Municipal solid waste incineration power generation system

A technology for municipal solid waste and incineration power generation, which is applied in information technology support systems, instruments, data processing applications, etc., to solve problems such as inability to understand whether heat transmission is blocked, metal recovery, and real-time monitoring of combustion conditions, etc. Garbage combustion efficiency, heating effect, heat raising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

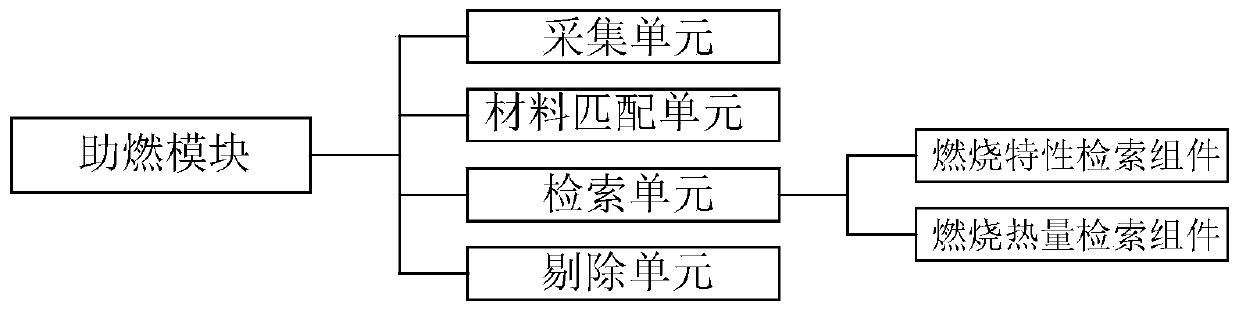

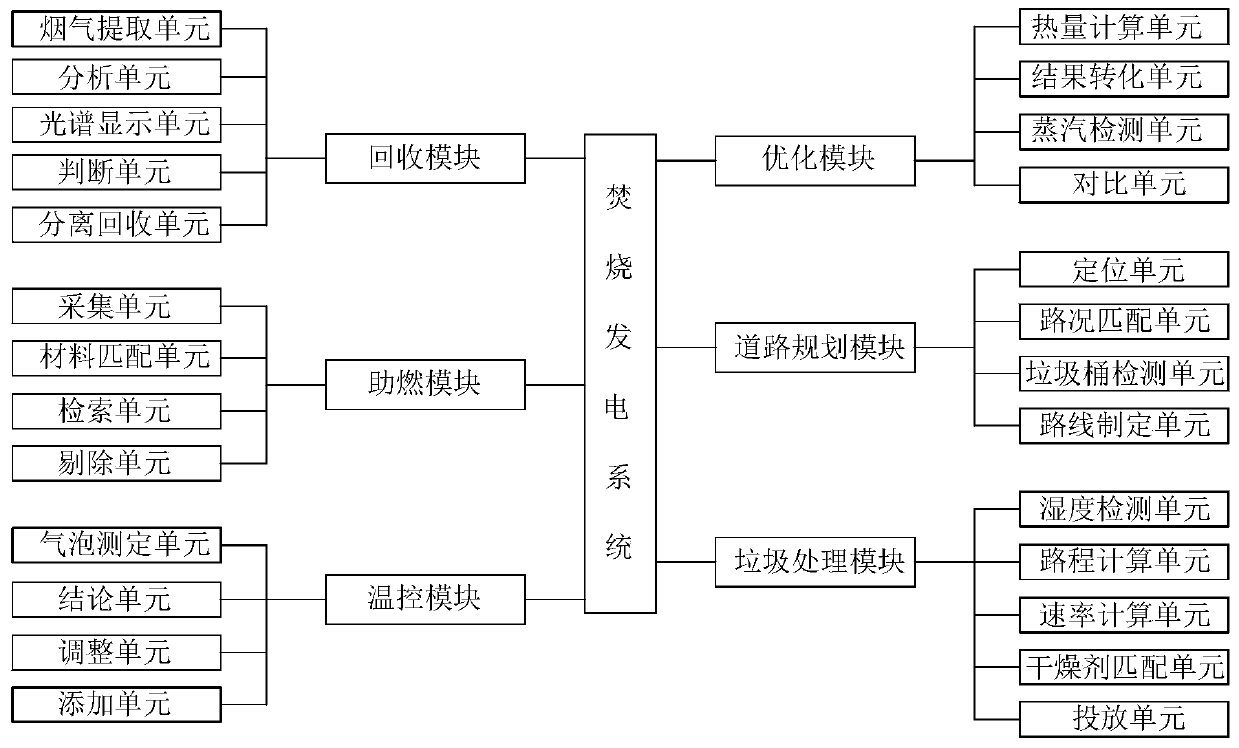

[0016] use Figure 1-Figure 2 A municipal solid waste incineration power generation system according to an embodiment of the present invention will be described as follows.

[0017] Such as Figure 1-Figure 2 As shown, a municipal solid waste incineration power generation system according to the present invention includes a recovery module, a combustion-supporting module, a temperature control module, an optimization module, a road planning module and a garbage treatment module; The metals are recycled; the combustion-supporting module is used to divide garbage with the same combustion characteristics to facilitate common combustion; the temperature control module is used to detect whether the temperature distribution of garbage is even when burning, and to improve it in a targeted manner; the optimization module It is used to detect the influence of pot ash on heat transfer when the garbage is burned; the road planning module is used to formulate the route for garbage trucks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com