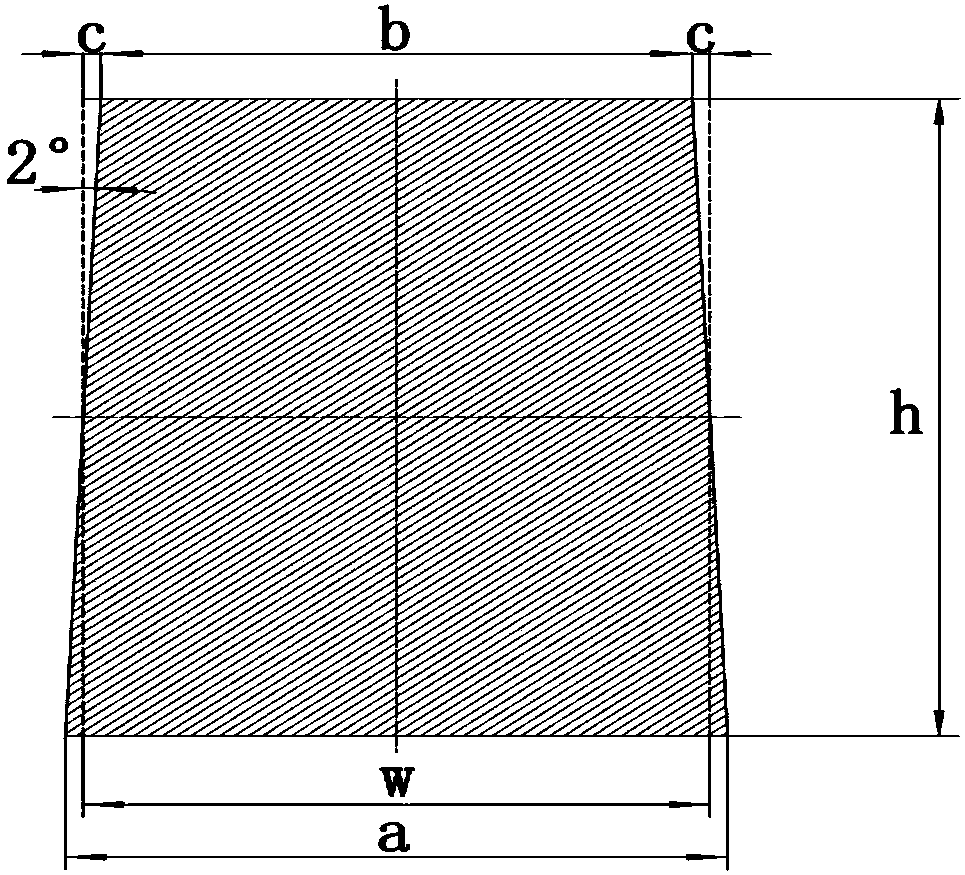

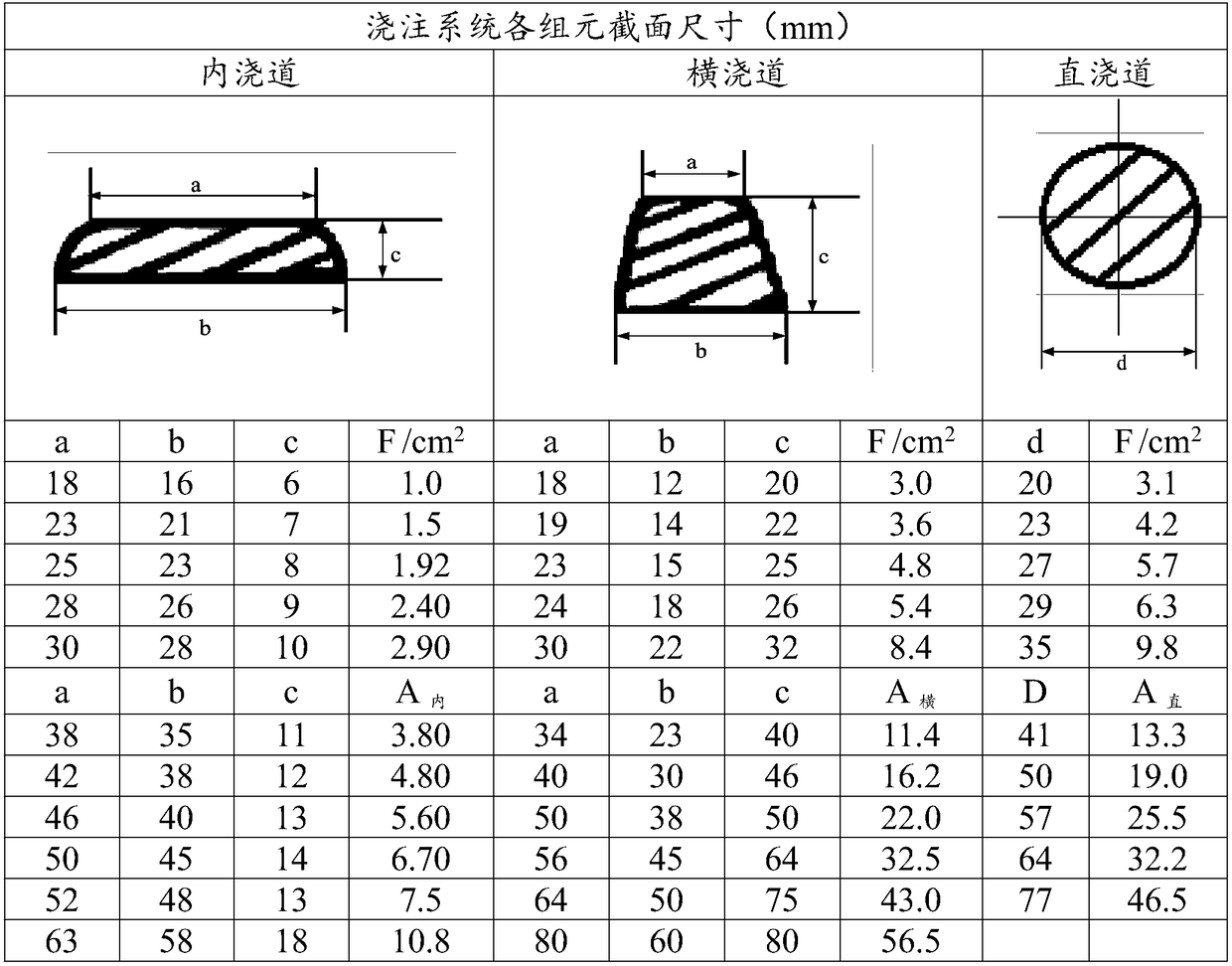

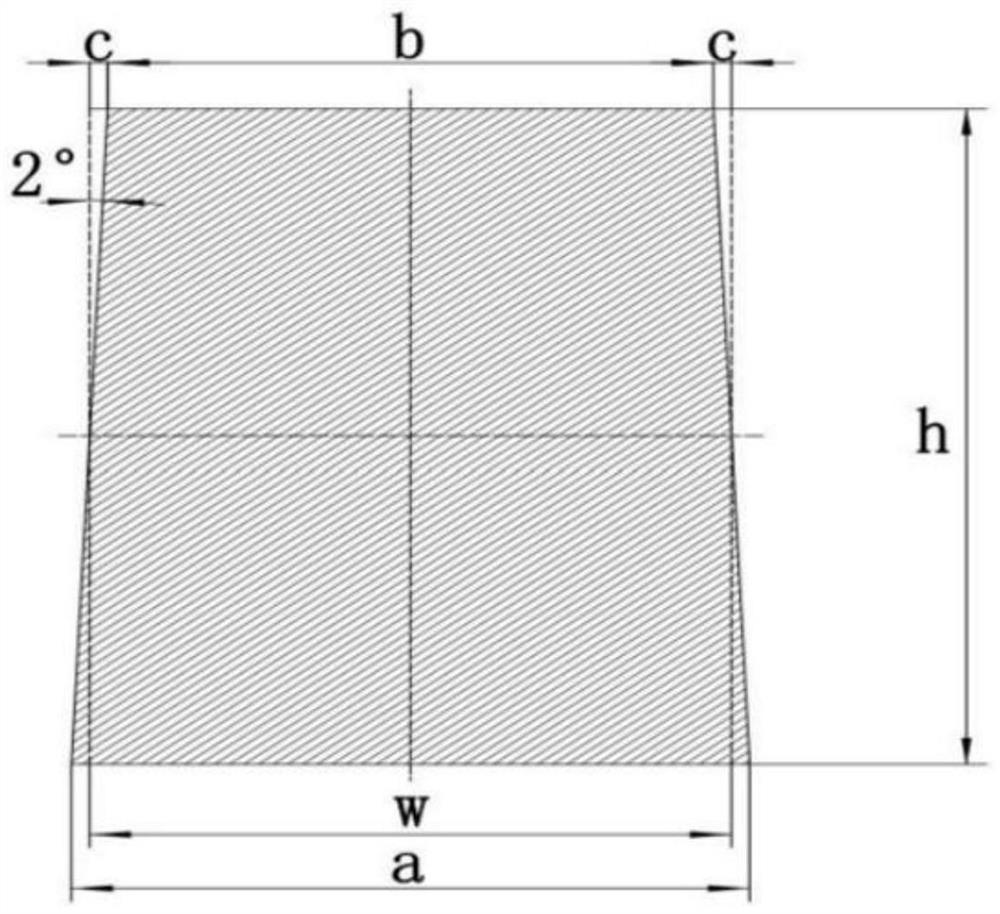

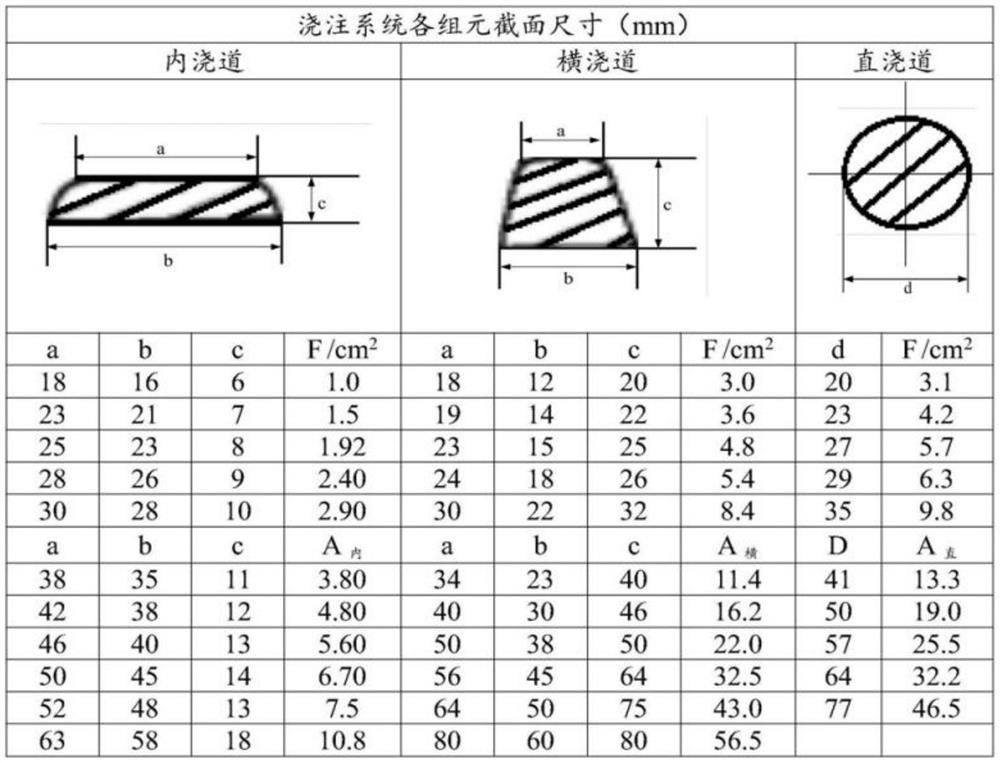

Calculation method for shape sizes of cross gate cross sections of gating systems for casting

InactiveCN108319746AAccurate dataSave metalGeometric CADFoundry mouldsMaterials scienceCalculation methods

The invention discloses a method for calculating shape sizes of cross gate cross sections of gating systems for casting, relates to the field of casting, and aims at solving the problem that existingcalculation methods are incorrect in calculation results, need table lookup in calculation processes, are complex to operate and waste time and labor. According to the calculation method, a golden section number 0.618 is adopted to calculate shape sizes of cross gate cross sections; a formula (as shown in the specification) is calculated for the golden section number 0.618 through an area formula(as shown in the specification) for cross gate cross sections of gating systems for casting and a specific value of a theoretical width w of a set cross gate cross section to a height of the cross gate cross section; and results that a is approximately equal to 0.636h and b is approximately equal to 0.601h are obtained through a calculation formula (as shown in the specification) of an upper sidelength c of the cross gate cross section, a calculation formula a=w+2c of a lower side length a of the cross gate cross section and a calculation formula b=w-2c of a practical width b of the cross gate cross section. According to the method, the calculation process does not need table lookup, and the calculation is simple and accurate.

