Casting method of tabular spheroidal iron piece and casting system thereof

A pouring system and pouring method technology are applied in the field of pouring of plate-shaped ductile iron parts, and the field of gating system of plate-shaped ductile iron parts, which can solve the problems such as cold insulation, unbalanced mechanical properties of castings, differences in metallographic structure of castings, etc. , to achieve the effect of prolonging the pouring time, good slag blocking effect and uniform metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

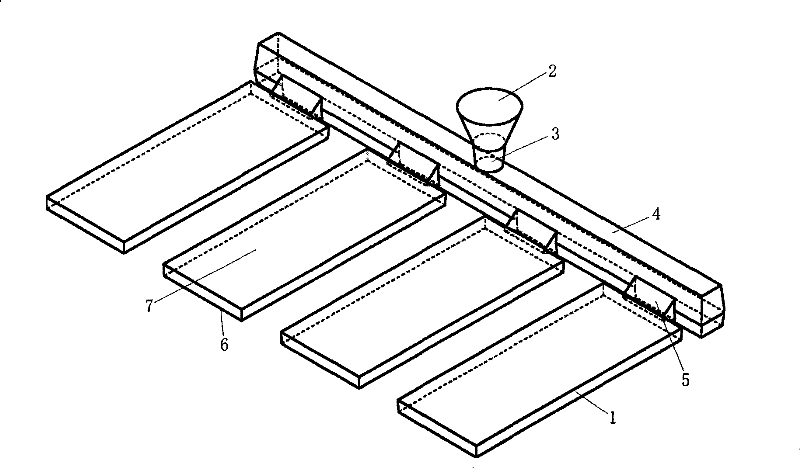

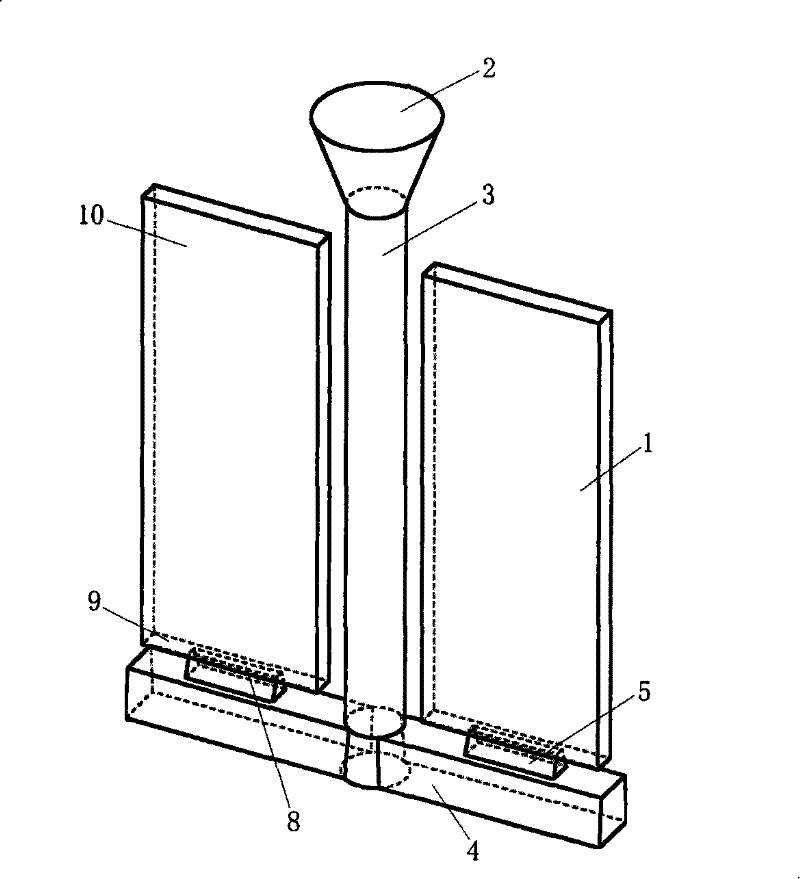

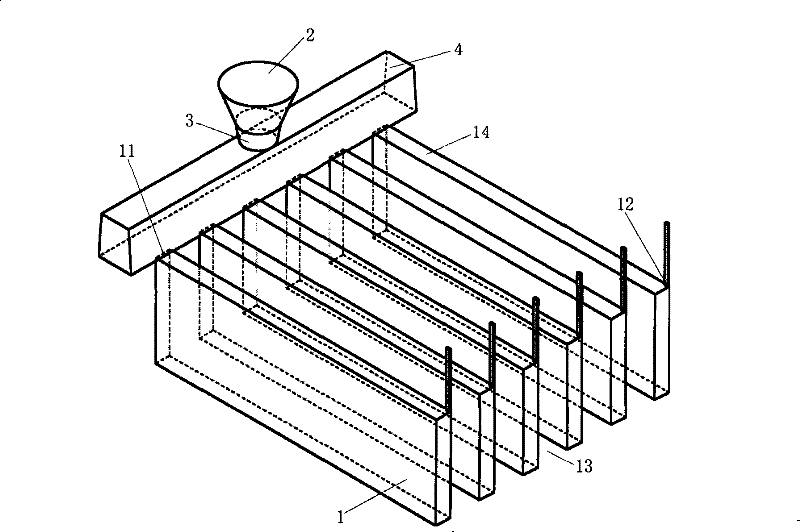

[0035] Such as image 3 As shown, the large planes of a group of 6 plate-shaped ductile iron parts 1 are placed vertically and parallel, and each casting is spaced at a certain distance 13 to ensure sufficient sand consumption. The runner 4 is placed on the side of the top 14 of the casting group, and the blank holder gate 11 formed has a blank holder width of 2 to 3 mm. The runner 4 is provided with a sprue 3 and a sprue cup 2. When pouring The molten metal enters the cavity through the sprue cup 2, the sprue 3, the runner 4 and the edge gate 11, goes down along the wall, and then completes the stable filling from the bottom to the top, forming a unilateral serial group of castings. Vents 12 are respectively provided on the other side of the top of each casting to facilitate smooth exhaust during the pouring process.

Embodiment 2

[0037] Such as Figure 4 As shown, the large planes of a group of 5 pieces of plate-shaped ductile iron parts 1 are placed vertically and parallel. On the basis of the first embodiment, another group of 5 pieces of plate-shaped ductile iron parts are placed symmetrically at the bottom of the runner 4 , and form the edge gate 11 on the other side. When pouring, the molten metal enters the cavity through the sprue cup 2, the sprue 3, the runner 4 and the edge gates 11 on both sides, and flows down the wall, and then The smooth filling is completed from bottom to top, and the exhaust is exhausted through the air outlet hole 12, finally forming a group of castings with two sides connected in series.

[0038] In the above embodiment, each group of plate-shaped nodular iron pieces placed in parallel may also contain other numbers of plate-like nodular iron pieces, but generally each group does not exceed 10 pieces, because too many pieces will also cause defects such as insufficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com