Application method of insulated feeder in evanescent mold casting

A technology of lost foam casting and heat preservation riser, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of short solidification time of molten metal, low utilization rate of molten iron, and difficulty in improving the yield of finished products. Metal melting and cutting riser costs, reducing sand and metal loss, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

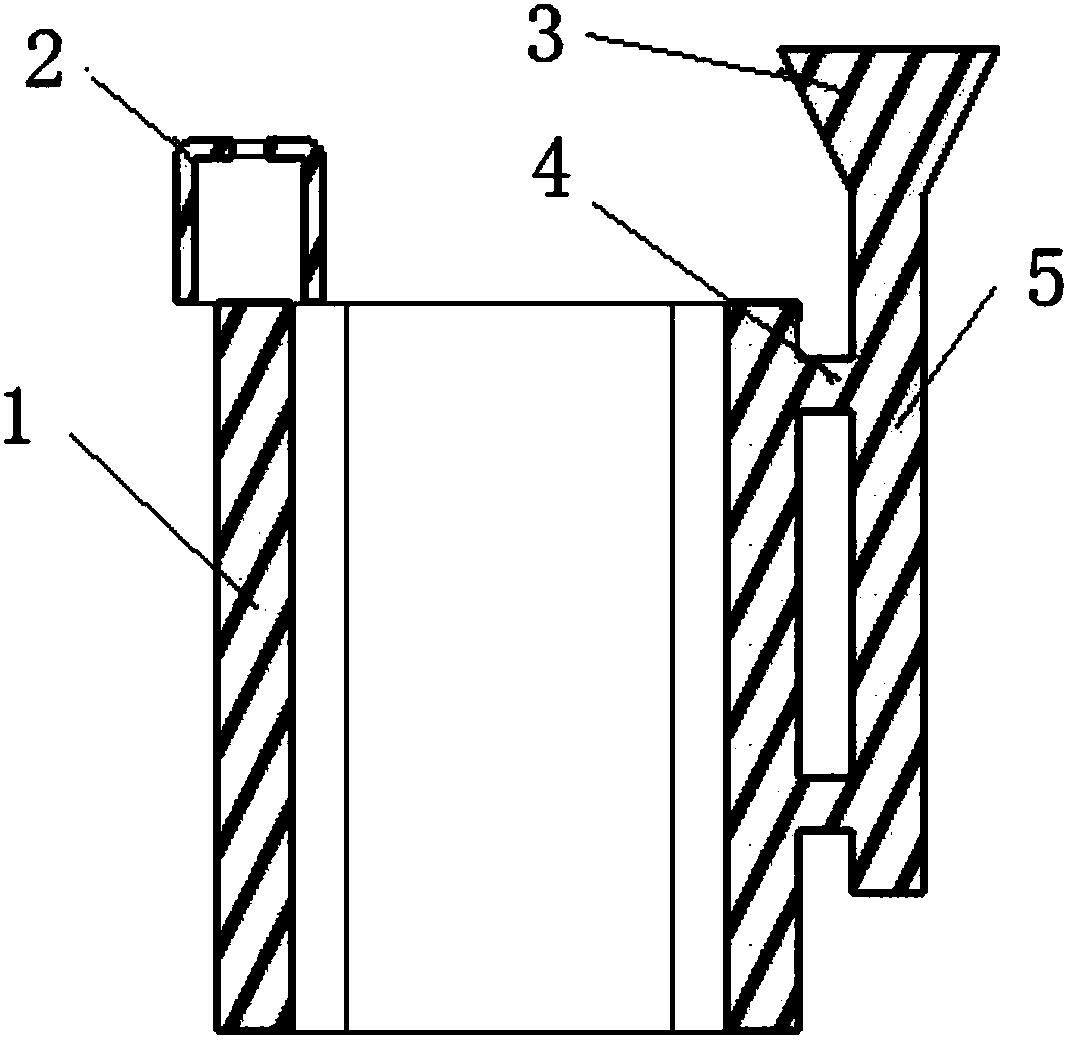

[0023] An application of heat preservation riser in lost foam casting. When casting castings on lost foam, the utilization rate of molten iron is improved by adding heat preservation riser, the cooling time of molten metal is prolonged, the feeding effect is enhanced, and the yield of castings is improved. . The position of increasing the insulation riser is on the left side of the casting, and the left insulation riser and the right gate are opposite to the two sides of the casting. The gate has a sprue, and the sprue is poured and cast through the upper and lower ingates.

[0024] The concrete implementation process of this embodiment:

[0025] The size of the casting is 700*700*1000mm, and the wall thickness is 100mm. A thermal insulation riser with a diameter of 140mm and a height of 200mm is placed on the upper left side of the casting. In the mold, after the molten iron is completely filled with the mold, during the cooling process of the molten iron, due to the slow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com