Owner:吉林省大洺液压件铸造技术科技开发有限公司

Multiple-energy source low-carbon energy-saving environment-friendly synchronous one-stroke opposite-explosion internal combustion engine

The invention relates to a multiple-energy source low-carbon energy-saving environment-friendly synchronous one-stroke opposite-explosion internal combustion engine which is different with existing internal combustion engines, such as a four-stroke or two-stroke internal combustion engine. A one-stroke free piston motor and a one-stroke opposite-explosion internal combustion engine authorized by the inventor are further perfected by the multiple-energy source low-carbon energy-saving environment-friendly synchronous one-stroke opposite-explosion internal combustion engine. The multiple-energy source low-carbon energy-saving environment-friendly synchronous one-stroke opposite-explosion internal combustion engine is characterized in that: two or more than two opposite cylinder heads are provided; an air inlet and air scavenging cylinder is installed at the back of main steam pumps (explosion working cylinders) to be connected with a middle engine body; a main shaft is used as the center; two cylinders and two pistons are arranged at each side, and both sides have the same structure and are on the same center line of the cylinders; a piston body is composed of the four pistons; the main shaft is driven by a half side shape similar gear pushed by an upper rack and a lower rack to be rotated clockwise so that both sides are oppositely exploded; and the purpose of synchronous operation failed to be achieved by the first two patents is achieved by external working of the main shaft. In addition, a multiple-energy source device is designed, multiple energy sources can be utilized so long as a plurality of parts on the same engine body is changed, and the multiple-energy source low-carbon energy-saving environment-friendly synchronous one-stroke opposite-explosion internal combustion engine is a revolution for the existing internal combustion engine.

Owner:向探真

Lead frame pin cutting structure and cutting method thereof

InactiveCN105810655AIncrease spacingSave metalSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention provides a lead frame pin cutting structure. The lead frame pin cutting structure comprises a pin connection portion, multiple pins and multiple pin end portions between the pins and the pin connection portion, wherein the quantity of the pins is equal to the quantity of the pin end portions, the pins and the pin end portions are arranged at two sides of the pin connection portion, the pins, the pin end portions and the pin connection portion are an integrated structure, and width of the pin end portions connected with the pins is smaller than width of the pins. According to the lead frame pin cutting structure, design of the pin end portions of the QFN lead frame is optimized, gaps among the pins are enhanced at an early design period, metal of a blade cutting portion is reduced, influence of a cutting stress on quality of products in a production process is ameliorated, cutting service life of a blade is prolonged, and product cutting quality is improved.

Owner:WUXI CHINA RESOURCE MICRO ASSEMBLY TECH

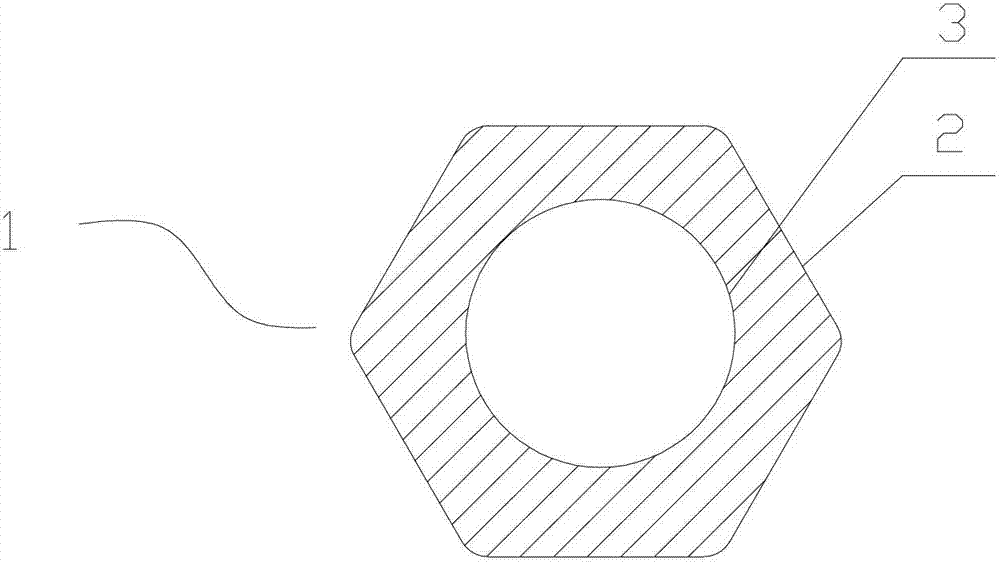

Seamless steel tube for screw spanner

InactiveCN103115239AImprove stabilityEasy to connect and useElongated constructional elementsThermal treatmentSteel tube

