Optimization method for shape and size of cross section of cross gate of gating system and casting method

A technology of cross-sectional shape and gating system, which is applied in casting molding equipment, design optimization/simulation, casting mold, etc., can solve the problems of complicated operation, time-consuming and laborious, and need to look up tables in the calculation process, and achieve the effect of saving metal and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

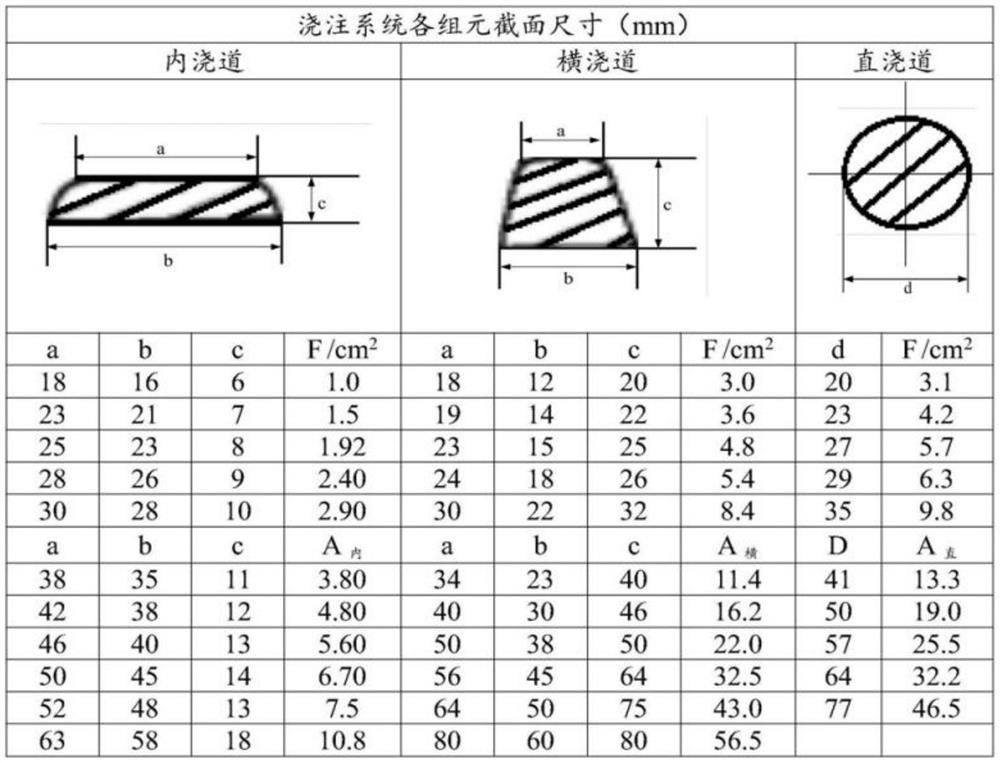

[0043] A method for optimizing the cross-sectional shape and size of the runner of the gating system and a casting method of the present invention calculate the cross-sectional shape and size of the runner by using a relational expression composed of a width / height ratio of 0.618 (the golden section number).

[0044] It mainly includes the following steps:

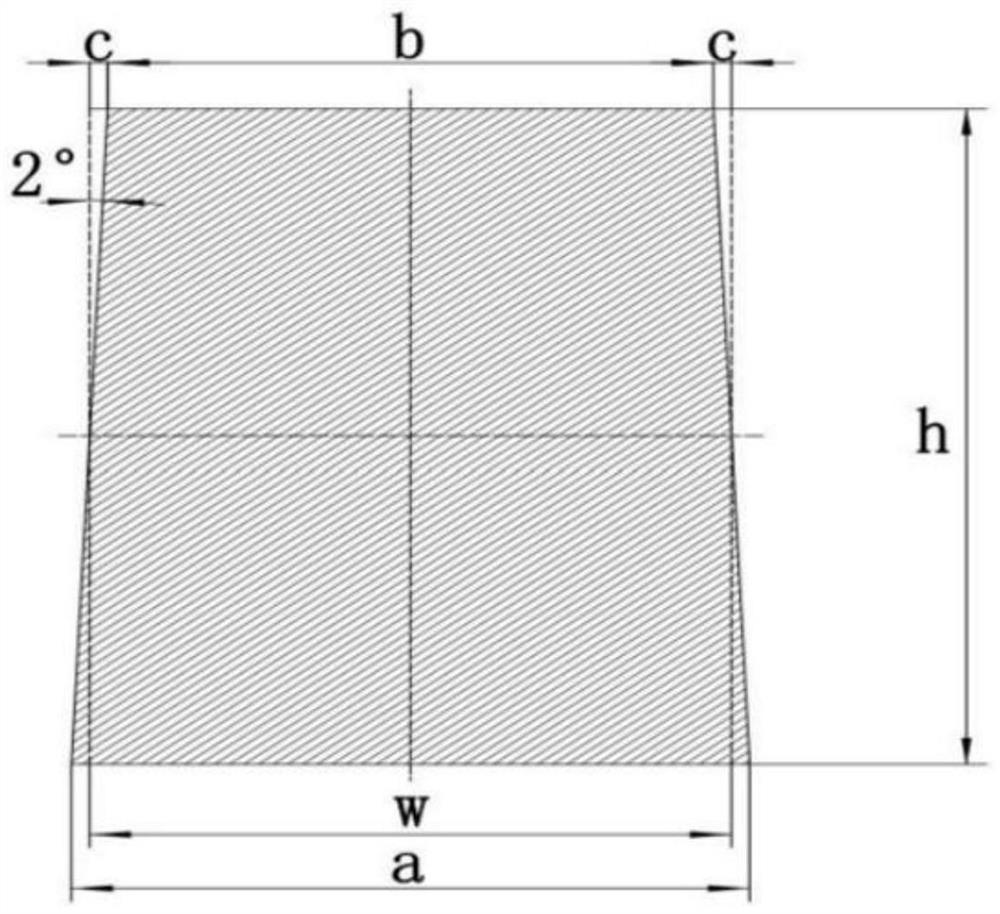

[0045] Step 1, such as figure 1 As shown, the area of the runner section of the casting gating system is shown in formula (1),

[0046] ∑Aru=h×w (1)

[0047] Step 2, the present invention adopts the golden section number that width / height ratio is 0.618 to calculate, as formula (2)

[0048] As shown, w=h×0.618 (2)

[0049] In the formula, ∑Aru represents the cross-sectional area of the runner, h represents the height of the runner section, and w represents the theoretical width of the runner secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com