The invention discloses a seamless steel tube for screw spanners. The section of the seamless steel tube is of a special-shaped structure, and the outer wall thereof is of a regular hexagonal structure. Transitional arcs are arranged between the two adjacent edges, and the inner wall of the seamless steel tube is of circular structure. The seamless steel tube made of steel No. 45 is formed by pulling and is subjected to normalizing thermal treatment. The seamless steel tube for screw spanners is low in production cost and high in strength.

Owner:JIANGSU HUACHENG IND PIPES

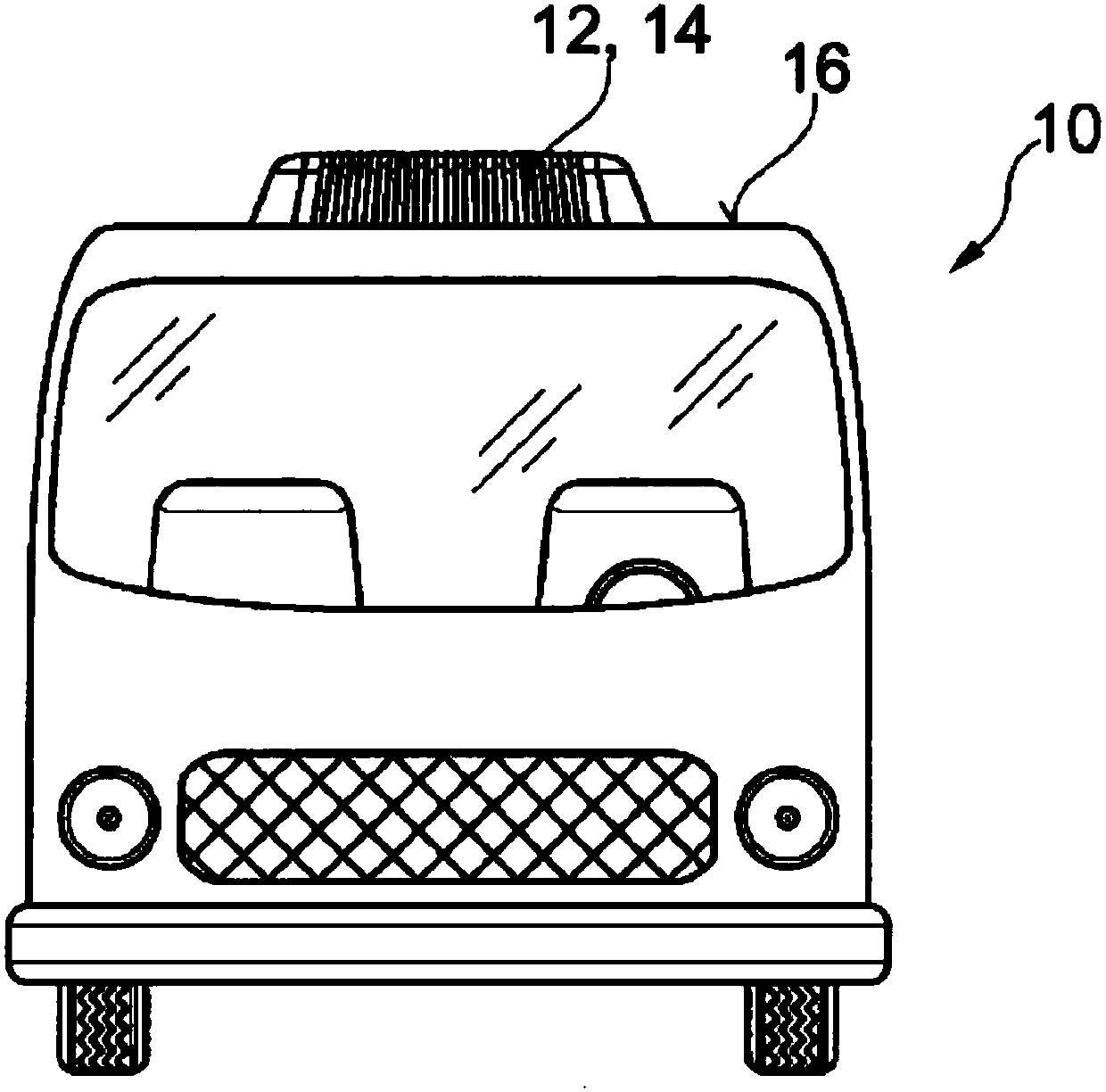

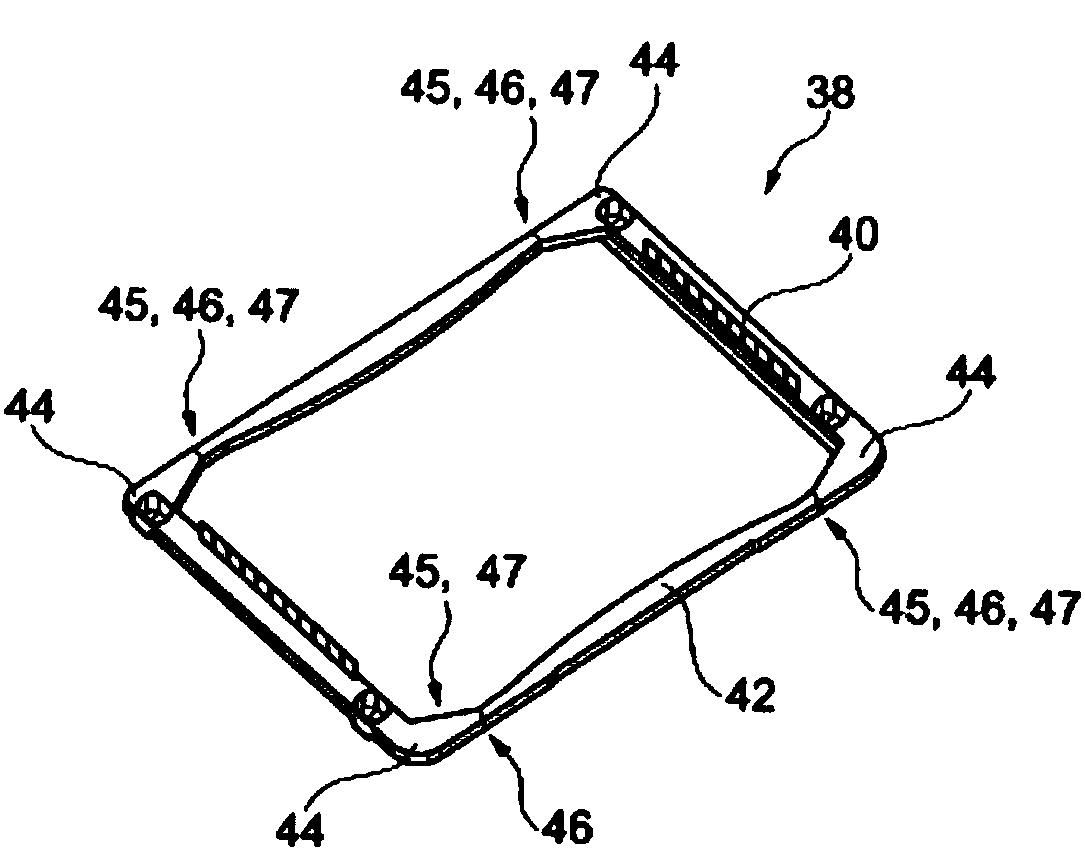

Air-conditioning system for a vehicle, in particular rooftop air-conditioning system, and vehicle having an air-conditioning system of said type

ActiveCN107771134AReduce production processReduce storage costsAir-treating devicesVehicle heating/cooling devicesDetentAir conditioning

The invention relates to an air-conditioning system for a vehicle, for example a bus, heavy goods vehicle or rail vehicle, in particular rooftop air-conditioning system for mounting on a vehicle roof,having a condenser module (18) which comprises a condenser housing (24) and a condenser (20) arranged in the condenser housing (24), and / or having an air-conditioning module (26) which comprises an air-conditioning housing (34) and an evaporator (28) arranged in the air-conditioning housing (34), and having a support frame (38) which bears the condenser module (18) and / or the air-conditioning module (26) and holds these on the vehicle roof. On the support frame (38) there is provided at least one detent connection (46) and / or a plug-type connection (45) with securing element (47) for the fastening of the support frame (38).

Owner:MAHLE INT GMBH

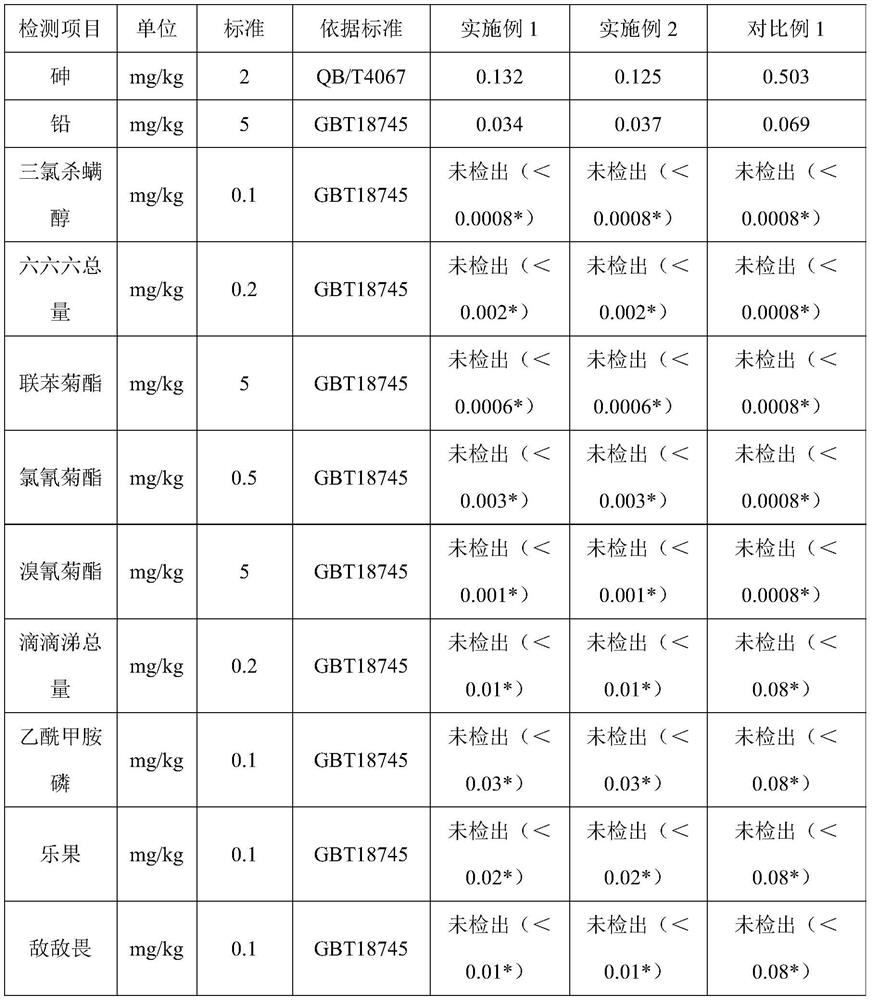

Extraction and separation method of multiple components of ganoderma lucidum and application of extraction and separation method in preparation of artificially planted ganoderma lucidum extract

ActiveCN114377039AHigh extraction purityHigh biosecurityChemical industryPlant ingredientsBiotechnologyTriterpene

The invention discloses a ganoderma lucidum multi-component extraction and separation method and application thereof in preparation of an artificially planted ganoderma lucidum extract, and belongs to the technical field of deep processing of ganoderma lucidum. The ganoderma lucidum multi-component extraction and separation method comprises the following steps that ganoderma lucidum is crushed and then extracted, multi-stage separation is conducted on an extract, a ganoderma lucidum polysaccharide enrichment and a ganoderma lucidum triterpene enrichment are obtained, the material-liquid ratio of extraction is 1: (18-22), the extraction temperature is 60-80 DEG C, and the extraction time is 1-2 h; the multi-stage separation comprises the following steps: separating the extract by adopting a nanofiltration membrane with the molecular weight of 1000 to obtain ganoderma lucidum polysaccharide, and separating by adopting a nanofiltration membrane with the molecular weight of 500 to obtain ganoderma lucidum triterpenes. According to the preparation method, the purity of the beneficial components is effectively improved, the purity of the ganoderma lucidum polysaccharide can reach about 10%, the production cost of a ganoderma lucidum product is reduced, heavy metal and pesticide residues are obviously reduced, and the product safety is good.

Owner:贵州中科分子生物有限公司

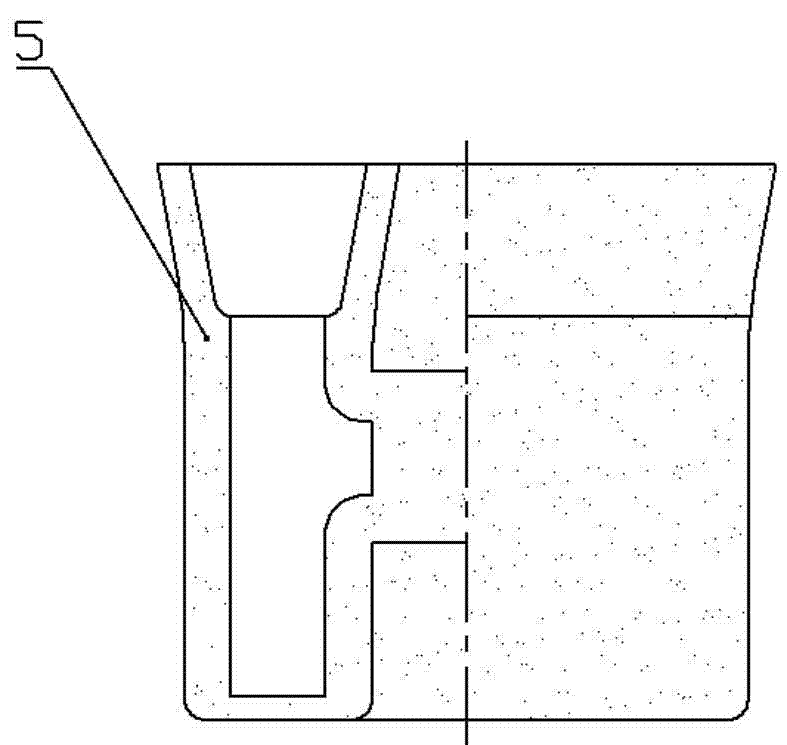

Application method of insulated feeder in evanescent mold casting

InactiveCN108127086AImprove yieldExtended cooldownFoundry mouldsFoundry coresLost-foam castingCooling time

The invention relates to an application method of an insulated feeder in evanescent mold casting and belongs to the technical field of evanescent mold casting. The application method of the insulatedfeeder in evanescent mold casting is characterized in that the application of the insulted feeder in evanescent mold casting is that during evanescent mold casting, the insulated feeder is additionally arranged on a casting part evanescent mold to increase the utilization ratio of molten iron, prolong the cooling time of the molten metal, enhance the feeding effect and increase the yield of casting parts. The application method of the insulated feeder in evanescent mold casting has the beneficial effects that the molten metal solidification time is long, metal is saved, the feeding effect is good, the utilization ratio of the molten iron and the yield are high, the molding sand and metal loss is reduced, the energy is saved, labor is saved, the production cost of the casting parts is reduced, and the application range is wide.

Owner:天津万石科技发展有限公司

Casting method of tabular spheroidal iron piece and casting system thereof

InactiveCN101301681BReasonable structureSimple structureMolten metal conveying equipmentsSlagSmall footprint

The invention discloses a pouring method and a pouring system used for a plate-shaped ball iron casting. The method adopts a sand casting technique; the pouring system comprises a sprue cup, a sprue, a horizontal runner and a plurality of plate-shaped castings; the method adopts a type that the large plane of the plate-shaped casting is vertically arranged in parallel; the horizontal runner and the plate-shaped casting form a narrow seam edge gate so as to lead the molten steel to flow in along the wall and be stably filled from bottom to top during the pouring process. When the method and the pouring system of the invention are adopted, the molten steel is filled along the wall during the pouring process and the metal is sequentially solidified from bottom to top, thus ensuring the uniformity and consistency of the metallographic structure of the plate-shaped ball iron casting; furthermore, by the narrow seam edge gate, the pouring time is prolonged, the shrinkage compensation effectis provided during the pouring process, furthermore, the slag retaining effect is good and the defects such as slag inclusion, sand inclusion, etc. are avoided; the plate-shaped ball iron casting pouring system of the invention has reasonable and simple structure, saves the metal and has high process yield; furthermore, the pouring system is convenient to be removed; the casting adopts serial pouring, thus having small land occupying and high production efficiency.

Owner:鑫工艺(上海)材料科技有限公司

Carton profiling air bag bell

A cartoon-type air-bag bell for bicycle is composed of air bag with cartoon shape, sounding reed, holder and fixing fastener.

Owner:王长江

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com